High-temperature-resistant anti-corrosion cleanable industrial dust removal device

A dust-removing device and corrosion-resistant technology, applied in gas treatment, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of dust adhered to the interior, reduce the service life of the device, damage, etc., so as to improve the service life and facilitate the movement of the device. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

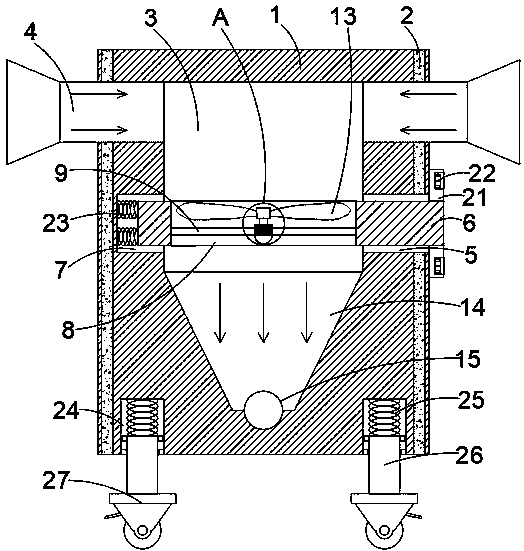

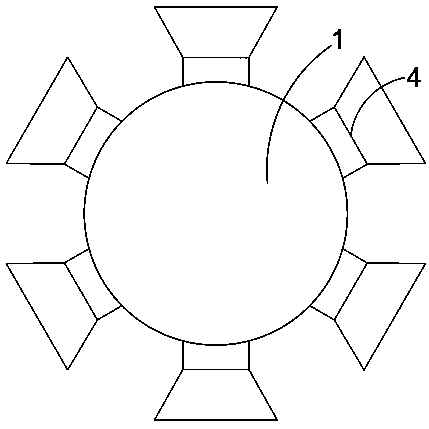

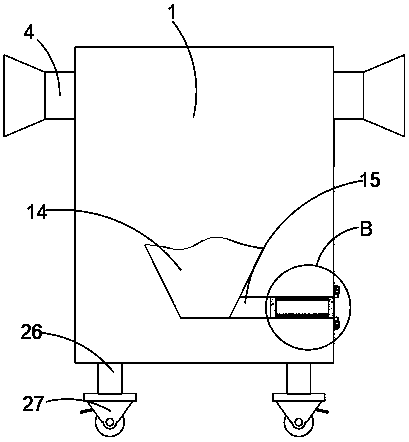

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0026] refer to Figure 1-5 , a high-temperature-resistant, corrosion-resistant and cleanable industrial dust removal device, including a housing 1, the lower end of the housing 1 is connected with a locking universal wheel 27 through a buffer mechanism, and by setting the locking universal wheel 27, the device can be adjusted when necessary When moving, the locking universal wheel 27 is unlocked to move the device, and the device is moved to the designated place. When the device is moved to the designated place, the device is braked and the locking universal wheel 27 is locked. , to facilitate the movement and braking of the device;

[0027] The buffer mechanism in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com