Patents

Literature

47results about How to "Realize continuous extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper bus bar with high strength, high conductivity and high toughness and preparation method thereof

InactiveCN102034563AImprove conductivityImprove equipment technologySingle bars/rods/wires/strips conductorsManufacturing extensible conductors/cablesLiquid cathodeLiquid copper

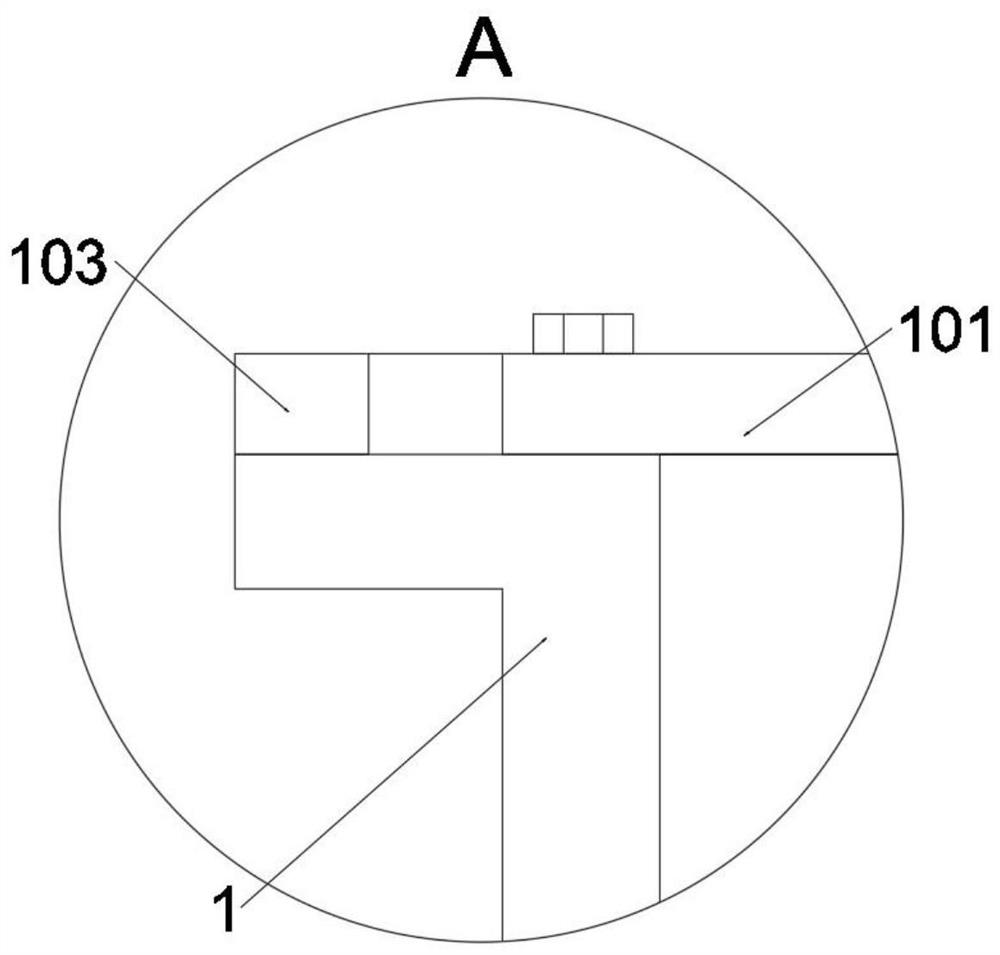

The invention relates to a copper bus bar with high strength, high conductivity and high toughness and a preparation method thereof. The copper bus bar is characterized in that the material comprises 99.96-99.998% of copper and silver, 0.002-0.02% of yttrium rare earth and 0-0.038% of impurities, wherein silver accounts for 0.0005-0.01% of copper and silver; and the copper master alloy containing the yttrium rare earth is used as a modifier. The preparation method comprises the following steps: (1) melting a copper material: heating the cathode copper in a mains frequency core induction furnace to melt the cathode copper into liquid cathode copper; (2) modifying liquid copper: melting the modifier in the liquid cathode copper and fully mixing the modifier with the liquid cathode copper; (3) drawing a continuously cast copper bar upwards: causing a crystallizer of a continuous casting machine to stretch into the liquid cathode copper, condensing the liquid cathode copper into the copper bar in the crystallizer and drawing the copper bar upwards by means of two pairs of drawing roll mechanisms in the continuous casting machine to lead the copper bar to a take-up machine via a wheel frame; (4) continuously extruding the copper bar at medium temperature and carrying out anti-oxidation cooling; and (5) carrying out draw forming: putting copper bus bar blanks on a drawing machine, carrying out draw forming on the copper bus bar blanks.

Owner:福州市广福有色金属制品有限公司

Preparation method of high-performance copper busbar

The invention relates to a preparation method of a high-performance copper busbar. The preparation method comprises the production process steps of A, copper material selection, B, copper material melting, C, copper liquid standing, D, copper liquid heat preservation, E, copper bar continuous casting, F, continuous extrusion, and G, molding by drawing. The purpose of the invention is to provide the preparation method of the high-performance copper busbar having the electric conductivity of greater than 100.3% IACS and the hardness of greater than or equal to 85HB, and bent by greater than or equal to 120 degrees.

