Patents

Literature

43results about How to "Implement loop filtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

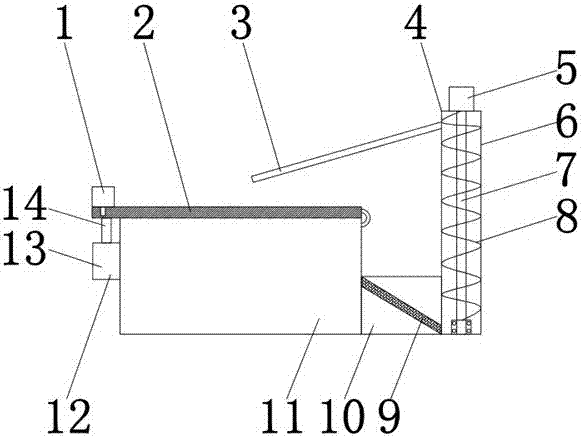

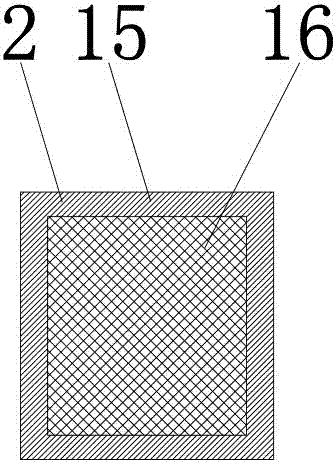

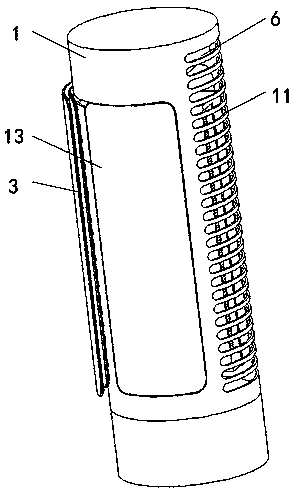

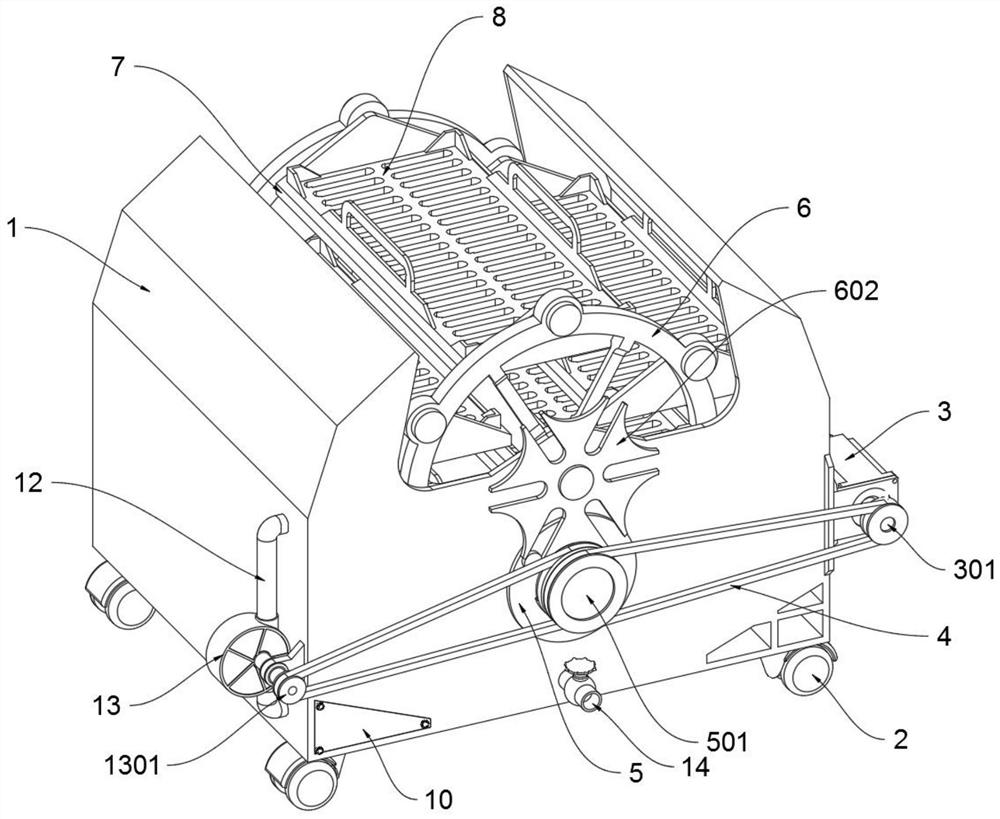

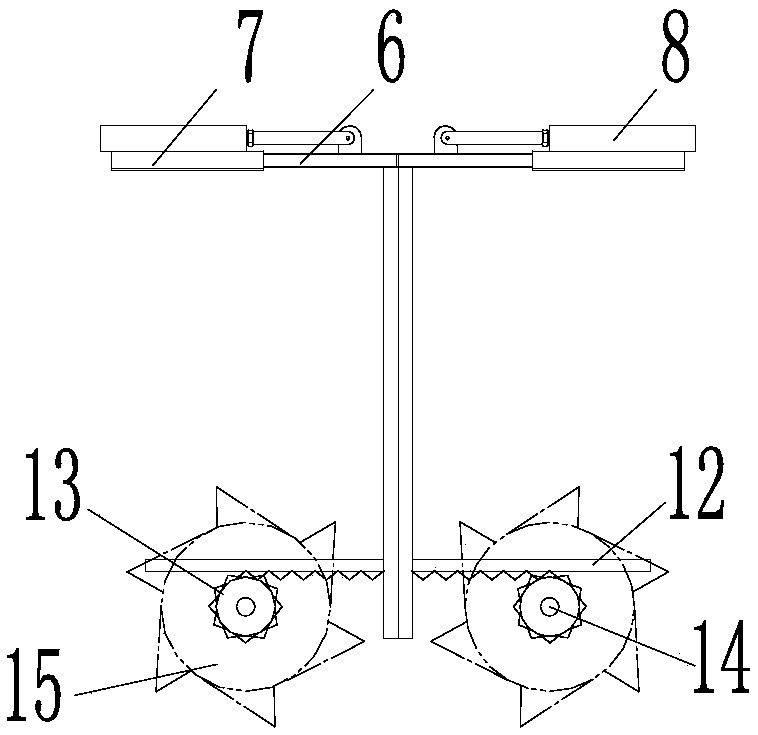

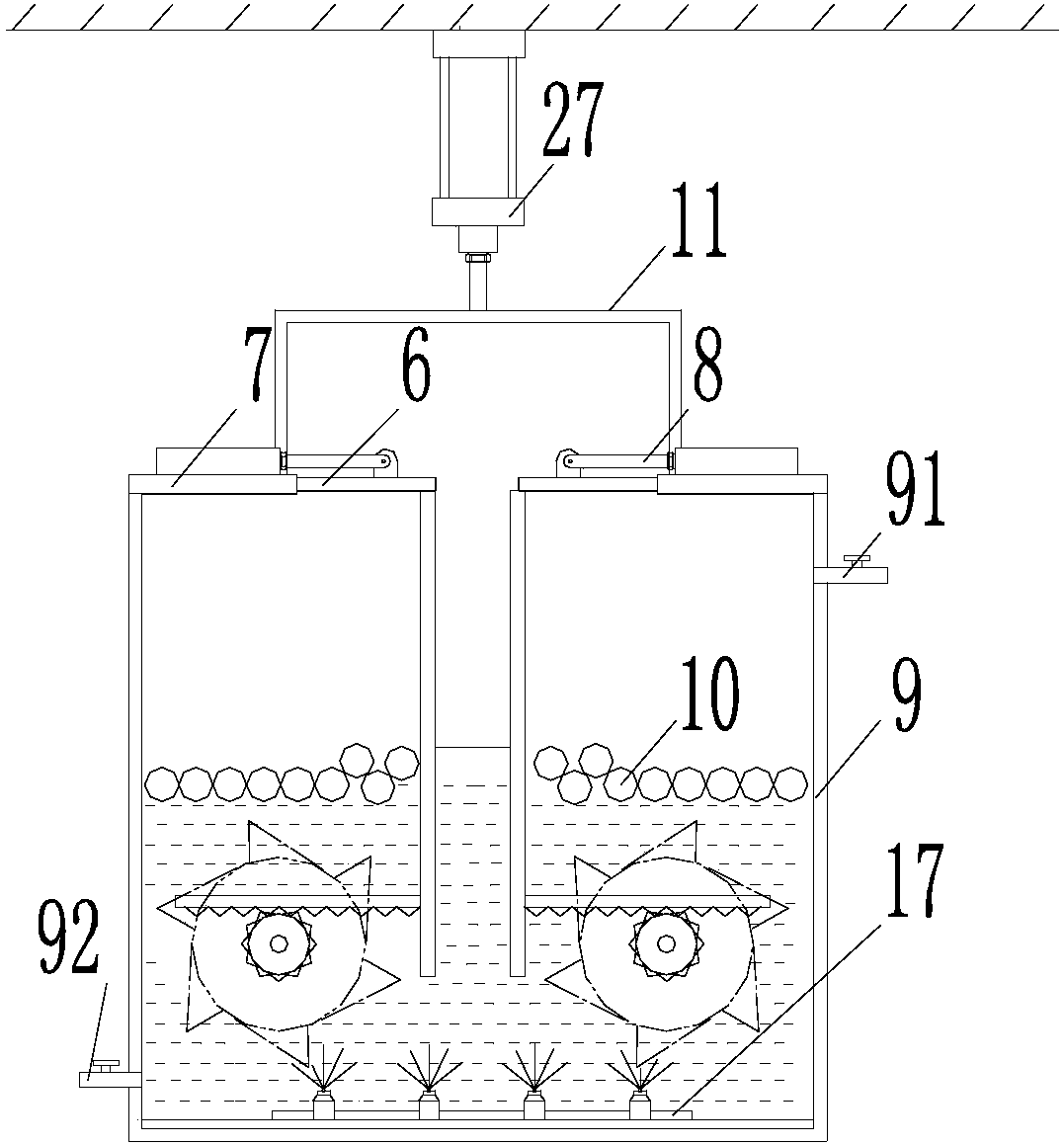

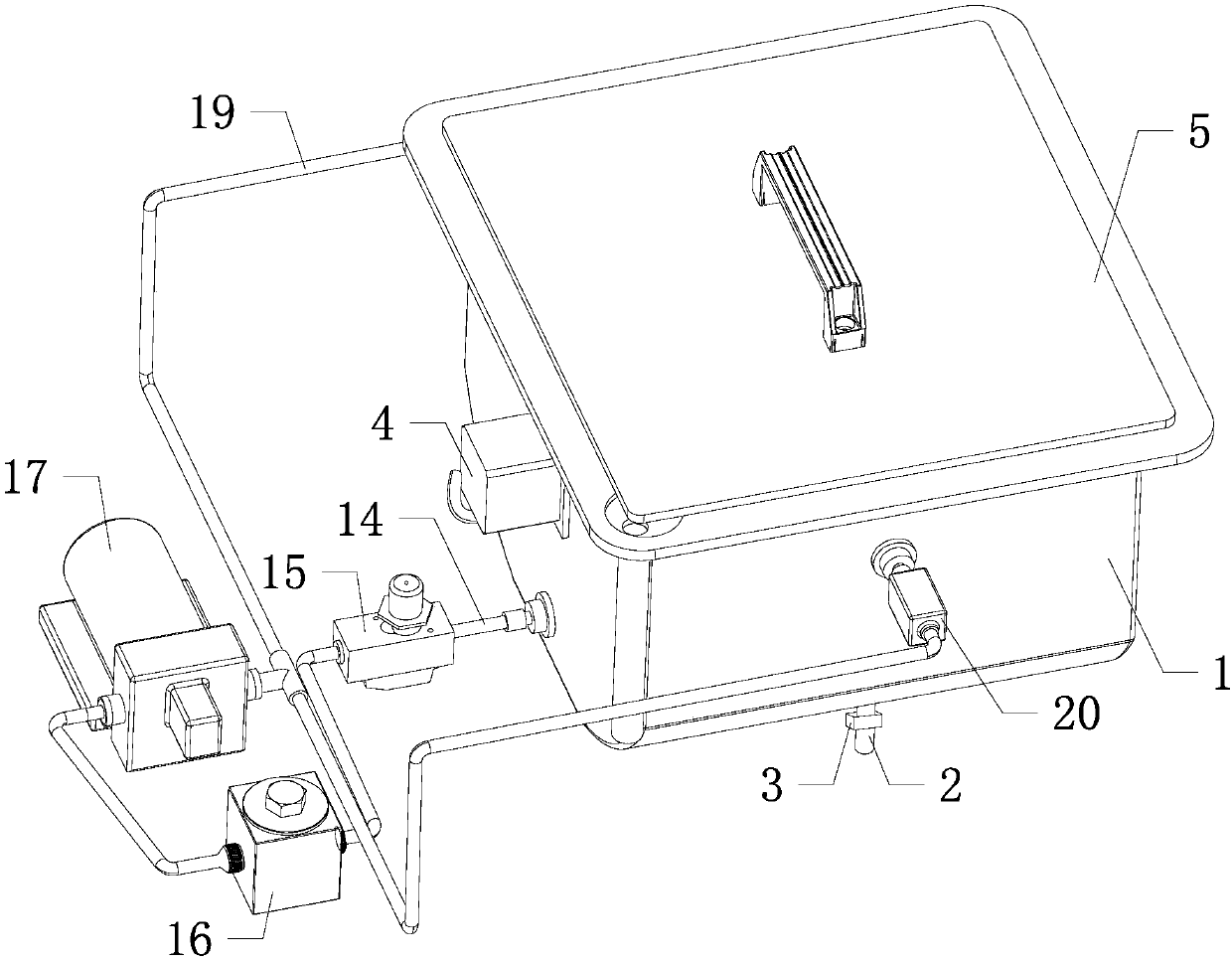

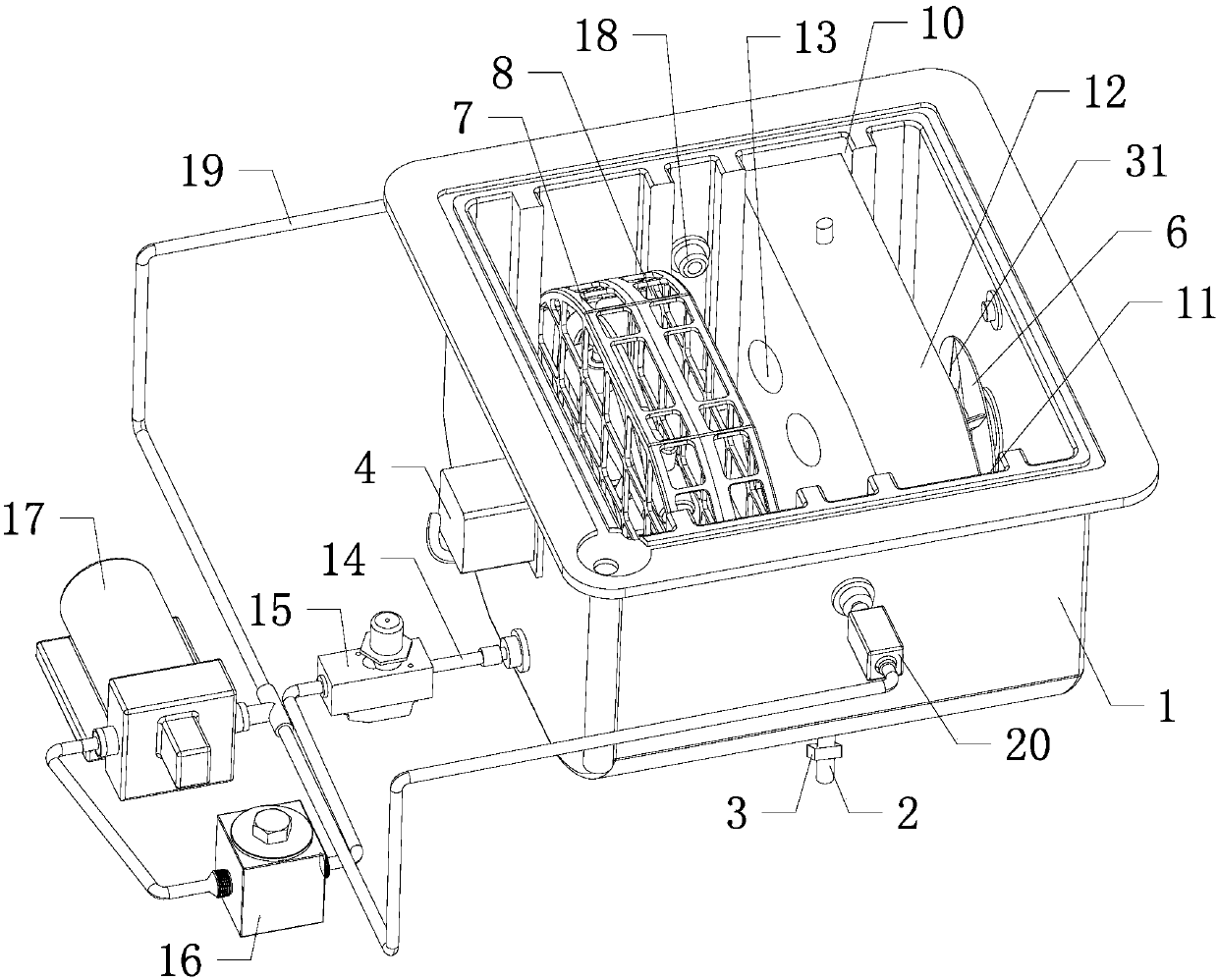

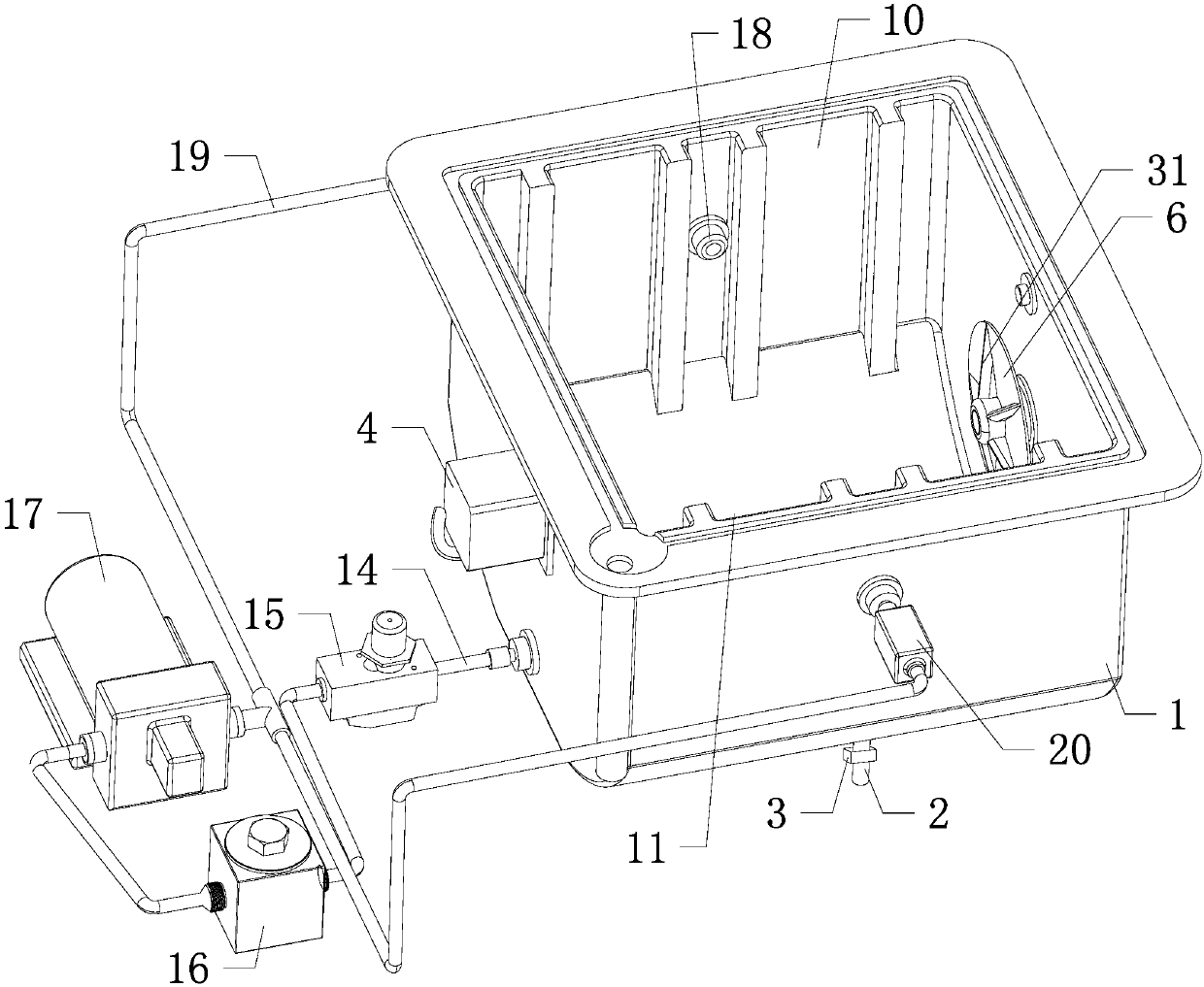

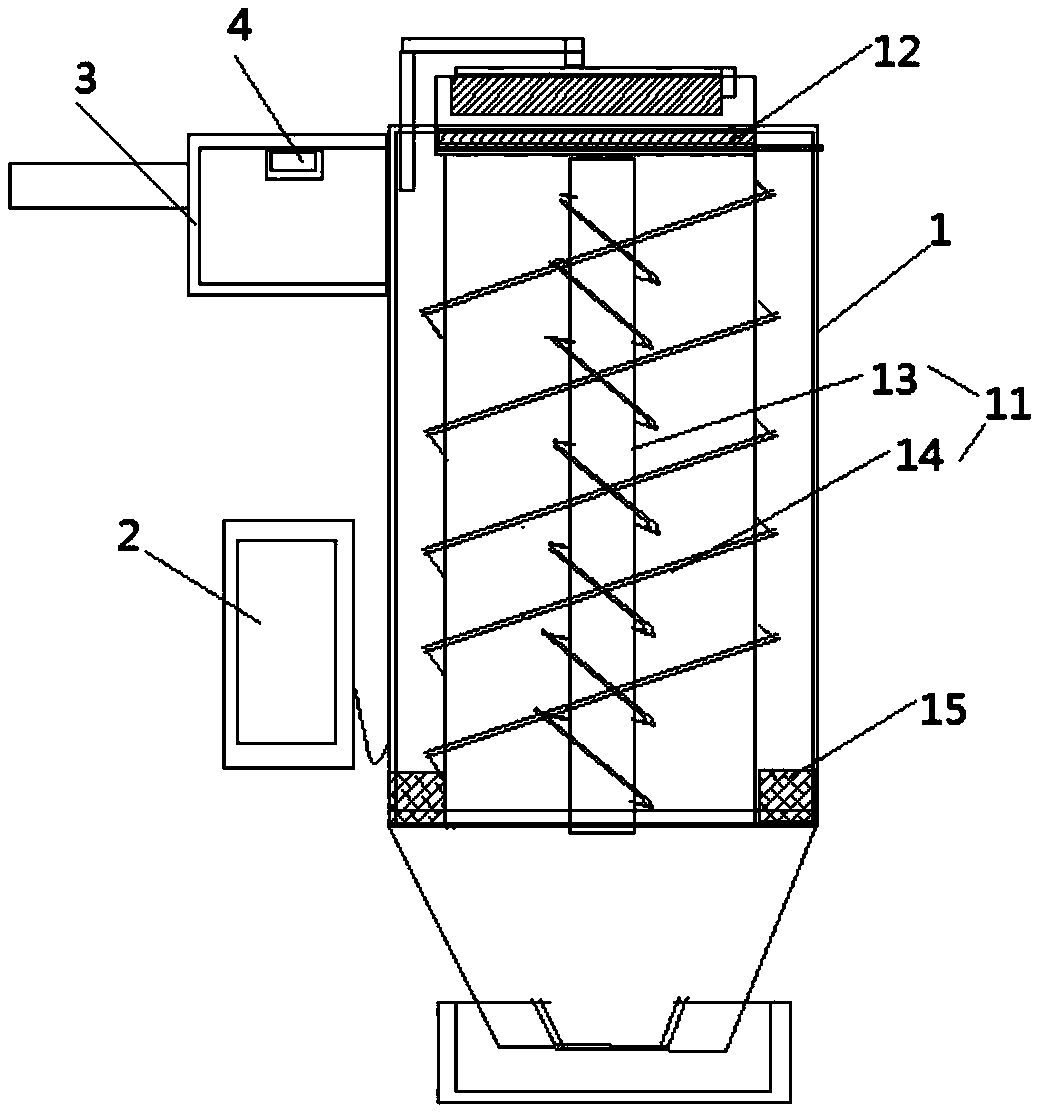

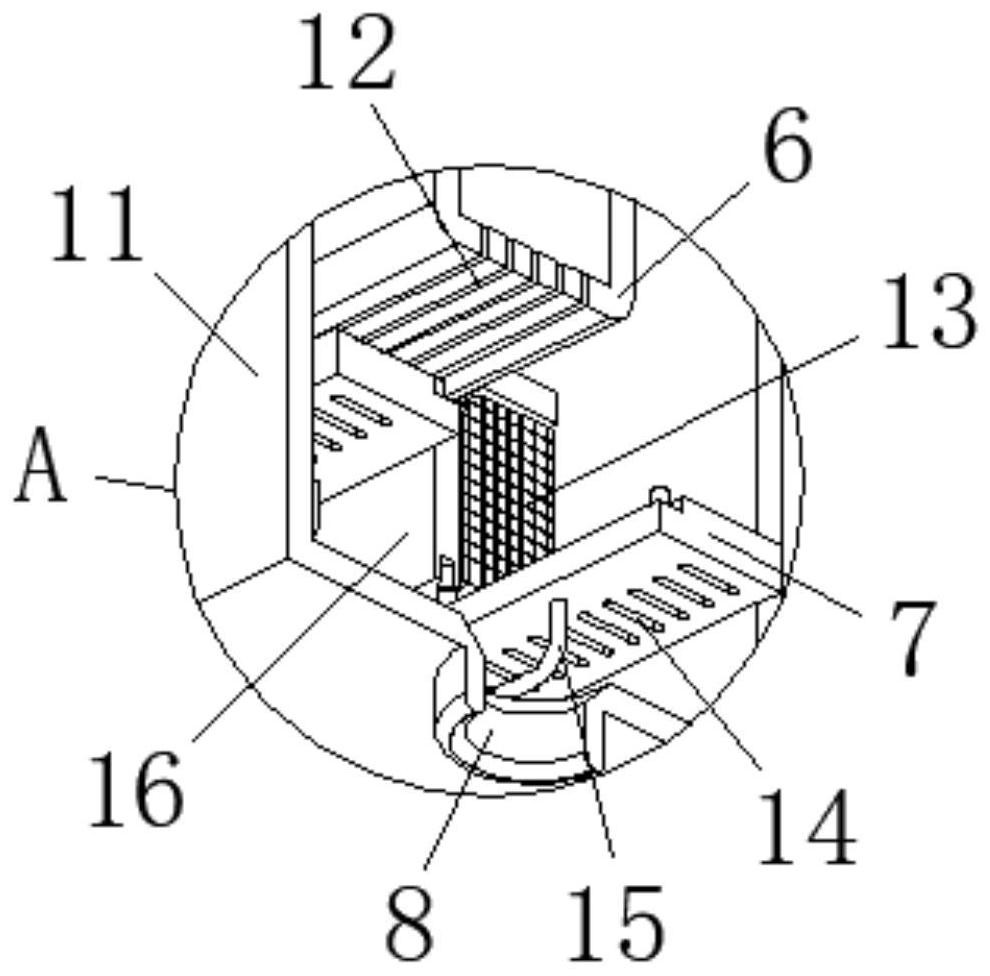

