Patents

Literature

32results about How to "Guaranteed wetting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrochemical device

InactiveCN108878748AImprove adhesionImprove protectionCell electrodesLi-accumulatorsConductive polymerElectrochemical cell

Owner:NINGDE AMPEREX TECH

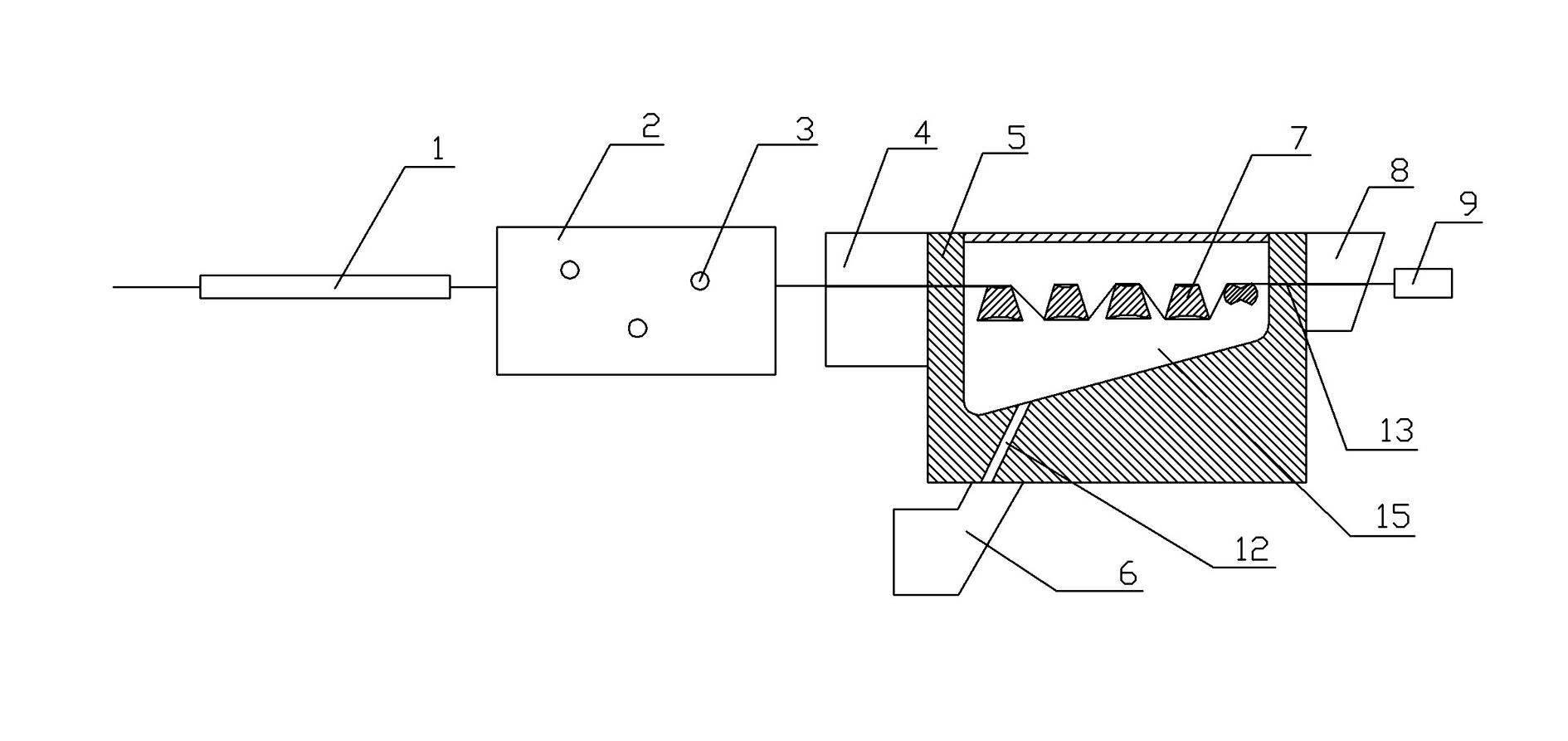

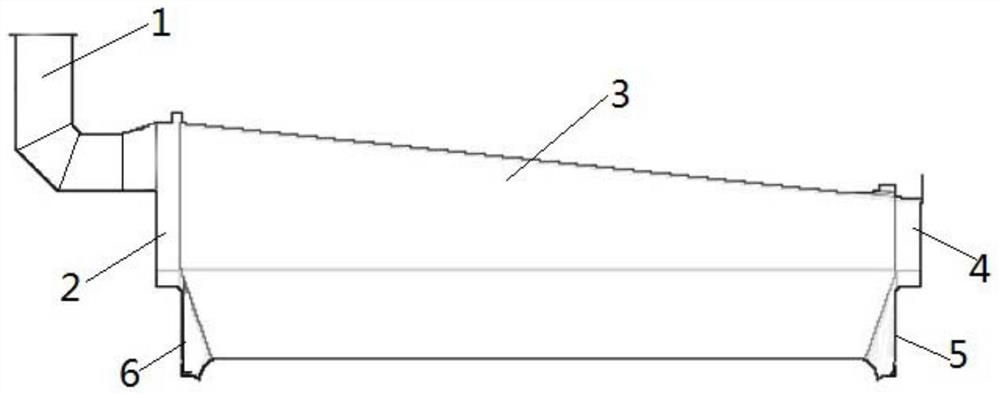

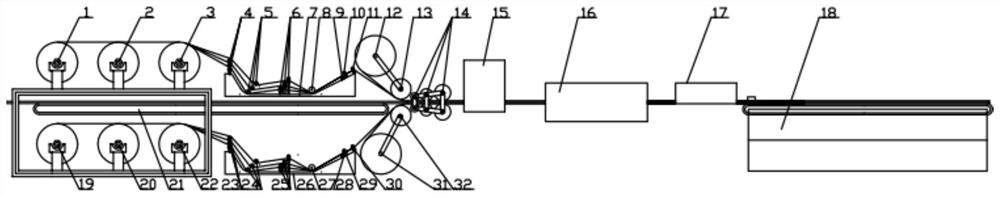

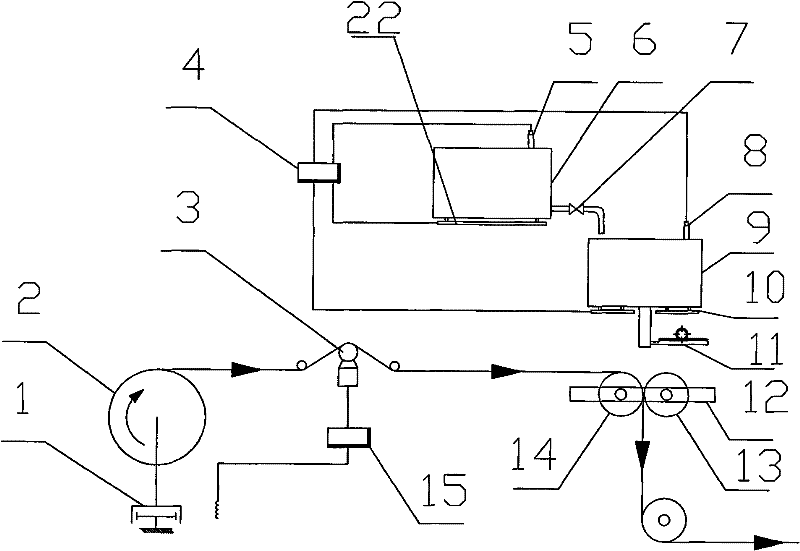

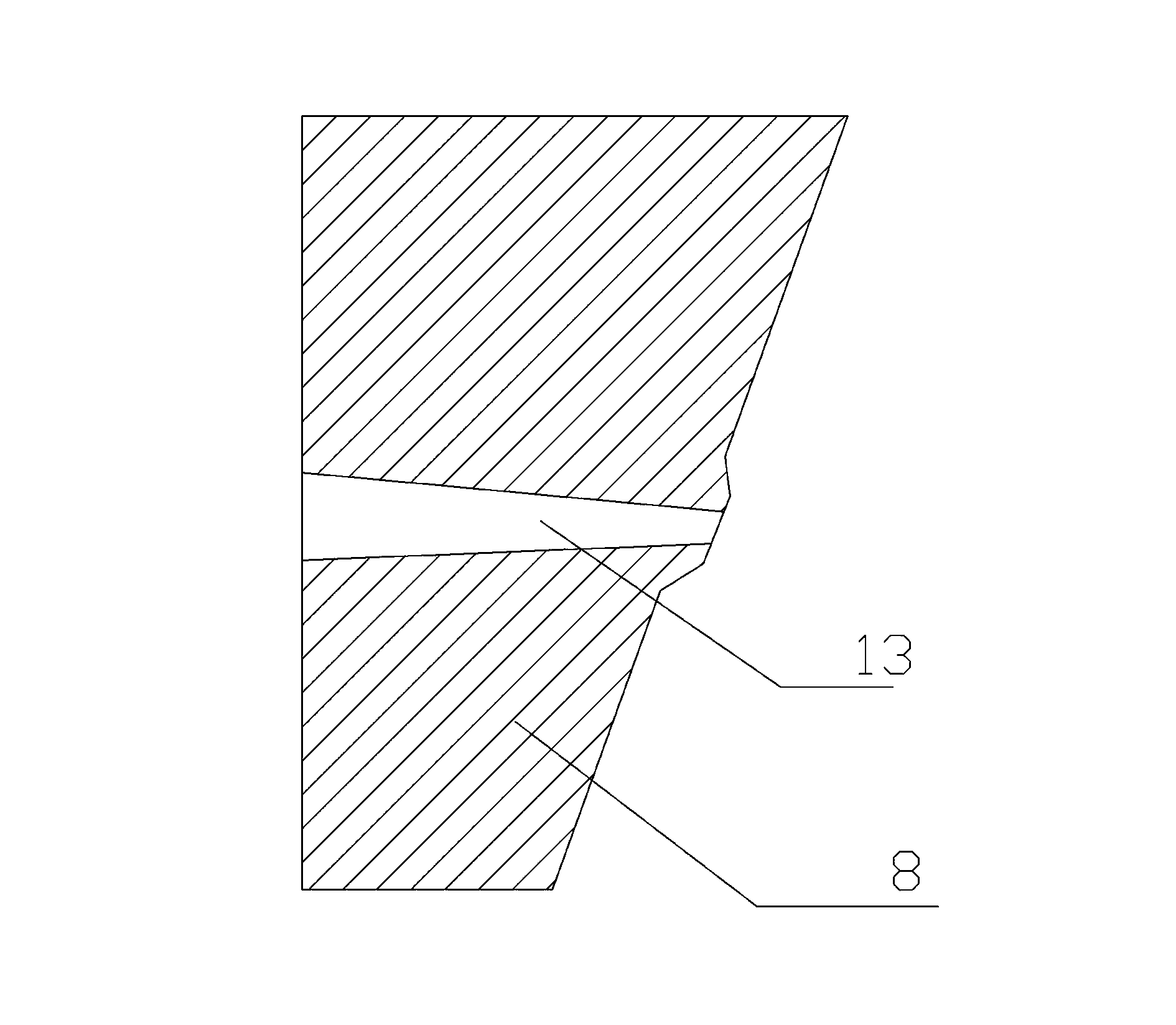

Forming equipment and forming method for macrofiber-reinforced thermoplastic resin