Owner:福州聚勤环保科技有限公司

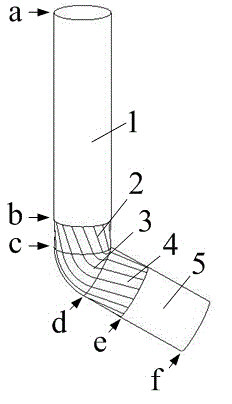

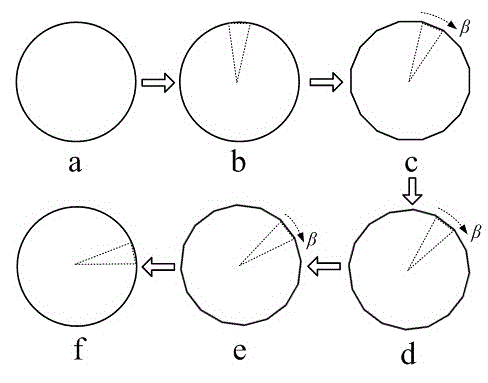

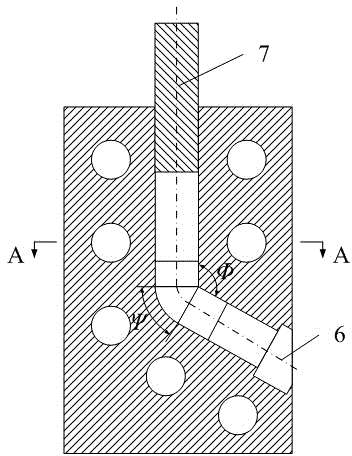

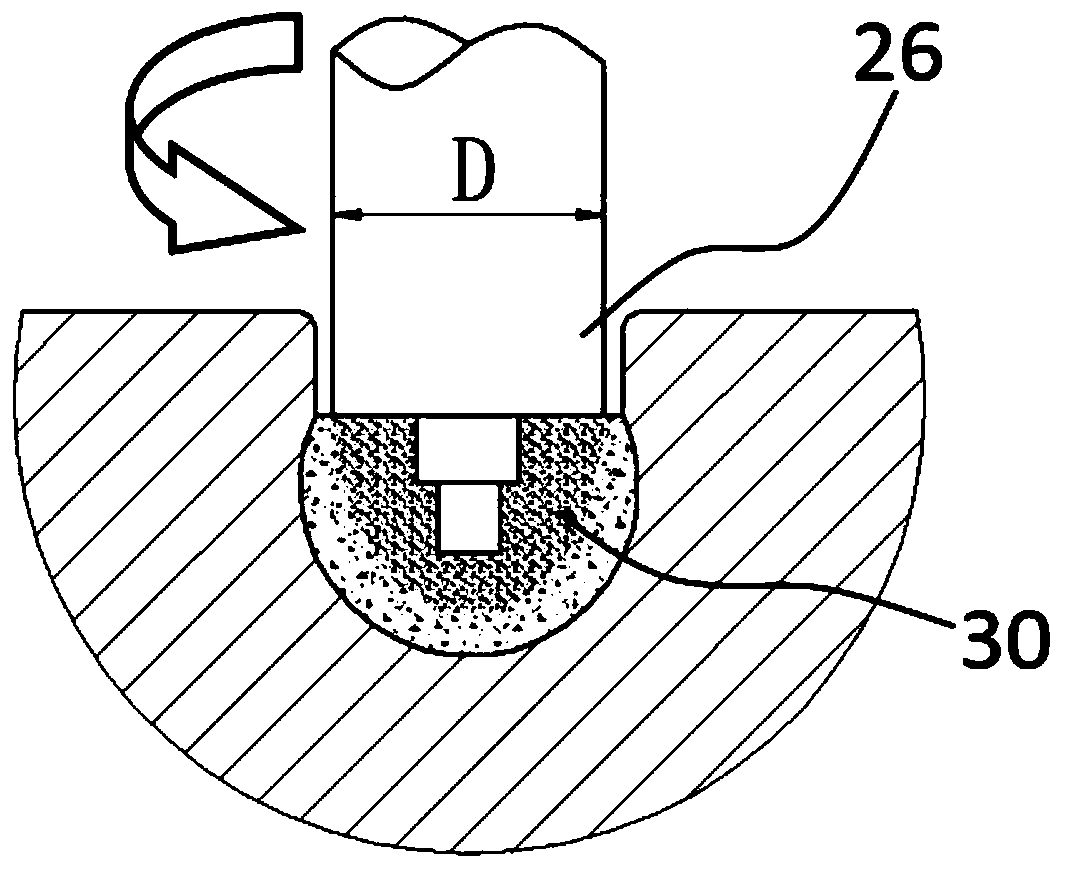

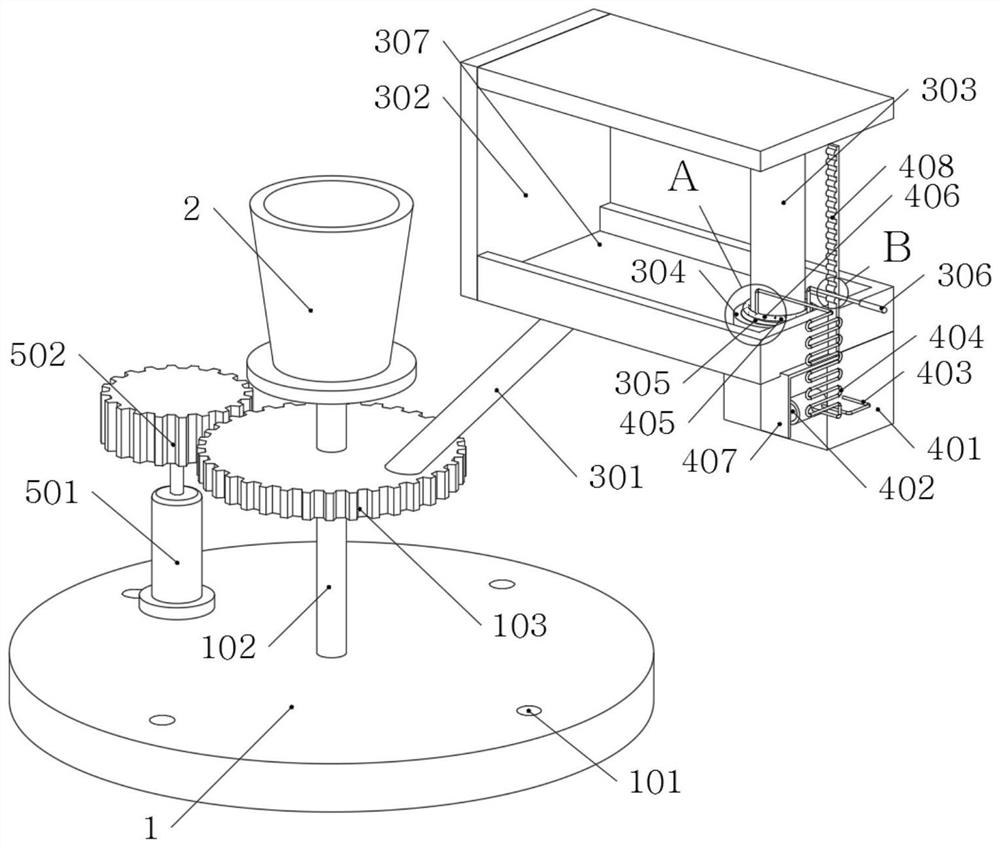

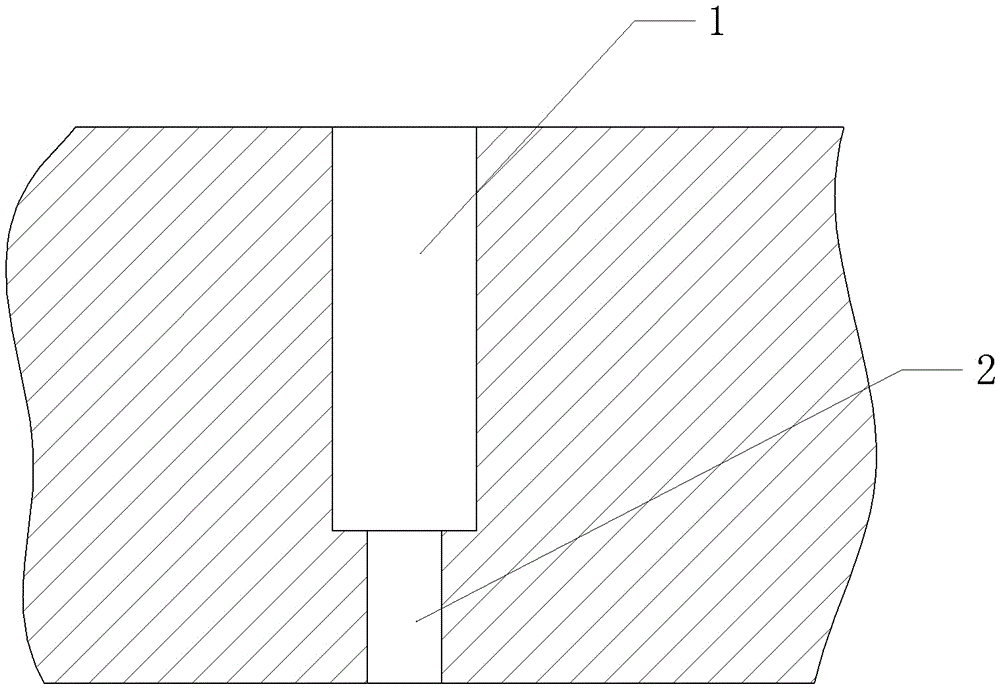

Equal-channel corner revolving extrusion die and method

The invention discloses an equal-channel corner revolving extrusion die and method and belongs to the field of material machining. The die comprises bolts and die sections, bolt holes are respectively and correspondingly arranged in the two die sections, and the two die sections are fastened with the bolts. Parting surfaces of the two die sections cling to each other completely to form a structure with the center being an extrusion cavity of the die, the extrusion cavity is an equal-channel corner extrusion die cavity, and the equal-channel corner extrusion die cavity is sequentially provided with a die cavity leading-in section, a die cavity leading-in transition section, a die cavity corner section, a die cavity leading-out transition section, a die cavity leading0out section and a die cavity taking-out section. The equal-channel corner revolving extrusion die has the advantages of high grain refining capability, convenience in operation, simple structure and continuous extrusion.

