Aluminum profile sealing device, aluminum profile production line and production method

A sealing device and aluminum profile technology, which is applied in chemical instruments and methods, mixing methods, transportation and packaging, etc., can solve the problems of large differences in sealing treatment effects of aluminum profiles, uneven temperature distribution of sealing liquid, and product quality issues. Improvement and other issues, to achieve the effect of stable sealing effect, high degree of automation, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

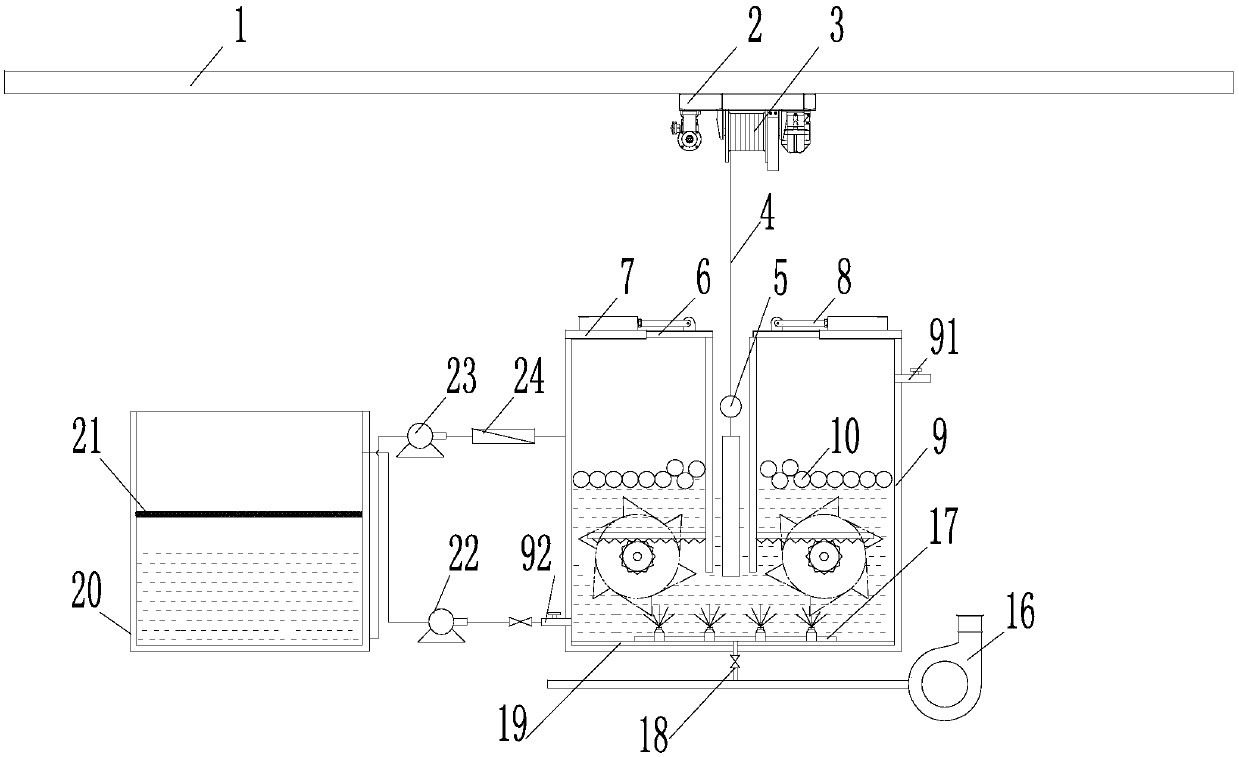

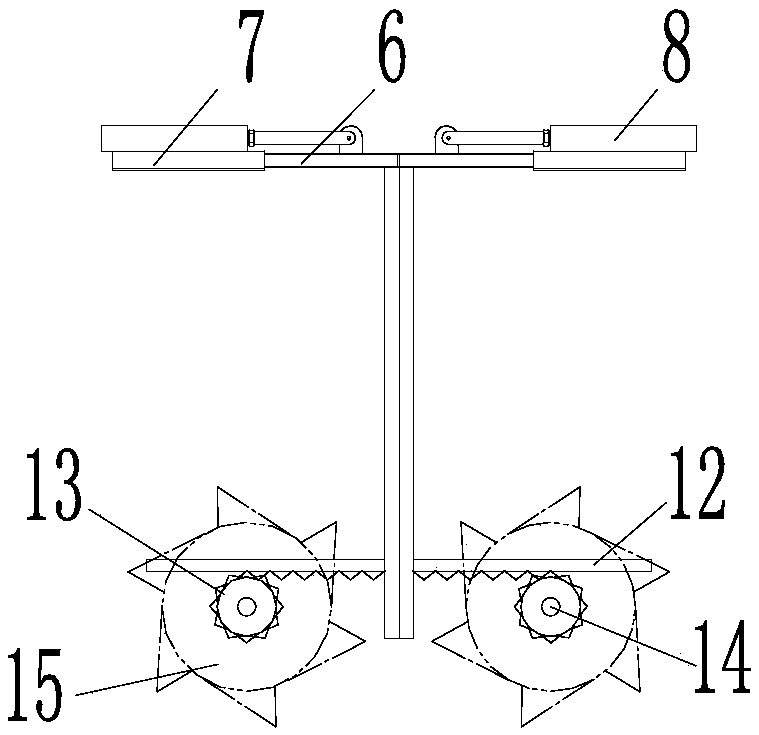

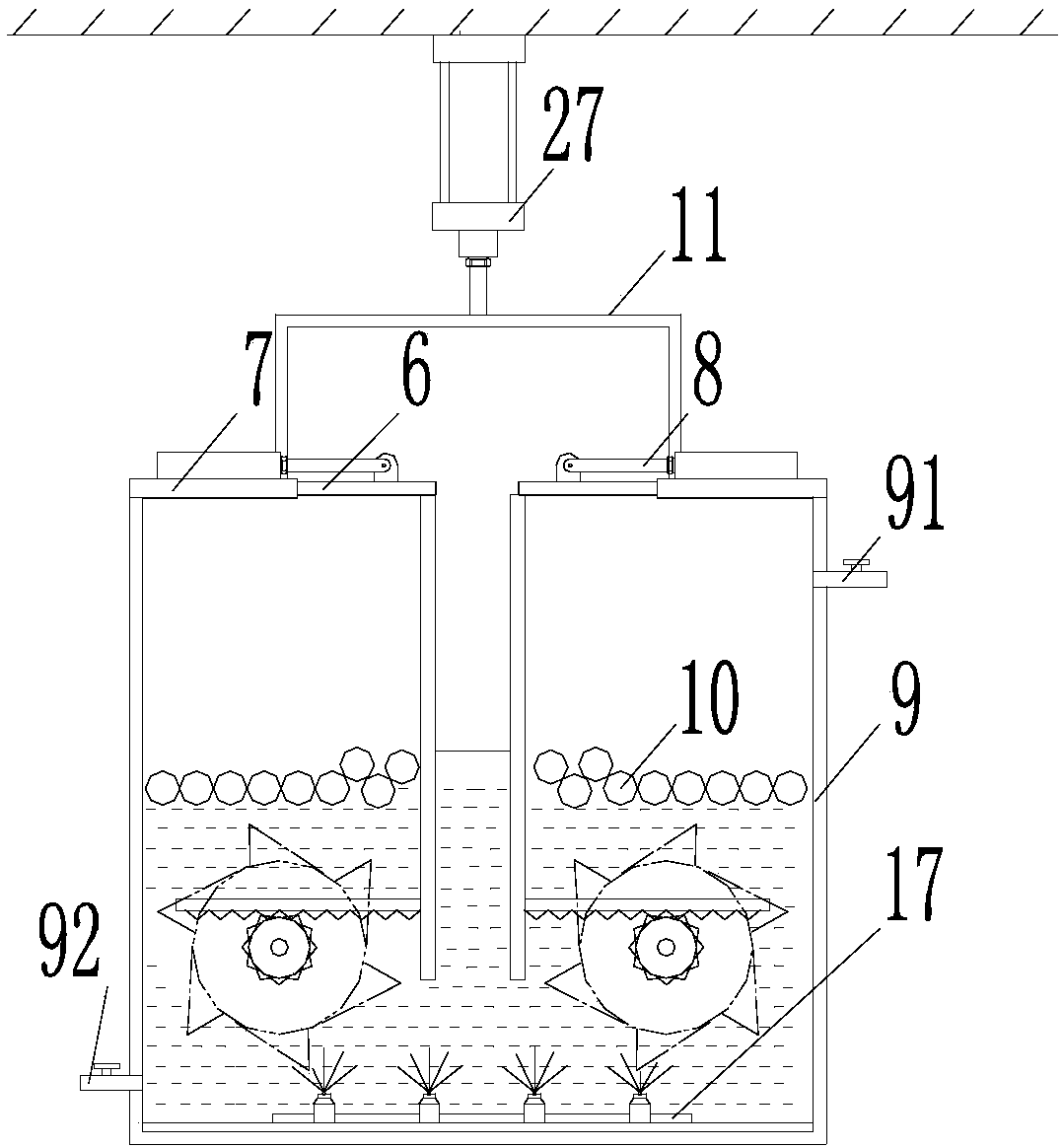

[0052] like figure 1 As shown, this embodiment discloses an aluminum profile sealing device, which includes a sealing groove 9, a conveying mechanism extending along the direction of the aluminum profile production line, and passing through the sealing groove 9, and the conveying mechanism is used for hoisting aluminum Profiles, the sealing liquid is filled in the sealing tank 9, and the heating device 19 for heating the sealing liquid is arranged in the sealing tank 9. The heating device 19 is a prior art, and the electric Heating tube, steam heating tube or other equipment with heating function.

[0053] The top of the sealing tank 9 is provided with a liquid inlet 91, and the bottom is provided with a liquid outlet 92, and the liquid inlet 91 and the liquid outlet 92 are both connected with control valves.

[0054] There are a plurality of floating balls 10 used for heat insulation floating on the liquid surface of the sealing liquid, and the opening of the sealing groove ...

Embodiment 2

[0072] The invention also discloses an aluminum profile production line, which includes an aluminum profile sealing device, and the aluminum profile sealing device is the above-mentioned aluminum profile sealing device.

Embodiment 3

[0074] The invention also discloses a method for producing an aluminum profile, comprising the following steps:

[0075] (1) Melting: Aluminum ingots, aluminum-silicon alloy ingots, and magnesium ingots are heated and smelted. Stirring is continued during the smelting process. The smelting temperature is 730-740°C. Using the same level close-packed top casting process, aluminum with preset diameter specifications is produced. Great;

[0076] (2) Homogenization of the ingot: rapid cooling after heat preservation at a temperature of 560-580°C for 5-6 hours;

[0077] (3) Extrusion: After heating the cooled aluminum rod to 420-460°C, put it into the preset mold, extrude the aluminum profile of the preset specification with an extrusion machine, and rapidly air-cool it;

[0078] (4) Aging: keep warm for 3-4 hours at a temperature of 190°C to 195°C, and then perform forced air cooling;

[0079] (5) Perform pretreatment operations on the aluminum profiles including water washing, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com