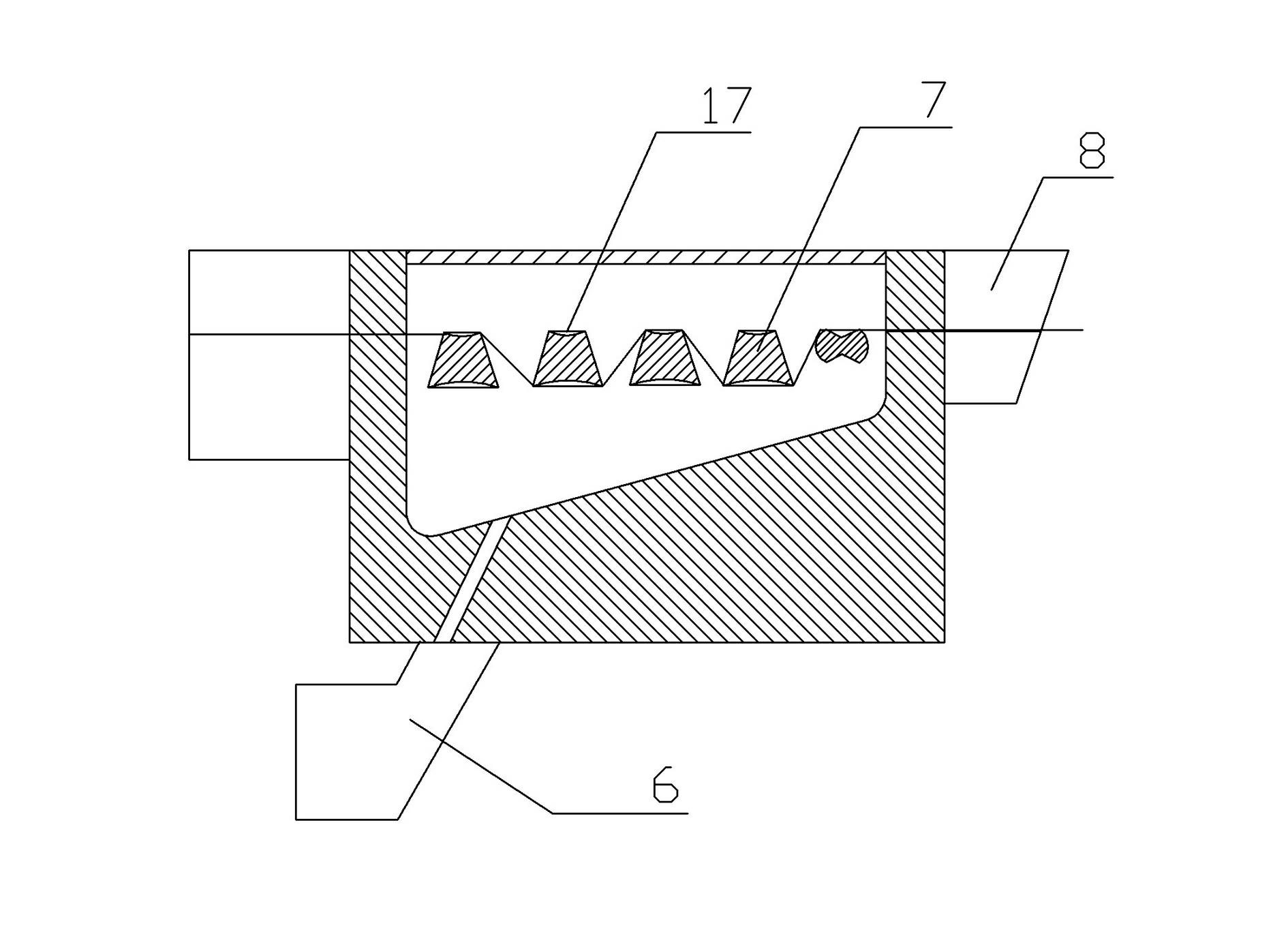

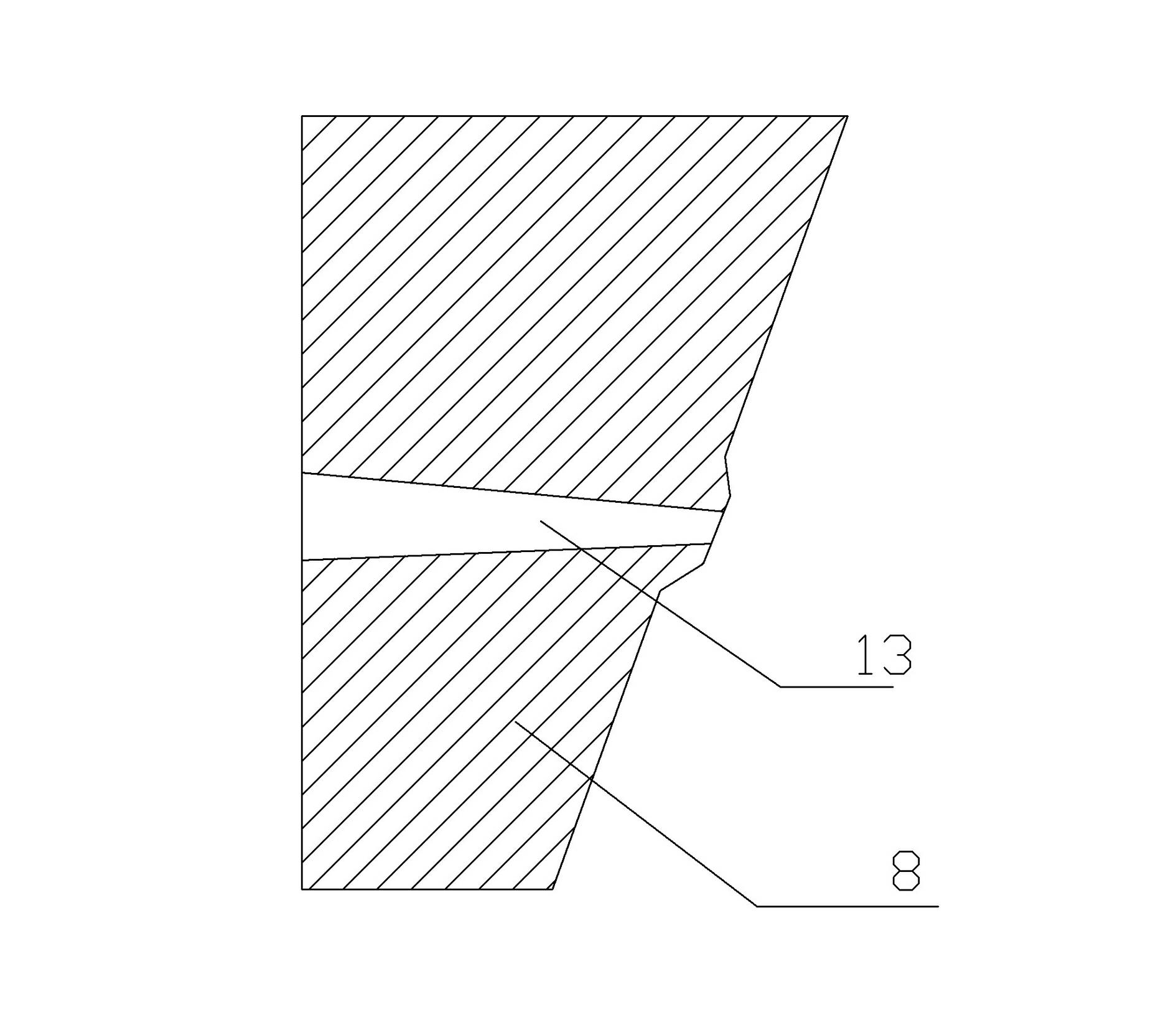

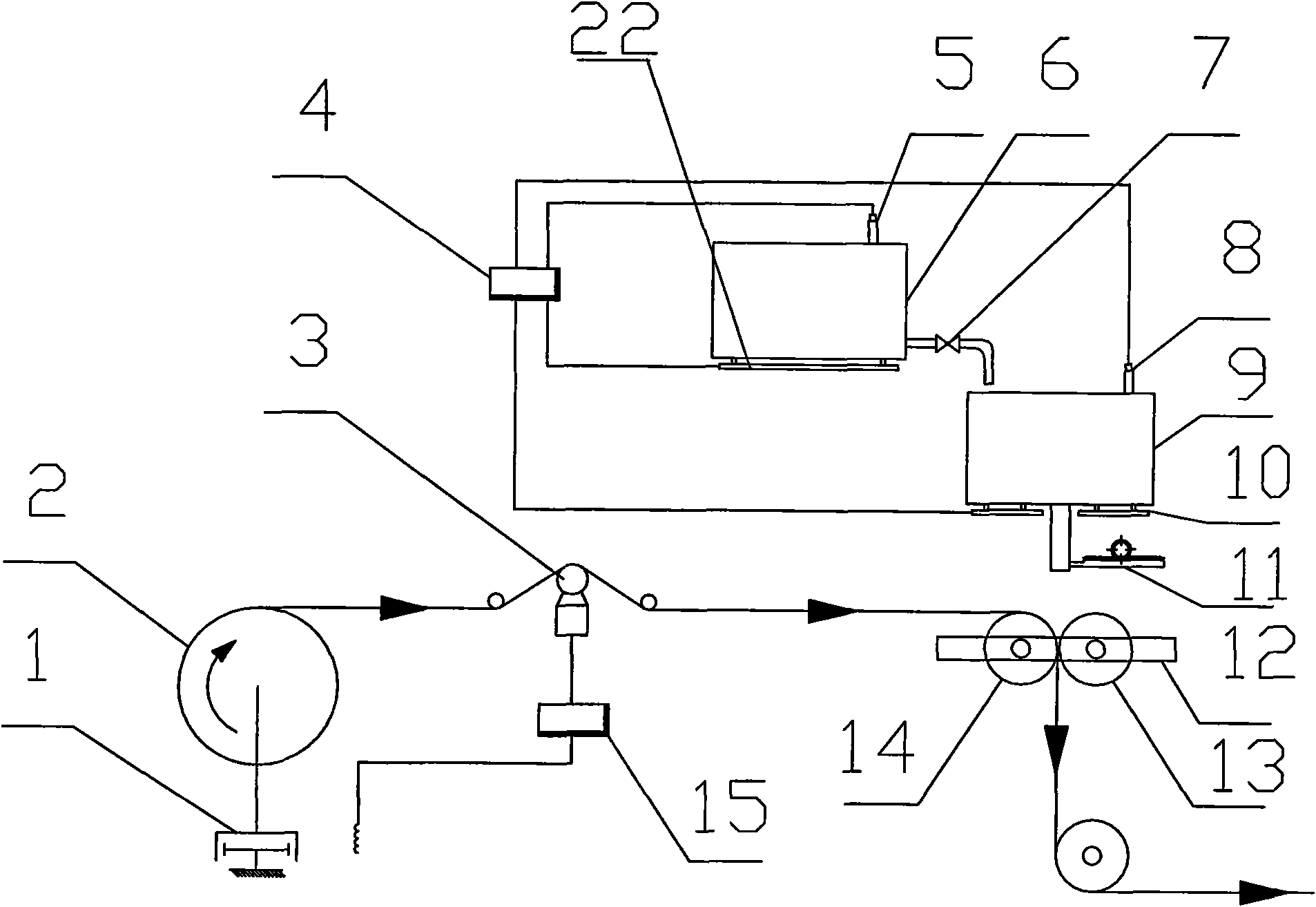

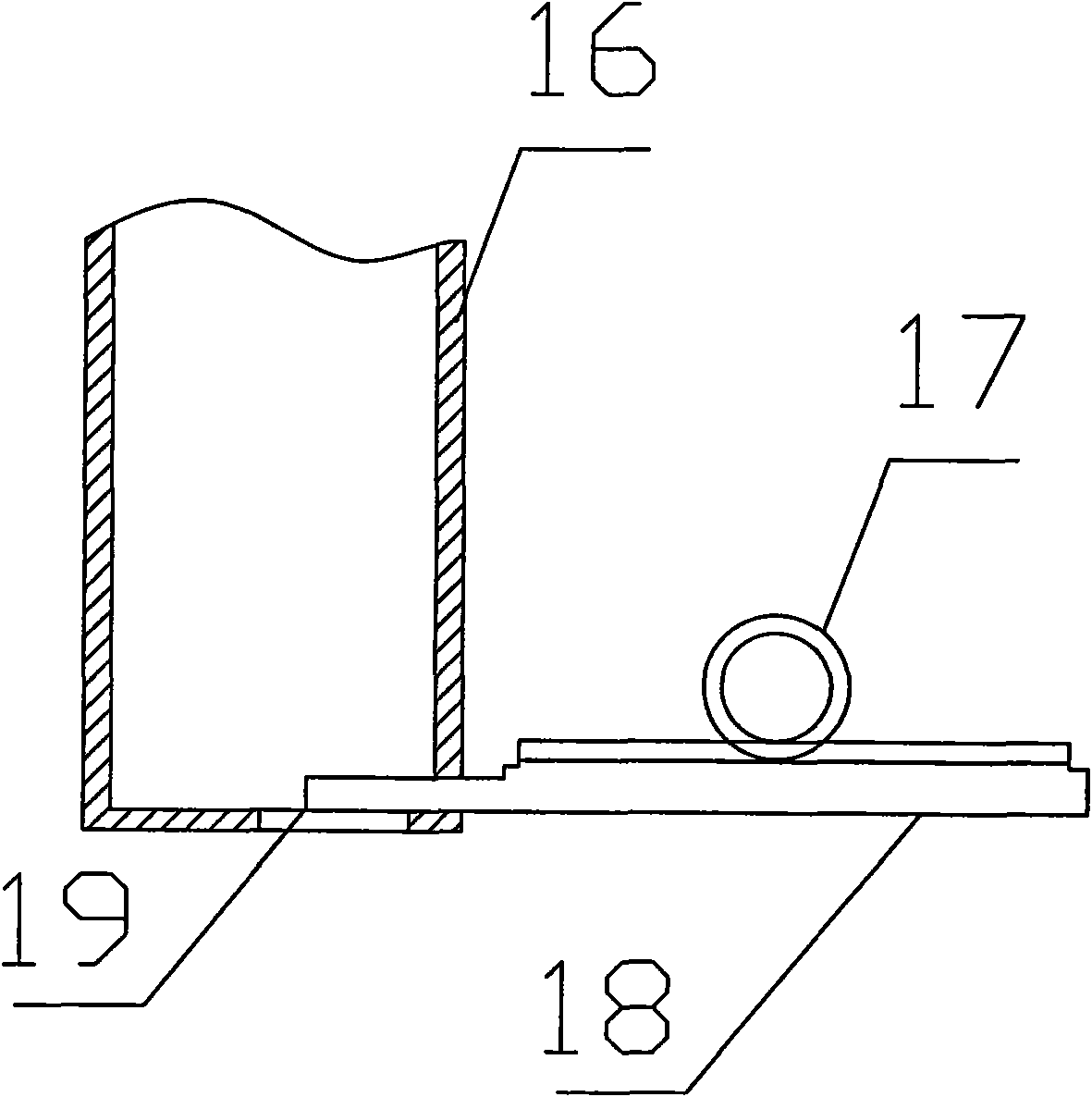

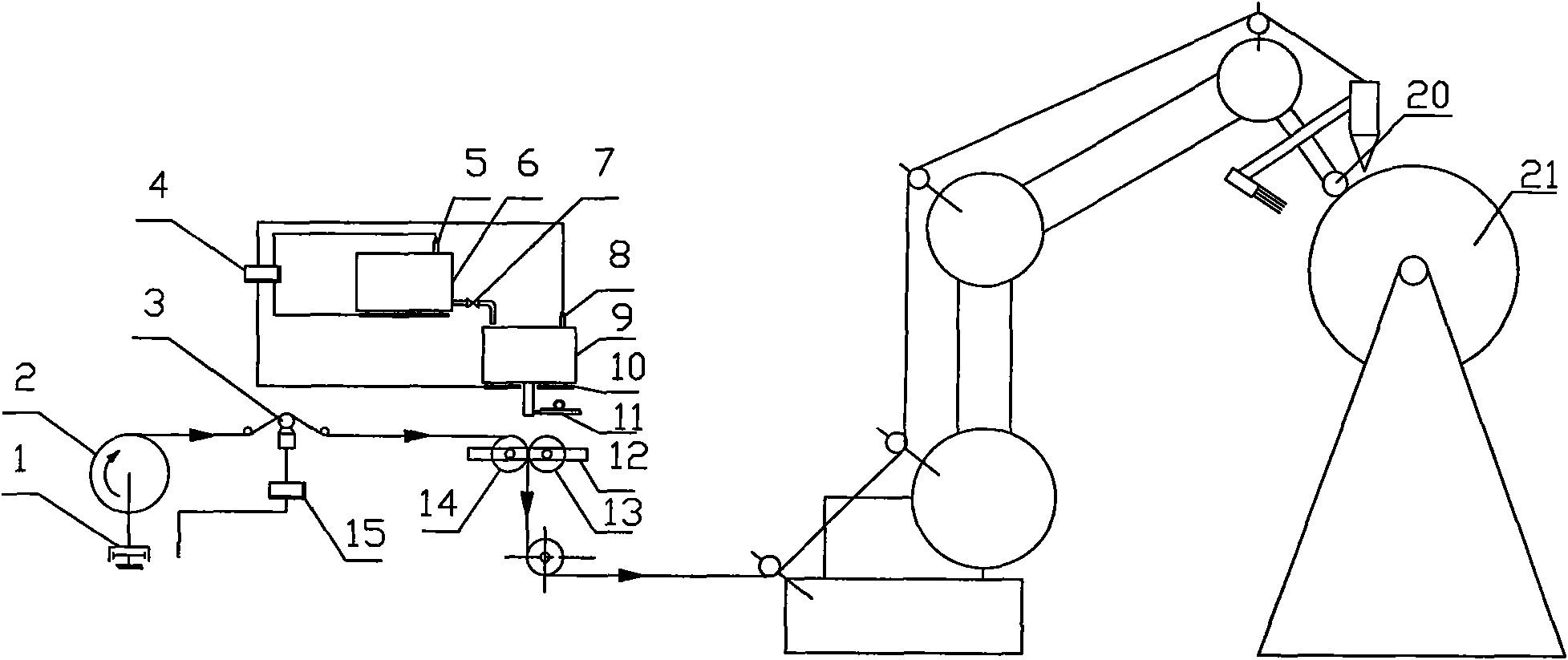

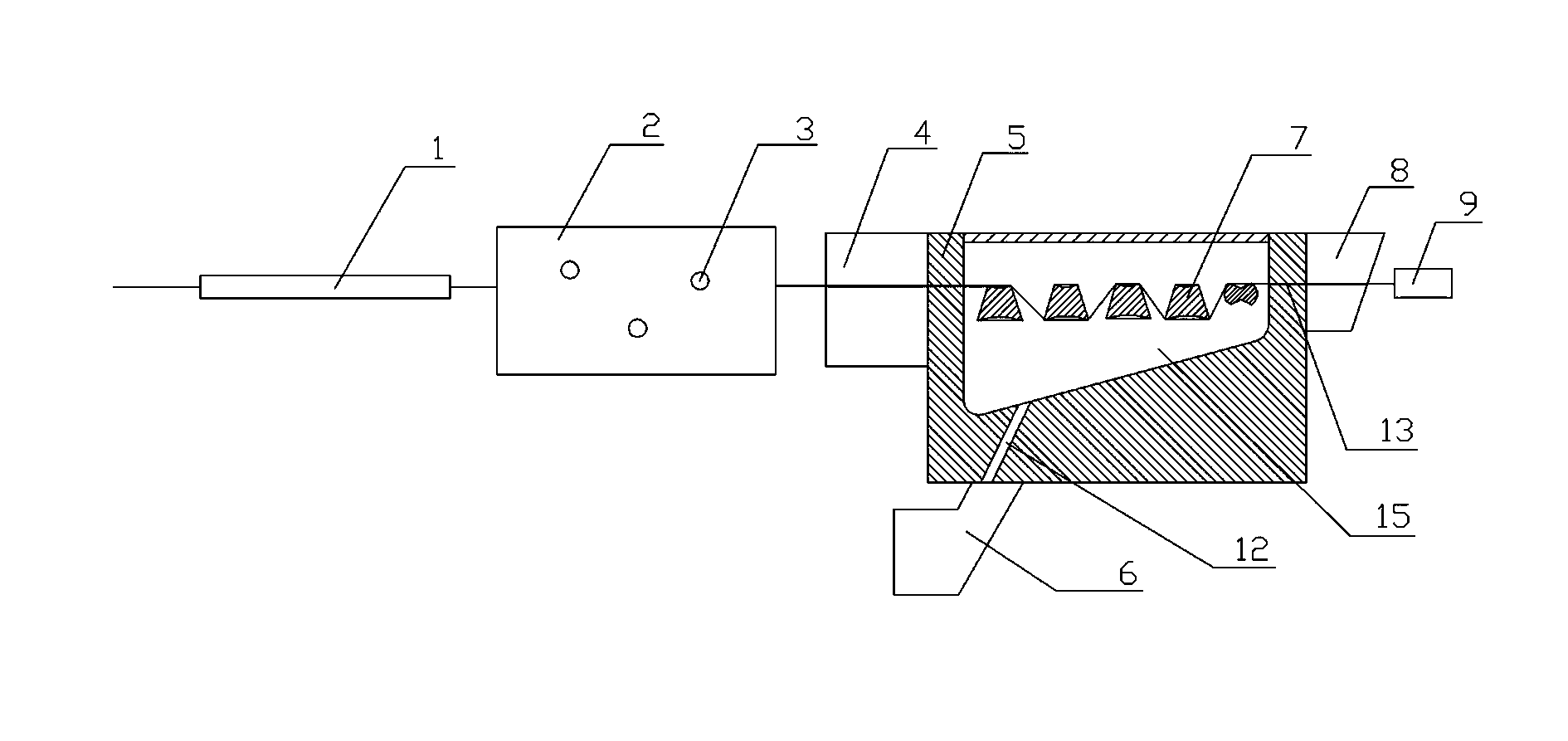

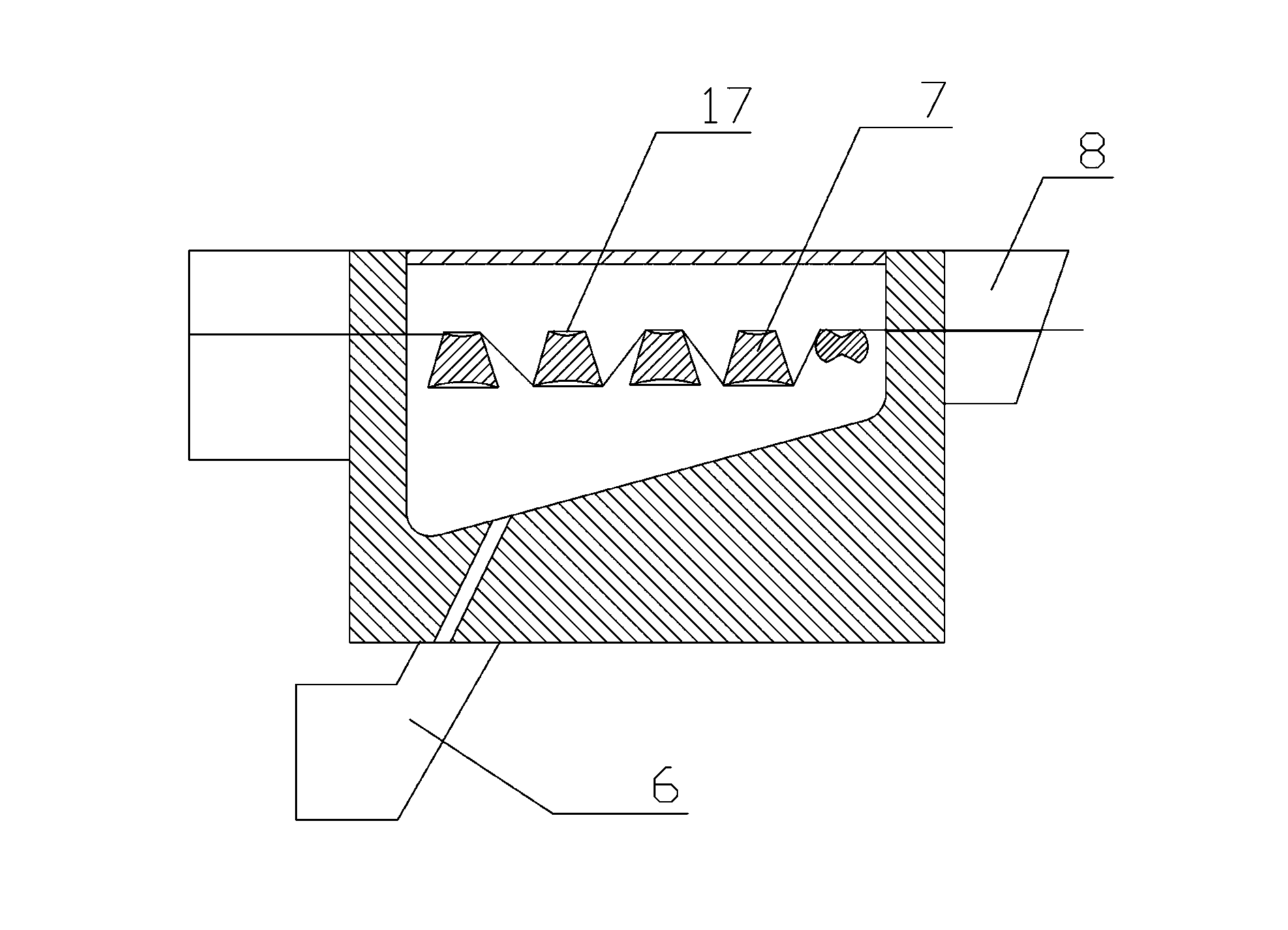

The invention discloses forming equipment for macrofiber-reinforced thermoplastic resin, which comprises equipment for decomposing fiber rings into fiber bundles and pretreating and equipment for impregnating fibers fully and forming by melting resin, wherein fiber bundle independent channels of the equipment for decomposing the fiber ring into the fiber bundle and pretreating are connected with a fiber pre-puffing and preheating system; a fusant inlet die of the equipment for impregnating the fibers fully and forming by the melting resin is communicated with a fiber impregnating body by a fuscant flowing channel and inclines upwards to form a certain angle, and a fiber inlet die is used for connecting the fiber pre-puffing and preheating system and the fiber impregnating body, so that the fibers enter the fiber impregnating body horizontally, and the other end of the fiber impregnating body is connected with a forming die. A preparation method for the macrofiber-reinforced thermoplastic resin comprises the following steps that: (1) after passing through respective independent channels, 20 to 40 bundles of fibers enter the fiber pre-puffing and preheating system in a mode of arranging in one line, and when the fiber bundles pass through a preheating guiding roller, the fibers contact a circular arc surface of the guiding roller, so that the fiber bundles are in a cloth or ribbon shape under the stretching action of traction, wherein the fiber bundles play the pre-puffing effect; (2) after being led into the fiber inlet die and a fiber input hole of the impregnating body horizontally, the pre-puffed and preheated fiber bundles pass through a fiber tension roller in the impregnating body up and down in a staggered mode, wherein the fiber bundles are in a cloth or ribbon shape when contacting the fiber tension roller; and (3) immersed macrofibers and material flow pass through an output channel and the forming die of the impregnating body.