Owner:TAIYUAN UNIV OF TECH

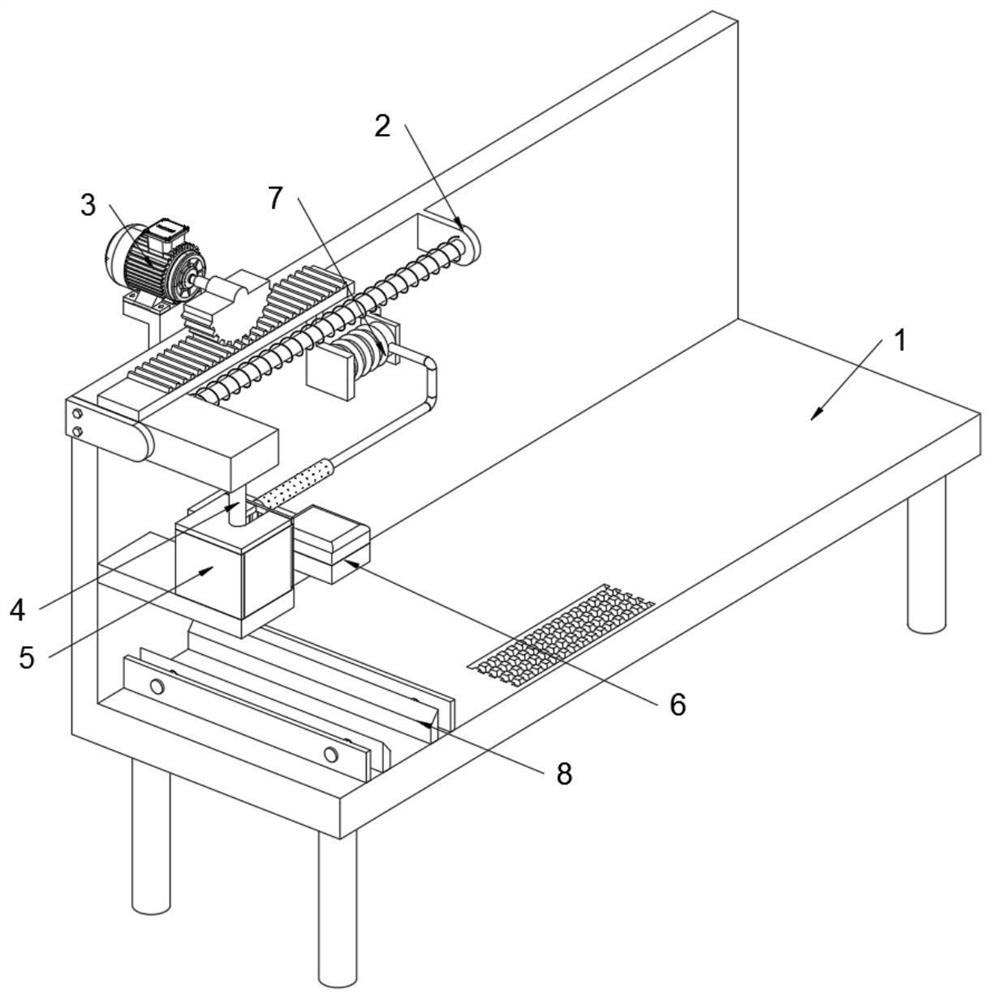

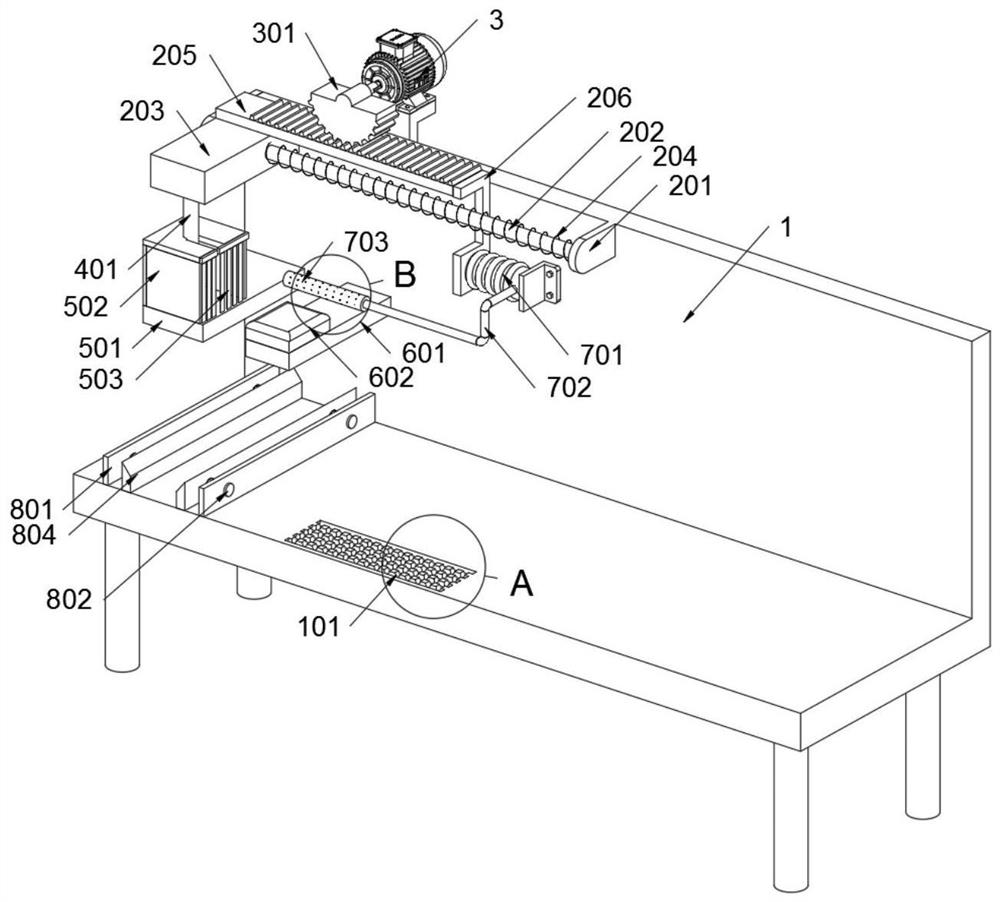

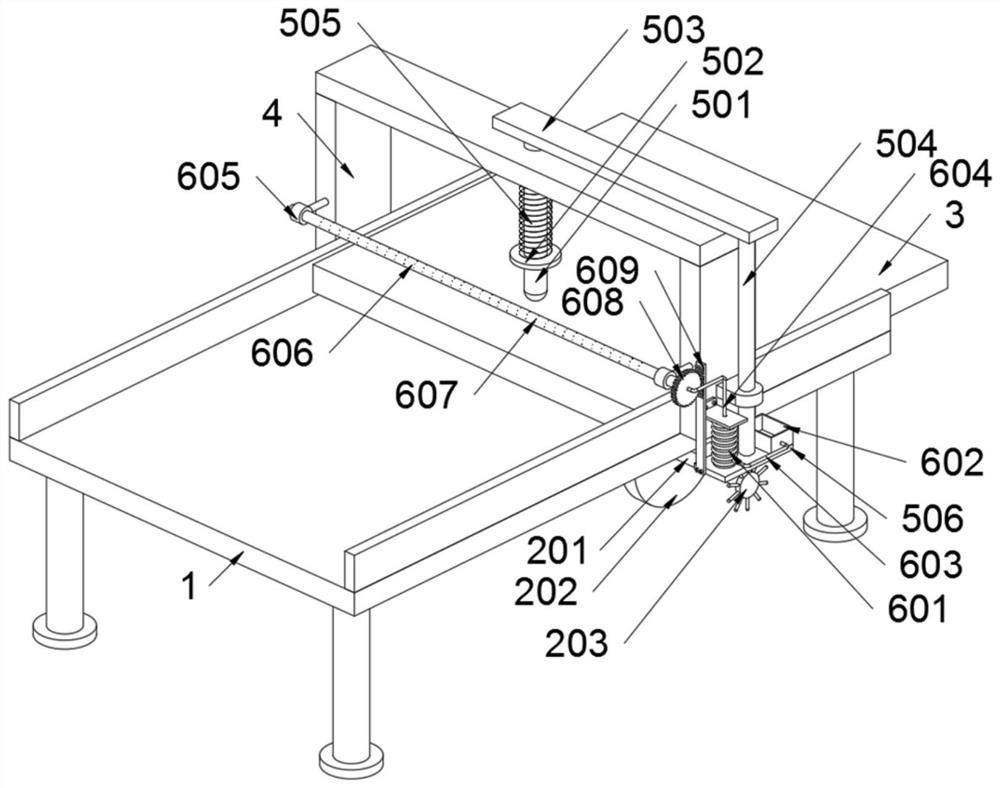

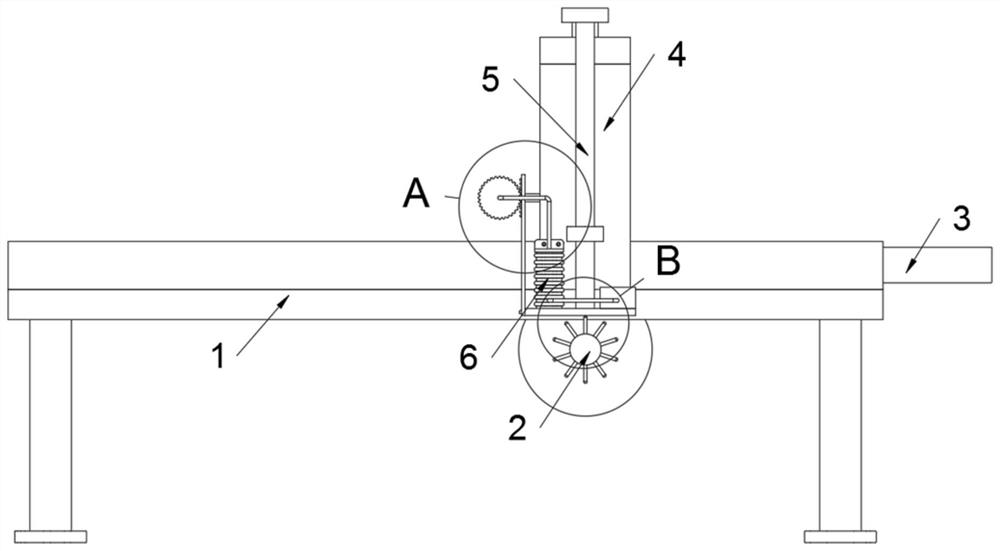

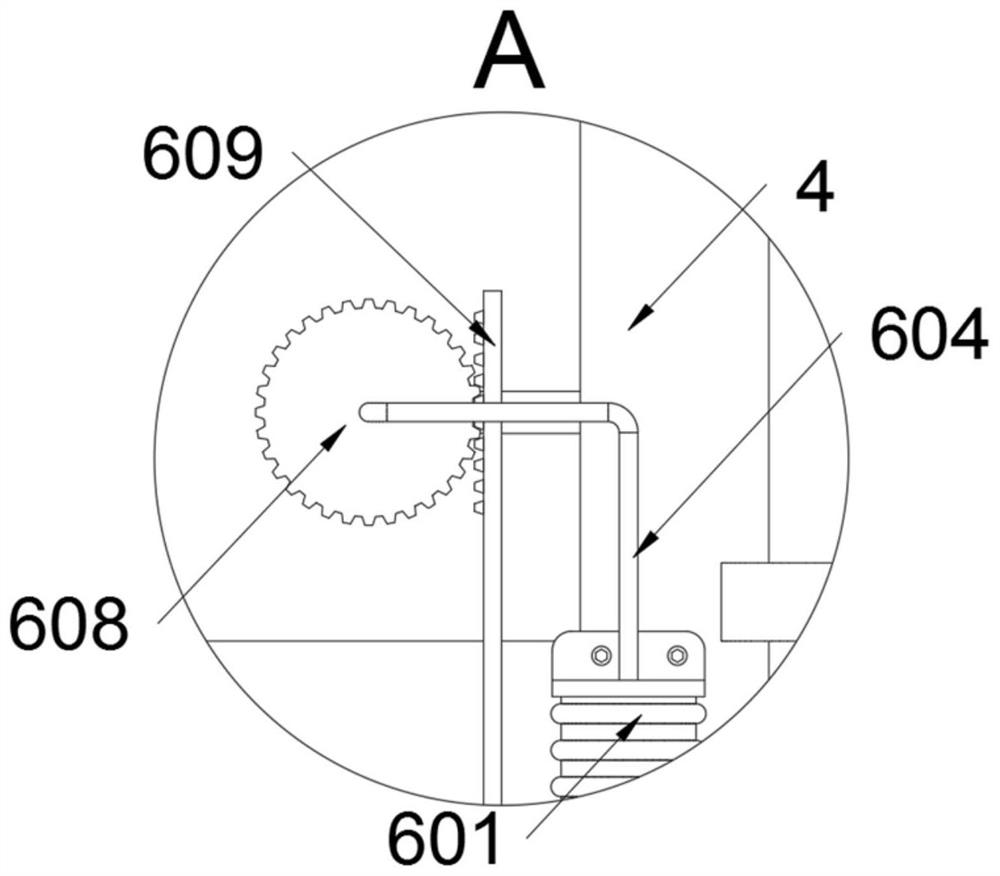

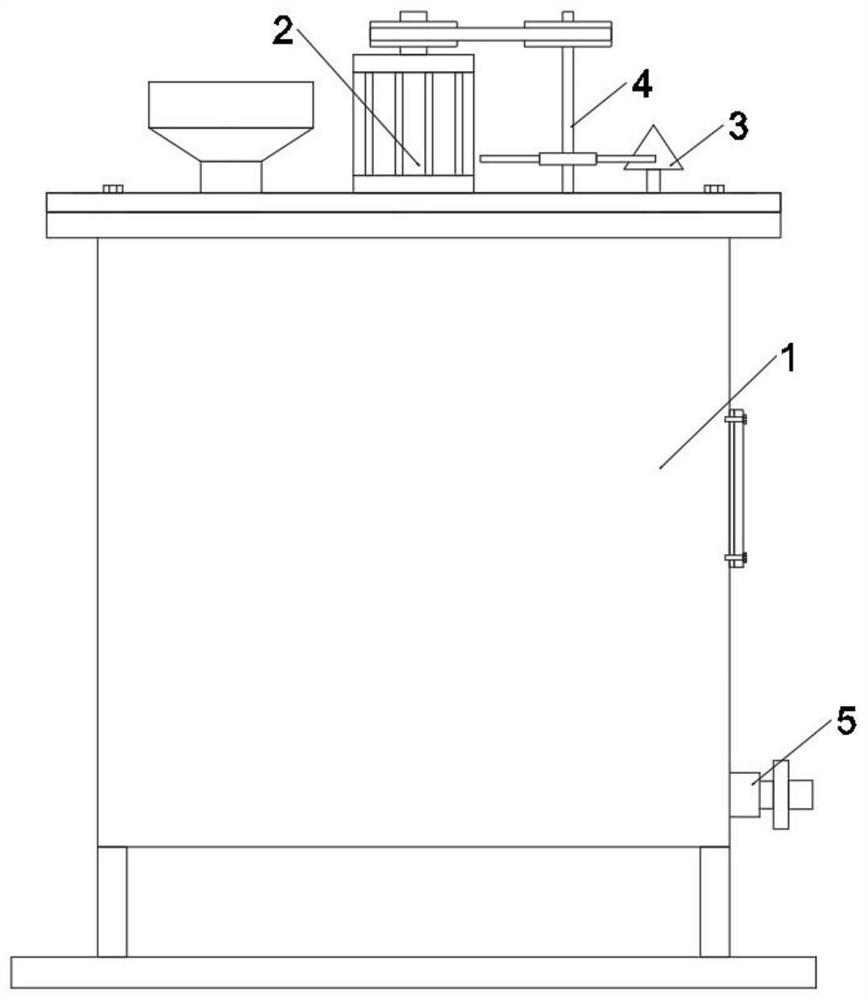

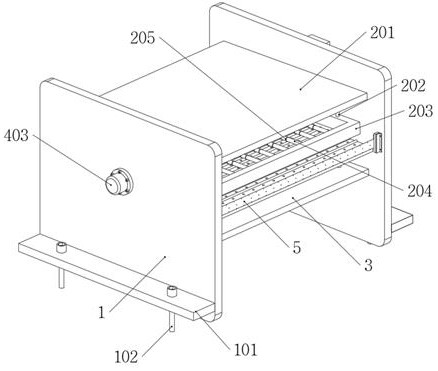

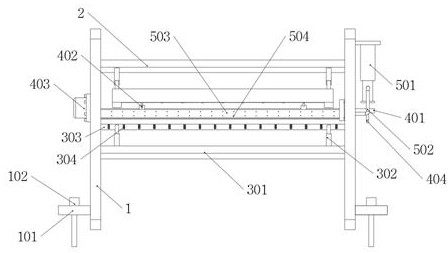

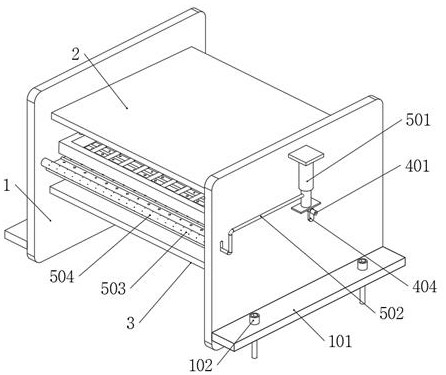

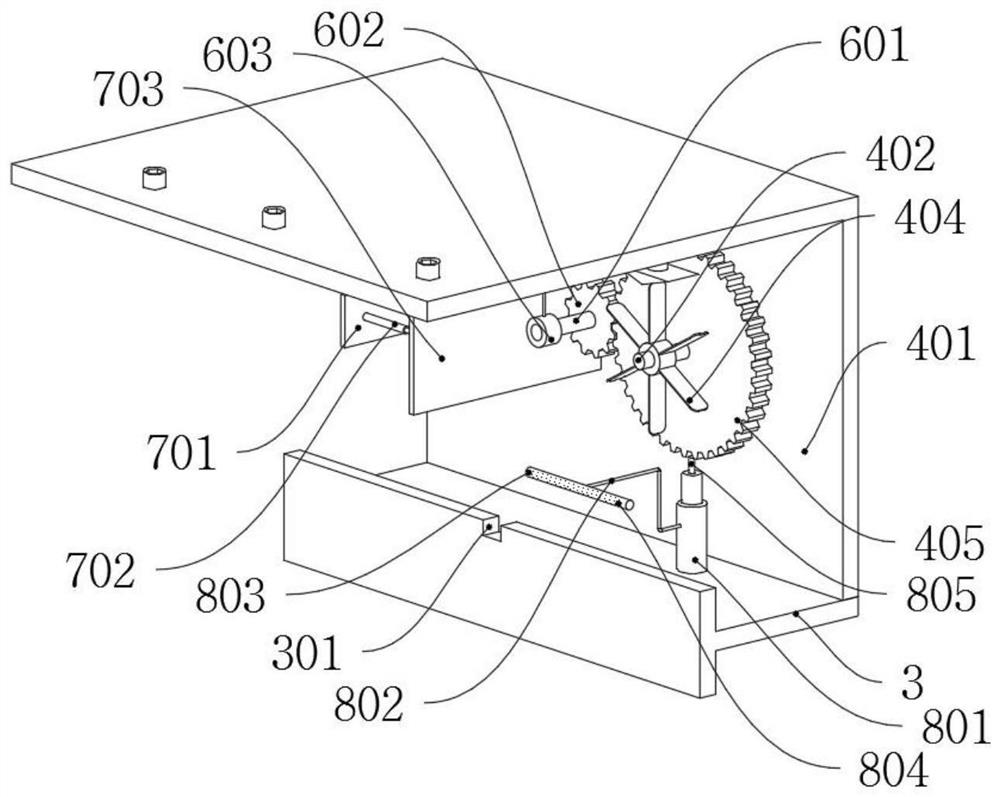

Special maintenance worktable for electronic information technology

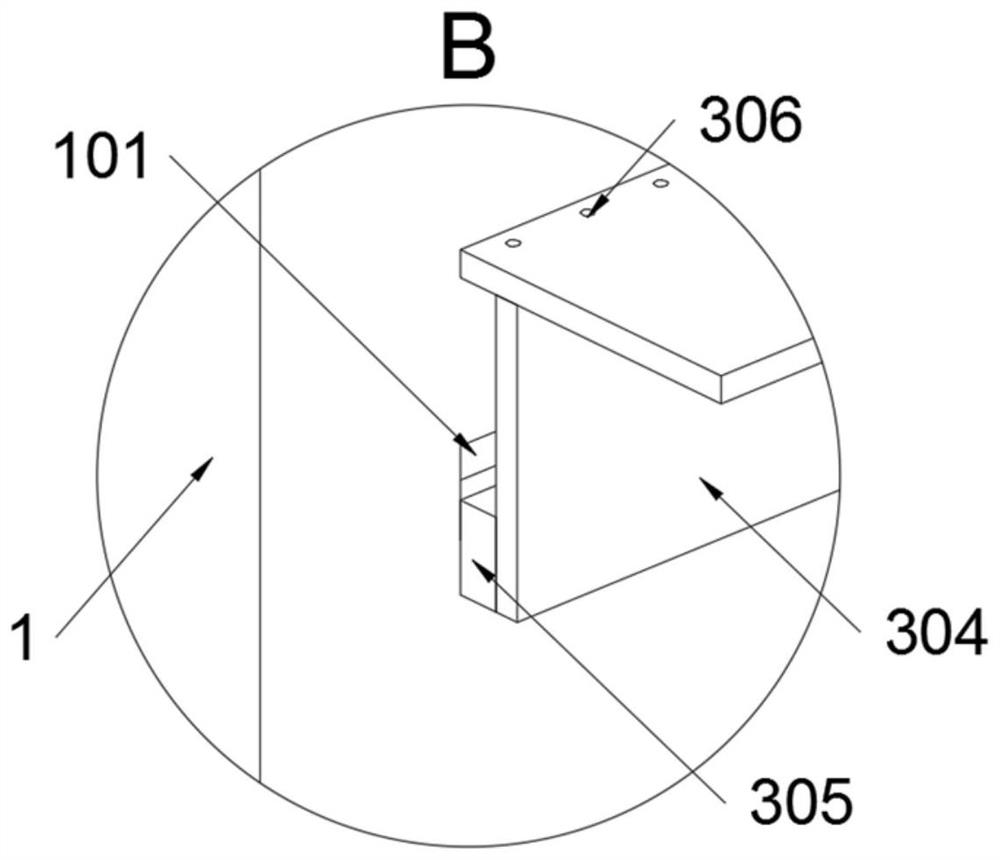

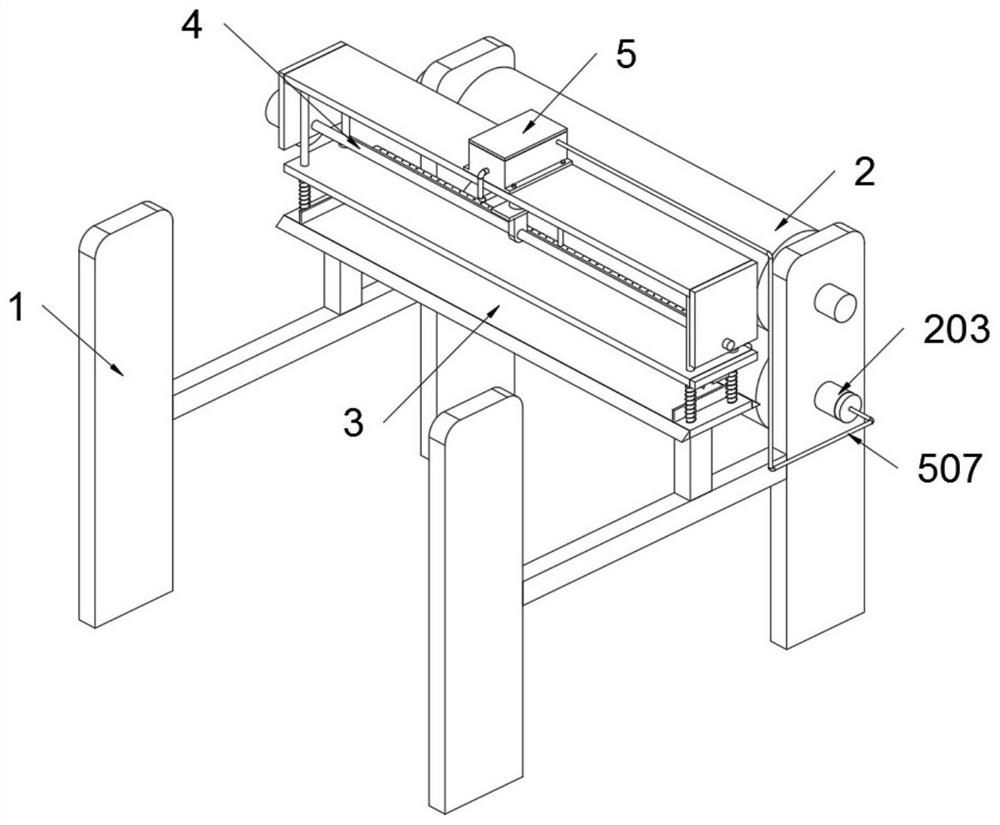

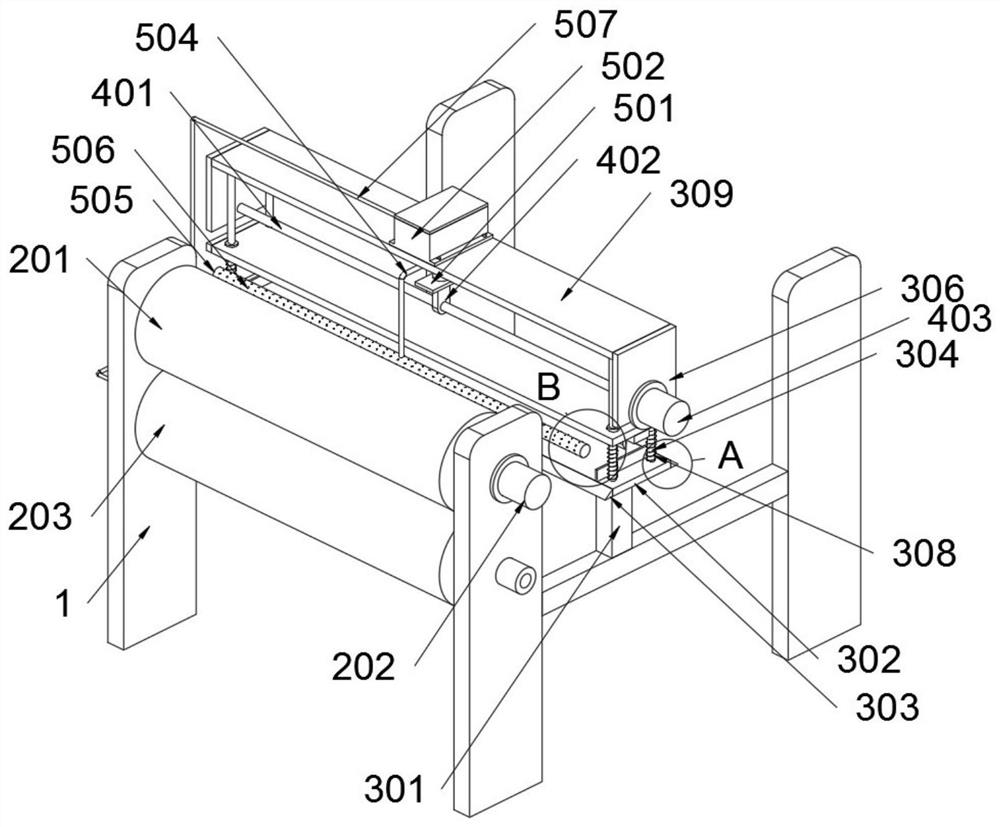

