Forming equipment and forming method for macrofiber-reinforced thermoplastic resin

A technology for enhancing thermoplasticity and molding equipment, which is applied in the field of long-fiber reinforced thermoplastic resin molding, and can solve the problem of reducing the infiltration effect of molten resin on circular bundle-shaped central fibers, affecting product quality and production efficiency, and excessive temperature difference between fibers and resins, etc. problems, to achieve the effect of reducing material renewal speed, improving production efficiency, and reducing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

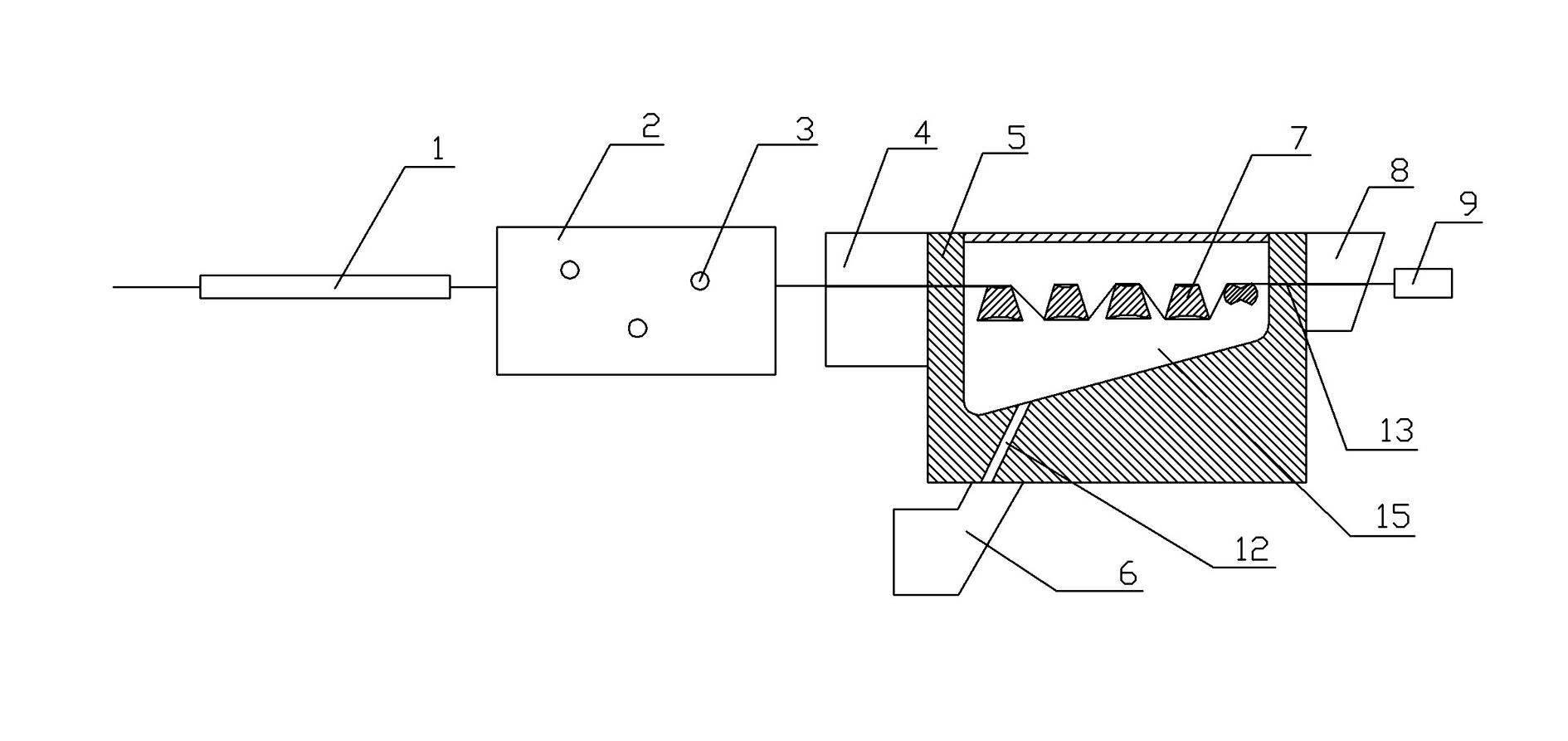

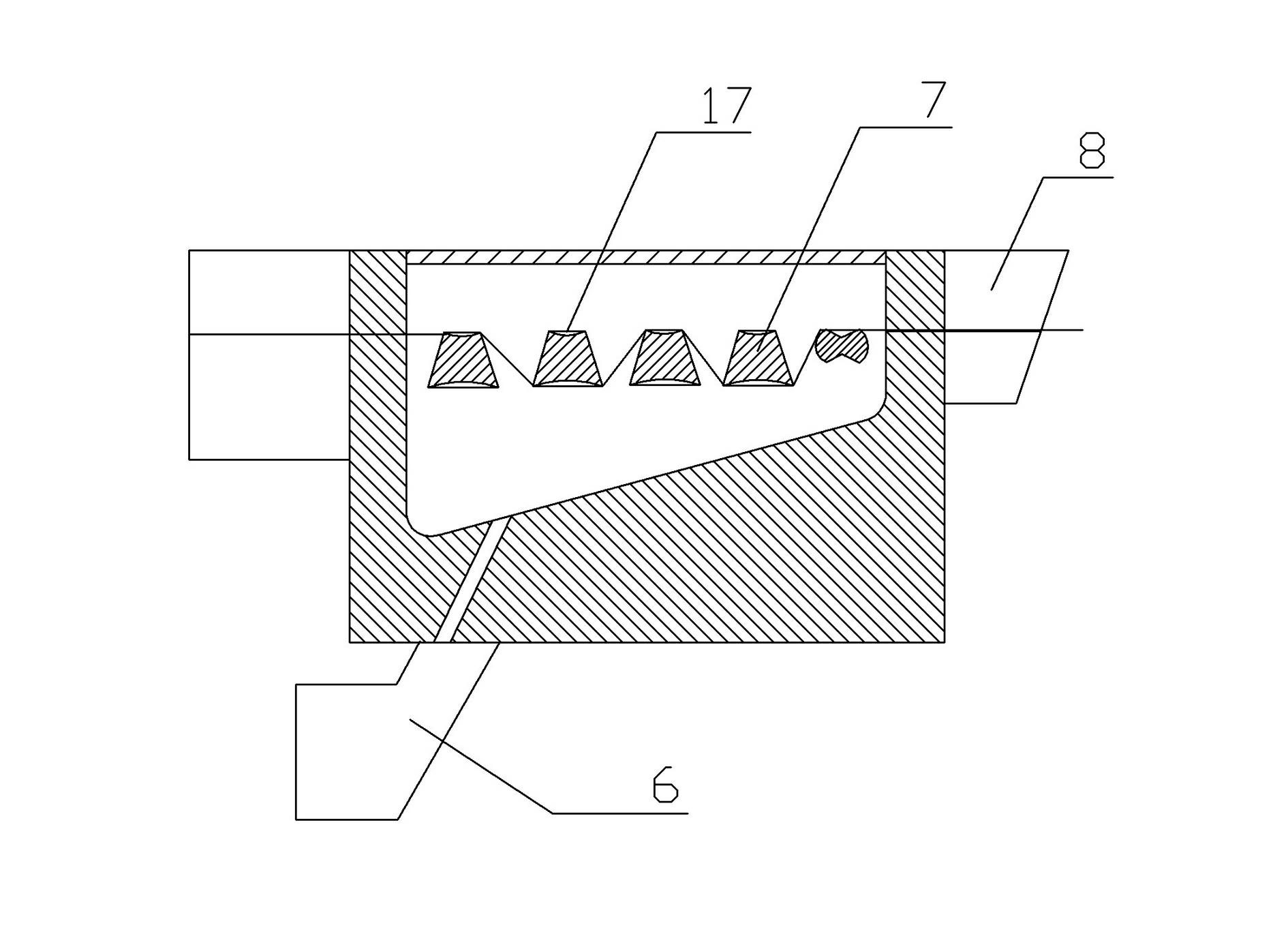

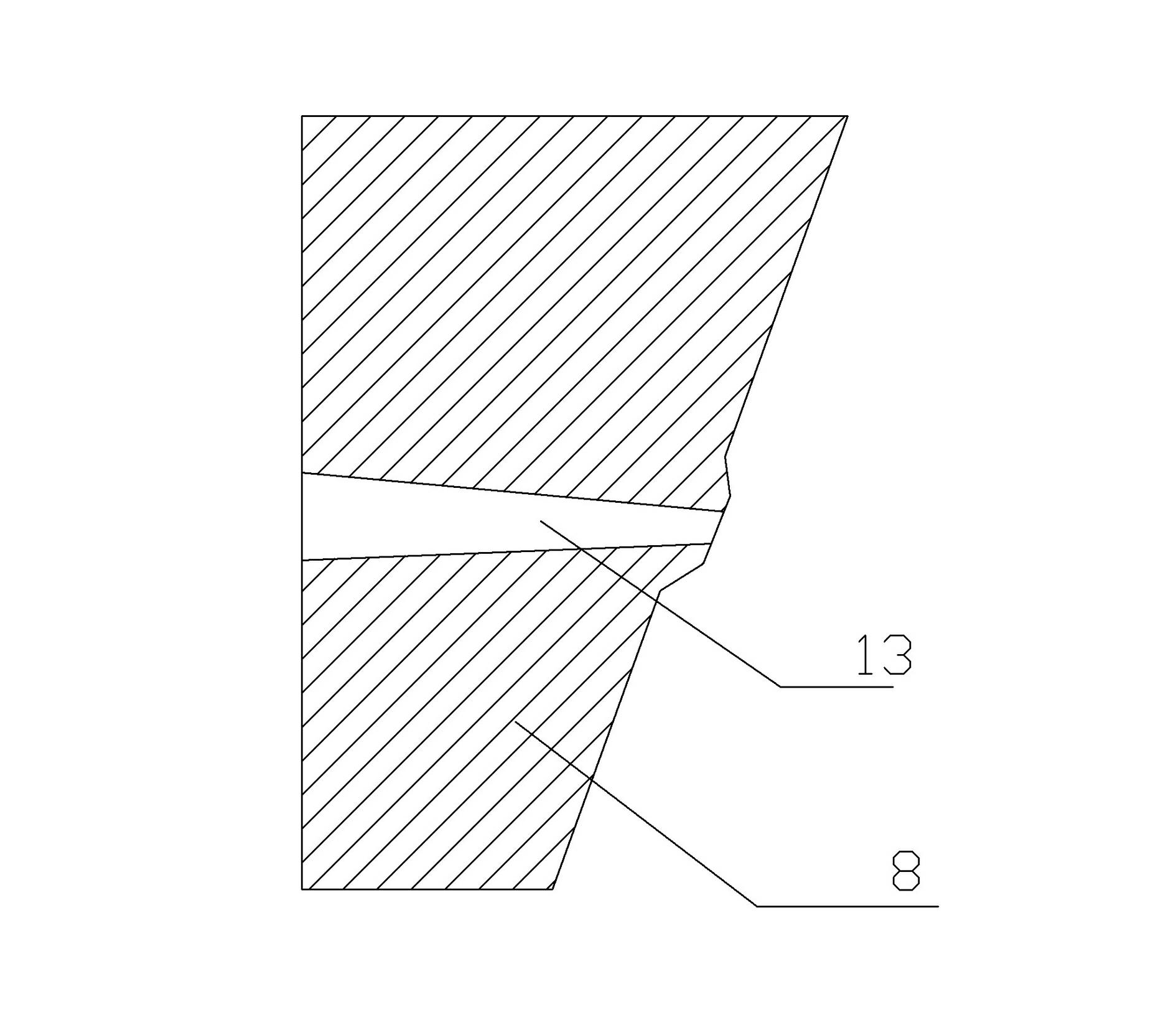

[0033] like Figure 1-3 The melt impregnation method shown is the equipment for producing long-fiber reinforced thermoplastic resin, including the equipment for decomposing fiber loops into fiber bundles and pretreating them. The fiber bundle independent channel 1 is connected with the fiber pre-fluffing and preheating system 2; Full impregnation and molding equipment, its melt inlet die 6 communicates with the fiber impregnated body 5 through the melt inflow channel 12, and is inclined upward at a certain angle, and the