Washing device for hydraulic system of tractor

A technology of hydraulic system and cleaning device, which is applied in the field of tractor hydraulic circulation cleaning system, and can solve problems such as oil temperature rise, joint blockage, dust and sundries entering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

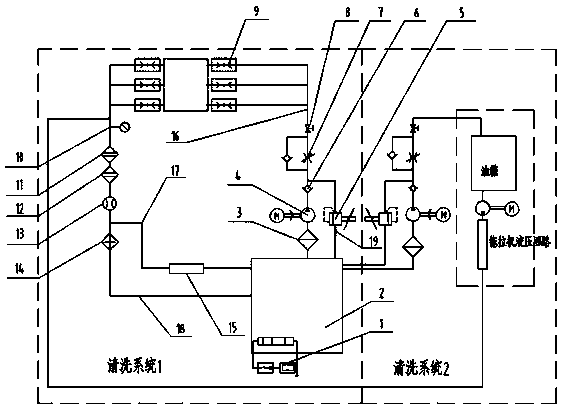

[0009] Attached below figure 1 , attached figure 2 The specific implementation of the tractor hydraulic system cleaning device will be further described. Such as figure 1 , when using the cleaning system 1 to clean the hydraulic components, first connect the oil inlet and outlet ports of the hydraulic components to the oil inlet and oil return circuits of the quick-change joint group 9 through the auxiliary oil pipe, and turn on the motor switch of the motor pump group 4 , start the cleaning system, at this time the hydraulic pump of the motor pump group 4 pumps the hydraulic oil in the cleaning oil tank 2 into the system through the oil suction filter 3, and the hydraulic oil passes through the overflow pipeline 19, the check valve 6, the check joint Flow valve 7, quick-change joint group 9, circulating crude oil filter 11, circulating essential oil device 12, flow meter 13, cooler 14, and oil return pipeline 18 flow back into the cleaning oil tank 2 to form a circulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com