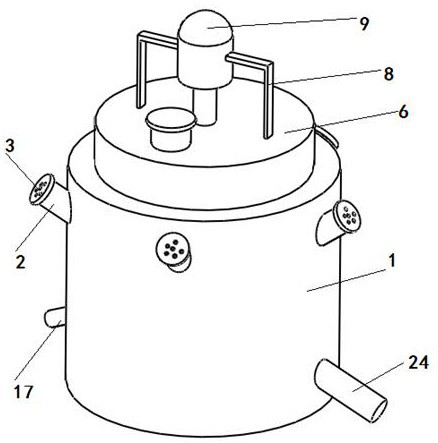

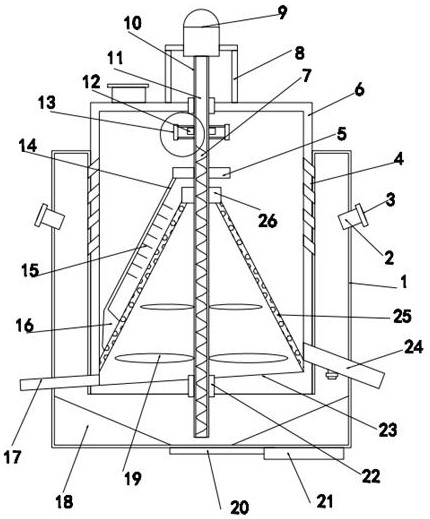

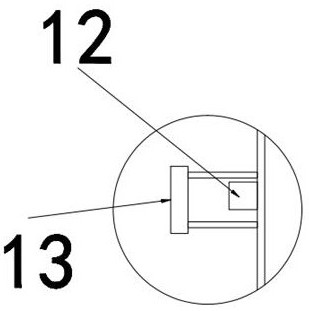

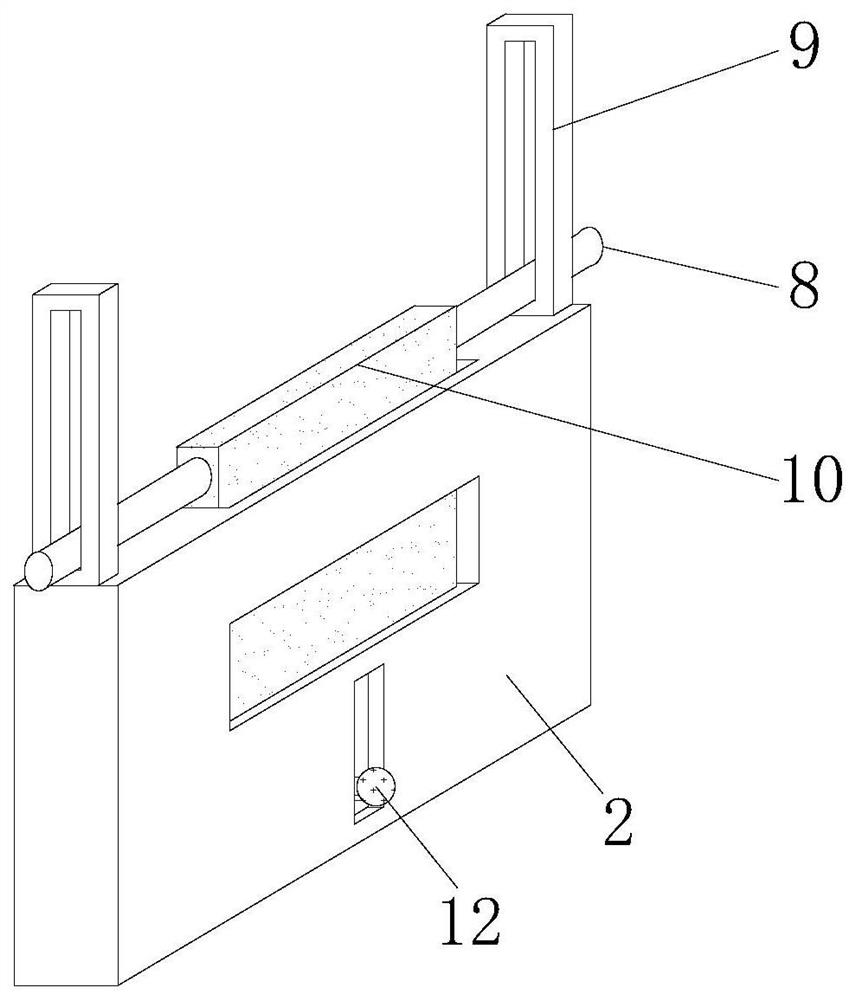

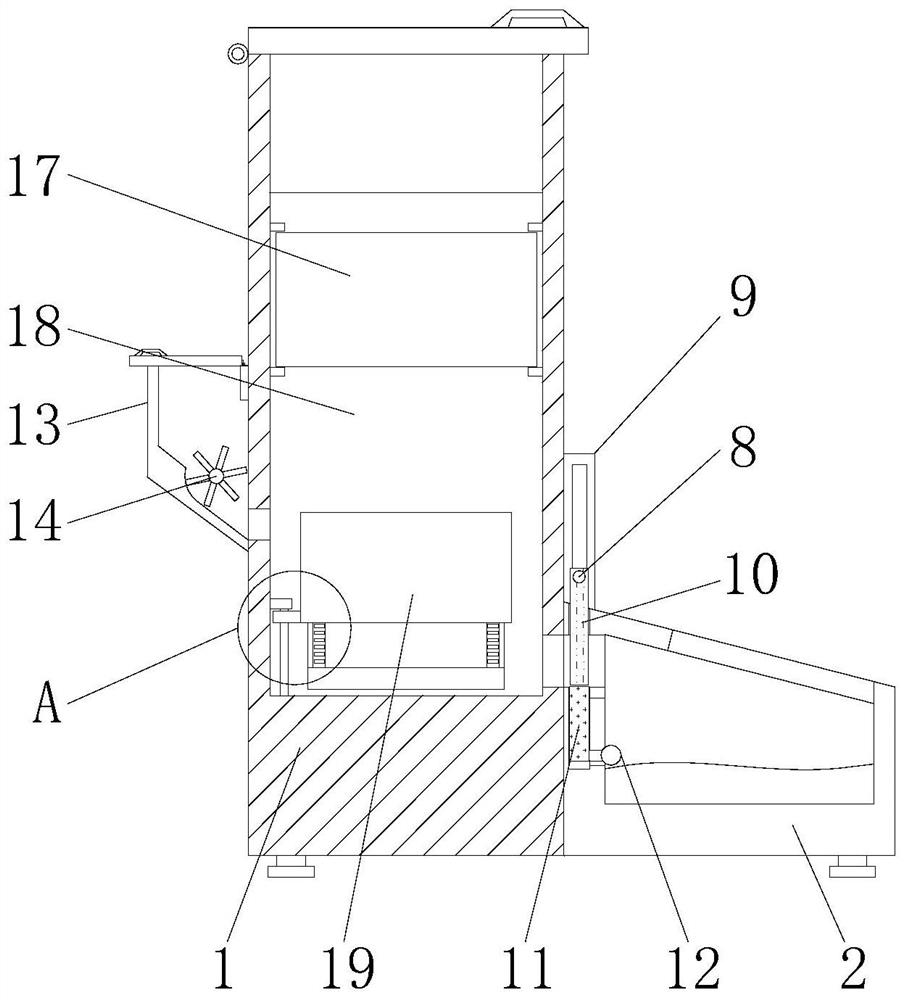

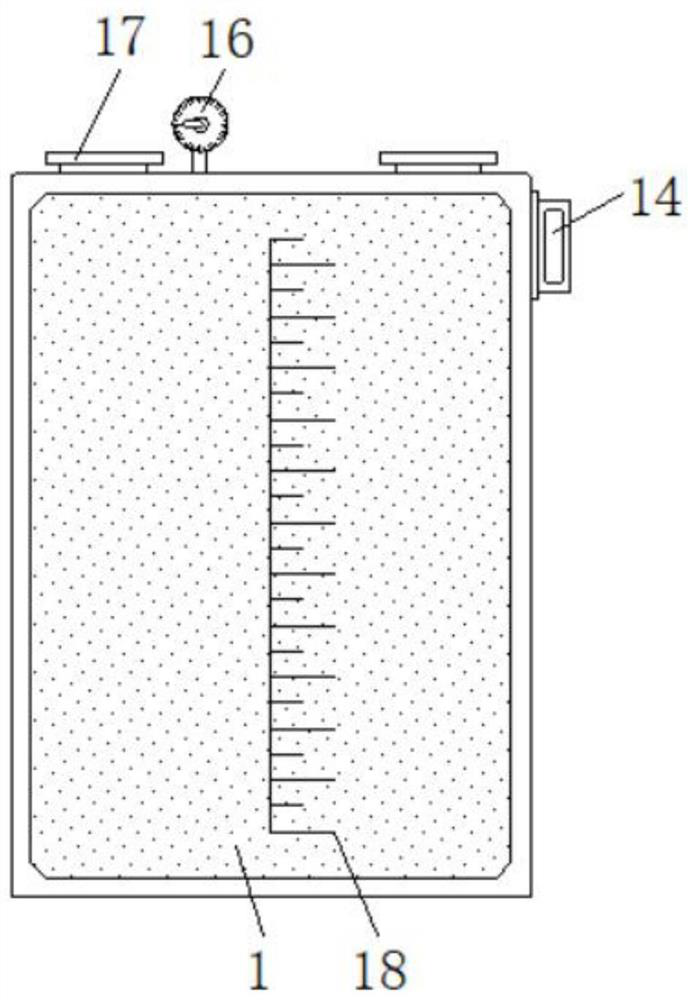

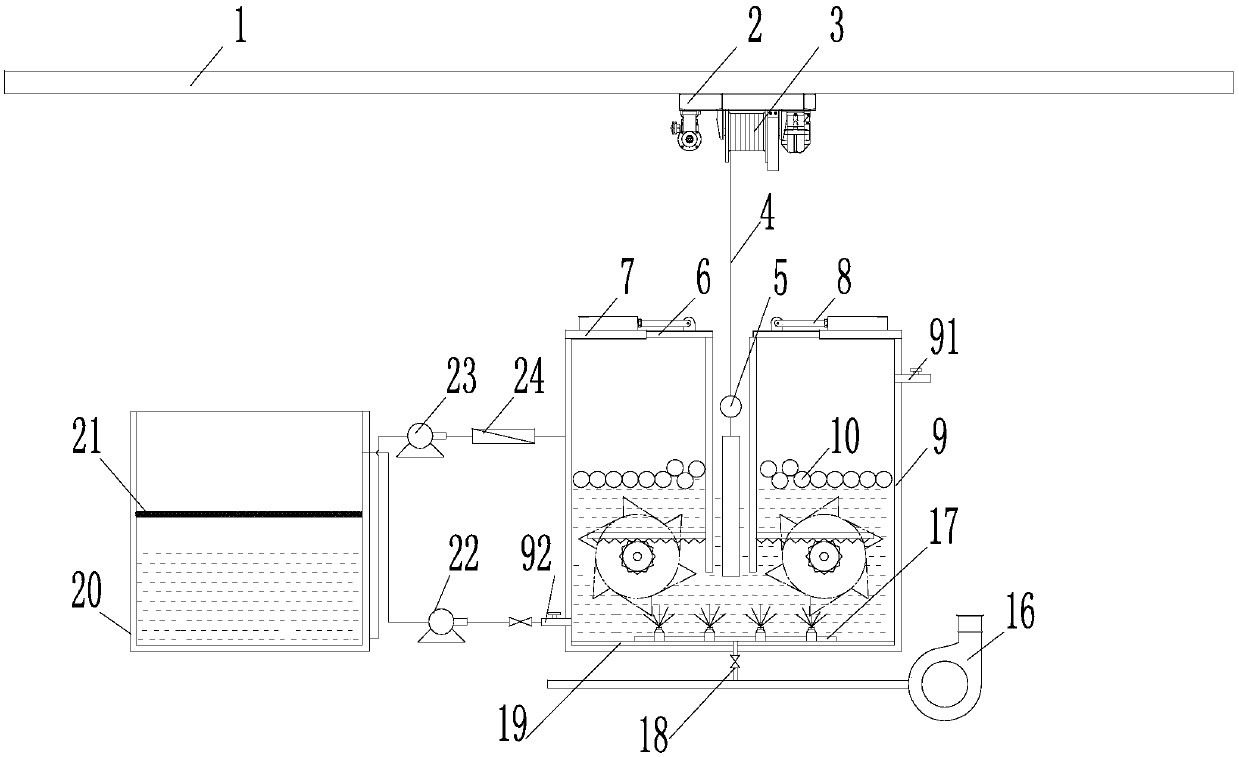

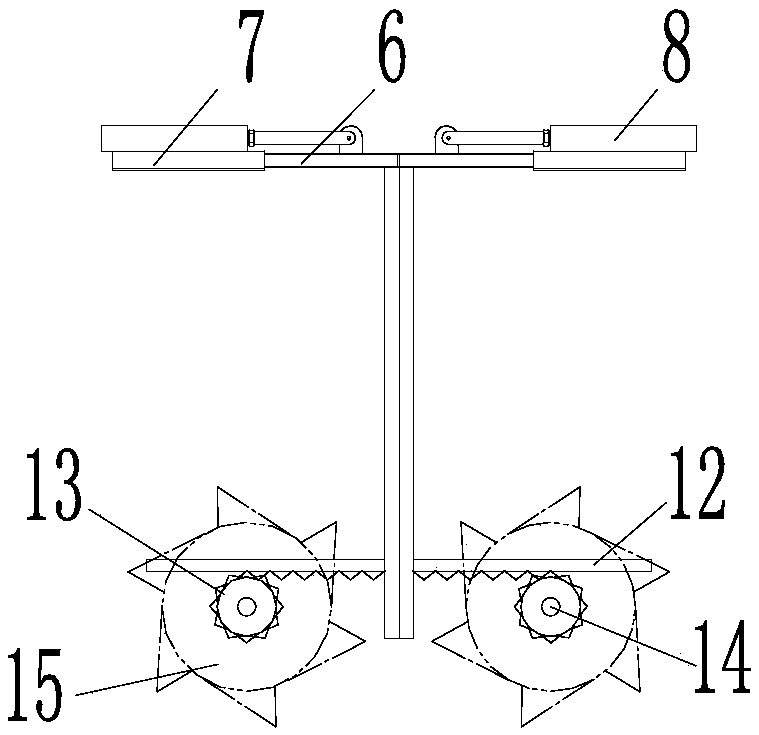

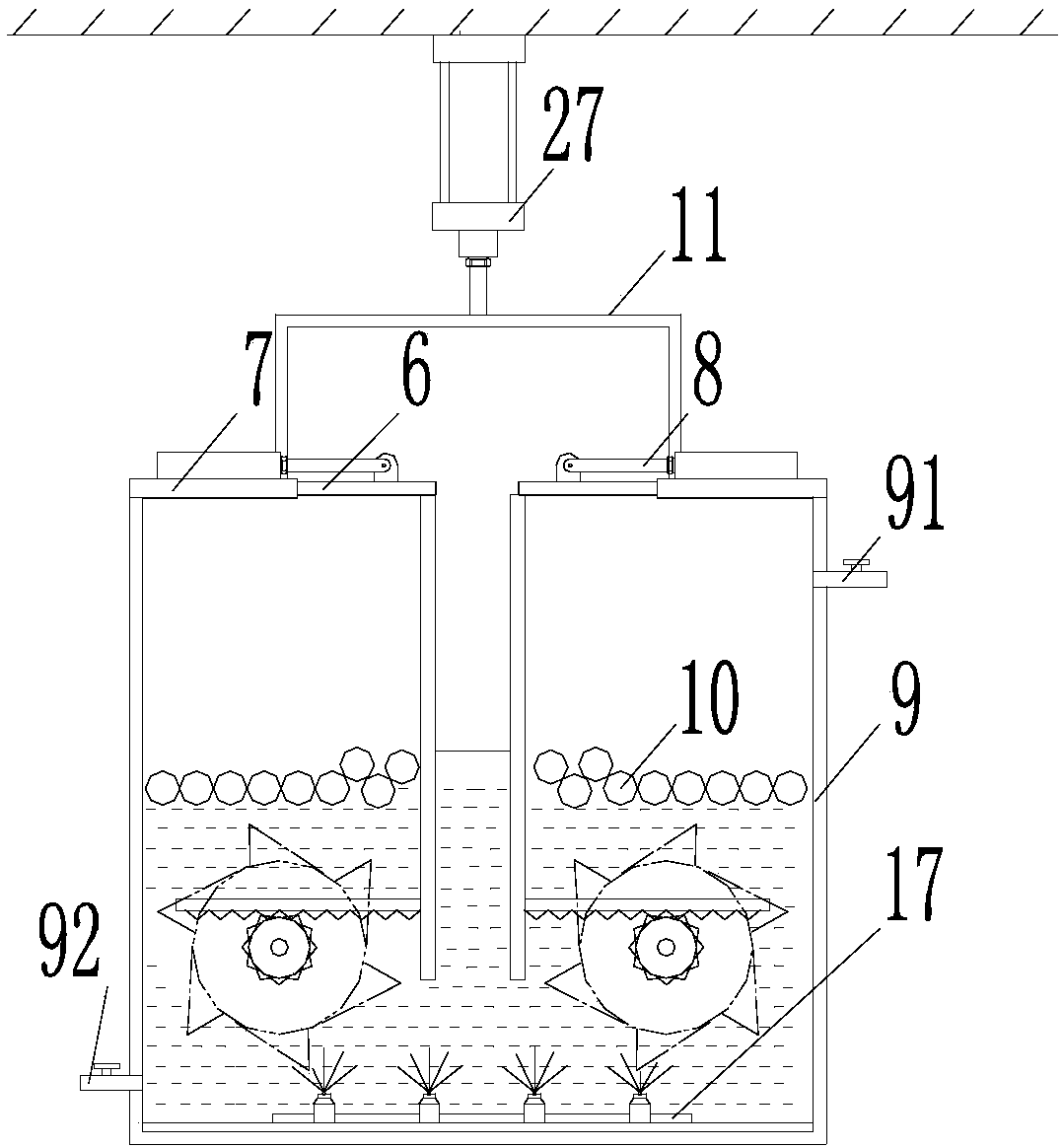

Circulatory sand screening device used for construction site

InactiveCN107497668AImplement automatic cleanupImplement loop filteringSievingScreeningHydraulic cylinderScreening effect