Owner:MIANYANG DONGFANG SPECIAL ENG PLASTIC +2

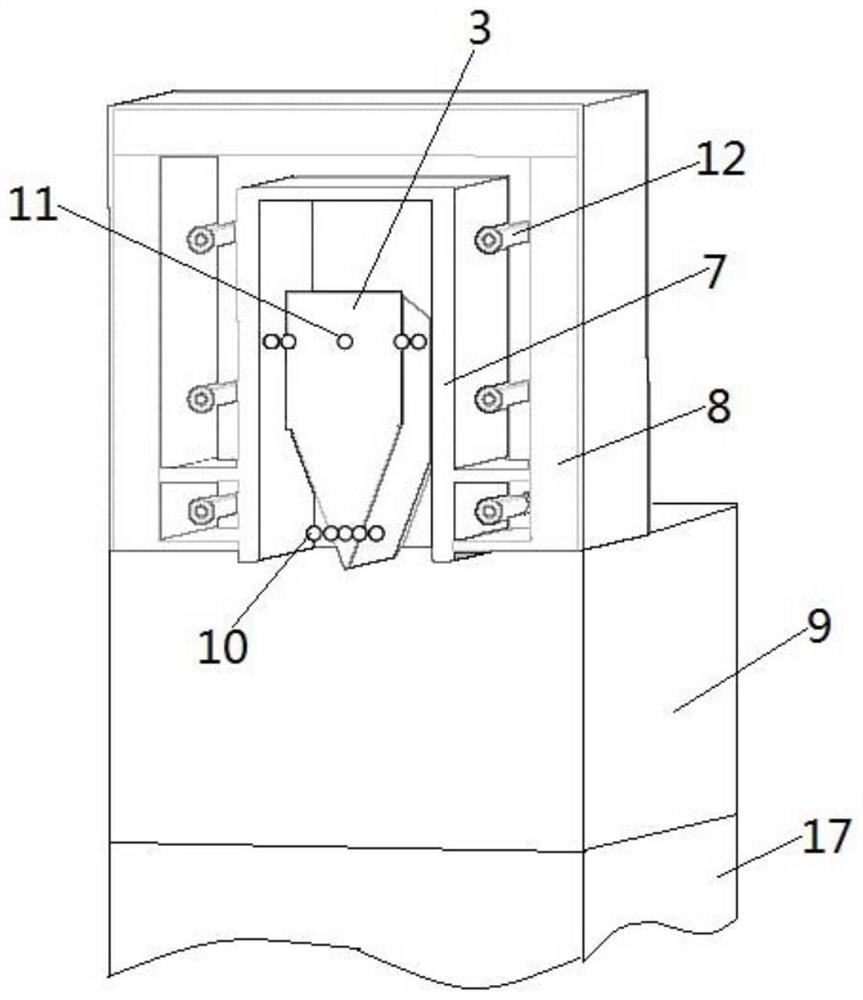

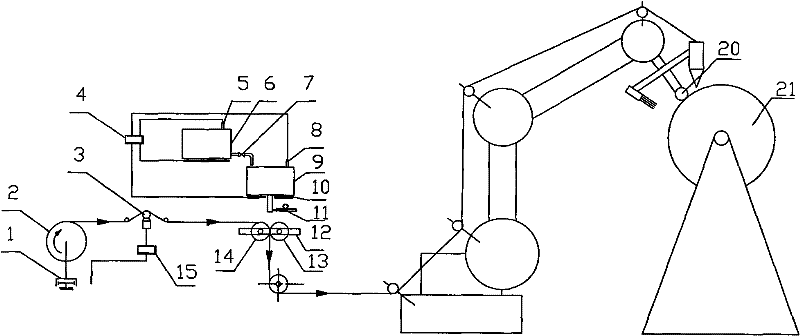

Device for controlling gel content of in-situ solidifying fiber placement machine

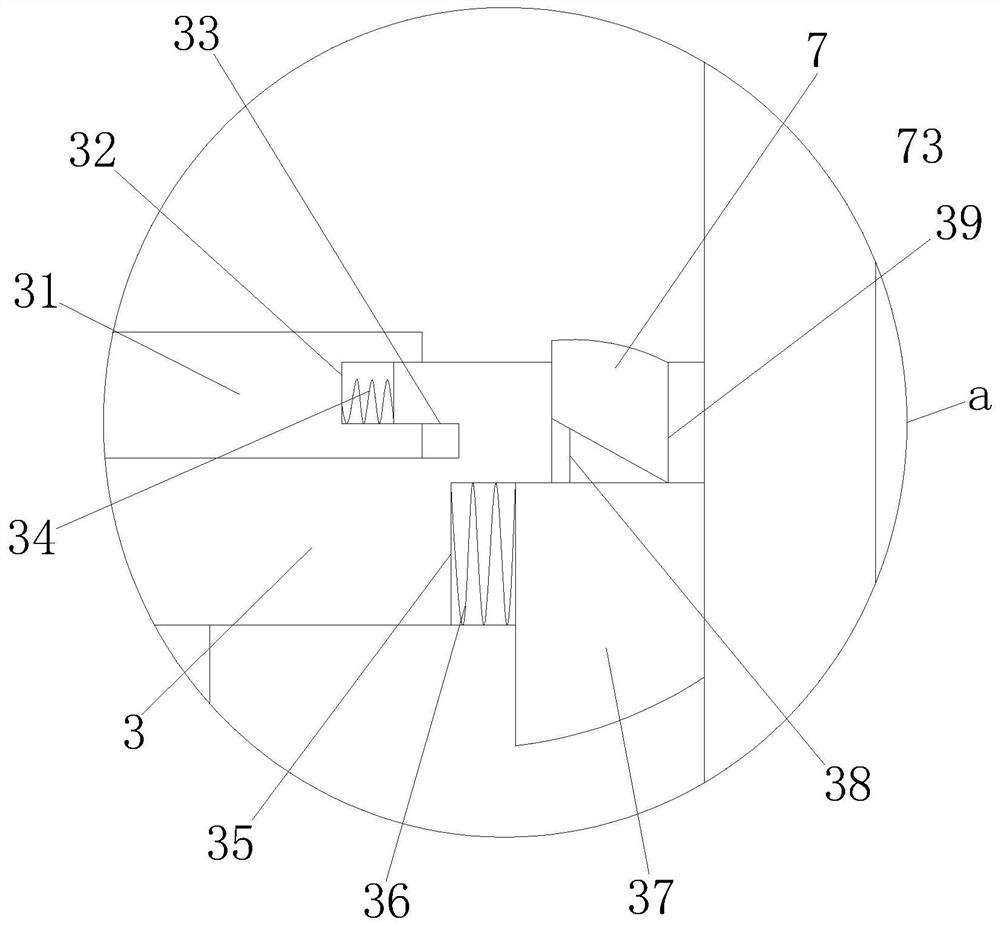

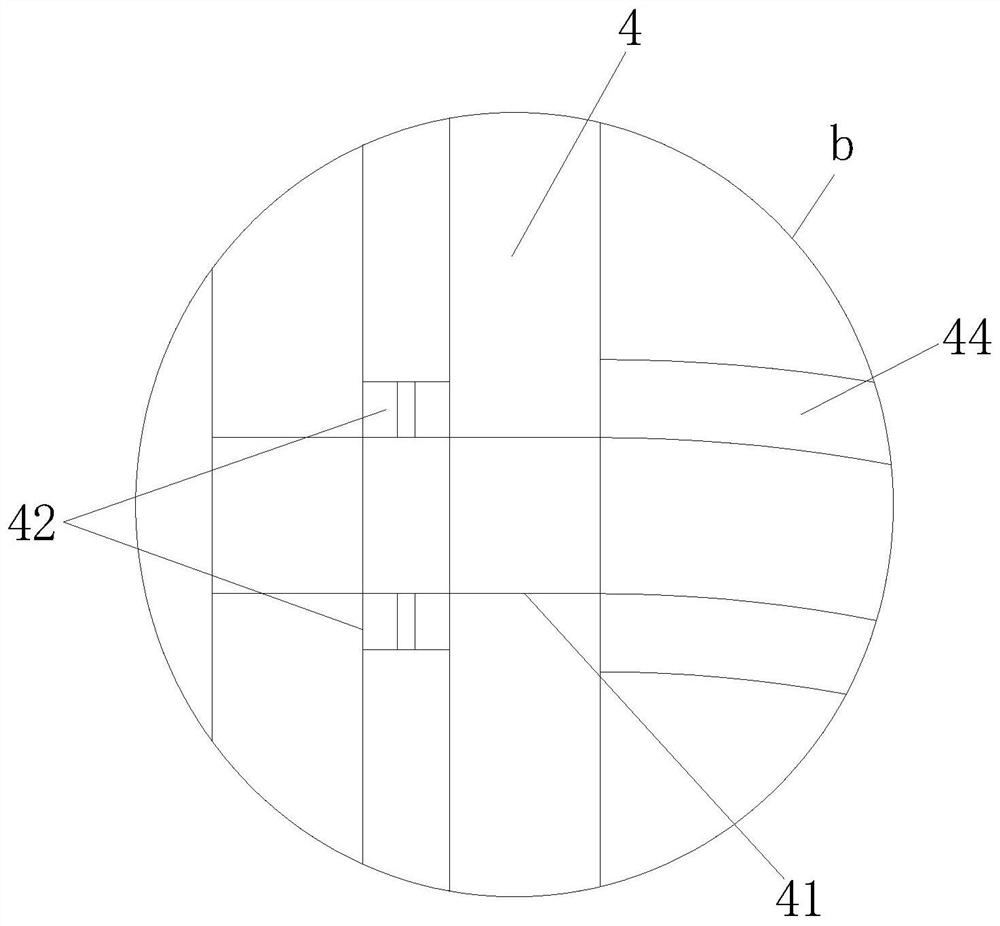

The invention discloses a device for controlling the gel content of an in-situ solidification fiber placement machine. The device comprises a resin-supplying control mechanism, a gel-extruding mechanism, a tension control mechanism and a flow control mechanism, wherein, the resin-supplying control mechanism is arranged above the gel-extruding mechanism; the tension control mechanism is arranged at the front end of the gel-extruding mechanism and used for adjusting the system tension of the device; the flow control mechanism is arranged at the bottom of the resin-supplying control mechanism and used for controlling the flow of resin pouring onto the glass fiber; and the flow control mechanism is used for pouring the resin onto the glass fiber, and the gel-extruding mechanism is used for extruding the resin on the glass fiber into the glass fiber. The invention has the advantages of simple structure, convenient use and low cost, and the invention can realize the accurate control over the gel content of glass fiber and carbon fiber by controlling the temperature of the resin-supplying groove, the flow of the flow control groove, the clearance of the gel-extruding mechanism and the tension of the fiber on a real-time basis.

Owner:XI AN JIAOTONG UNIV

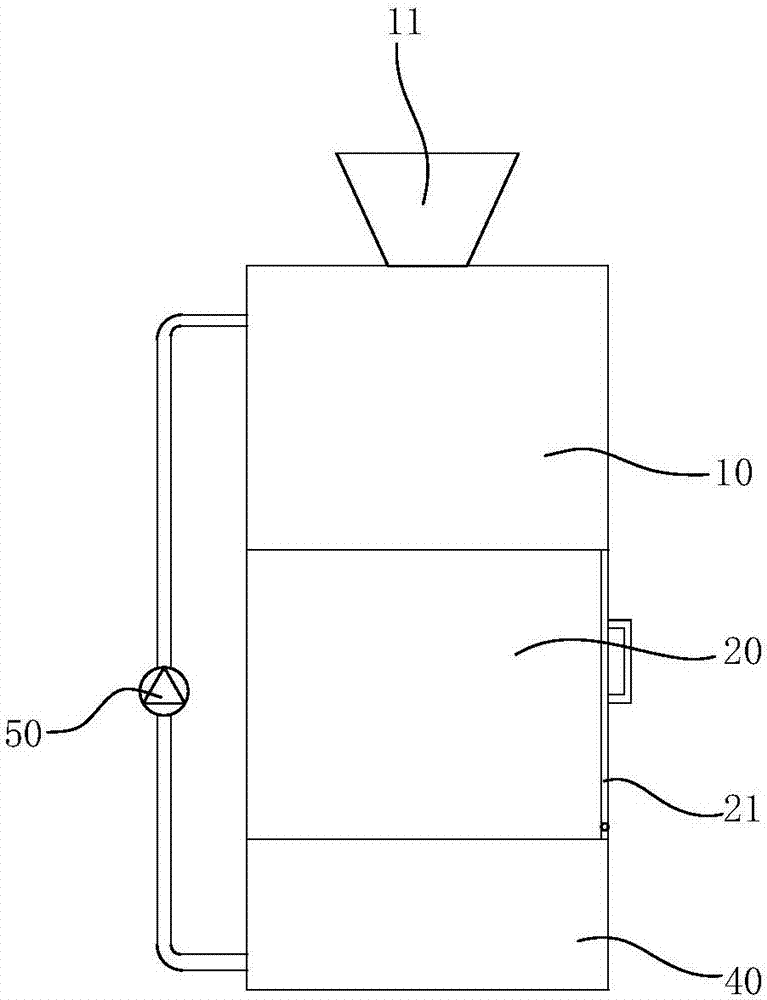

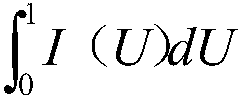

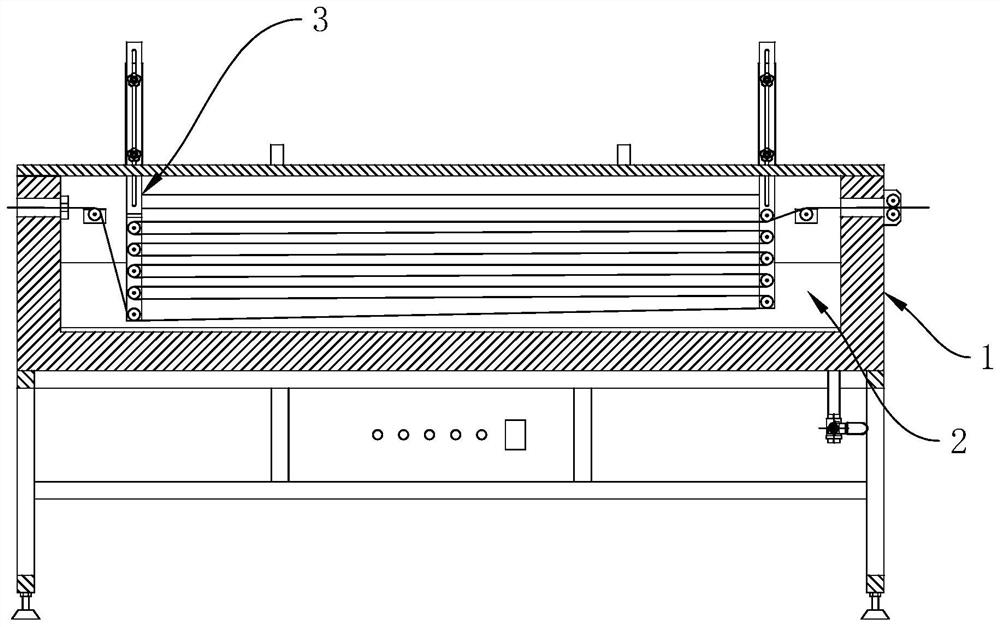

Agricultural device for soaking seeds in medicine

InactiveCN107241973AGuaranteed wetting effectReduce pollutionAgriculture tools and machinesHarvested fruit hanging devicesMedicinePollution

The invention relates to an agricultural device for soaking seeds in medicine. The agricultural device for soaking the seeds in the medicine comprises a medicine soaking box, wherein a feeding opening is formed in the upper end of the medicine soaking box; a discharging opening is formed in the lower end of the medicine soaking box; a stirring unit is arranged in the medicine soaking box; the discharging opening of the medicine soaking box communicates with a feeding opening of a separating box; a filtering screen plate is arranged in the separating box; a liquid medicine storage box is arranged on the lower plate surface of the filtering screen plate and communicates with an inlet of a pump through a pipeline; an outlet of the pump communicates with the medicine soaking box through a pipeline; the separating box is further provided with a seed discharging opening; an openable baffle is arranged at the opening; the seeds are thrown into the feeding opening of the medicine soaking box; the pump and the stirring unit are started to soak and stir the seeds; the liquid medicine and seed wetting effect is ensured; the completely soaked seeds are guided out from the discharging opening; by the filtering screen plate, the liquid medicine in the seeds is filtered; the liquid medicine which is filtered out is guided into the liquid medicine storage box, and is guided and fed into the medicine soaking box by the pump for circulatory use; and pollution of waste water can be reduced.

Owner:高鹏

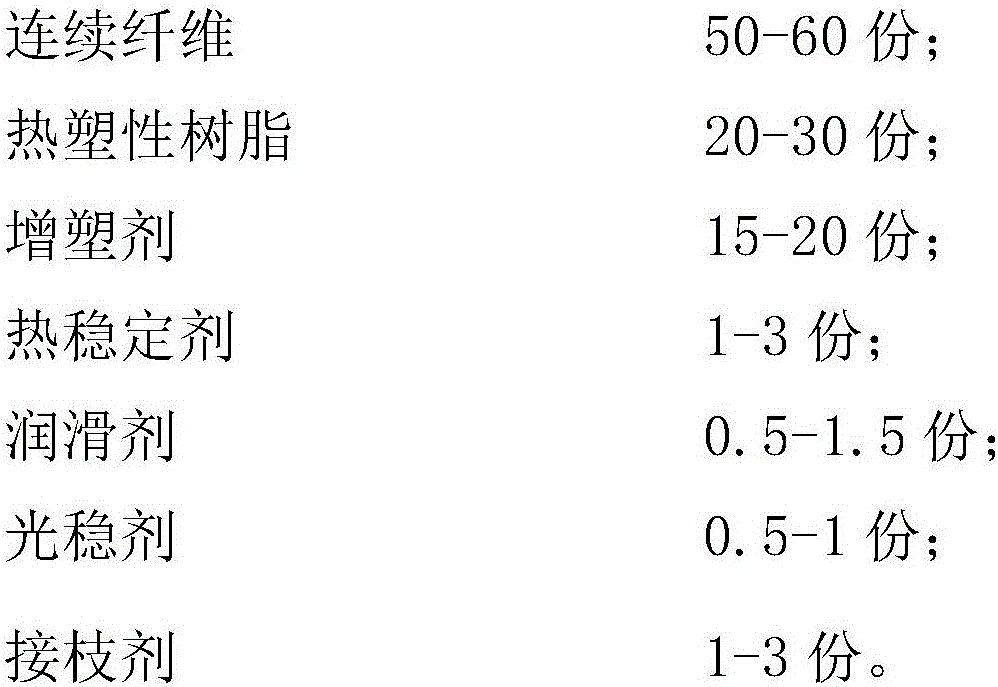

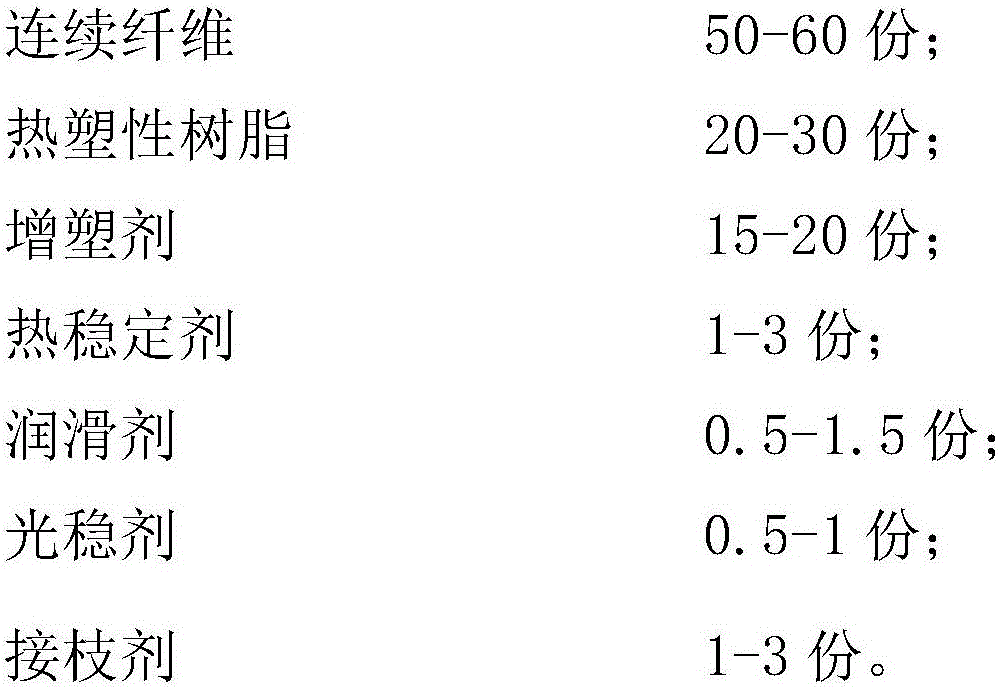

Continuous fiber reinforced PVC pre-dip material and preparation method thereof

The invention provides a continuous fiber reinforced PVC pre-dip material and a preparation method thereof. The continuous fiber reinforced PVC pre-dip material comprises the following components: 50-60 parts of continuous fiber, 20-30 parts of thermoplastic resin, 15-20 parts of a plasticizer, 1-3 parts of a heat stabilizer, 0.5-1.5 parts of a lubricant, 0.5-1 part of a light stabilizer, and 1-3 parts of a grafting agent. The pre-dip material and the preparation method can solve the disadvantages of poor heat stability and poor liquidity of the original product, and the invention provides the moulding method with continuous production and stable performance, can keep the raw material characteristic with maximum degree, improves the processing moulding problem, can reach continuous production, and increases the comprehensive energy efficiency.