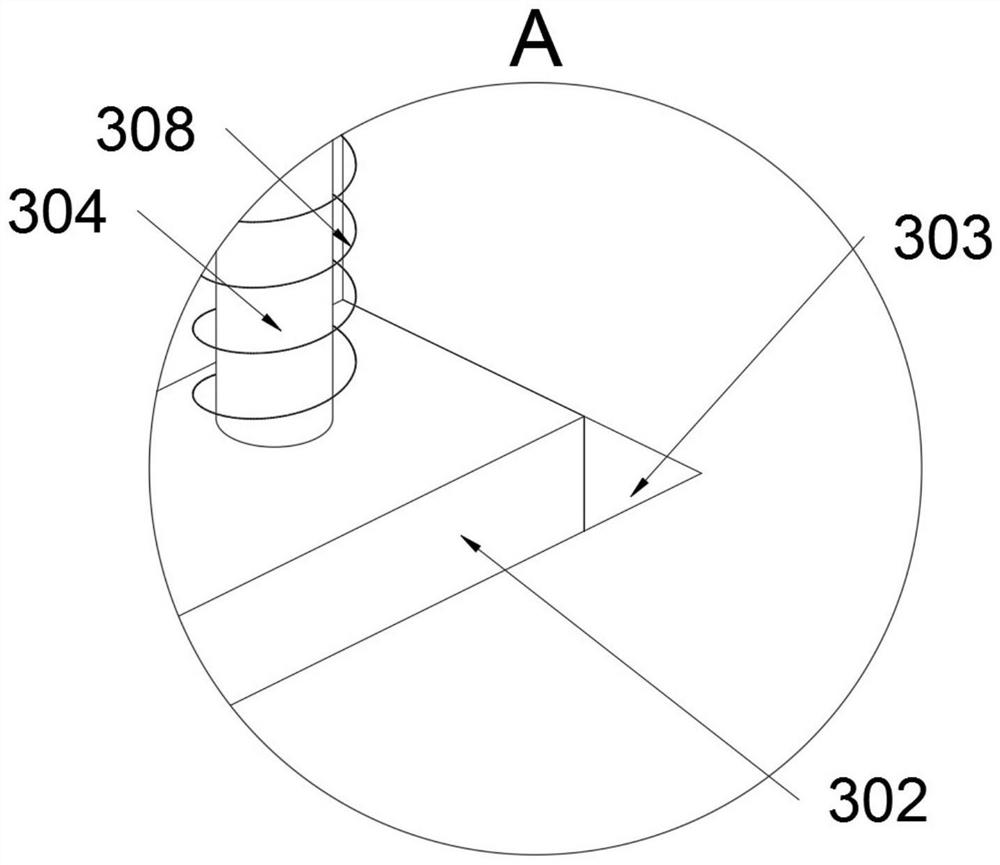

InactiveCN112338878ARealize reciprocating motionRealize dustproofFouling preventionElectrical testingElectric machineryDrive motor

The invention provides a special maintenance worktable for electronic information technology, relates to the technical field of maintenance worktables and solves the problems that reciprocating detection cannot be achieved by means of structural improvement, a detection head cannot be scrubbed and cleaned while reciprocating detection is performed and linked dedusting and cleaning of a scrubbing structure cannot be achieved, and small screw parts that are placed are easy to fall and miss. The special maintenance worktable for electronic information technology comprises a worktable main body, wherein a sliding structure is welded to the worktable main body, a driving motor is mounted on the worktable main body, and a detection structure is mounted on the sliding structure. A spray pipe is connected to a connecting pipe and is aligned with a cleaning block in position. The spray pipe is of a columnar tubular structure, spray holes are formed in the spray pipe in an annular array manner,and the spray holes formed in an annular array manner form a diffused cleaning type structure for sundries on the cleaning block.

