Patents

Literature

74results about How to "Fast traction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

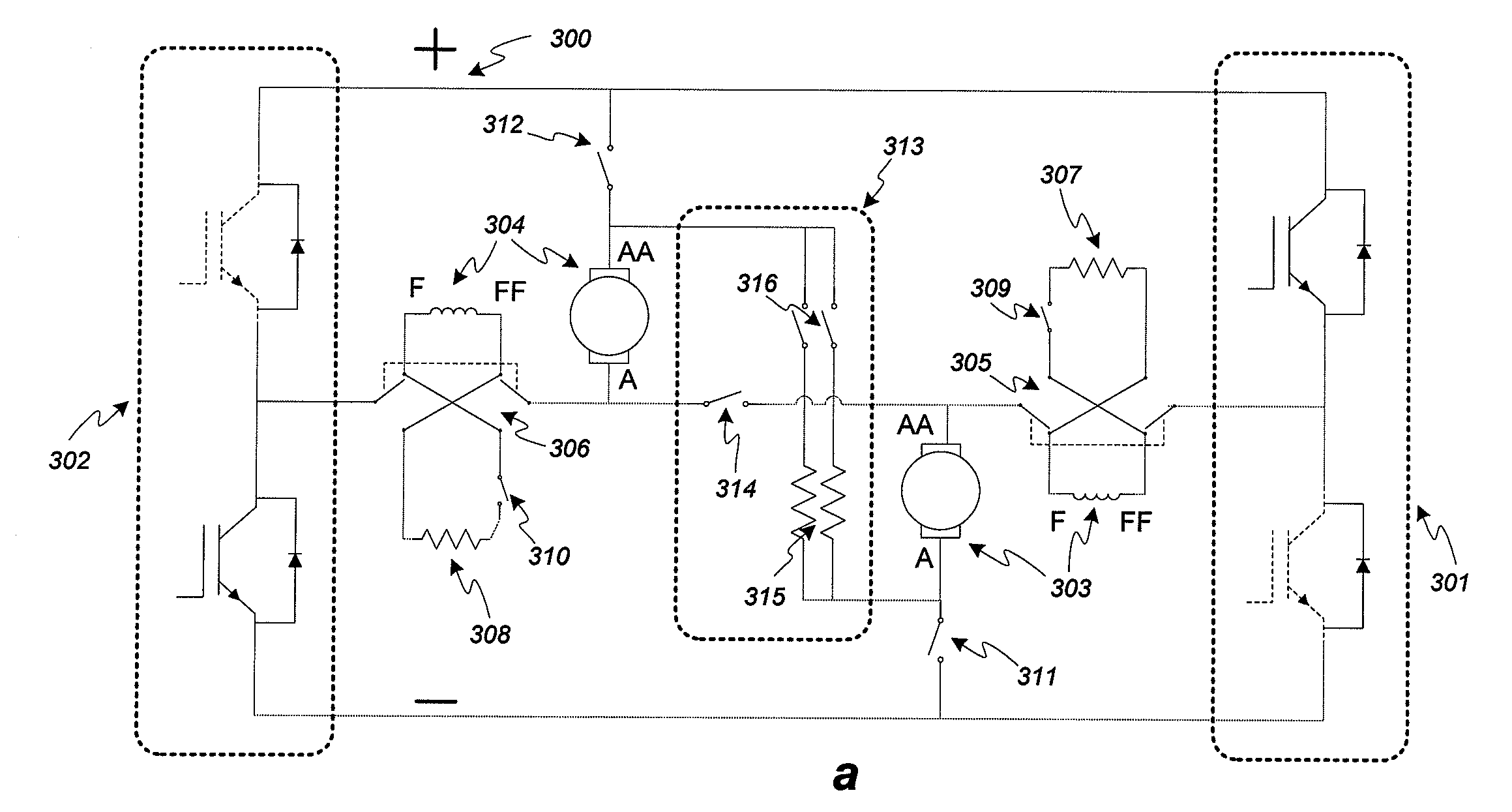

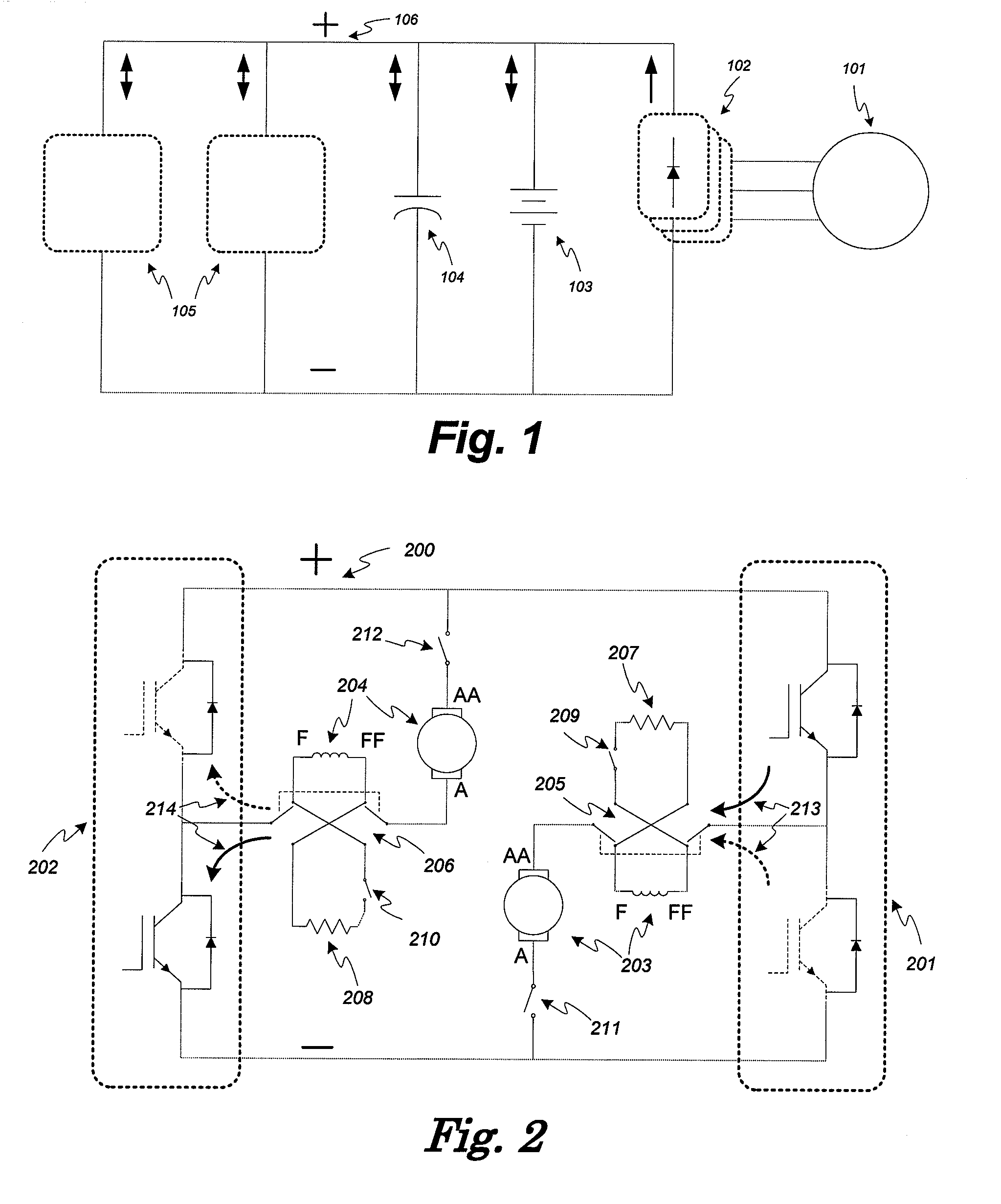

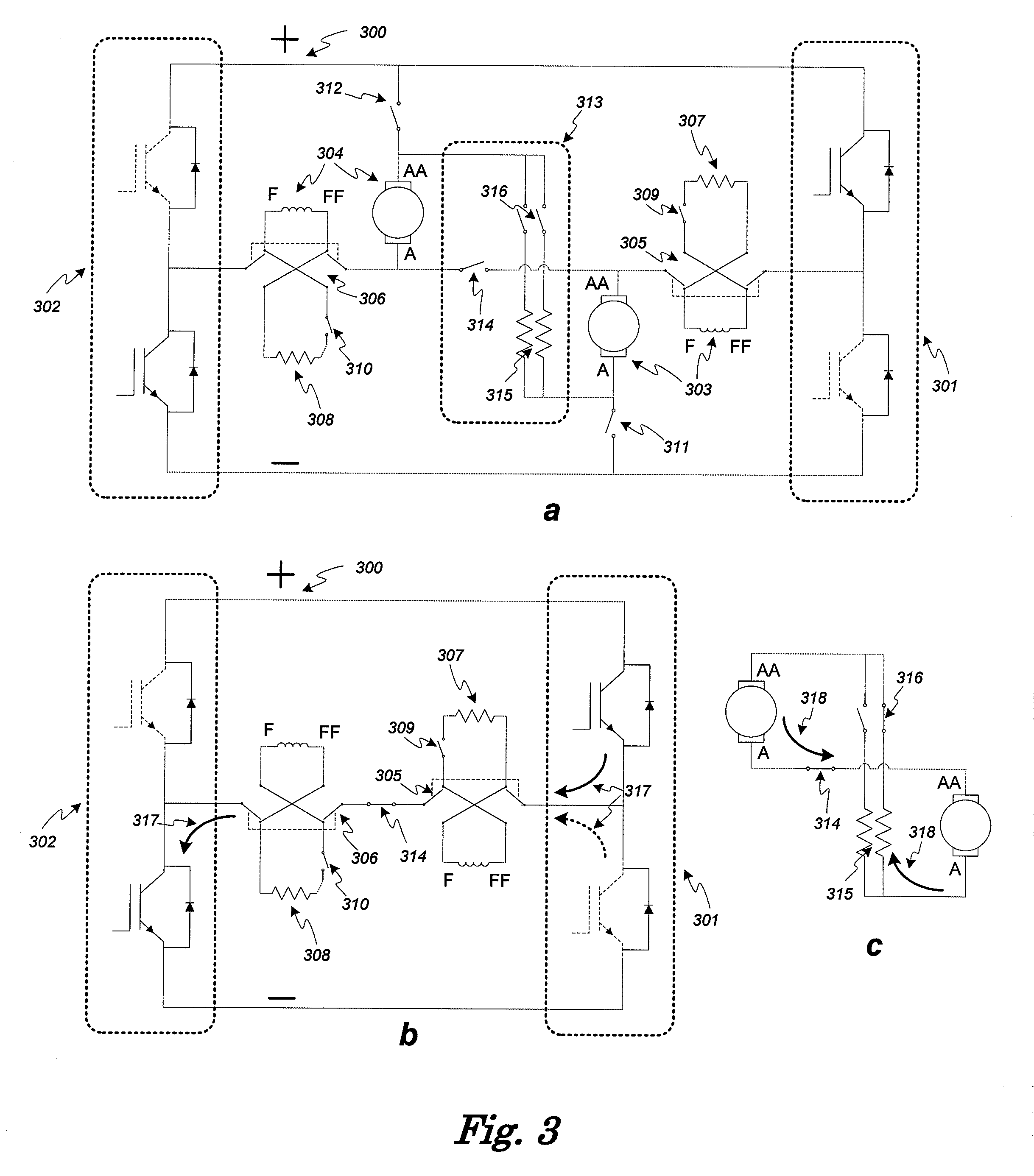

Power architecture and braking circuits for DC motor-propelled vehicle

InactiveUS20080290825A1Fast tractionAvoid developmentElectric devicesElectrodynamic brake systemsLow speedExcitation current

A dynamic braking circuit that can be operated with stability over both high and low speed regimes. This circuit has the advantage of using fewer components than previous circuits. In addition, when in braking mode, the armature and field currents tend to oppose each other across the main braking switch hence reducing electromechanical stresses when in high current regime. According to a second embodiment, a dynamic braking circuit implements a “soft” extended braking function with the capability of providing a smoother braking action at high braking effort at little extra cost resulting from the replacement of a contactor by a reverser. The main advantages of this preferred embodiment are that the current generated by the armatures during braking can be controlled independently from the excitation of the field windings at low speeds and that it enables simultaneous self supply, regeneration and dynamic braking.

Owner:RAILPOWER LLC

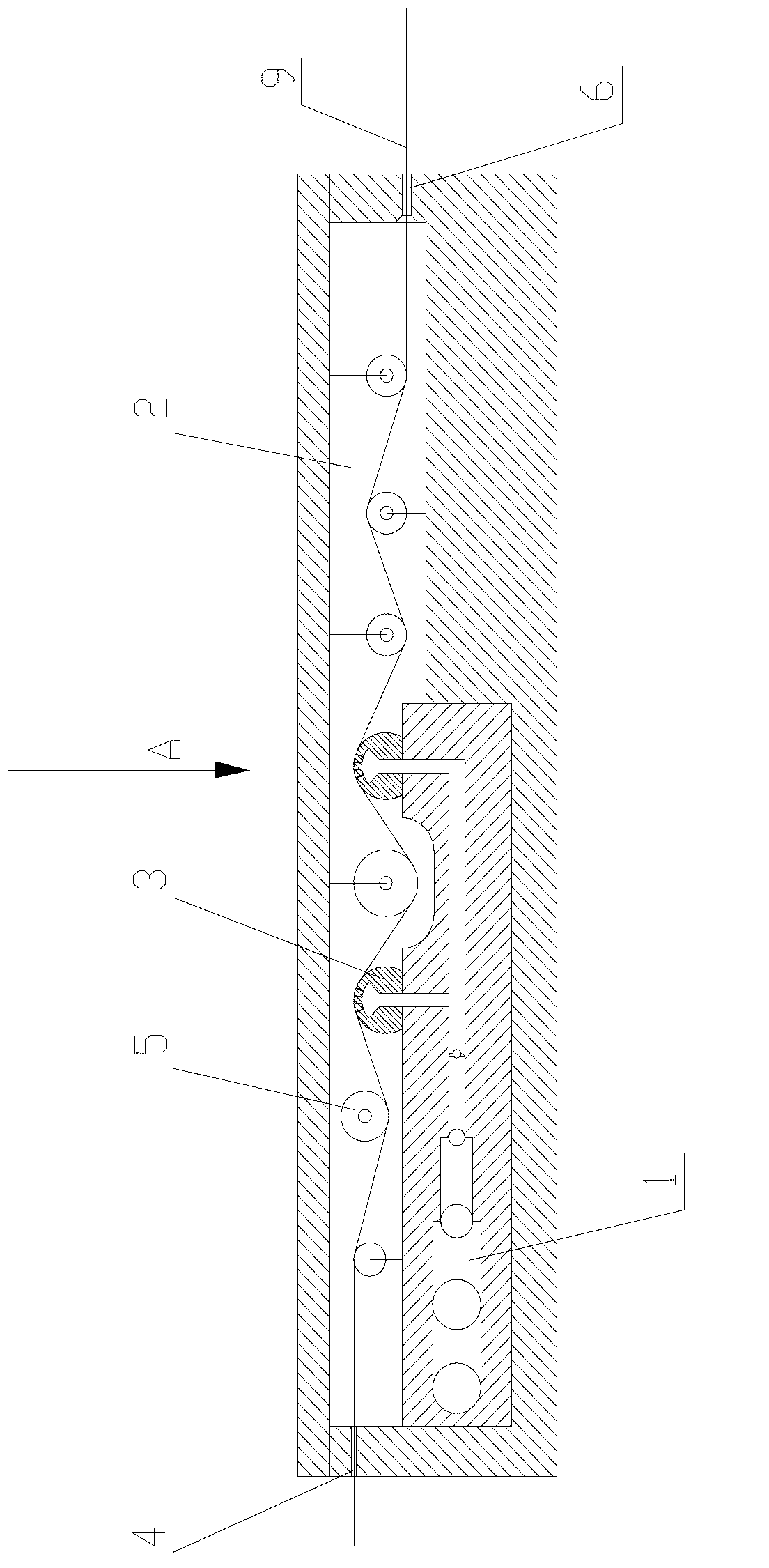

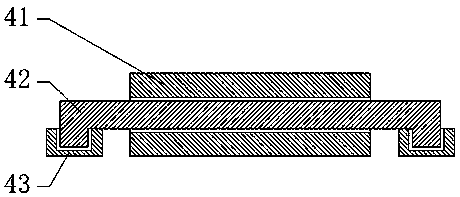

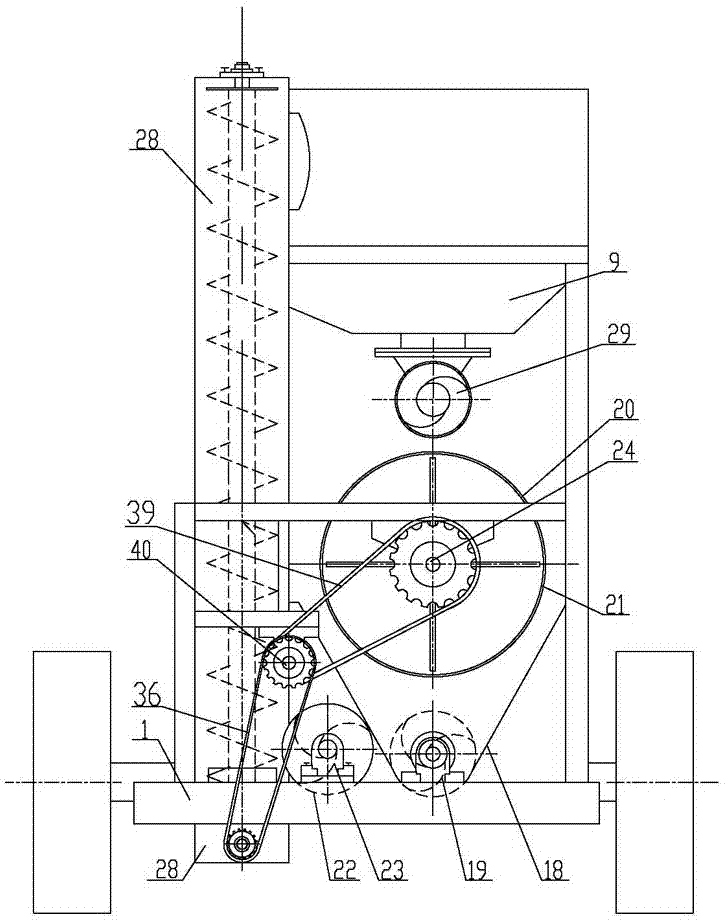

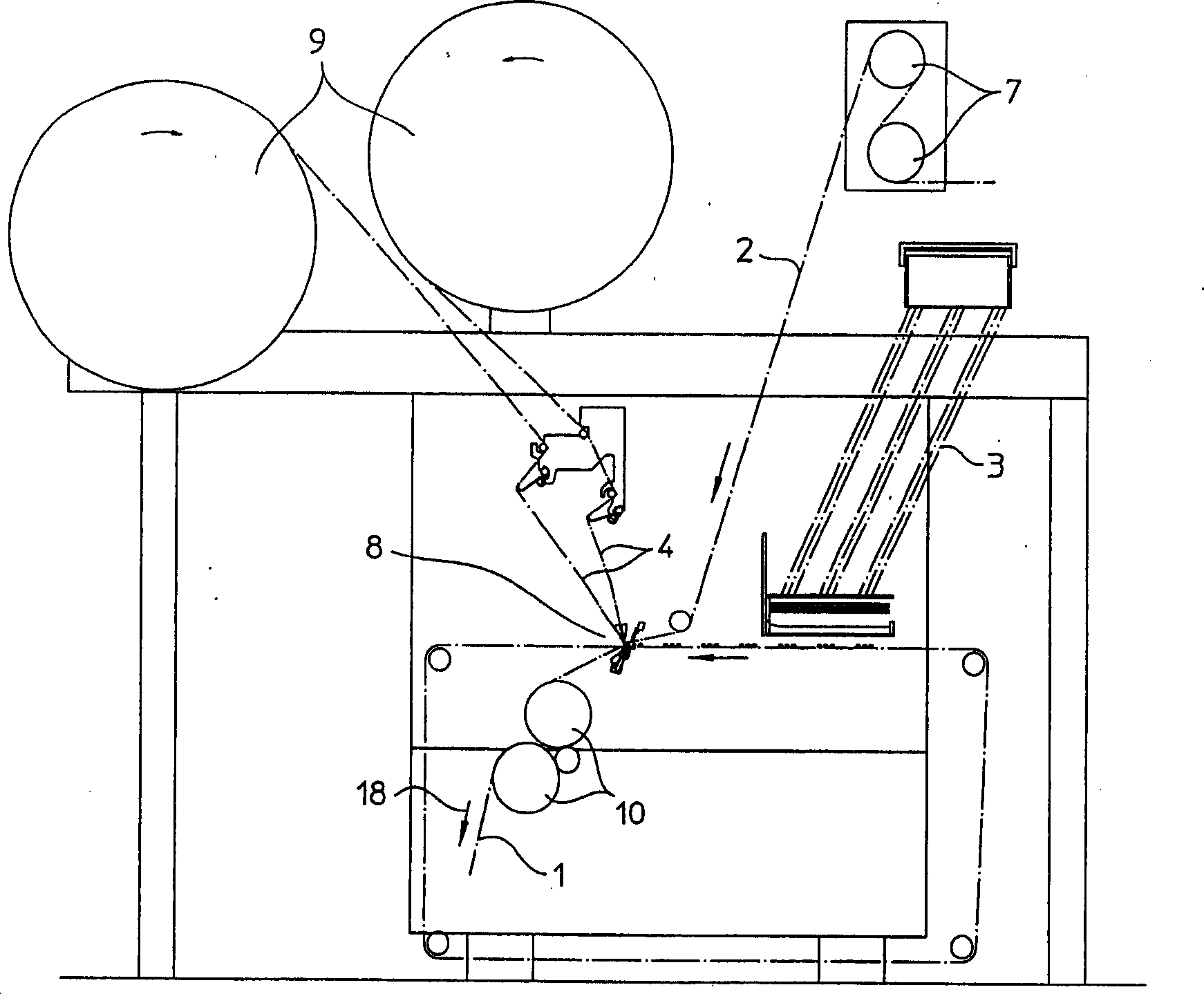

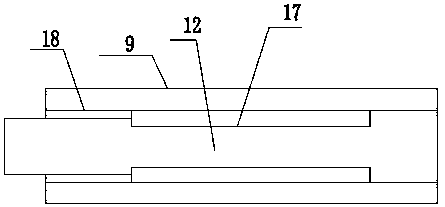

Continuous melting dipping machine head and method for forming long fiber reinforced thermoplastic resin

InactiveCN102848489ABalanced impregnation effectImprove impregnation uniformityCoatingsGlass fiberFiber bundle

The invention discloses a continuous melting dipping machine head and a method for forming a long fiber reinforced thermoplastic resin. According to the melting dipping machine head, a melt distributing flow channel and a dipping flow channel are arranged in the machine head; each material outlet of the melt distributing flow channel is connected with the dipping flow channel through a discharging roller; an inlet channel and an outlet channel are arranged at two ends of the dipping flow channel; at least one group of tension rollers are arranged between the inlet channel and the discharging roller; and at least one group of the tension rollers are arranged between the outlet channel and the discharging roller. The method comprises the following steps of: feeding continuous long fiber bundles into the dipping flow channel through the inlet channel, and drawing out of the continuous long fiber bundles from the outlet channel after the continuous long fiber bundles penetrate through the discharging roller, in a process, thermoplastic melt penetrates through a discharging roller permeating glass fiber through the melt distributing flow channel and is fed into the dipping flow channel; and further dipping the continuous long fiber bundles. According to the melting dipping machine head provided by the invention, the melt distributing flow channel is arranged and is connected with the dipping flow channel through the discharging roller, thus, melt contacted with each long fiber bundle can be consistent in pressure and flow rate, and balance of a dipping effect of each continuous long fiber can be ensured.

