Electric precipitator anode plate repairing method

A technology of electrostatic precipitator and repair method, applied in the direction of electrode structure, electrostatic separation, etc., which can solve the problems of low dust removal efficiency, large size of anode plate, high cost of replacing the anode plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

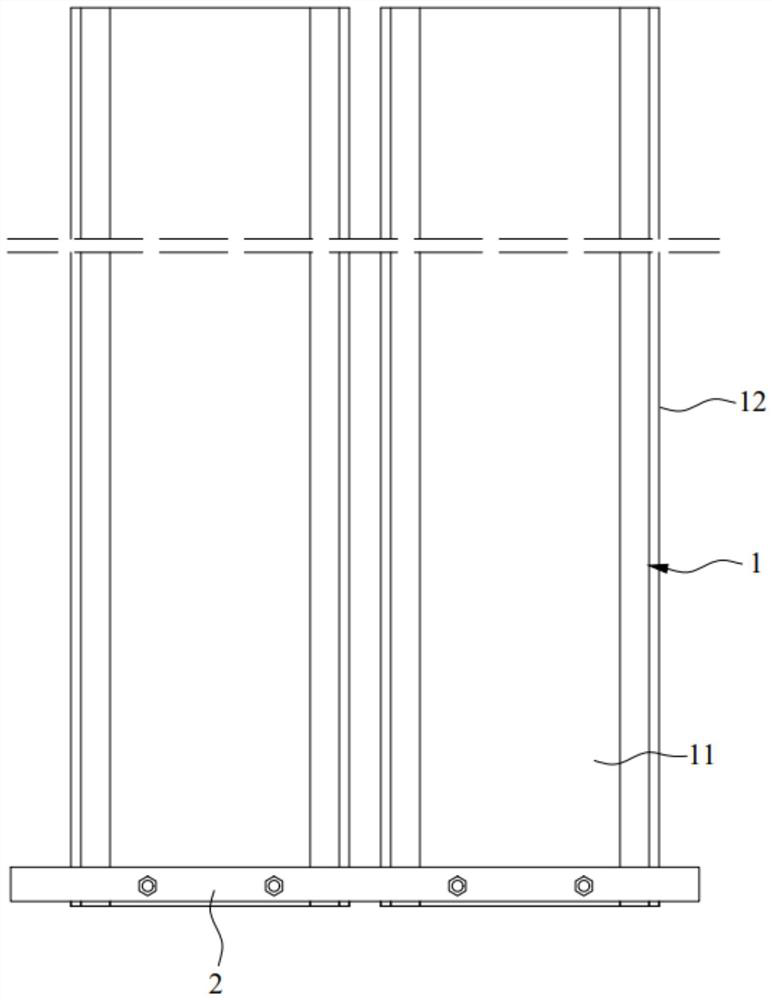

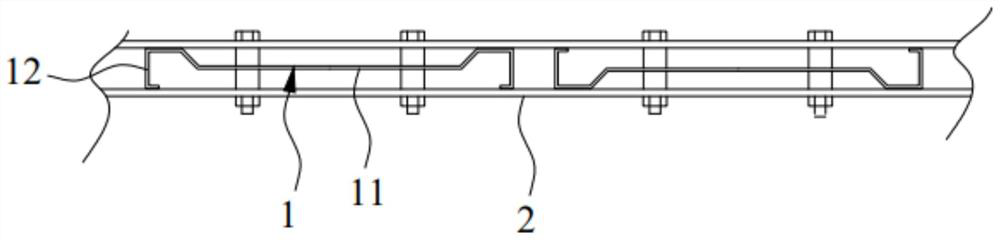

[0035] like Figure 1-Figure 5 As shown, the embodiment of the present invention provides a method for repairing an anode plate of an electrostatic precipitator, comprising the following steps:

[0036] Step S1, removing the connecting steel plates 2 on both sides of the bottom of the anode plate 1 to be repaired in the electrostatic precipitator;