Owner:宿州市成荣信息服务有限公司

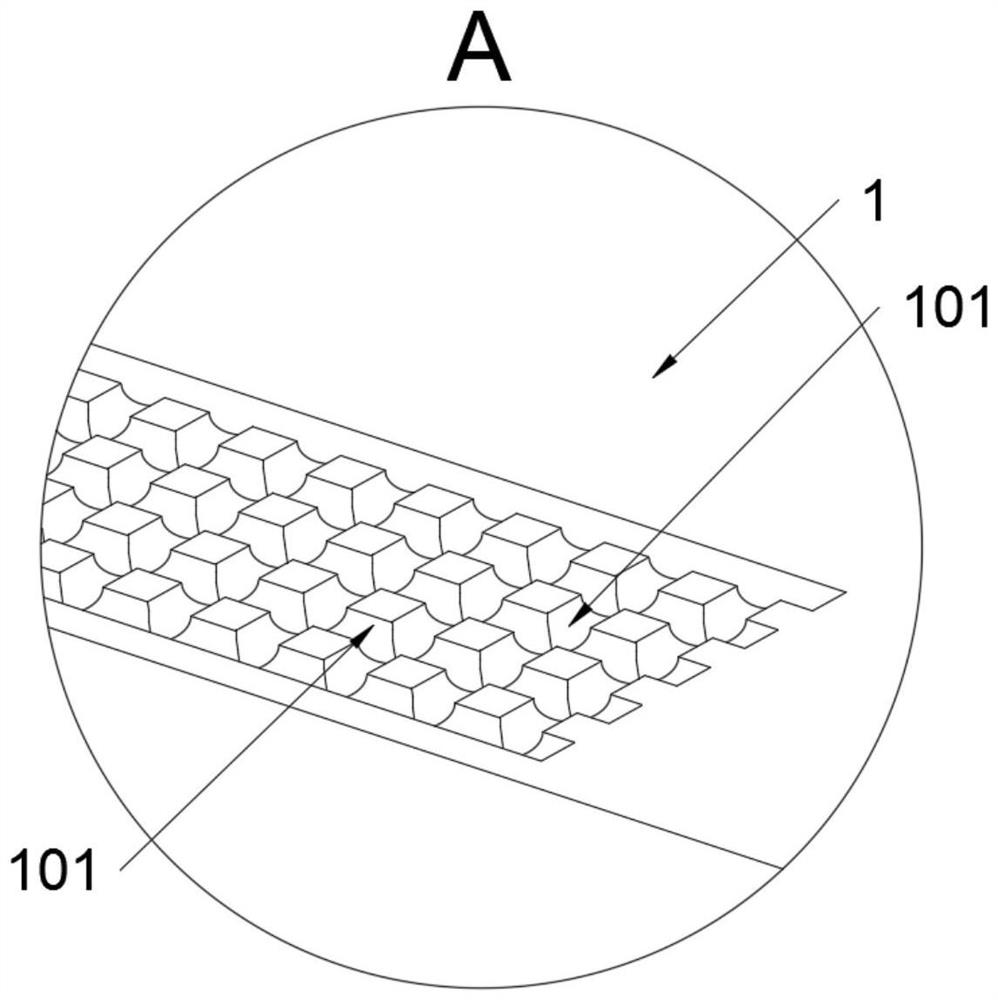

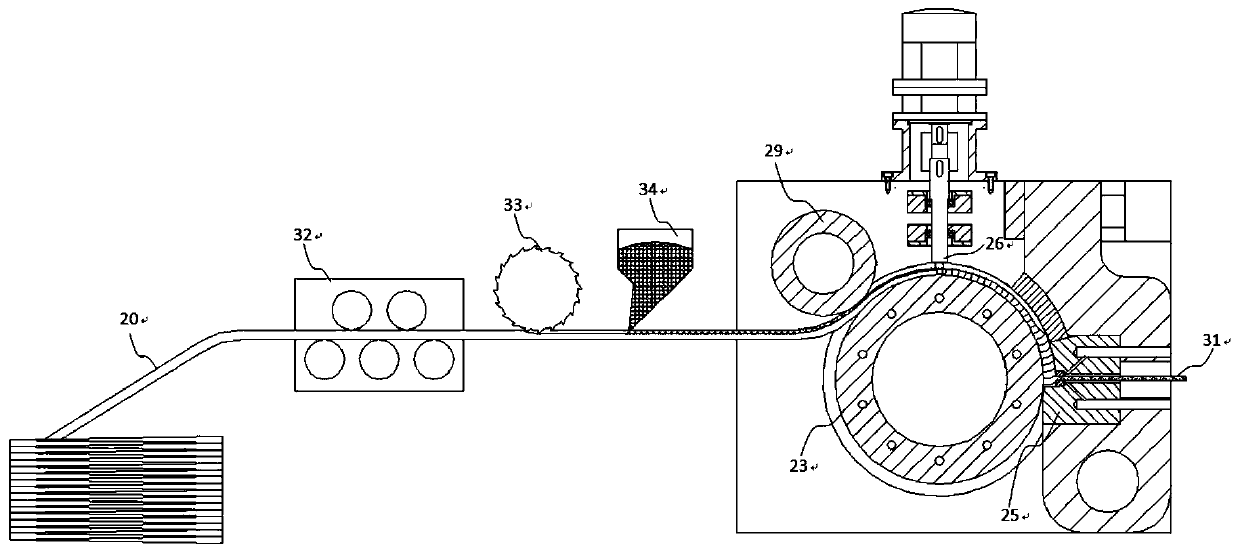

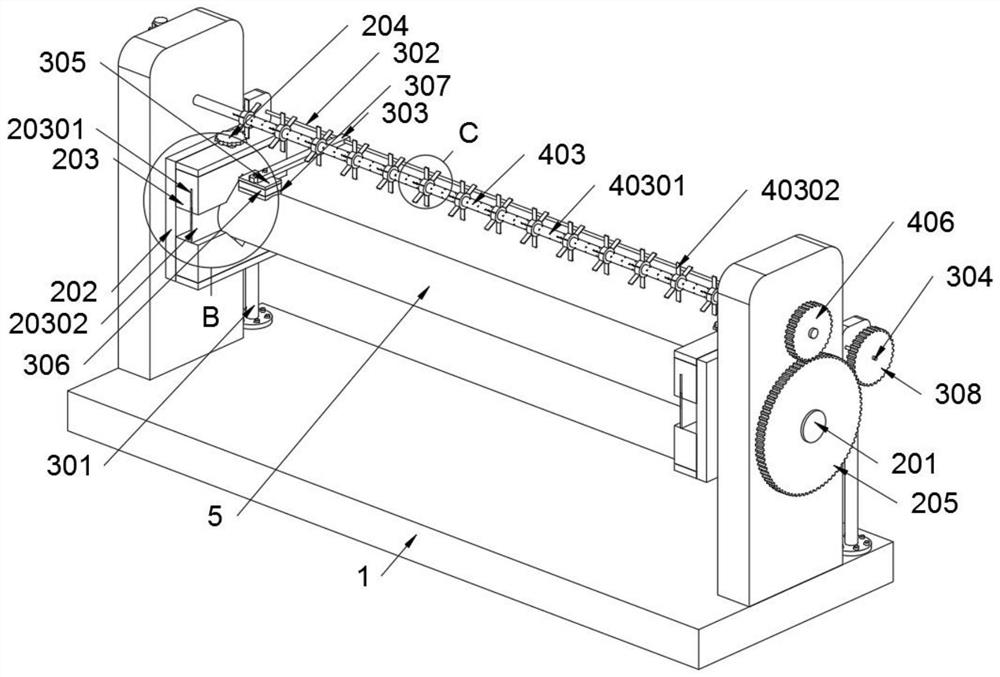

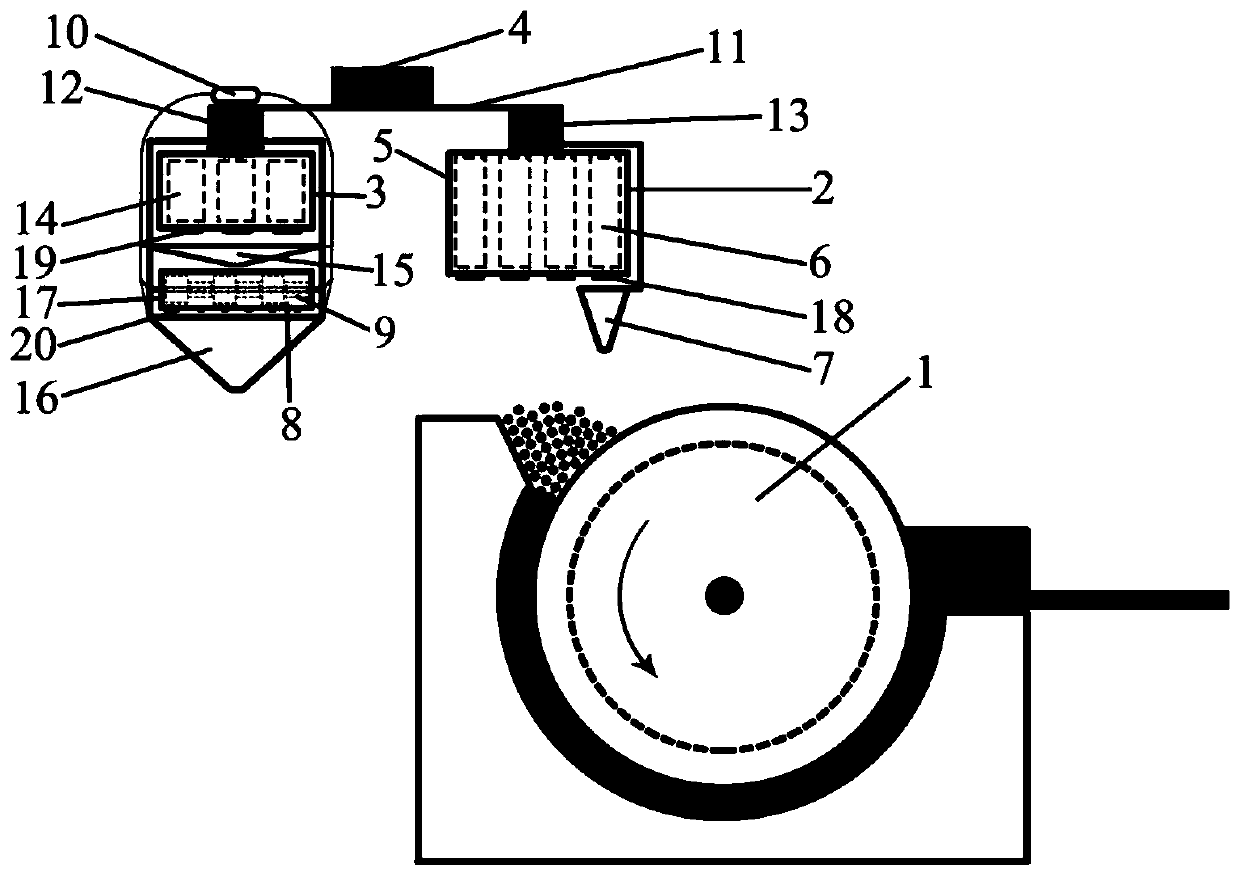

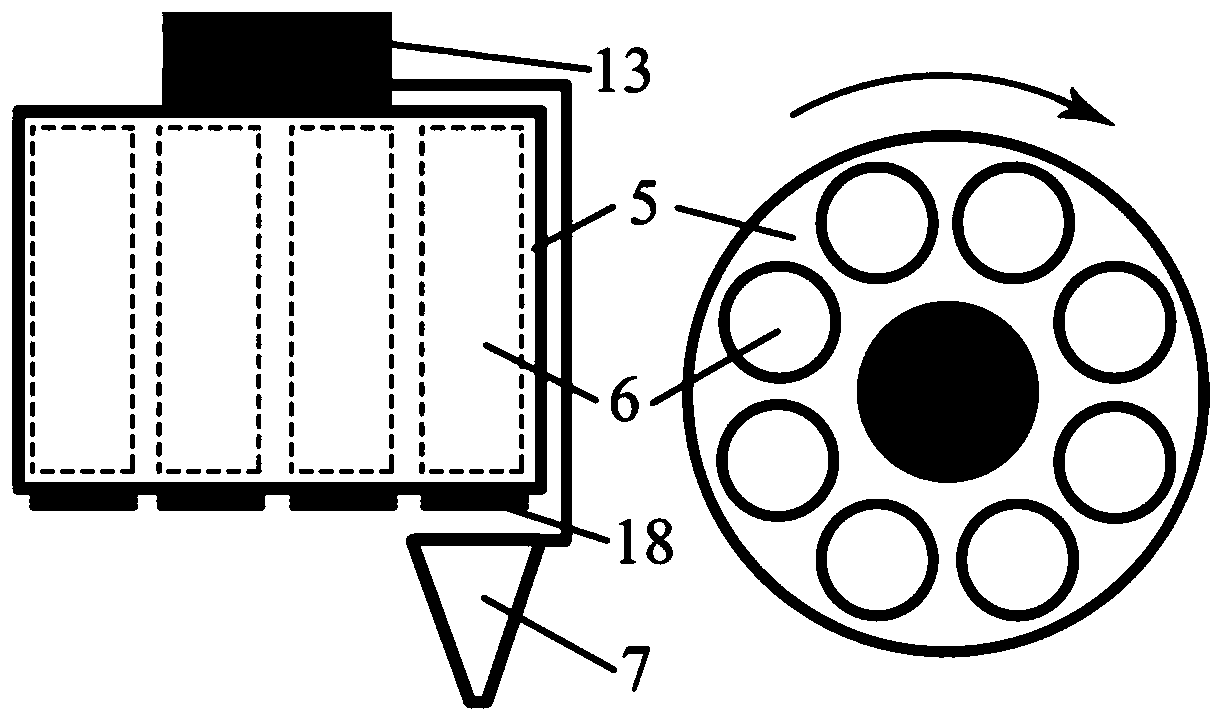

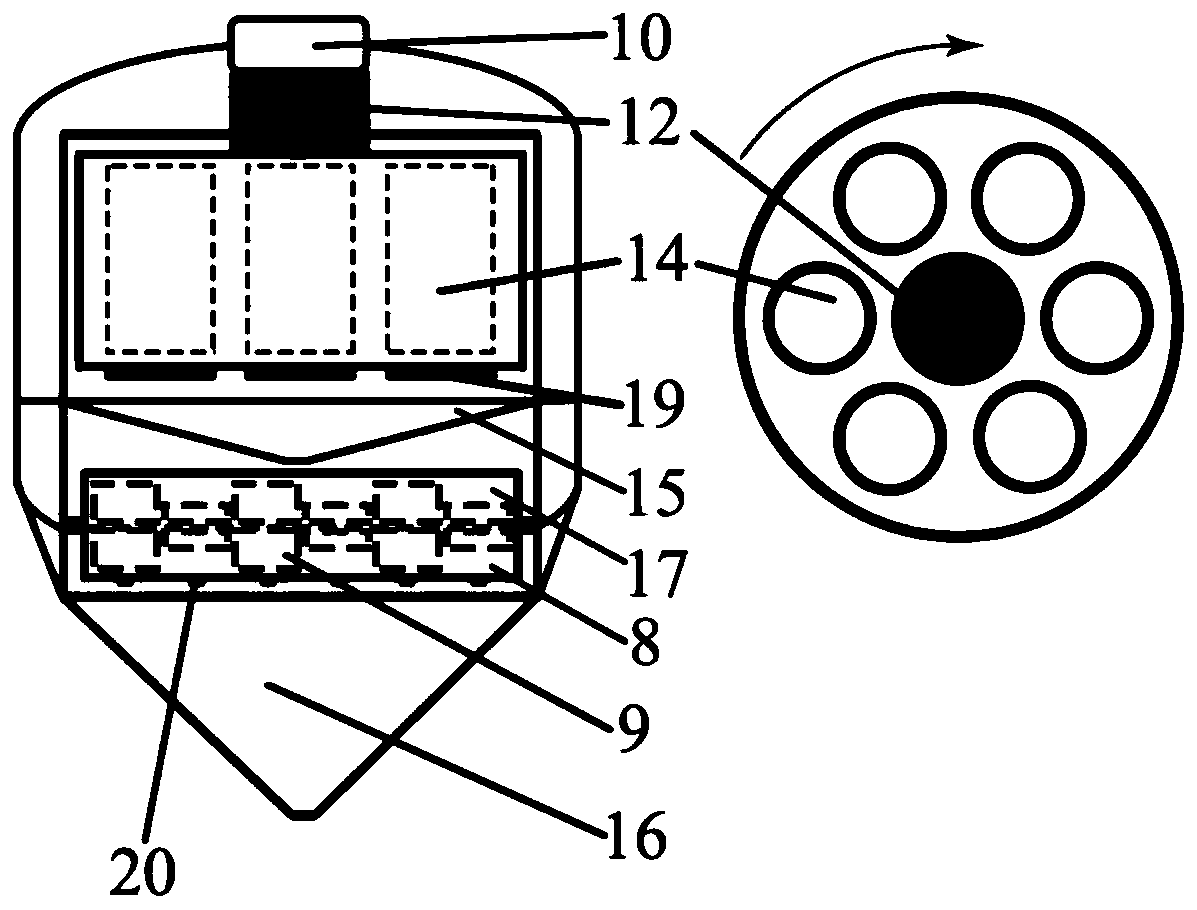

Continuous friction stir and extrusion production method for metal matrix composite and production device thereof

PendingCN110576069AGrain refinementUniform and stable tissueExtrusion diesWire rodMetal matrix composite

The invention provides a continuous friction stir and extrusion production method for a metal matrix composite and a production device thereof. According to the method and the device, a concave grooveis processed on a straightened matrix metal bar, a reinforcement is added into the concave groove, a composite blank is pressed into an annular groove of an extrusion wheel through a material pressing wheel and is clamped, the blank is driven to move towards a stirring head through rotation of the extrusion wheel, friction stir processing is carried out on the blank in the annular groove betweenthe material pressing wheel and a mold cavity at least once through rotation of the stirring head, the flowing direction is changed after the stirred blank is blocked by a material blocking block, theblank is extruded out from an inner hole of a mold, and therefore a continuous large-length metal matrix composite wire product is formed.