Owner:KINGFA SCI & TECH CO LTD +1

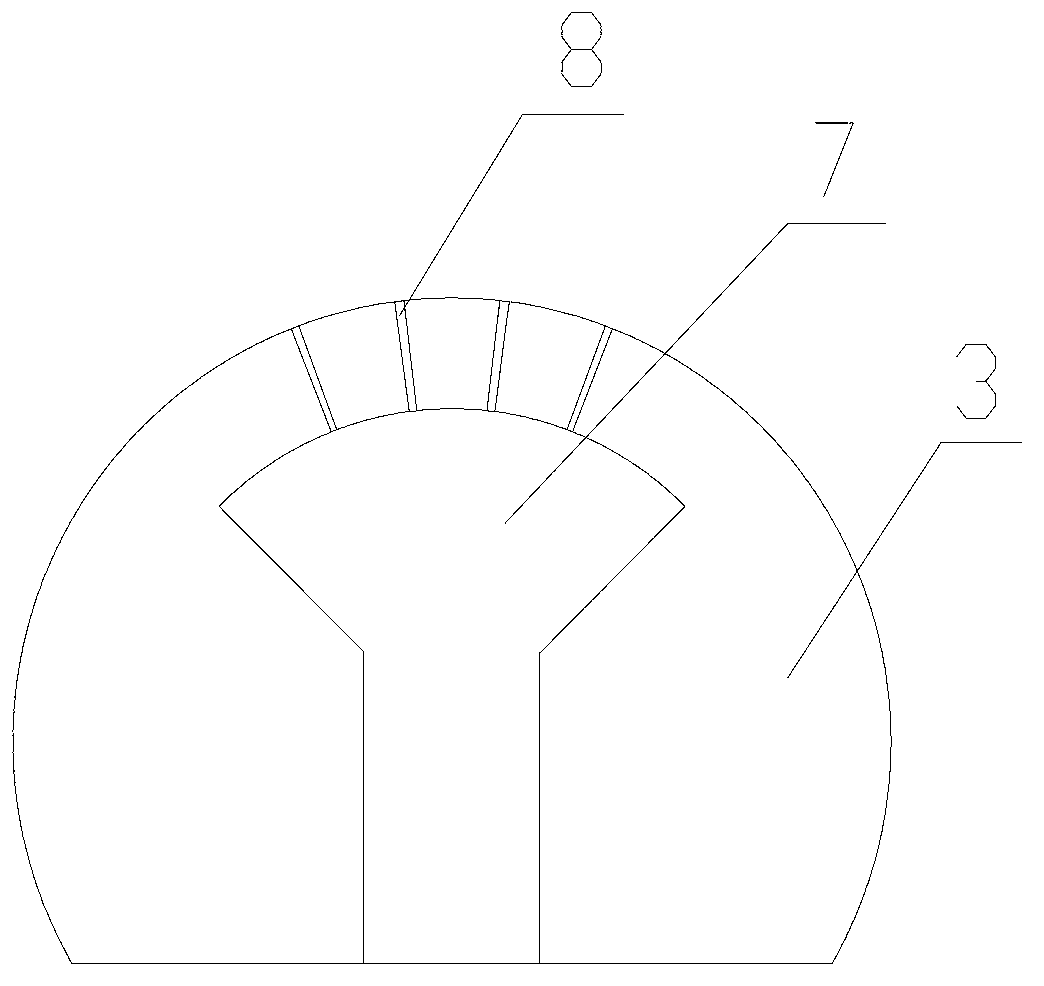

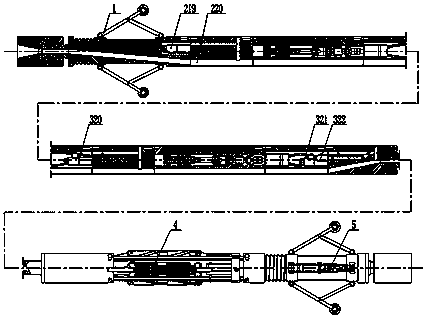

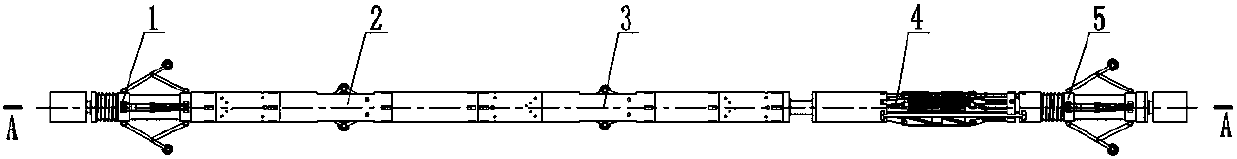

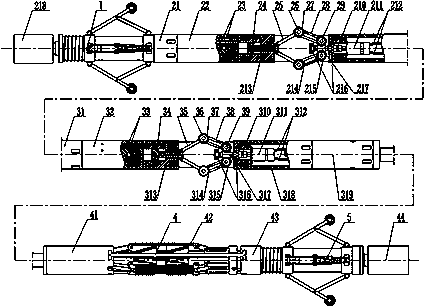

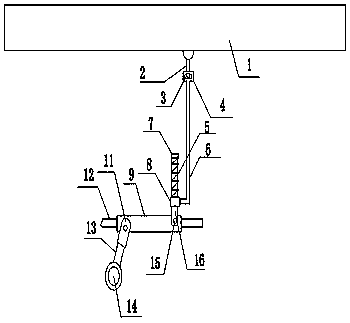

Large-displacement horizontal well continuous tubing drilling robot

ActiveCN108868603ASingle mode of operationVarious ways of operationDirectional drillingFlushingWell drillingResource development

The invention relates to a large-displacement horizontal well continuous tubing drilling robot, which comprises a former centralizer, a rear centralizer, a front motion short joint, a back motion short joint and an extension shortening section; the front motion short joint, the back motion short joint and the extension shortening section are connected to each other in turns; the former centralizers and the rear centralizers are respectively installed at the front end and the rear end of the front motion short joint and the extension shortening section. The large-displacement horizontal well drilling robot is provided with a mud flow channel, which can circulate mud in tow continuous tubing and drilling, therefore the resistance of mud is reduced to the maximum extent. The large-displacement horizontal well drilling robot can carry on two-way haulage, which can solve the jam problem of the robot to a great extent. The large-displacement horizontal well continuous tubing drilling robot is not only suitable for hot dry rock development, but also suitable for unconventional oil and gas (natural gas hydrate, coalbed methane, tight oil and gas, shale gas) and conventional oil and gas resources development.

Owner:SOUTHWEST PETROLEUM UNIV

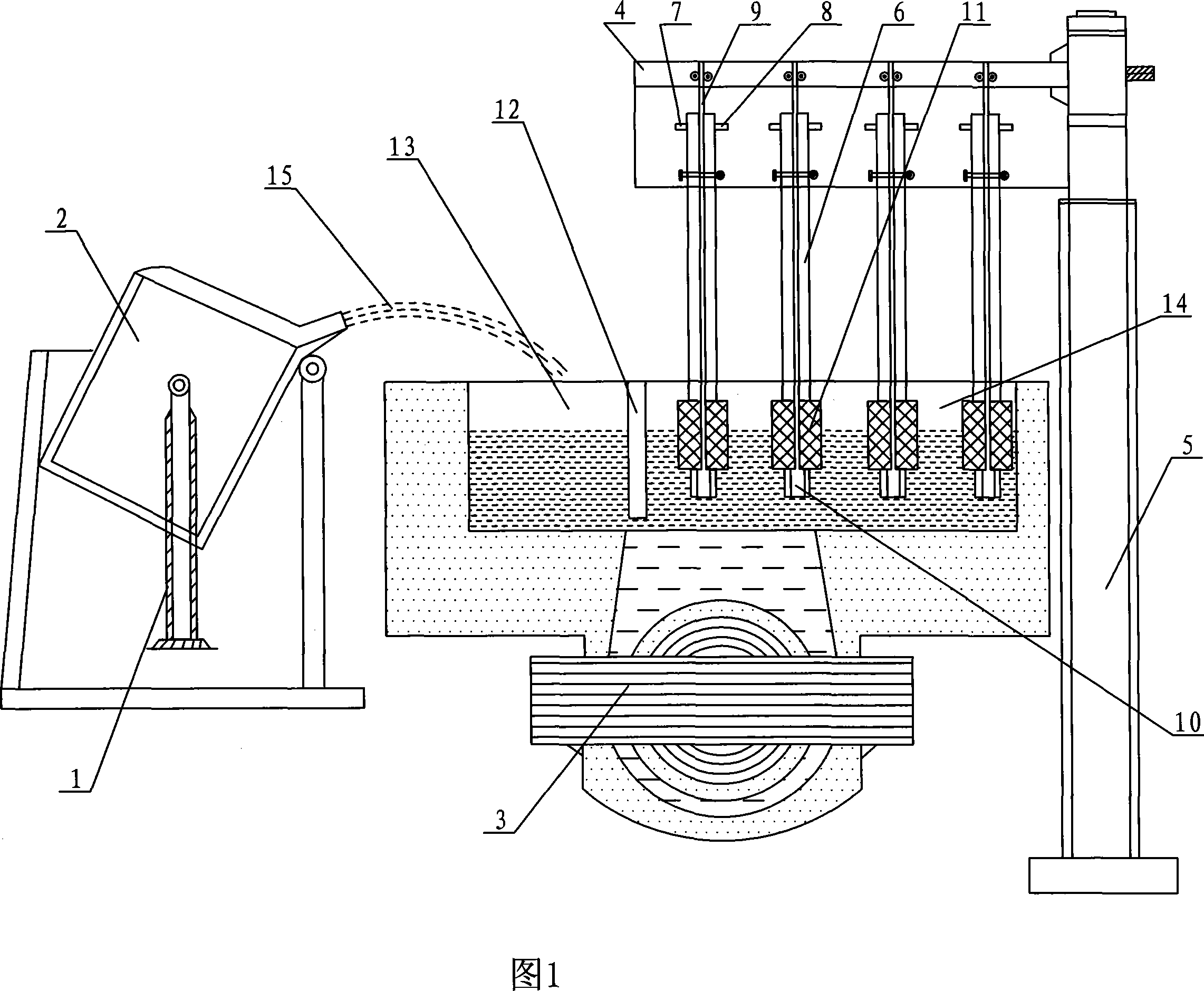

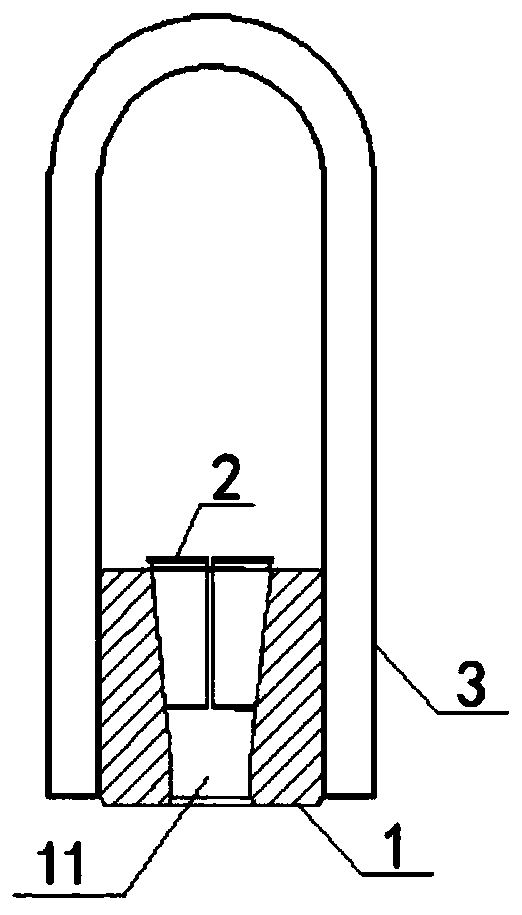

Upper-drawing casting device for the silicon bronze bar blank

The invention discloses an up-drawing casting device for silicon bronze bar billet, comprising a smelter positioned on the landing control device. A side face of the smelter is provided with a power frequency furnace with an iron core, the upper surface of the power frequency furnace with an iron core is provided with a plurality of drawing devices which are positioned on a rolling crane. The drawing devices are provided with a crystallizer, the upper end of which is provided with a water inlet port and a water outlet port respectively. The dummy bars of the drawing devices are arranged through and in the crystallizer. The lower end of the crystallizer is provided with a graphite mould. The outside of the connection of the graphite mould and the crystallizer is provided with graphite protecting jacket. The invention has the advantages that the casting temperature of the up-drawing casting device for silicon bronze bar billet is low, the drawing speed is fast, the productivity effect is high, the grain of silicon bronze bar billet produced by the invention is uniformity and the production safety is good, thereby avoiding the dangerous accidents in operation.

Owner:GAOXIN ZHANGTONG

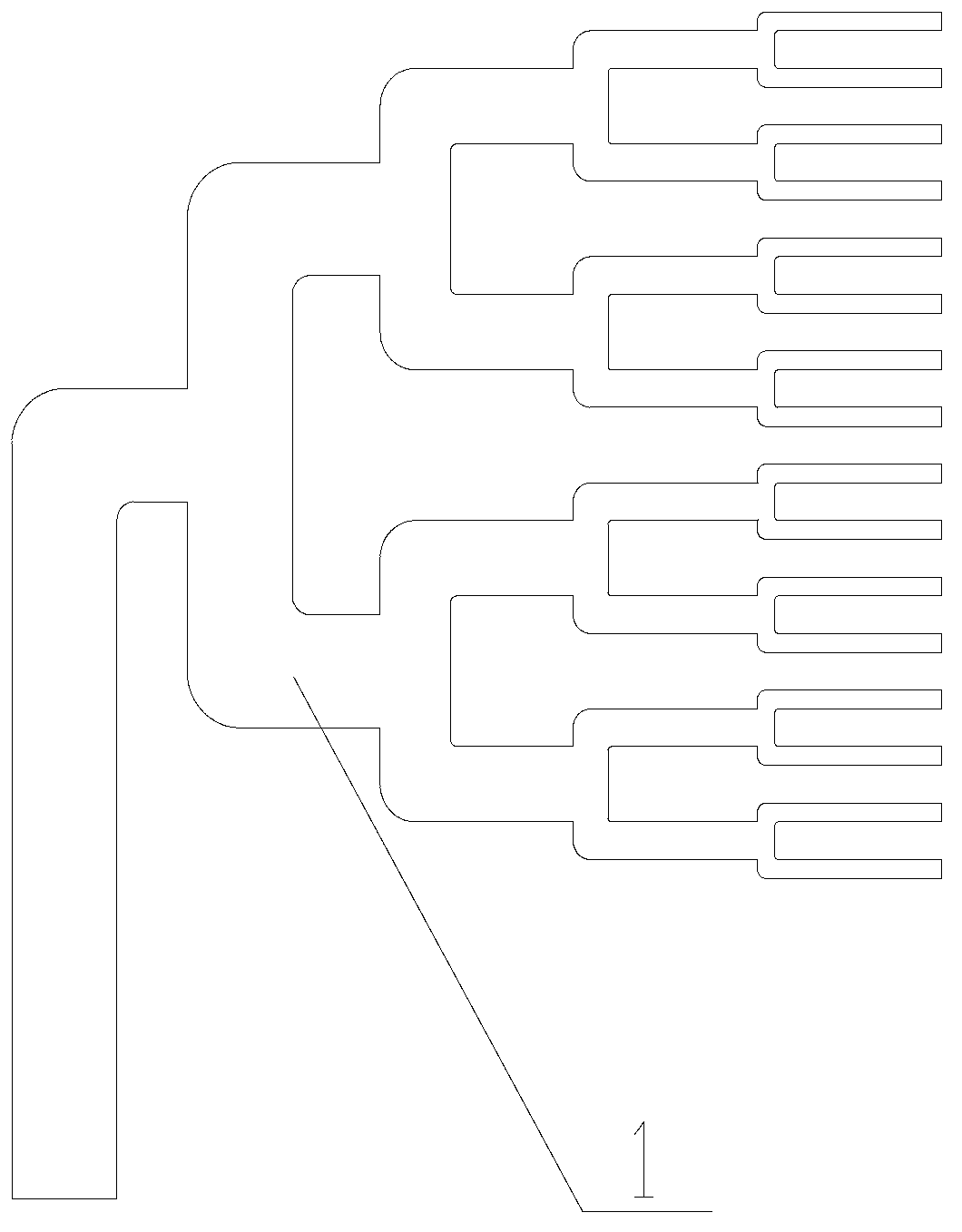

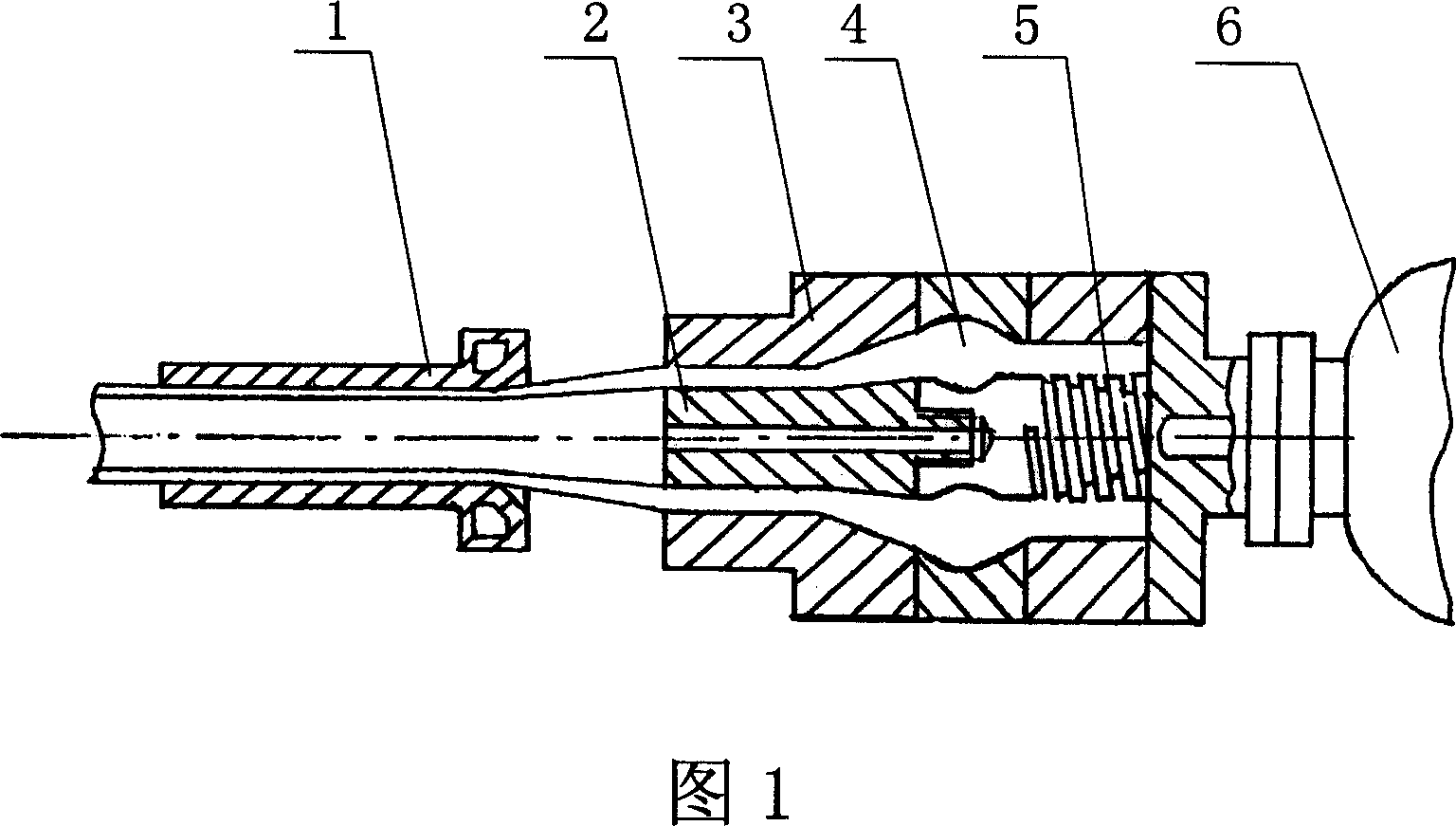

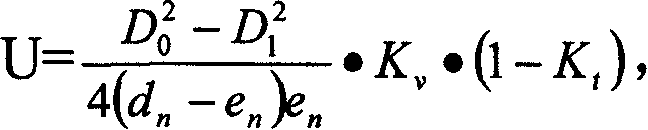

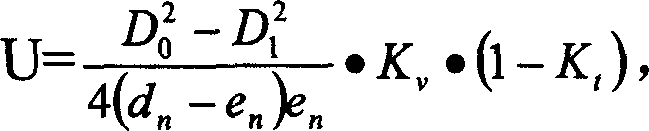

Method for producing multi-specification plastic pipe material by fixed diameter-opening mould and its ram-head mould

The invention is concerned with the method and the bolt head mould for using the sizing opening-module to produce multi-standard plastic pipe, the method is: puts in the material, heats to melt, extrudes, sizing cooling, tows, cutting to length, the heating melted material extrudes from the opening module, then tows in the sizing mould, the inside diameter of the opening mould is bigger that the inside diameter of the sizing mould, the linear velocity ratio of the heating melted material extrusion and the sizing cooling produce is U<=1, the inside cavity diameter of the opening mould is bigger than the inside cavity diameter of the sizing mould, between the opening mould and the sizing mould is a gap. The features of the invention are: can produce multi-standard pipe, save material, improve efficiency, high output.