Owner:红石极威实业集团有限公司

High-hardness high-wear-resistant surfacing electrode for multilayer surfacing

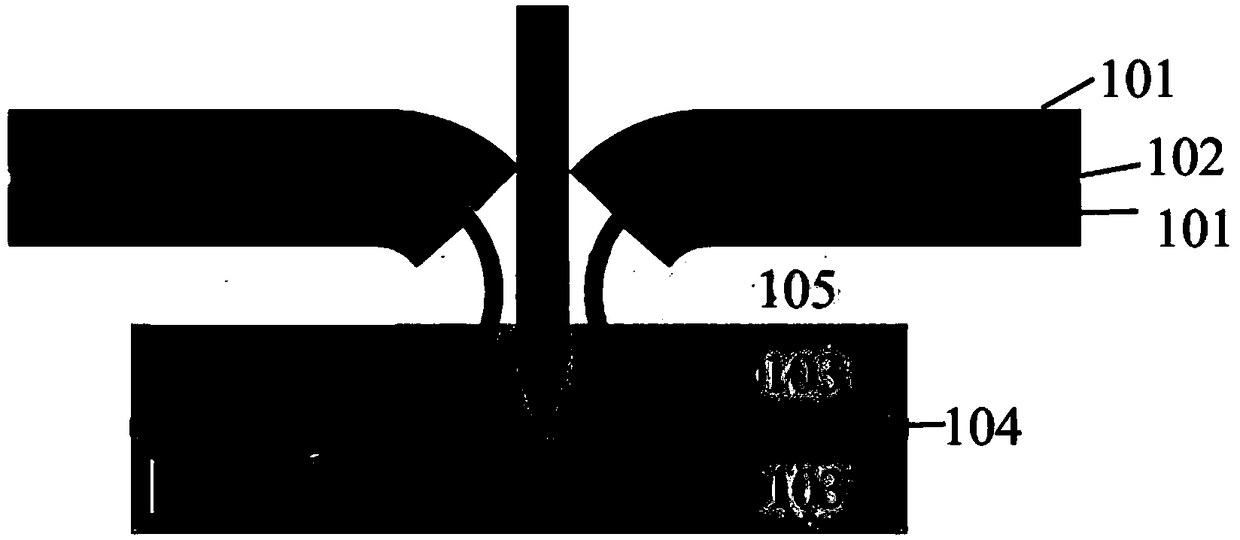

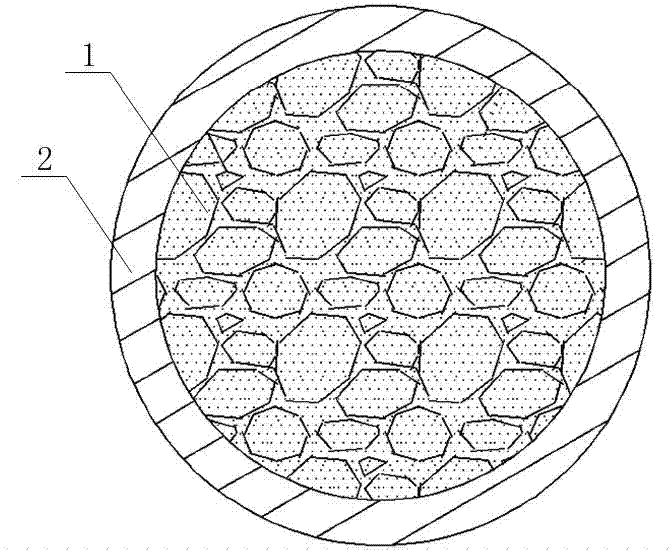

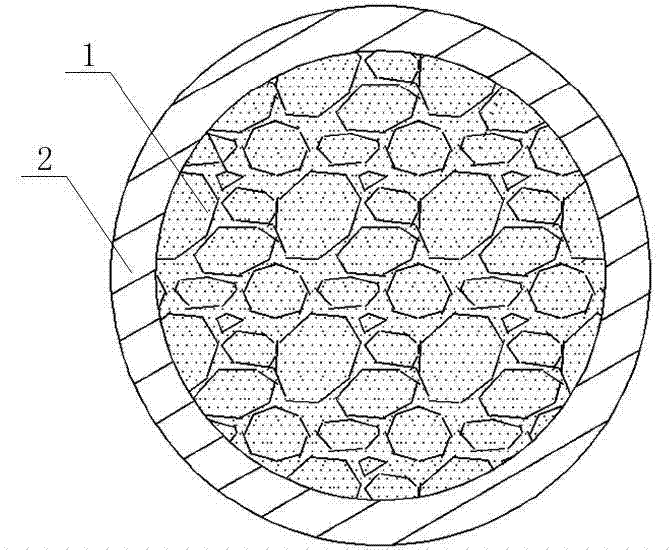

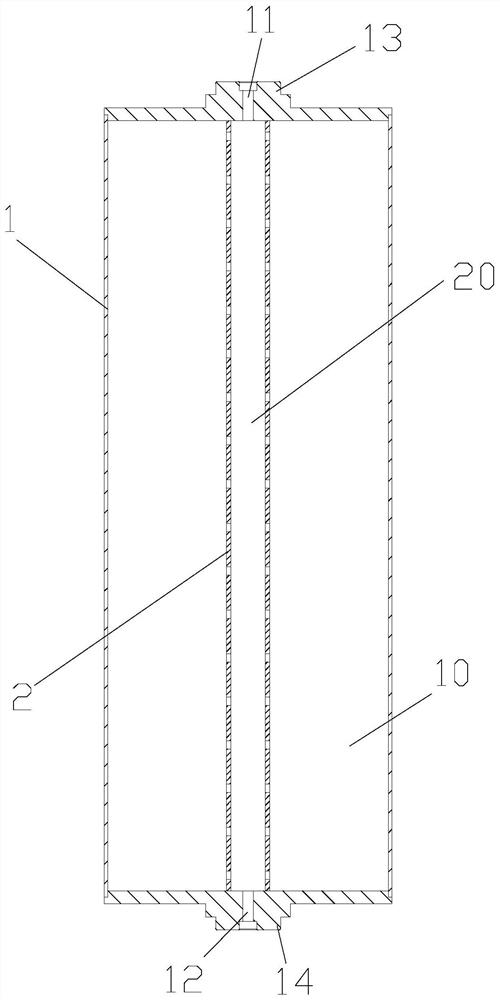

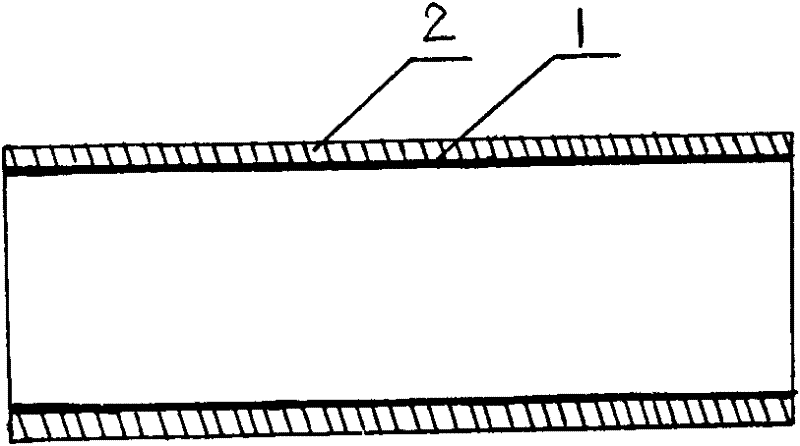

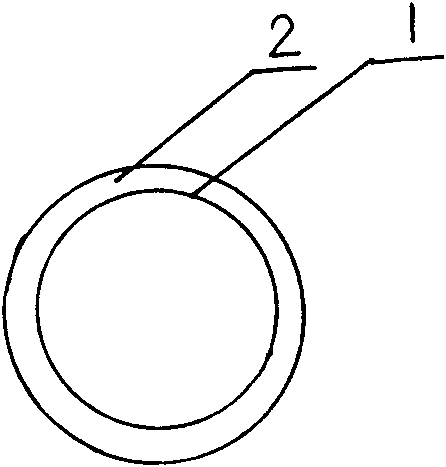

InactiveCN102513728ALow priceThe formula is scientific and reasonableWelding/cutting media/materialsSoldering mediaWear resistantCarbide

The invention discloses a high-hardness high-wear-resistant surfacing electrode for multilayer surfacing, which comprises a welding covering (1) and a flux core (2), wherein the welding covering (1) is a thin-walled tube, the flux core (2) is filled inside the welding covering (1), and two ends of the welding covering (1) are sealed. The flux core (2) comprises the following components in weight percent: 18-26% of metalized diamond, 22-35% of hard alloy and 38-55% of pre-alloyed powder. The high-hardness high-wear-resistant surfacing electrode has the advantages that the electrode is reasonable in structure, scientific in formula and low in cost, the surfacing hardness of a multilayer surfacing layer using the electrode can reach HRC (Rockwell hardness) 62-66, the wear resistance of the electrode is 3-5 times as high as that of a chromium-iron complex carbide surfacing electrode, the electrode is not easy to strip so that the service life of a workpiece is greatly prolonged, and the two ends of the welding covering are sealed so that the flux core is well sealed and is free of powder leakage and moisture absorption.

Owner:SOUTHWEST PETROLEUM UNIV

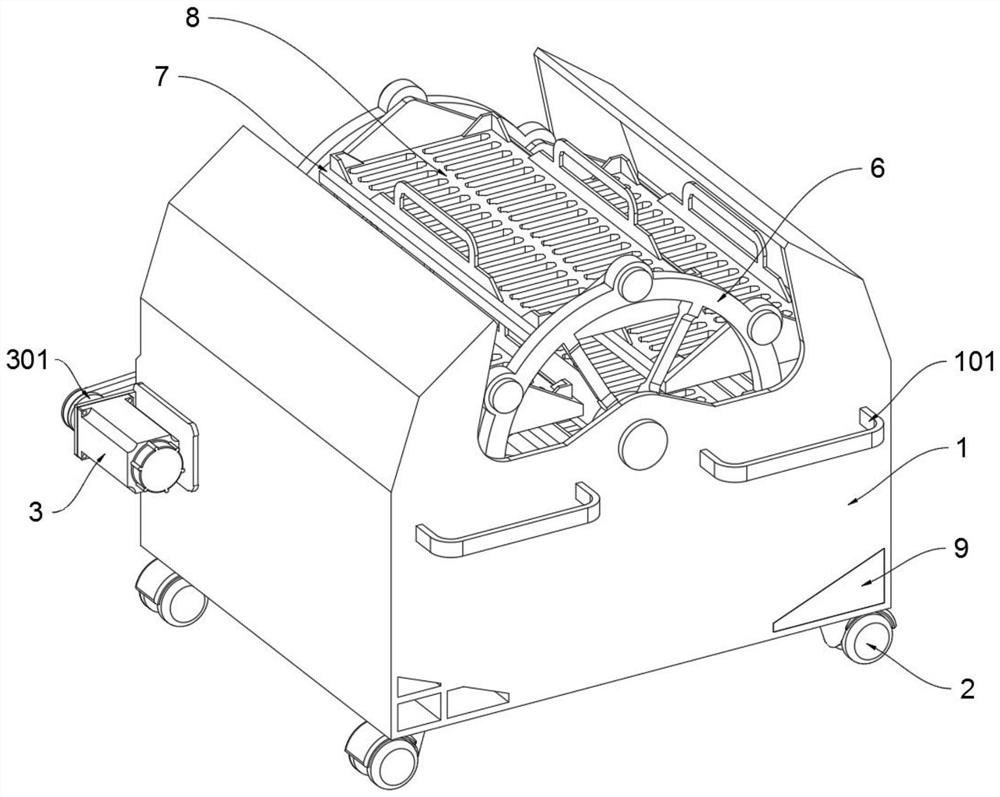

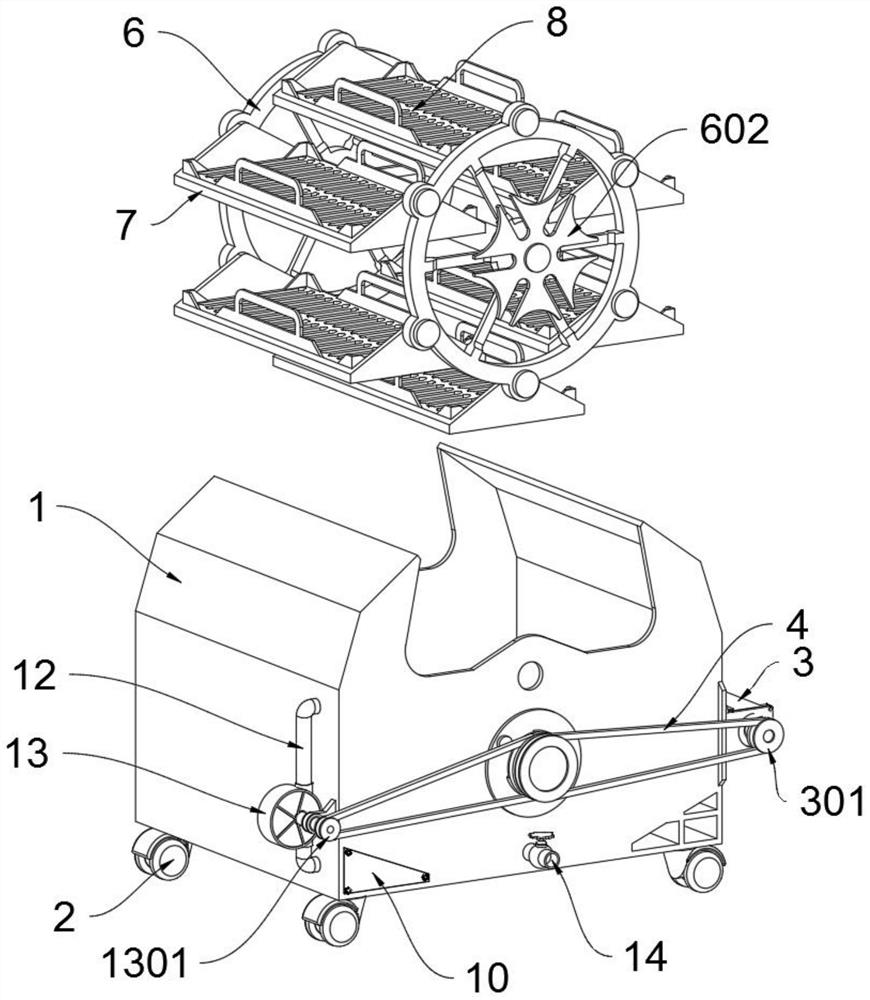

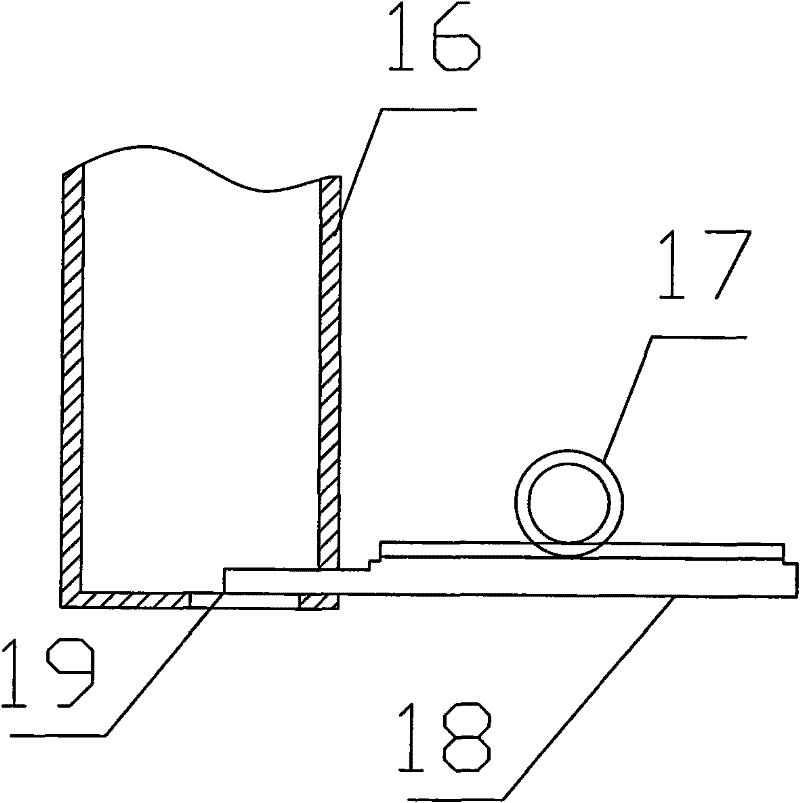

Surface wetting device capable of preventing sewage outflow for ceramic ground laying

InactiveCN111997326AEasy access for replacementGuaranteed wetting effectBuilding constructionsStationary filtering element filtersWater storage tankElectric machinery

The invention provides a surface wetting device capable of preventing sewage outflow for ceramic ground laying, and relates to the technical field of ceramic ground laying. The device solves the problems that before traditional ceramic tile laying, ceramic tiles always need to be manually and slowly placed in a large-capacity water bucket, the labor intensity for wetting the ceramic tiles is large, and the laying efficiency is low especially during one-person laying. The device comprises an adjusting support frame; the interior of a water storage tank is of a hollow structure, two push handlesare symmetrically arranged on the left side of the water storage tank, and a mounting cavity is formed in the front end of the bottom of the water storage tank; and the four corners of the bottom ofthe water storage tank are each fixedly provided with a universal wheel, and a driving motor is fixedly mounted on the rear end face of the water storage tank through bolts. According to the device, when the ceramic tiles are placed on a supporting plate on the top of a horizontal bearing frame, the adjusting support frame drives the horizontal bearing frame to rotate to the bottom, so that the ceramic tiles on the top of the supporting plate are immersed below the water surface, the ceramic tiles are soaked, and the ceramic tile surface wetting effect is guaranteed.

Owner:李媛菲

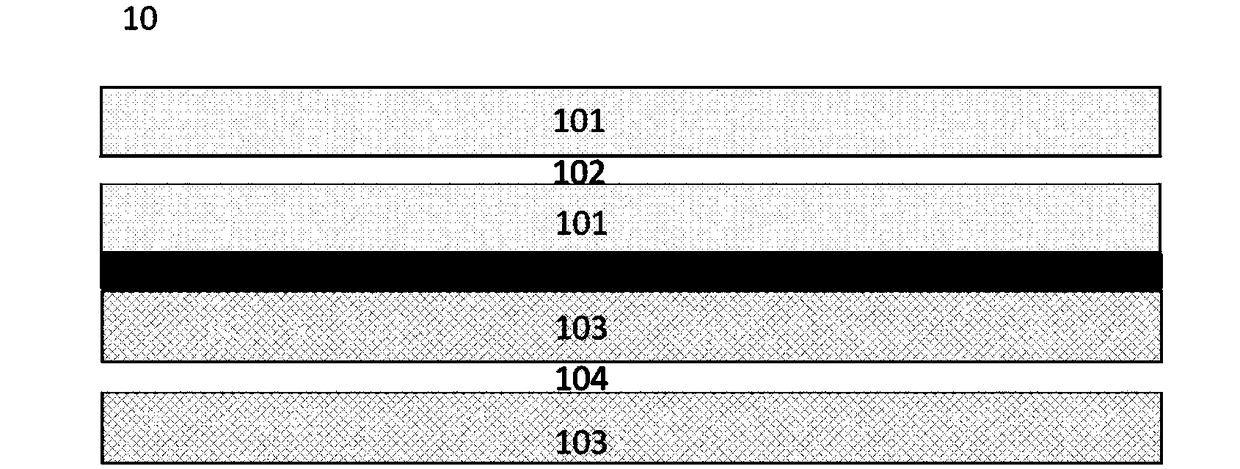

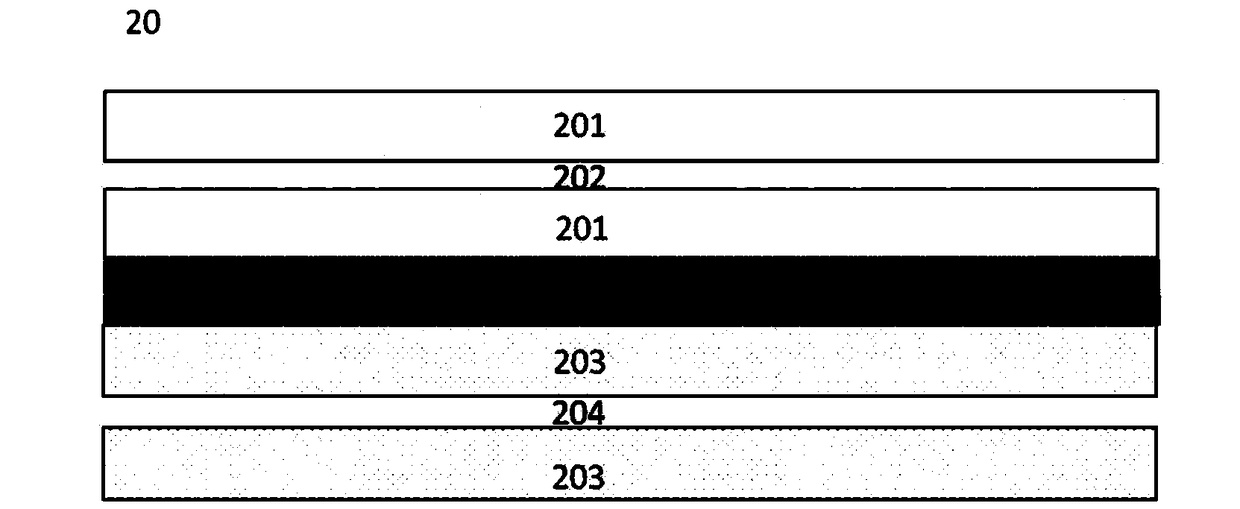

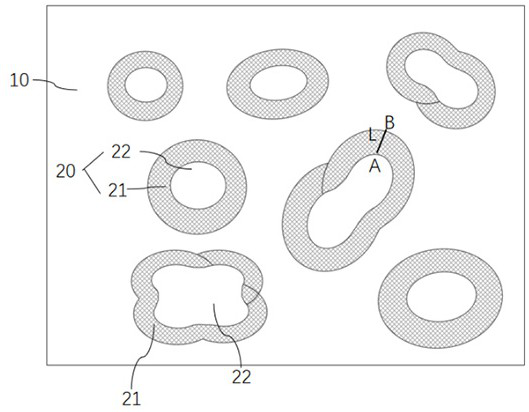

Diaphragm with excellent cohesiveness and air permeability and preparation method thereof