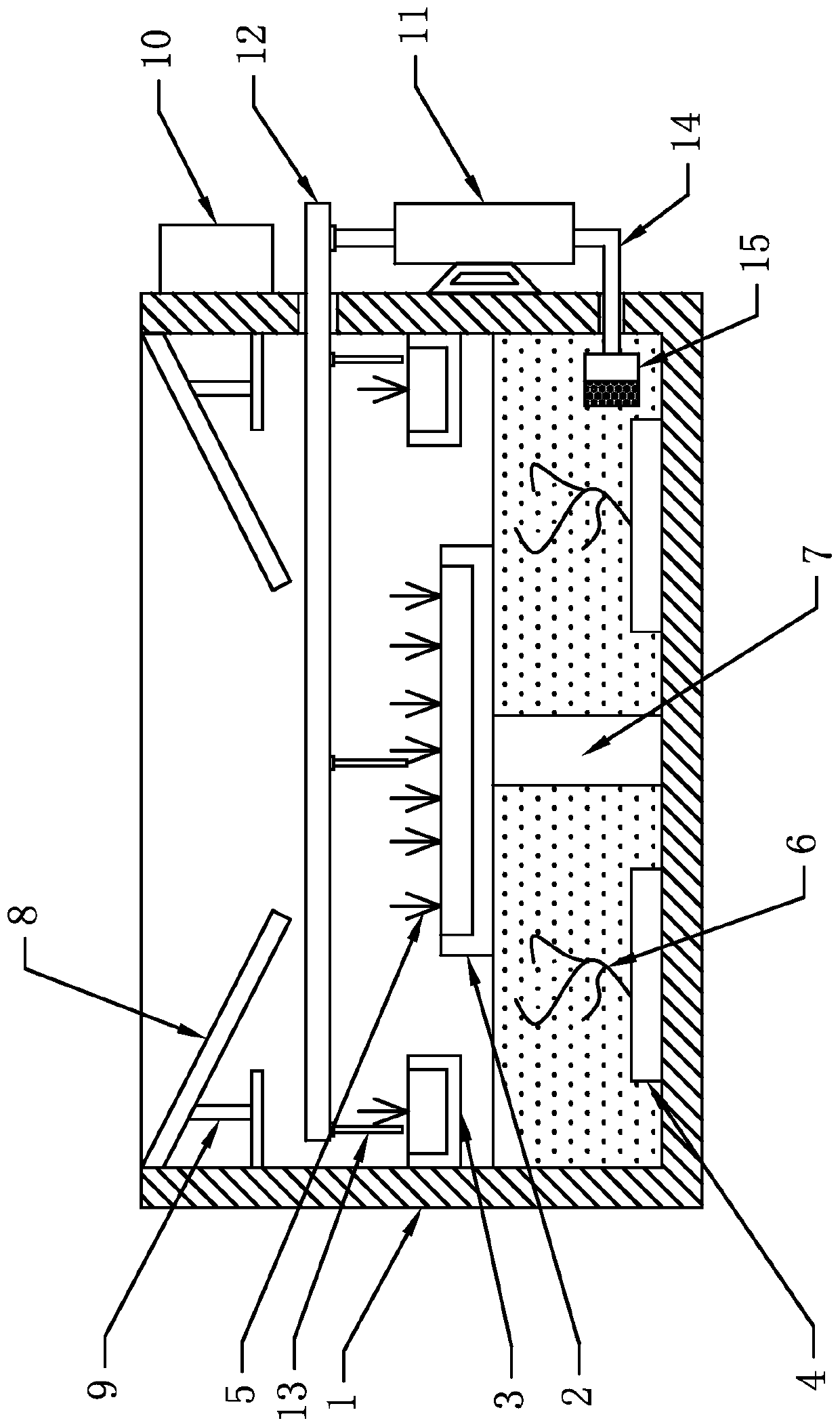

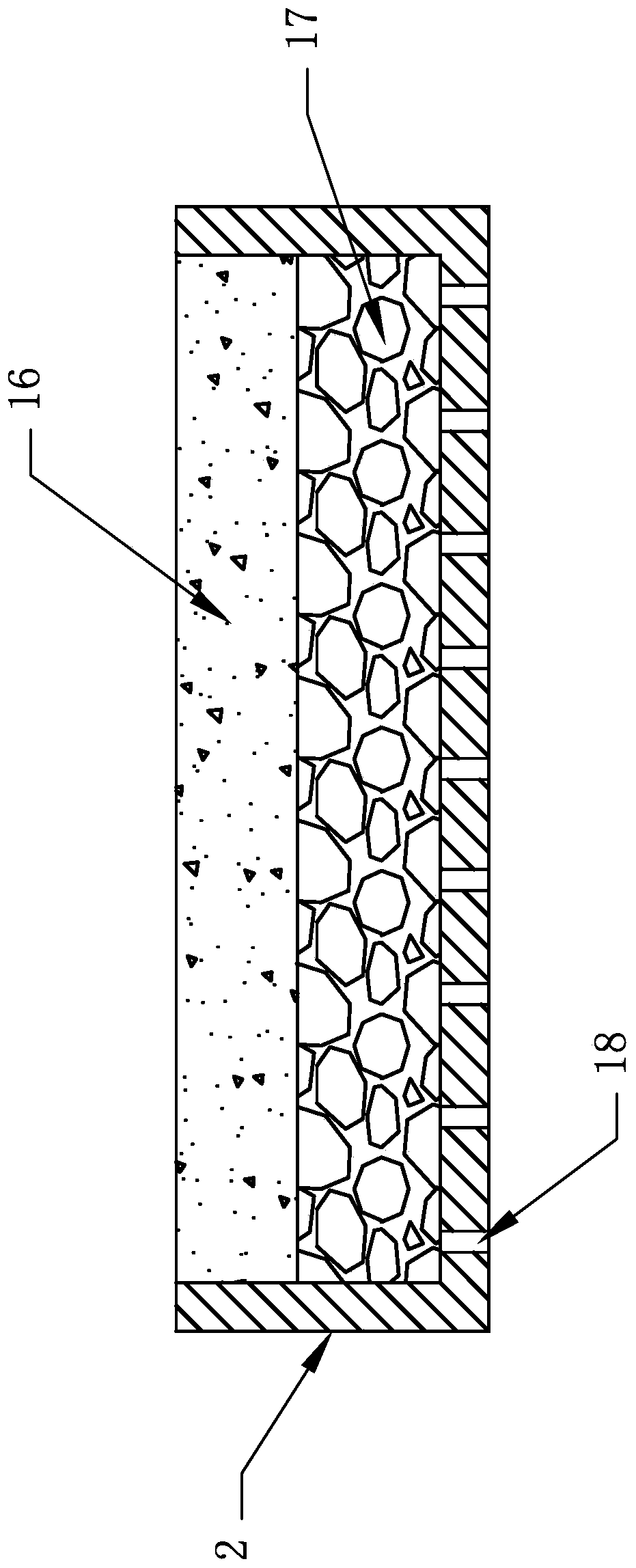

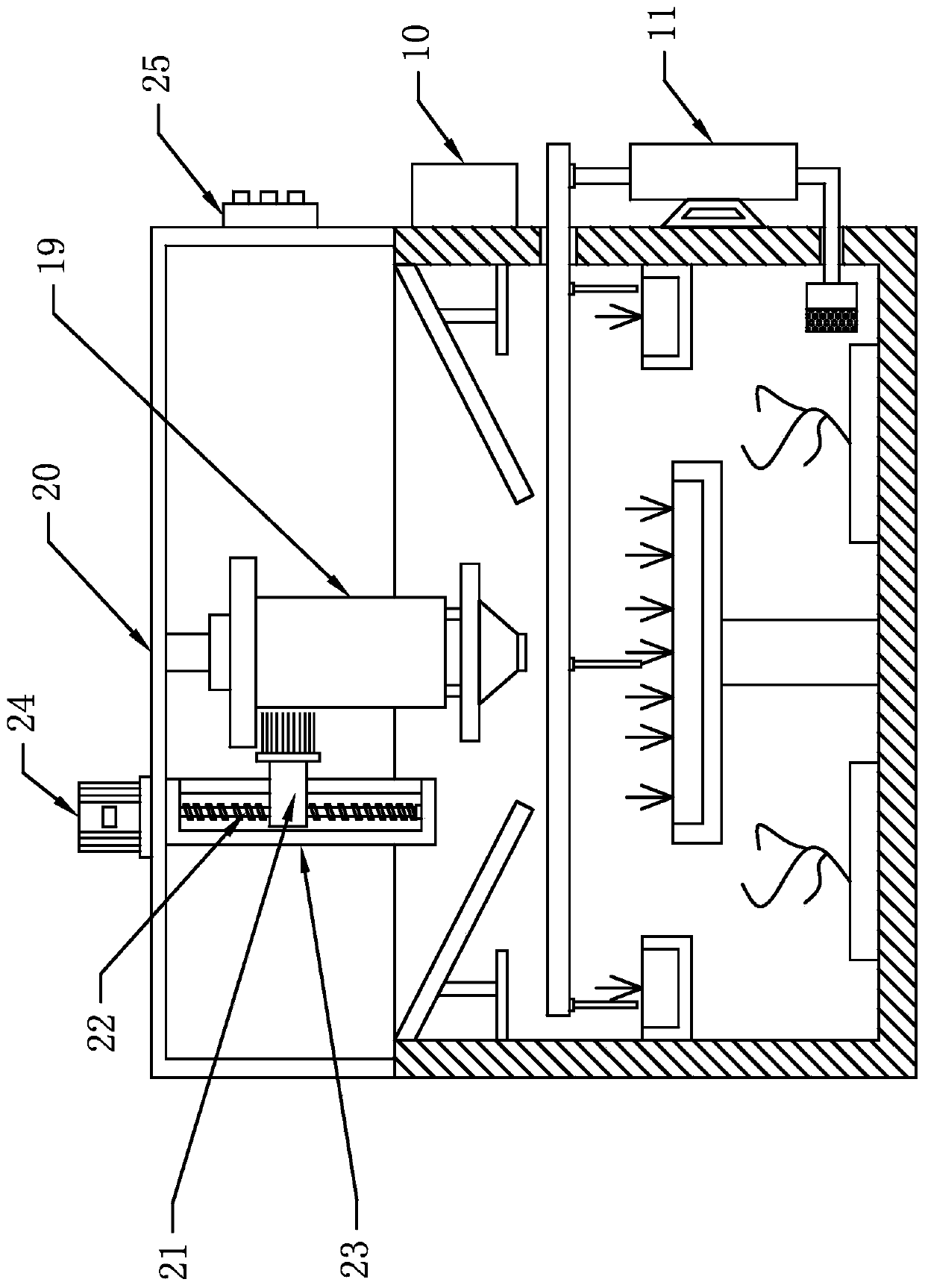

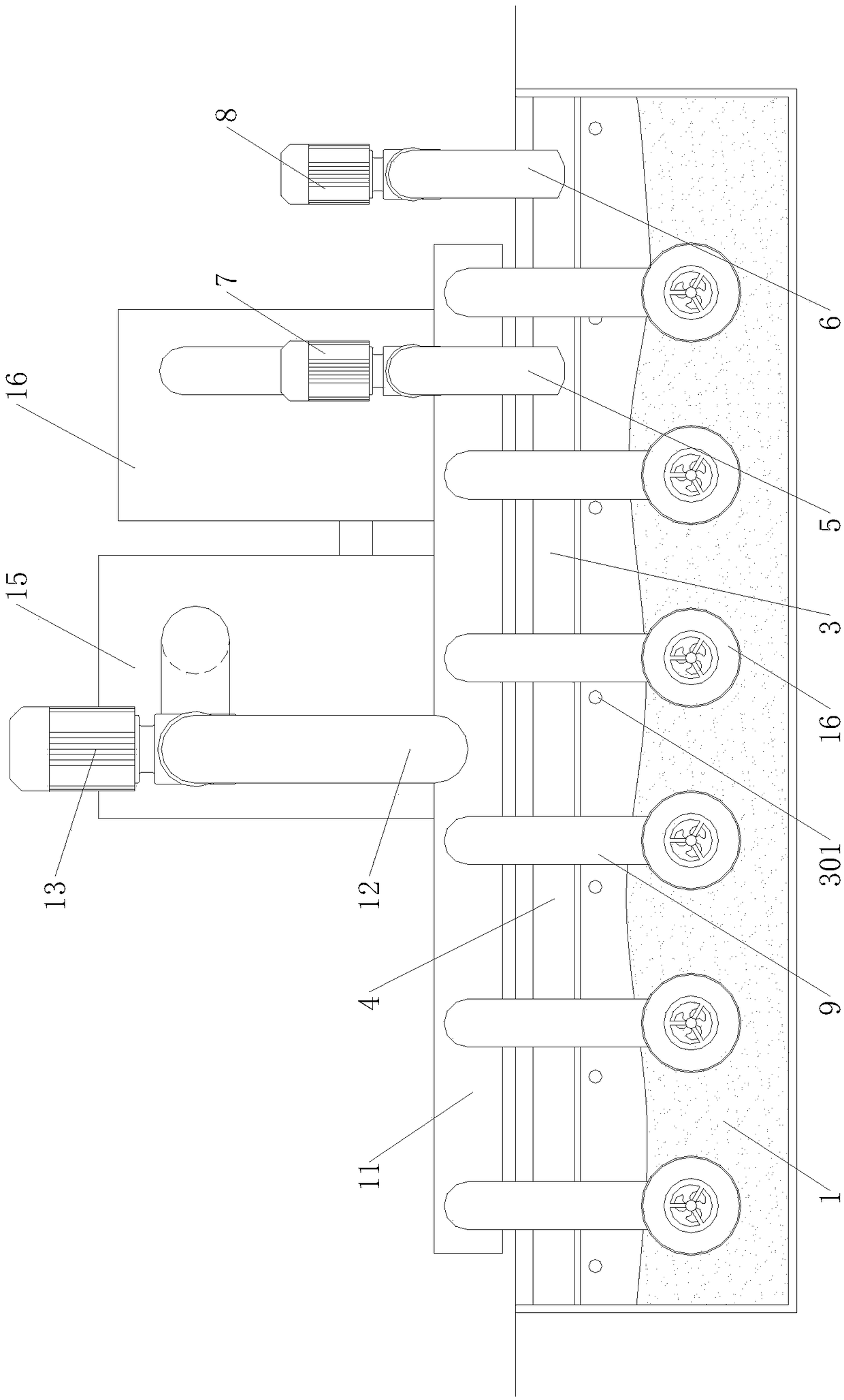

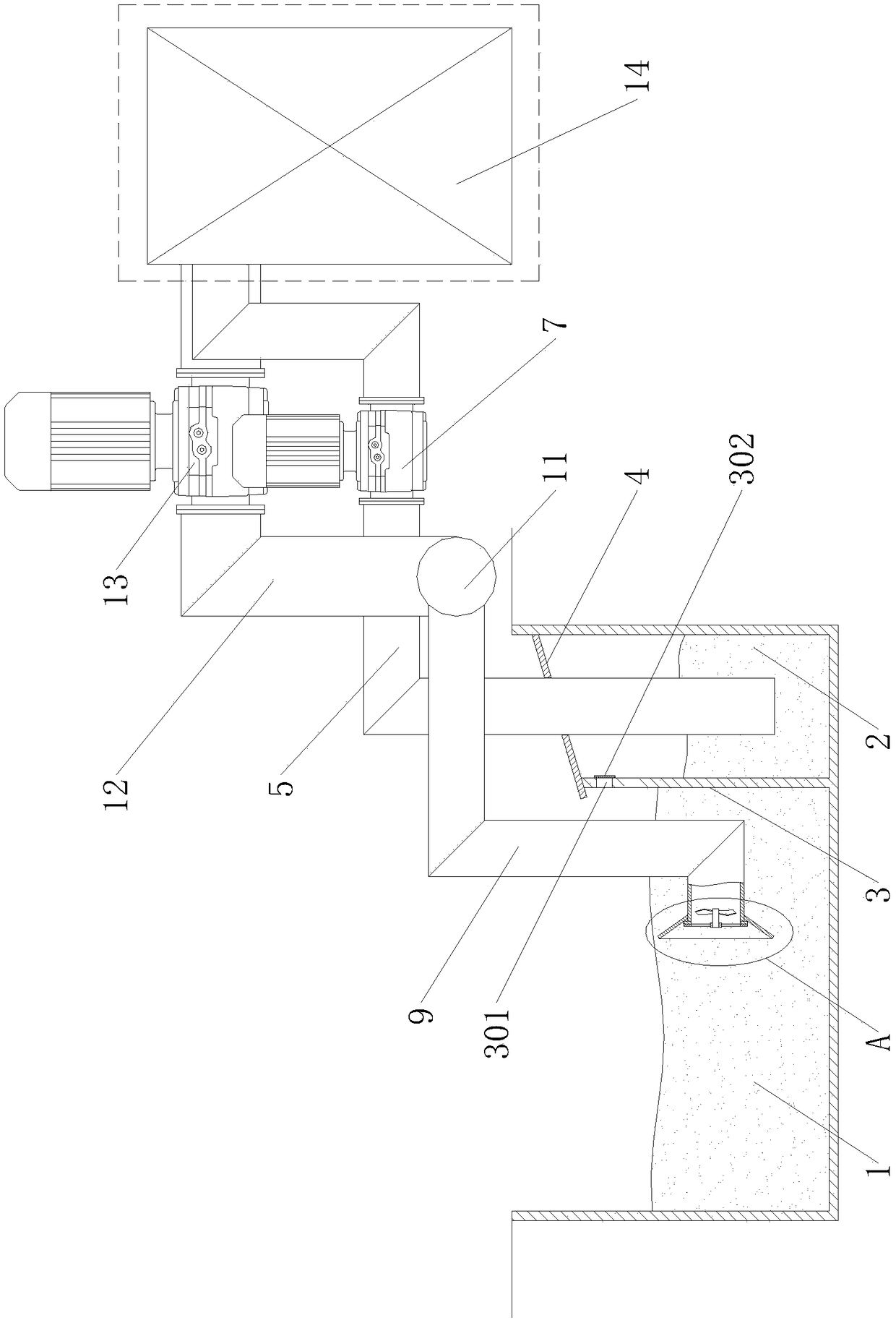

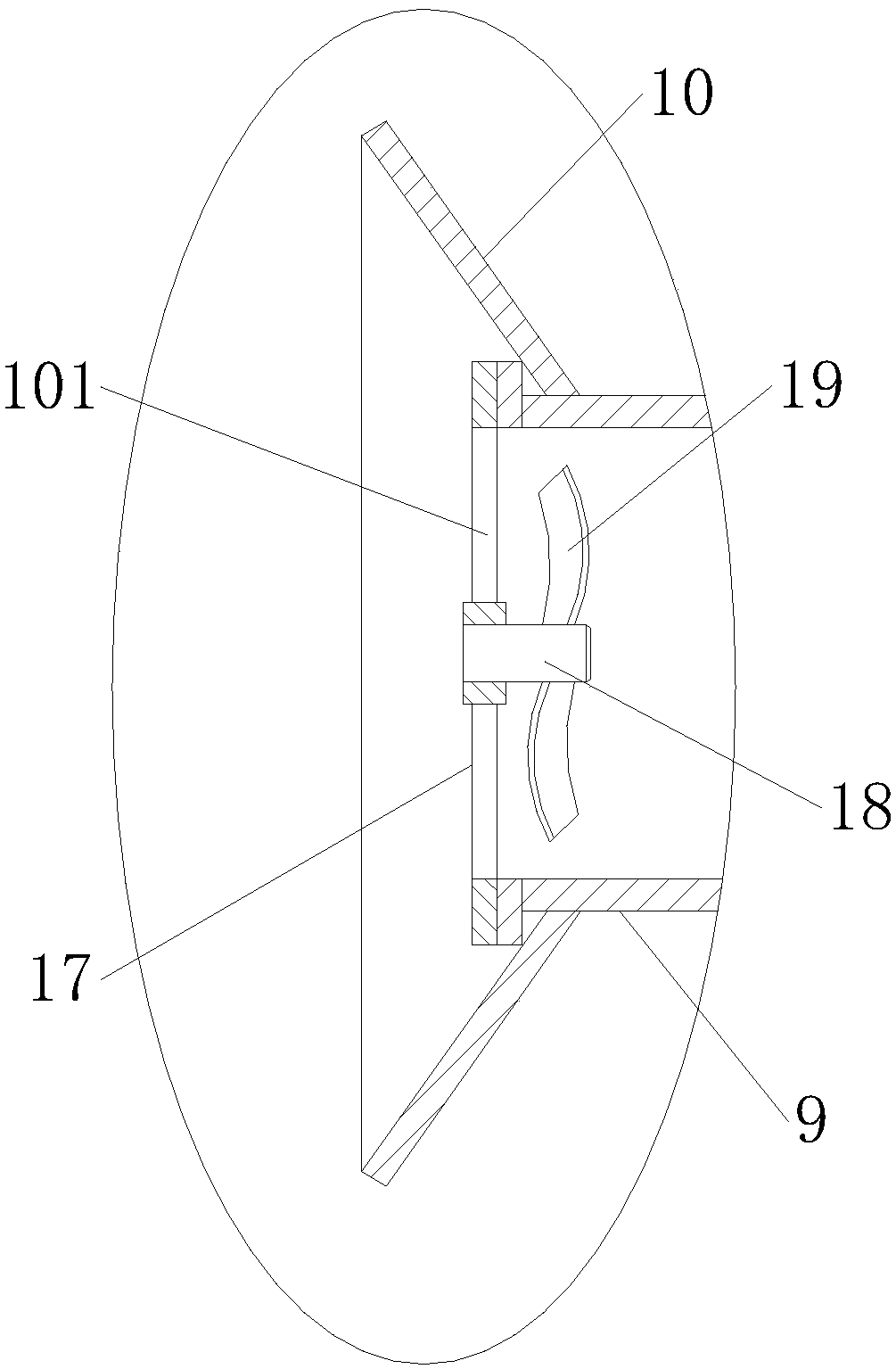

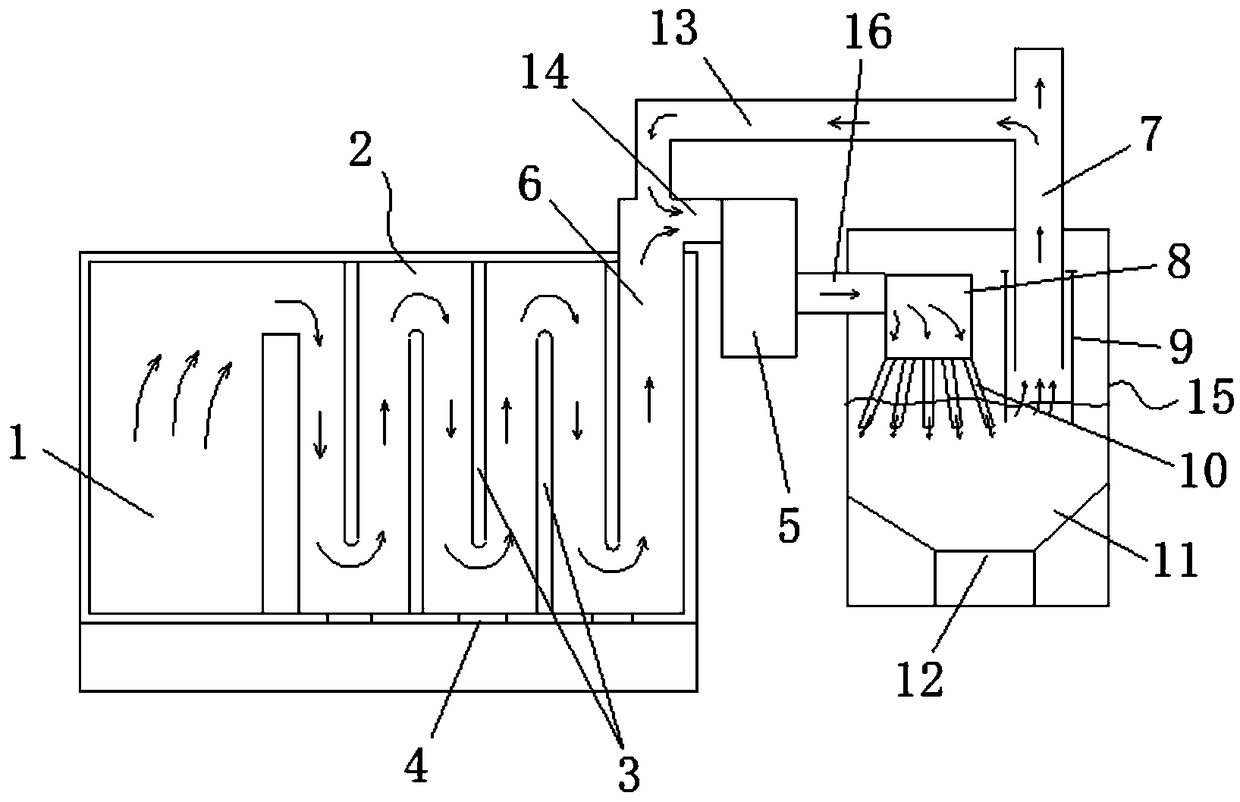

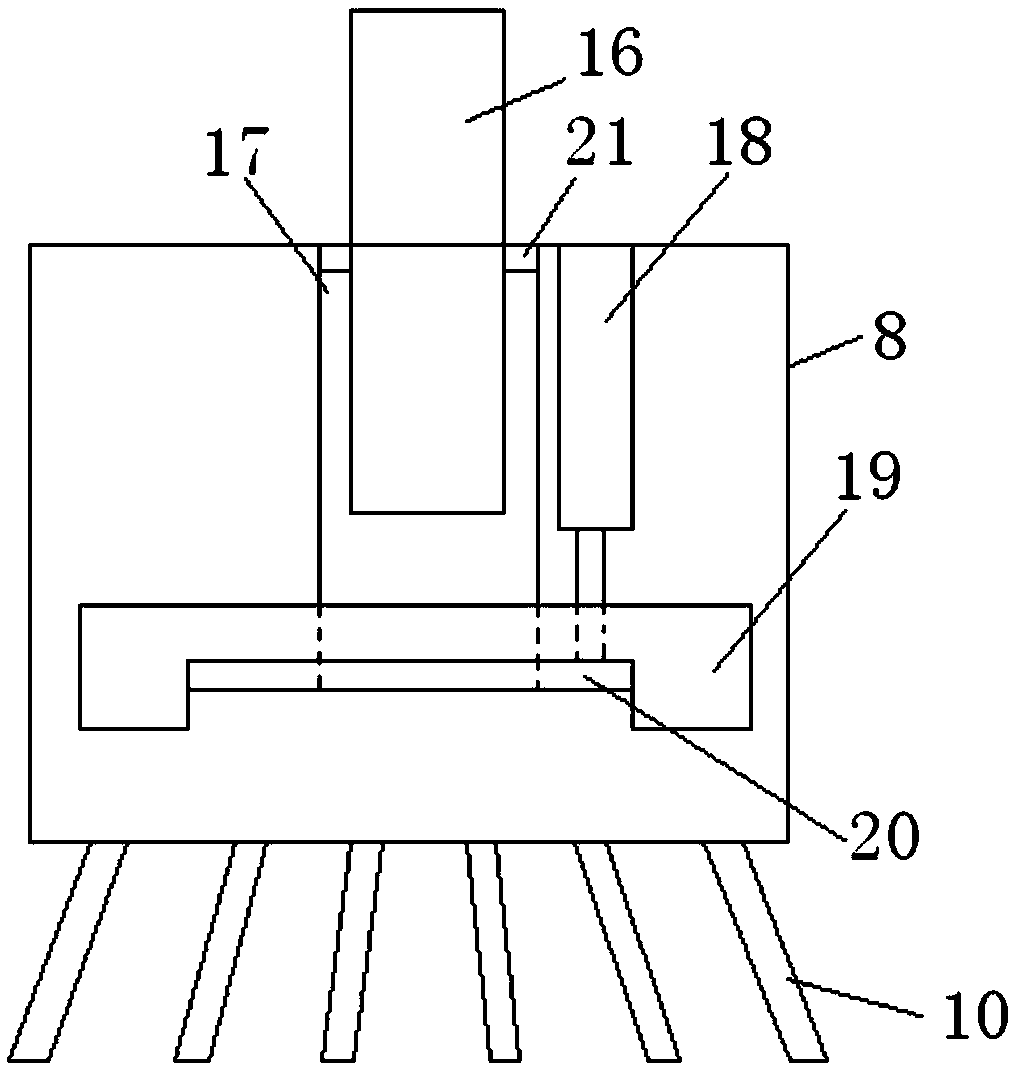

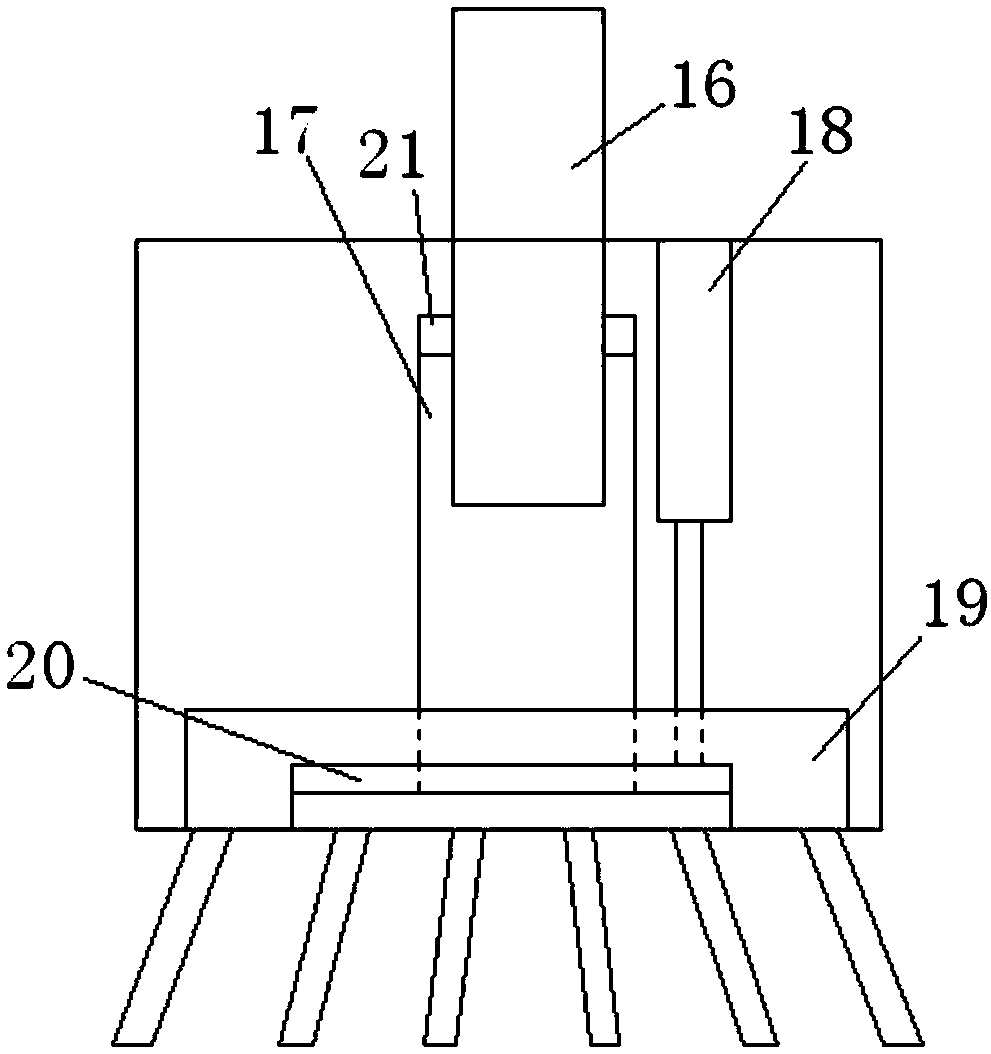

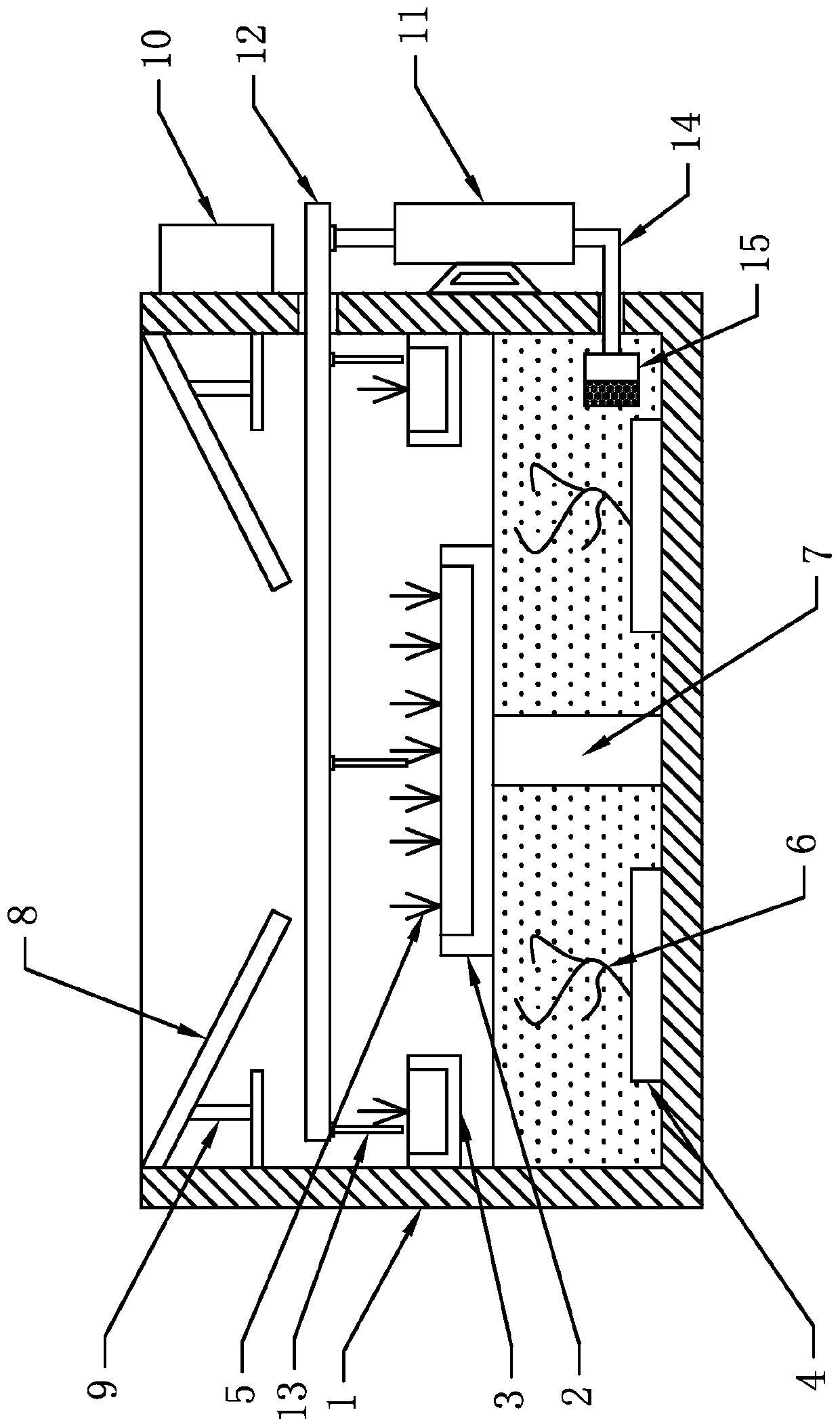

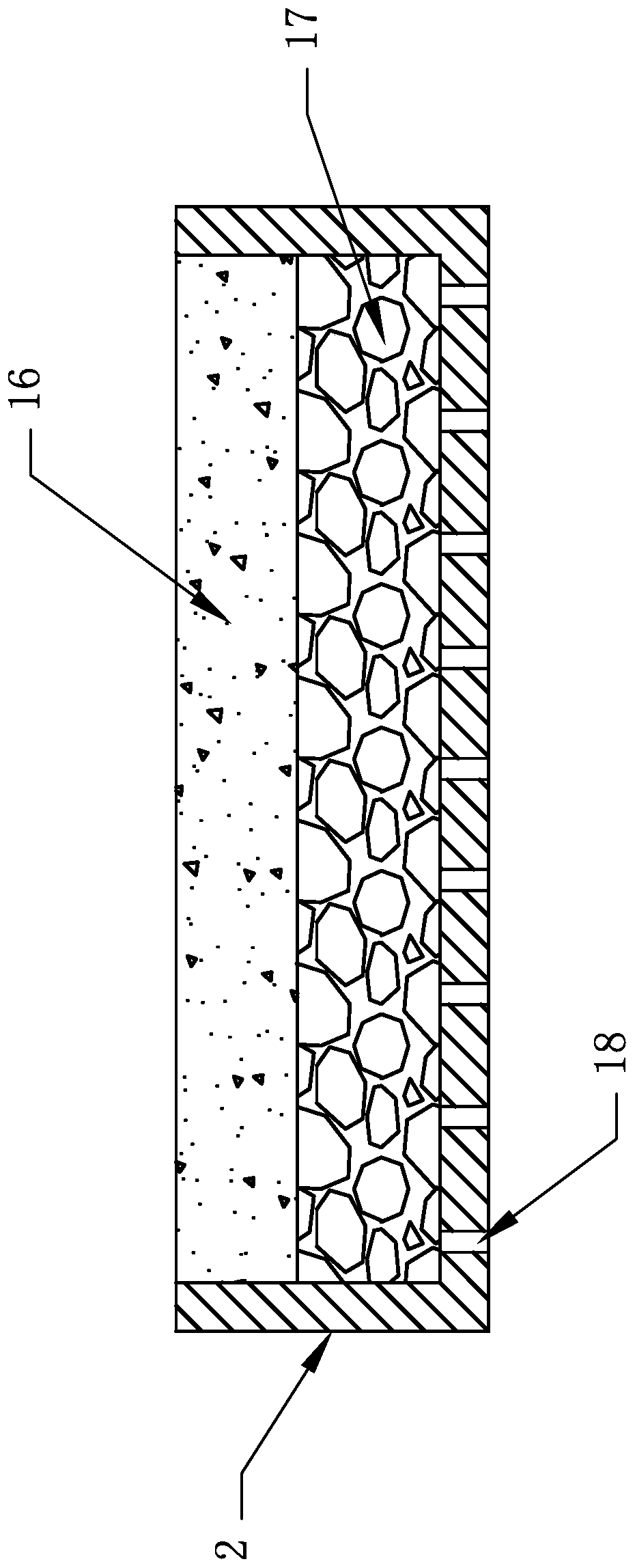

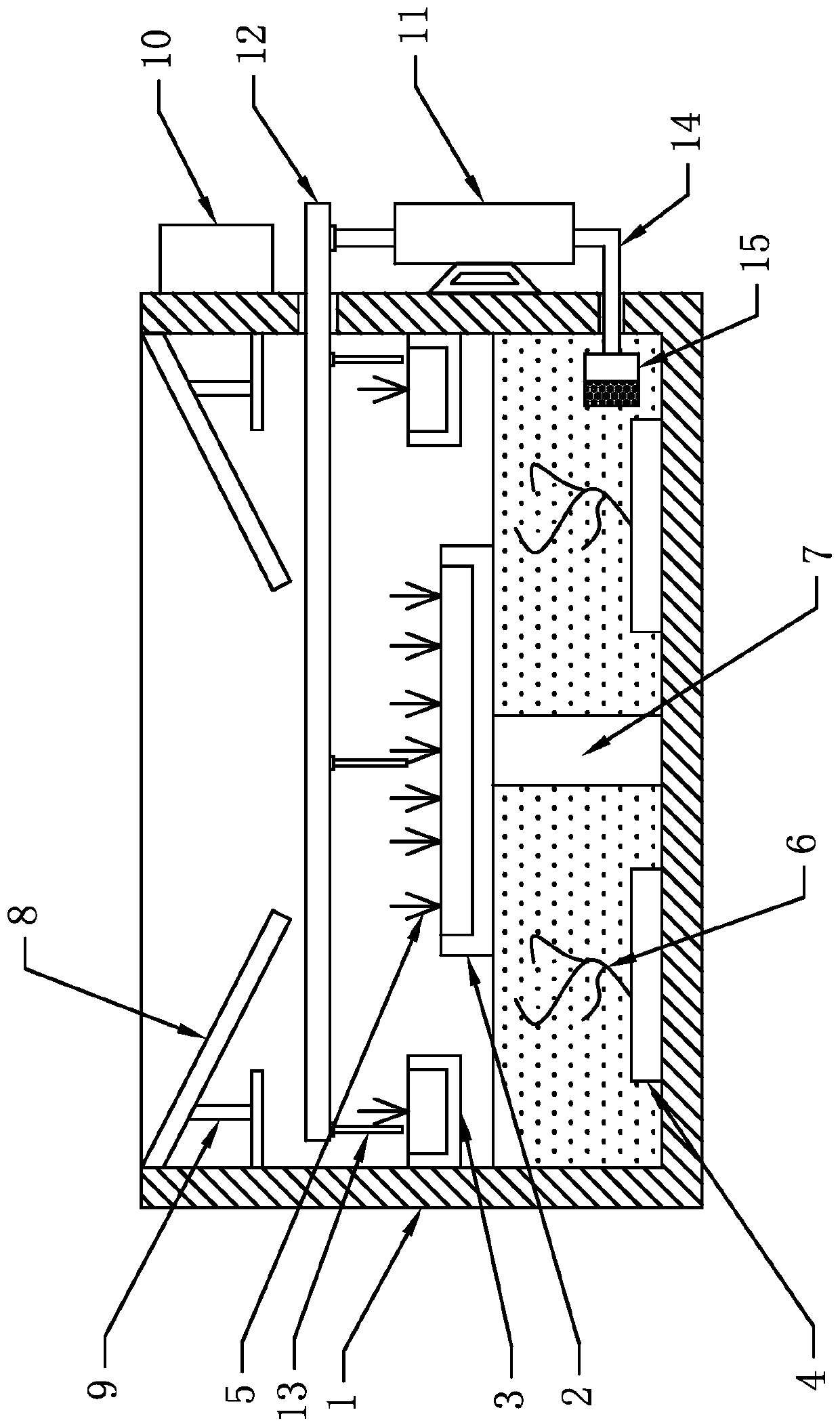

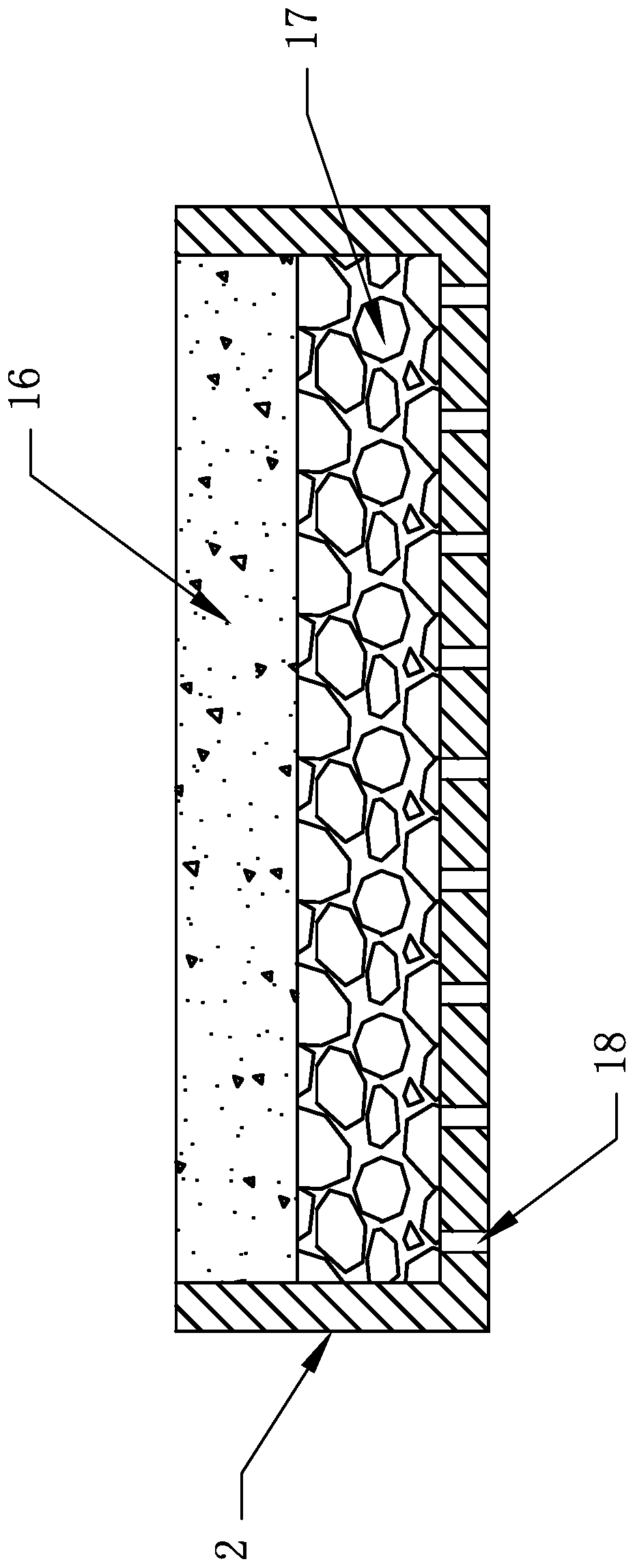

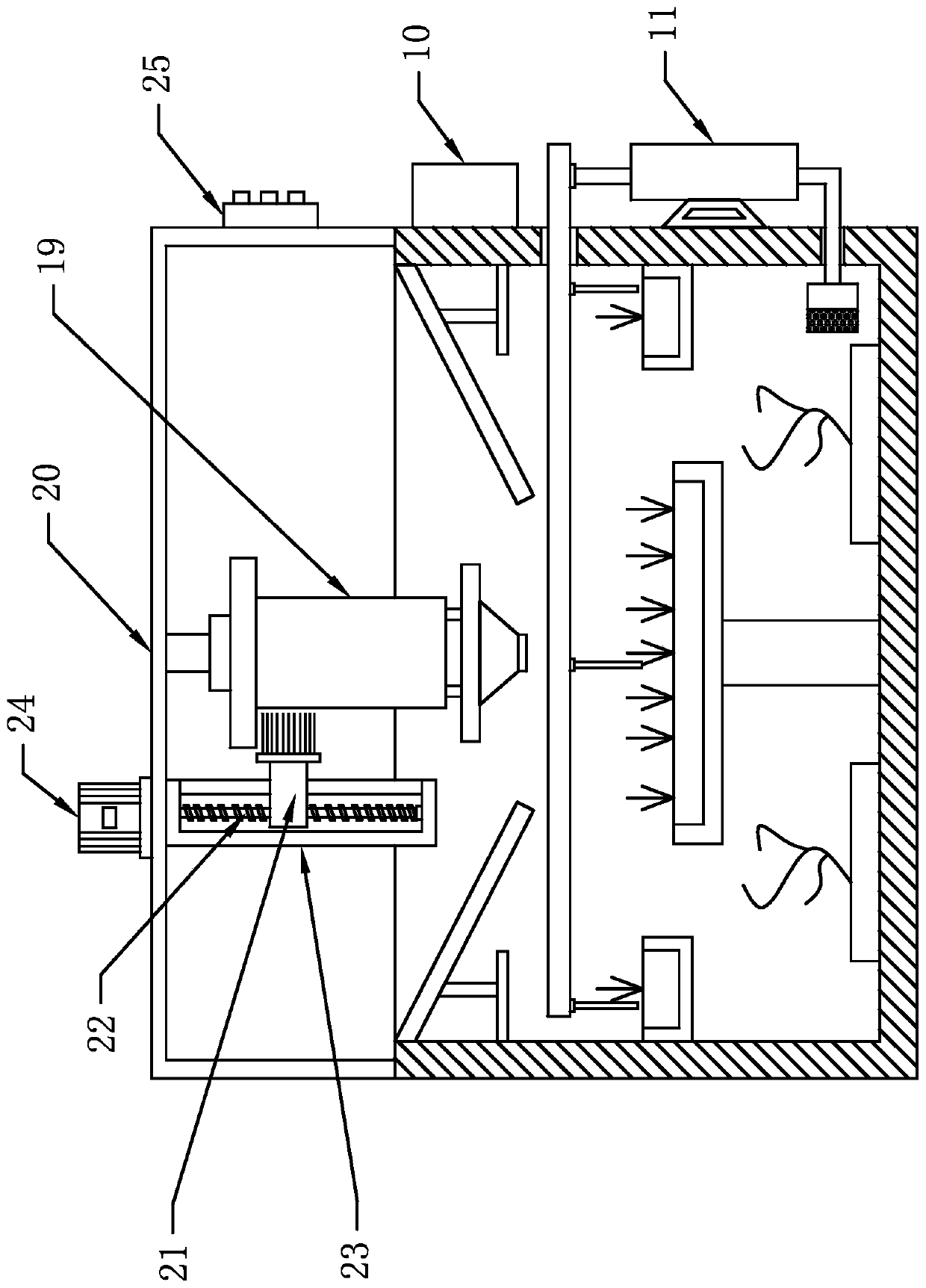

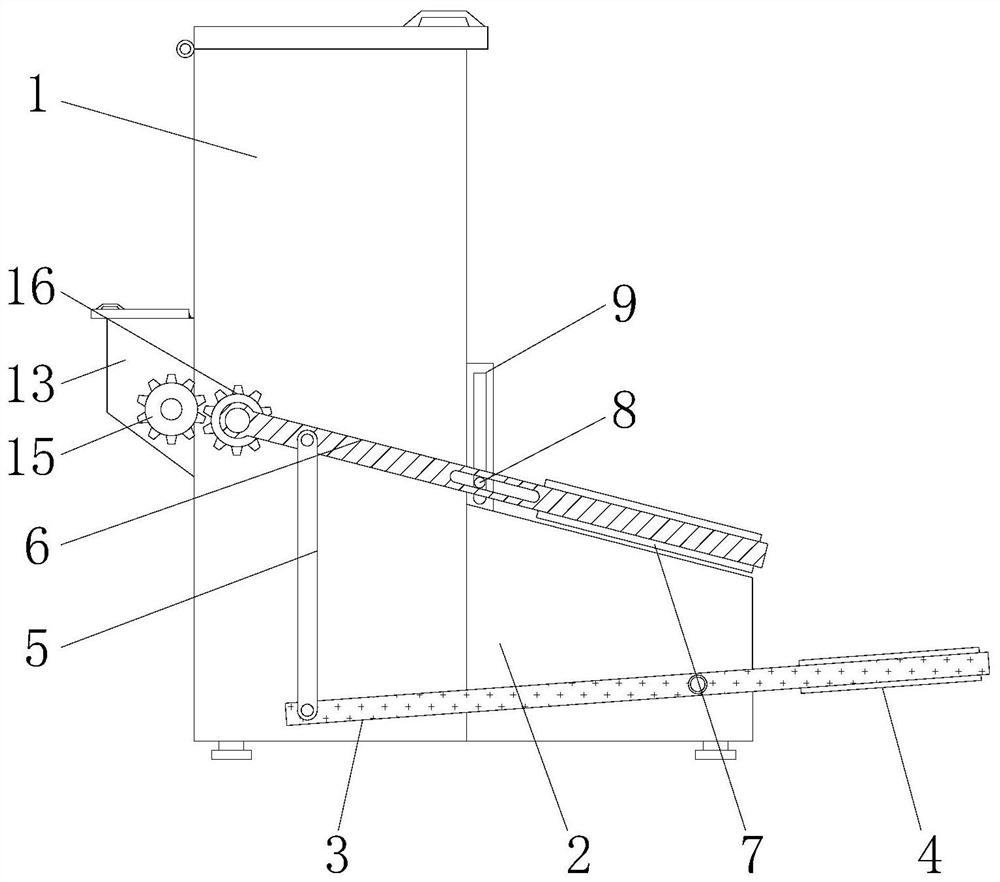

The invention discloses a circulating sand screening device for a construction site, which comprises a vibrating motor, a screen, a hydraulic cylinder and a circulating conveying device. The vibration of the vibrating motor is used to speed up the screening of the sand by the screen, and at the same time, the sand screening of the sand screen is avoided. The holes cause blockage and affect the normal use of the screen. The screen is set horizontally to fully screen the sand, and the hydraulic cylinder is used to drive the hydraulic rod to extend and then push the frame to rotate along the side hinged with the box, thus realizing the screen. The inclined setting of the screen makes the sand that does not pass through the screen fall into the collection tank under the action of gravity, which realizes the automatic cleaning of the sand that does not pass through the screen, improves the practicability of the equipment, and falls from the screen into the collection tank The sand inside further slides into the cylinder body along the slanting plate, thereby realizing the circular screening of the sand and improving the effect of sand screening.