Owner:DALIAN JIAOTONG UNIVERSITY

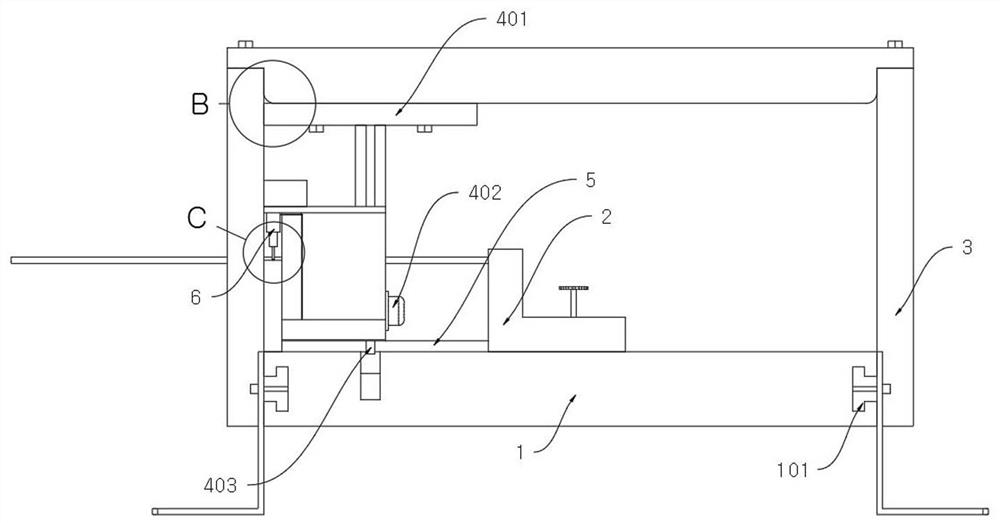

Pipeline anti-corrosion treatment facility

InactiveCN112589549AImplement automatic conversionRealize continuous extrusionGrinding carriagesRevolution surface grinding machinesThermodynamicsEngineering

The invention provides a pipeline anti-corrosion treatment facility, and relates to the technical field of pipeline anti-corrosion treatment. The problems that removal of residues attached to the outer wall of a pipeline cannot be synchronously achieved after polishing operation is accomplished, displacement of a polishing structure cannot be synchronously achieved in the pipeline rotary polishingachieving process through the structural improvement, and quick clamping and collision protection of an adjusting structure cannot be achieved are solved. The pipeline anti-corrosion treatment facility comprises a body base. Two clamp structures are installed on the body base, a polishing structure is further installed on the body base, and a pipeline is clamped on the clamp structures. Due to the facts that poke rods make contact with a stress block, and the stress block is of a triangular prism structure, when a poke base drives the poke rods to rotate, continuous extrusion of an elastic telescopic bottle can be achieved. A spray pipe is connected to a connecting pipe and located at the position 5cm above the pipeline, and therefore when the elastic telescopic bottle is extruded, pneumatic removal of the polishing residues on the pipeline can be achieved through the spray pipe.