ActiveCN114094283AGuaranteed bonding effectGuaranteed breathabilityCell seperators/membranes/diaphragms/spacersSecondary cellsChemistryBonding strength

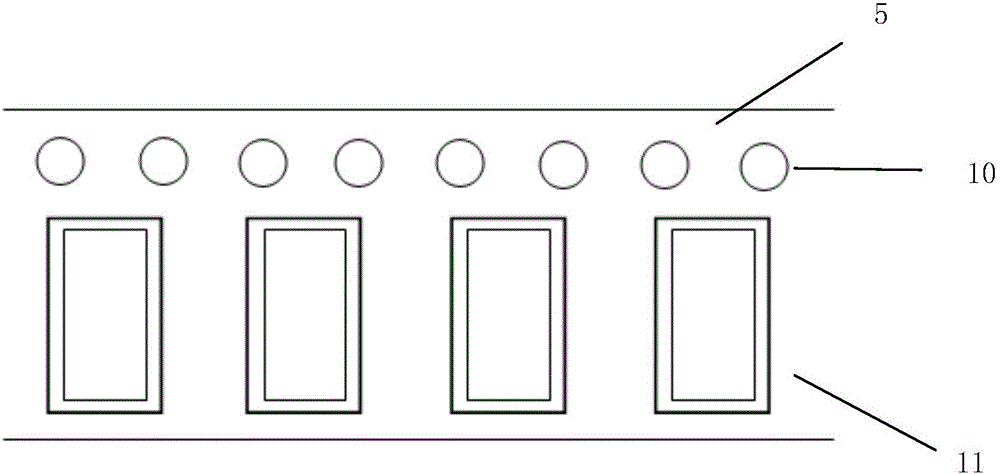

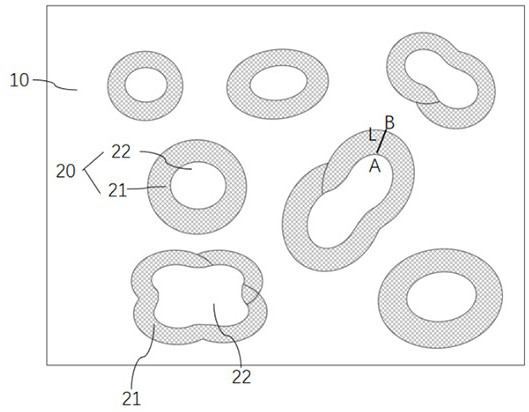

The invention relates to the technical field of lithium batteries, in particular to a diaphragm with excellent cohesiveness and air permeability and a preparation method thereof. The diaphragm comprises a base film and a bonding layer, the bonding layer is arranged on at least one surface of the base film and comprises a plurality of hollowed-out structures, each hollowed-out structure is fixed to the surface of the base film, the hollowed-out structures are defined by protruding parts, and the inner parts enclosed by the protruding parts are hollowed-out parts. According to the diaphragm with excellent cohesiveness and air permeability and the preparation method of the diaphragm, the thermal shrinkage performance of a ceramic coated diaphragm is maintained, the bonding strength between the diaphragm and a pole piece is met through relatively low glue content, the good air permeability of the diaphragm is also maintained, and the comprehensive performance of a battery is improved.

Owner:JIANGSU ADVANCED MATERIAL TECH CO LTD +2

Molten aluminum deslagging agent

The invention discloses a molten aluminum deslagging agent which comprises NaCl, KCl, Na2SiF6 and CaF2, wherein the weight ratio of the NaCl, the KCl, the Na2SiF6 and the CaF2 is 8:6:5:1. A preparation method for the molten aluminum deslagging agent comprises the following steps of adding the NaCl, the KCl, the Na2SiF6 and the CaF2 into a smelting furnace according to the ratio, melting and stirring the mixture, and preparing powder after the mixture is cooled. The molten aluminum deslagging agent has the advantages of high reliability, high separation capability, convenience in preparation, simplicity in use, low cost and the like, and is widely applied to the refining of molten aluminum.

Owner:江苏宏马科技股份有限公司

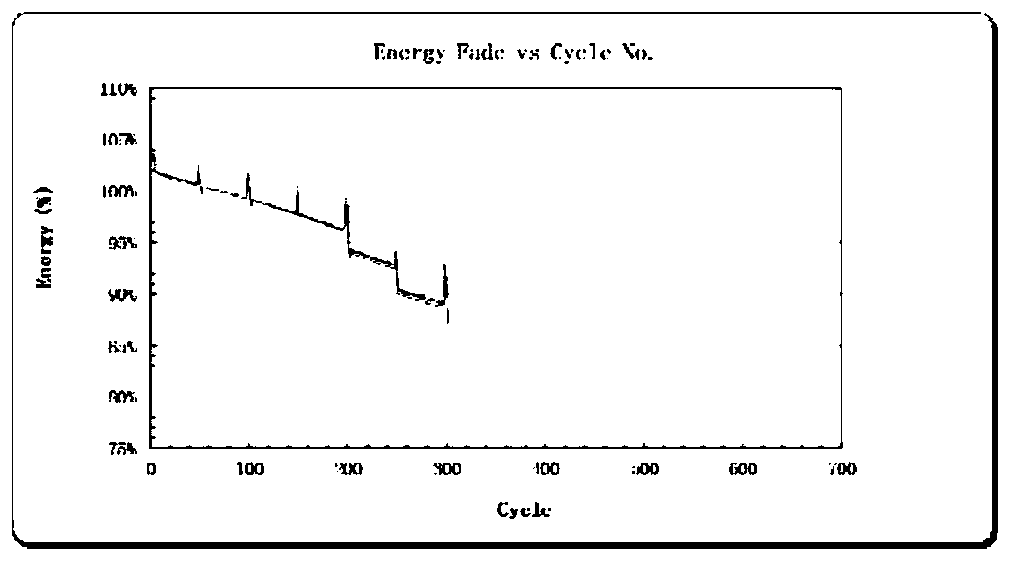

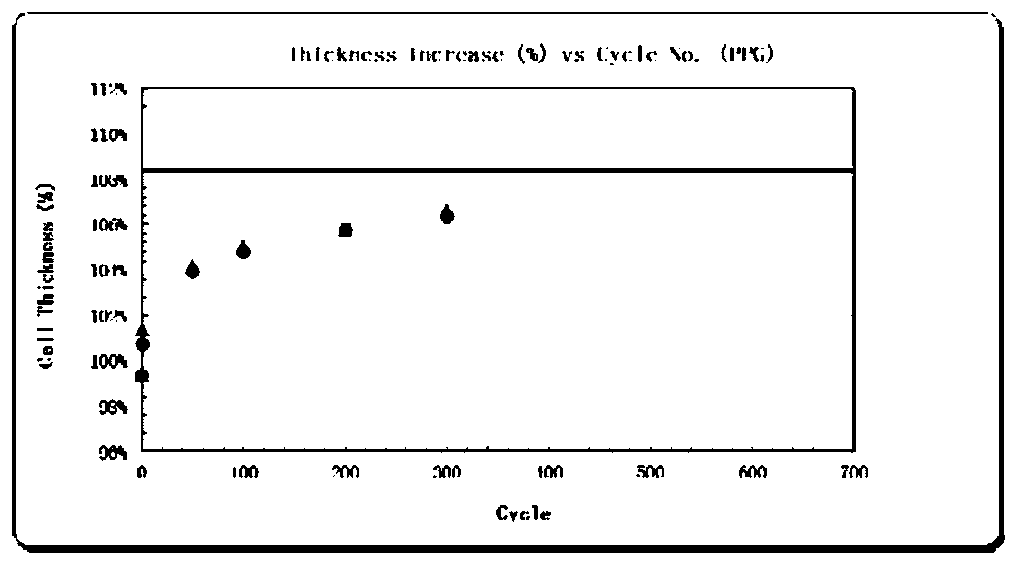

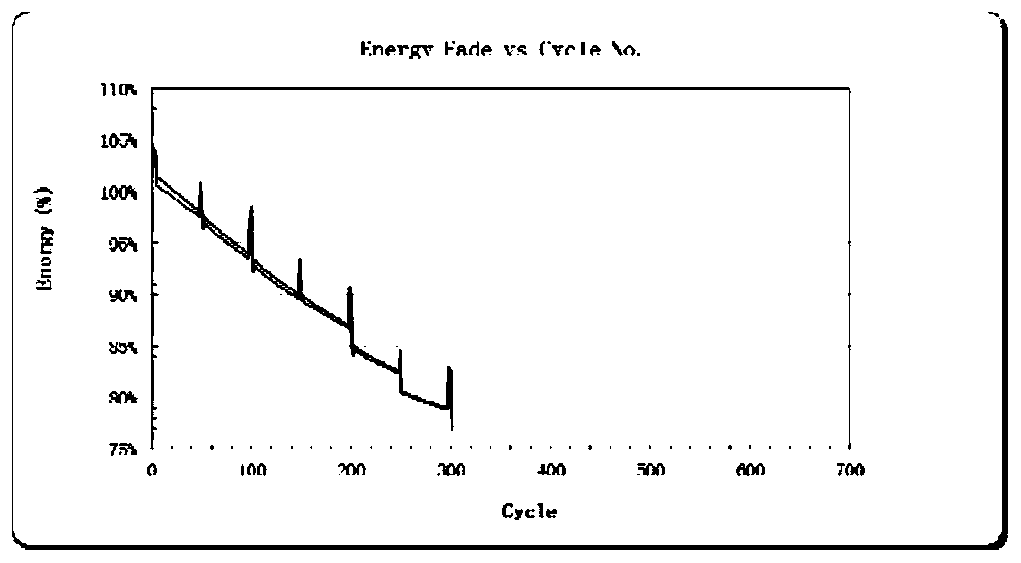

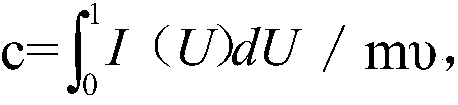

Formation process for improving cycle thickness expansion of soft package lithium-ion battery

InactiveCN111129627AAccurate monitoring of infiltration statusGuaranteed forceFinal product manufactureSecondary cells charging/dischargingEngineeringLithium-ion battery

The invention relates to the technical field of lithium-ion batteries, in particular to a formation process for improving cycle thickness expansion of a soft package lithium-ion battery. The process comprises the following steps: 1, standing battery cells after liquid injection, putting a plurality of battery cells into an Arbin test system for voltage measurement, and drawing a voltage and time curve graph; and 2, standing the battery cells, and putting the battery cells into clamp formation equipment for formation. The infiltration state of an electrolyte in the battery cell can be accurately monitored, and the infiltration effect is ensured. In the clamp formation process, all layers of interfaces in the battery cells can be in close contact by exhausting air from the battery cells, sothat the battery cells are uniformly stressed and heated.

Owner:TIANJIN LISHEN BATTERY

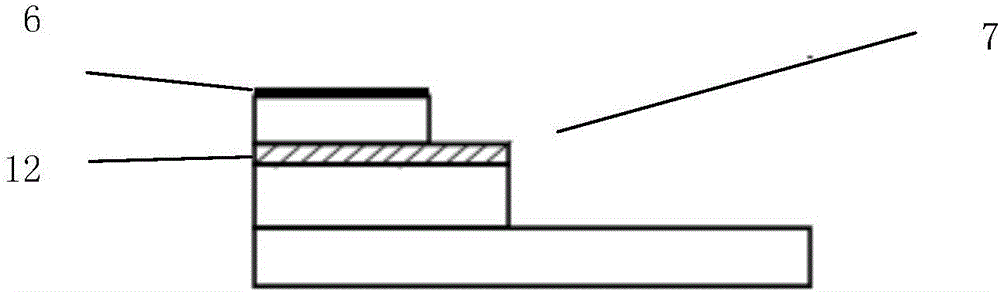

Packaging technology and packaging structure of ceramic chip

InactiveCN106653622AAir tightness effectGood adhesionSemiconductor/solid-state device detailsSolid-state devicesSealantAir tightness

The invention provides a packaging technology of a ceramic chip. The packaging technology comprises the following steps of (I) dispensing and film-forming, before chip assembly, coating the edge of one side, which needs to be packaged with a cover plate, of a ceramic carrier with a liquid-like dual-curable sealant through a glue dispenser, and curing and setting the dual-curable sealant through UV light irradiation to form a structural film on the ceramic carrier; (2) chip assembly, namely carrying out chip assembly on the ceramic carrier; and (3) cured sealing, after chip assembly is completed, bonding the cover plate matched with the ceramic carrier in size and the ceramic carrier through heating the structural film and then carrying out cured sealing. The packaging structure of the ceramic chip has the practical advantages of high bonding strength, good surface wettability, high air-tightness and the like, the roll-to-roll automatic dispensing process can be achieved and the production efficiency is obviously improved.

Owner:NANJING NUOBANG NEW MATERIAL CO LTD

Overflow brick forming quality stability control method

ActiveCN111807684AGuaranteed wetting effectStabilize the quality of lead plateGlass forming apparatusAdaptive controlProduction lineBrick

The invention discloses an overflow brick forming quality stability control method which comprises the following steps: S1, determining design parameters according to an overflow brick structure, determining a glass forming temperature T0 according to the forming viscosity of a molten glass material and a material viscosity-temperature characteristic curve, and setting a far-end wetting temperature increment delta T; S2, sequentially calculating overflow brick far-end wetting process parameters, overflow brick near-end wetting process parameters and overflow brick middle-end wetting process parameters; S3, carrying out far-end wetting according to the parameters determined in the S1 and the S2; S4, carrying out near-end wetting according to the parameters determined in the S1 and the S2; S5, carrying out middle wetting according to the parameters determined in the S1 and the S2. According to the design of a glass substrate product, the design of a forming device, the design of an overflow brick assembly and the lead-out amount required by wetting of the far end, the near end and the middle part of an overflow brick; the optimal wetting process is designed, the wetting effect of theoverflow brick is guaranteed, and therefore the phenomenon that due to the unreasonable wetting process, the forming quality of a production line fluctuates uncertainly is effectively avoided.

Owner:IRICO DISPLAY DEVICES

Thermosetting roll forming system for fuel cell hydrogen energy automobile and forming method thereof

PendingCN112606437AImprove cleanlinessNo pollution in the processDomestic articlesFuel cellsRoll forming

The invention discloses a thermosetting roll forming system for a fuel cell hydrogen energy automobile. The system comprises a first feeding roller, a rolling system and a conveying crawler belt, and a second feeding roller and a third feeding roller are sequentially arranged on the right side of the first feeding roller. And a first layered steering rolling shaft and a second layered steering rolling shaft are sequentially arranged on the right side of the third feeding roller, and a first layered extrusion rolling shaft, a first resin groove, a first tensioning roller and a first resin filter screen are sequentially arranged on the right side of the second layered steering rolling shaft. The thermosetting roll forming system has the beneficial effects that the interlayer type design feeding mechanism is available through the first feeding roller, the second feeding roller, the third feeding roller, a fourth feeding roller, a fifth feeding roller and a sixth feeding roller, and the requirements of various laying schemes can be met; and by means of the layered forced infiltration method of the first layered extrusion rolling shaft and the second layered extrusion rolling shaft, and meanwhile multiple layers of materials can be infiltrated at the same time, and the infiltration effect of each layer is guaranteed.

Owner:黄冈格罗夫氢能汽车有限公司

Molten aluminum slag remover and preparation method and application thereof

The invention discloses a molten aluminum slag remover and a preparation method and application thereof, and belongs to the technical field of molten aluminum refining. The slag remover comprises the following raw materials in parts by weight: 30-50 parts of sodium chloride, 20-40 parts of potassium chloride, 10-20 parts of sodium fluosilicate and 4-8 parts of fluorite. The preparation method comprises the following steps of: preparing 35 parts of sodium chloride, 25 parts of potassium chloride, 12 parts of sodium fluosilicate and 7 parts of fluorite into the slag remover; mixing the slag remover and inputting into molten aluminum in a furnace for stirring; inputting gas D into the molten aluminum while stirring; and finally, filtering out dross to complete refined aluminum purification. The infiltration effect of the molten aluminum is guaranteed by using sodium chloride and potassium chloride, and separation of hydrogen in the molten aluminum is guaranteed by using potassium chloride; and as the partial pressures of the gas D and hydrogen in the molten aluminum are different, hydrogen generated in the molten aluminum enters bubbles and then escapes from the liquid surface, so that hydrogen generated in the molten aluminum can be removed, generation of pores is avoided, and the separation effect is strong.

Owner:GUANGDONG HONGBANG ALUMINUM METAL IND CO LTD

Molten aluminum alloy refining slag removal agent

A molten aluminum alloy refining slag removal agent is characterized by being composed of, by weight, 25%-30% of silicon dioxide, 10%-15% of sodium chloride, 10%-15% of potassium oxide, 5%-10% of sodium oxide, 5%-10% of sodium sulfate, 1%-5% of sodium fluoroaluminate, 5%-10% of sodium fluorosilicate, 1%-5% of titanium dioxide, 5%-10% of calcium fluoride, 2%-4% of potassium fluoride, 2%-4% of hydrogen fluoride and 2%-4% of silicic acid. The molten aluminum alloy refining slag removal agent has the advantages that by the adoption of the sodium chloride and the potassium fluoride, the infiltration effect of molten aluminum is guaranteed, separation of hydrogen in the molten aluminum is guaranteed by the adoption of the potassium fluoride, the molten aluminum alloy refining slag removal agentis high in reliability, high in separation capacity, convenient to prepare, easy to use, low in cost and the like, and meanwhile the molten aluminum alloy refining slag removal agent can be widely applied to the molten aluminum refining aspect.

Owner:徐州思源铝业有限公司

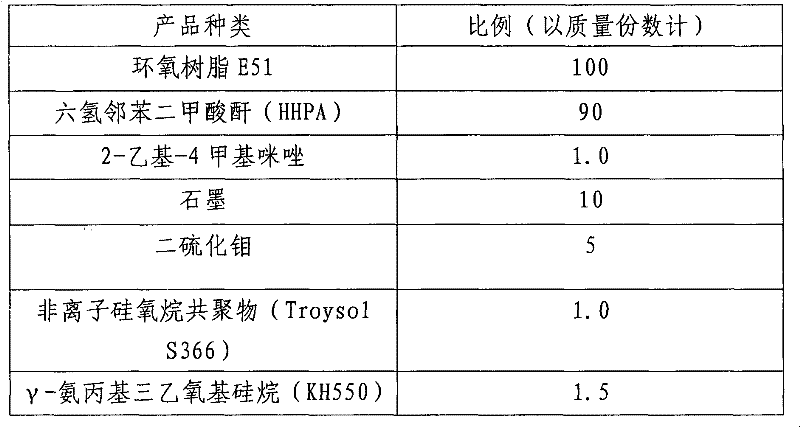

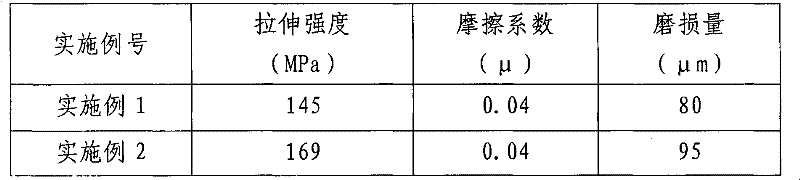

Fiber reinforced resin matrix self-lubricating compound sliding bearing and manufacturing method thereof

ActiveCN101936340BGood self-lubricating performanceAnti-foreign body damageBearing componentsCorrosionPolytetrafluoroethylene

The invention discloses a fiber reinforced resin matrix self-lubricating compound sliding bearing and a manufacturing method thereof. The fiber reinforced resin matrix self-lubricating compound sliding bearing comprises an inner layer and a back lining, wherein the inner layer is a self-lubricating polytetrafluoroethylene (PTFE) soft band form by mixing self-lubricating polytetrafluoroethylene (PTFE) resin powder with at least one of graphite, molybdenum disulfide, tin bronze powder, glass fiber and carbon fiber; the back lining is formed by dipping and winding alkali-free long glass fiber and epoxy resin glue solution; and the epoxy resin glue solution is prepared by evenly mixing epoxy resin, curing agent, curing accelerator, filler and organic accessory ingredient. The sliding bearing prepared by the method of the invention has the advantages of good self-lubricating property, corrosion resistance, shock absorption, noise reduction, xenembole damage resistance, low cost and the like and is suitable to use at normal temperature.