Owner:南京苏格信息技术有限公司

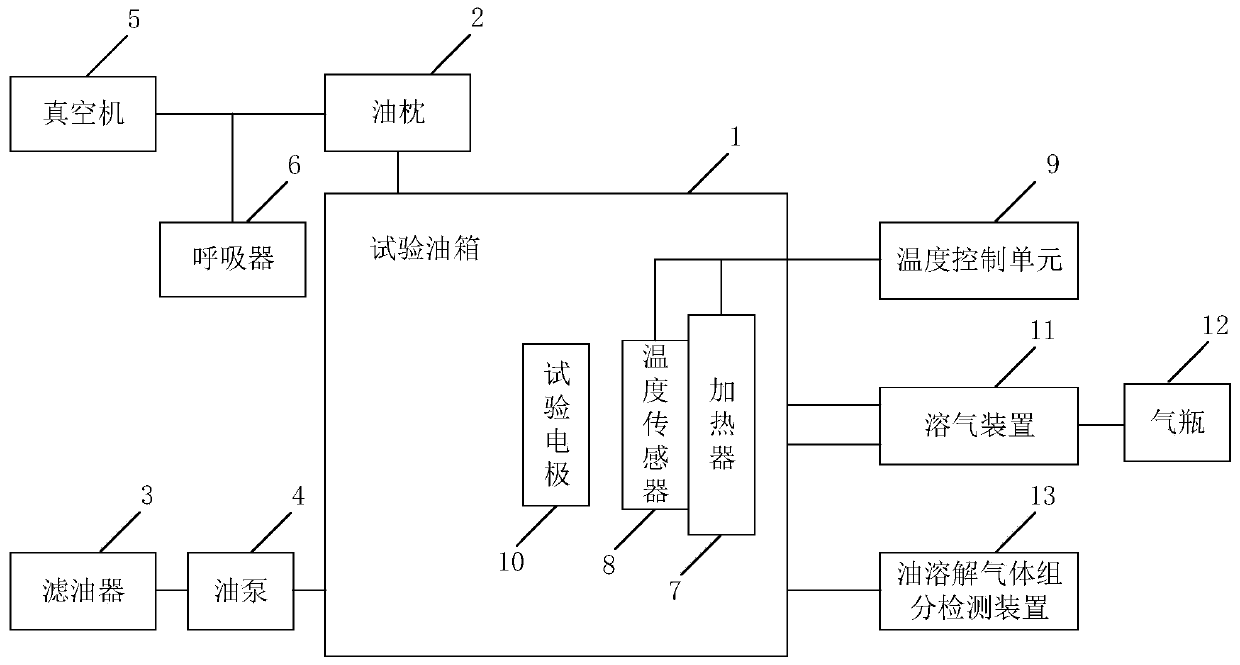

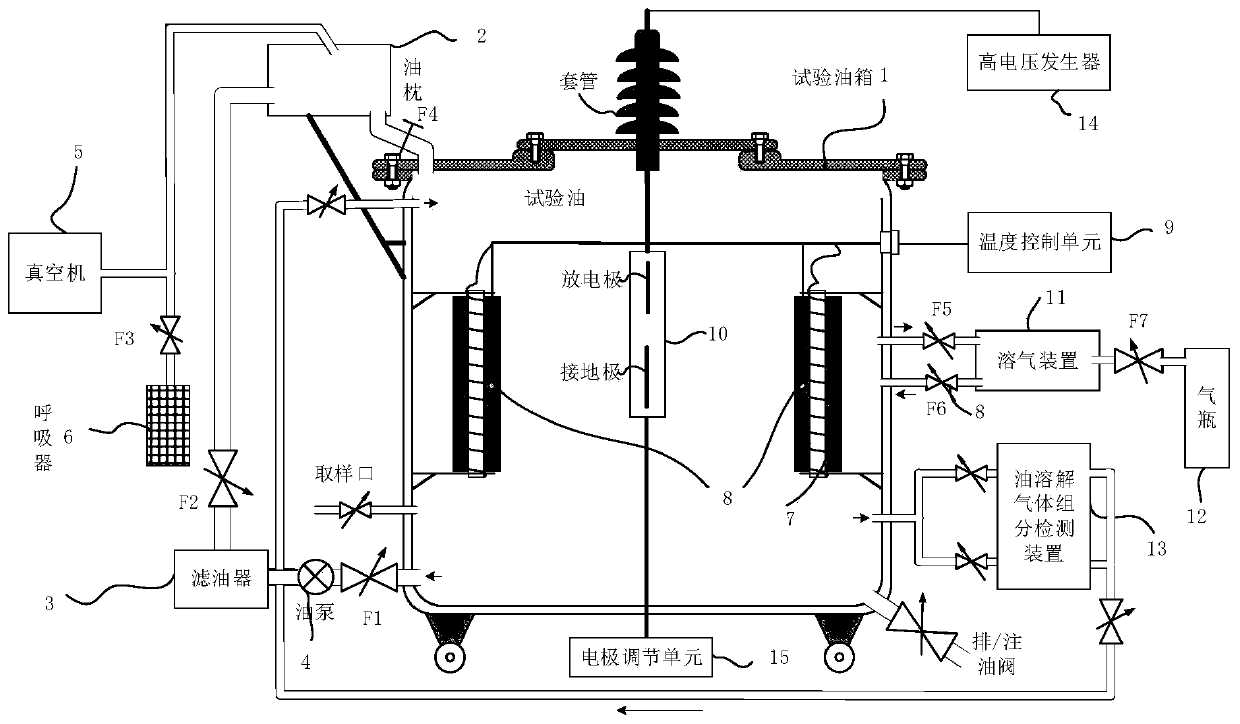

Transformer oil degradation test system and method

InactiveCN110794266AAvoid wastingImprove cleanlinessTesting dielectric strengthMaterial analysisPhysicsEngineering

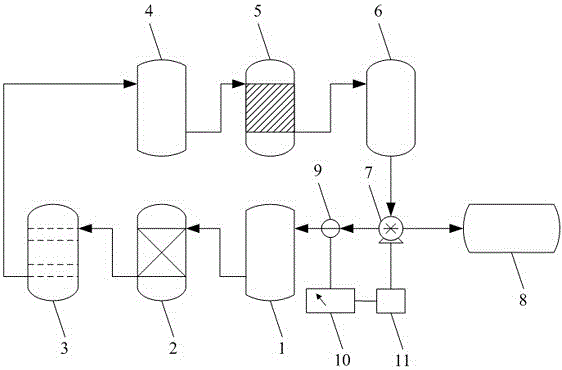

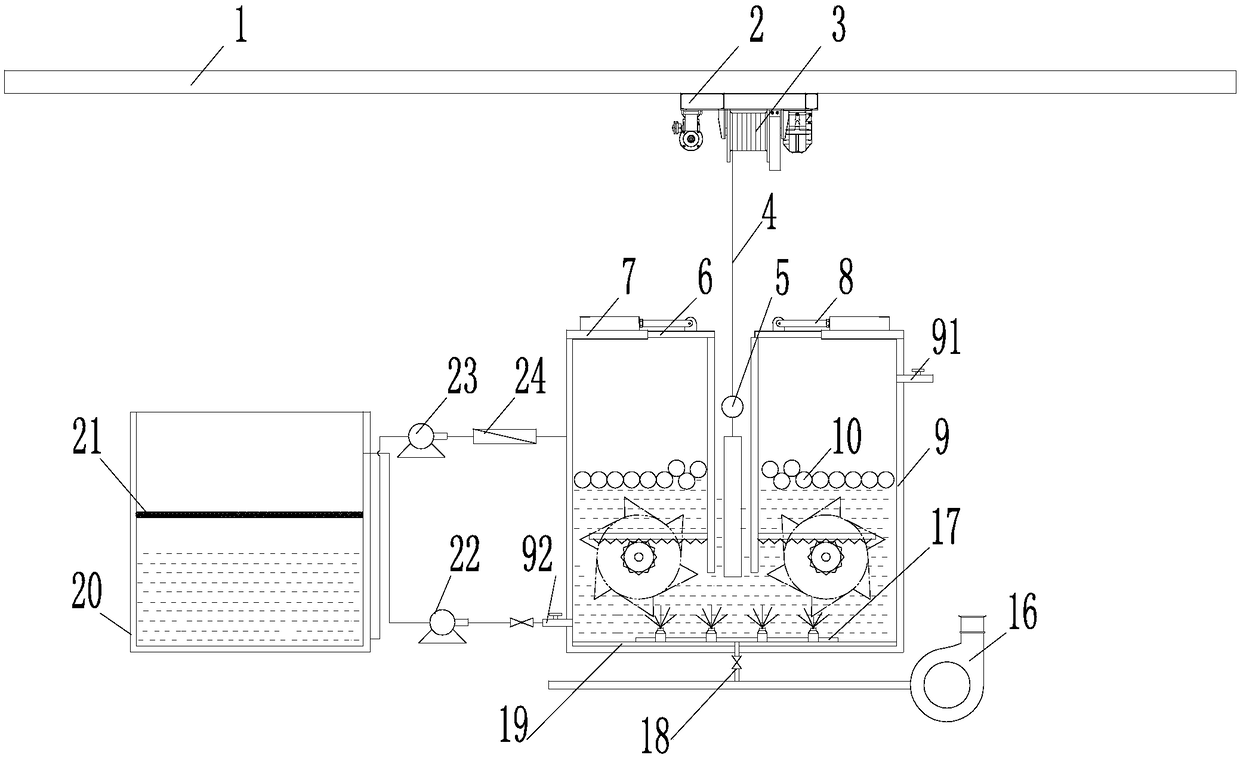

The invention discloses a transformer oil degradation test system. The transformer oil degradation test system comprises a test oil tank, an oil conservator, an oil filter, an oil pump, a vacuum machine, a respirator, a heater, a temperature sensor, a temperature control unit, a test electrode, a gas dissolving device, a gas cylinder and an oil dissolved gas component detection device connected with the test oil tank, wherein the oil conservator is connected with the top of the test oil tank through a pipeline; the vacuum machine and the respirator are connected with the top of the oil conservator through pipelines; the oil pump is connected to the bottom of the test oil tank through a pipeline; the oil filter is connected to the bottom of the oil conservator through a pipeline; the heateris mounted inside the test oil tank; the temperature sensor is mounted on the surface of the heater; the gas cylinder is connected to the gas dissolving device through a pipeline; the gas dissolvingdevice is connected with the test oil tank through a pipeline. The transformer oil degradation test system provided by the invention can effectively test the aging decomposition characteristics of insulating oil and the effectiveness of detection of degradation decomposition products of transformer oil. The invention further provides a transformer oil degradation test method.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD

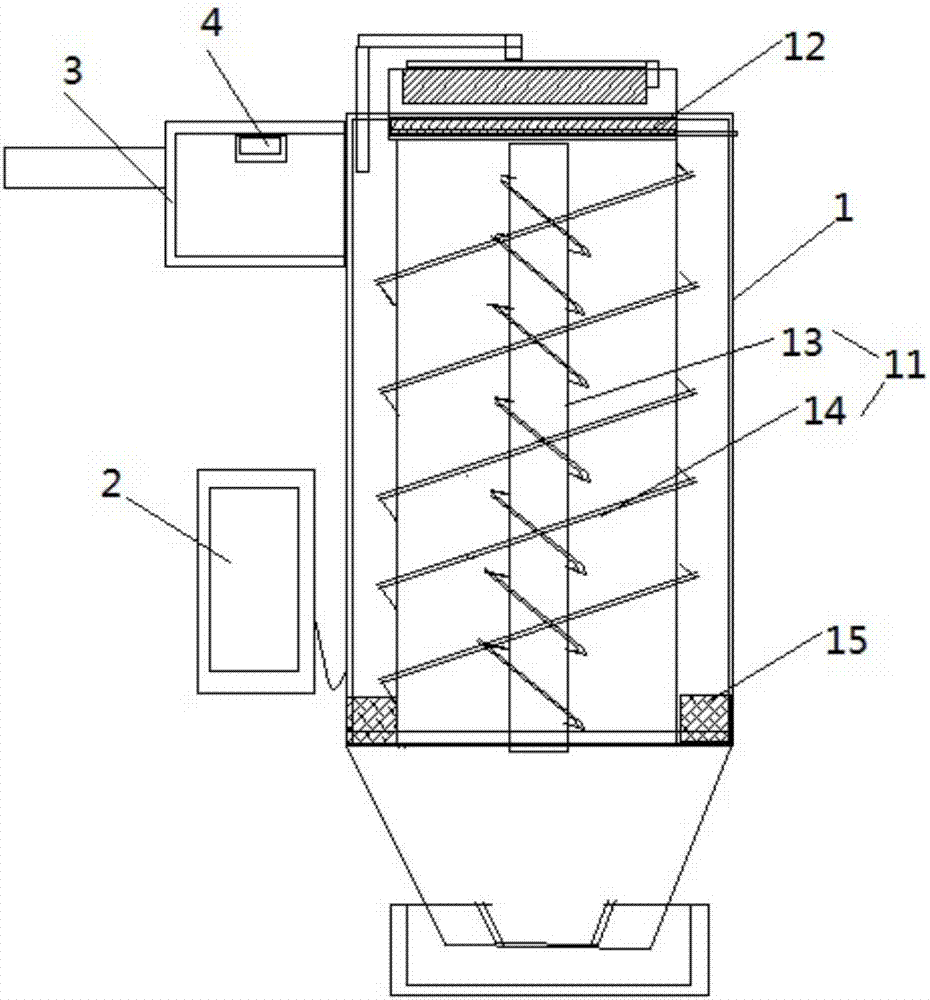

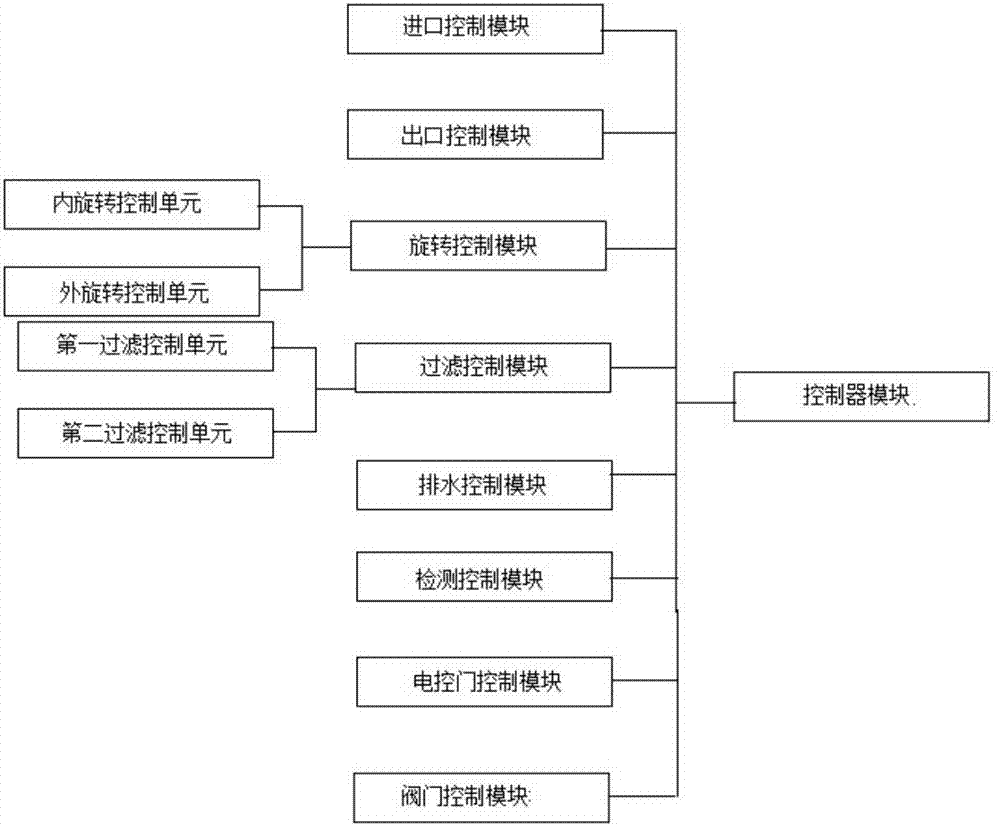

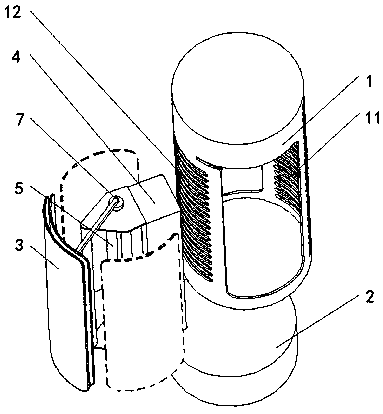

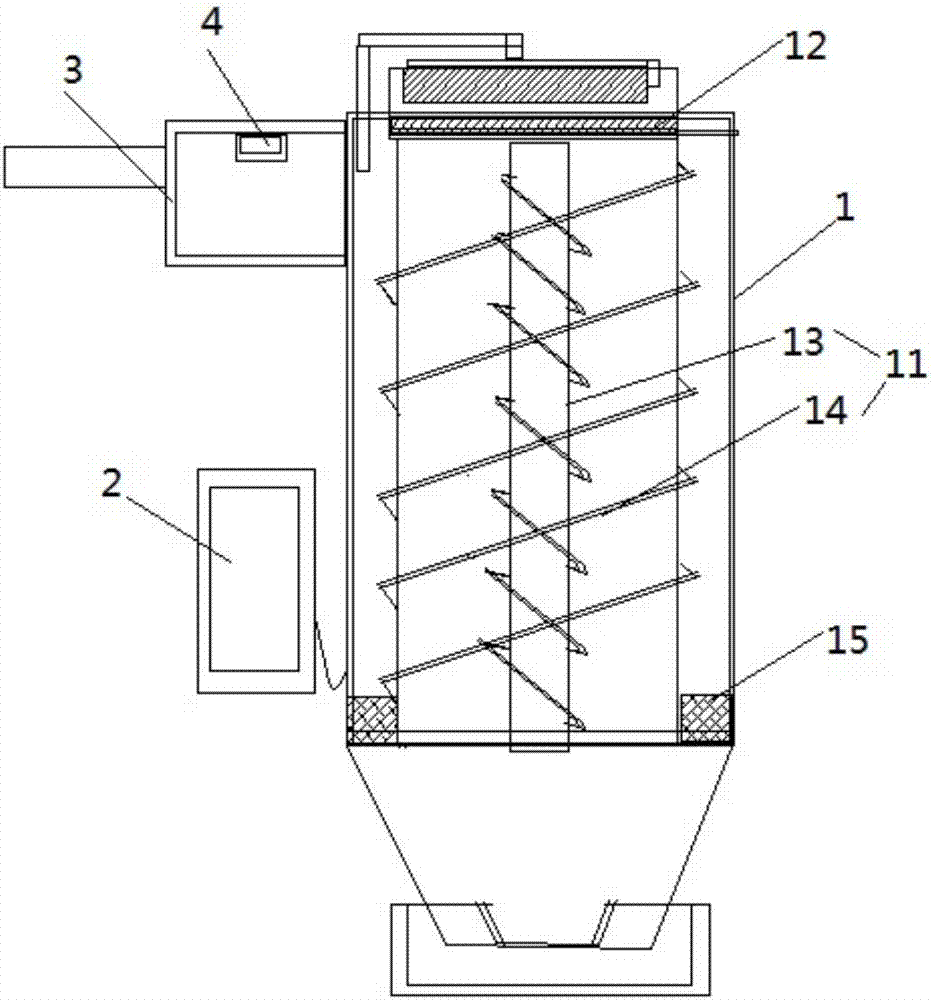

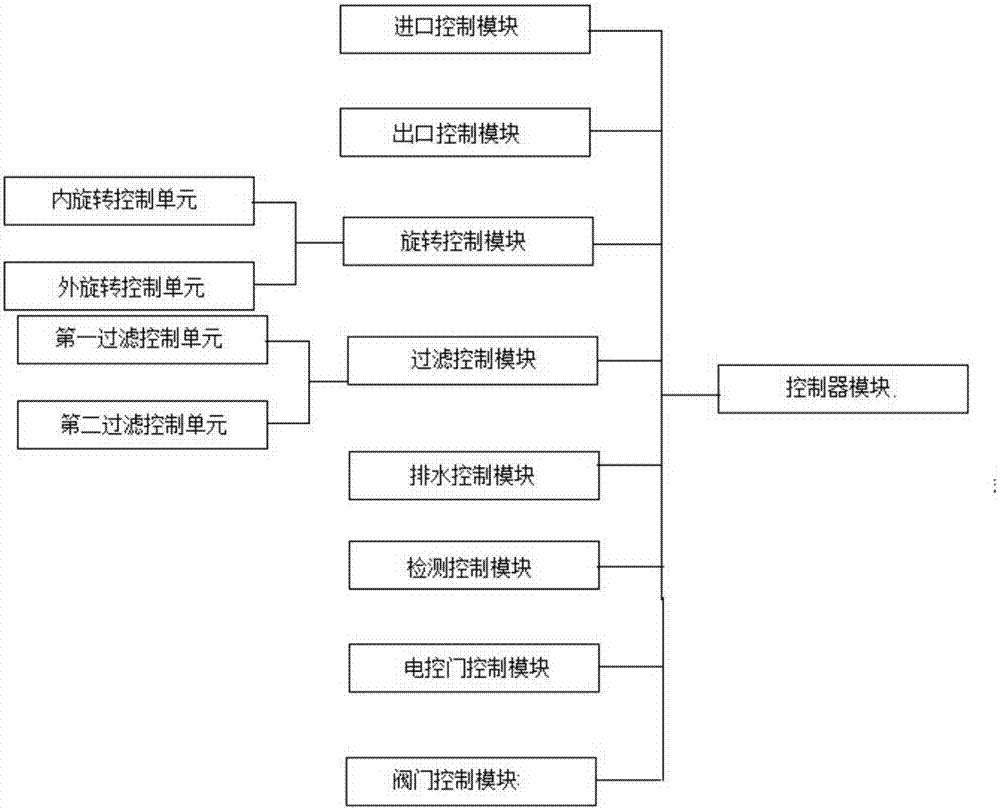

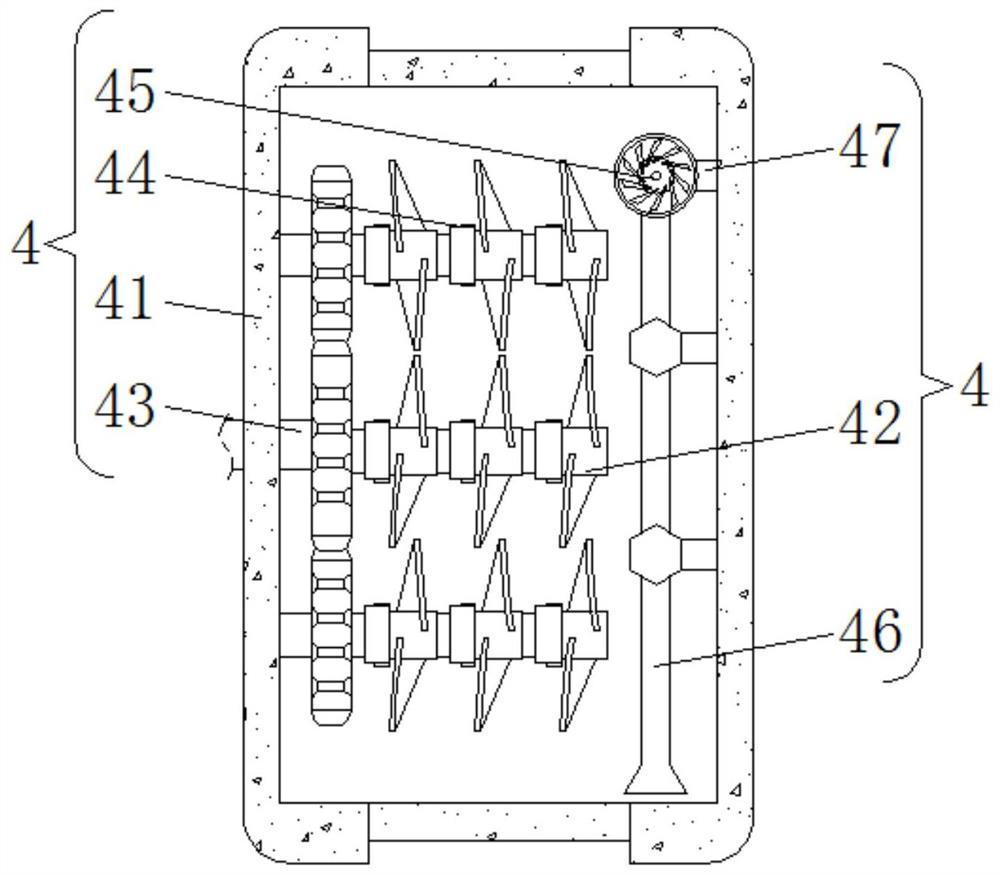

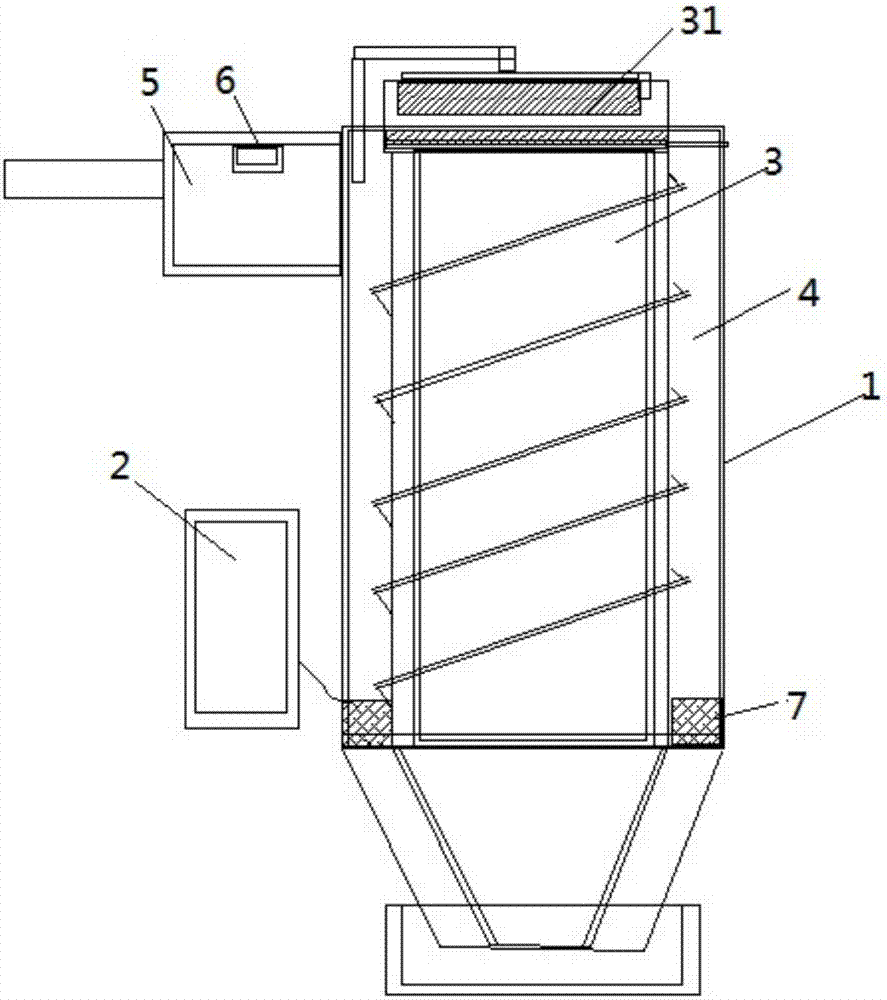

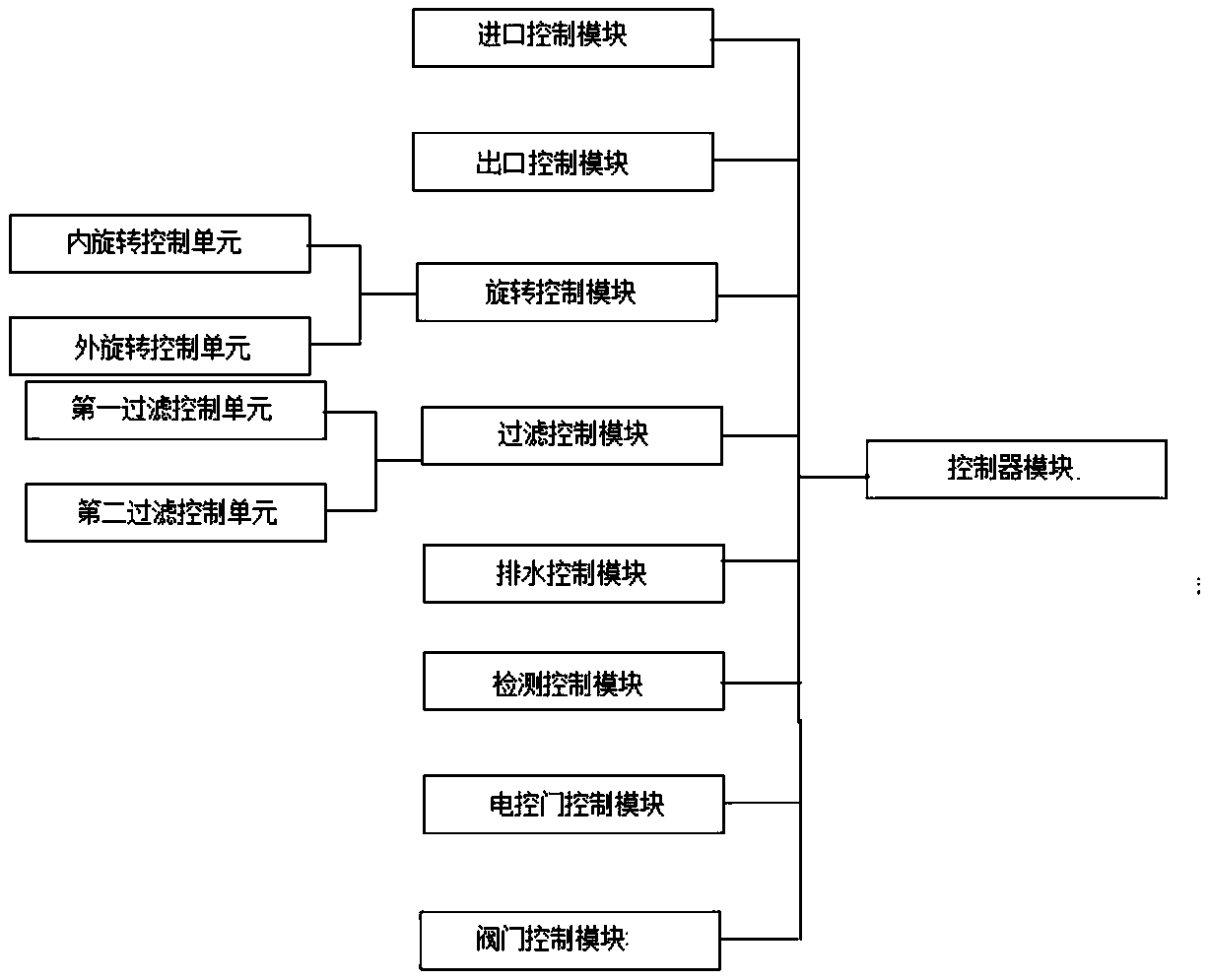

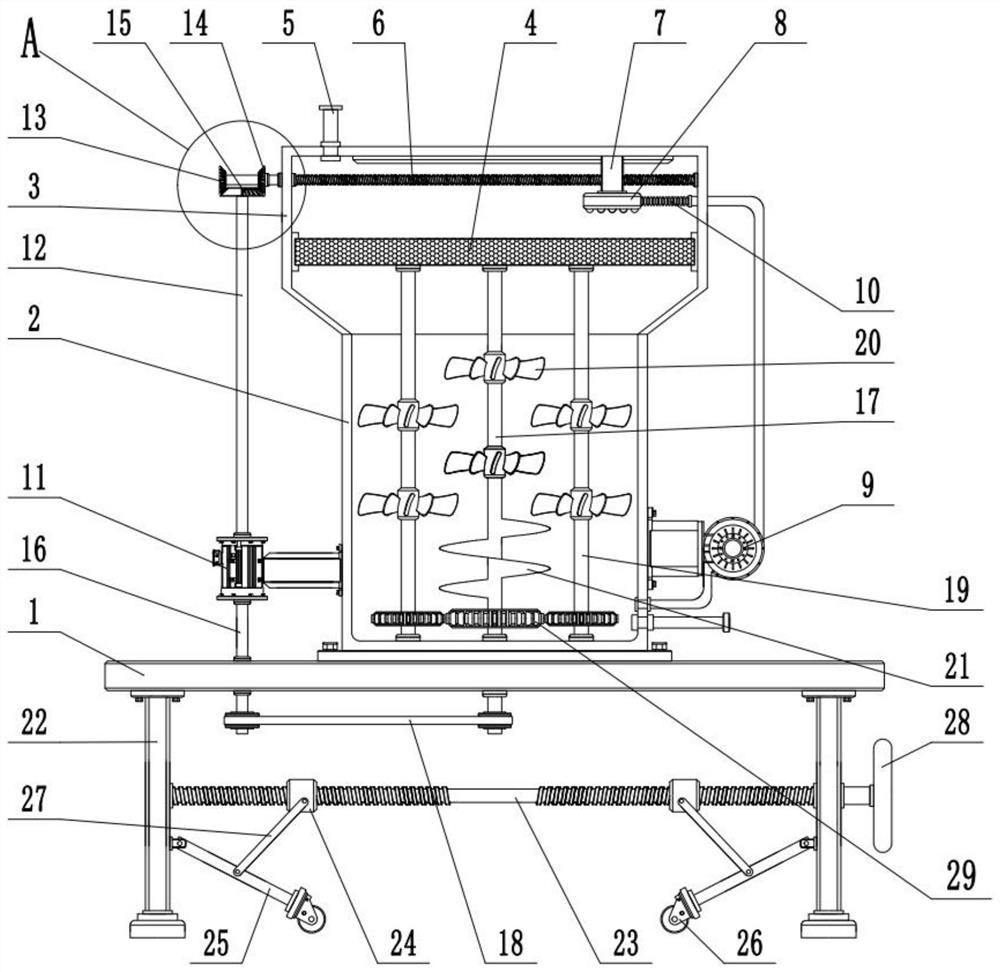

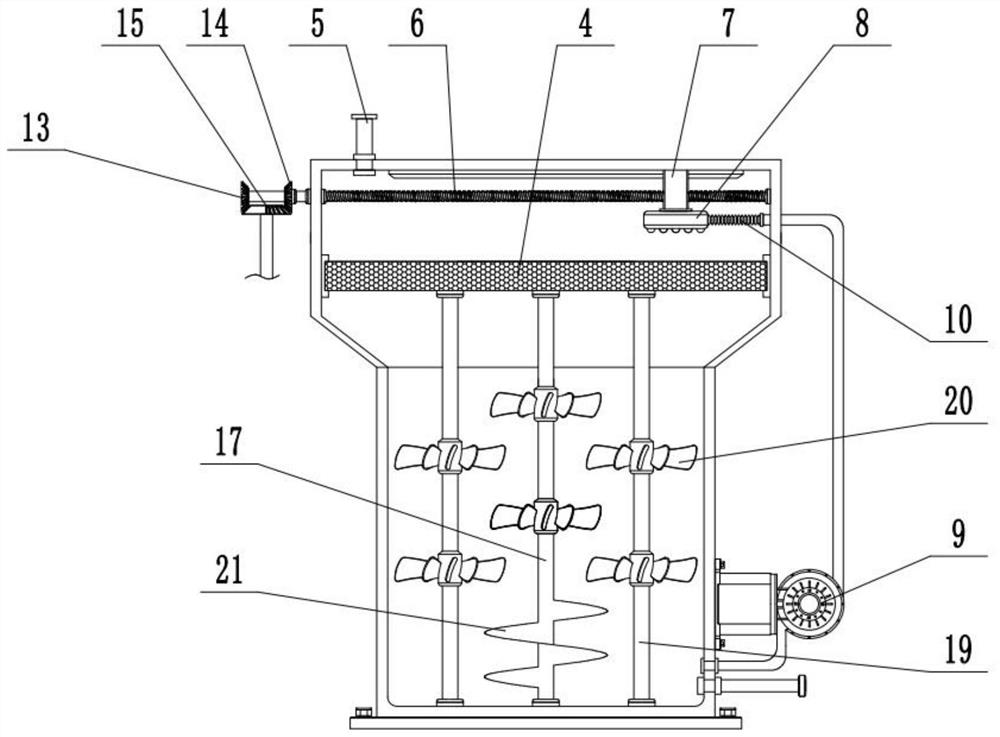

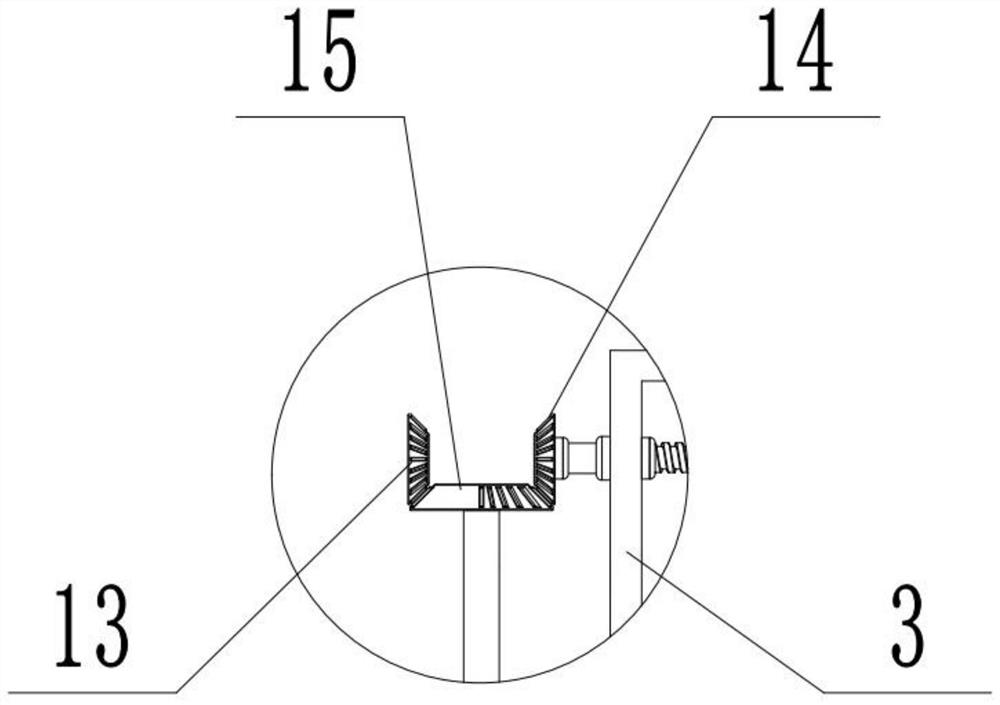

Intelligent high-efficient dust removal device and working method thereof

InactiveCN107362645AImprove filtering effectSimple structureCombination devicesIntelligent lightingProduct gas

The invention discloses a working method of an intelligent high-efficient dust removal device. The intelligent high-efficient dust removal device comprises a shell and a control apparatus, wherein an air inlet is provided with an air collection chamber, a rotating mechanism and a first filter mechanism are arranged inside the shell, an inner rotating mechanism and an outer rotating mechanism are arranged in the rotating mechanism, the inner rotating mechanism and the outer rotating mechanism are arranged in opposite directions, the first filter mechanism is arranged at an outlet of the inner rotating mechanism, a gas detection mechanism is arranged in the gas collection chamber, and the rotating mechanism, the first filter mechanism and the gas detection mechanism are respectively connected with the control apparatus. The air inlet is provided with the gas collection chamber, the content and concentration of impurities in gas are detected by virtue of the gas detection mechanism, and the dust removal time and times are determined according to a detection result; and the inner rotating mechanism and the outer rotating mechanism are arranged inside the shell, so that an outer eddy current and an inner eddy current can be formed, the dual separation can be realized by utilizing natural gravity, and the further filtering is carried out by virtue of the filter mechanism.

Owner:太仓市除尘设备厂

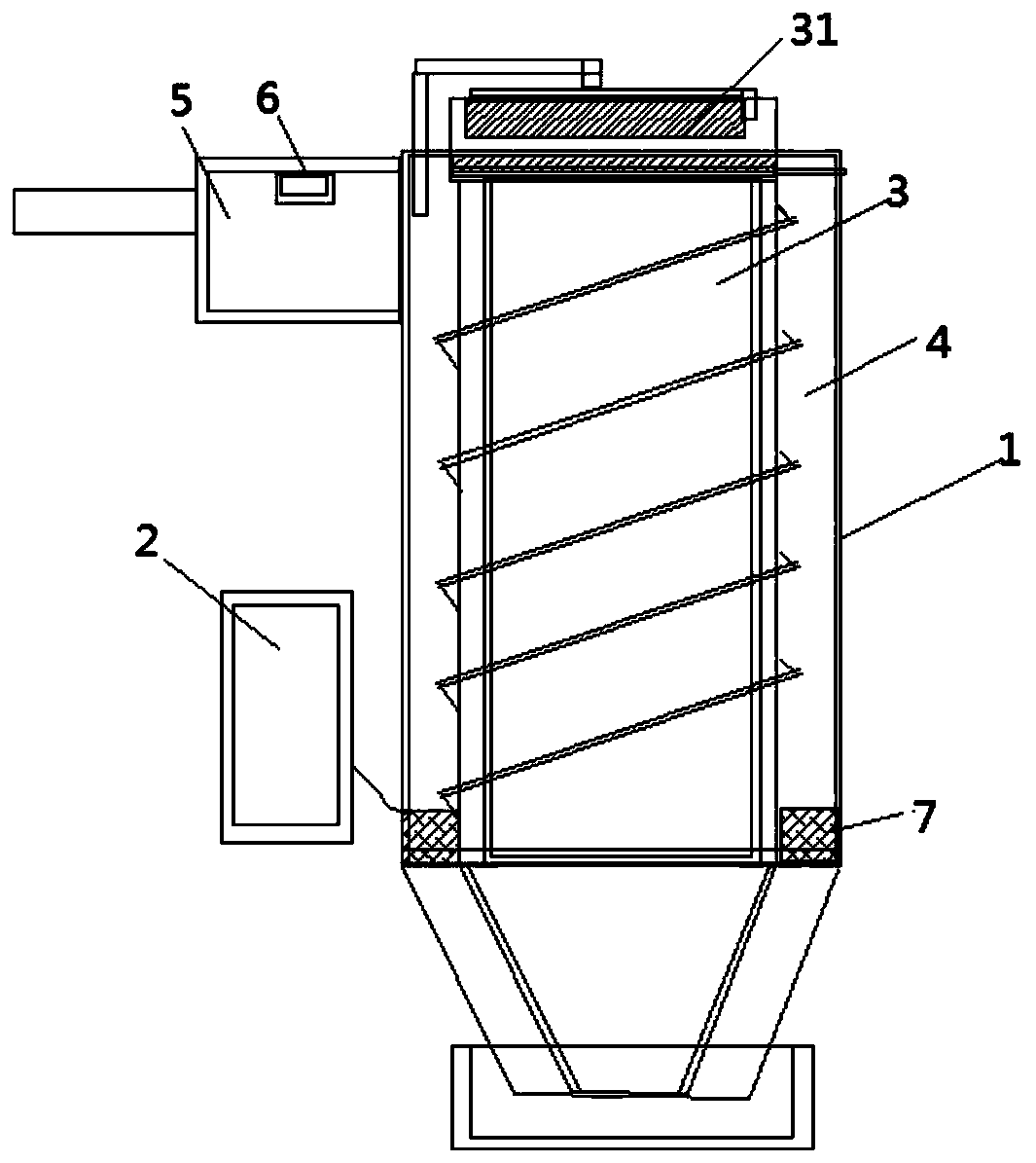

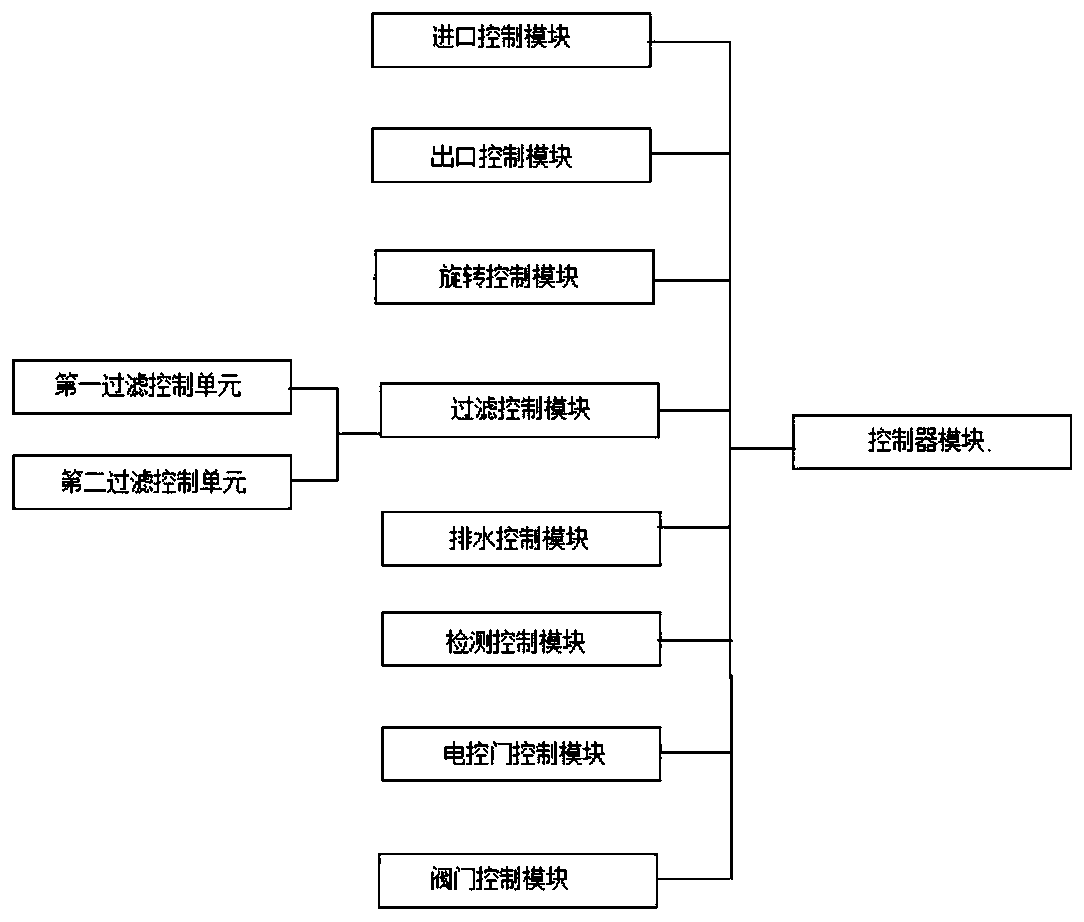

A high cleanliness dust removal equipment

InactiveCN107362644BImprove filtering effectSimple structureCombination devicesFiltrationEngineering

The invention discloses a high-cleanliness dust removal device, comprising: a housing and a control device, the housing is provided with a group of air inlets and an air outlet, and the housing is provided with an inner cavity and an outer cavity, The air inlet is provided with a gas collection chamber, the inner cavity is arranged inside the outer cavity, the outer cavity is provided with a rotating mechanism, and the outlet of the inner cavity is provided with a first filter mechanism, so A gas detection mechanism is arranged in the gas collection chamber, and the rotation mechanism, the first filtering mechanism and the gas detection mechanism are all connected with the control device. In the present invention, a gas collection chamber is arranged at the air inlet, and the impurity content and concentration in the gas are detected by a gas detection mechanism, and the time and frequency of dust removal are determined according to the detection results. It can form a downward airflow, use natural gravity to achieve double separation, and then perform deep filtration through the filtering mechanism, greatly improving its filtering effect.