Owner:烟台东邦塑料建材有限公司

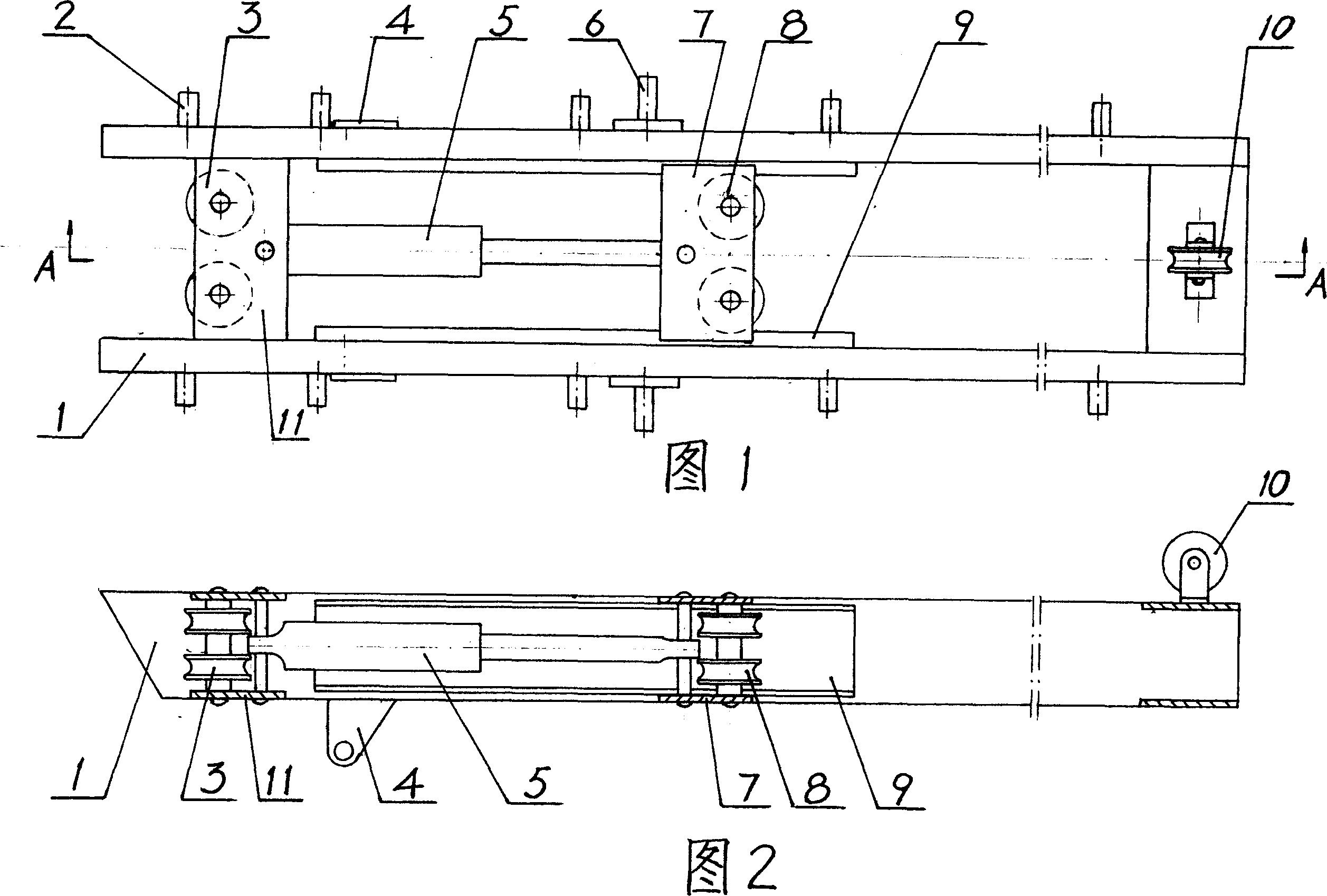

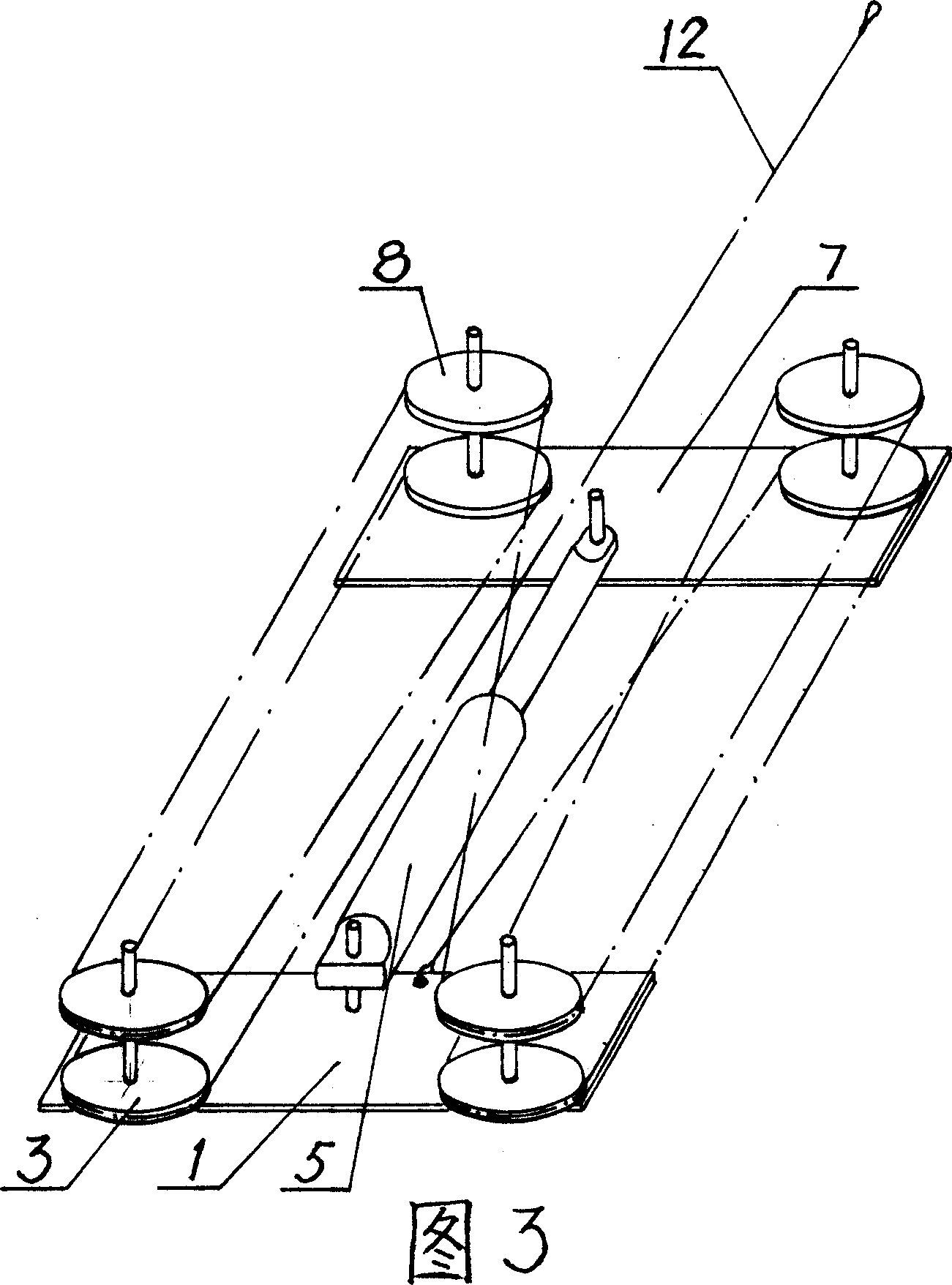

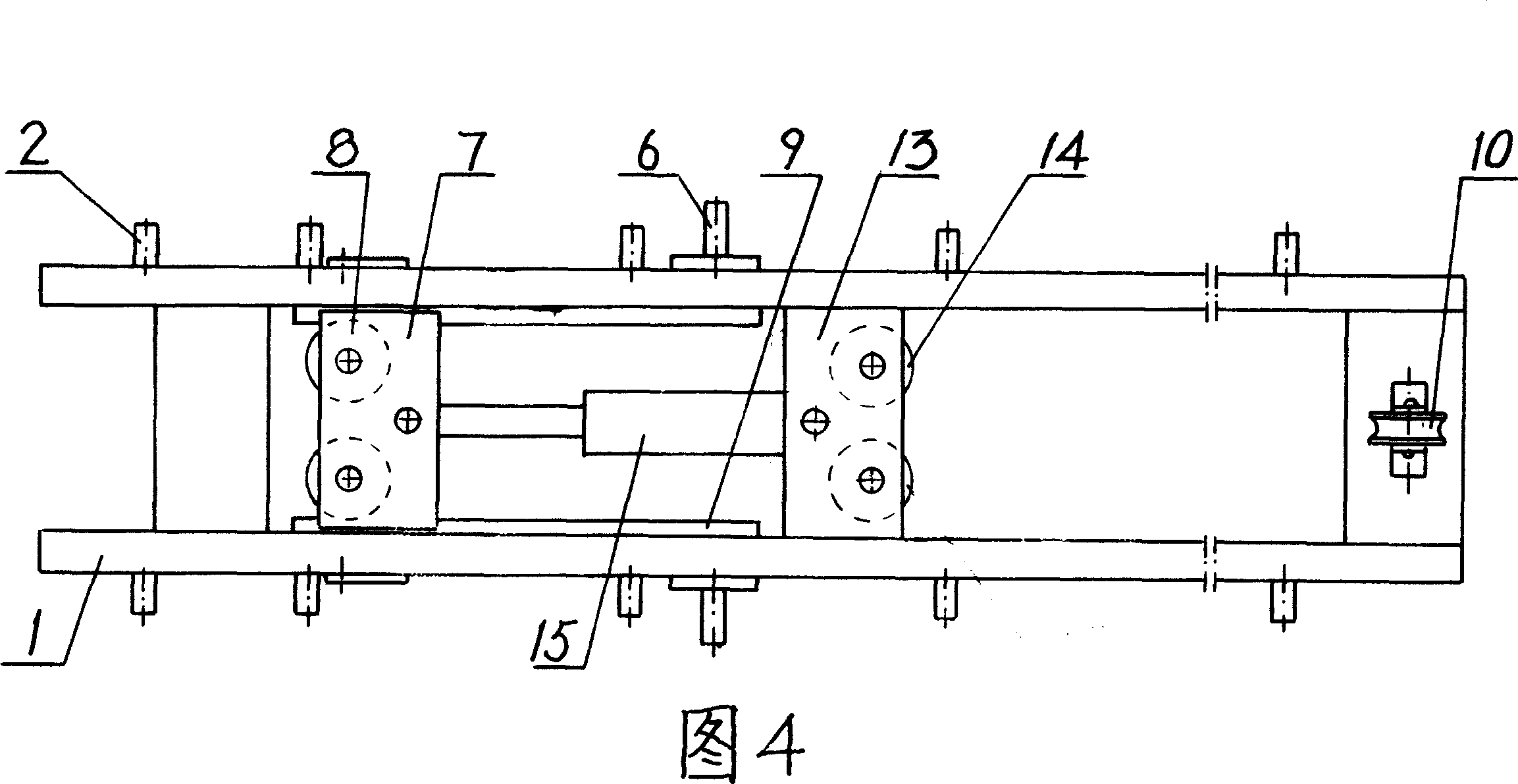

Driving device for automobile container loading and unloading

InactiveCN1927620AIncrease the itineraryShort tripVehicle with tipping movementVehicle with loading rampVehicle frameFixed frame

The invention provides a handling driving devices used for vehicle packing box. Its features are: installing dragging main fixed pulley of packing box on the front of car subframe between the vehicle chassis and the cargo box, equipping fixed frame on the car subframe and installing two revolution axis in the fixed frame side by side and vertically; installing two-oriented fixed pulleys on the two revolution axis respectively; fixing the sliding blocks moves to and fro and its guide rail on the inside of the car subframe, and fixing two movable pulleys in the sliding blocks in corresponding the two-oriented fixed pulleys; fixing a driving fuel tank between the fixed frame and the sliding frame of the car subframe. It simplifies the handling driving devices used for packing box, avoids the problems that the two original tanks are synchronously. In addition, the invention is also simple, easy to manufacturing and the driving speed is fast.

Owner:陆家起

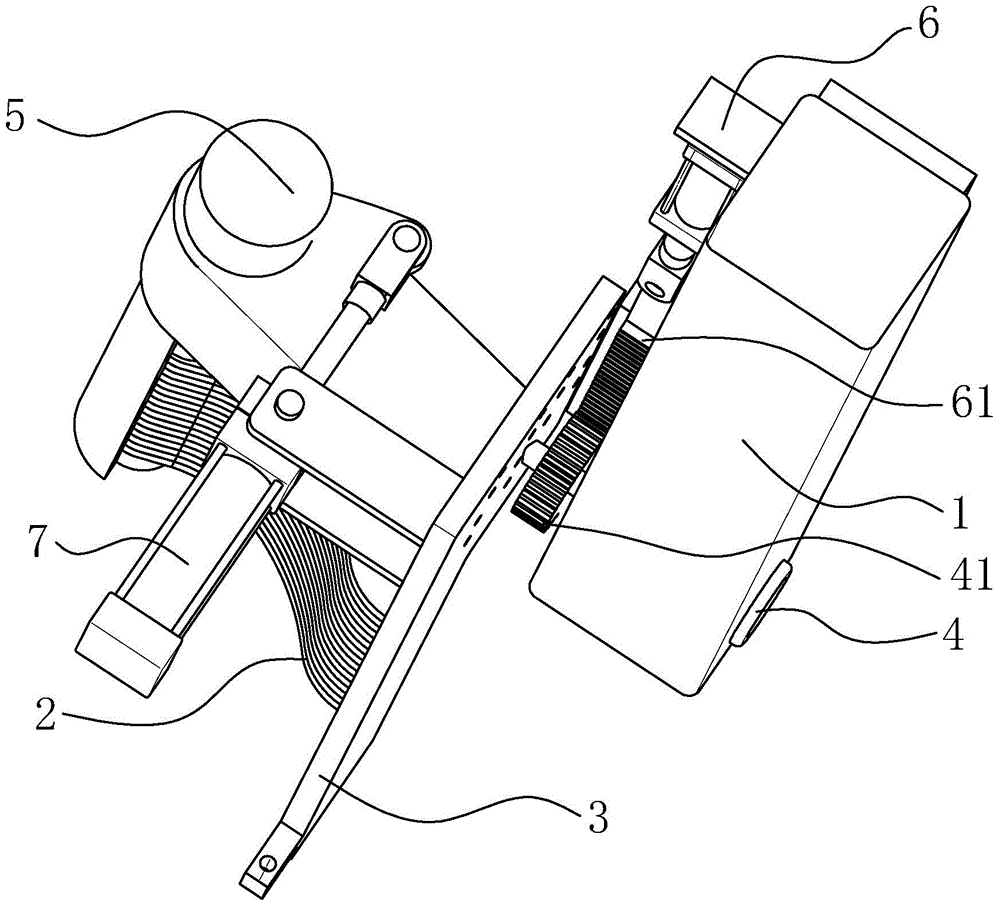

Novel profile pulling method

The invention provides a novel profile pulling method. A vertical pulling robot is used for pulling a profile. The vertical pulling robot is formed by overlapping and splicing M pulling units in the vertical direction. Each pulling unit is provided with a vertical type walking track and a mechanical arm moving on the vertical type walking track. M is a natural number which is greater than or equal to 2. The mechanical arms of every two adjacent pulling units are hung on the vertical type walking tracks and move in a cooperatively alternating and mutual avoiding mode, so that the profile is pulled in a cooperatively alternating mode. According to the novel profile pulling method, the practicality is high, the pulling speed is high, the profile can be fully automatically pulled in a multi-track mode according to production requirements, and therefore the profile pulling efficiency is improved, an efficient and stable pulling effect can be achieved, full-automatic and intelligent profile pulling processing is achieved, and the novel profile pulling method is suitable for large-scale production.

Owner:广东省智行机器人科技有限公司

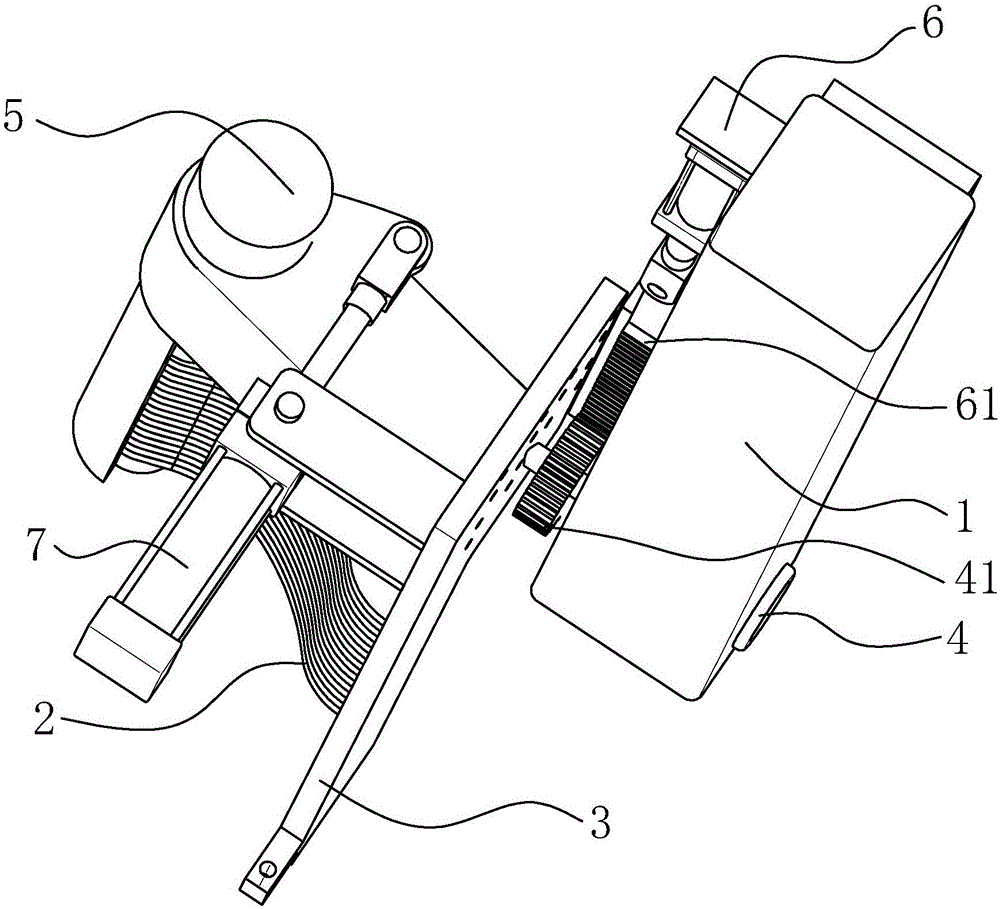

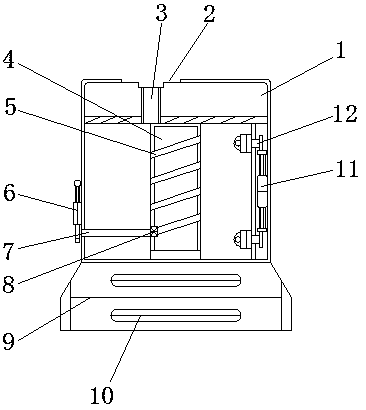

High-reliability cable pay-off traction clamp

The invention discloses a high-reliability cable pay-off traction clamp, which comprises a suspension loop, a clamping mechanism and an outer sleeve, wherein the suspension loop is fixedly connected with one end of the outer sleeve; an inner sleeve is sleeved with the outer sleeve; the clamping mechanism is arranged on side walls of the outer sleeve and the inner sleeve in common; a transmission gear is arranged on an outer side wall of the outer sleeve and comprises a box body; the box body is fixedly connected to the outer side wall of the outer sleeve; the lower surface in the box body is fixedly connected with a bearing block; the internal part of the bearing block is rotationally connected with a rotating shaft through a bearing; one end of the rotating shaft penetrates through the box body and extends to the outside of the box body; one end, which extends to the outside of the box body, of the rotating shaft is fixedly connected with a handle; and one end, far away from the handle, of the rotating shaft is fixedly connected with a first bevel gear. According to the high-reliability cable pay-off traction clamp, cable traction can be quickly and conveniently completed in the absence of an external tool, and meanwhile, the cable subjected to traction is conveniently taken out from the clamp on the basis of not damaging the clamp.