Owner:COB PRECISION PARTS

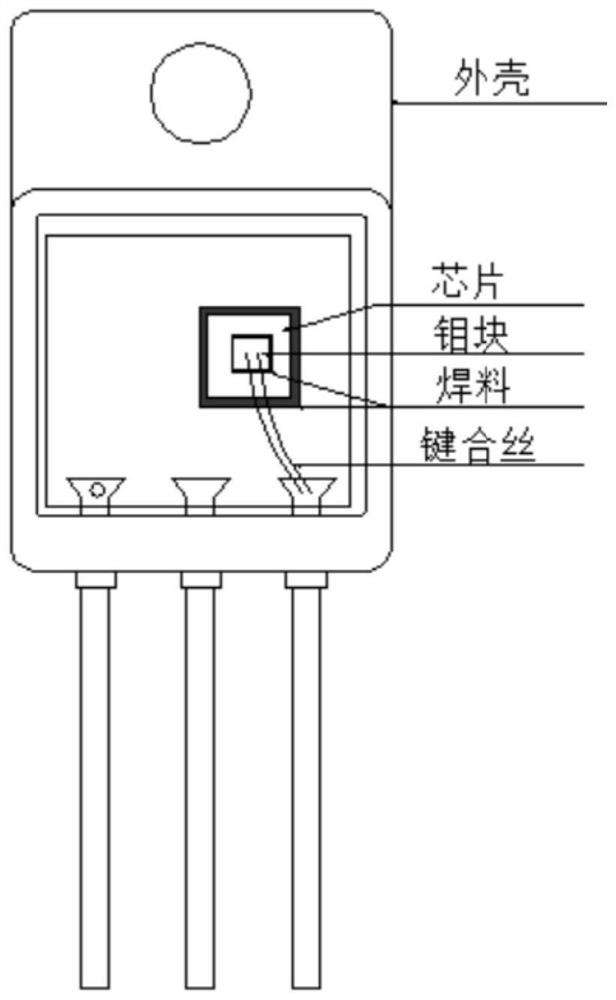

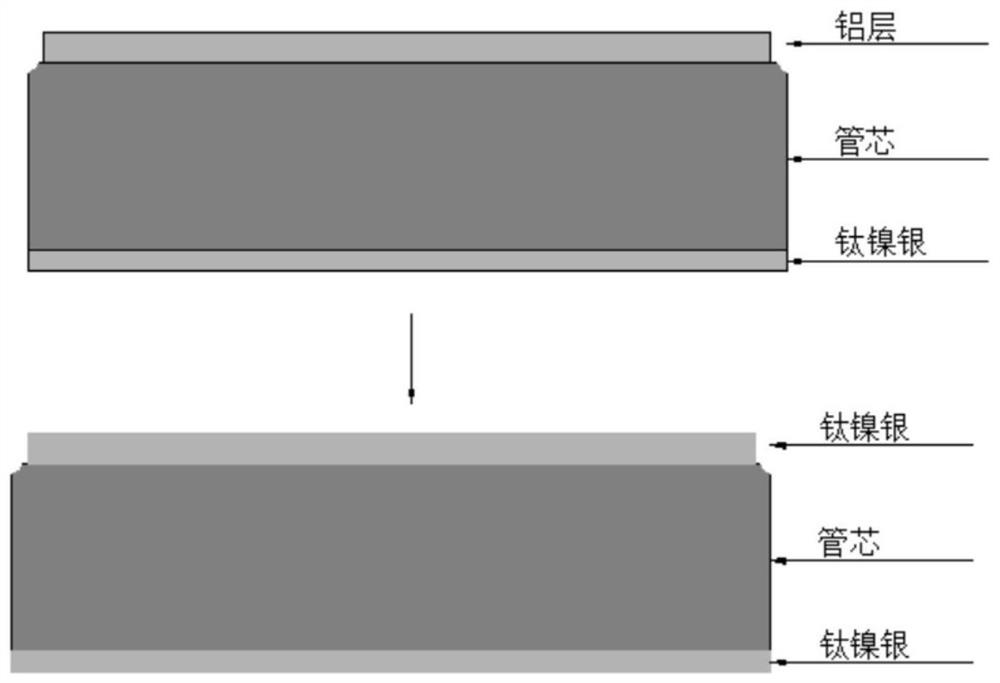

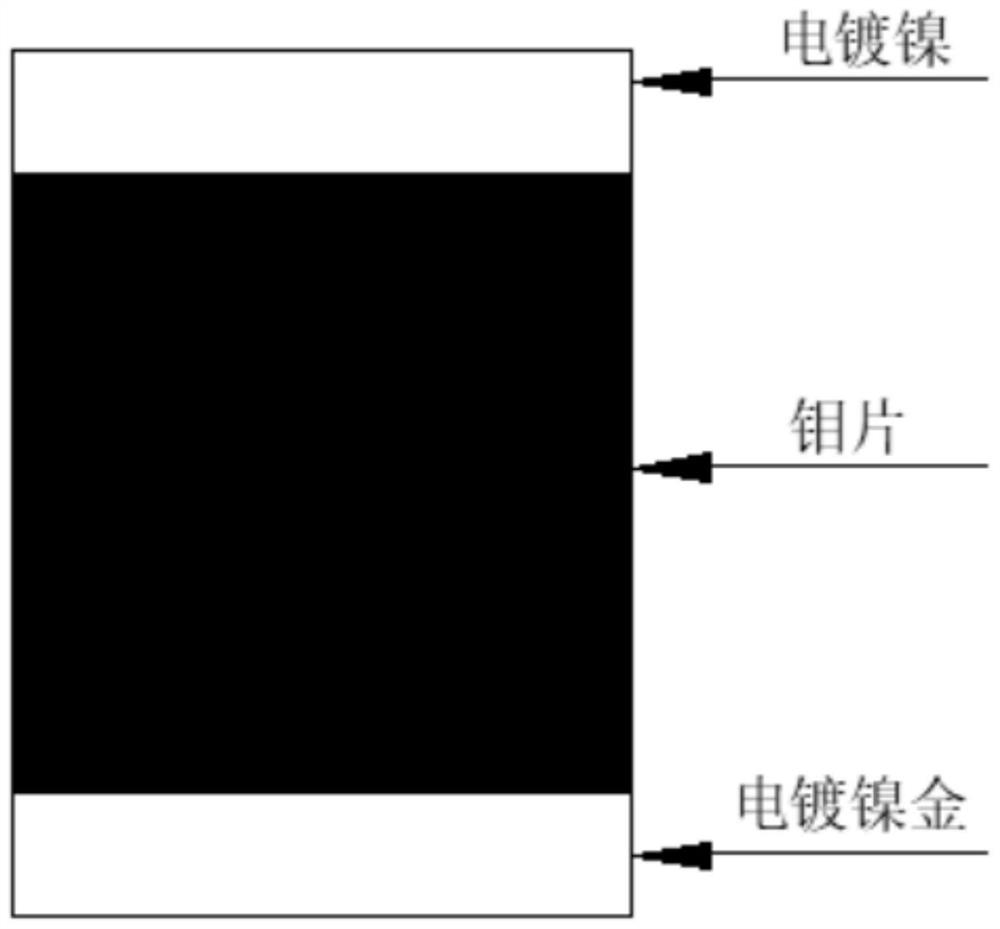

Bonding packaging structure of diode and process thereof

PendingCN114496967AAdvanced technologyAvoid welding processSemiconductor/solid-state device detailsSolid-state devicesDie bondingElectroplated nickel

The invention discloses a bonding packaging structure of a diode and a process thereof. The bonding packaging structure comprises a chip, a molybdenum sheet and a bonding wire, titanium-nickel-silver metallization is carried out on the chip, nickel-gold is electroplated on one side of the molybdenum sheet, nickel is electroplated on the other side of the molybdenum sheet, the nickel-gold electroplated side of the molybdenum sheet is welded on the chip, and the nickel-plated side of the molybdenum sheet is ultrasonically bonded with the bonding wire. A metal layer on the surface of the chip is changed, and a molybdenum sheet is added as a transition sheet, so that the problems of low chip bonding reliability, mismatched thermal expansion coefficients, non-uniform current and the like in the prior art are solved, and the long-term reliability of a product is improved.

Owner:济南市半导体元件实验所

Preparation method of perovskite solar cell

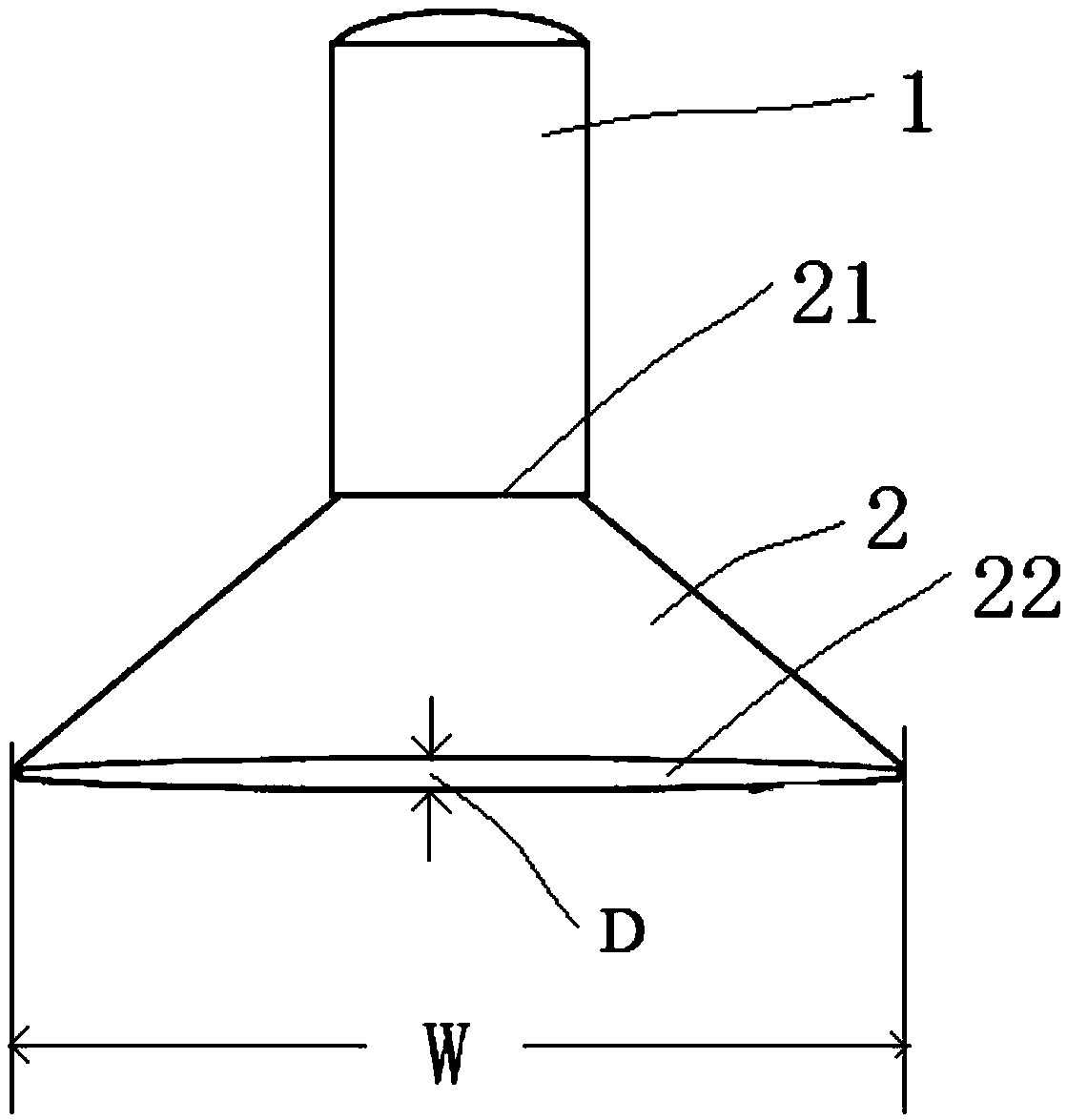

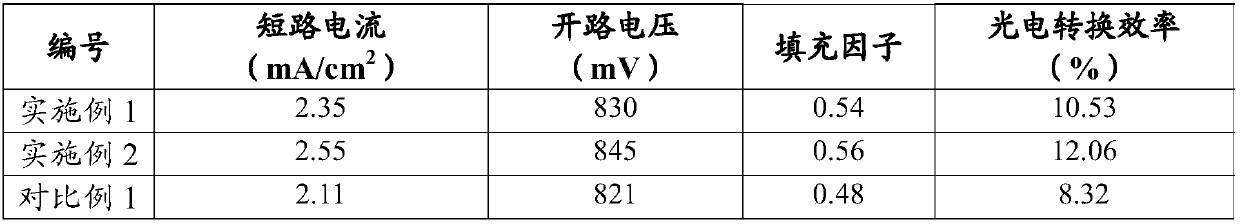

InactiveCN110620178APrevent movementImprove fill uniformitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellEngineering

The invention discloses a preparation method of a perovskite solar cell. The method comprises steps that perovskite precursor solution is coated on a substrate by adopting a flat needle head; the flatneedle head comprises an interface part and a needle head part which are communicated with each other, the interface part is used for being connected with a storage container of the perovskite precursor solution, and the needle head part is used for coating the perovskite precursor solution; the needle head part comprises an opening end and a connecting end, and the connecting end is connected with the interface part; the opening end is of a flat structure, the width of the opening end is 5-20000 times of the maximum thickness of the connecting end, and the width of the opening end is 2-100 times of the width of the connecting end. The method is advantaged in that coating efficiency can be improved, and photoelectric conversion efficiency of the solar cell is improved.

Owner:HUBEI WONDER SOLAR LLC

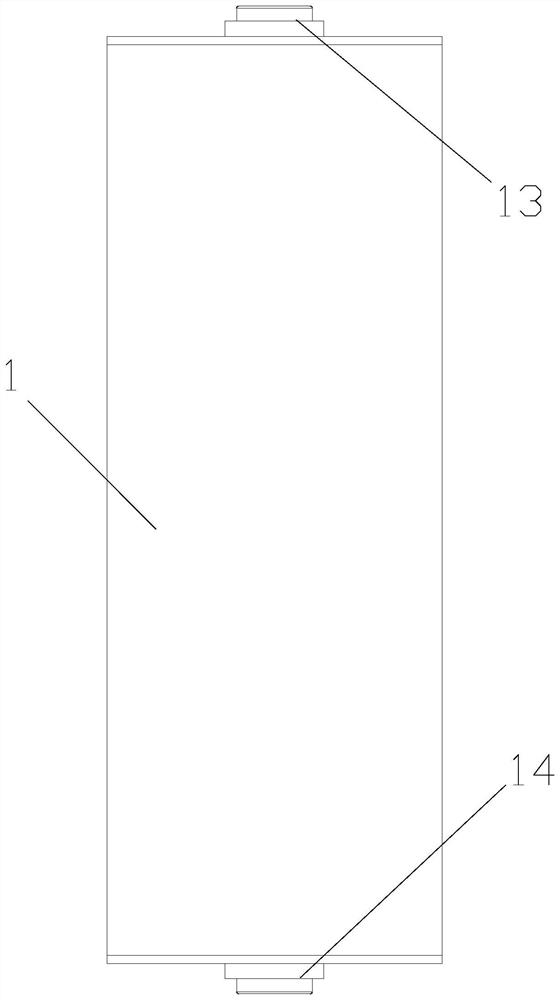

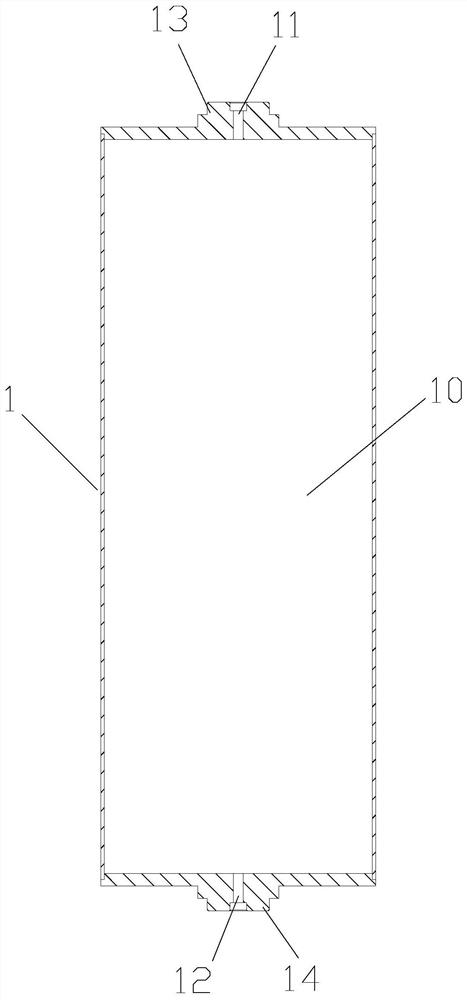

Battery and battery manufacturing method

PendingCN112510293AImprove performanceFully pouredPrimary cell manufactureAssembling battery machinesElectrical batteryCell fabrication

The invention provides a battery and a battery manufacturing method, the battery comprises: a shell, wherein the shell is internally provided with an accommodating cavity, the accommodating cavity isfilled with an electrode slice, a diaphragm and an electrolyte, the shell is provided with a first end and a second end which are oppositely arranged, the first end of the shell is provided with a first open hole, the second end of the shell is provided with a second open hole, and the first open hole and the second open hole communicate the containing cavity with the outer space of the shell; andtwo plugging pieces which are arranged at the first end of the shell and the second end of the shell in a one-to-one correspondence mode so as to plug the first open hole and the second open hole through the two plugging pieces. The battery provided by the invention solves the problem of poor battery performance caused by insufficient electrolyte filling in the prior art.

Owner:成都格力钛新能源有限公司 +1

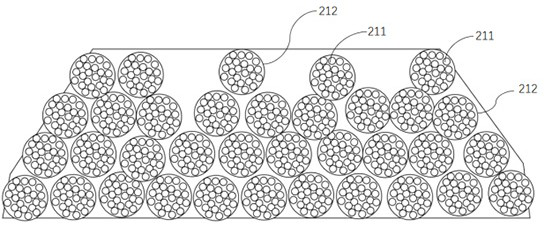

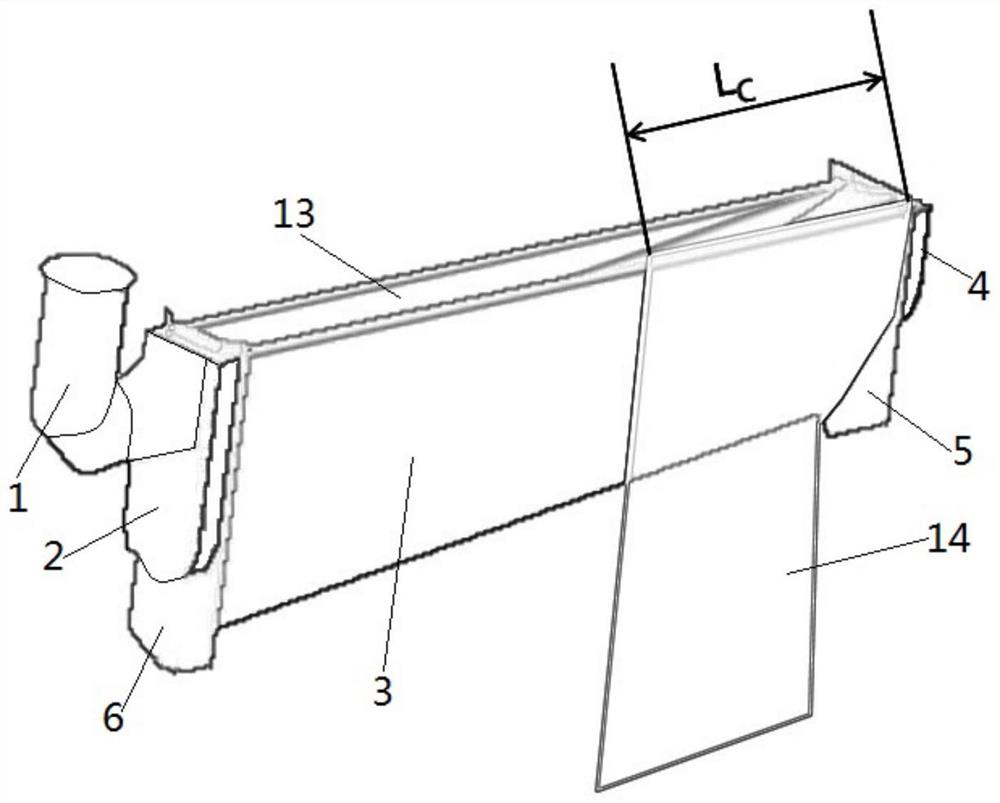

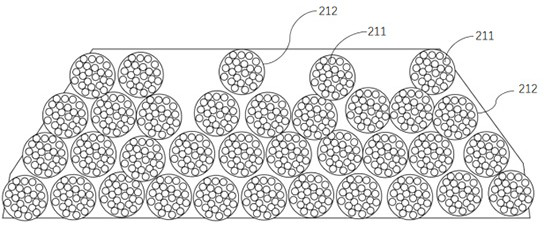

Fiber wound reinforced self-lubricating composite bearing and manufacturing method thereof

ActiveCN101929506BGuaranteed wetting effectGuaranteed smoothnessCarbon fibresBearing componentsPolyesterGlass fiber

The invention discloses a fiber wound reinforced self-lubricating composite bearing and a manufacturing method thereof. The bearing comprises an inner winding layer and an outer winding layer, the inner winding layer is formed by the way that polytetrafluoroethylene fiber and other high wearable fiber are mixed and dipped by resin glue solution and then winding is carried out, wherein other wearable fiber is one or two of aramid fiber, polyester fiber, ultrahigh molecular weight polyethylene fiber and carbon fiber; and the outer winding layer is wound on the inner winding layer by virtue of alkali-free long glass fiber dipped in resin glue solution, thus being as the backing of the bearing. The fiber wound reinforced self-lubricating composite bearing of the invention has the characteristics of high bearing capacity, good wear resistance and low cost, can be used for preparing self-lubricating radial sliding bearing and is widely applied to lubrication free work places in rotating, swinging, reciprocating and sliding motion modes.

