Dust-removal filter bed

A filter bed and filter plate technology, which is applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of large energy consumption, complex regeneration and cleaning process of filter bed, and low economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

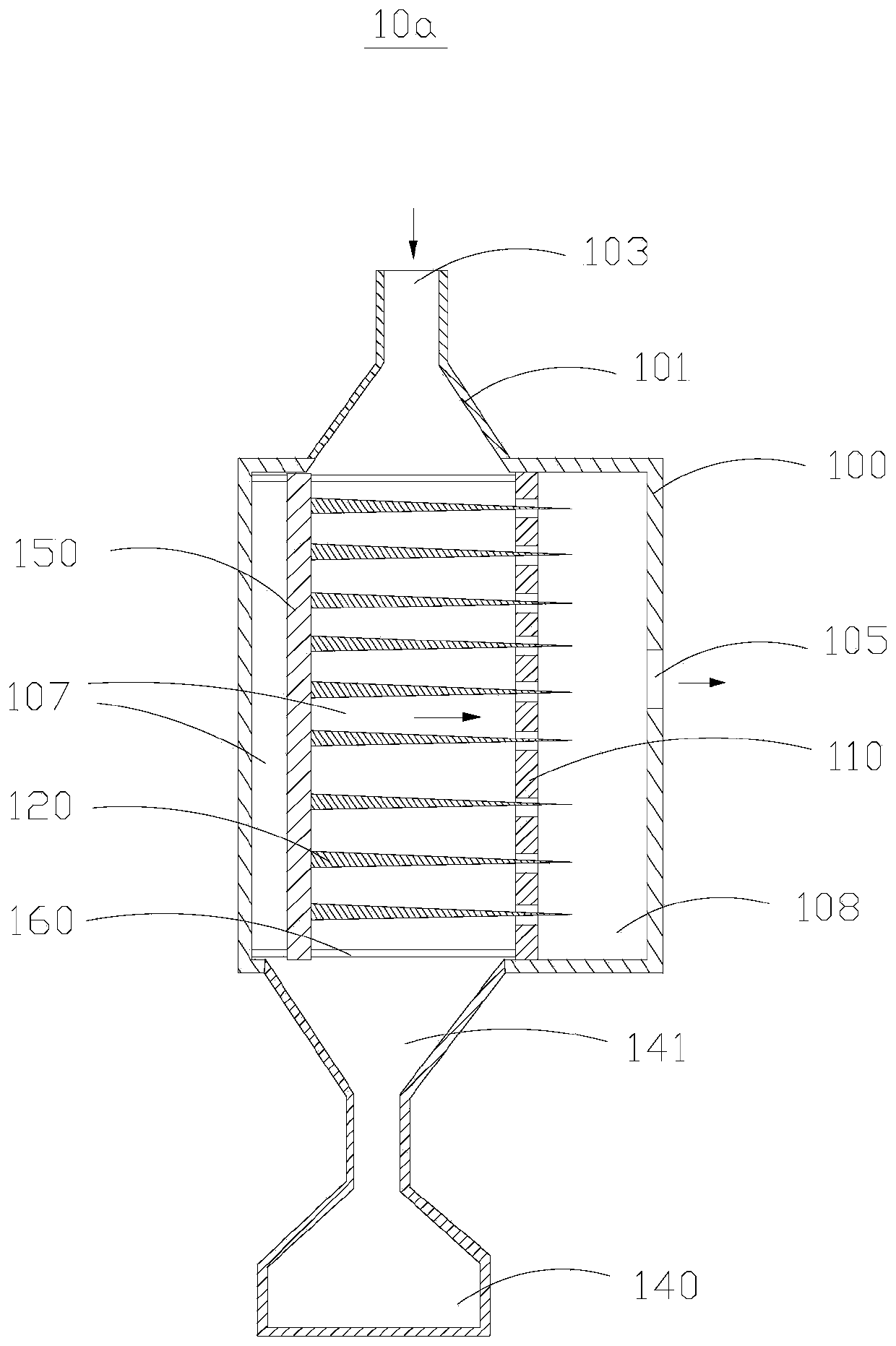

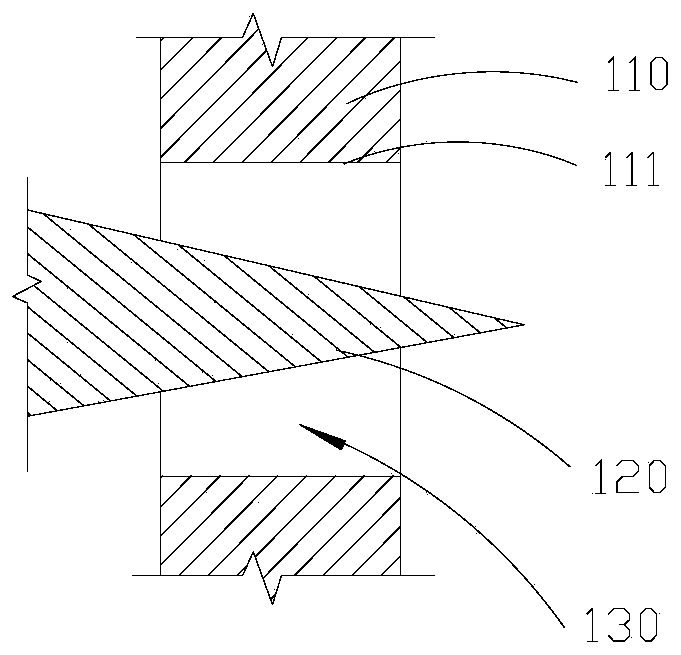

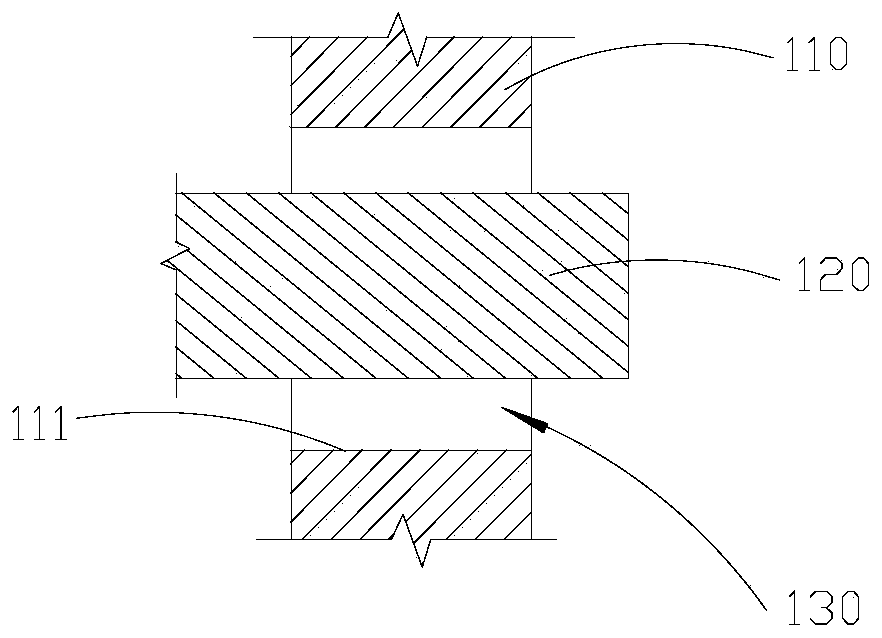

[0044] see figure 1 , the present application provides a dust removal filter bed 10 a, which includes a body, a filter plate 110 , a plurality of pore adjustment members 120 and a dust collection bin 140 .

[0045] Wherein, the body has a housing chamber defined by a housing wall 100, and the housing wall 100 is provided with an inlet 103 and an outlet 105 communicating with the housing chamber. Wherein, the inlet 103 is mainly used to input the fluid to be cleaned, and the outlet 105 is mainly used to output the cleaned fluid. The fluid can be water or gas, which mainly refers to gas in this application.

[0046] Specifically, the material of the housing wall 100 may be metal such as stainless steel, or may be a polymer material, which can be set by those skilled in the art according to actual requirements. The shape of the housing wall 100 may be a cylinder, and in this embodiment, the cross-sectional shape of the housing wall 100 is square.

[0047] see figure 1 as well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com