Owner:ANHUI CHUNHUI INSTR CABLE GROUP

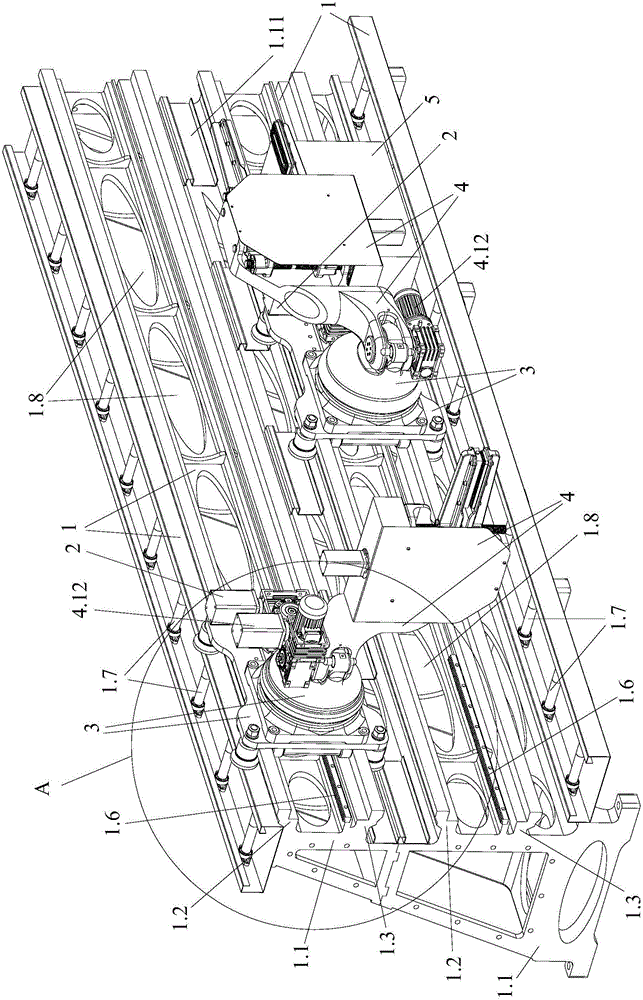

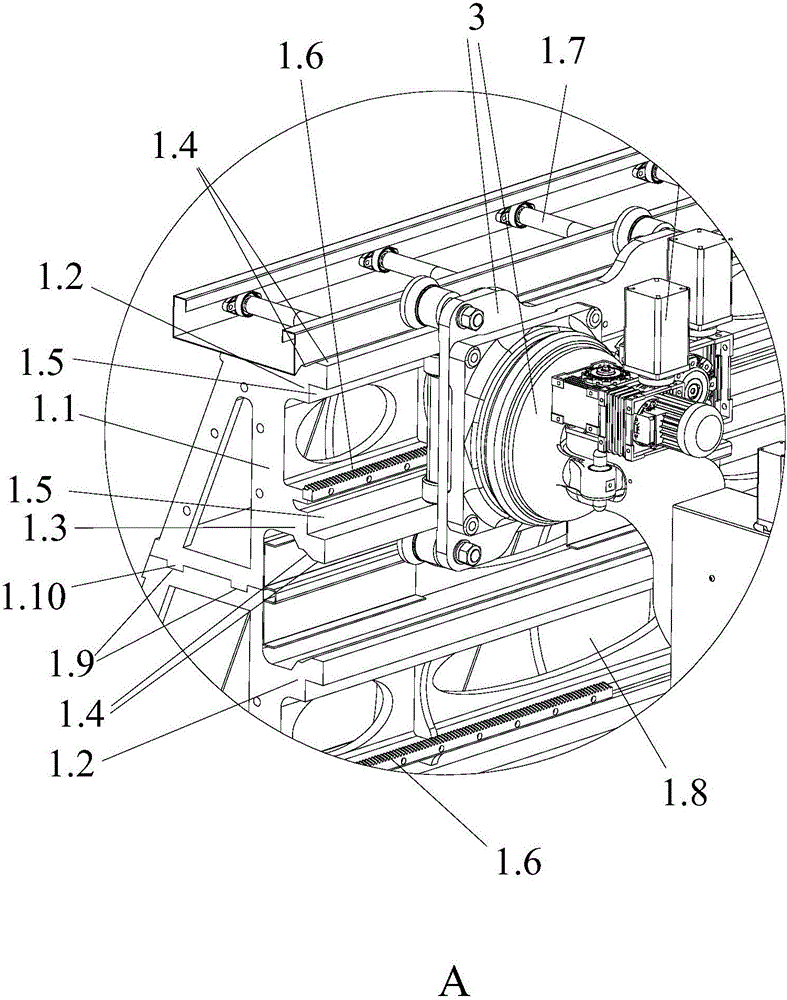

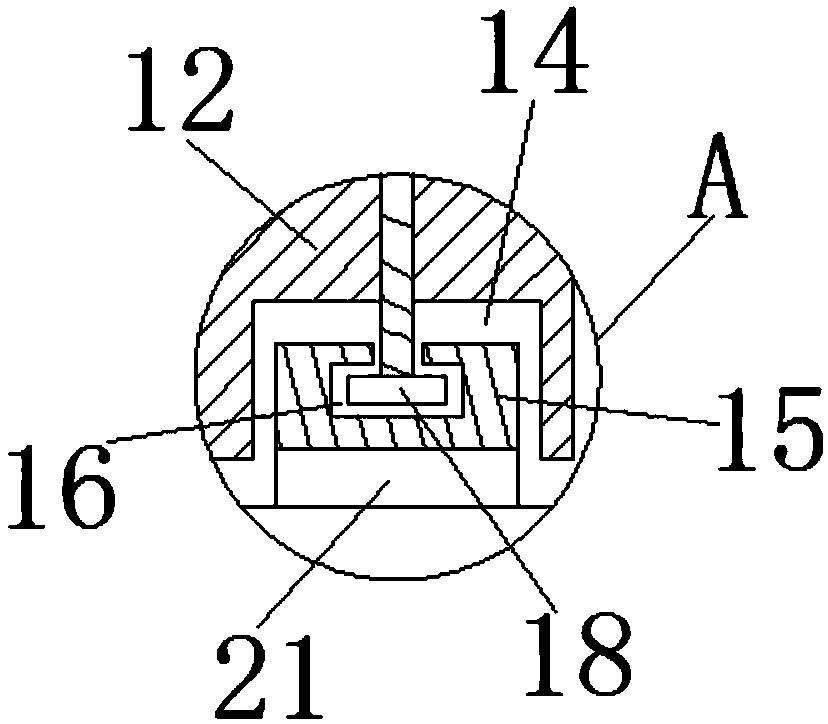

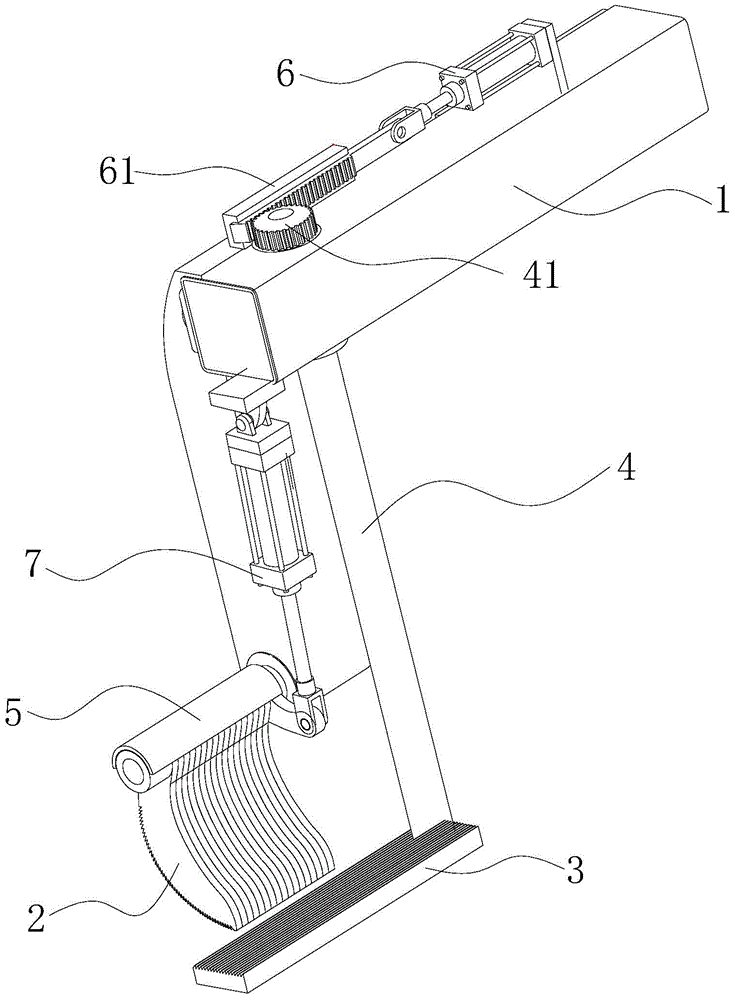

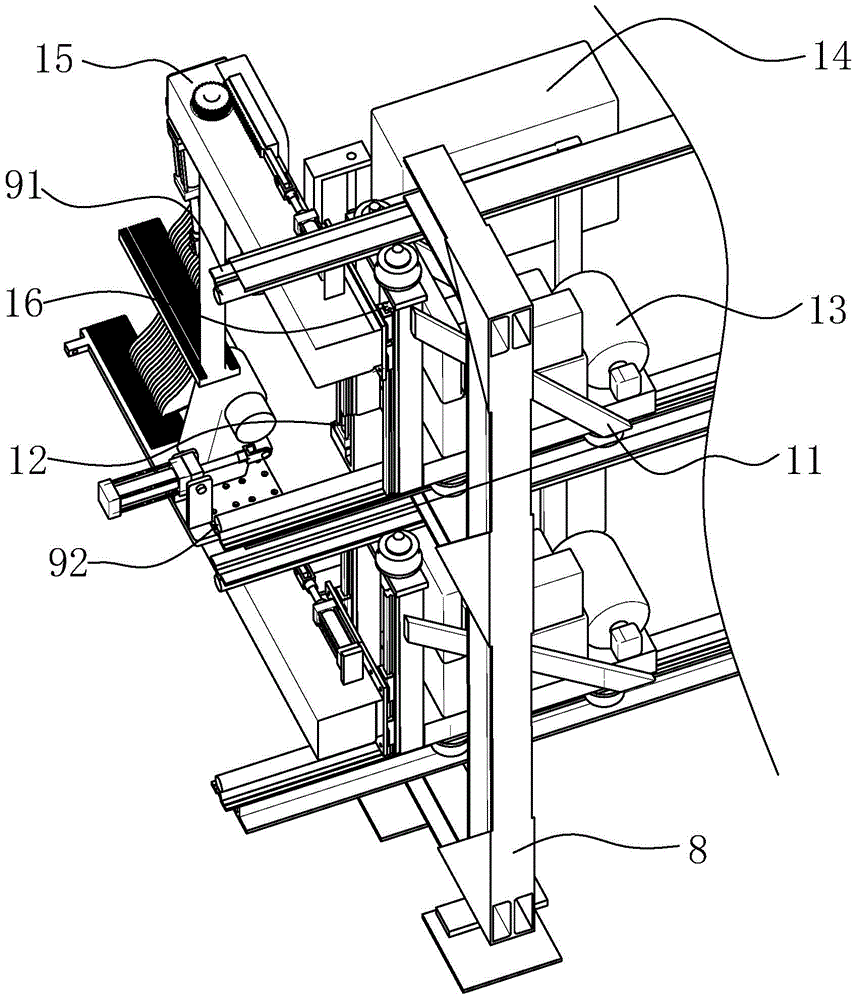

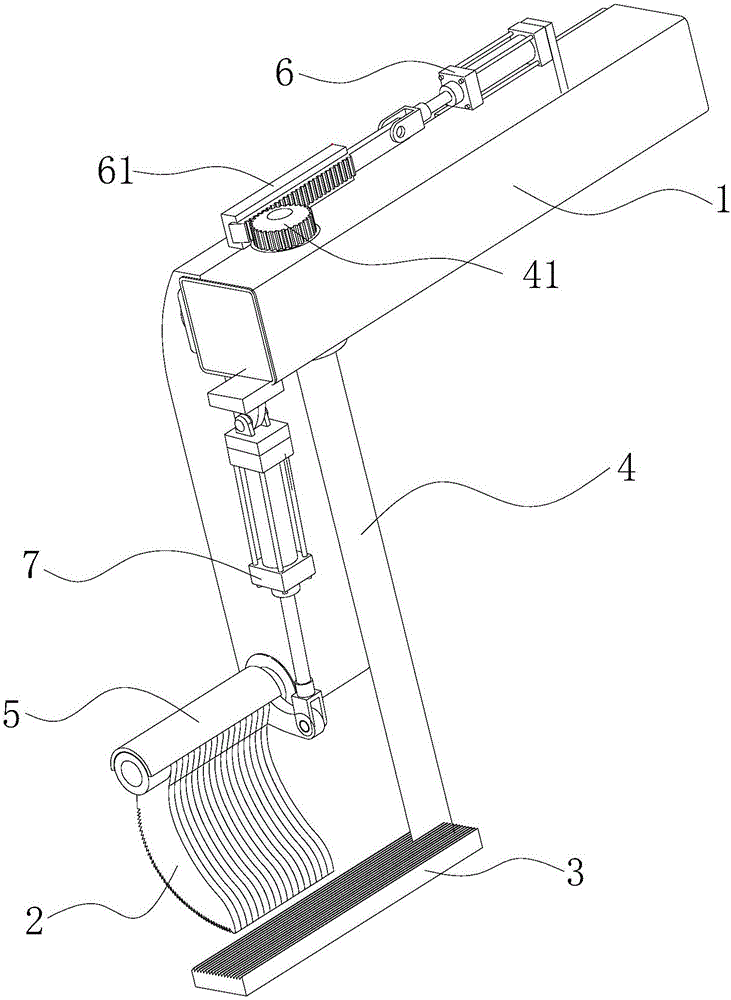

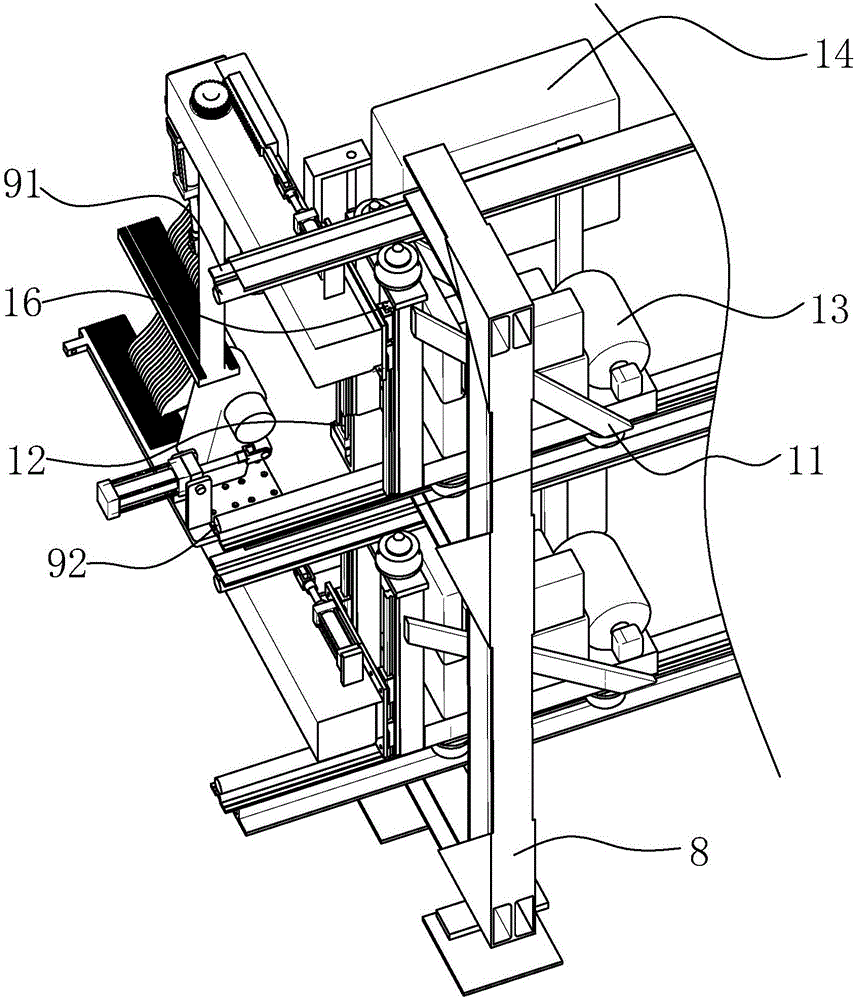

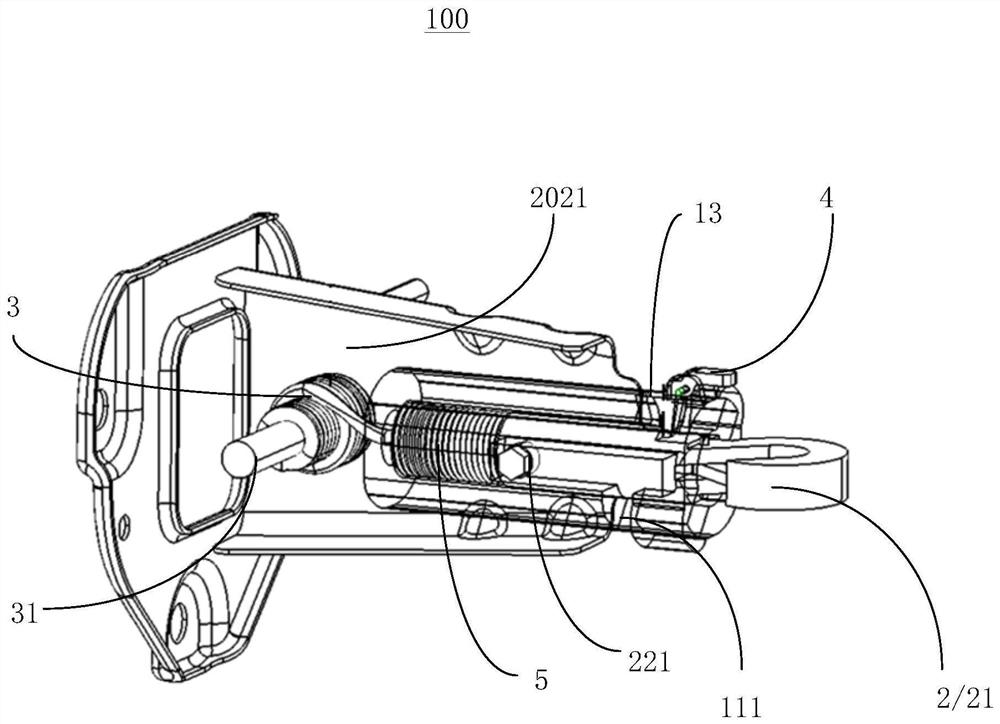

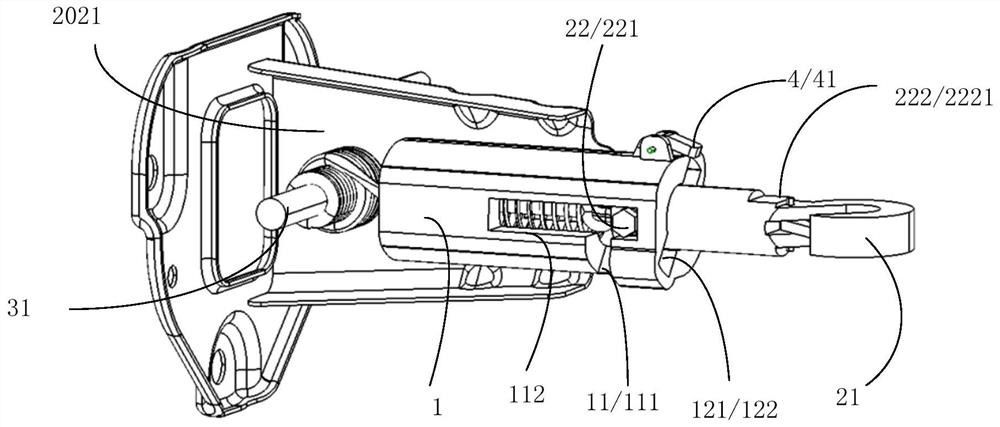

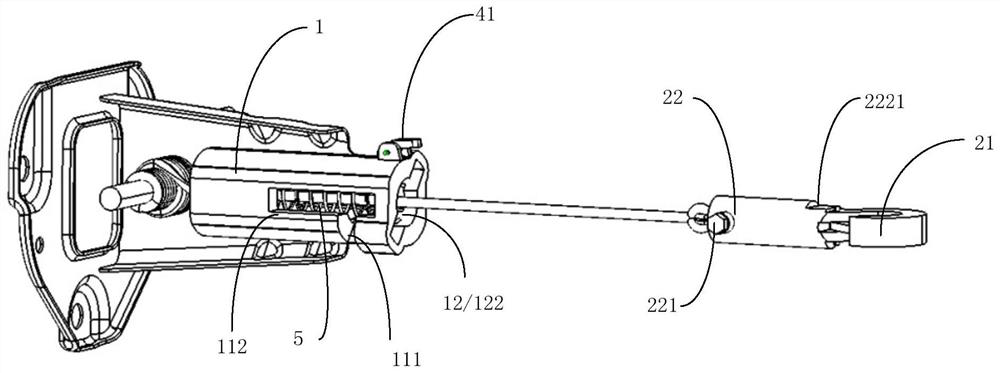

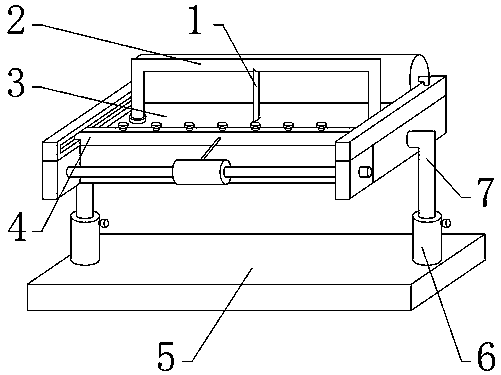

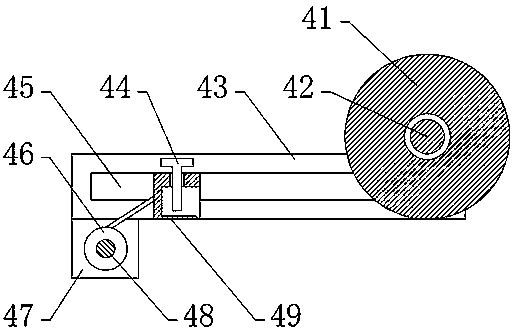

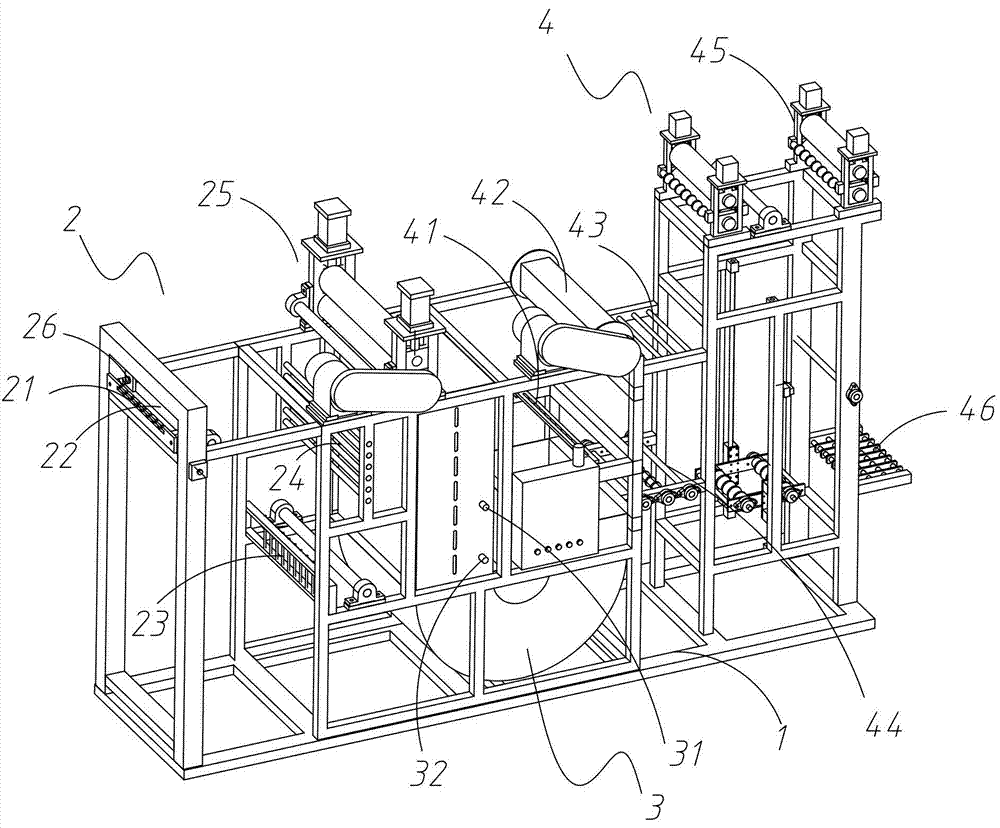

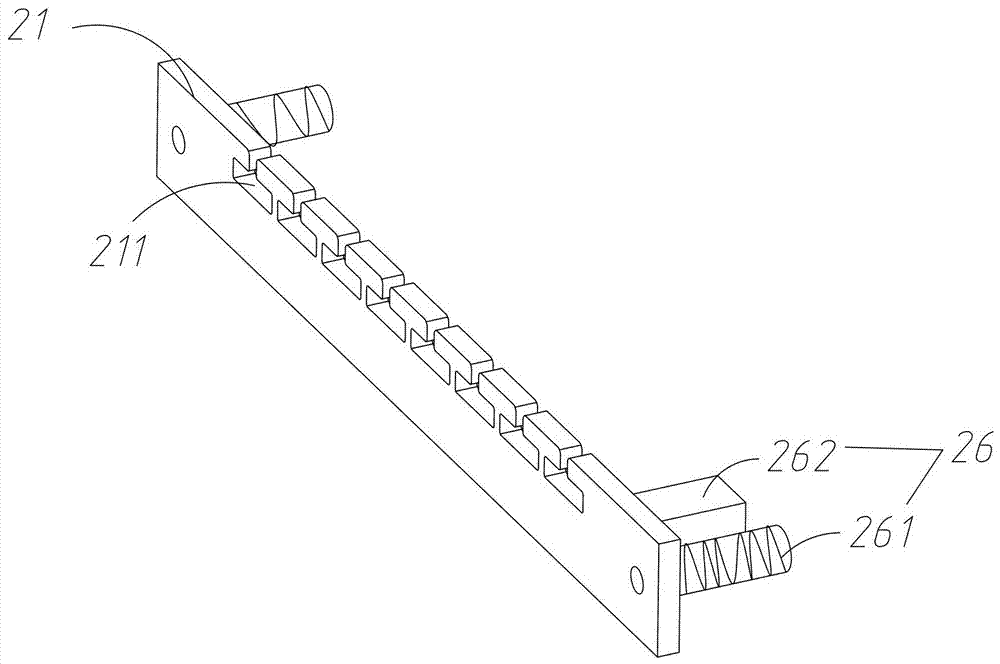

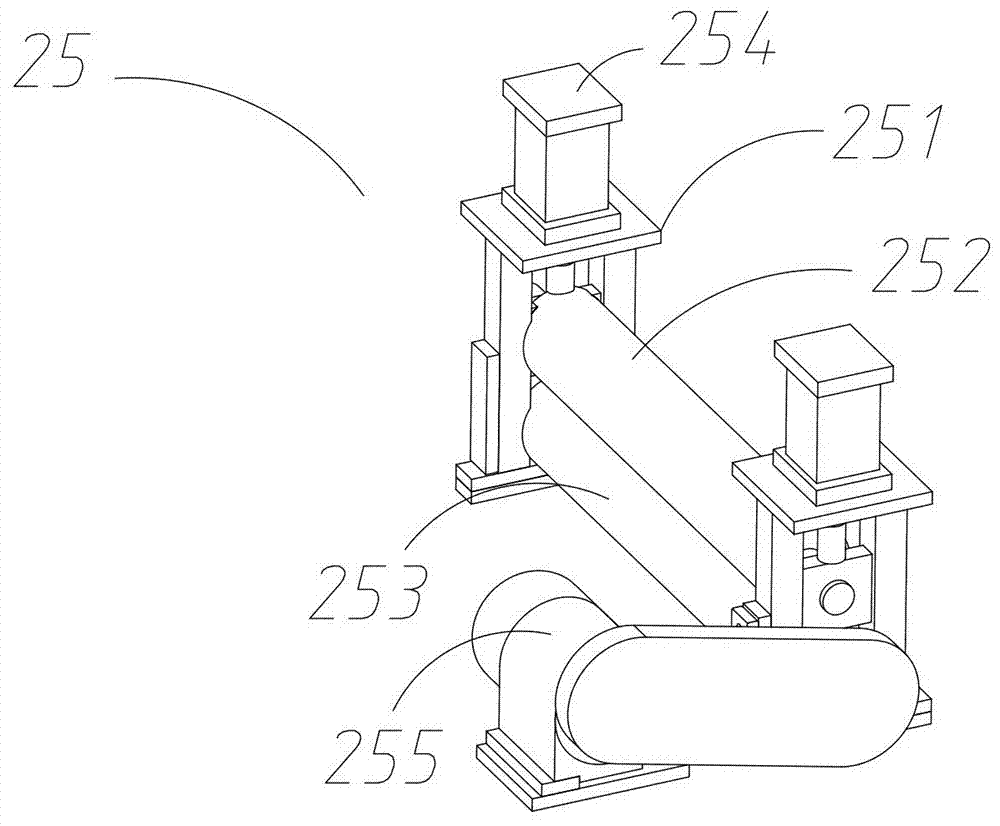

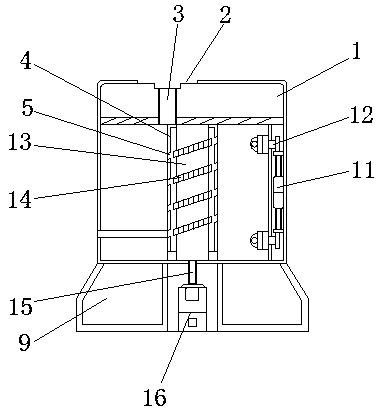

Clamping mechanism and tractor applying clamping mechanism

The invention discloses a clamping mechanism. The clamping mechanism comprises a base frame component and a clamping component, wherein the base frame component is provided with a longitudinal shaft component longitudinally extending and a transverse shaft component transversely extending; the clamping component comprises an upper jaw component and a support plate; the support plate is connected with the longitudinal shaft component, and rotates around the axis thereof; the upper jaw component is connected with the transverse shaft component, and rotates around the axis thereof; the longitudinal shaft component is connected with a longitudinal shaft driving component; the upper jaw component is connected with a transverse shaft driving component; and the longitudinal shaft driving component and the transverse shaft driving component are arranged on the base frame component. The transverse shaft driving component drives the upper jaw component to upwards rotate to release a profile in unloading; then, the longitudinal shaft driving component enables the support plate to rotate by a certain angle to leave from the bottom end of the profile; and the profile automatically drops down due to gravity, so that the time is saved, and the profile is not damaged. A tractor provided with the clamping mechanism can quickly tow the profile, and can quickly unload while undamaging the profile. The clamping mechanism and the tractor are used for large-span profiles, in particular for the clamping and quick traction of aluminum profiles.