Owner:太仓市除尘设备厂

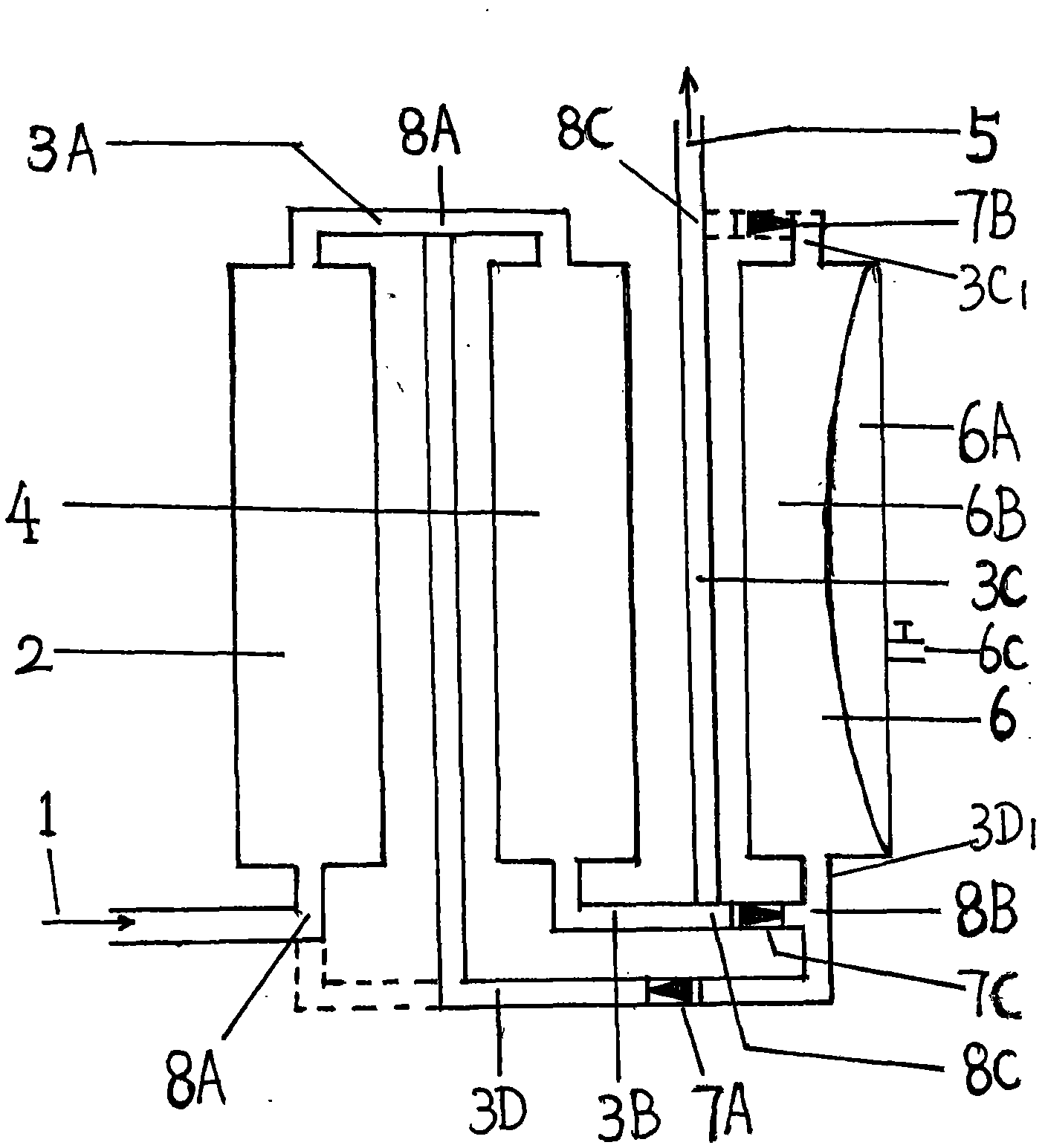

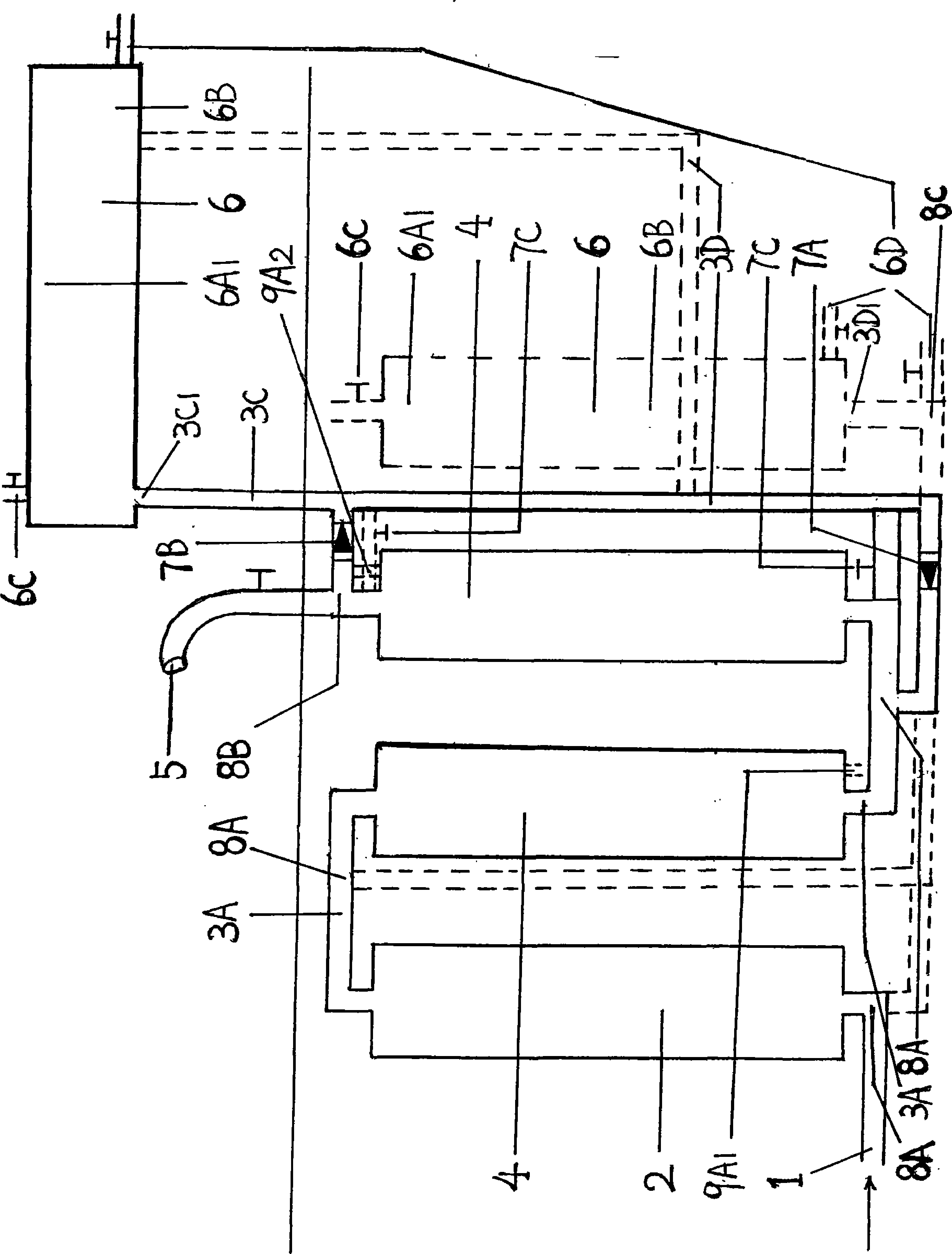

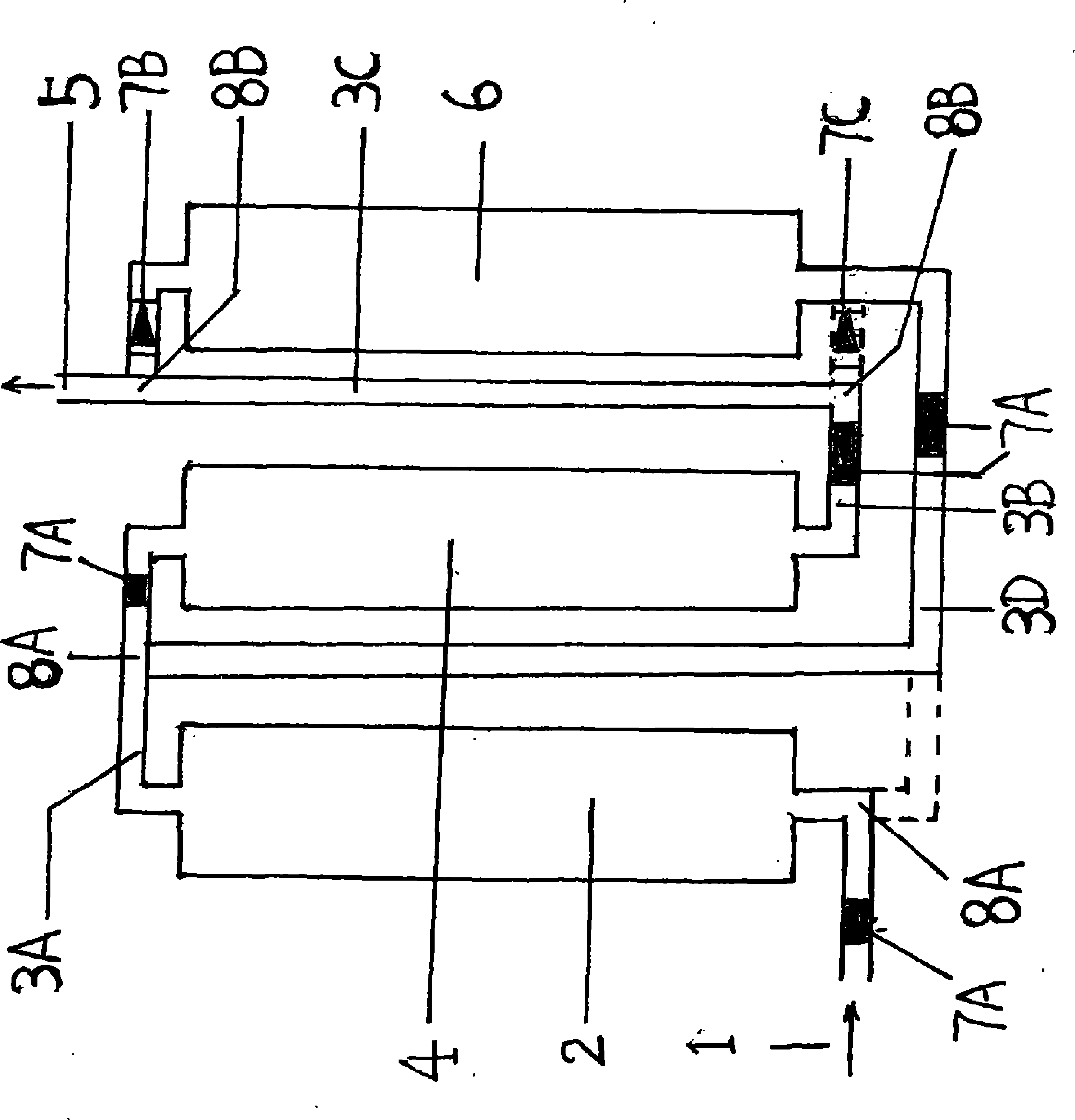

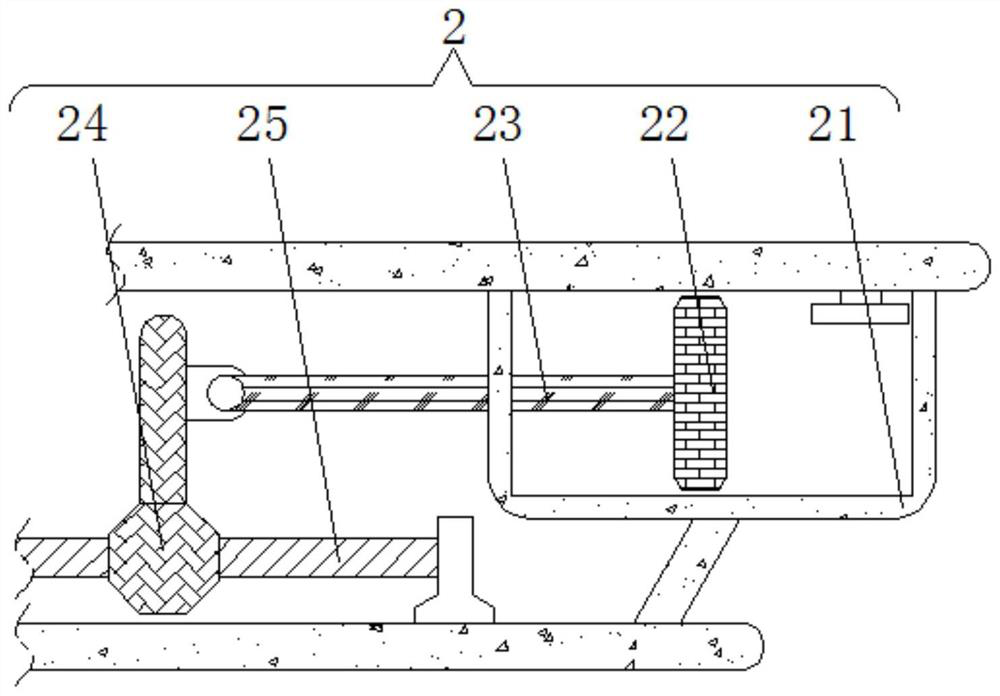

Water purifier or water purifying plant with circulating filtration function of filter elements and manufacturing method

InactiveCN102989230AImprove filtering effectLow costMultistage water/sewage treatmentFiltration circuitsWater storageFiltration

The invention relates to a water purifier or water purifying plant with a circulating filtration function of filter elements; the water purifier or water purifying plant comprises a raw water inlet (1), an electromagnetic valve or an intelligent valve A (2), a zero-stage or one-stage or above than one-stage preposed filter element (3), a one-stage or above than one-stage filter element (4), a pump, an RO (Reverse Osmosis) membrane or a nanofiltration membrane or an ultrafiltration membrane or a microfiltration filter element, a concentrated water pipeline, a connecting pipeline 6B, a tee joint 6B1, zero or one or more than one pressure water storage barrels, zero or one or more than one postposed filter elements with air pressure or without air pressure or pressure water storage cavities or barrels or connecting pipes, a purified water outlet or a next-stage filter element interface, an electromagnetic valve or an intelligent valve and the like; the raw water inlet is communicated with the electromagnetic valve or the intelligent valve A, a connecting pipeline 2A, the zero-stage or one-stage or higher than one-stage preposed filter element, a connecting pipeline 2B, the one-stage or above than one-stage filter element, a connecting pipeline 2C, a tee joint 5A, the pump, and the RO membrane or the nanofiltration membrane or the ultrafiltration membrane or the microfiltration filter element; and the tee joint 5A is communicated with the pump, the RO membrane or the nanofiltration membrane or the ultrafiltration membrane or the microfiltration filter element, a connecting pipeline 2E, the zero or one or more than one postposed filter elements with air pressure or without air pressure or the pressure water storage cavities or the barrels or the connecting pipes, a connecting pipeline 2D and the tee joint 5A in a circulation manner.

Owner:唐伟钊

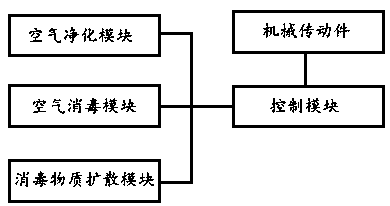

Multi-mode air disinfection machine

PendingCN111588898AImplement loop filteringRealize disinfectingGaseous substancesDeodrantsAntiseptic sterilizationProcess engineering

The invention discloses a multi-mode air disinfection machine. The multi-mode air disinfection machine comprises a machine shell; an air inlet and an air outlet are formed in the peripheral side of the machine shell; the air inlet and the air outlet are in communication and together form an air duct in the machine shell; an air purification module used for driving air to flow and achieving the airpurification effect and an air disinfection module used for carrying out sterilization and disinfection on the air are arranged in the air duct; and a disinfection substance diffusion module used forcontaining disinfection substances and diffusing disinfection substances into the air through a gasification / atomization means is arranged in the machine shell. By combining multiple technical means,circulating filtration of the air in a large-space environment and sterilization of pathogens are realized. Free switching among a plurality of disinfection modes is supported, an operator can flexibly select the corresponding disinfection modes based on different actual use requirements of users and different device application scenes, and the air disinfection performance of the machine is optimized.

Owner:SUZHOU BEIAN ELECTRONICS SCI & TECH CO LTD

Efficient dust removal device

InactiveCN107376573AImprove filtering effectSimple structureCombination devicesAuxillary pretreatmentEngineeringDeep level

Owner:太仓市除尘设备厂

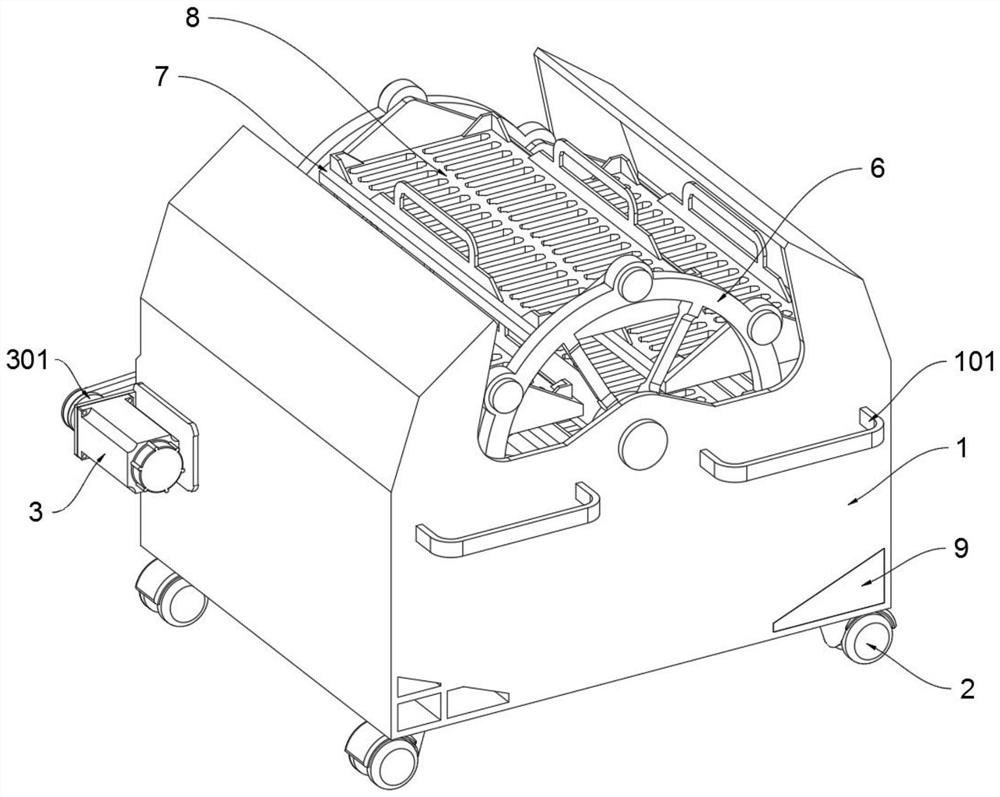

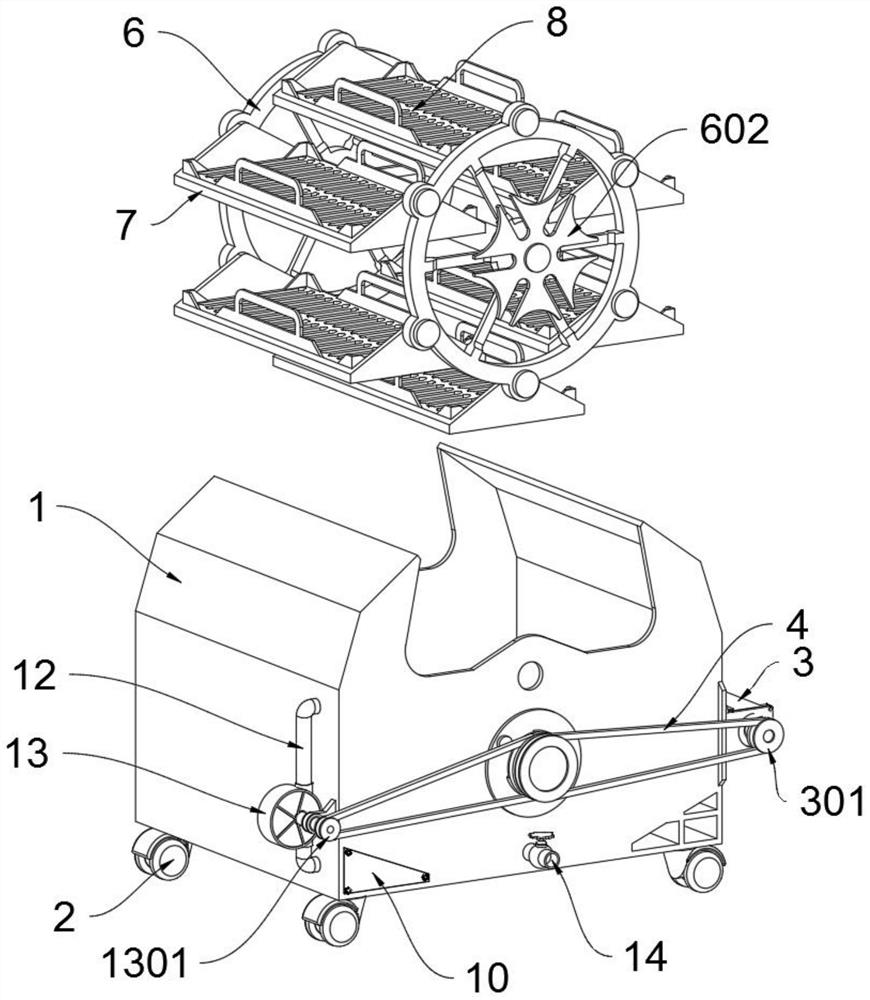

Surface wetting device capable of preventing sewage outflow for ceramic ground laying

InactiveCN111997326AEasy access for replacementGuaranteed wetting effectBuilding constructionsStationary filtering element filtersWater storage tankElectric machinery

The invention provides a surface wetting device capable of preventing sewage outflow for ceramic ground laying, and relates to the technical field of ceramic ground laying. The device solves the problems that before traditional ceramic tile laying, ceramic tiles always need to be manually and slowly placed in a large-capacity water bucket, the labor intensity for wetting the ceramic tiles is large, and the laying efficiency is low especially during one-person laying. The device comprises an adjusting support frame; the interior of a water storage tank is of a hollow structure, two push handlesare symmetrically arranged on the left side of the water storage tank, and a mounting cavity is formed in the front end of the bottom of the water storage tank; and the four corners of the bottom ofthe water storage tank are each fixedly provided with a universal wheel, and a driving motor is fixedly mounted on the rear end face of the water storage tank through bolts. According to the device, when the ceramic tiles are placed on a supporting plate on the top of a horizontal bearing frame, the adjusting support frame drives the horizontal bearing frame to rotate to the bottom, so that the ceramic tiles on the top of the supporting plate are immersed below the water surface, the ceramic tiles are soaked, and the ceramic tile surface wetting effect is guaranteed.