Owner:COB PRECISION PARTS

Separator with excellent adhesion and air permeability and preparation method thereof

ActiveCN114094283BReduce thicknessGuaranteed wetting effectCell seperators/membranes/diaphragms/spacersSecondary cellsElectrical batteryPhysical chemistry

Owner:JIANGSU ADVANCED MATERIAL TECH CO LTD +2

Device for controlling gel content of in-situ solidifying fiber placement machine

Owner:XI AN JIAOTONG UNIV

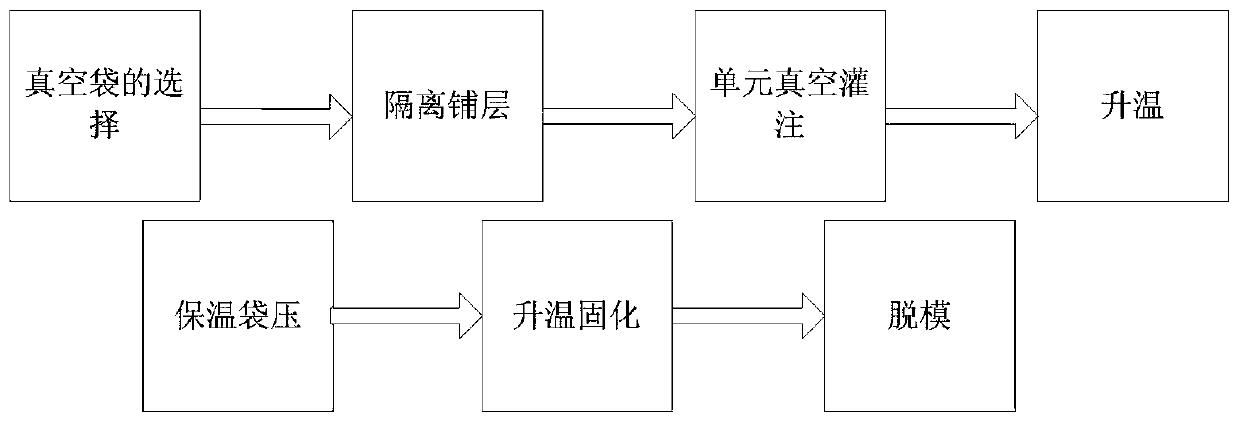

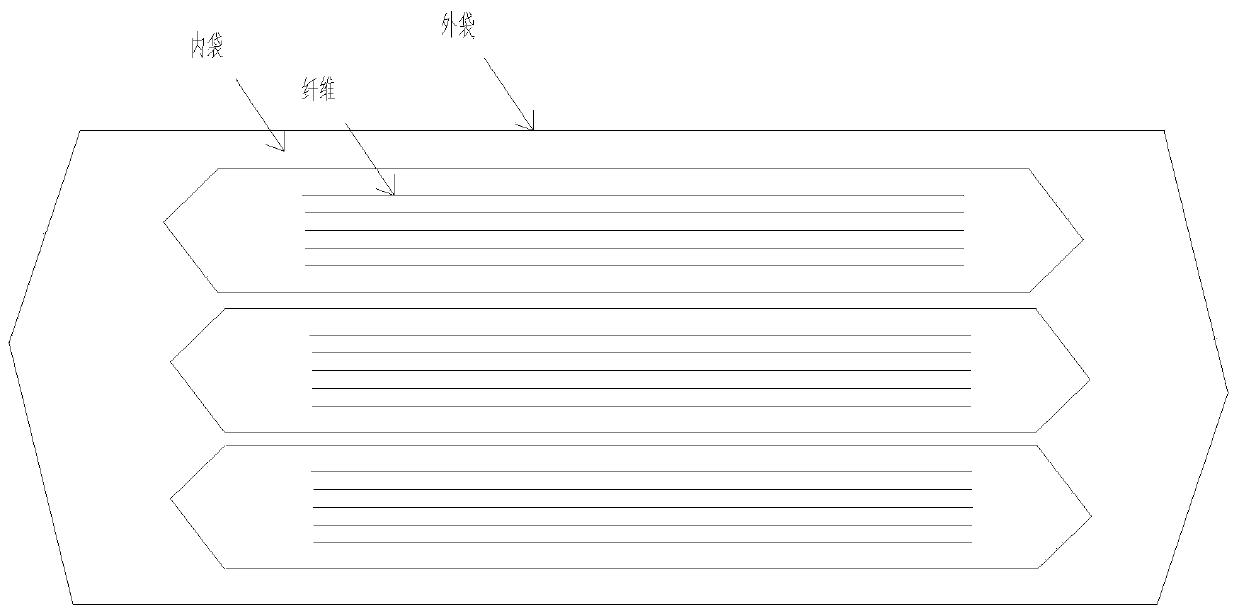

A kind of resin matrix composite material, preparation method and used vacuum bag

ActiveCN108297454BImprove interlayer tougheningImprove impact resistanceResin matrixResin-Based Composite

The invention provides a resin matrix composite material and a preparation method and a vacuum bag for the resin matrix composite material. The concept of "layered manufacturing" is proposed. A large-thickness product is divided into a plurality of micro unit layers on the thickness by low-melting-point plastic films, and heating and pressurizing are performed after vacuum infiltration, so that internal defect of the product is reduced, and the molding speed is accelerated. The low-melting-point plastic is mixed with thermosetting resin after melting to form a layered toughening layer at the micro level, so that interlayer toughness of the product is improved. The concept of "layered manufacturing" provides a new idea for the manufacture of the resin matrix composite material.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

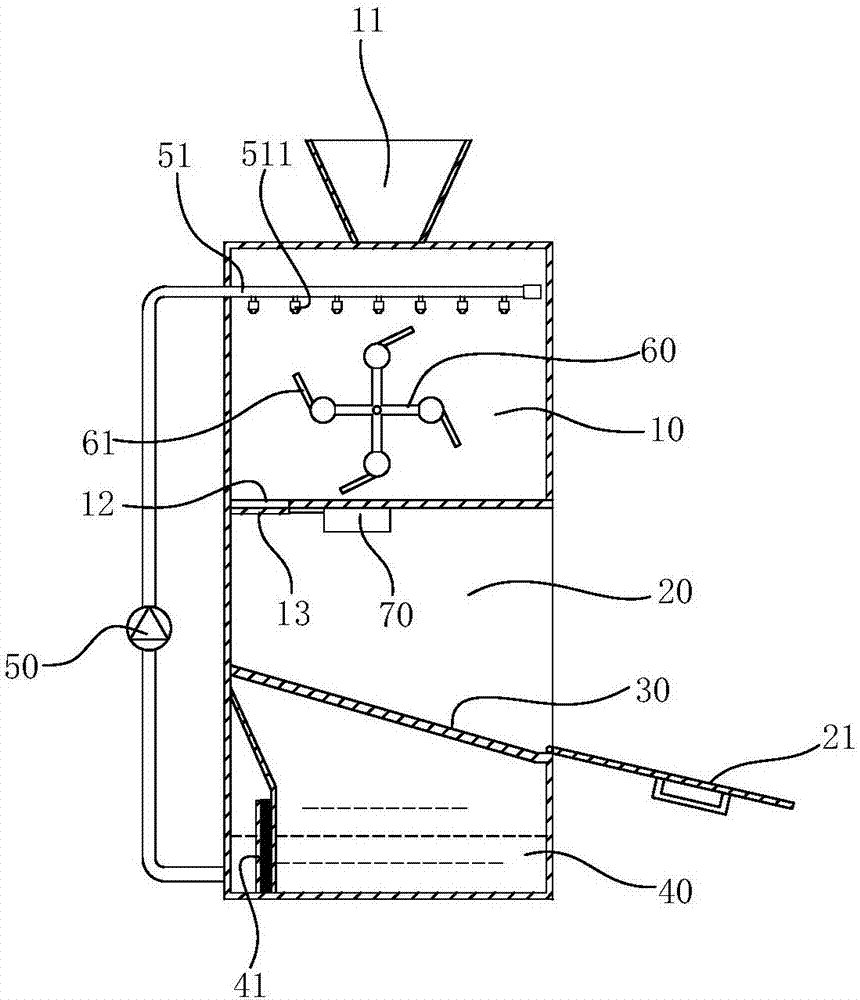

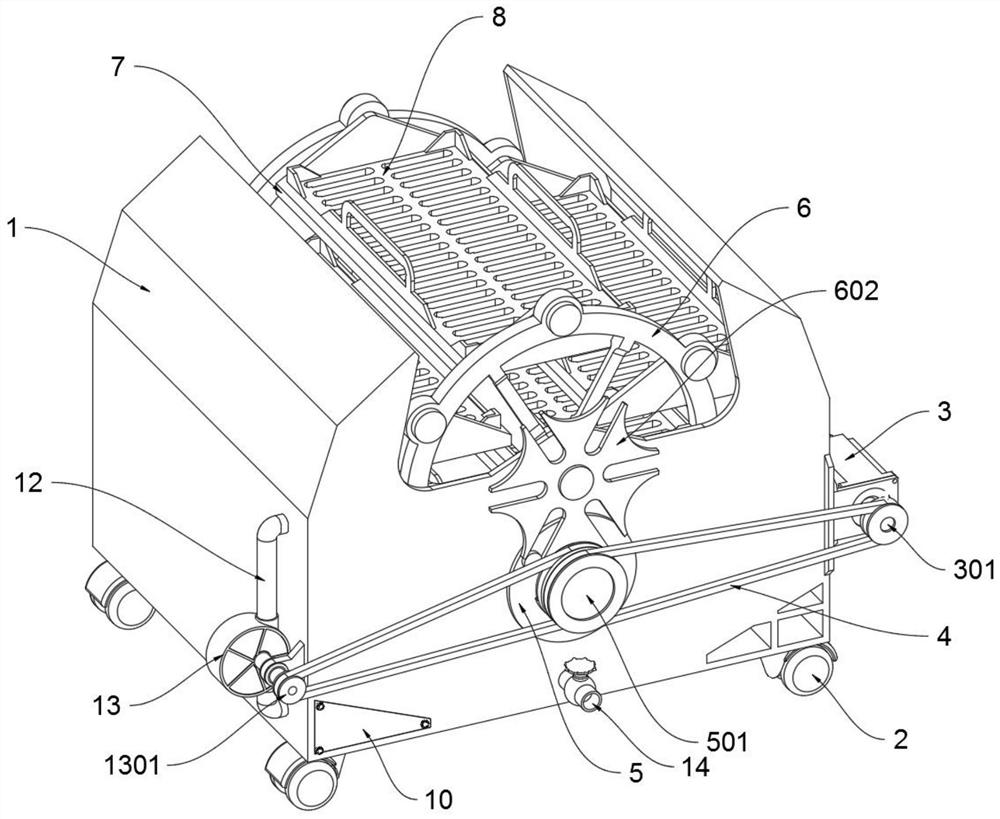

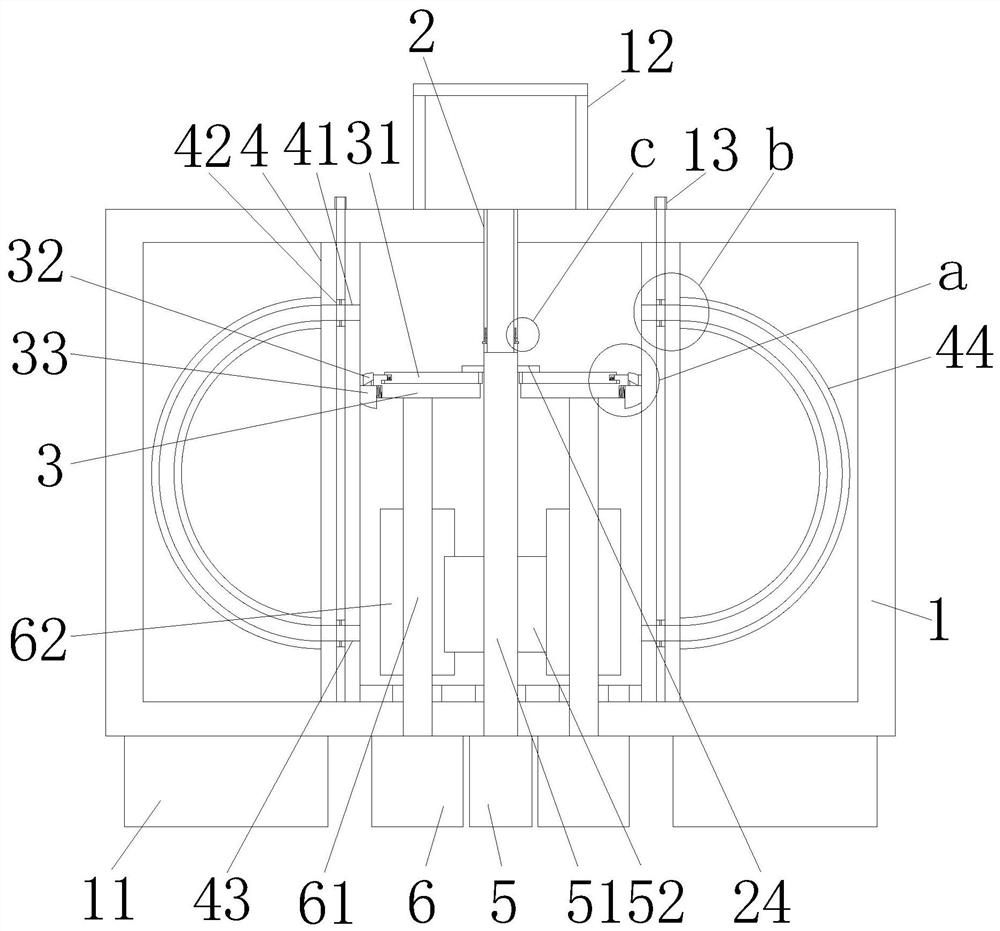

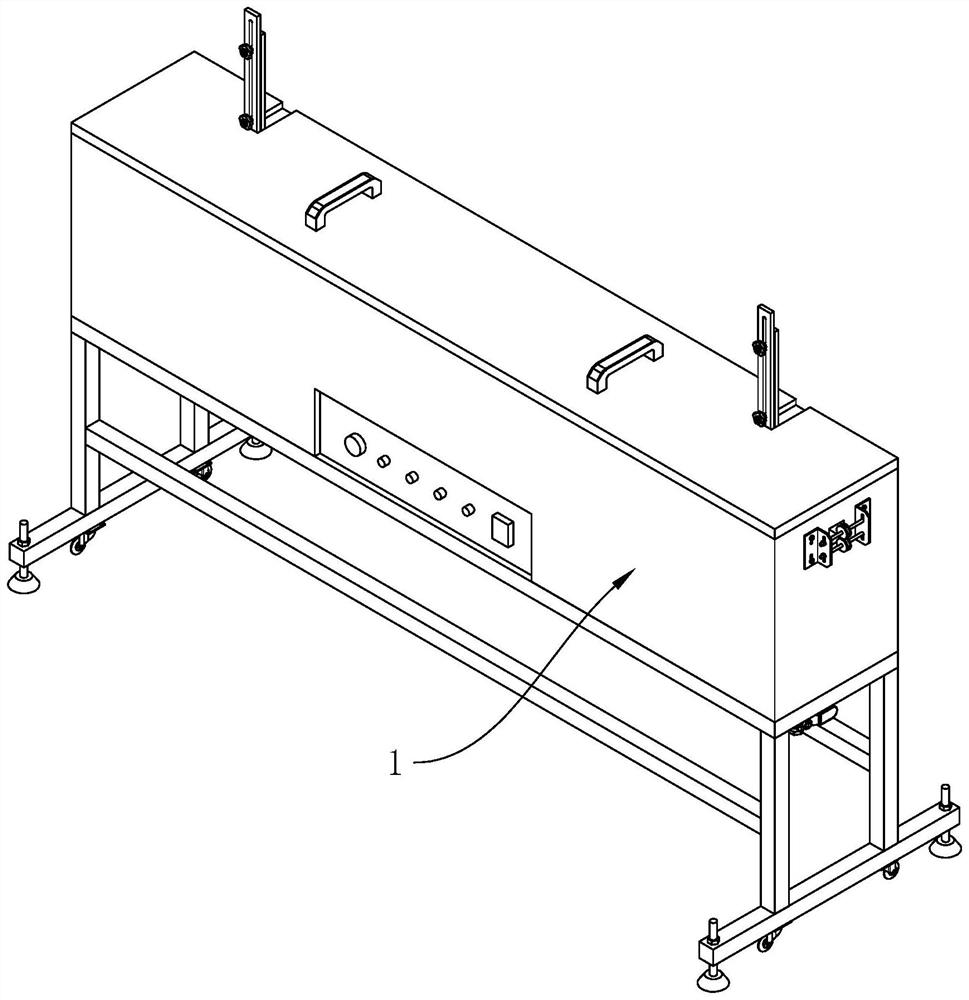

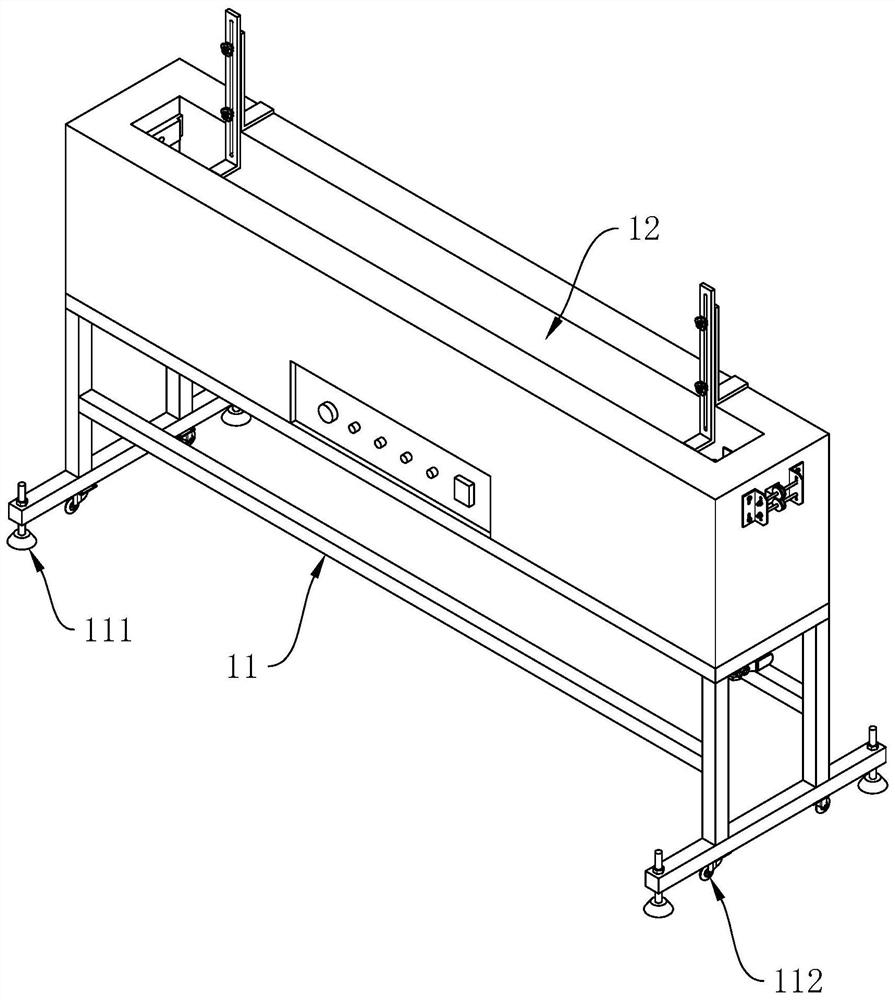

Billet wetting equipment for processing edible vegetable oil and its application method

ActiveCN111408295BSimilar degree of infiltrationGuaranteed wetting effectShaking/oscillating/vibrating mixersRotary stirring mixersVegetable oilProcess engineering

The invention relates to the technical field of edible vegetable oil processing, and discloses a billet wetting equipment for edible vegetable oil processing and its use method, which includes a processing bin and a feeding bin. There is a discharge port on the top, a movable plate is installed inside the processing chamber, a rotating rod is fixedly installed at the lower end of the discharge pipe, a vibrating plate is installed movable above the movable plate, and a feeding hole and a The discharge hole, the feed hole and the discharge hole are fixed with arc tubes, which connect the feed hole and the discharge hole. Using the effect of the movable plate reciprocating up and down, the blanks enter the feeding hole and are transported to the processing bin after soaking. At the same time, the soaked billets are stirred and mixed in the processing bin so that all the billets are in contact with each other to ensure that all The degree of blank wetting is similar to ensure the wetting effect of all blanks.