Owner:佛山市腾和机械制造有限公司

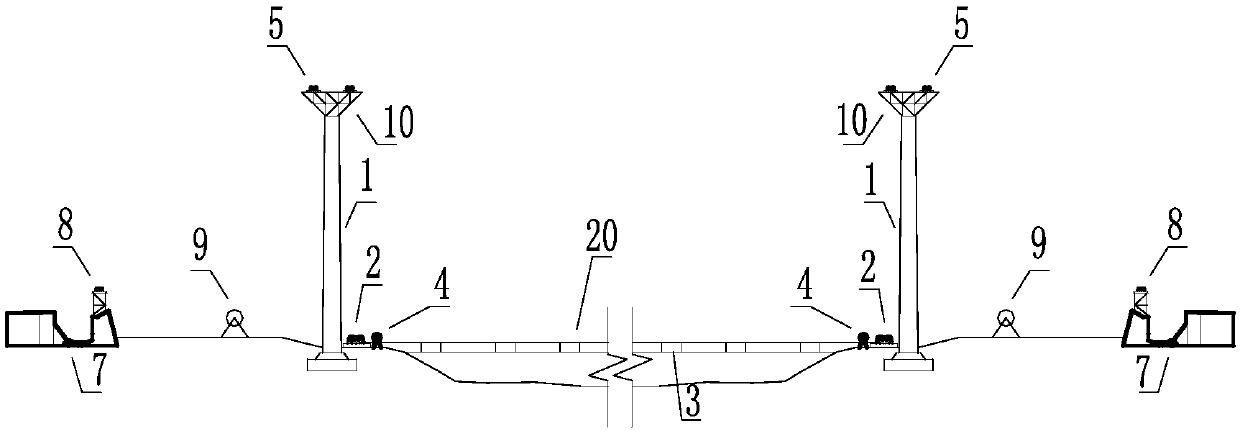

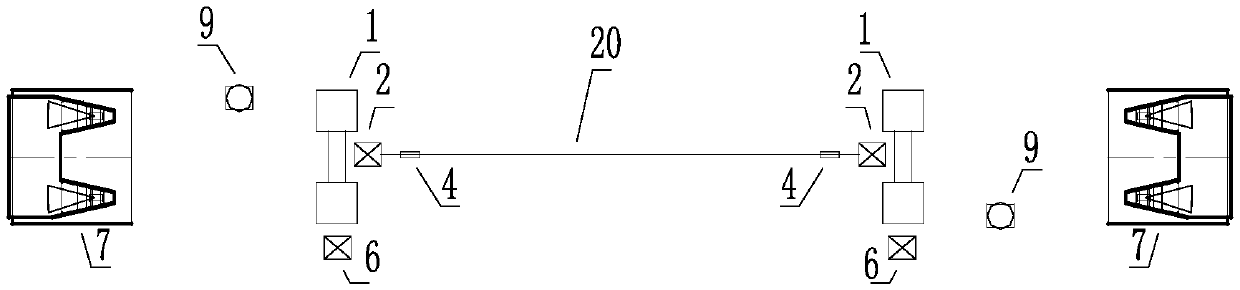

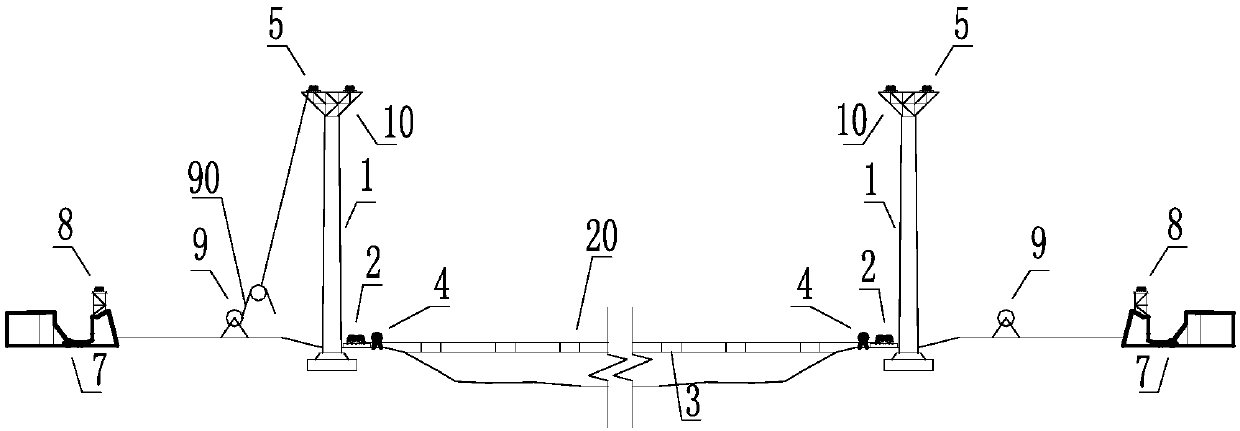

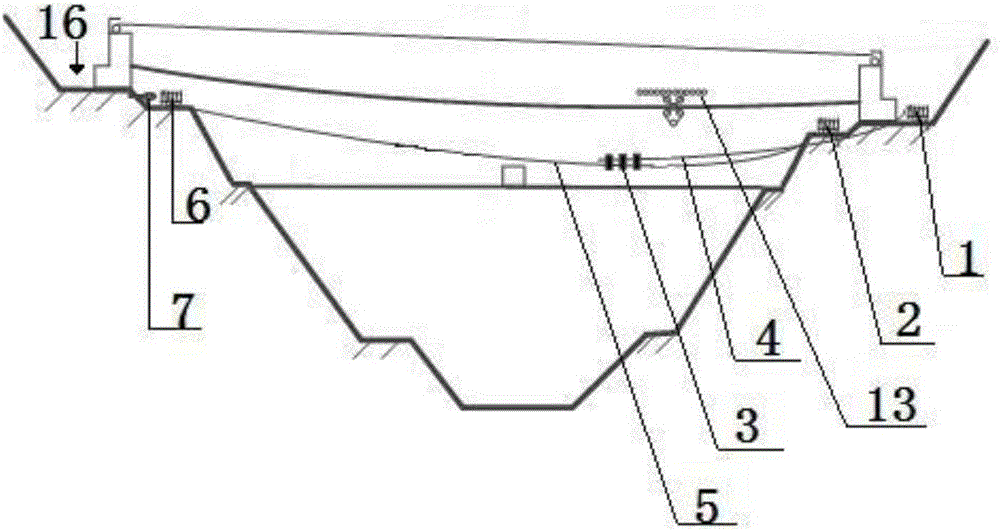

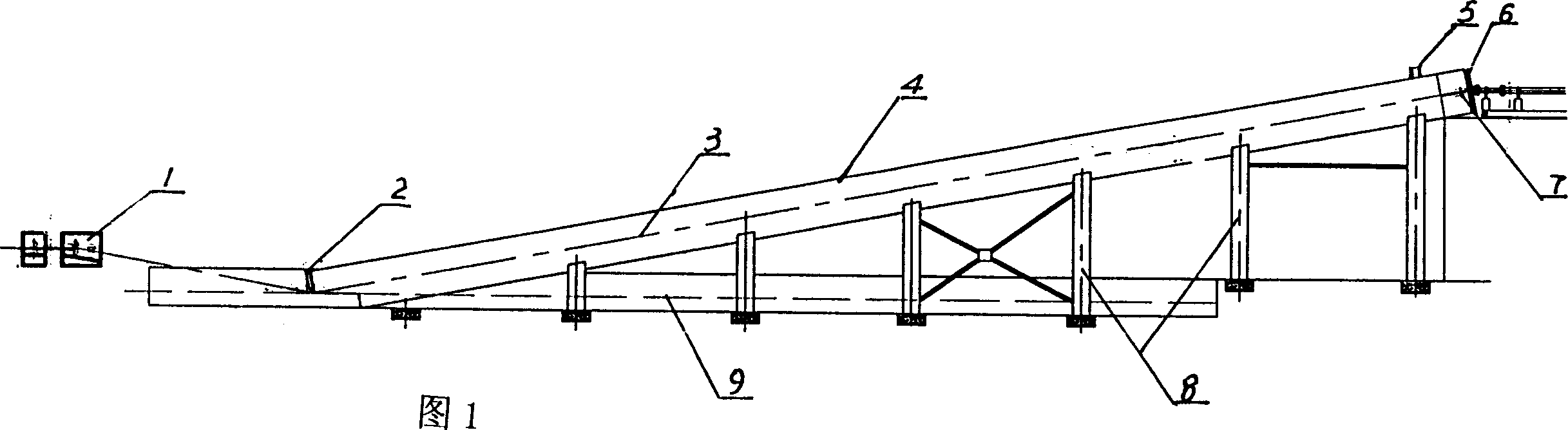

Catwalk cable erecting and hauling system for unnavigable waters and quick catwalk erecting method

PendingCN108018778AReduce the difficulty of towingReduce security risksBridge erection/assemblyEngineeringBuoy

The invention discloses a catwalk cable erecting and hauling system for unnavigable waters. The catwalk cable erecting and hauling system is separately arranged on two main towers on the two sides ofa water, and comprises two first wire reeling devices arranged on the two sides of the water, a buoy device floating on a water surface, two guide devices and two second wire reeling devices. The twofirst wire reeling devices are arranged along a bridge axis and located between the two main towers, and steel wire ropes of the two first wire reeling devices are connected and form a reciprocating haulage cable. The buoy device is used for bearing the haulage cable and a catwalk cable, and the buoy device comprises a plurality of buoys distributed in the direction of the bridge axis at intervals. The guide devices are used for guidance of the catwalk cable, and are arranged beside the two first wire reeling devices. The two wire reeling devices are arranged on the tops of the two main towerscorrespondingly. The invention further discloses a quick catwalk cable erecting method. According to the catwalk cable erecting and hauling system, the catwalk cable is changed to be hauled from thehigh altitude to be hauled on a ground water, the needed hauled force is small, the hauled speed is high, the hauling difficulty is lowered, and the safety risk is lowered.

Owner:中铁大桥局集团第六工程有限公司 +1

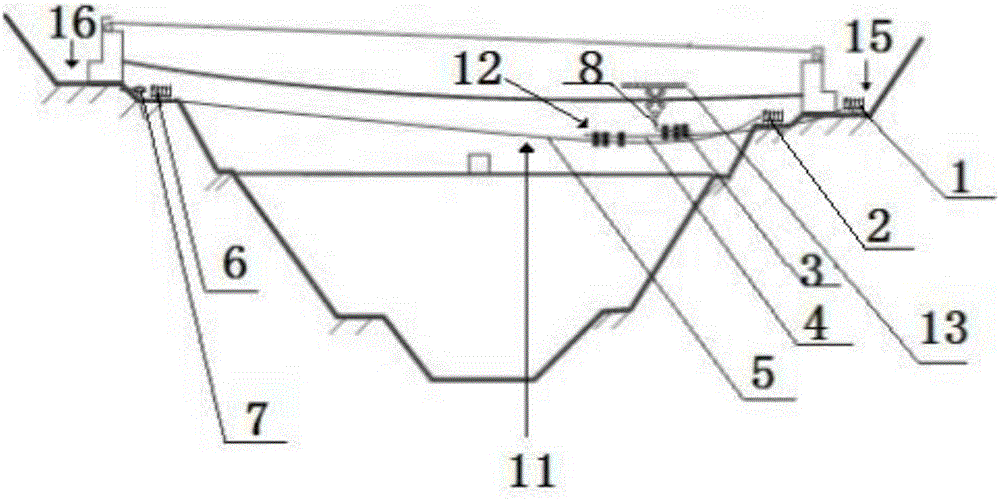

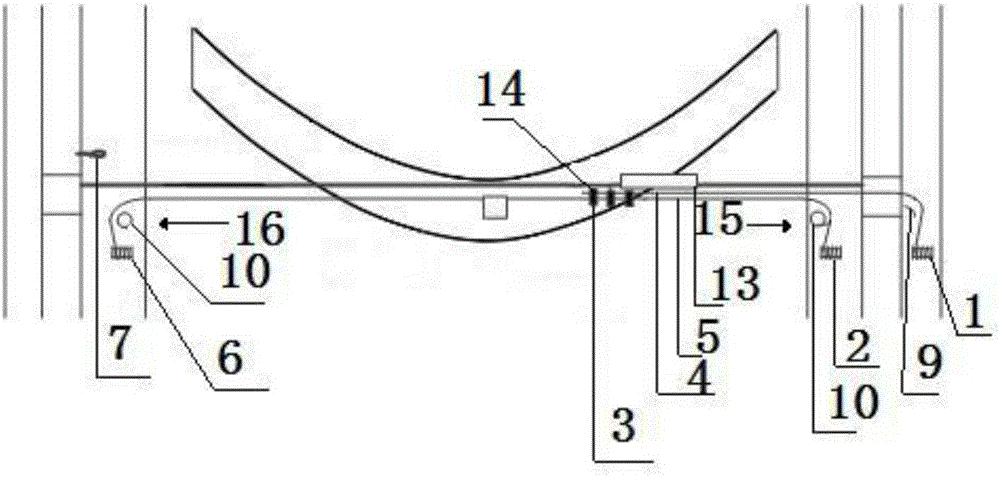

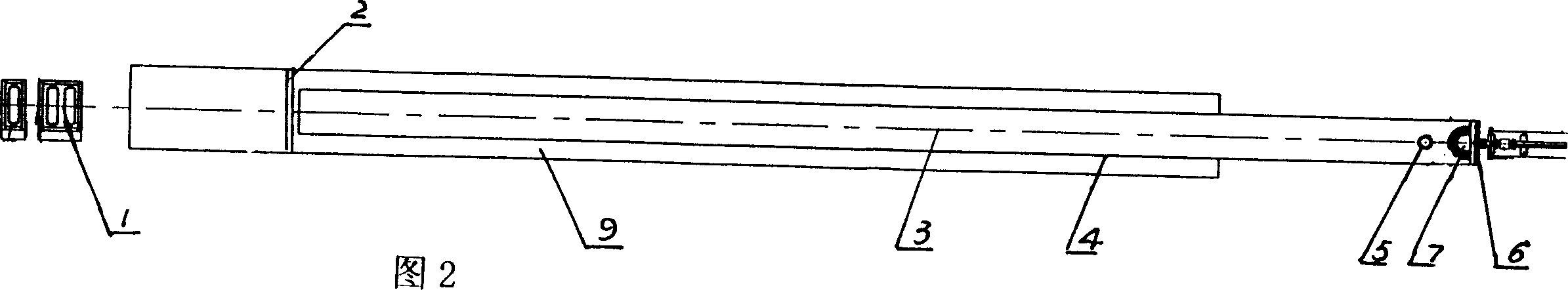

Structure and method for assisting traction skyline to cross river by cable crane traveling trolley

ActiveCN106044579AGuarantee the construction qualityAvoid entanglementWinding mechanismsCable carsTraction systemEngineering

The invention discloses a structure for assisting a traction skyline to cross a river by a cable crane traveling trolley. The structure comprises a traction system, a connection system, the cable crane traveling trolley and a lifting traction rope; the traction system comprises the cable crane traveling trolley, a reciprocating rope, a skyline windlass, an unwinding-side reciprocating rope windlass, a non-unwinding-side reciprocating rope windlass, a bent track and a guiding roller; the connection system comprises a rope clamp, a filling steel wire, an anchor device and the lifting traction rope; the lifting traction rope is connected with the skyline and the cable crane traveling trolley; the unwinding-side reciprocating rope windlass and the skyline windlass reel off ropes, the non-unwinding-side reciprocating rope windlass takes in the rope, and the cable crane traveling trolley moves towards a non-unwinding side under the drive of a traction mechanism. The structure overcomes the disadvantages, i.e., low efficiency, long construction period and potential safety hazards in the prior art and has the advantages of short construction period, stable traction process, high economic benefit and high coefficient of safety of river crossing. The invention further discloses a method for assisting the traction skyline to cross the river by the cable crane traveling trolley.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

A clamping mechanism and traction machine using the clamping mechanism

The invention discloses a clamping mechanism. The clamping mechanism comprises a base frame component and a clamping component, wherein the base frame component is provided with a longitudinal shaft component longitudinally extending and a transverse shaft component transversely extending; the clamping component comprises an upper jaw component and a support plate; the support plate is connected with the longitudinal shaft component, and rotates around the axis thereof; the upper jaw component is connected with the transverse shaft component, and rotates around the axis thereof; the longitudinal shaft component is connected with a longitudinal shaft driving component; the upper jaw component is connected with a transverse shaft driving component; and the longitudinal shaft driving component and the transverse shaft driving component are arranged on the base frame component. The transverse shaft driving component drives the upper jaw component to upwards rotate to release a profile in unloading; then, the longitudinal shaft driving component enables the support plate to rotate by a certain angle to leave from the bottom end of the profile; and the profile automatically drops down due to gravity, so that the time is saved, and the profile is not damaged. A tractor provided with the clamping mechanism can quickly tow the profile, and can quickly unload while undamaging the profile. The clamping mechanism and the tractor are used for large-span profiles, in particular for the clamping and quick traction of aluminum profiles.

Owner:佛山市腾和机械制造有限公司

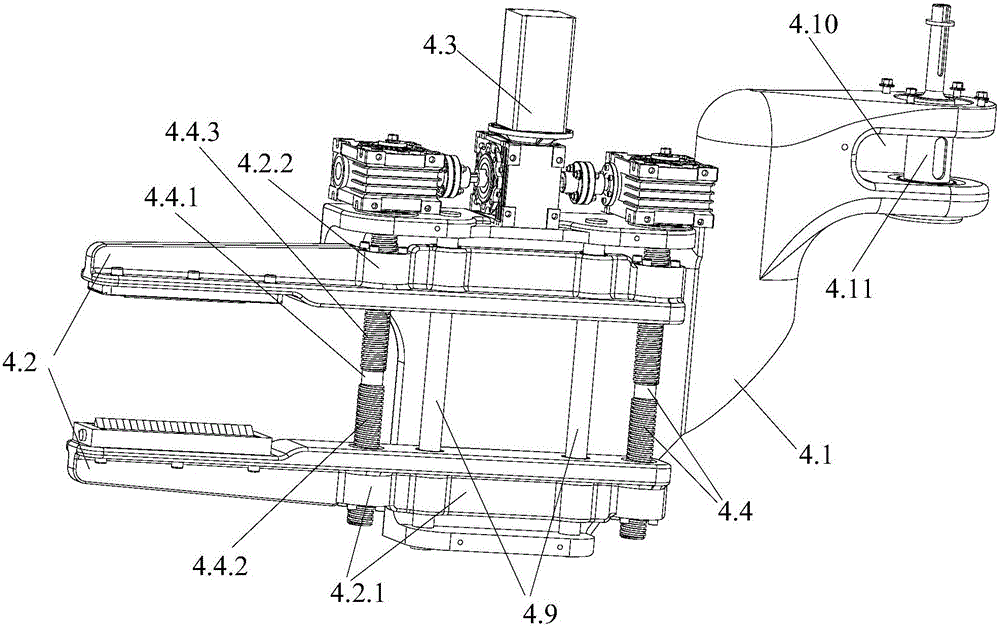

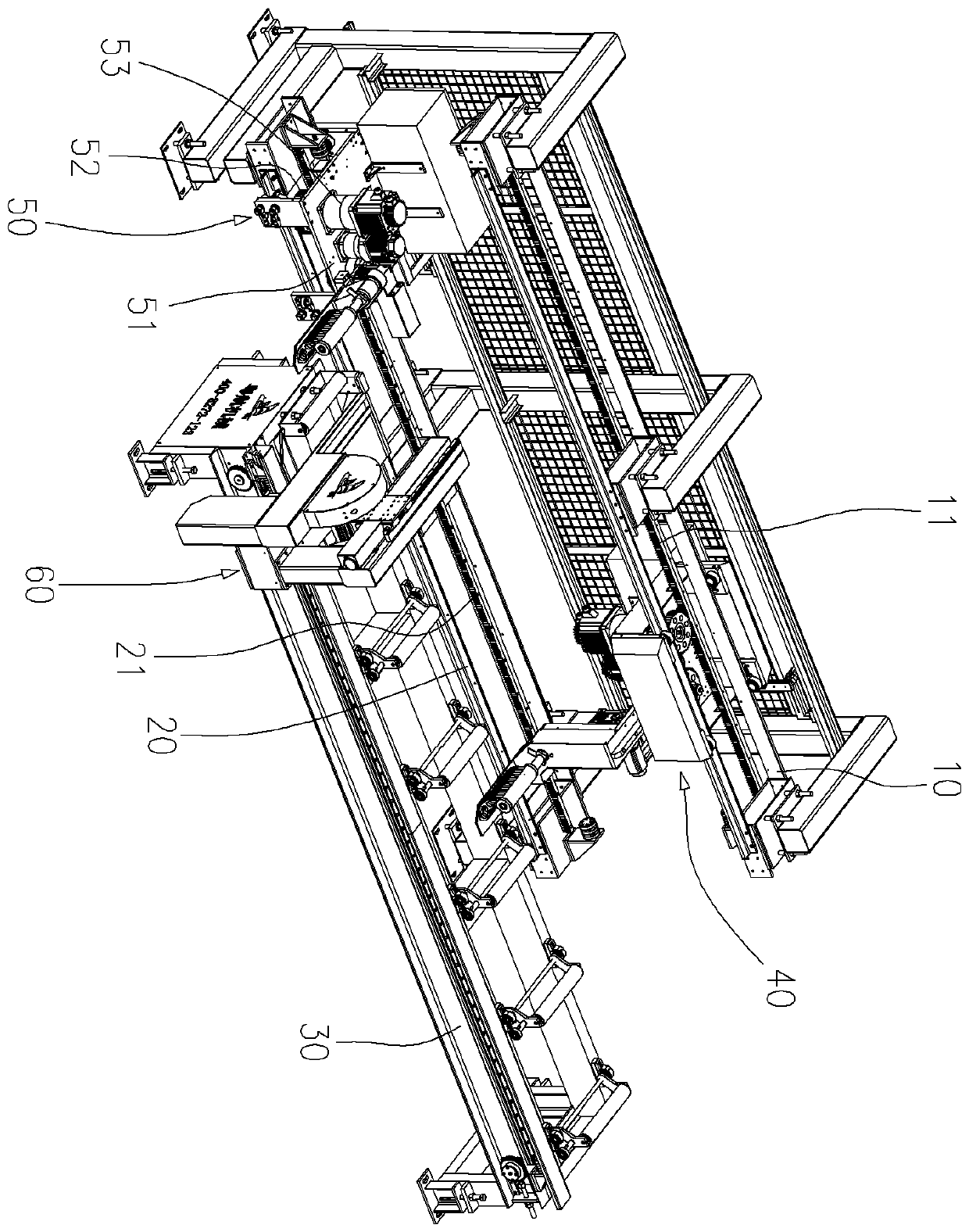

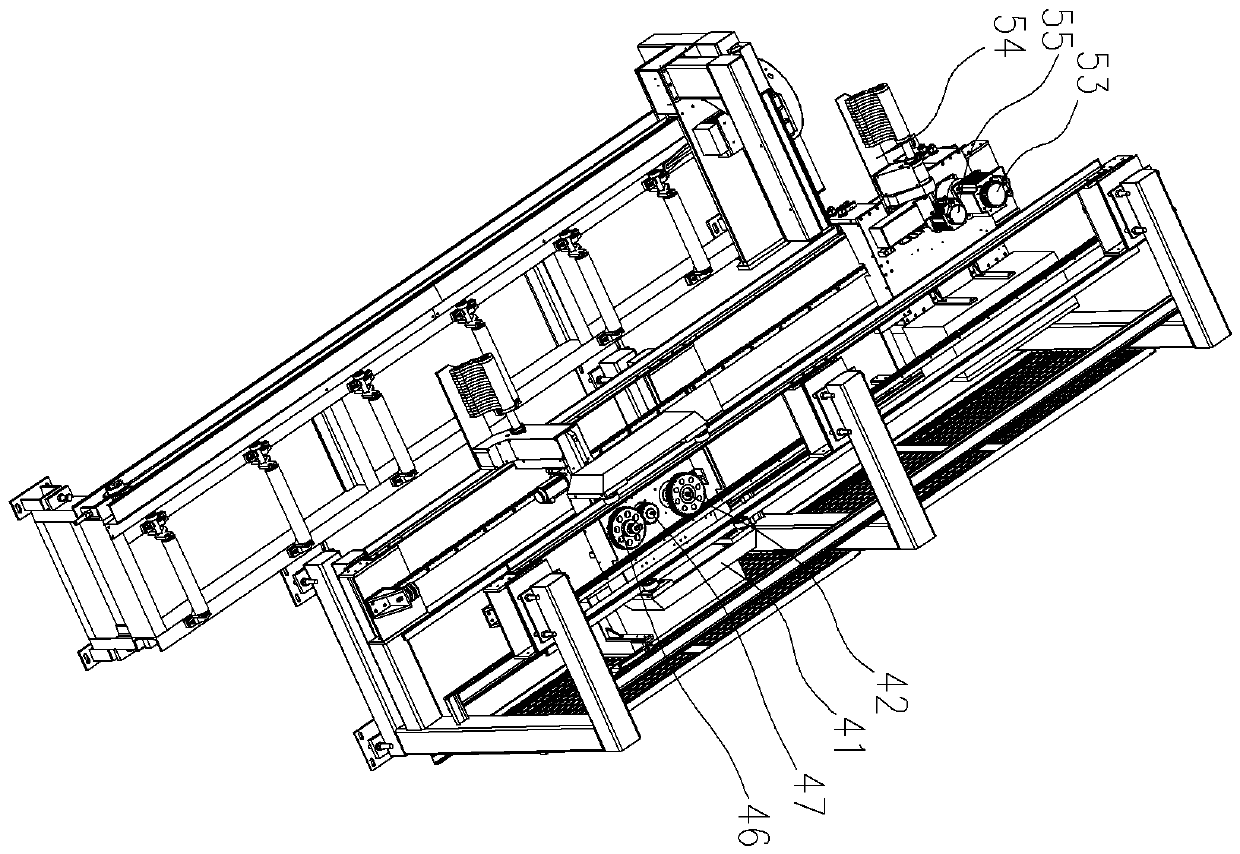

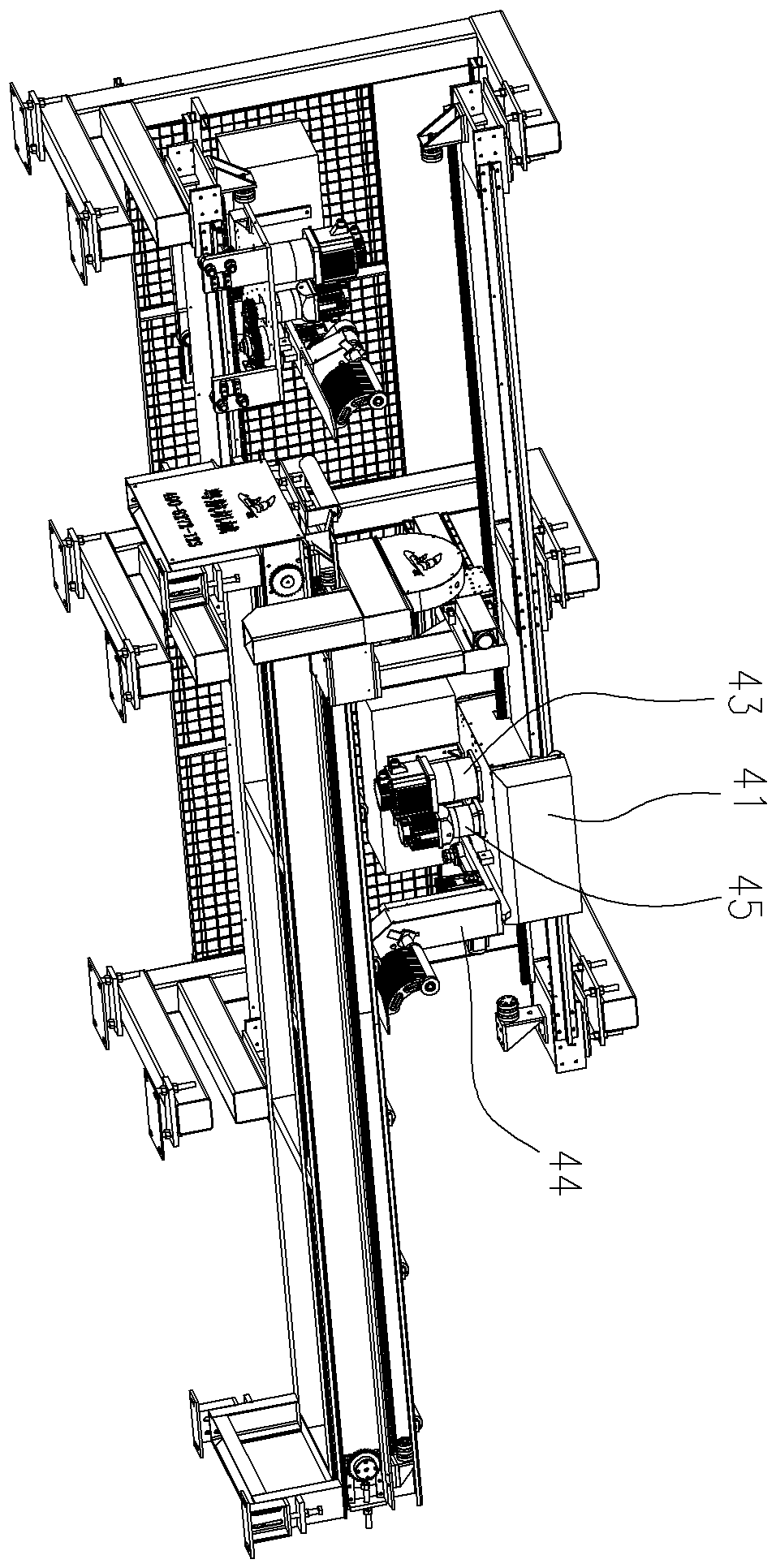

1000T pure-electric three-head tractor

The invention provides a 1000T pure-electric three-head tractor. The 1000T pure-electric three-head tractor comprises an upper layer guide rail unit, a lower layer guide rail unit, a roller frame, a first drawing head, a second drawing head and an automatic interruption saw; the middle part of the upper layer guide rail unit is provided with a first rack; the middle part of the lower layer guide rail unit is provided with a second rack; the first drawing head comprises a first drawing vehicle, a first driving gear and a first servo motor, wherein the first driving gear is arranged inside the first drawing vehicle and is engaged with the first rack; the first servo motor is reversely arranged at the bottom of the first drawing vehicle and is in transmission connection with the first drivinggear; the second drawing head comprises a second drawing vehicle, a second driving gear and a second servo motor, wherein the second driving gear is arranged inside the second drawing vehicle and isengaged with the second rack; and the second servo motor is reversely arranged at the top of the second drawing vehicle and is in transmission connection with the second driving gear. The 1000T pure-electric three-head tractor provided by the invention has the advantages of extremely high drawing speed, flexible start and braking, small inertia, relatively low running noise, stable performances, low fault rate and the like.