Owner:李媛菲

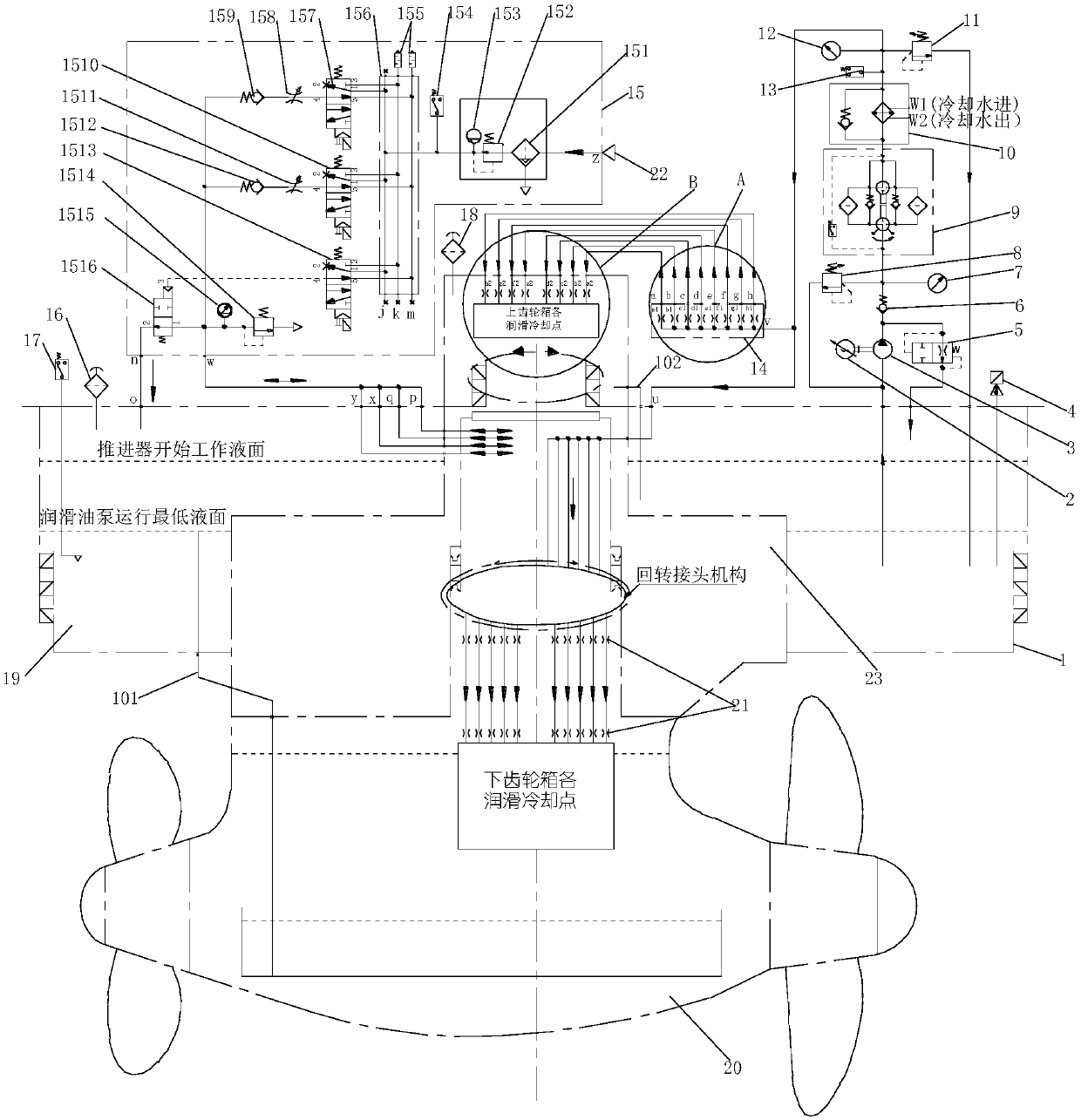

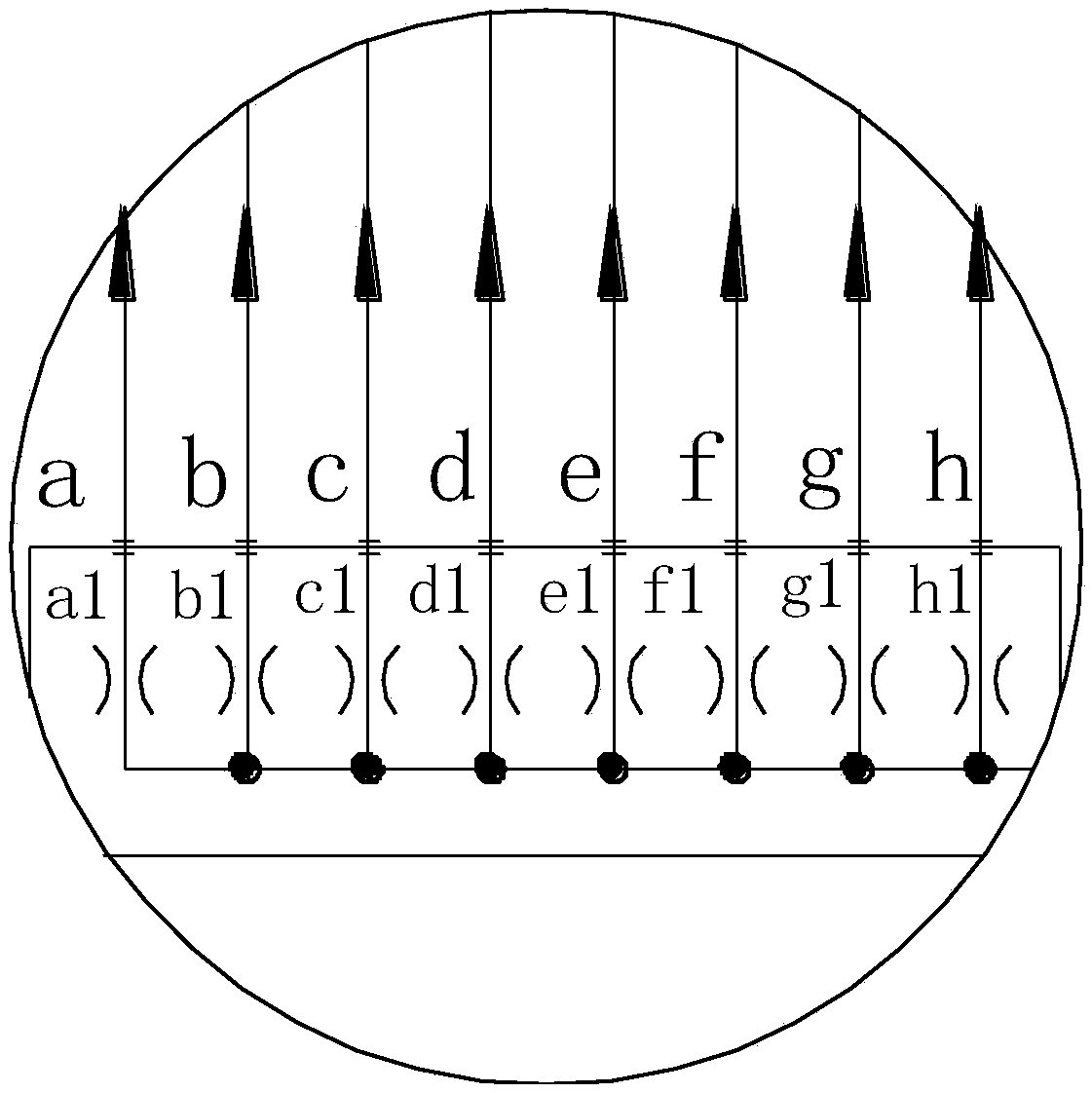

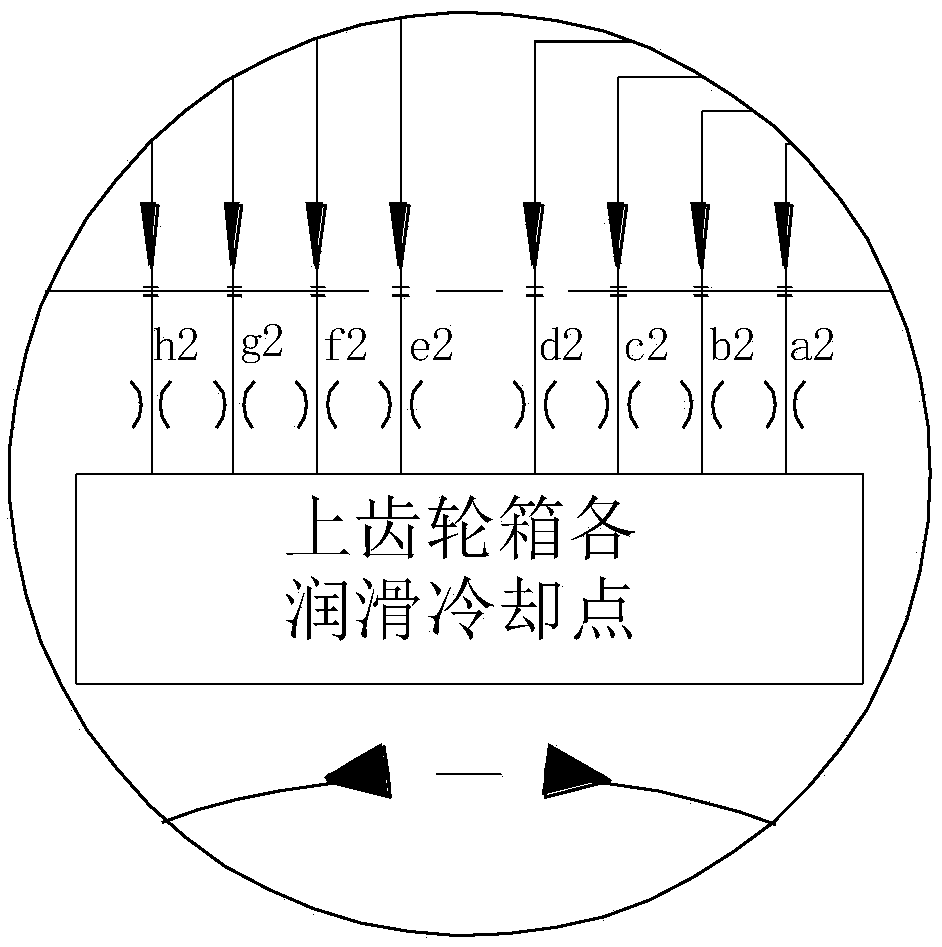

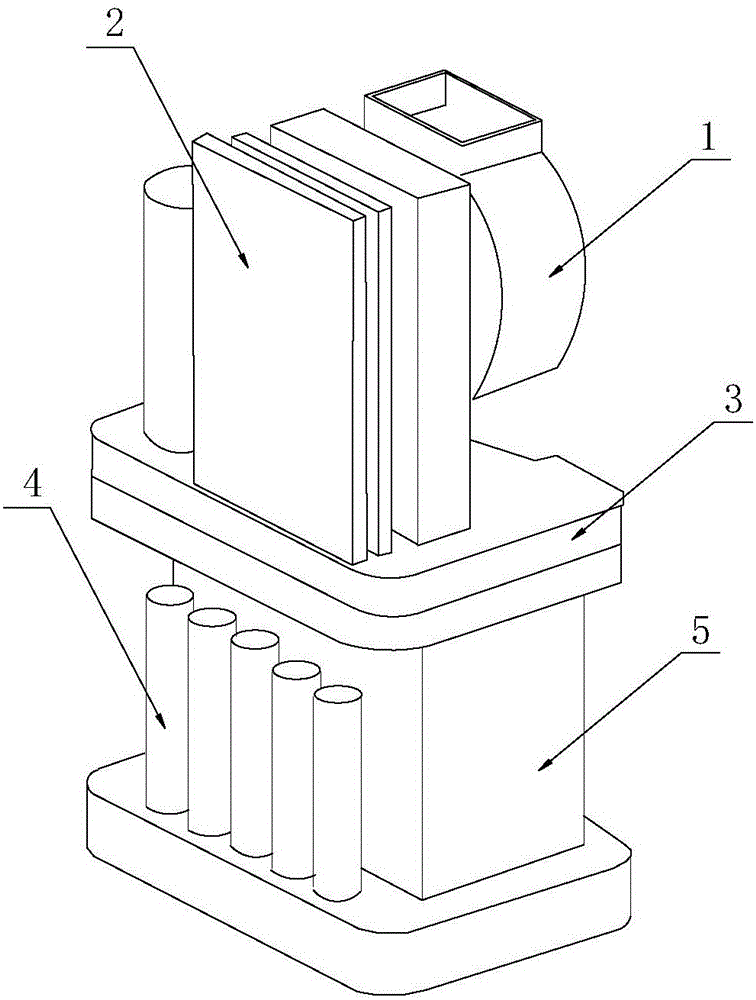

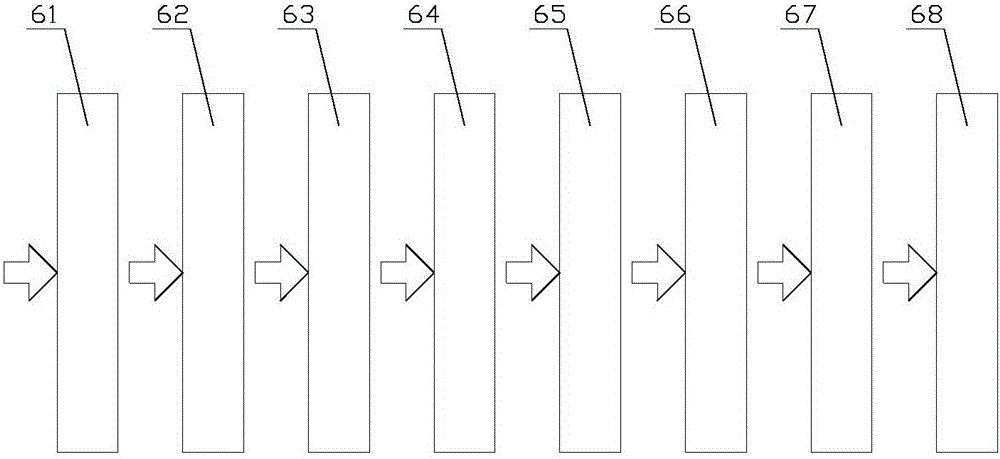

High-power contra-rotating full-revolving propeller fuel injection lubrication cooling system

The invention discloses a high-power contra-rotating full-revolving propeller fuel injection lubrication cooling system. The system comprises a contra-rotating full-revolving propeller body mechanism,a frequency conversion motor, a lubricant pump, a temperature sensor, an air exhausting valve, a pump opening one-way valve, a pump opening pressure gauge, a safety valve, a double-cylinder pipelinefilter, a water-cooled cooler, an overflow valve, an overflow pressure gauge, a pressure relay, an oil circuit block, a pneumatic control unit, a first air filter, a liquid level relay and a second air filter, and the contra-rotating full-revolving propeller body mechanism comprises an upper gear box body, a lower gear box body and an oil box body, wherein, the lower gear box body is the sealed cavity body. The high-power contra-rotating full-revolving propeller fuel injection lubrication cooling system totally adopts fuel injection lubrication, fixed-point quantitative lubrication cooling canbe achieved, oil impact and box vibration are completely avoided, the power loss is effectively reduced, and the cycle filtration and cooling use of lubrication cooling oil can be achieved.

Owner:合肥倍豪海洋装备技术有限公司

Air water generator high in water purification efficiency

InactiveCN105926720AImprove forwarding speedHigh speedCombination devicesTreatment involving filtrationWater storageAir filtration

The invention relates to an air water generator high in water purification efficiency. The air water generator comprises a water purification mechanism. The water purification mechanism comprises a PP cotton filtering mechanism and a purification assembly which are sequentially arranged. A water storage mechanism, the PP cotton filtering mechanism and the purification assembly are sequentially arranged. In the air water generator high in water purification efficiency, through multiple filtering of the PP cotton filtering mechanism and the purification assembly, high efficiency in water purification is guaranteed; through cross flow of a deflector in a filter cartridge, the efficiency in water purification is improved, the water quality is detected through a water quality detection mechanism, water circulating filtration is performed by matching of a three-way valve, and the reliability in water purification is improved. Moreover, in a water quality monitoring circuit, a conventional component is adopted to replace an expensive integrated circuit, the cost of the air water generator is reduced, and the market competiveness of the air water generator is improved; multilayer air filtration is performed, and the air purification quality is improved; three forms are adopted for water discharge, the practicality is improved, and the air water generator has high time-to-market values.

Owner:张萍

Circulating sewage treatment device capable of avoiding blockage

PendingCN113730987AAvoid cloggingEasy to handleMixersStationary filtering element filtersFiltrationSewage

The invention relates to the technical field of sewage treatment, and discloses a circulating sewage treatment device capable of avoiding blockage. The device comprises a pneumatic mechanism, the pneumatic mechanism comprises a sealed cabin, a pressing plate is slidably connected to the interior of the sealed cabin, an ejector rod is hinged to the side face of the pressing plate, a sliding sleeve is hinged to the end, away from the pressing plate, of the ejector rod, and a lead screw is rotationally connected into the sliding sleeve. The device further comprises a circulating mechanism, and the circulating mechanism comprises a stirring bin. According to the circulating type sewage treatment device capable of avoiding blockage, through cooperative use of the circulating mechanism and the filtering bin, circulating filtration of sewage between the stirring bin and the filtering bin can be achieved, the sewage treatment effect is improved to the maximum extent, and through cooperative use of the pneumatic mechanism and a connecting pipe, during sewage treatment, gas sprayed by the pneumatic mechanism is sprayed above a filter plate through the connecting pipe, so that the filter plate is prevented from being blocked by impurities, and the sewage treatment efficiency is improved.

Owner:王芹

Frog breeding method

InactiveCN109997778ABreeding method is reasonableImprove survival rateFood processingTreatment involving filtrationPotassium permanganatePericarpium citri reticulatae

The invention provides a frog breeding method. The invention solves the technical problem of low survival rate and the like in an existing frog breeding process. The frog breeding method is characterized by comprising the following steps: S1, selection of a site and construction of a frog pond: selecting a place which is sufficient in water source, convenient to drain and irrigate, good in water quality, quiet in environment, warm in winter and cool in summer, free of drought and waterlogging and convenient to manage as a breeding farm, constructing a large pond per mu, and dividing each largepond into three small ponds on average, wherein the three small ponds are a tadpole pond, a young frog pond and an adult frog pond respectively; S2, disinfection: throwing 6 kg of quicklime per mu atfirst, and 3-4 days later, carrying out disinfection and epidemic prevention by using potassium permanganate and a traditional Chinese medicine according to the proportion of 1: 10, wherein the traditional Chinese medicine comprises the following components by main content: coptis chinensis 1.25%-2.5%, liquorice 2.5%-7.5%, radix bupleuri 3.75%-6%, pericarpium citri reticulatae 5%-10%, and the balance of euphorbia humifusa. The frog breeding method has the advantage of high survival rate in a frog breeding process.

Owner:安徽白云岩生态养殖有限公司

Circulating filtration treatment equipment for water

InactiveCN105036414AHigh reuse rateReduce processingMultistage water/sewage treatmentWater storage tankSewage treatment

The invention discloses circulating filtration treatment equipment for water. The filtration treatment equipment comprises a water storage tank, a large-particle filter, a multi-media filter, an alum flocculation tank, an EPS foam bead filter, an activated carbon filter and a circulating flow splitting pump which are sequentially connected through pipelines; if the quality of water treated by the activated carbon filter meets the purified water quality specification, the circulating flow splitting pump is controlled to send the standard water into the purified water tank for storage; if the quality of water treated by the activated carbon filter does not meet the purified water quality specification, the circulating flow splitting pump is controlled to send the nonstandard water into the water storage tank for circulating filtration treatment again. Through the adoption of the filtration treatment equipment, industrial sewage can be effectively purified, circulating filtration of the industrial sewage is realized, the repeated utilization ratio of industrial water is improved, the sewage treatment capacity is relieved, the discharge capacity of the industrial sewage is reduced, water body pollution is reduced, and then considerable economic benefits are achieved.

Owner:上海宇海企业发展集团有限公司

Concentrated heating and filtering device for mercerizing spraying alkali liquor

ActiveCN108505263AImplement loop filteringRealize the heating workTextile treatment machine arrangementsTextile/flexible product manufactureFilter effectChemistry

The invention discloses a concentrated heating and filtering device for mercerizing spraying alkali liquor. The device includes an alkali liquor dropping-in pool composed of an alkali liquor recycle pool and a pure alkali liquor pool, the alkali liquor recycle pool and the pure alkali liquor pool are mutually separated through a partition, the top of the pure alkali liquor pool is provided with aninclined guide cover plate, the pure alkali liquor pool is internally provided with a liquor drainage pipe and a spraying pipe in parallel, the liquor drainage pipe and the spraying pipe are providedwith a first water pump and a second water pump respectively, the end of the liquor drainage pipe is connected with a heating and filtering device body, multiple liquor pumping branch pipes are distributed in the alkali liquor recycle pool at intervals, one ends of the liquor pumping branch pipes are connected with a liquor pumping main pipe through a first connecting pipe, a third water pump isarranged on the liquor pumping main pipe, and the end of the liquor pumping main pipe is connected with the heating and filtering device body. The concentrated heating and filtering device can filterand heat the alkali liquor without affecting the normal work of a mercerizing machine, the working stability is high, and the filter effect is good.

Owner:ZHEJIANG MIZUDA TEXTILE PRINTING & DYEING TECH CO LTD

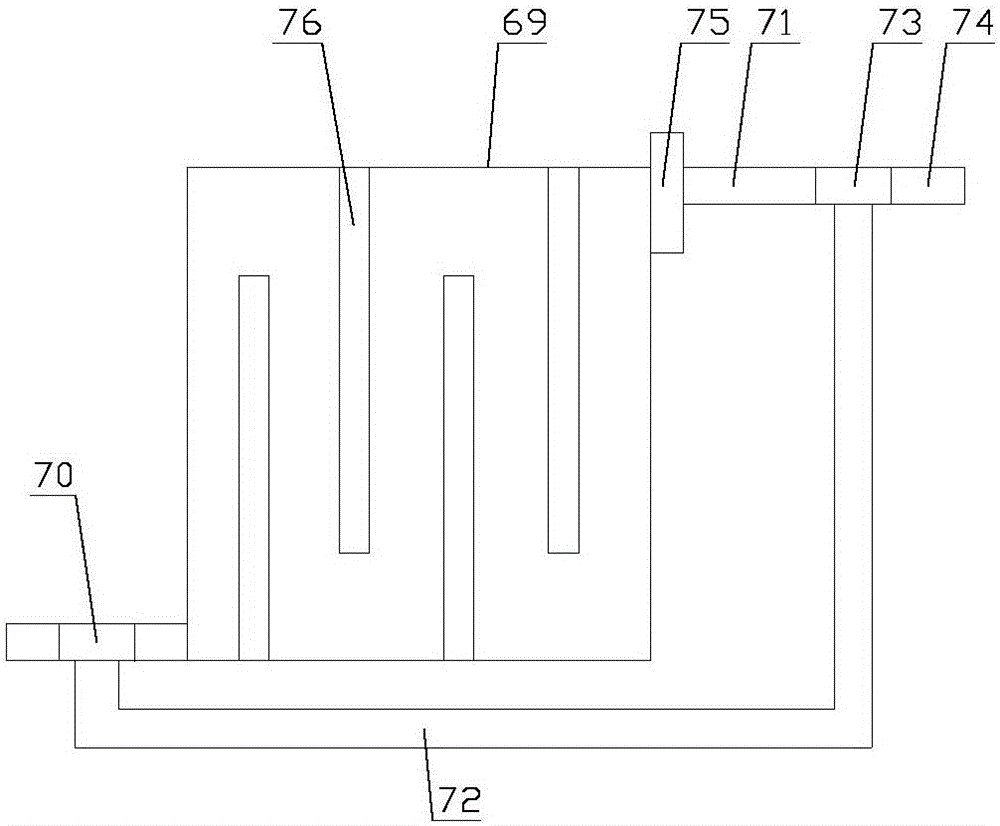

Aluminum profile material hole sealing device, aluminum profile material production line and production method

ActiveCN108070893AImprove heat utilizationNot easy to loseSemi-permeable membranesMixing methodsProduction lineThermal insulation

The invention relates to an aluminum profile material hole sealing device comprising a hole sealing groove and a conveying mechanism. The hole sealing groove is internally filled with hole sealing liquid. A heating device used for heating the hole sealing liquid is arranged in the hole sealing groove. A plurality of floating balls used for thermal insulation float on the liquid face of the hole sealing liquid. A groove cover covers an opening of the hole sealing groove and comprises two fixed plates connected to the two sides of the top of the hole sealing groove correspondingly. The oppositesides of the two fixed plates are each slidably connected with a movable plate. A channel through which an aluminum profile material can penetrate can be formed between the two movable plates. The movable plates are L-shaped plates. The horizontal parts of the movable plates are inserted to the fixed plates. The vertical parts of the movable plates extend perpendicularly downwards and are locatedbelow the liquid face of the hole sealing liquid. The fixed plates and the movable plates are connected through first air cylinders. The fixed ends of the first air cylinders are connected to the fixed plates. The piston ends of the first air cylinders are connected to the movable plates. The invention further discloses an aluminum profile material production line and production method. The automation degree is high, thermal efficiency of the heating device is high, the service life of the aluminum profile material hole sealing device is long, and machining cost is low.

Owner:奋安铝业股份有限公司

Intelligent high-cleanliness dust collection equipment and working method thereof

InactiveCN107413155AImprove filtering effectSimple structureCombination devicesAuxillary pretreatmentDeep levelEngineering

The invention discloses a working method of intelligent high-cleanliness dust collection equipment. The equipment comprises a shell and a control device, wherein a group of air inlets and an air outlet are formed in the shell; an inner cavity and an outer cavity are formed in the shell; the air inlet is provided with a pumping chamber; the inner cavity is arranged inside the outer cavity; a rotating mechanism is arranged in the outer cavity; a first filter mechanism is arranged at an outlet of the inner cavity; an air detection mechanism is arranged in the pumping chamber; the rotating mechanism, the first filter mechanism and the air detection mechanism are connected with the control device. According to the working method, the air inlet is provided with the pumping chamber, the air detection mechanism is used for detecting the content and density of impurities in air, and time and frequency of dust collection are determined according to the detection result; and the rotation mechanism arranged in the shell enables air to form a downward airstream so as to realize double separation by utilizing natural gravity, and the air is deeply filtered by virtue of the filter mechanism, so that the filter effect is greatly improved.

Owner:太仓市除尘设备厂

Decontamination device

PendingCN107900011ASimple structureReasonable designCleaning using liquidsChemicalsBiological tissueElectromagnetic valve

The invention relates to the field of medical decontamination equipment, in particular to a decontamination device. The decontamination device comprises a shell body, and a cavity in the shell body forms a decontamination space; a plurality of fluctuating devices are arranged on the inner side walls of the shell body, the outer ends of the fluctuating devices extend out of the shell body and are connected with a driving device, and the junctions of the fluctuating devices and the shell body are sealed and connected by sealing members; a drain pipe connecting the inside and the outside of the shell body is arranged at the bottom of the shell body, and a first electromagnetic valve is arranged on the drain pipe; a plurality of decontamination basket assemblies for placing appliances to be decontaminated are arranged in the shell body; and a top cap is movably fastened at the top of the shell body. According to the decontamination device, the fluctuating devices drive the liquid to wash the appliances to be decontaminated continuously in the process of decontamination, the remaining biological tissue and secretions on the external surface of the appliances to be decontaminated are effectively avoided, the decontamination is more thorough, and the requirements of people can be effectively met.

Owner:济南市利东医疗设备有限公司

Zero-smoke emission combustion furnace

ActiveCN108758612AAvoid damageImplement loop filteringSolid fuel combustionCombustion technology mitigationSmoke EmissionFilter effect

The invention relates to the field of boilers and particularly relates to a zero-smoke emission combustion furnace. The zero-smoke emission combustion furnace comprises a filter chamber, an induced draft fan, a flue and an air return pipe, wherein a smoke outlet of a convective heat exchange chamber is connected with the input end of the induced draft fan through a first connecting pipe; a filtercavity and a filter tank are arranged in the filter chamber; the output end of the induced draft fan is connected with the filter cavity through a second connecting pipe; the lower side of the filtercavity is provided with a plurality of filter pipes, and when a system works, the end openings of the output ends of the plurality of filter pipes are all located below the liquid surface in the filter tank; the lower end of the flue extends into the filter chamber, and when the system works, the lower end of the flue is located above the liquid surface in the filter tank; and the part, extendingout of the filter chamber, of the flue is connected with the first connecting pipe through the air return pipe. By utilizing the flue to lead out the air return pipe, smoke circulating filtering is realized, the filtering effect is greatly improved, zero-smoke or little-smoke emission also can be realized, and the environment protecting requirement of the boiler is fully met.

Owner:DANDONG BLUESKY ENVIRONMENT PROTECTION BOILERS

Farming method of Rana catesbiana (bullfrog)

InactiveCN109997779AImprove survival rateIncrease productionFood processingTreatment involving filtrationWater sourceWater quality

The invention provides a farming method of Rana catesbiana (bullfrog) and solves the technical problems that, for instance, existing Rana catesbiana has low output value. The farming method of Rana catesbiana comprises the steps of S1, selecting a farming land, wherein a water source is free of industrial or agricultural wastewater pollution, the water is fresh and well transaprent, the environment is mute, ponds are divided by mu, a tadpole pond and a frog pond are set per mu, each pond is surrounded with 40-mesh boulting cloth which is about 1 meter off taller than the pond bottom, the bottom of the boulting cloth is buried in soil by 20-30 cm, pond ridges are 40 cm in height, the pond-slope ratio is 1:3, and the water level is 30-40 cm; S2, sterilizing, to be specific, sterilizing the farming ponds in two manners of using 50-75 kg of quick lime per mu and using 10-15 kg of bleaching powder per mu, and putting fry in the ponds 10 days after sterilization. The farming method of Rana catesbiana has the advantage of high output value of Rana catesbiana.

Owner:安徽白云岩生态养殖有限公司

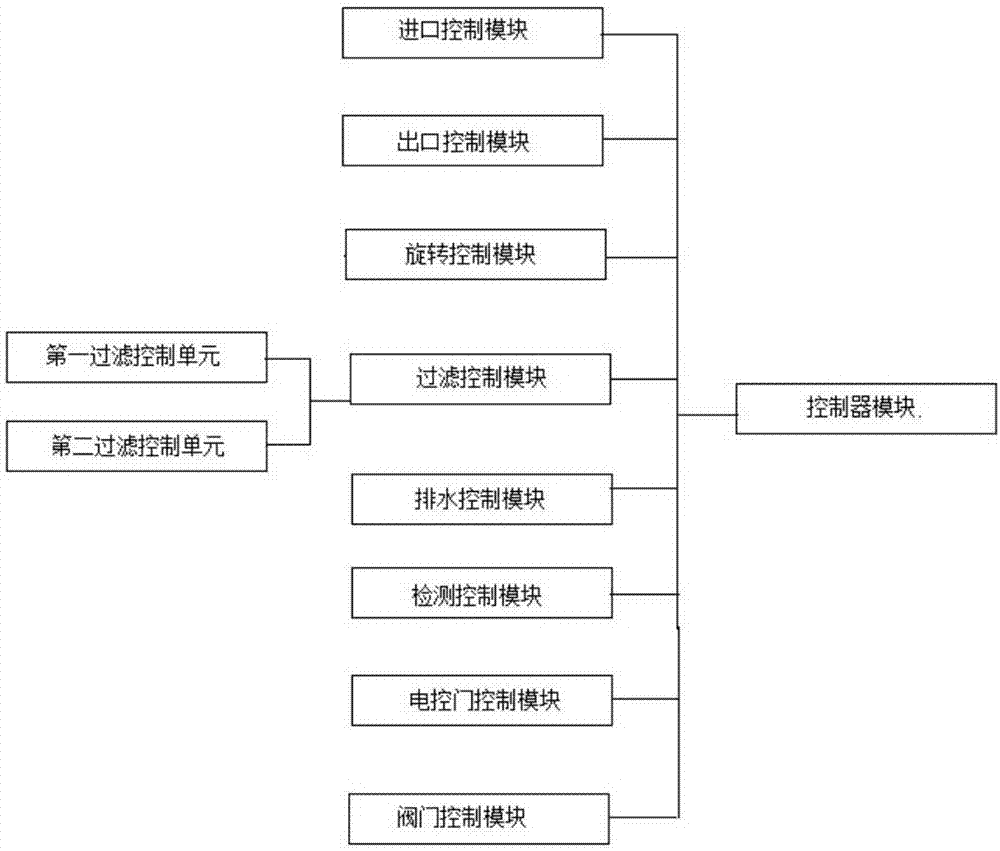

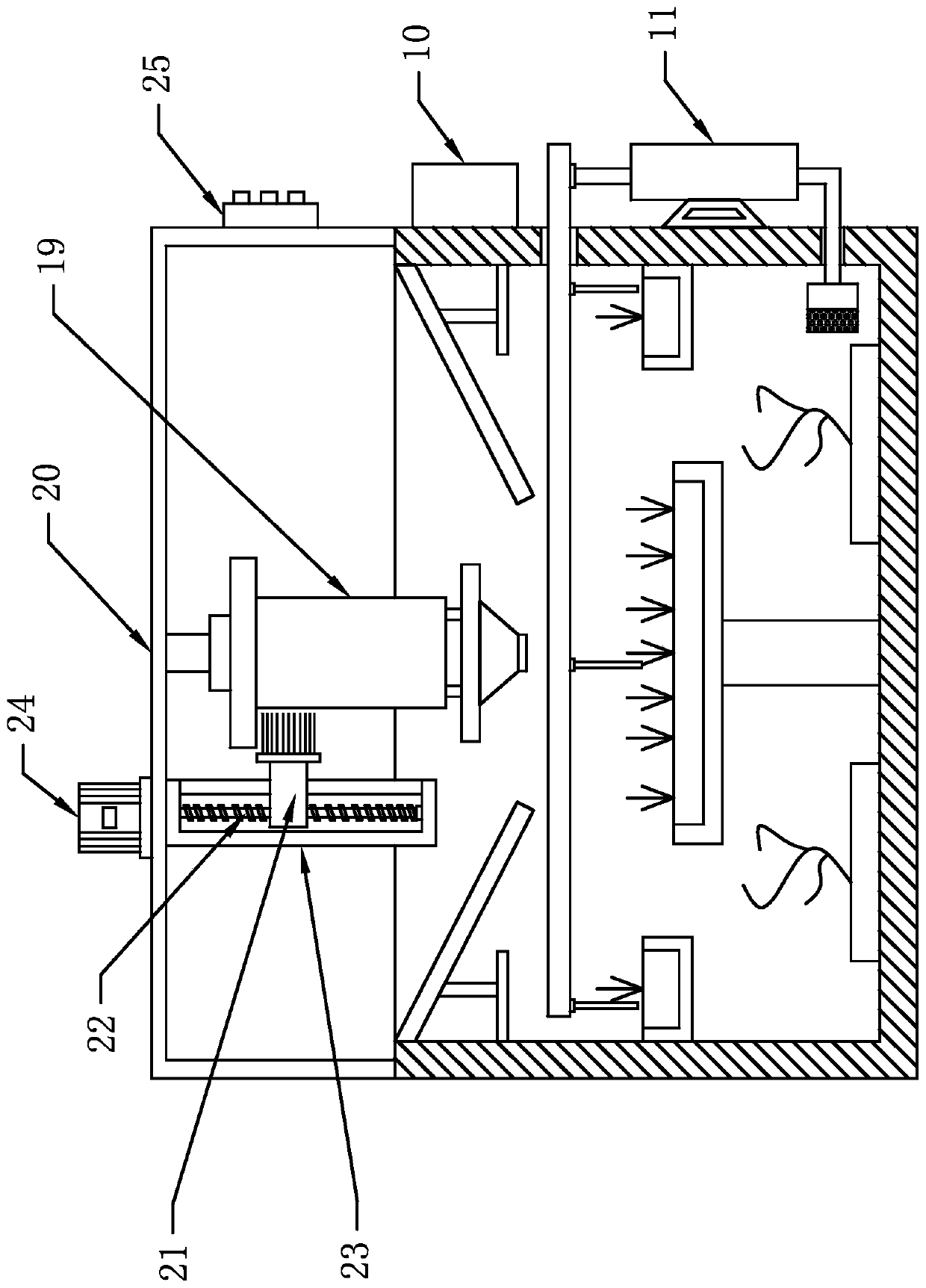

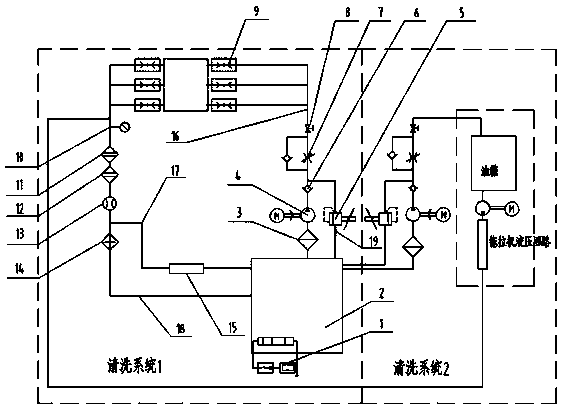

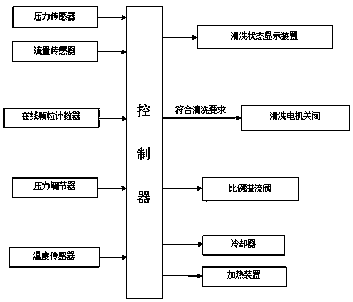

Washing device for hydraulic system of tractor

ActiveCN109675856AAchieve variable pressureImplement loop filteringHollow article cleaningCleaning using liquidsProcess engineeringHeating system

The invention provides a washing device for a hydraulic system of a tractor, and belongs to the technical field of agricultural mechanical equipment. The washing device for the hydraulic system of thetractor is mainly used for washing the hydraulic system and a hydraulic element of the tractor. The device comprises a washing system 1, a washing system 2 and a control system, wherein the system 1is a hydraulic element washing system and comprises a washing oil tank, a heating system, a motor pump set, a proportional overflowing valve, a flow rate control valve, a quick switching joint set, apressure gauge, a combined filtering device, a cooler and an online pollution detecting device; the washing system 2 is a tractor hydraulic system loop washing system and comprises a motor pump set, aproportional overflowing vale and a flow rate control valve; and the control system comprises a controller, a washing state displaying device, a cooling control device, a heating control device, a pollution degree detecting device, a proportional pressure regulating system and a temperature, pressure and flow rate sensor and is used for controlling the cooler, the heater, the washing time, the washing pressure and the temperature, pressure and flow rate displaying of the washing systems.