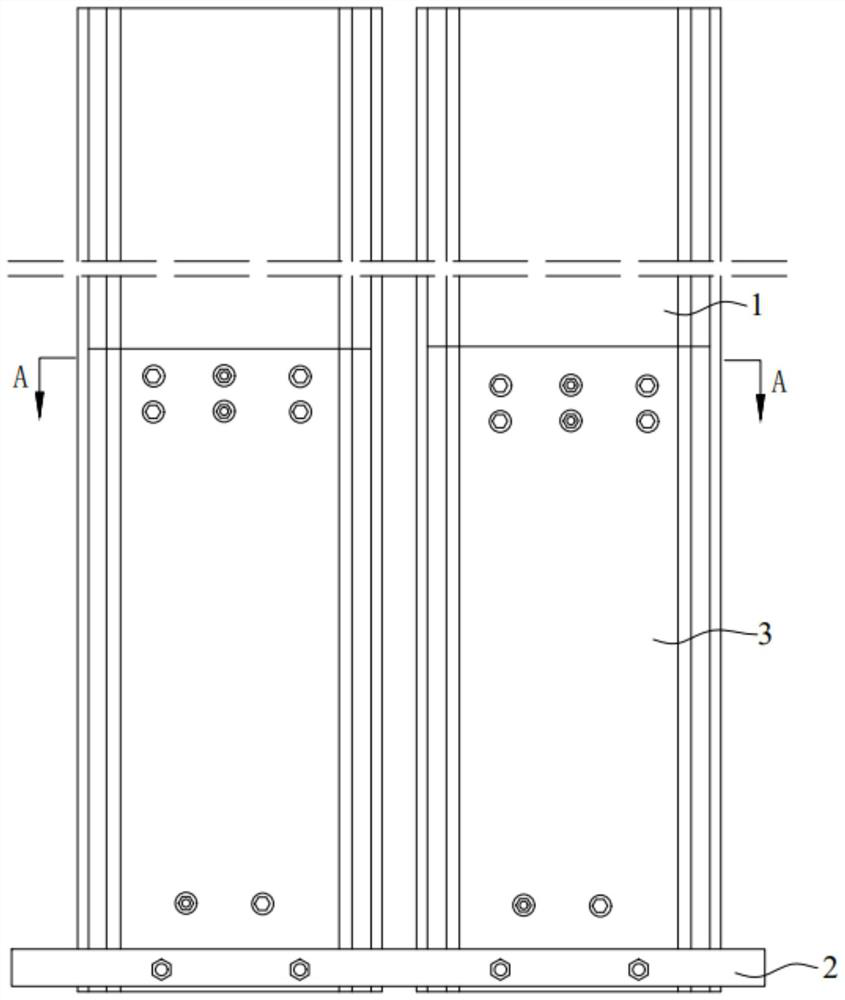

[0037] Step S2, the first protective plate 3 is fixedly connected to one side of the anode plate 1 to be repaired, and the first protective plate 3 is attached to one side of the anode plate 1 to be repaired;

[0038] Step S3, the second protective plate 4 is fixedly connected to the other side of the anode plate 1 to be repaired away from the first protective plate 3, and the second protective plate 4 is attached to the other side of the anode plate 1 to be repaired away from the first protective plate 3 one side;

[0039] Step S4 , fixedly connect the dismantled connecting steel plate 2 to both sides of the bottom of the repair...

Embodiment 2

[0047] In this embodiment, the steps of the method for repairing the anode plate of the electrostatic precipitator are basically the same as in the first embodiment, and both sides of the corroded anode plate 1 are respectively fixedly connected with the first protective plate 3 and the second protective plate 4 , by bonding the first protective plate 3 and the second protective plate 4 and covering the damaged part of the anode plate 1 to be repaired, the low dust removal efficiency caused by the short circuit of the electric field is avoided. In step S2 and step S3 of this embodiment, the material of the first protective plate 3 and the second protective plate 4 is further preferably a cermet material. Cermet has the advantages of both metal and ceramics. It not only has the toughness, high thermal conductivity and good thermal stability of metal, but also has the characteristics of high temperature resistance, corrosion resistance and wear resistance of ceramics. And embrit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com