Owner:FOSHAN JINHANYUE HAIHANG MACHINERY EQUIP

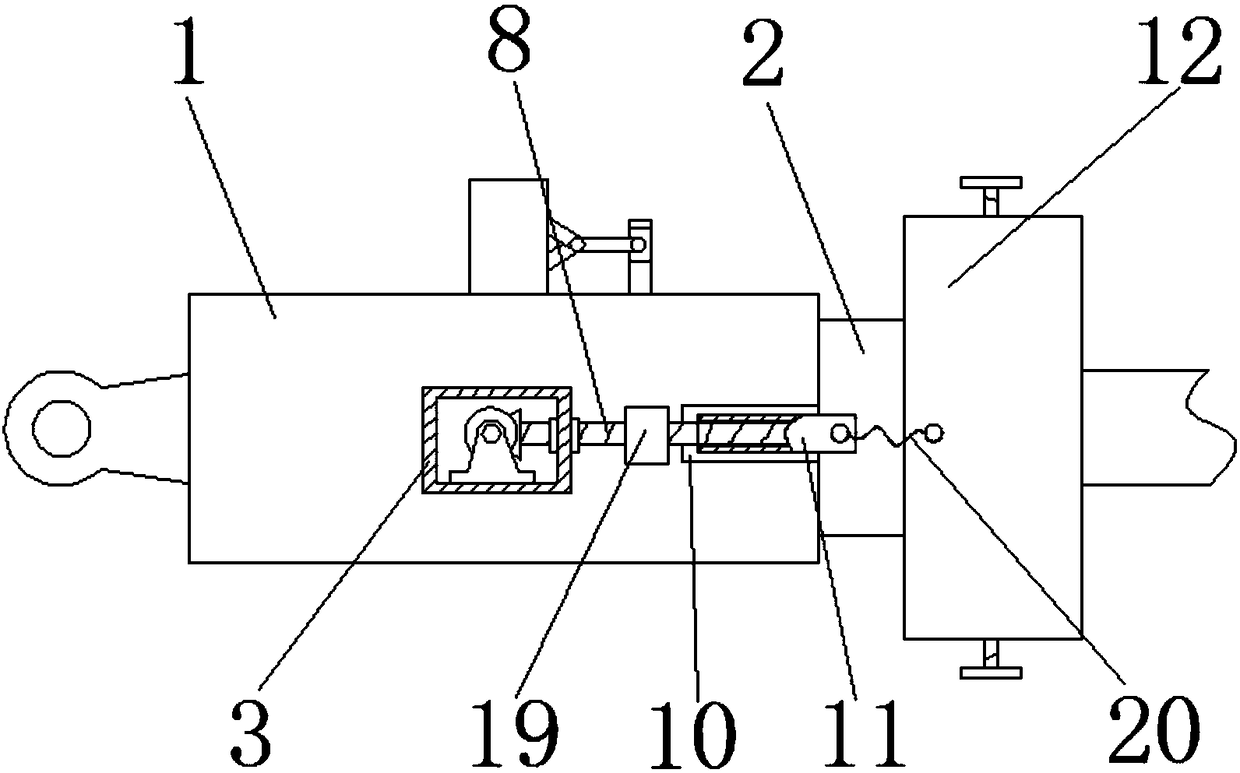

Automobile trailer structure and automobile

ActiveCN113415112AFast tractionImprove rescue efficiencyTowing devicesBumpersControl theoryMechanical engineering

The invention discloses an automobile trailer structure and an automobile. The automobile trailer structure comprises a mounting seat, a trailer hook and a trailer rope, wherein the mounting seat is used for being arranged on an anti-collision beam; the tow hook is detachably mounted on the mounting seat and is provided with a mounting position fixed on the mounting seat and a separation position separated from the mounting seat; one end of the towing rope is connected to the mounting seat in a retractable manner, and the other end of the towing rope is connected with the towing hook. The automobile trailer structure is advantaged in that one end of the tow rope is connected to the mounting seat in a retractable manner, and the other end of the tow rope is connected with the tow hook, so the tow rope and the tow hook are integrated, the tow rope is directly pulled out through the tow hook to assemble an anchored vehicle, rapid vehicle traction is realized, and rescue efficiency is improved.

Owner:DONGFENG LIUZHOU MOTOR

Vacuum cylinder for producing cystosepiment

The invention relates to a vacuum cylinder which can be used to produce the thermal plastic foam sheet as polyethylene, polyphenylacetylene, etc, wherein it comprises: a vacuum cylinder, a transmit band, a support column, and a water groove; said vacyym cylinder contains transmit band, while its lower part has support column; said cylinder is inclined mounted on the support column, while its upper part has vacuum exhaust open through to the vacuum pump; the lower part of cylinder has a water groove with water baffle plate; the high end of cylinder has vacuum sealing plate; and the high part of vacuum cylinder ahs the foaming sheet inlet, while its lower part has the foaming sheet outlet; the difference between the high and lower parts is 2-10m; and the diameter of said vacuum cylinder is 1-4m.

Owner:南京法宁格挤塑保温隔热板有限公司

MuLtifunctionaL garment-Lace processing device

InactiveCN108867016AEasy Steering AdjustmentImprove use comfort performanceSevering textilesEngineeringBolt connection

The invention provides a muLtifunctionaL garment-Lace processing device. The muLtifunctionaL garment-Lace processing device comprises a roLLer wheeL, a U-shaped frame, connecting pLates, Locking boLts, sLiding grooves, a puLLing rope, ear pLates, a rotating rod and sLiding strip bLocks, wherein the roLLer wheeL is in roLLing connection on the U-shaped frame, the U-shaped frame is arranged at the upper ends of the connecting pLates, the ear pLates are fixed to the front portions of the Lower end faces of the connecting pLates through boLts, and are connected on the Left side and the right sideof the rotating rod through bearings, the puLLing rope is wound around the rotating rod, and is fixed in the middLes of the front end faces of the sLiding strip bLocks through screws, the sLiding grooves are formed in the inner side faces of the connecting pLates, the sLiding strip bLocks are arranged on the sLiding grooves, the Locking boLts are connected at the upper ends of the sLiding strip bLocks, and the Lower ends of the Locking boLts extend into the sLiding strip bLocks. Garment Lace can be rapidLy puLLed through the design, the muLtifunctionaL garment-Lace processing device is convenient to use and operate and capabLe of rapidLy puLLing, and the using comfort degree is improved.

Owner:江苏阳光毛纺服装技术开发有限公司

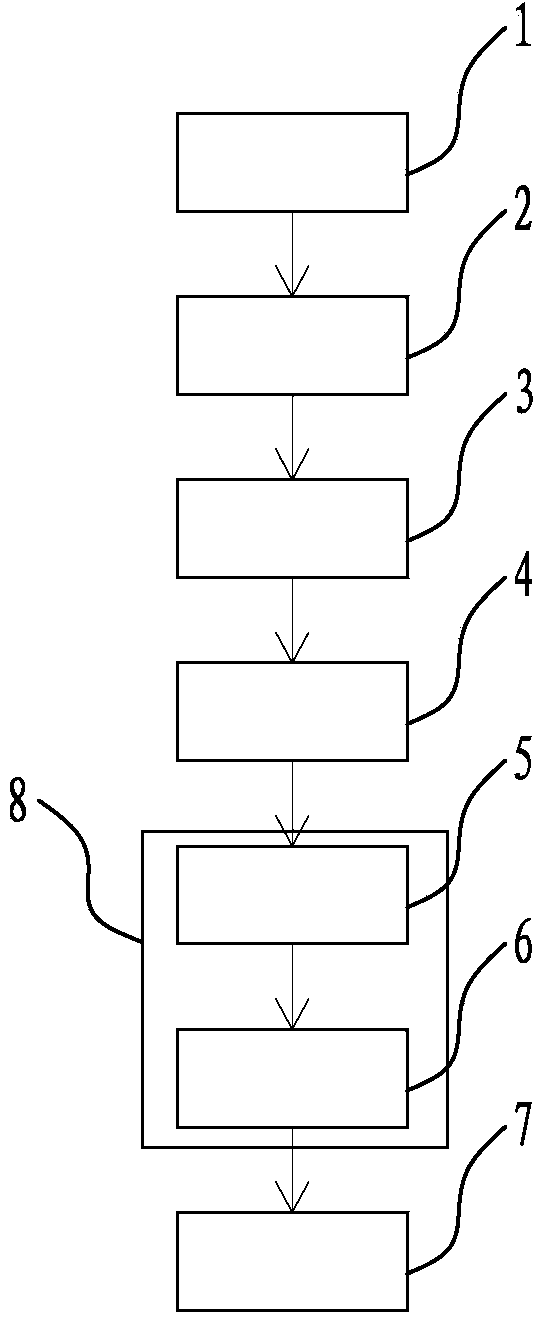

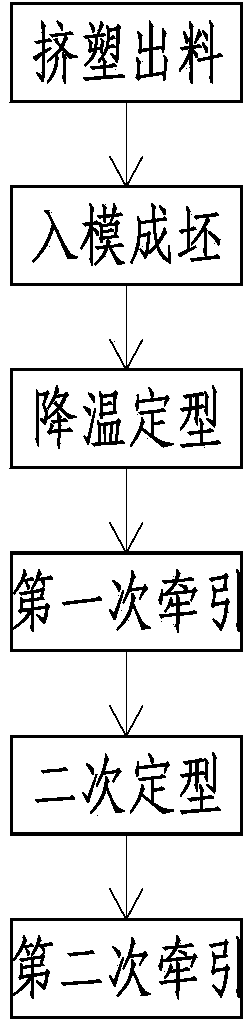

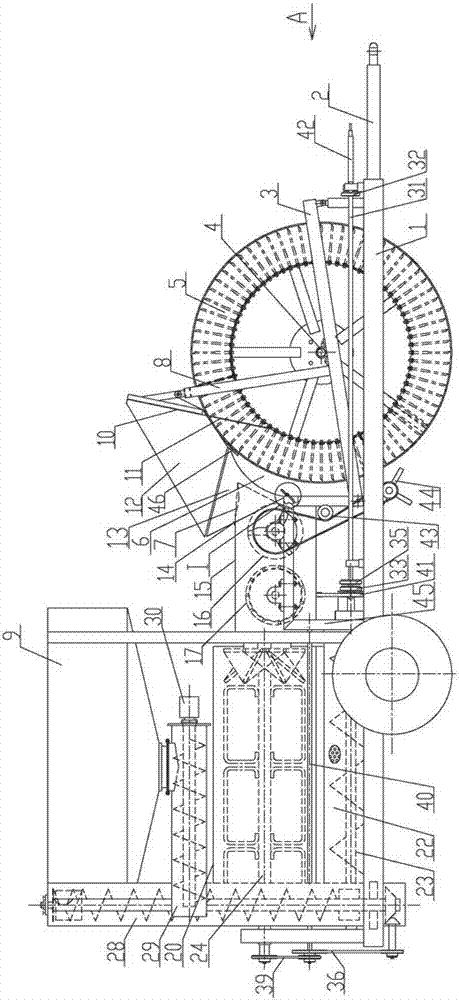

Production process and production equipment for secondary shaping of PVC (Polyvinyl Chloride) foaming core plate

ActiveCN103895212AAvoid stabilityAvoid easy to cause shrinkage changes to cause cracksPolyvinyl chlorideManufacturing engineering

The invention relates to the field of production of PVC (Polyvinyl Chloride) foaming plates and particularly relates to production process and production equipment for secondary shaping of a PVC foaming core plate, aiming at the technical defects that the finished PVC foaming core plate product manufactured by using an existing one-time shaping production process easily has contraction deformation and arch bending. The production process comprises the following sequential steps: (1) extruding and discharging; (2) putting materials into a die to form a blank; (3) cooling and shaping; (4) drawing for the first time; (5) shaping for the second time; and (6) drawing for the second time. According to the production process and the production equipment, the PVC foaming core plate is machined by carrying out two-time temperature raising on the materials and the plate blank and carrying out two-time cooling and shaping on the plate bank, so as to effectively reduce shrinkage ratio and the arch bending rate of the PVC foaming core plate and improve the product quality of the PVC foaming core plate; the problems caused by existing one-time shaping process and equipment of the PVC foaming core plate are solved.

Owner:ZHEJIANG TIANZHEN BAMBOO & WOOD DEV

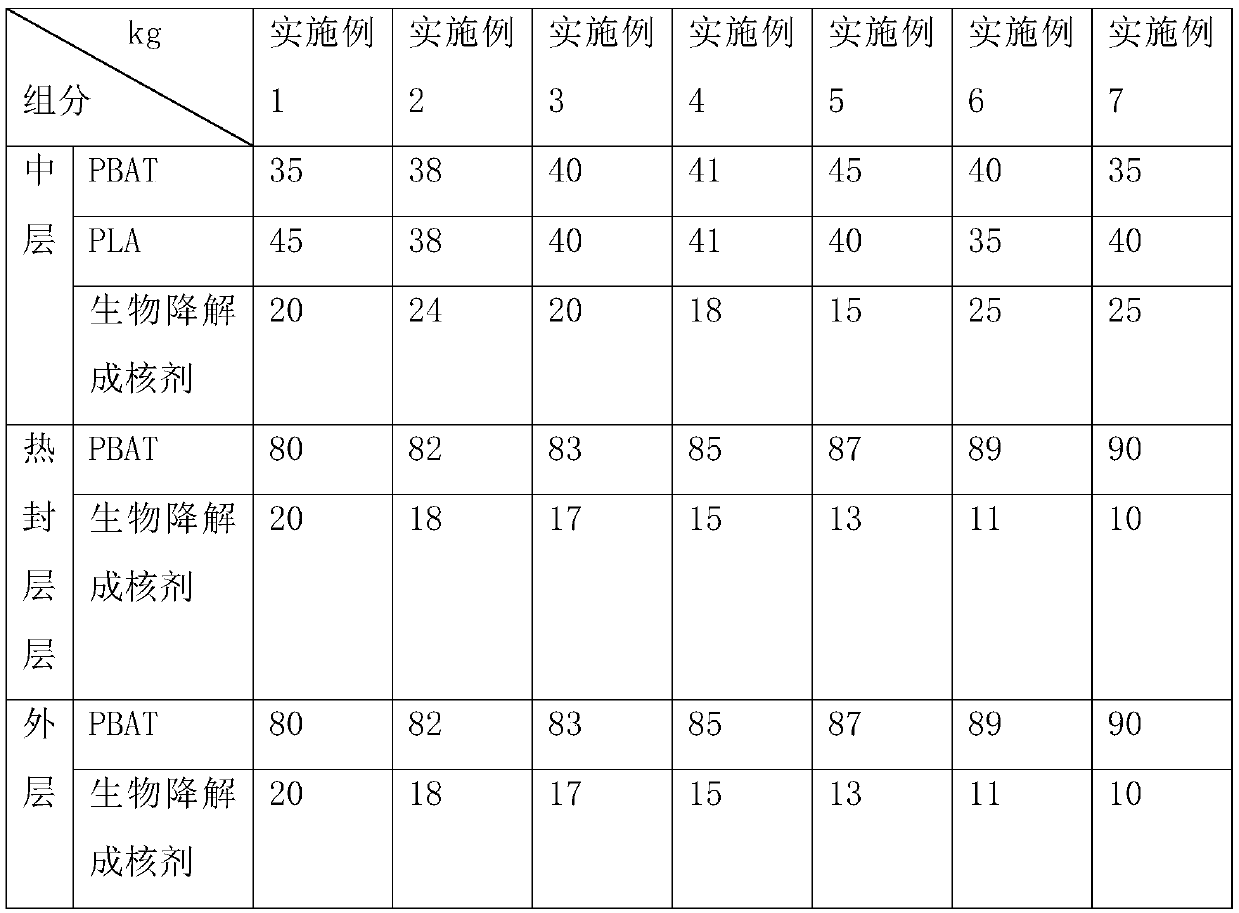

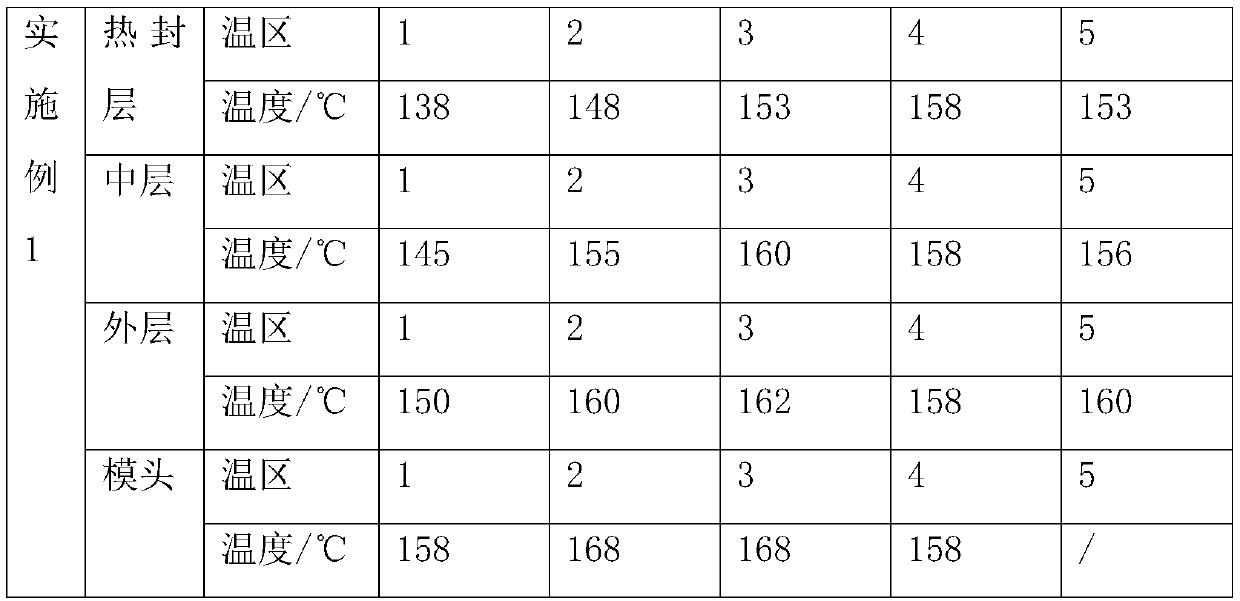

Degradable heat sealing film for compounding and preparation method thereof

InactiveCN111055564AAvoid gelatinizationAchieve secondary stretchSynthetic resin layered productsFlat articlesPolymer sciencePolymer chemistry

The invention discloses a degradable heat sealing film for compounding and a preparation method thereof. The degradable heat sealing film comprises a heat sealing layer, a middle layer and an outer layer, which are connected in sequence. The middle layer comprises the following components in parts by weight: 35 to 45 parts of PBAT, 35 to 45 parts of PLA, and 15 to 25 parts of a biodegradable nucleating agent; the heat sealing layer comprises the following components in parts by weight: 80 to 90 parts of PBAT and 10 to 20 parts of a biodegradable nucleating agent; and the outer layer comprisesthe following components in parts by weight: 80-90 parts of PBAT and 10-20 parts of a biodegradable nucleating agent. The degradable heat sealing film has the advantages that the crystallization rateof an extruded material is high, the melt strength is high, the film is not easy to break under traction, the film is easy to form, the heat sealing property is good, the printing effect is good, thehardness is moderate, certain softness and certain stiffness can be considered, and the degradable heat sealing film can be compounded with a printed film to be used as a heat-sealing layer and can beindependently made into bags.

