High-temperature industrial waste gas multi-stage dust removal system

A high-temperature industry, dust removal system technology, applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of secondary pollution, change of gas composition, waste of heat resources, etc., to avoid dust and less joints Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

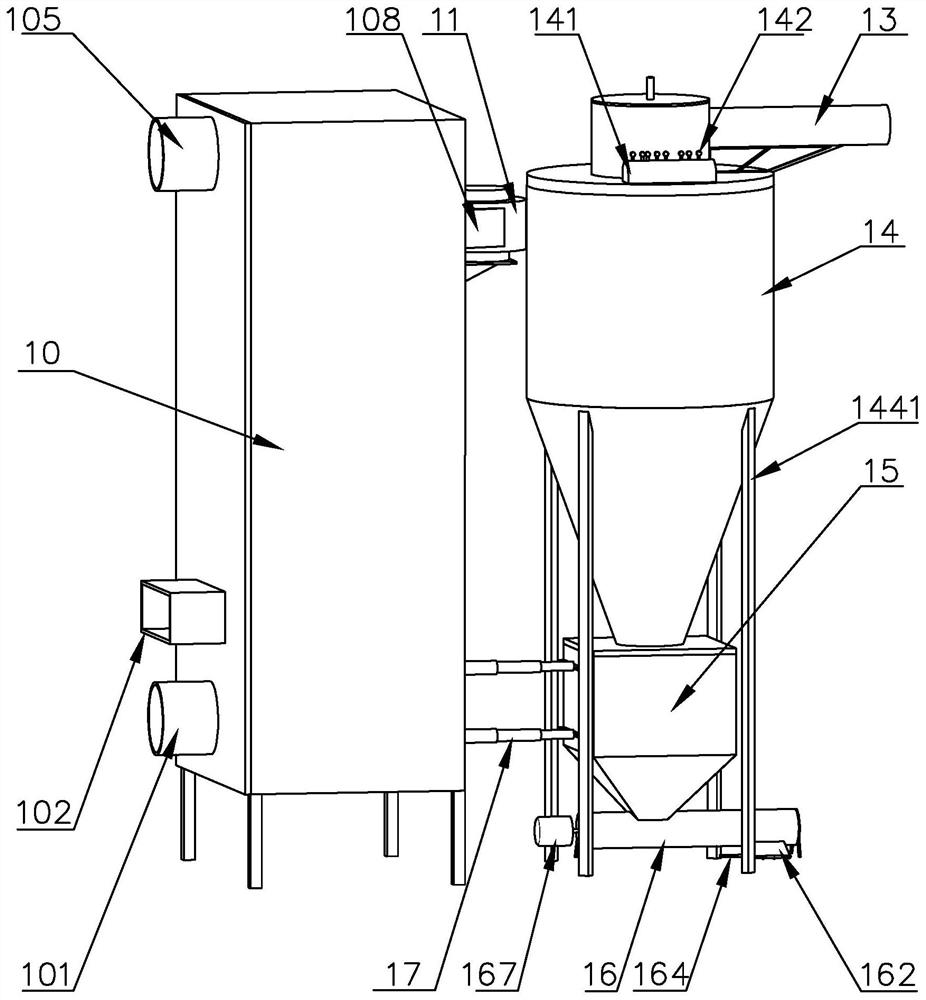

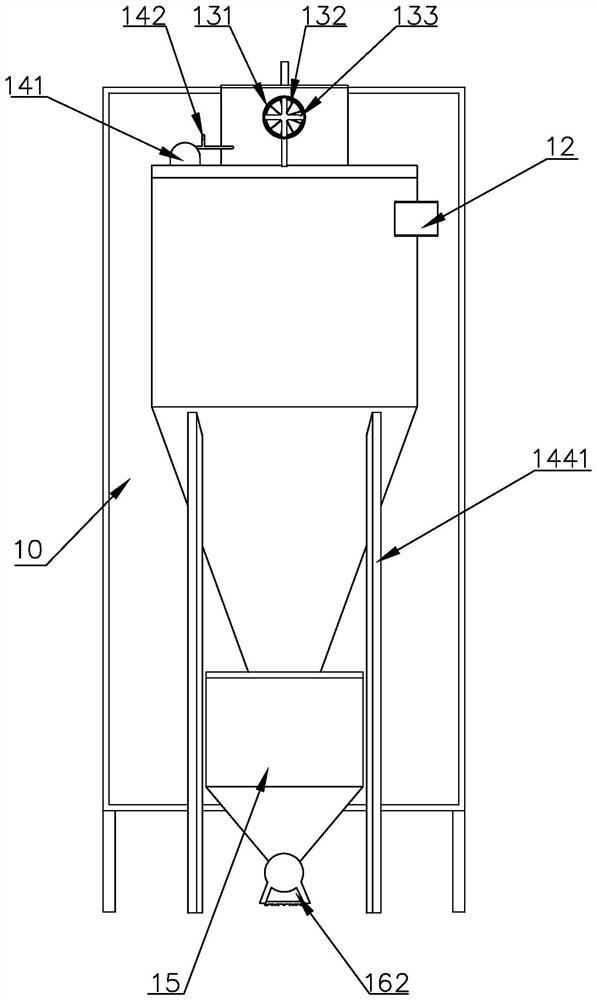

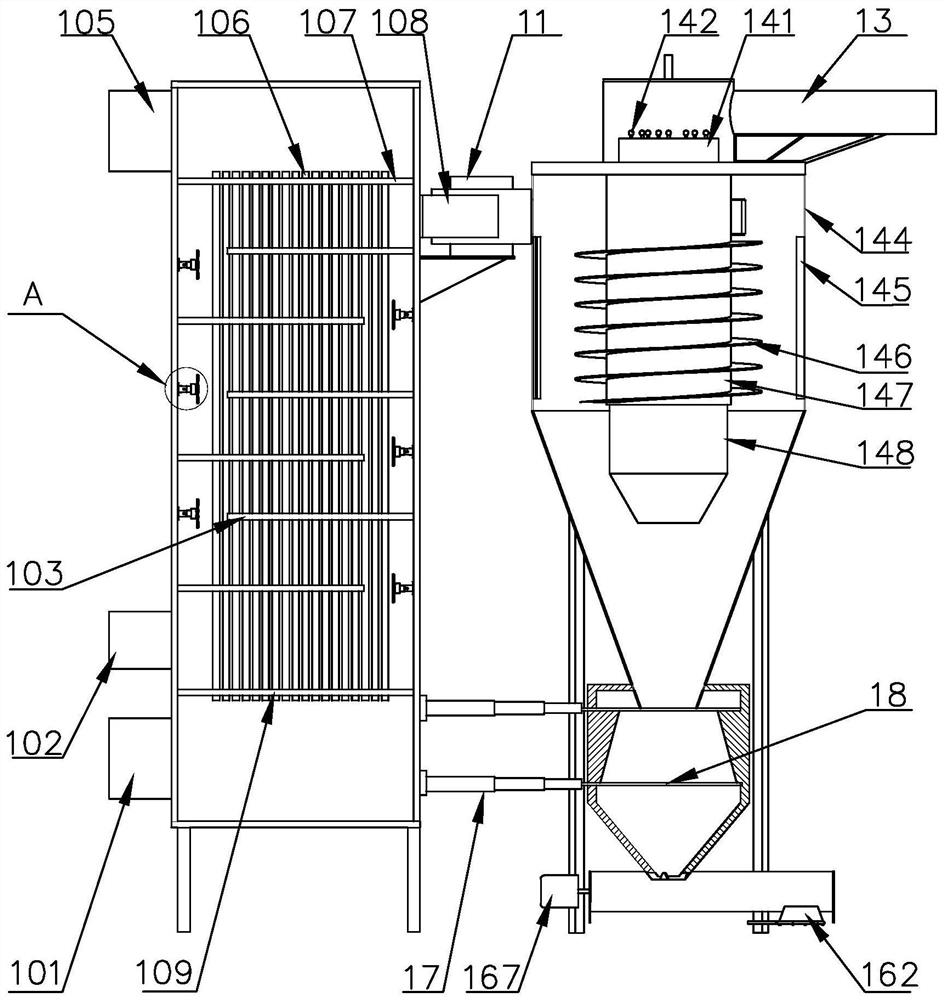

[0027] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-9 , to further specifically describe the technical solution of the present invention.

[0028] A multi-stage dust removal system for high-temperature industrial waste gas, including a heat exchange box 10, a fan 11, an air duct 12, a dust removal box 14, an ash storage box 15, a hydraulic cylinder 17, a baffle plate 18, a screw conveying device 16, and an exhaust device 13 , the heat exchange box 10 includes a water inlet 101, an air inlet 102, a water outlet 105, an air outlet 108, a lower partition 109, an upper partition 107, a deflector 103, a heat exchange tube 106, and a spoiler fan 104. The water outlet 101 is located on one side of the heat exchange box 10, below the lower partition 109, the water outlet 105 is located on the same side, above the upper partition 107, and the air inlet 102 is located on the side of the heat exchange box 10 betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com