Owner:江西五百里井冈特产有限公司

Forming equipment and forming method for macrofiber-reinforced thermoplastic resin

The invention discloses forming equipment for macrofiber-reinforced thermoplastic resin, which comprises equipment for decomposing fiber rings into fiber bundles and pretreating and equipment for impregnating fibers fully and forming by melting resin, wherein fiber bundle independent channels of the equipment for decomposing the fiber ring into the fiber bundle and pretreating are connected with a fiber pre-puffing and preheating system; a fusant inlet die of the equipment for impregnating the fibers fully and forming by the melting resin is communicated with a fiber impregnating body by a fuscant flowing channel and inclines upwards to form a certain angle, and a fiber inlet die is used for connecting the fiber pre-puffing and preheating system and the fiber impregnating body, so that the fibers enter the fiber impregnating body horizontally, and the other end of the fiber impregnating body is connected with a forming die. A preparation method for the macrofiber-reinforced thermoplastic resin comprises the following steps that: (1) after passing through respective independent channels, 20 to 40 bundles of fibers enter the fiber pre-puffing and preheating system in a mode of arranging in one line, and when the fiber bundles pass through a preheating guiding roller, the fibers contact a circular arc surface of the guiding roller, so that the fiber bundles are in a cloth or ribbon shape under the stretching action of traction, wherein the fiber bundles play the pre-puffing effect; (2) after being led into the fiber inlet die and a fiber input hole of the impregnating body horizontally, the pre-puffed and preheated fiber bundles pass through a fiber tension roller in the impregnating body up and down in a staggered mode, wherein the fiber bundles are in a cloth or ribbon shape when contacting the fiber tension roller; and (3) immersed macrofibers and material flow pass through an output channel and the forming die of the impregnating body.

Owner:MIANYANG DONGFANG SPECIAL ENG PLASTIC +2

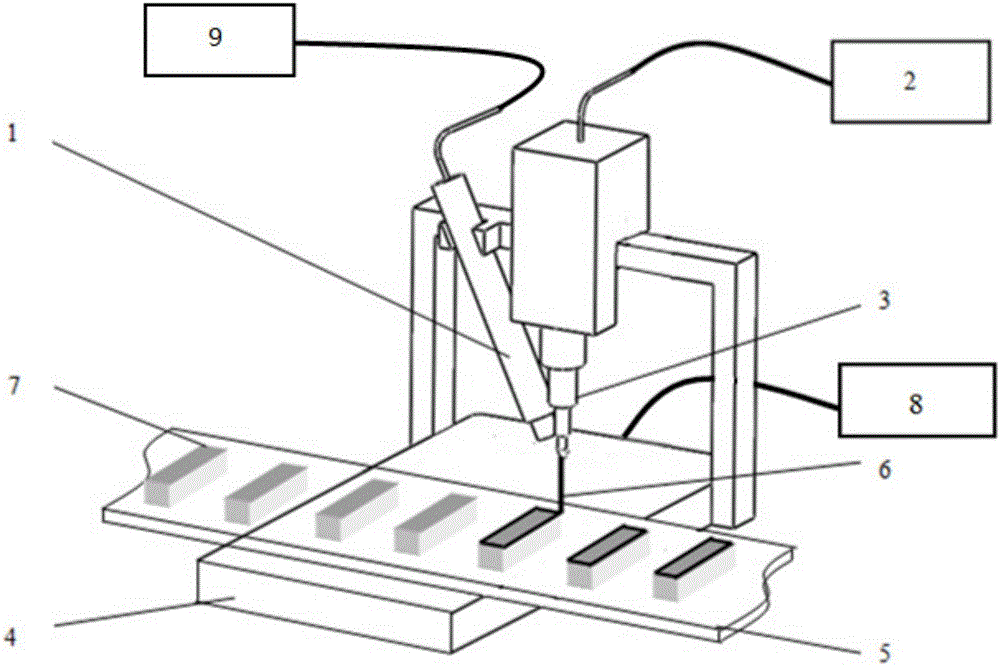

A vacuum injection device

ActiveCN105576276BImprove injection effectSimple structureFinal product manufactureSecondary cells manufactureEngineeringVacuum pump

The invention relates to a vacuum liquid injection device, which comprises a vacuum chamber, a Clifford joint, a vacuum pumping part and a syringe filled with an electrolyte. Inserted in the opening of the top cover, the vacuum pumping part includes a connecting pipe, a hose and a vacuum pump, and the two ends of the hose are respectively connected to the vacuum pump and the connecting pipe, and the open joint includes the first connecting pipe and the vacuum chamber. A claf joint and a second claf joint for connecting the syringe containing the electrolyte to the vacuum chamber. The Clifford connector of the present invention includes a shell, a sealing cover and a connecting conduit, has good airtightness, and can cooperate with a vacuum pumping component and a syringe filled with electrolyte to realize vacuum pumping and liquid injection functions. The vacuum liquid injection device of the present invention has the advantages of simple structure, small volume, good liquid injection effect, precise liquid injection volume, fast liquid injection speed and comprehensive beneficial effects such as meeting the injection requirements of different electrolytes.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

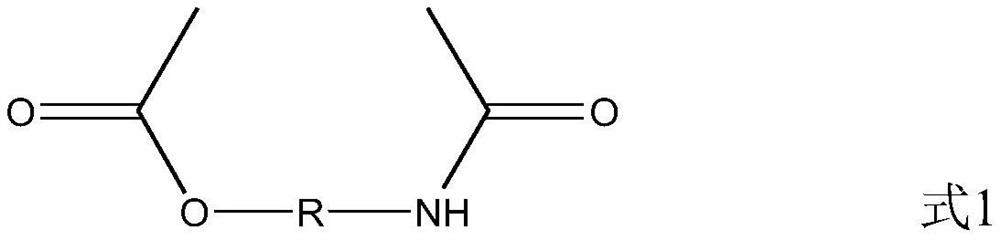

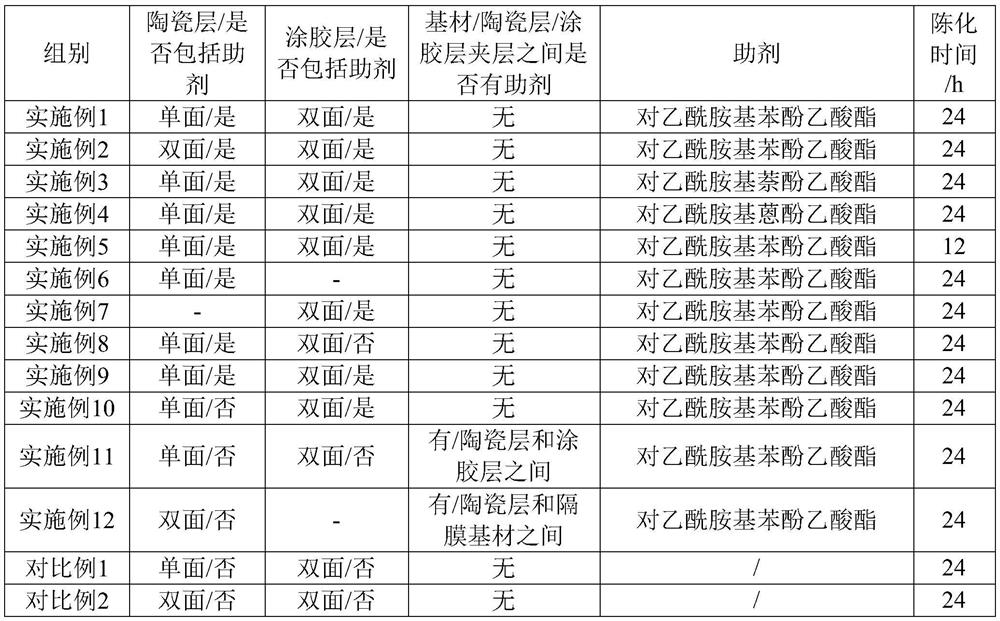

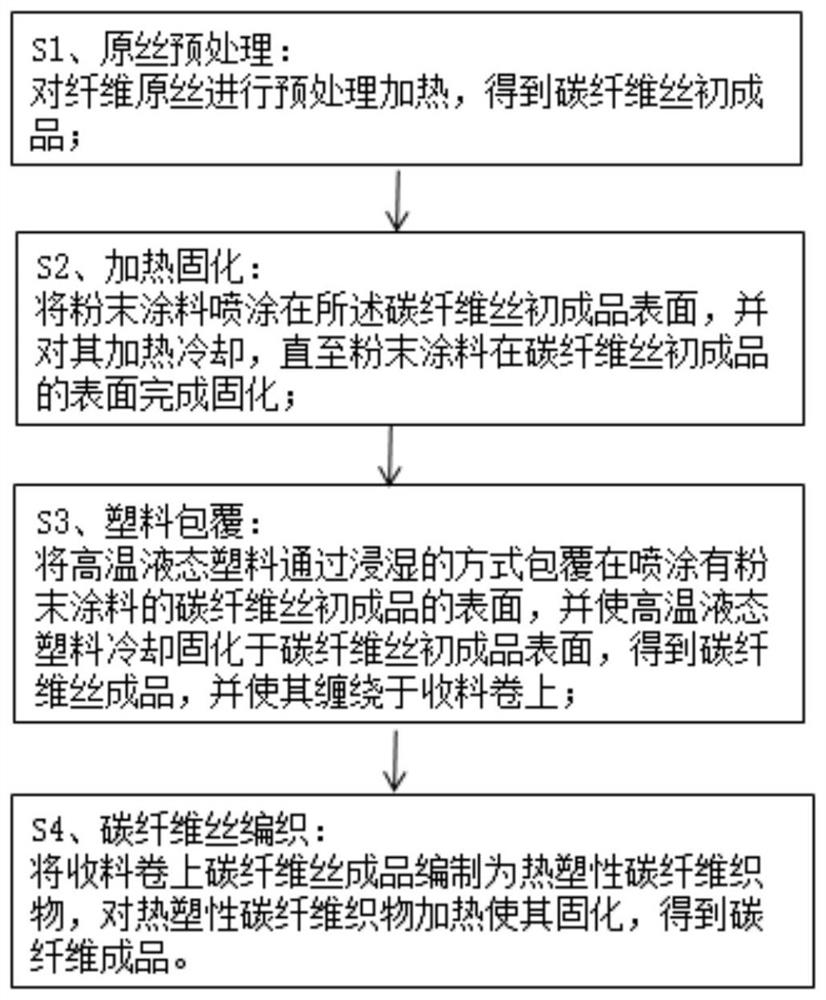

A separator and a lithium ion battery comprising the separator

ActiveCN113300048BIncrease the burdenGuaranteed wetting effectSecondary cellsCell component detailsElectrolytic agentPhysical chemistry

The invention provides a diaphragm and a lithium ion battery including the diaphragm. In the past, improving the infiltration of the positive electrode active material by the electrolyte generally starts with the electrolyte, and adds additives with high liquid absorption capacity in the electrolyte, but the side reactions of the electrolyte are relatively low. If it is too much, the added additives will be consumed by the reaction at the negative electrode, which increases the burden of the electrolyte to a certain extent. The dispersing aid of the present invention is added to the rubber coating layer and / or ceramic layer of the separator, so as to ensure the infiltration effect of the electrolyte, and at the same time, it can stabilize the coating and bonding effect of the inorganic nanoparticles and the binder, and ensure the effective performance of the ceramic layer. play. Using the intermolecular force between the imino group of the dispersing aid and O in the inorganic nanoparticles and between the active hydrogen on the aromatic ring and PVDF, the adhesiveness and dispersion uniformity of the ceramic layer of the coating separator are effectively improved .

Owner:浙江冠宇电池有限公司

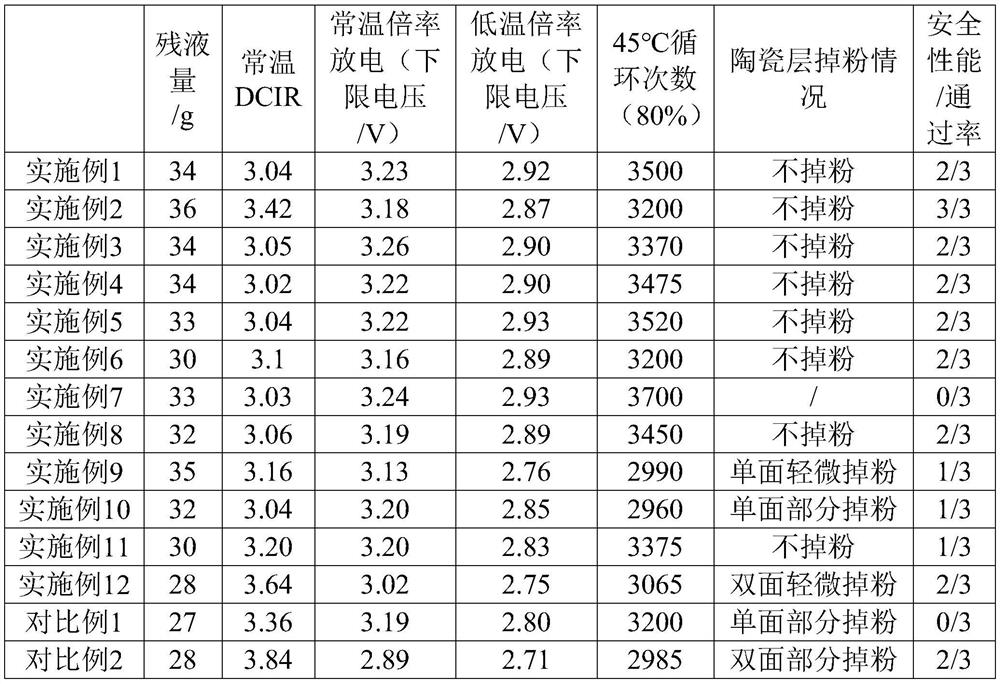

Manufacturing method of carbon fiber product for fuel cell hydrogen energy automobile

PendingCN112695527AAvoid performance degradationPerformance is not affectedCarbon fibresBraidYarnFiber

The invention discloses a manufacturing method of a carbon fiber product for a fuel cell hydrogen energy automobile. The manufacturing method comprises the following steps: S1, precursor pretreatment; S2, heating and curing; S3, plastic coating; and S4, carbon fiber yarn weaving. According to the manufacturing method of the carbon fiber product for the fuel cell hydrogen energy automobile, a layer of plastic is additionally arranged on the surface of the carbon fiber in a plastic coating process, the situation that the performance of the carbon fiber is reduced can be effectively avoided, and therefore it is guaranteed that the performance of the carbon fiber is not affected; According to the method, in a carbon fiber weaving process, the carbon fibers are combined into the plied yarn and woven into fabric, a carbon fiber forming process can be simple by adopting a weaving forming method, and manufacturing of the carbon fiber product is facilitated.

Owner:WUHAN GROVE HYDROGEN AUTOMOBILE CO LTD

Glass fiber infiltration system for high-tech materials

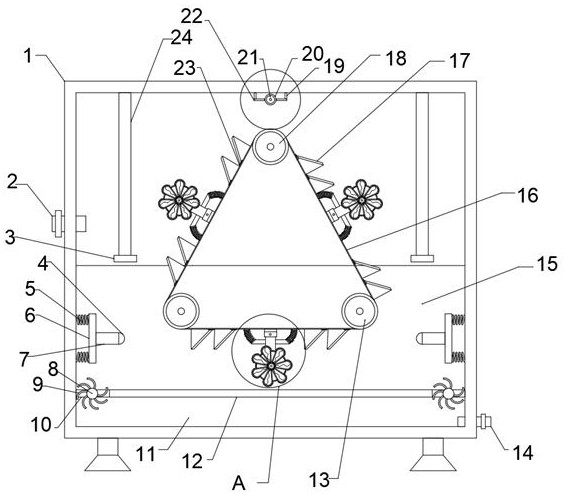

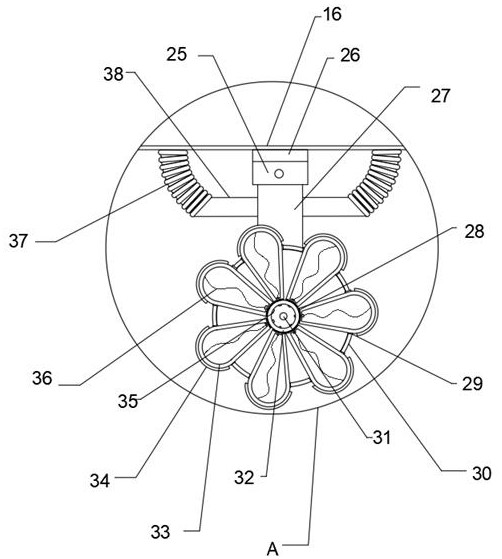

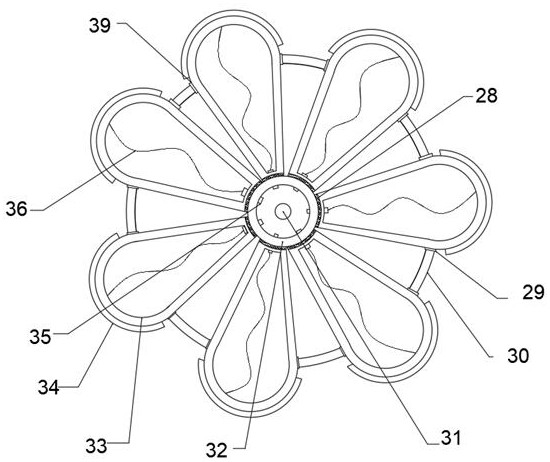

InactiveCN114477796AGuaranteed wetting effectTo achieve the purpose of rotational infiltrationEngineeringMechanical engineering

The invention belongs to the technical field of glass fibers, particularly relates to a glass fiber infiltration system for high-tech materials, and aims to solve the problems that glass fiber infiltration is not thorough enough, the infiltration effect is poor, and use is not facilitated, the following scheme is provided, the glass fiber infiltration system comprises a box body, and the outer wall of one side of the box body is fixedly connected with a driving mechanism; the outer wall of one end of the box body is fixedly connected with a liquid inlet pipe, and the interior of the box body is rotationally connected with a driving roller. According to the glass fiber cleaning device, the driving mechanism is arranged to drive the driving roller to rotate, so that the driven roller which is in transmission connection through the belt is driven to rotate, finally, the loading mechanism on the outer wall of the belt can move on the belt, an impregnating compound is introduced into the cleaning bin in the box body through the liquid inlet pipe, and then glass fibers are loaded into the loading mechanism; the moving loading mechanism drives the glass fibers to enter the impregnating compound, and the matching belt moves in the impregnating compound, then is separated from the impregnating compound and finally enters the impregnating compound again, so that the purpose of circulating and efficient infiltration is achieved, and the infiltration effect is guaranteed.

Owner:无锡赟迪新材料科技有限公司

Infiltration tank for cable processing and assembly line

ActiveCN113393981AGuaranteed waterproof performanceRaise the infiltration temperatureInsulating conductors/cablesStructural engineeringAssembly line

The invention relates to an infiltration tank for cable processing and an assembly line. The infiltration tank comprises a tank body, a heating assembly and a tensioning assembly; The tank body is used for containing waterproof glue; the heating assembly is used for heating the waterproof glue; the tensioning assembly is used for continuously and repeatedly tensioning a cable core located in the tank body. The infiltration tank can improve the waterproof capability of an existing cable.

Owner:SHENZHEN MPD HITECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com