Device and method for carrying out dust removing treatment on dust-containing steam in steel slag treating and rolling zone

A technology for processing rollers and steam, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve problems such as low dust removal efficiency, failure to meet environmental protection standards, and short cleaning cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

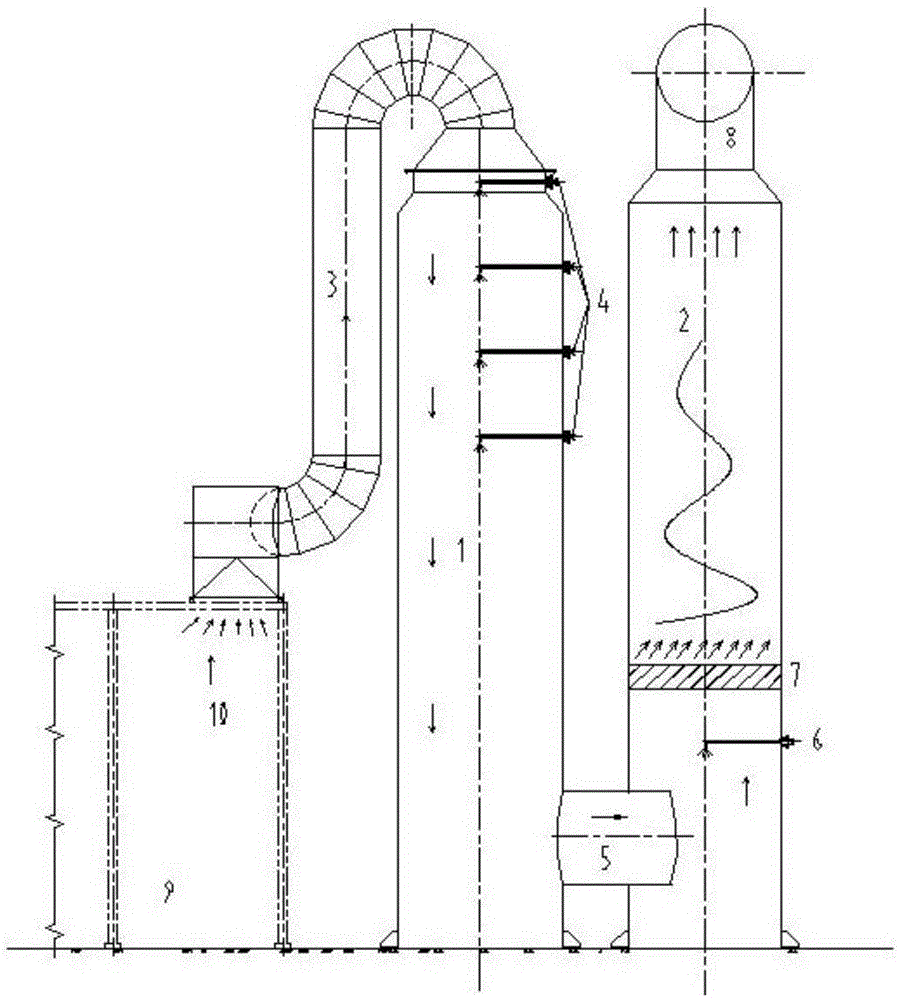

[0014] Such as figure 1 As shown, a device for dust-removing dust-containing steam in the steel slag treatment rolling area, which includes a spray tower 1, a swirl tower 2, a first pipeline 3, a second pipeline 5, and a first high-pressure spray gun 4 And the second high-pressure spray gun 6, the top of the spray tower 1 is provided with the first high-pressure spray gun 4, and the top of the spray tower 1 is provided with the first opening, and the first opening is connected with the rolling area 9 by the first pipeline 3, for The dust-containing steam 10 produced in the rolling area is introduced into the top of the spray tower 1, and the second pipeline 5 connecting the spray tower 1 and the swirl tower 2 is arranged at the bottom of the spray tower 1 and the swirl tower 2 for spraying The dust-laden steam treated by the shower tower 1 is introduced into the swirl tower 2 along the tangential direction and continues to flow. A second high-pressure spray gun 6 is set at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com