fiber inlet die 4 is used to connect the fiber pre-fluffing and preheating system 2 and the fiber The impregnated body 5 can make the fiber enter the fiber impregnated body 5 horizontally, and the other end of the fiber impregnated body 5 is connected with the forming die 8 .

[0034] In addition, the melt inlet die 6, the fiber inlet die 4, the forming die 8 and the fiber impregnated body 5 are detachable and flexibly combined; the fiber bundle independent ch...

Embodiment 2

[0040] like Figure 1-3 The melt impregnation method shown is the equipment for producing long-fiber reinforced thermoplastic resin, including the equipment for decomposing fiber loops into fiber bundles and pretreating them. The fiber bundle independent channel 1 is connected with the fiber pre-fluffing and preheating system 2; Full impregnation and molding equipment, its melt inlet die 6 communicates with the fiber impregnated body 5 through the melt inflow channel 12, and is inclined upward at a certain angle, and the fiber inlet die 4 is used to connect the fiber pre-fluffing and preheating system 2 and the fiber The impregnated body 5 can make the fiber enter the fiber impregnated body 5 horizontally, and the other end of the fiber impregnated body 5 is connected with the forming die 8 .

[0041] In addition, the melt inlet die 6, the fiber inlet die 4, the forming die 8 and the fiber impregnated body 5 are detachable and flexibly combined; the fiber bundle independent ch...

Embodiment 3

[0044] like Figure 1-3 The melt impregnation method shown is the equipment for producing long-fiber reinforced thermoplastic resin, including the equipment for decomposing fiber loops into fiber bundles and pretreating them. The fiber bundle independent channel 1 is connected with the fiber pre-fluffing and preheating system 2; Full impregnation and molding equipment, its melt inlet die 6 communicates with the fiber impregnated body 5 through the melt inflow channel 12, and is inclined upward at a certain angle, and the fiber inlet die 4 is used to connect the fiber pre-fluffing and preheating system 2 and the fiber The impregnated body 5 can make the fiber enter the fiber impregnated body 5 horizontally, and the other end of the fiber impregnated body 5 is connected with the forming die 8 .

[0045] In addition, the melt inlet die 6, the fiber inlet die 4, the forming die 8 and the fiber impregnated body 5 are detachable and flexibly combined; the fiber bundle independent ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circular diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com