Flue gas dust removal device

A dust removal device and flue gas technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of manual cleaning, troublesome operation, and reduced adsorption capacity of filter elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further detailed explanation through specific implementation mode below:

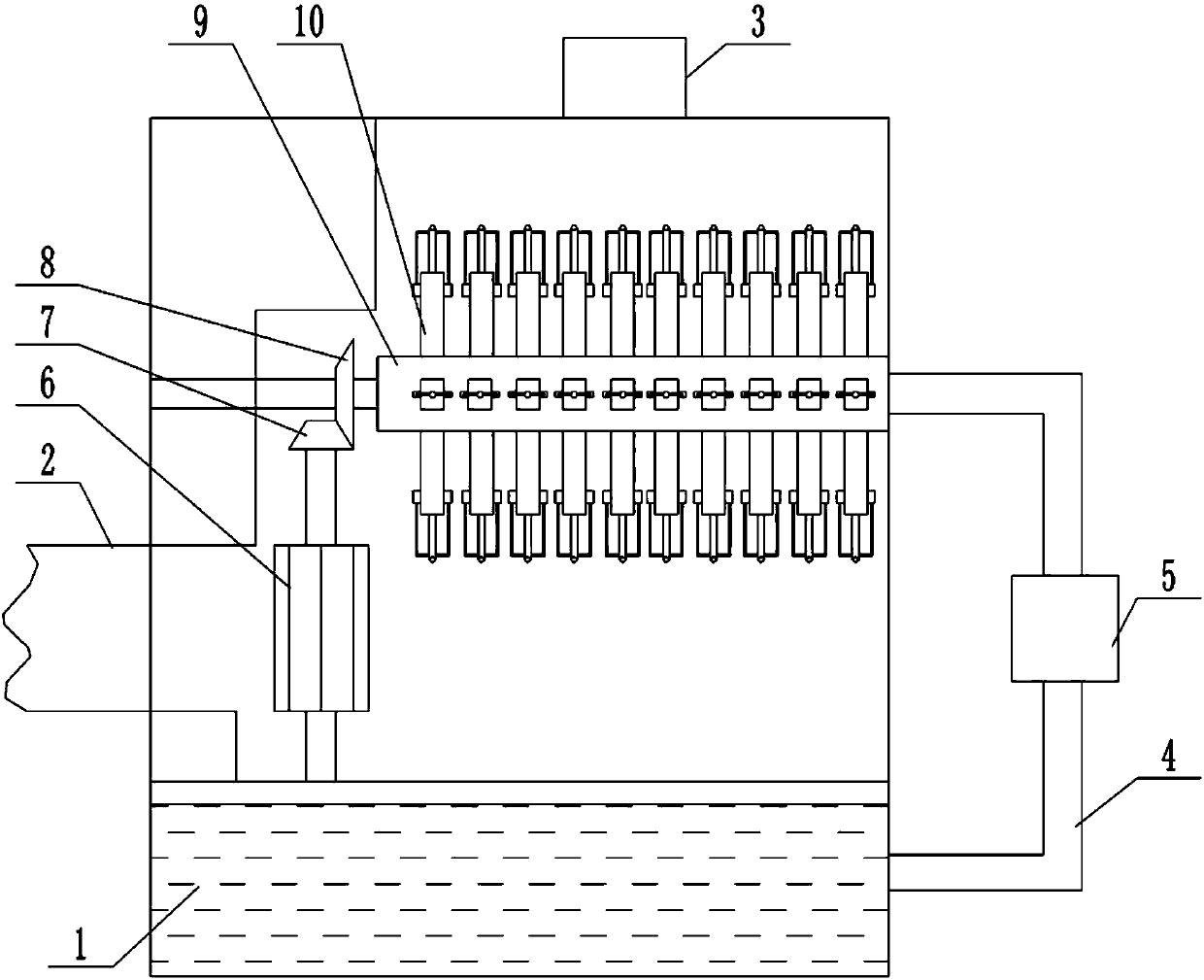

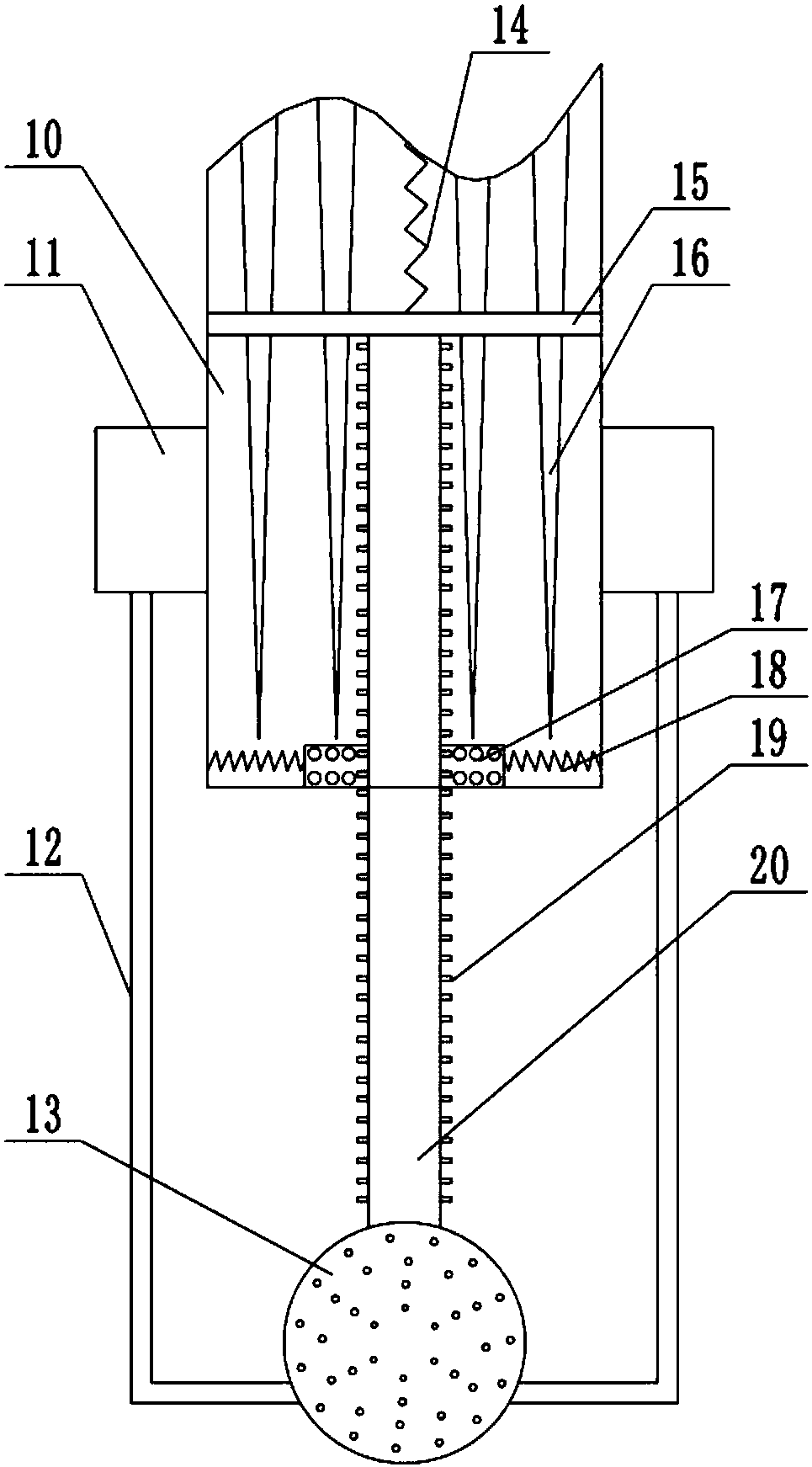

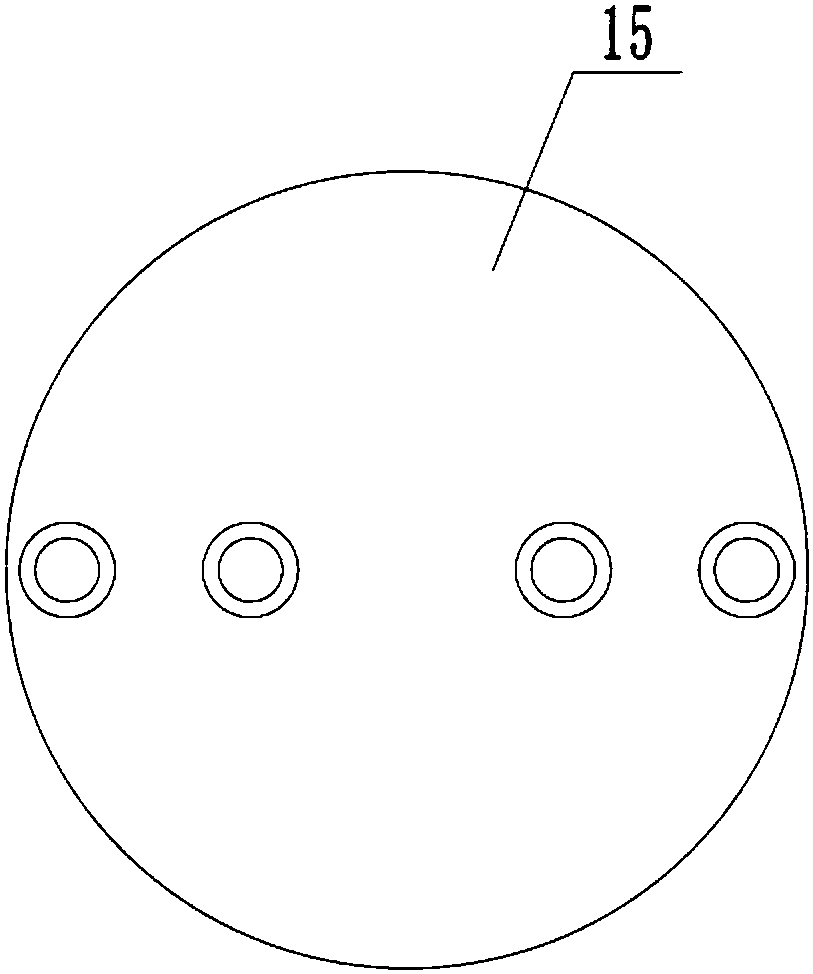

[0016] The reference signs in the drawings of the description include: water tank 1, air intake pipe 2, air outlet pipe 3, connecting pipe 4, water pump 5, wind wheel 6, first bevel gear 7, second bevel gear 8, rotating part 9, blade 10 , cleaning block 11, connecting rod 12, water polo 13, extension spring 14, baffle plate 15, vertical rod 16, pressing block 17, spring 18, pressure valve 19, water pipe 20.

[0017] The embodiment is basically as attached Figure 1-Figure 3 Shown: a flue gas dedusting device, including a housing, a filter element is provided above the housing, the filter element includes a rotating part 9 and a blade 10, a first cavity is provided in the rotating part 9, and a second cavity is provided in the blade 10 The blade 10 is provided with an opening communicating with the second cavity, and the first cavity communicates with the second cavity. The second cavity is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com