Owner:SHANDONG UNIV OF TECH

An intelligent high-efficiency dust removal device and its working method

InactiveCN107362645BImprove filtering effectSimple structureCombination devicesDust controlEngineering

The invention discloses a working method of intelligent high-efficiency dust removal equipment. The intelligent high-efficiency dust removal equipment includes: a housing and a control device, an air inlet is provided with a gas collection chamber, and the inside of the housing is provided with a rotating mechanism and a first filtering mechanism. The rotating mechanism is provided with an inner rotating mechanism and an outer rotating mechanism, and the inner rotating mechanism and the outer rotating mechanism are arranged in opposite directions. The mechanism, the first filter mechanism and the gas detection mechanism are all connected with the control device. The present invention sets a gas collection chamber at the air inlet, detects the impurity content and concentration in the gas through the gas detection mechanism, and judges the time and frequency of dust removal according to the detection result. The external rotation mechanism allows it to form an external vortex and an internal vortex, using natural gravity to achieve double separation, and then perform deep filtration through the filter mechanism.

Owner:太仓市除尘设备厂

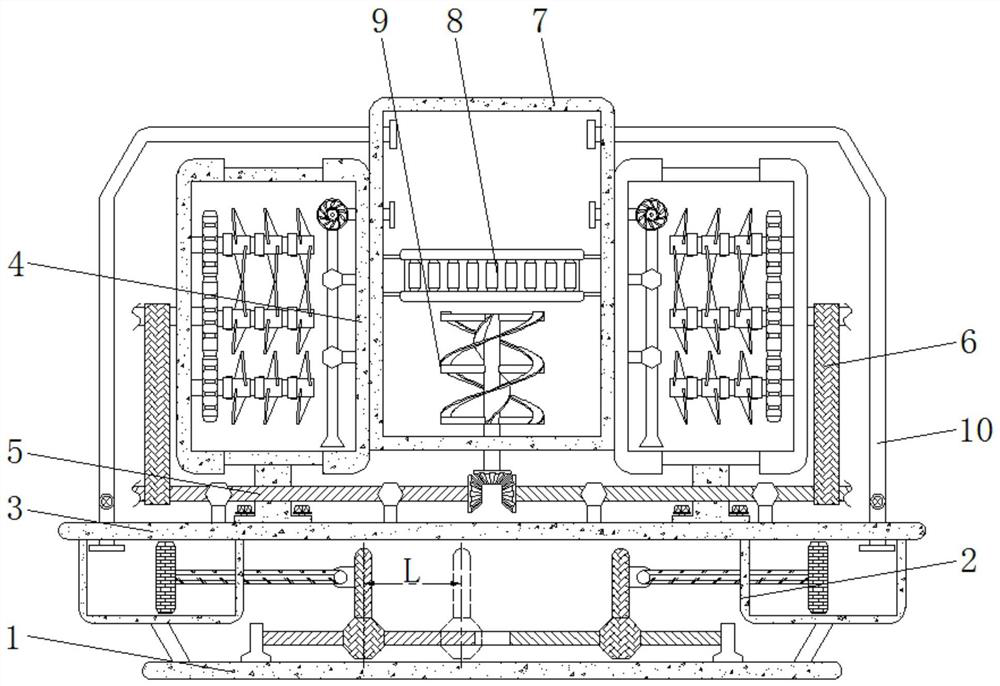

Dairy product processing device with automatic purifying and homogenizing integrated function

PendingCN112774499AWell mixedImplement loop filteringFlow mixersRotary stirring mixersReciprocating motionProcess engineering

The invention relates to the technical field of food processing, in particular to a dairy product processing device with an automatic purifying and homogenizing integrated function, the dairy product processing device with the automatic purifying and homogenizing integrated function comprises a base, a homogenizing bin is fixedly mounted on the upper surface of the base, and a filtering bin is fixedly mounted at the top of the homogenizing bin; a filtering assembly is installed in the filtering bin, a main stirring assembly is installed in the homogenizing bin, a driving assembly is installed on the outer side wall of the homogenizing bin, the driving assembly is used for driving the main stirring assembly and an auxiliary stirring assembly to operate synchronously, dairy product raw materials are stirred and homogenized, and the dairy product raw materials are mixed more evenly; the milk product raw materials are conveyed to the spray head through the booster pump and sprayed on the filter screen, so that circulating filtration of the milk product raw materials is realized, the purification effect is greatly improved, and the spray head is driven to do transverse reciprocating motion while the driving assembly runs, so that the filtering efficiency is improved.

Owner:湖南海佳食品科技股份有限公司

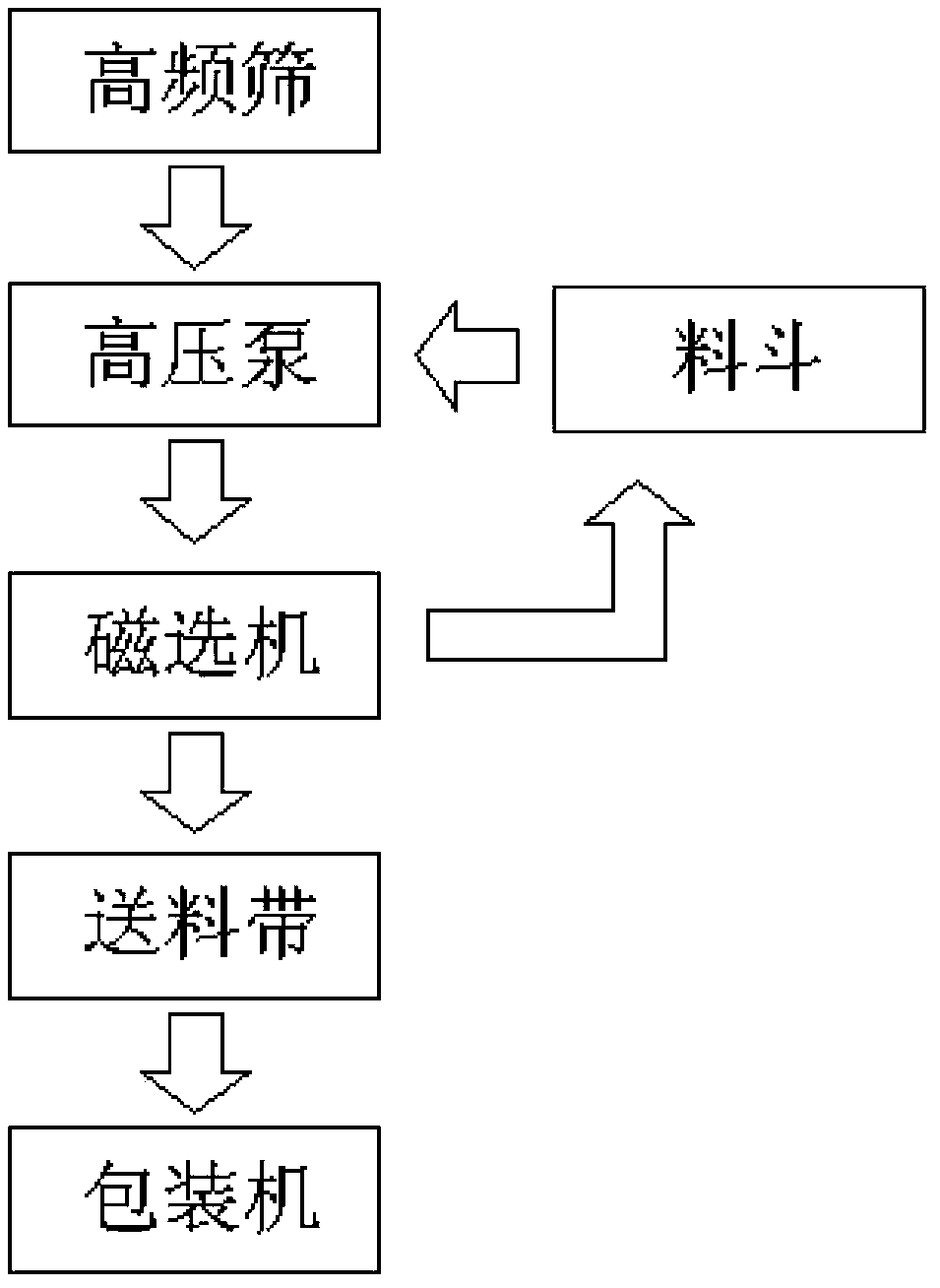

Circulated screening process for fine iron powder

InactiveCN104226473AAvoid churnImplement loop filteringSievingScreeningHigh pressureMaterials science

The invention relates to a circulated screening process for fine iron powder. The process includes: (1) conveying materials, feeding a coarse iron ore powder raw material into a high-frequency screen, and separating the coarse iron ore powder by high frequency vibration; (2) conveying the raw material after primary screening by the high-frequency screen into a high-pressure pump; (3) feeding the raw material into magnetic separators by the high-pressure pump; performing magnetic separation, screening fine iron powder from the raw material, conveying the fine iron powder to a conveyor belt of the next step, conveying the fine iron powder to a packaging machine by the conveyor belt, and packaging, thus completing screening; and (4) feeding waste dregs of the magnetic separators into a material hopper through pipelines, feeding the waste dregs into the high-pressure pump by the material hopper, and repeating the step (1) to the step (3) to perform circulated screening. The magnetic separation process for the fine iron power can continuously circulate and return the waste dregs after screening of the coarse powder into the magnetic separators, thus finishing fine screening of high-purity iron powder step by step, achieving circulated screening of the waste dregs and avoiding loss of a certain amount of the iron element in the waste dregs.

Owner:天津德晟铁选有限公司

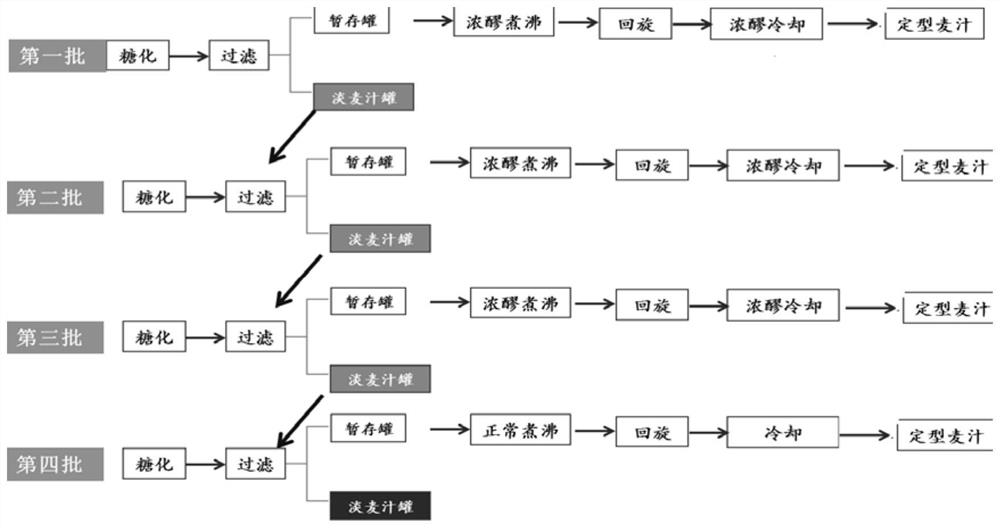

Preparation method of extra high concentration wort

ActiveCN111718812BImplement loop filteringAchieving the first mash boilWort preparationChaptalizationProcess engineering

The invention provides a method for preparing extra-high-concentration wort, which belongs to the technical field of beer brewing. The method only utilizes existing saccharification equipment to develop a high-efficiency and low-energy-consumption wort preparation process, and realizes the second wort circulatory filtration and the first wort filtration. 1. The innovation of preparation technology such as wort thick mash boiling not only solves the problems of difficult wort filtration and prolonged filtration time in the preparation process of high-concentration wort, but also breaks through the technology of low raw material utilization rate in the preparation process of ultra-high-concentration wort Bottleneck, to achieve the industrial production requirements of ultra-high-concentration wort.

Owner:TSINGTAO BREWERY

An indoor wastewater purification device

ActiveCN108996599BPrevent escapeReduce adverse effectsSpecific water treatment objectivesWater/sewage treatment by sorptionActivated carbonWastewater

The invention discloses an indoor waste water purification device, which comprises an outer shell, an inner shell is arranged at the middle position inside the outer shell, and one end of a telescopic water guide pipe is connected to the lower side of the outer shell body, and the telescopic water guide pipe The other end is connected to the external drainage pipe, and two sets of water-retaining bosses are arranged symmetrically on both sides of the inner shell, and the lower sides of the water-retaining bosses are all provided with rectangular through-slots, and the rectangular through-slots The interior of the water retaining boss is equipped with an activated carbon adsorber, and the side of the water retaining boss close to the activated carbon adsorber is connected with a bottom cover through a hexagon socket bolt. Cause adverse effects, the outer shell and the inner shell are positioned and connected with the positioning hole through the positioning column, so as to facilitate disassembly and cleaning to remove accumulated dirt. The U-shaped leaking sieve plate can filter out the large waste residue in the wastewater, which is convenient to use and easy to promote.

Owner:SUZHOU BATAO INFORMATION TECH CO LTD

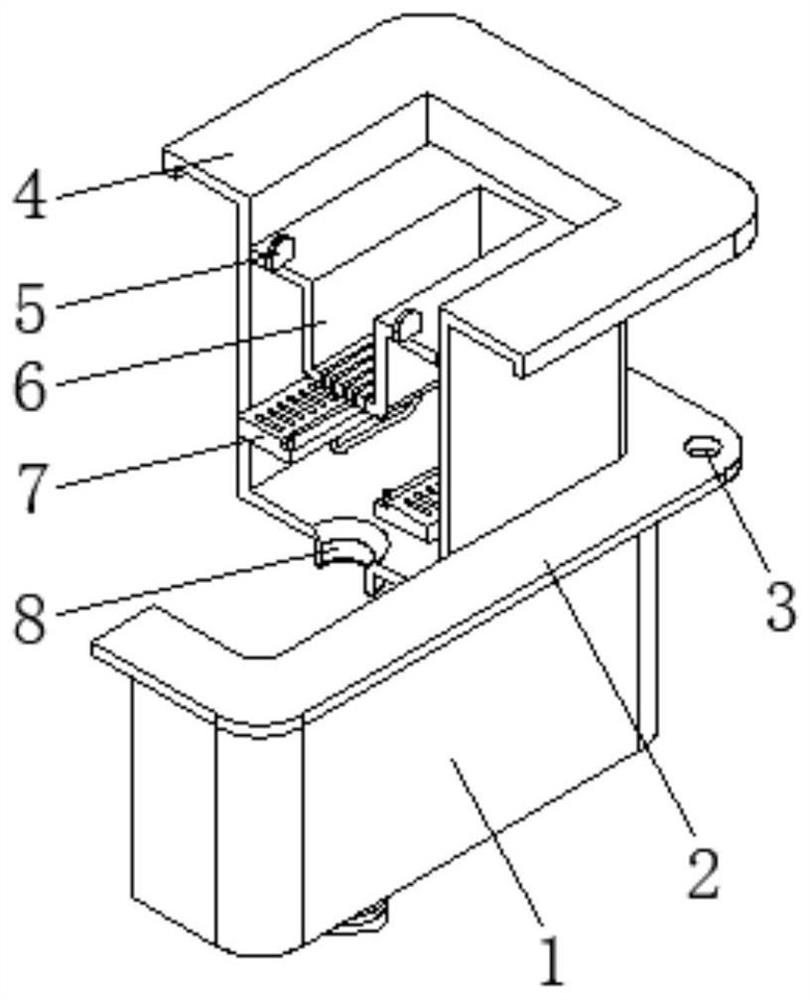

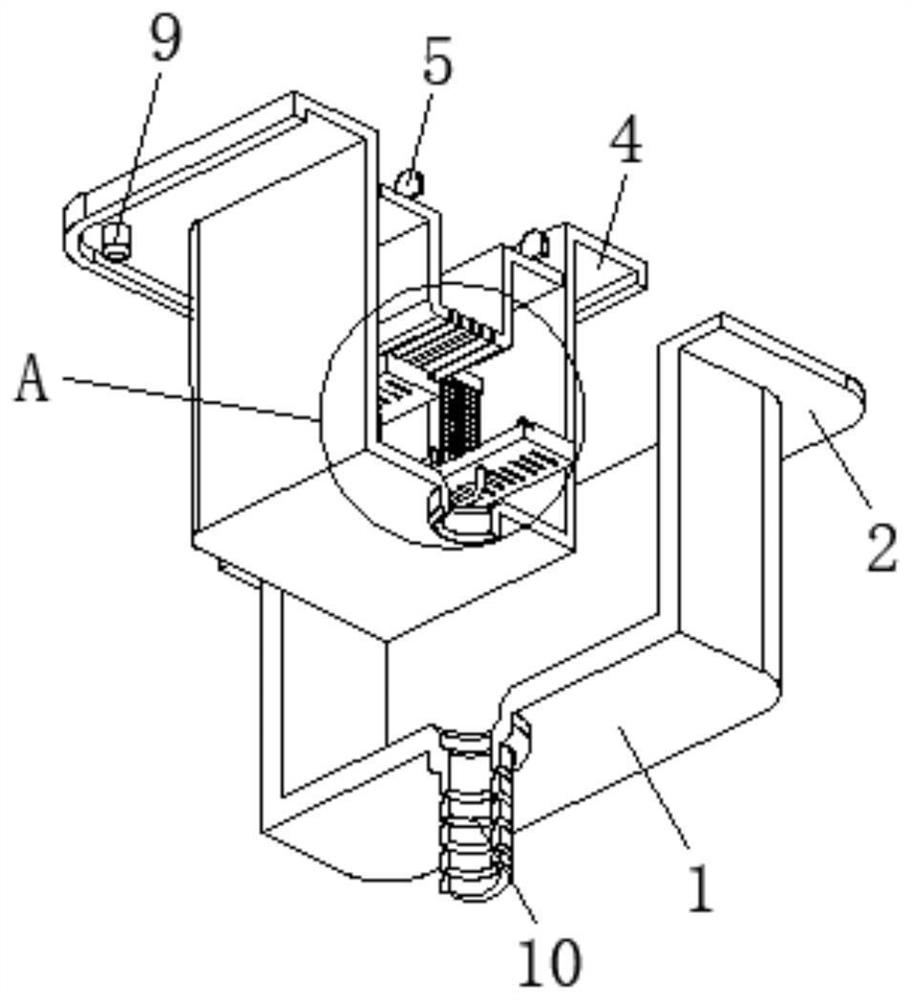

A kind of solid raw material pretreatment device and method for nanocomposite preparation

ActiveCN111112079BImplement loop filteringAvoid wastingSievingGas current separationMechanical engineeringRaw material

The invention discloses a solid raw material pretreatment device and method for preparing nanocomposite materials, comprising an inner box and an outer box arranged outside the inner box, the upper end of the inner box is provided with a drive motor through a fixing frame, and the drive motor The output end is connected to the upper end of the rotating shaft, and the lower end of the rotating shaft runs through the upper and lower end surfaces of the inner box; the lower end surface of the outer box is provided with a discharge port, and the discharge port is equipped with a movable sealing plate for blocking. The right end is connected to a push cylinder for driving it to move left and right. The bottom of the outer box where the discharge port is located is provided with a collection bucket for collecting materials. This invention is designed for the disadvantages of existing devices and realizes the circular screening of materials. , to avoid the waste of materials, the air selection and the mesh screen are combined in the screening to ensure the screening effect, and the screened impurities can also be removed to avoid the accumulation of impurities, which is very practical.

Owner:南京牧科纳米科技有限公司

Method for breeding rana spinosa

InactiveCN109997780AConvenient facilitiesEasy to operateTreatment involving filtrationAnimal feeding stuffLower yieldRana spinosa

The invention provides a method for breeding rana spinosa. The technical problem of low yield and the like of existing rana spinosa is solved. The method for breeding rana spinosa is characterized bycomprising the following steps: S1, site selection: selecting a breeding site at a position under the foot of a mountain area or at the source of a stream, wherein in the place, the vegetation is rich, the water flow is pollution-free, and the content of mineral substances does not exceed the standard; S2, construction of a tadpole pool: constructing a pool according to the specifications of 1 meter in height, 1.5 meters in width and 2 meters in length, wherein the pool is provided with a water inlet and a water outlet and does not need to be covered; S3, construction of an adult frog pool: digging a pool in the mountain area or a field with the specifications of 2 meters in depth, 3.2 meters in width and 80-100 meters in length in a circuitous manner in a shape of 'M' or 'Z', wherein theperiphery of the dug pool is built into an inner wall by cement bricks, a water tank with a width of 0.8-1 m and a depth of 0.1-0.15 m is built on one side of the bottom of the tank, a slope with a width of 2.4 m is reserved on the other side, the water tank and the bottom of the tank are coated with cement, and the whole tank is separated by plastic nets or wire nets at a distance of 5-10 m to form relatively closed small tanks. The method has the advantage of high yield of the rana spinosa.

Owner:安徽白云岩生态养殖有限公司

Circulating filtration type automatic water adding device for duckling feeding

InactiveCN113966721AConvenient drinking waterImprove protectionAvicultureFiltration circuitsWater storageWater storage tank

The invention discloses a circulating filtration type automatic water adding device for duckling feeding, which comprises a large-capacity water storage tank, an impurity filtering mechanism, an electric telescopic rod and a driving motor, a dustproof water feeding tank is arranged on the right side of the bottom of the large-capacity water storage tank, a fixed pedal is arranged at the right end of a connecting rod, a second fixing block is mounted at the left end of a mounting rod, a medicine shifting plate is connected to the rear portion of the first fixing block, the impurity filtering mechanism is connected to the inner side of the top end of the large-capacity water storage tank through bolts, and a rectangular groove-shaped structure is formed in the bottom end of a water blocking and separating plate. According to the circulating filtration type automatic water adding device for duckling feeding, when ducklings stand on the fixed pedal and the connecting rod rotates under the action of gravity, under the action of a pushing rod, the mounting rod and a dustproof sealing plate can be pushed to rotate anticlockwise, the dustproof water feeding tank is opened, the ducklings can drink water conveniently, and when the ducklings leave, the dustproof water feeding tank is sealed through the dustproof sealing plate, so that drinking water is conveniently protected and prevented from being polluted by impurities.

Owner:中新振荣(山东)生态农业科技有限公司

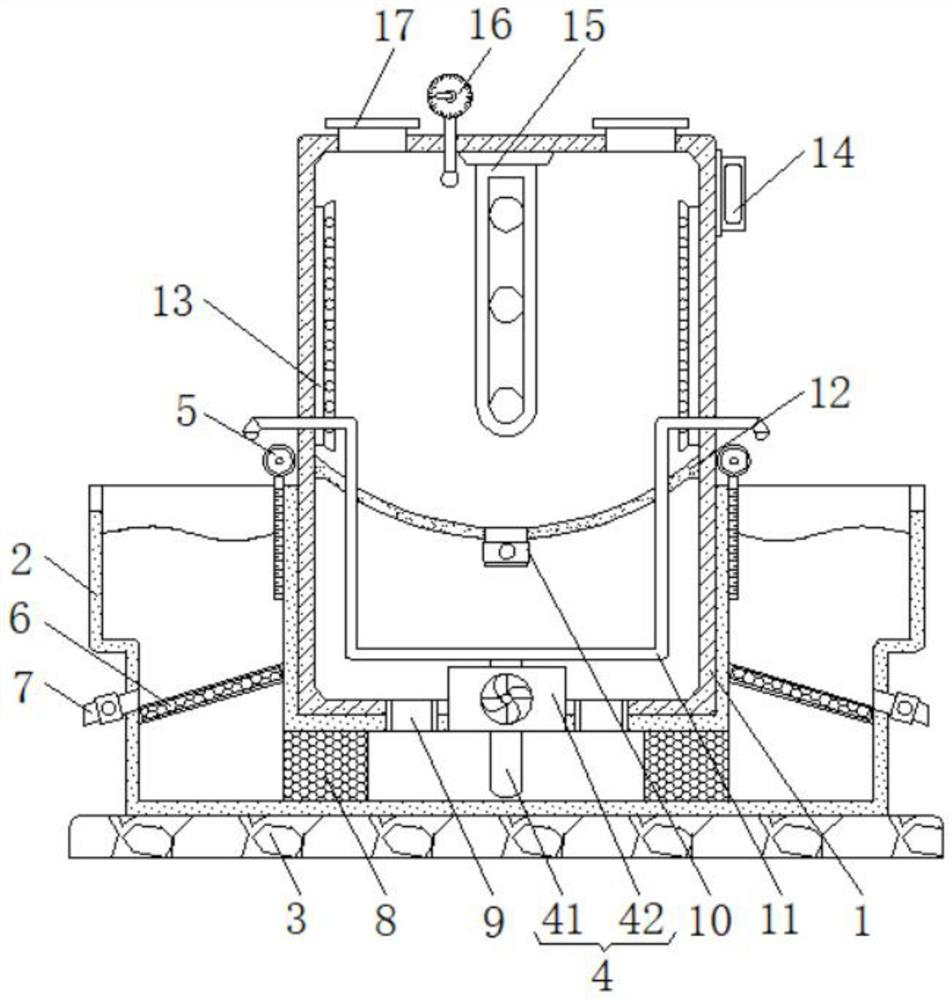

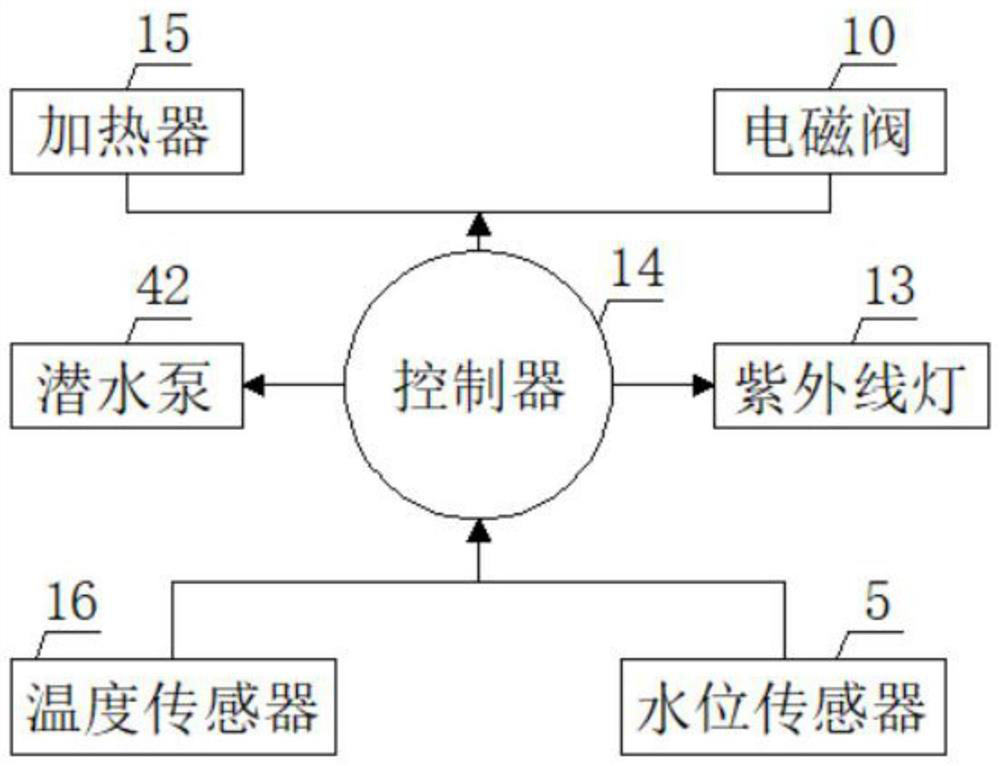

Water supply system for pig feeding

InactiveCN111887170ACause harmNormal growthWater treatment parameter controlWater/sewage treatment by irradiationFiltrationLivestock breeding

The invention discloses a water supply system for pig feeding, and belongs to the technical field of livestock breeding. The water supply system includes a water tank; a water sink is arranged below the water tank; the lower surface of the water sink is fixedly connected to the upper surface of a base plate; the same extraction assembly is in clamping connection with the lower surface of the watertank and the upper surface on the inner wall of the water sink; the water outlet end of the extraction assembly communicates with a spraying pipe; the two ends of the spraying pipe pass through partition plates and are in clamping connection with the left and right side surfaces of the water tank; and the spraying pipe is located above the water sink. Through the arrangement of a submersible pump, filter plates, filter elements, the spraying pipe, an extraction pipe and the water sink, water can be filtered and purified again by the filter elements, so that the treated water can be sprayed into the water sink from the spraying pipe so as to realize the circulating filtration of the water in the water sink; and through the continuous flowing of the water, impurities can be adhered on the filter plates due to the attractive force generated by suction, so that the water cannot easily ferment with residues to generate pathogenic bacteria, therefore, harm to pigs can be avoided, and the normal growth of the pigs can be achieved.

Owner:武汉中畜智联科技有限公司

Aluminum profile sealing device, aluminum profile production line and production method

ActiveCN108070893BImprove heat utilizationNot easy to loseSemi-permeable membranesMixing methodsEngineeringManufacturing line

The invention relates to an aluminum profile sealing device, which includes a sealing tank and a conveying mechanism. The sealing tank is filled with a sealing liquid. The sealing tank is provided with a heating device for heating the sealing liquid. The sealing liquid is There are a number of floating balls floating on the surface for heat insulation. The opening of the sealing groove is covered with a groove cover. The groove cover includes two fixing plates respectively connected to the top sides of the sealing groove. The two fixing plates are opposite to each other. There are movable plates slidingly connected on both sides, and a channel for aluminum profiles to pass can be formed between the two movable plates. The movable plate is an "L"-shaped plate, and its horizontal part is plugged into the fixed plate, and its vertical part is vertically downward. Extended and located below the liquid surface of the sealing liquid; the fixed plate and the movable plate are connected through the first cylinder, the fixed end of the first cylinder is connected to the fixed plate, and the piston end of the cylinder is connected to the movable plate. The invention also discloses an aluminum profile production line and a production method. The invention has high degree of automation, high thermal efficiency of the heating device, long service life of the device and low processing cost.

Owner:奋安铝业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com