Owner:青岛东海包装产业有限公司

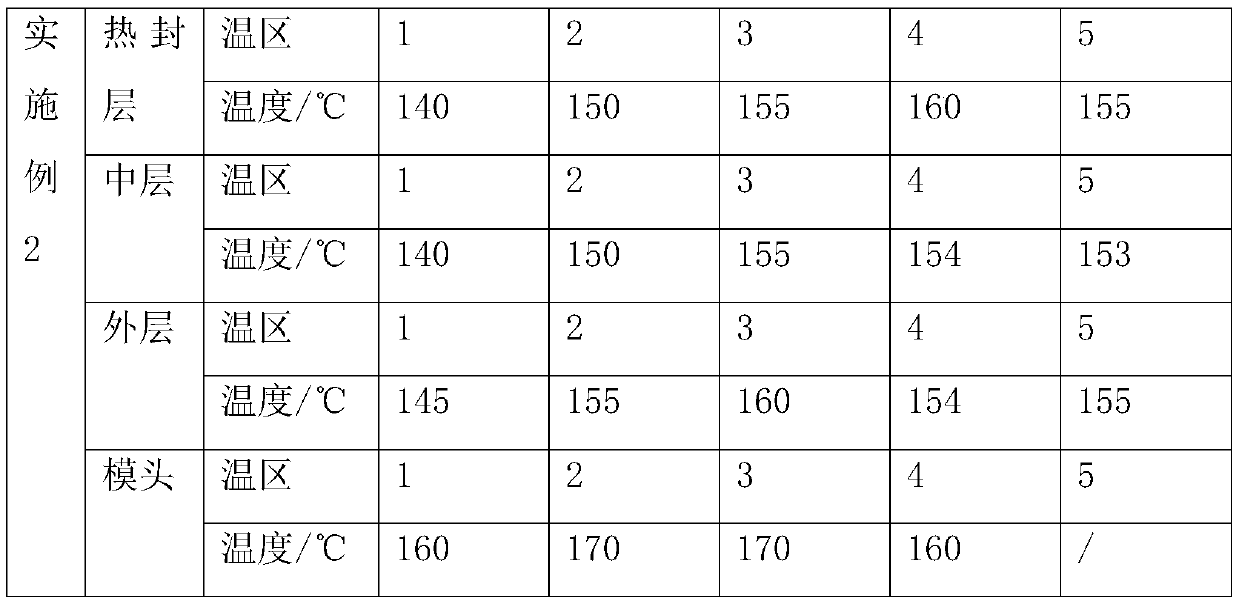

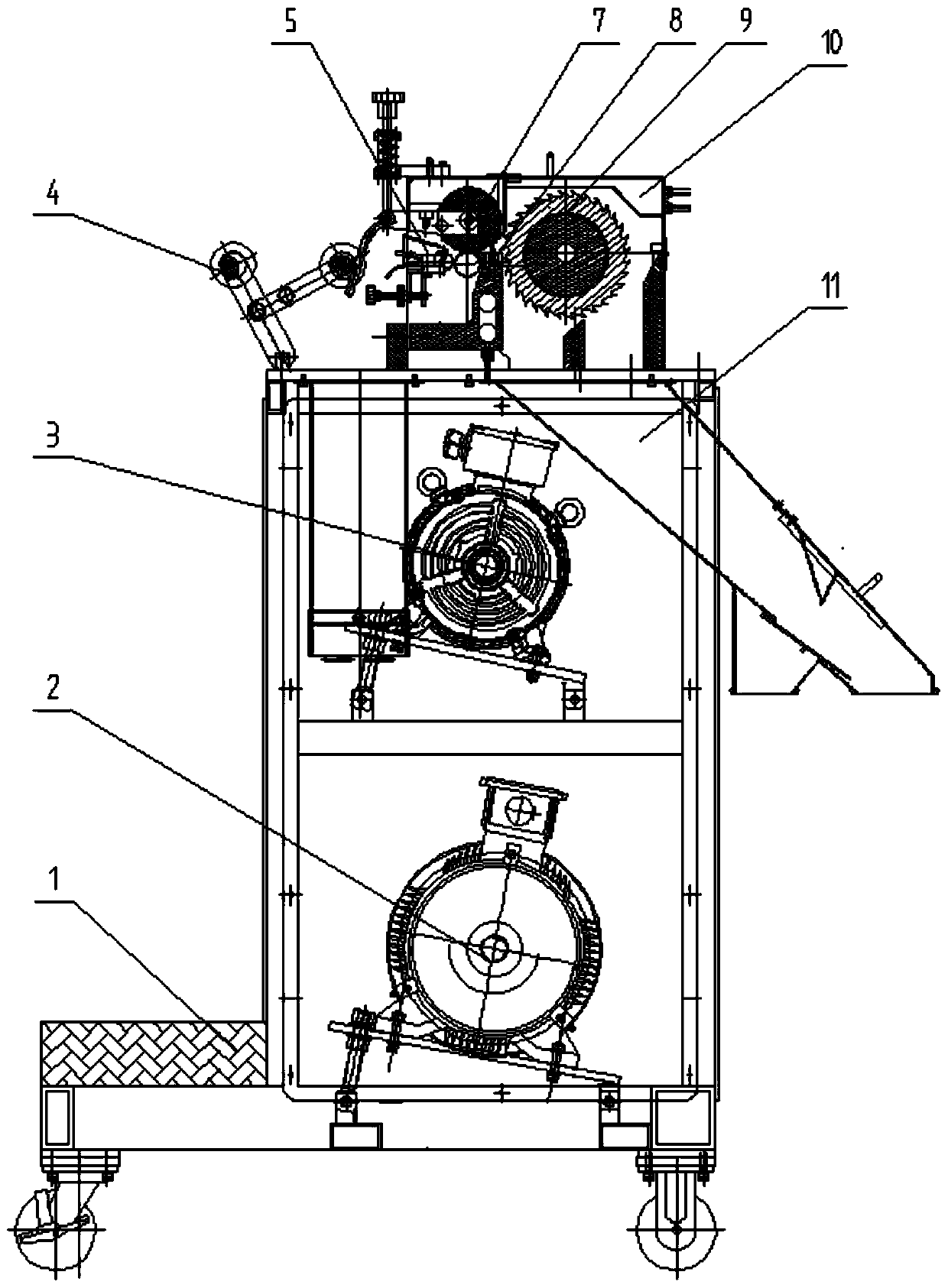

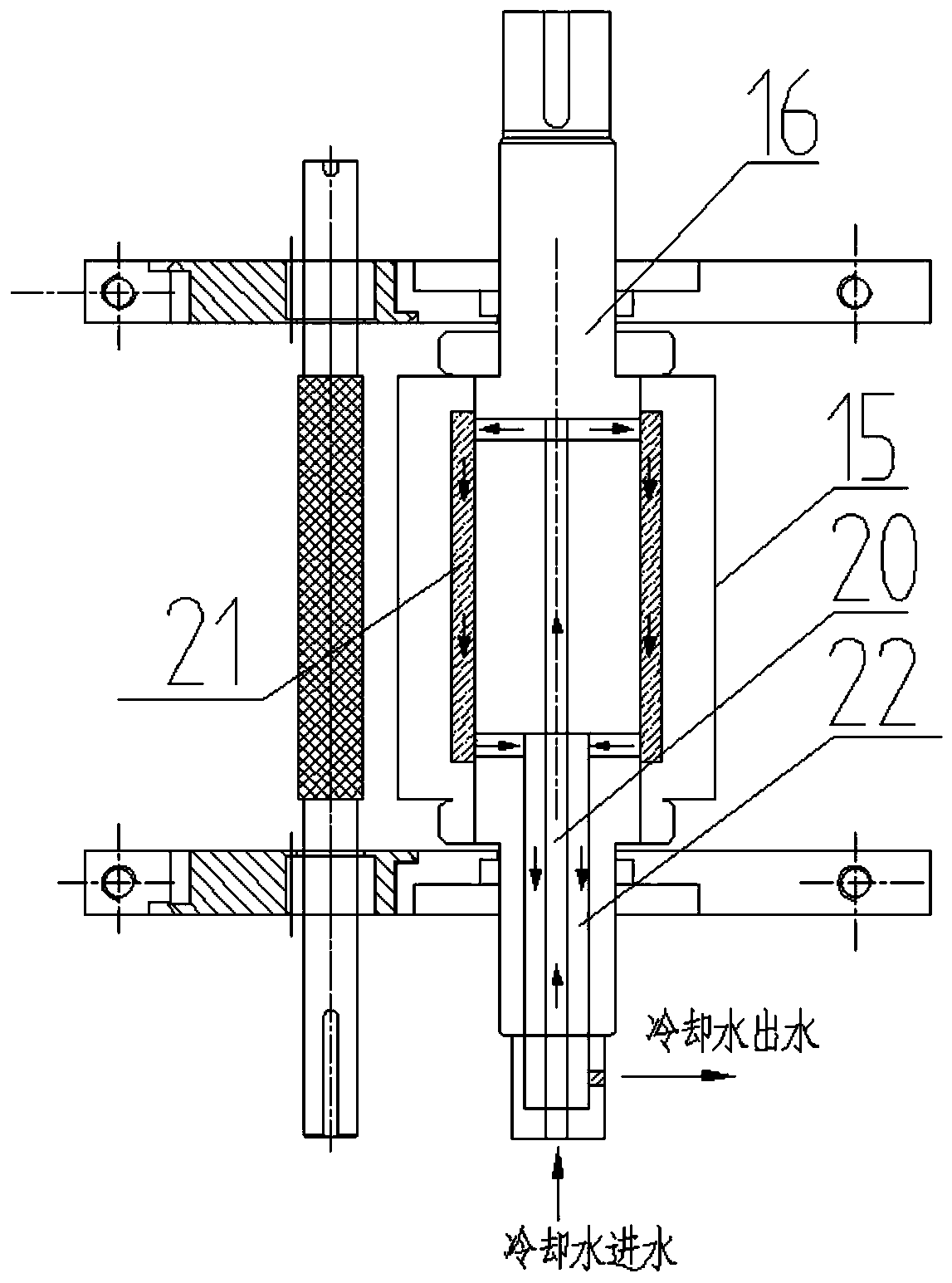

Water-cooled bracing and dicing machine

PendingCN111590675ANovel structureStable structureMetal working apparatusThermal dilatationStructural engineering

The invention discloses a water-cooled bracing and dicing machine, and belongs to the technical field of bracing and dicing machines. The water-cooled bracing and dicing machine comprises a bracing and dicing machine body used for dicing a material strip, the bracing and dicing machine body comprises a movable cutter assembly, the movable cutter assembly comprises a movable cutter shaft and a movable cutter installed on the movable cutter shaft, and a cooling water channel is formed in the movable cutter shaft. After cooling water is introduced into three parts including the cooling water channel in the movable cutter shaft, a first cooling water cavity in a fixed cutter holder and a second cooling water cavity in the side wall of a dicing chamber, the service life of the movable cutter and a fixed cutter can be prolonged, meanwhile, thermal expansion is avoided, and the phenomenon that the movable cutter and the fixed cutter collide with each other when a gap is small is prevented. Due to the water cooling effect, the secondary cutting phenomenon generated due to the fact that the material strip adheres to the movable cutter after being cut off due to the fact that static electricity is generated can be prevented.

Owner:成都煜翔机械有限公司

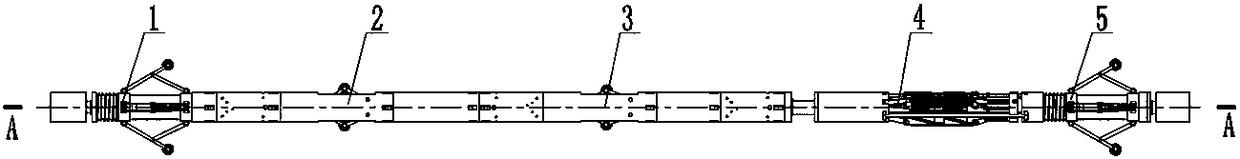

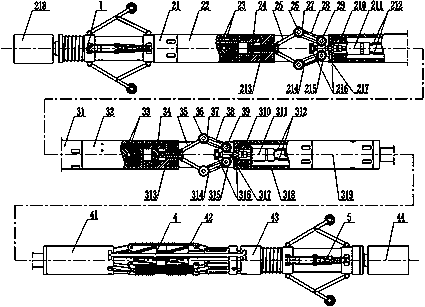

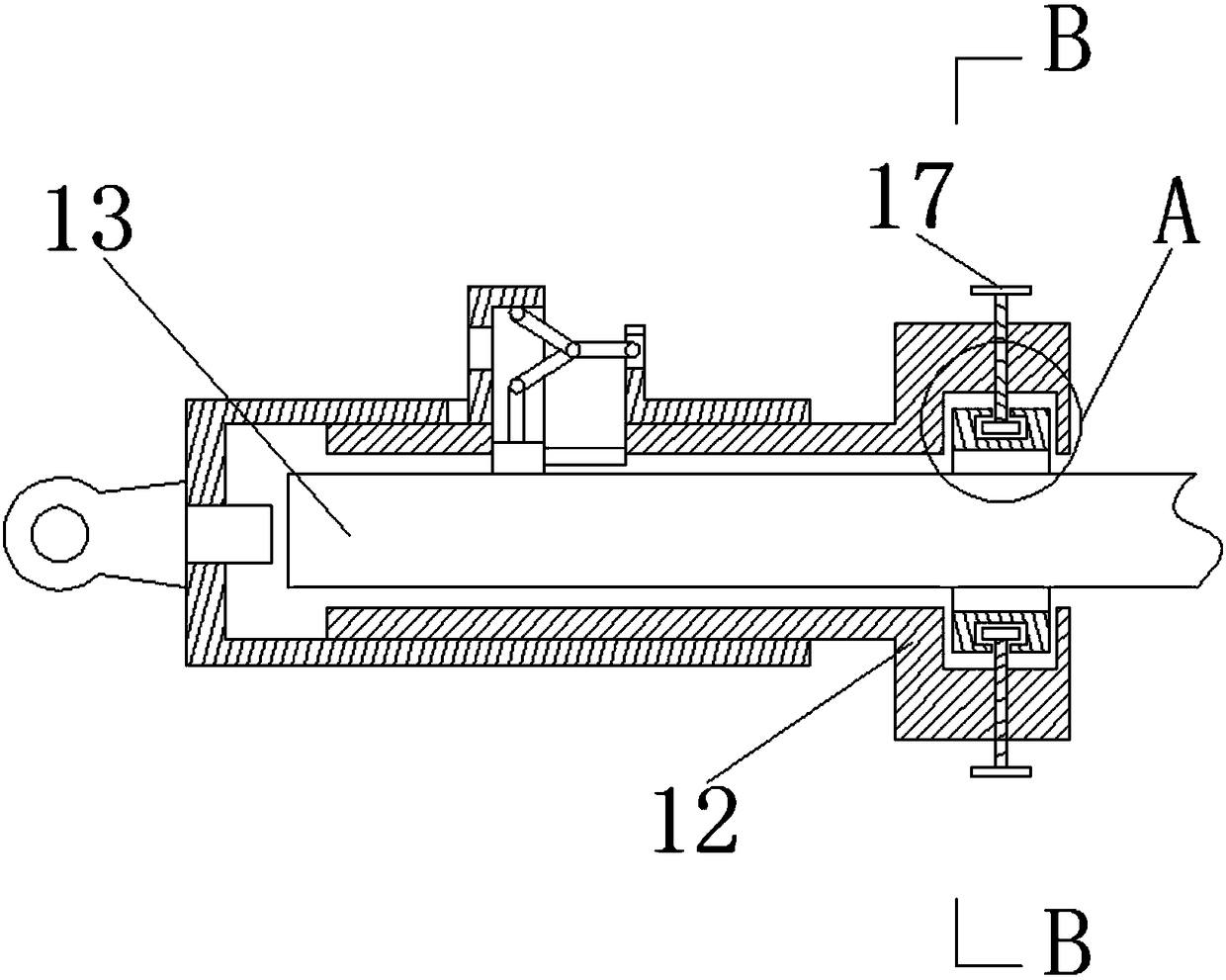

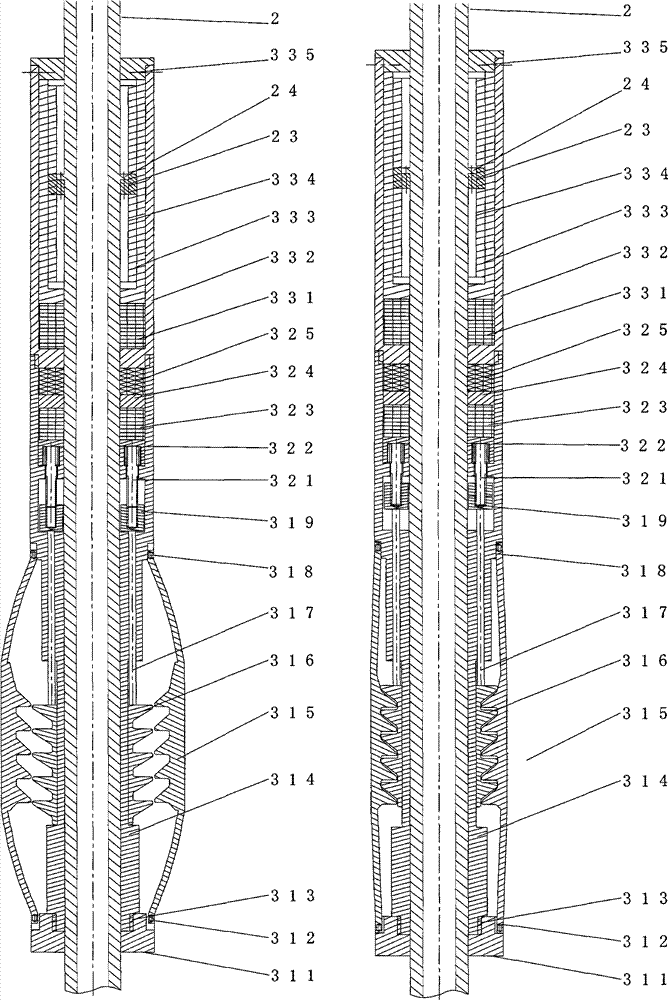

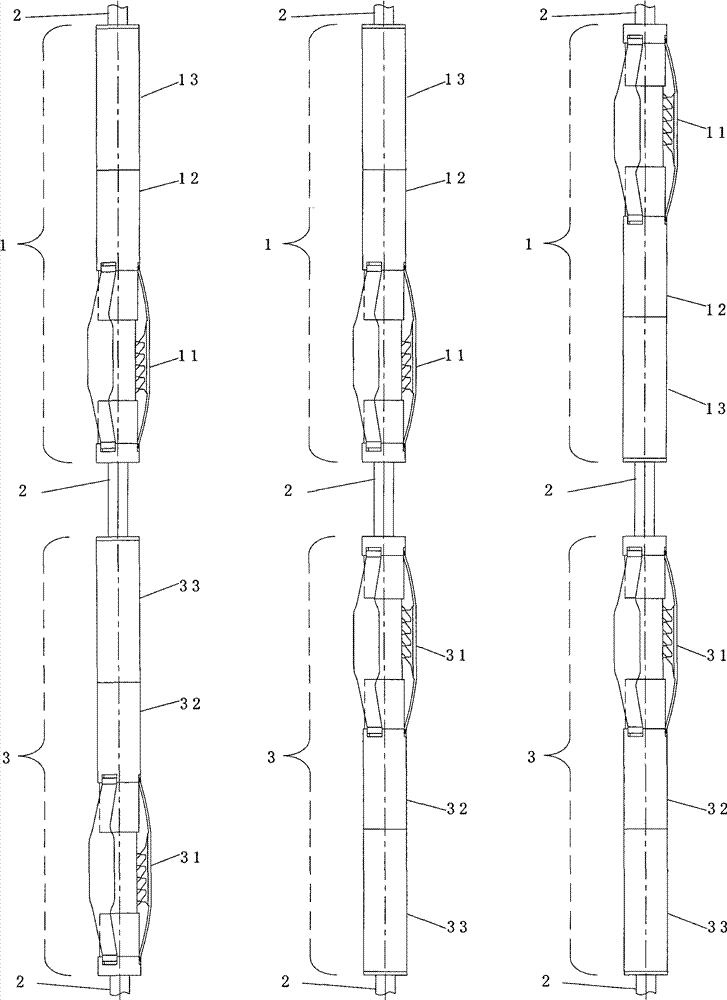

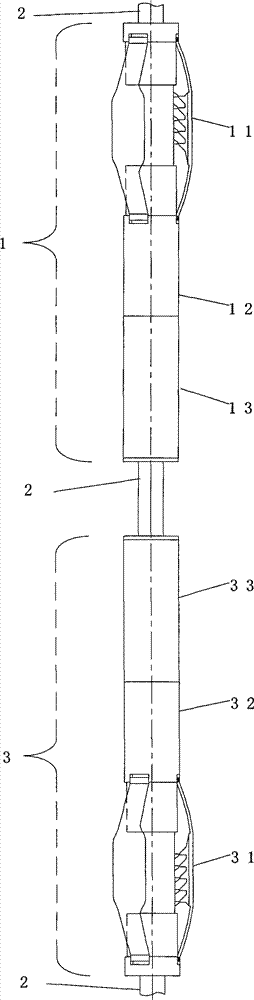

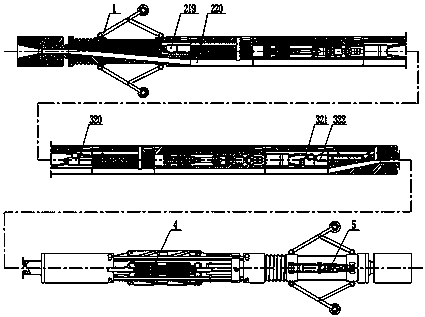

Motor-driven underground tractor for coiled tubing

The invention belongs to the field of oil and gas field development and relates to a tractor used for drilling, logging and well repair engineering of a coiled tubing and favorable for the coiled tubing to extend into a horizontal well section for a longer distance. A motor-driven underground tractor for the coiled tubing comprises an upper tractor system, a hexagonal central sliding pipe and a lower tractor system, wherein the upper tractor system comprises an upper supporting unit, an upper electric drive and control unit and an upper traction unit; and the upper tractor system and the lower tractor system have the same structure, and are connected at the upper part and the lower part of the hexagonal central sliding pipe respectively in a sleeving way and mounted in the same or opposite direction. The tractor is directly driven and controlled by a servo stepper motor, so that the dependence on liquid energy in the process of driving the tractor by using circulating liquid and the complexity of control of a hydraulic valve of the circulating liquid on a pipeline are reduced and most of space occupied by the hydraulic pipeline is saved; and the tractor can perform dual-direction traction, is good in stability, flexible in traction and fast in traction speed, can be suitable for underground traction work of small well holes, and can guarantee normal underground liquid circulation in the traction process.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Belt shaping conveyor

PendingCN107500005ARealize automatic adjustment of belt tensionAvoid knotsWebs handlingFunction indicatorsEngineeringMechanical engineering

Owner:东莞方皓汽车配件有限公司

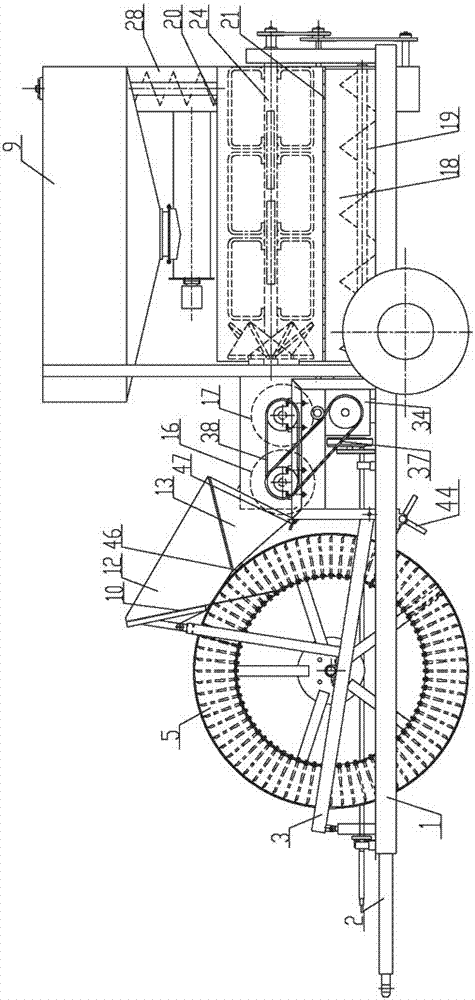

Normal traction seed melon pick-up and de-seeding combined machine

The invention relates to the technical field of play melon de-seeding and harvesting equipment, in particular to a normal traction seed melon pick-up and de-seeding combined machine which comprises a frame, a traction frame, a lifting cylinder frame, a play melon pick-up roller, a crushing device, a melon combing device, a separating device, a conveying device, a seed box, a driving shaft and a transmission device. The traction frame is fixed to the front end of the frame, the lifting cylinder frame is mounted at the upper end of the front of the frame, a pick-up rotating shaft is mounted on the lifting cylinder frame through a left shaft seat and a right shaft seat, and the play melon pick-up roller is mounted on the pick-up rotating shaft. The normal traction seed melon pick-up and de-seeding combined machine is reasonable and compact in structure, convenient to use and low in cost, the front-end normal traction play melon pick-up roller can early contact play melons, waste caused by melon breaking is decreased, the play melons can fall into the crushing device downwards and crushed, rotating processes are decreased, so that the play melons are rapidly crushed, loads of the play melon pick-up roller are relieved, traction and movement are more flexible, the play melons are linearly conveyed from front to back from crushing to separating, de-seeding efficiency is improved, and the shape size of the combined machine is reduced.

Owner:玛纳斯县祥和农机有限责任公司

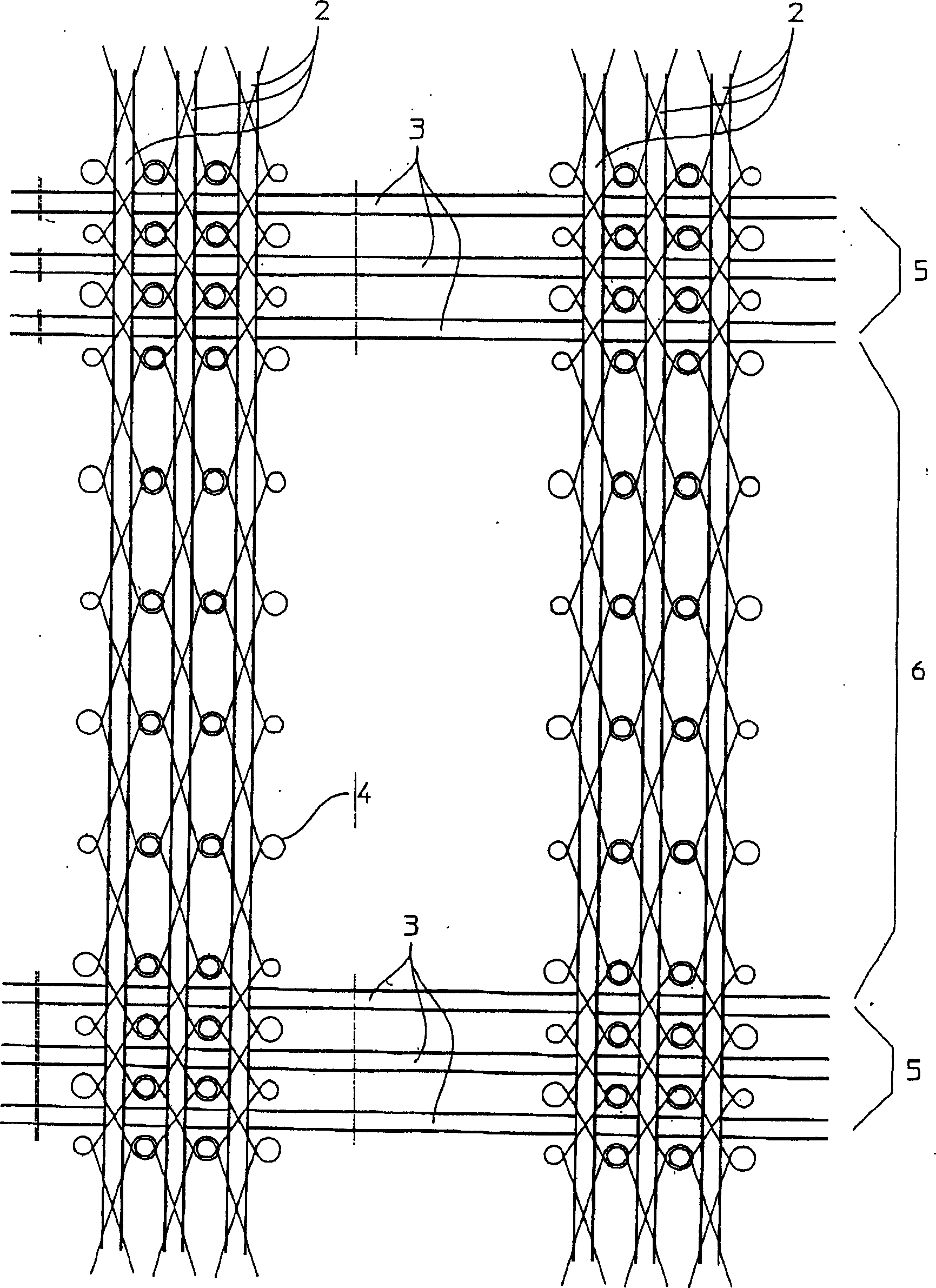

Method for preparing flat ruche with large crystalline host lattice perforated twin-shaft mesh structure

InactiveCN1769557ADoes not slow down workAchieve fixationOrnamental textile articlesTextile/flexible product manufactureEngineeringCross over

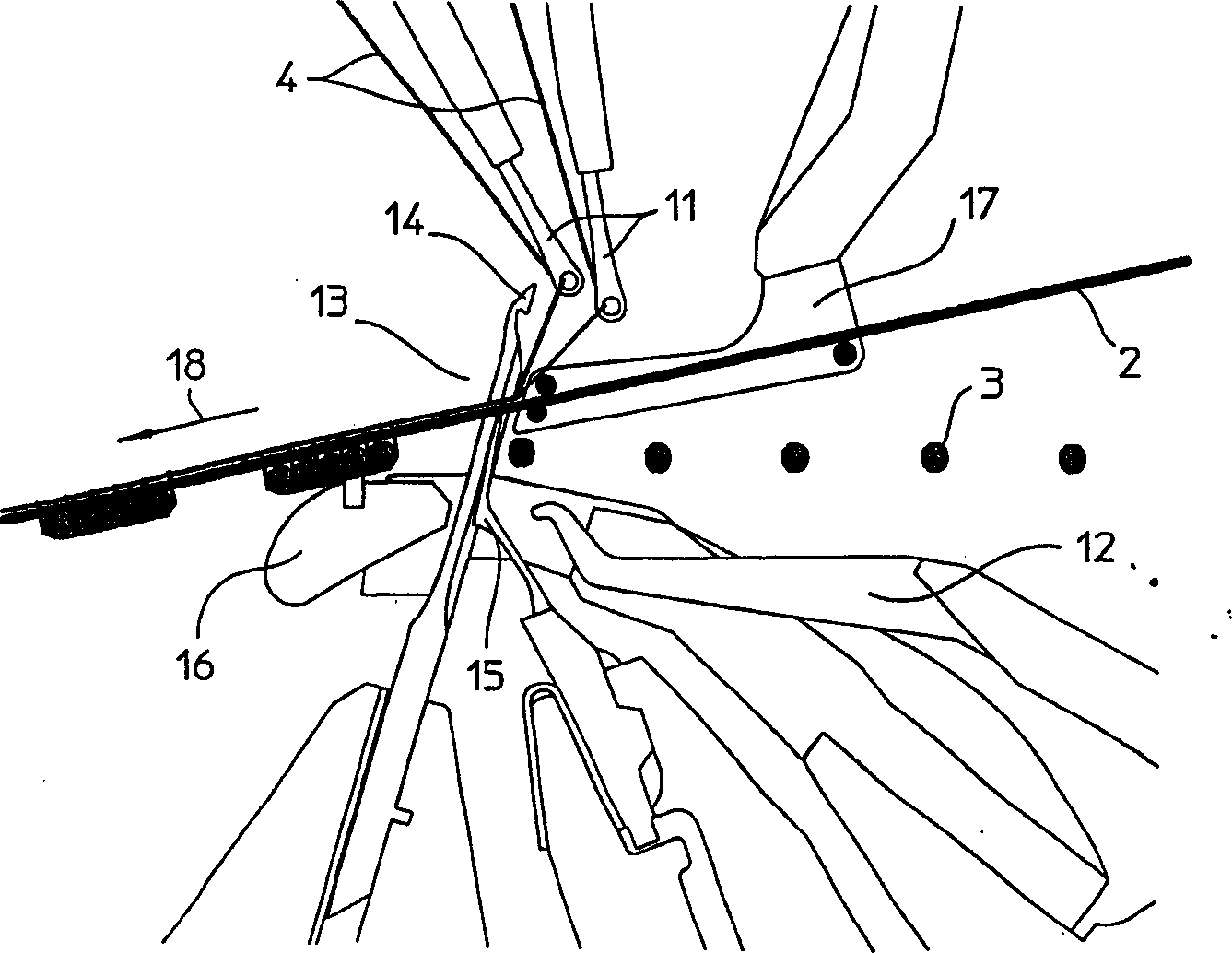

A method for making wide-mesh warp knit fabric involves forming tricot-laid loops of fixing threads (4) along the warp threads (2) at both the coss-overs and the mesh openings without twisting (2), running (2) through the knitting tools with no misalignment, binding warp and weft threads together with (4) at the cross-overs and periodically changing the pull-off speed to make it lower when the cross-overs pass through the knitting station and higher when the mesh openings pass through. A method for the production of warp knit fabric with a biaxial wide-mesh structure, in which (a) a crosswise arrangement of warp (2) and weft (3) threads (singly or in groups) is taken to a knitting station (8), (b) loops (20) of fixing threads (4) are formed along the warp threads both at the cross-over points (5) and also at the mesh openings (6), (c) the loops (20) are tricot-laid, (d) the warp threads run through the knitting tools with no misalignment, (e) the loops (20) are formed without twisting the warp threads, (f) the warp and weft threads (2, 3) are bound together by the fixing threads (4) at the cross-overs (5), (g) the mesh structure is pulled off the station (8) and (h) the pull-off speed is periodically changed, being lower when the cross-overs (5) are passing through the knitting station (8) and higher when the mesh openings (6) are passing through.

Owner:LIBA MASCHFAB

Long-reach horizontal well coiled tubing drilling robot

ActiveCN108868603BSingle mode of operationVarious ways of operationDirectional drillingFlushingResource developmentWell drilling

The invention relates to a large-displacement horizontal well continuous tubing drilling robot, which comprises a former centralizer, a rear centralizer, a front motion short joint, a back motion short joint and an extension shortening section; the front motion short joint, the back motion short joint and the extension shortening section are connected to each other in turns; the former centralizers and the rear centralizers are respectively installed at the front end and the rear end of the front motion short joint and the extension shortening section. The large-displacement horizontal well drilling robot is provided with a mud flow channel, which can circulate mud in tow continuous tubing and drilling, therefore the resistance of mud is reduced to the maximum extent. The large-displacement horizontal well drilling robot can carry on two-way haulage, which can solve the jam problem of the robot to a great extent. The large-displacement horizontal well continuous tubing drilling robot is not only suitable for hot dry rock development, but also suitable for unconventional oil and gas (natural gas hydrate, coalbed methane, tight oil and gas, shale gas) and conventional oil and gas resources development.

Owner:SOUTHWEST PETROLEUM UNIV

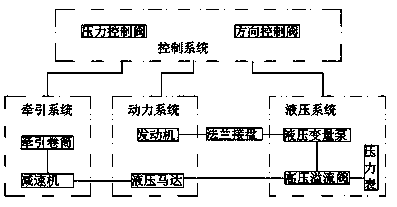

Full-hydraulic split type cableway traction machine

InactiveCN104129728AMeet towing requirementsSimple driveWinding mechanismsHydraulic motorTraction system

The invention relates to a full-hydraulic split type cableway traction machine. The full-hydraulic split type cableway traction machine comprises a power system, a hydraulic system and a traction system, wherein the power system, the hydraulic system and the traction system are arranged independently. The full-hydraulic split type cableway traction machine is characterized in that the power system comprises an engine and a hydraulic motor, the hydraulic system comprises a hydraulic variable pump which is driven by the engine, the hydraulic variable pump is used for driving the hydraulic motor, a high-pressure overflow valve is arranged between the hydraulic motor and the hydraulic variable pump, and the traction system comprises a traction drum which is driven by the hydraulic motor through a speed reducer. The full-hydraulic split type cableway traction machine further comprises a control system which is arranged independently, wherein the control system comprises a pressure control valve and a directional control valve, the pressure control valve is used for controlling the power system, the hydraulic system and the traction system, and a pressure gauge is arranged on the high-pressure overflow valve. According to the full-hydraulic split type cableway traction machine, stepless speed change is achieved, transmission is easy, hydraulic brake is reliable, and operation is easy; in addition, the continuous traction force is large, the traction speed is high, and the traction requirement of heavy-load cableways is met.

Owner:STATE GRID CORP OF CHINA +2

A rolling traction device for a hydrogen-fueled unmanned aerial vehicle

ActiveCN106711867BReduce power consumptionImprove battery lifeApparatus for laying cablesGround rollerHydrogen fuel cell

The invention discloses a rolling type traction device of a hydrogen fuel-based unmanned aerial vehicle, comprising an unmanned aerial vehicle powered by a hydrogen fuel battery, wherein a quick separation mechanism is arranged at the lower end of a vehicle body of the unmanned aerial vehicle, a supporting plate is arranged at the lower end of the quick separation mechanism, a bracket is mounted at the top of the supporting plate in a rotational manner through a rotary shaft, a shaft rod is arranged at the upper end of the bracket in a protruded manner, a shaft sleeve is movably sleeved on the shaft rod, one end of the shaft sleeve is connected with the quick separation mechanism through a traction cable, a roller mechanism is arranged, away from the shaft rod, at the bottom of the supporting plate, an electric cable is placed in a fixed cavity formed in the upper end of the supporting plate, and is firmly clamped by clamping plates at two sides of the inner wall of the fixed cavity. The rolling type traction device of the hydrogen fuel-based unmanned aerial vehicle disclosed by the invention is mainly used for the conveying of the electric cables and the like in rugged mountain road areas, and can realize quick traction by means of semi-traction of the unmanned aerial vehicle; as the rolling type traction device is partially in contact with ground rollers, electric power consumption of the unmanned aerial vehicle is reduced, cruising ability of the unmanned aerial vehicle is increased, quick separation can be realized, and working efficiency can be increased.

Owner:TAICANG TAOXIN INFORMATION TECH CO LTD

Polyvinyl chloride hollow fiber ultrafiltration membrane and preparation method thereof

InactiveCN107486035AExtended service lifeLarge water flowMembranesUltrafiltrationHollow fibreWater baths

The invention relates to a polyvinyl chloride hollow fiber ultrafiltration membrane. A membrane casting solution used for preparing the polyvinyl chloride hollow fiber utlrafiltration membrane is prepared from ingredients in weight percentage: 10 to 30% of polyvinyl chloride, 3 to 10% of hydrophilic agent, 5 to 10% of pore forming agent and 50 to 82% of solvent. A preparation method of the polyvinyl chloride hollow fiber ultrafiltration membrane comprises the following steps: A, preparing the membrane casting solution by all the ingredients according to the weight ratio; B, fully and evenly stirring the membrane casting solution under 45 to 80 DEG C to remove air bubbles; C, pumping the membrane casting solution into an insert tube type hollow fiber spinning nozzle, staying in air 0.2 to 2 seconds and entering solidifying water bath to form the membrane, wherein a traction speed is 30 to 110meter / minute. The polyvinyl chloride hollow fiber ultrafiltration membrane disclosed by the invention has the following beneficial effects of longer service life, larger water discharge capacity, lower energy consumption, high elongation at break, strong hydrophilicity, high bearable pulling speed and strong applicability.

Owner:广东万和净水设备有限公司

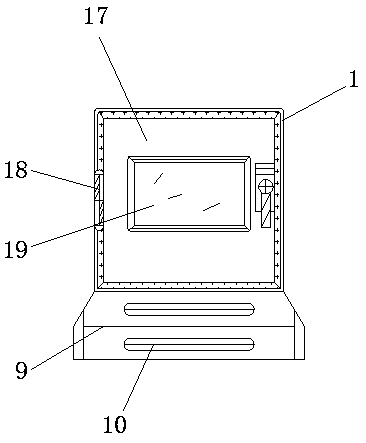

A fast connection electric wire device with a fault diagnosis function

InactiveCN109103726AImprove work performanceImprove workabilityLine/current collector detailsTransverse axisEngineering

The invention relates to a fast connection electric wire device with a fault diagnosis function, which includes a main body, a wire inlet and a display screen, a fixing groove is fixed on the inner side of the top of the main body, and an outlet port is arranged inside the main body, a frame is mounted on the inner side of the main body, and the interior of the frame is fixed with rails, the bottom outer side of the track is movably provided with a gear clamp block. The invention has the advantages that: in accordance with the present invention, the main body, the camera, the bidirectional telescopic bar, the movable board, the movable block and a movable slot are arranged, and the camera is symmetrical about the transverse axis of the bidirectional telescopic bar; when the device is working quickly to connect the wires, through the camera, workers can observe and operate the working condition inside the device, so that the staff can know whether the device has faults or not in real time through the display screen, and can diagnose and operate some common faults when the equipment is working through the function of the relevant parts inside the equipment, so as to improve the efficiency of wiring work of the equipment.

Owner:DONGGUAN UNIV OF TECH

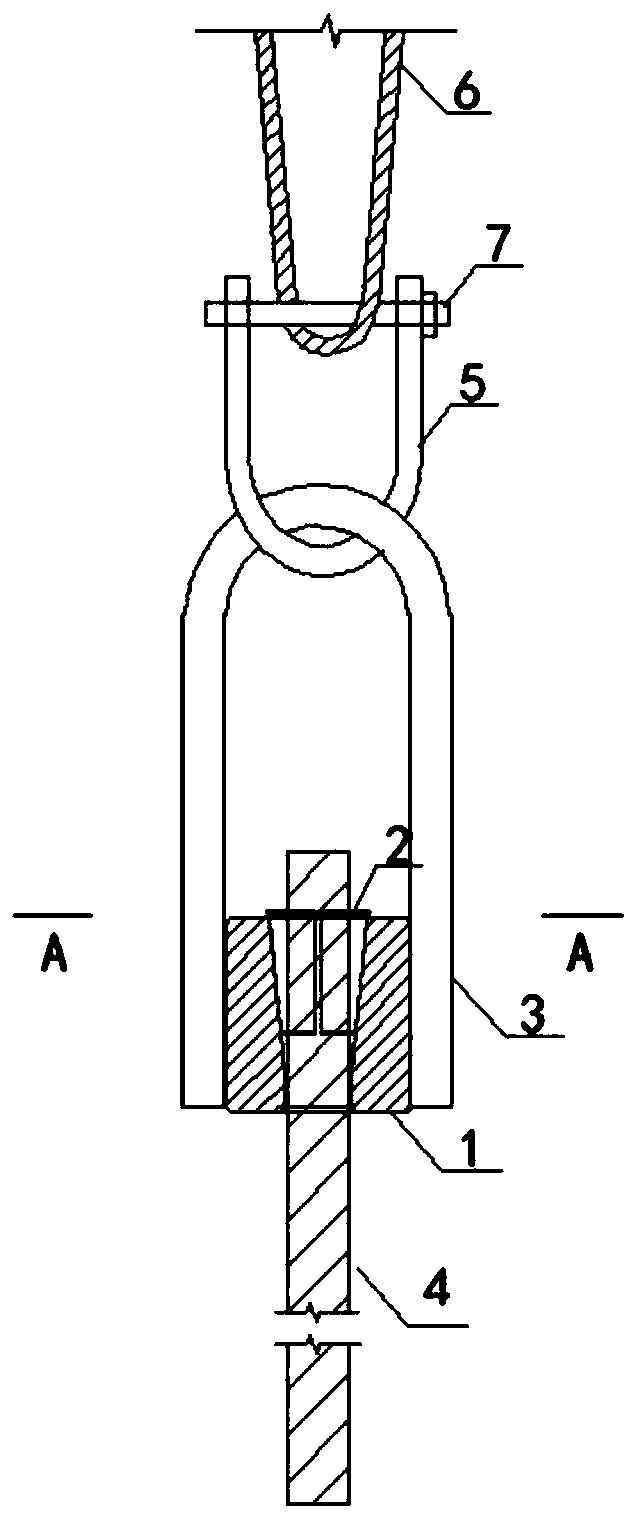

Traction connection device for steel wire rope and steel strand and installation method of traction connection device

InactiveCN111188872AFast tractionImprove work efficiencyRopes and cables for vehicles/pulleyTextile cablesEngineeringWinch

The invention discloses a traction connection device for a steel strand and a steel wire rope and an installation method of the traction connection device. The traction connection device for the steelstrand and the steel wire rope comprises a U-shaped hanging ring, an anchor ring and a four-blade clamping piece, the ends of two arms of the U-shaped hanging ring are welded on the outer wall of theanchor ring, the anchor ring is axially provided with a tapered through hole through which the steel strand passes, a thick end of the tapered through hole is internally provided with the four-bladeclamping piece, the steel strand passes through the tapered through hole and is fixed with the four-blade clamping piece, and the steel wire rope is connected with the U-shaped hanging ring through aU-shaped shackle, that is, the steel wire rope is connected with the steel strand after passing through the traction connection device. The traction connection device is used for connecting the steelwire rope with the single steel strand, installation is convenient and rapid, a single steel strand is pulled by using the steel wire rope of a winch, and the traction installation efficiency of the steel strand is improved.

Owner:中铁大桥局第七工程有限公司

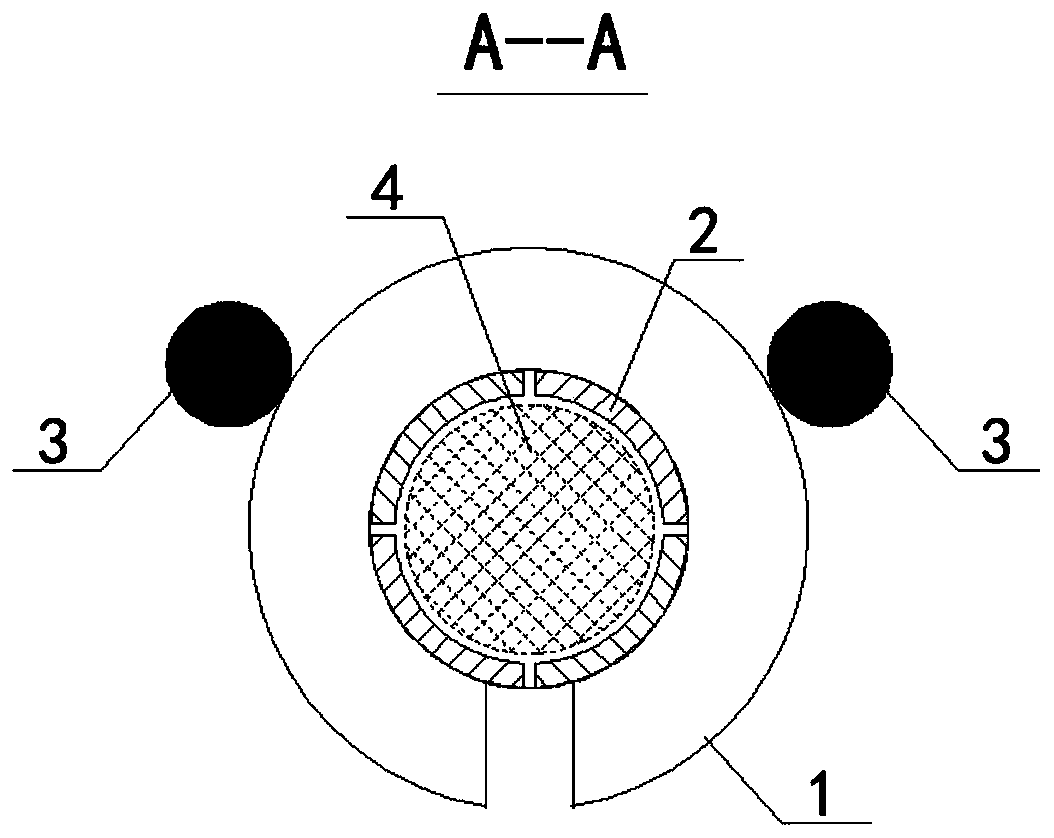

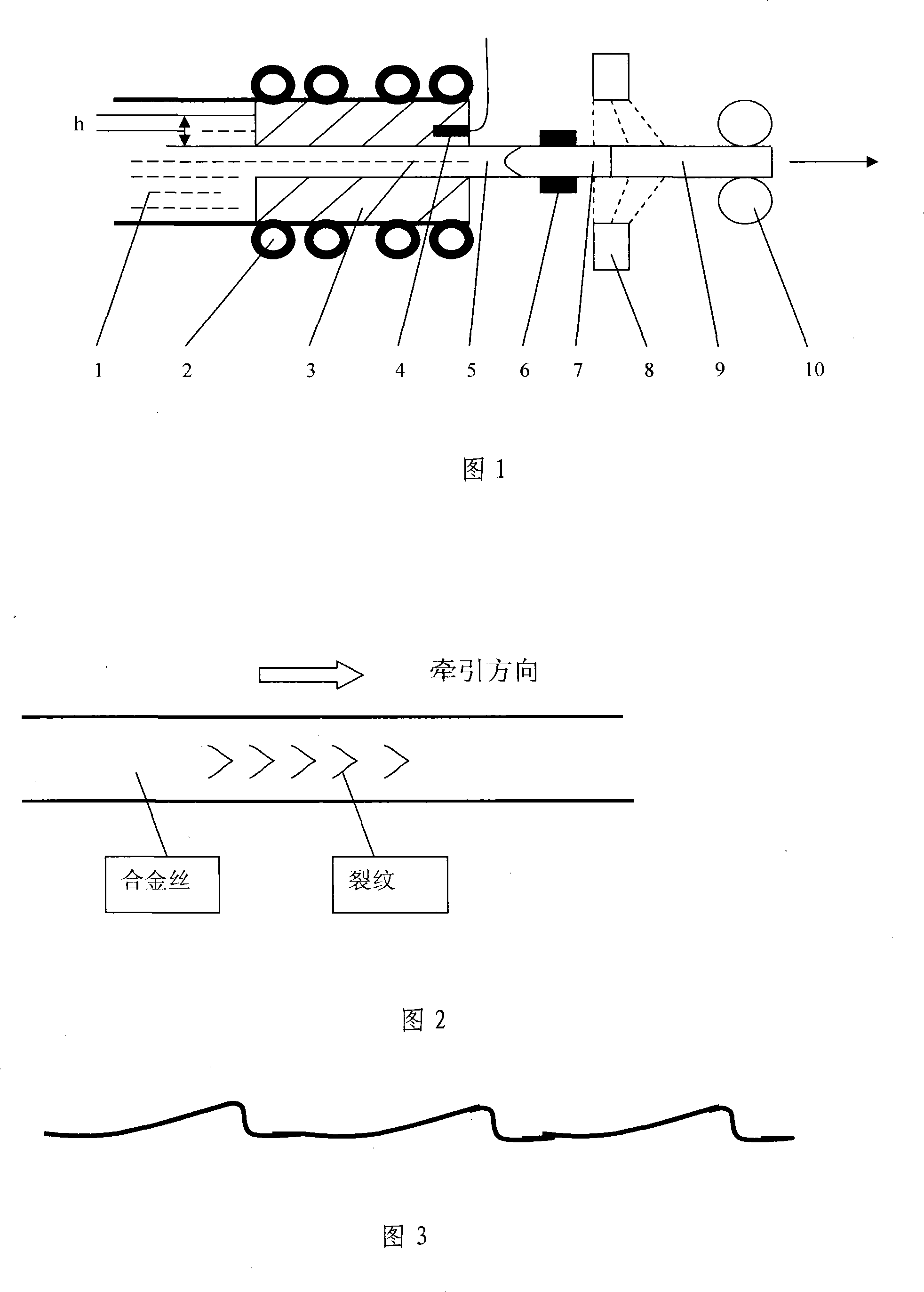

Apparatus and method for continuously casting copper base shape memory alloy wire

The invention relates to an equipment of continuous casting memory alloy wire of Cu-based shape and a production method thereof. The equipment of the invention comprises a heater provided on cast mould, guiding wires and a cooler; one end of the cast mould is introduced into alloy liquid, the height of which is higher than the molding cavity of the cast mould; the other end of the cast mould is inserted with guiding wire that is bound with liquid column flowing out of the molding cavity and drawn by a drawing mechanism; the cooler is arranged between the cast mould and the drawing mechanism. The steps of the invention are that: 1) heating the cast mould to 1050-1100 DEG C; 2) alloy liquid entering the molding cavity from one end of the cast mould and the other end being inserted with guiding wire; after the guiding wire and alloy liquid are bound; the drawing mechanism is started to form a suspending liquid column out of the molding cavity of the cast mould; the liquid column is cooled by the cooler arranged outside of the cast mould, leading the liquid column to be solidified into guiding wire in vertical direction. By adopting the equipment of the invention, surface crack and wave-shaped tortuous can be avoided. The invention is of simple operation method and convenient use.

Owner:黎沃光

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com