Owner:莱西市盈德装备技术中心

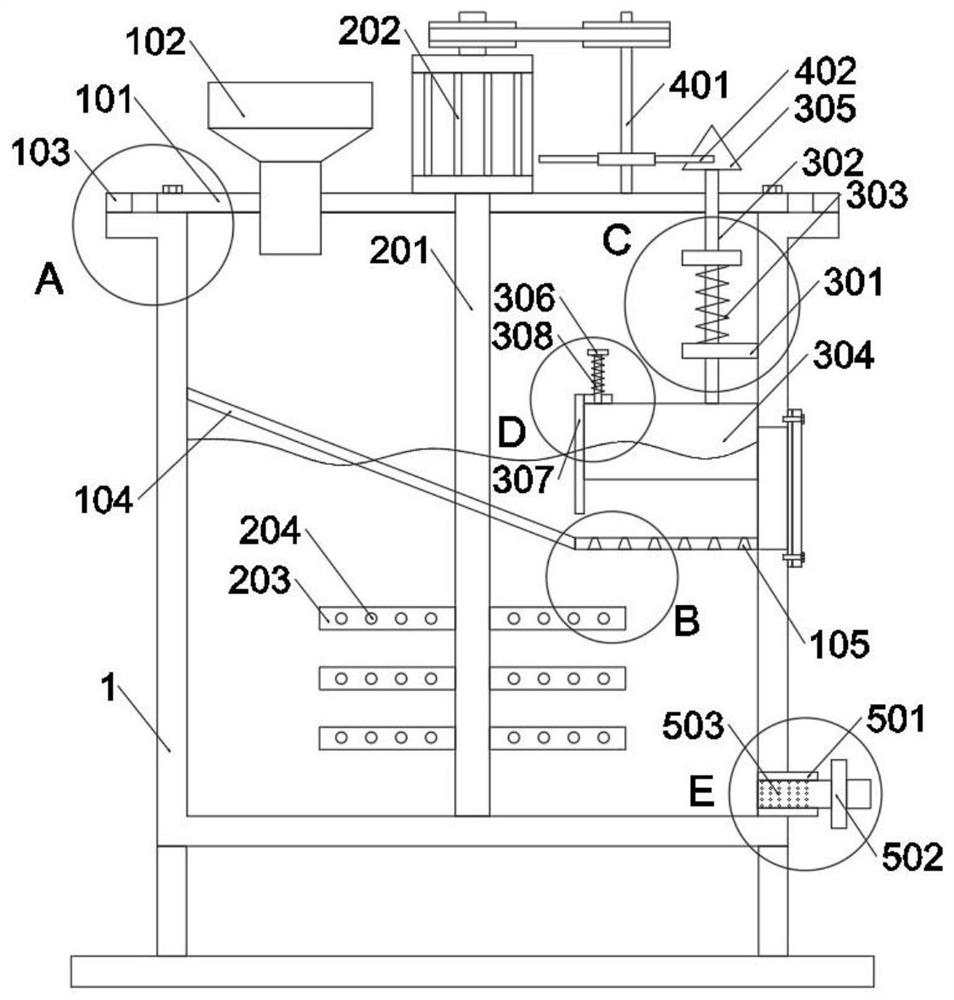

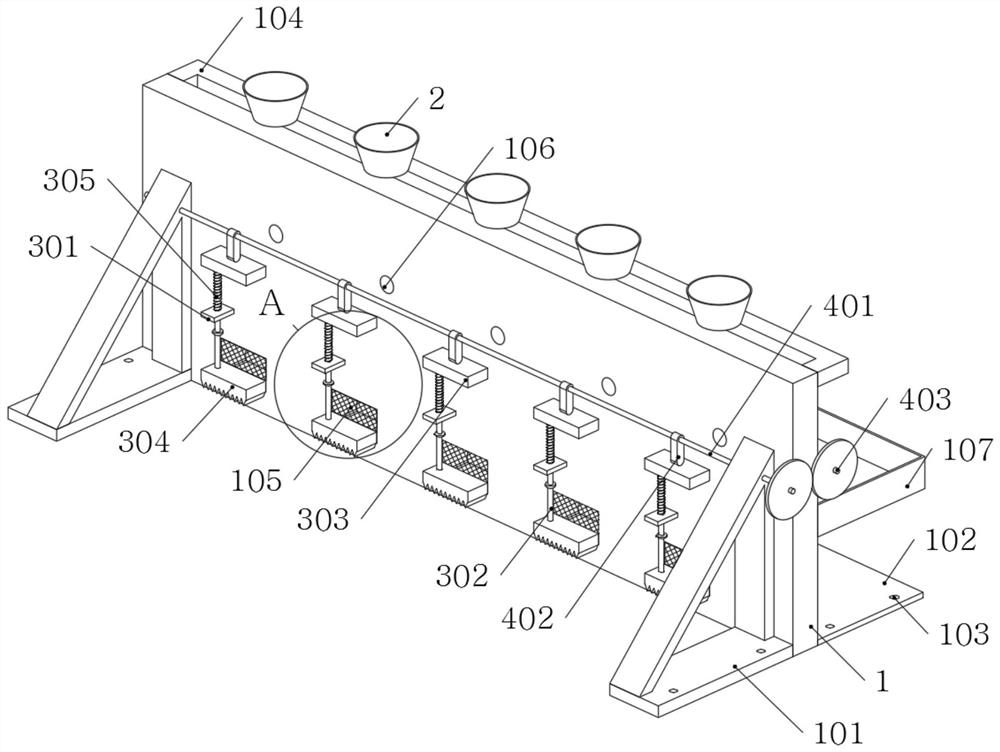

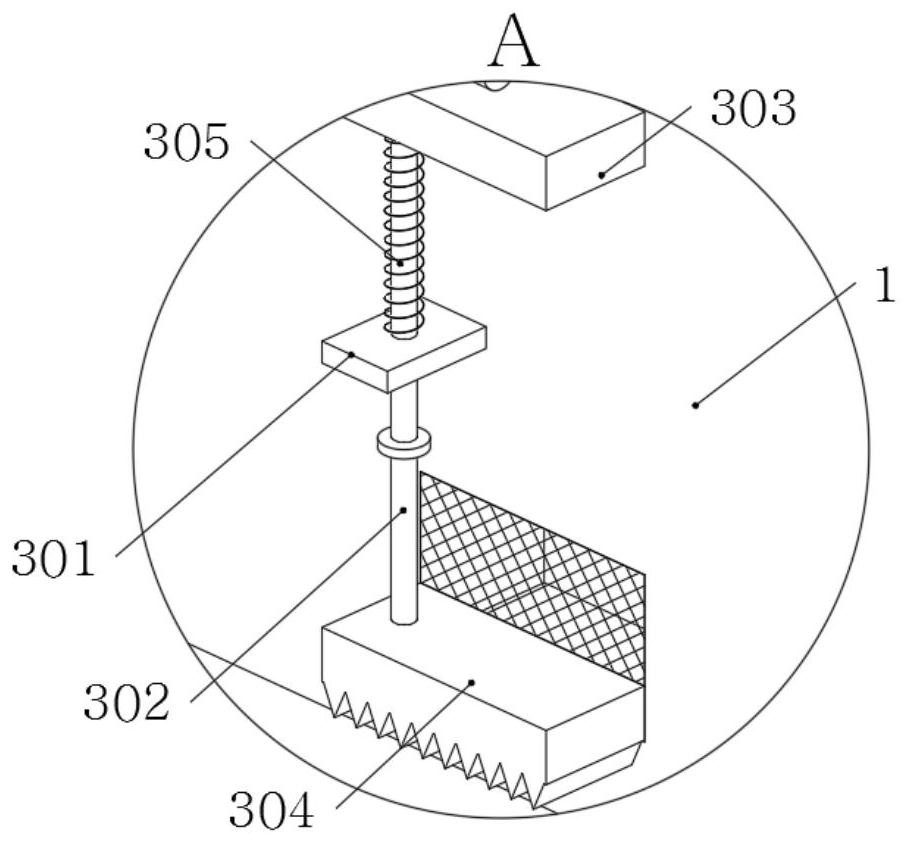

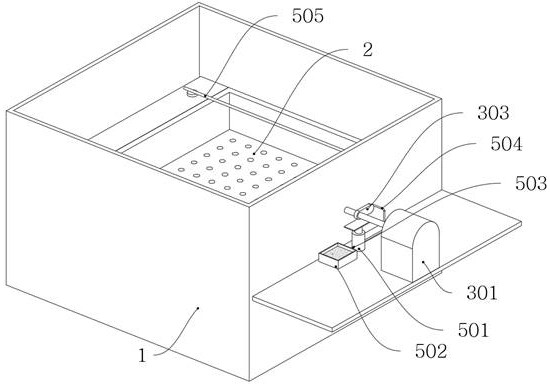

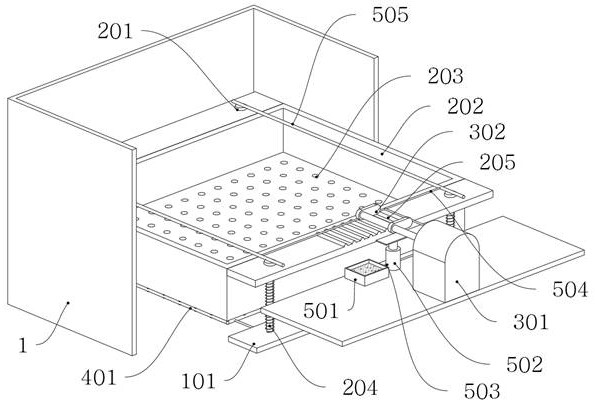

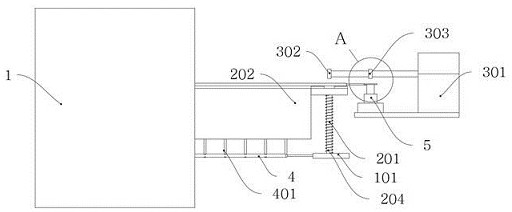

Concrete hardness detection device for building construction

InactiveCN112611631AEnables continuous impact detectionRealize continuous extrusionInvestigating material hardnessWater storageArchitectural engineering

The invention provides a concrete hardness detection device for building construction, relates to the technical field of concrete detection, and solves the problems that detection cannot be realized through linkage in a concrete block moving process through structural improvement, the detection of the concrete block in a humid state cannot be realized, and organic combination of a detection structure and other structures cannot be realized. The concrete hardness detection device for building construction comprises a workbench. A driving structure is mounted on the workbench, and a concrete block is placed on the workbench. A water storage box is fixedly connected to a stress plate through a bolt, the water storage box is connected with a water inlet pipe, and the stress plate is in contact with the tail end of a telescopic bottle, so that continuous extrusion of the telescopic bottle can be realized when the stress plate reciprocates; fourthly, a spray pipe is of a cylindrical tubular structure, and spray holes are formed in the outer wall of the spray pipe in an annular array shape; and the spray holes are of a circular hole-shaped structure, and the spray holes formed in the annular array form a diffusion spray type structure of the spray pipe together.

Owner:孙学志

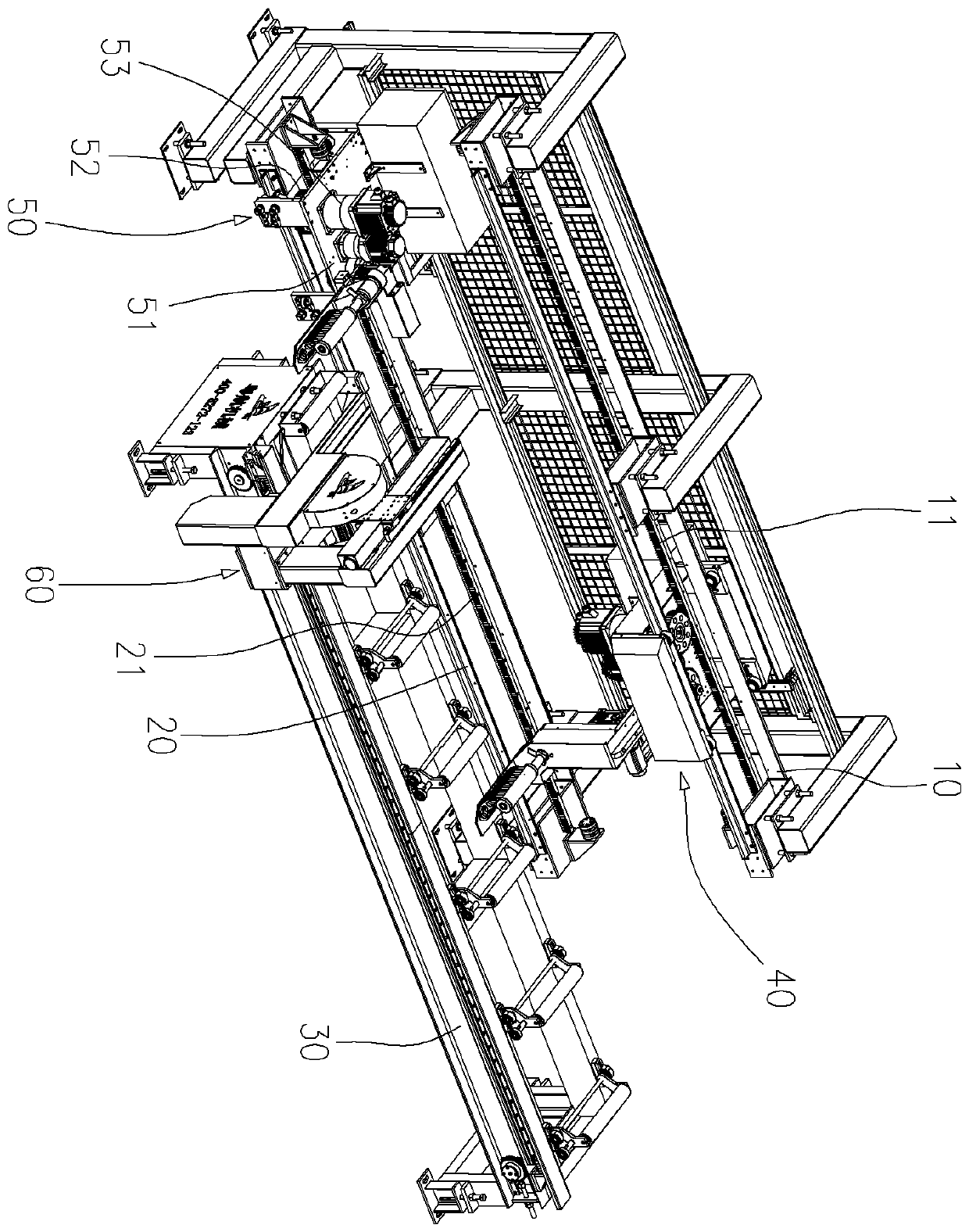

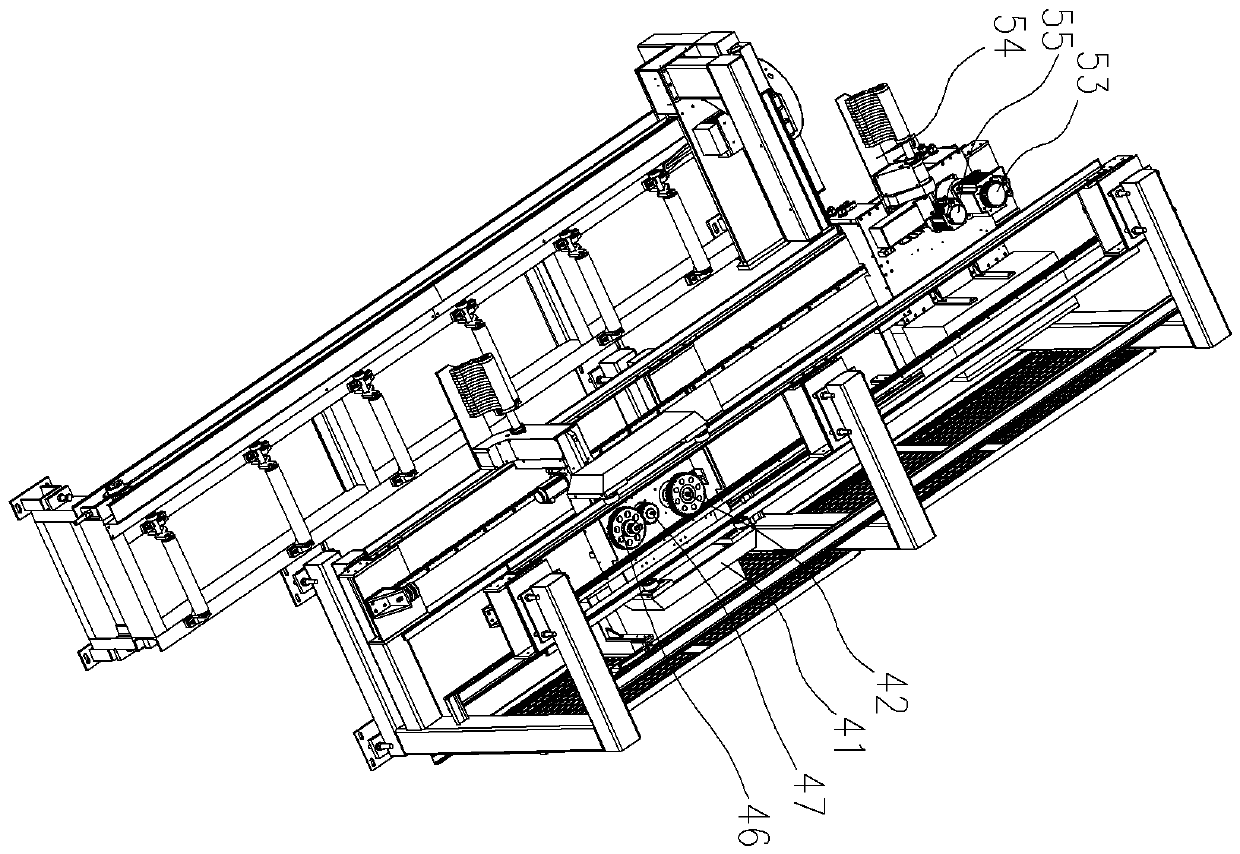

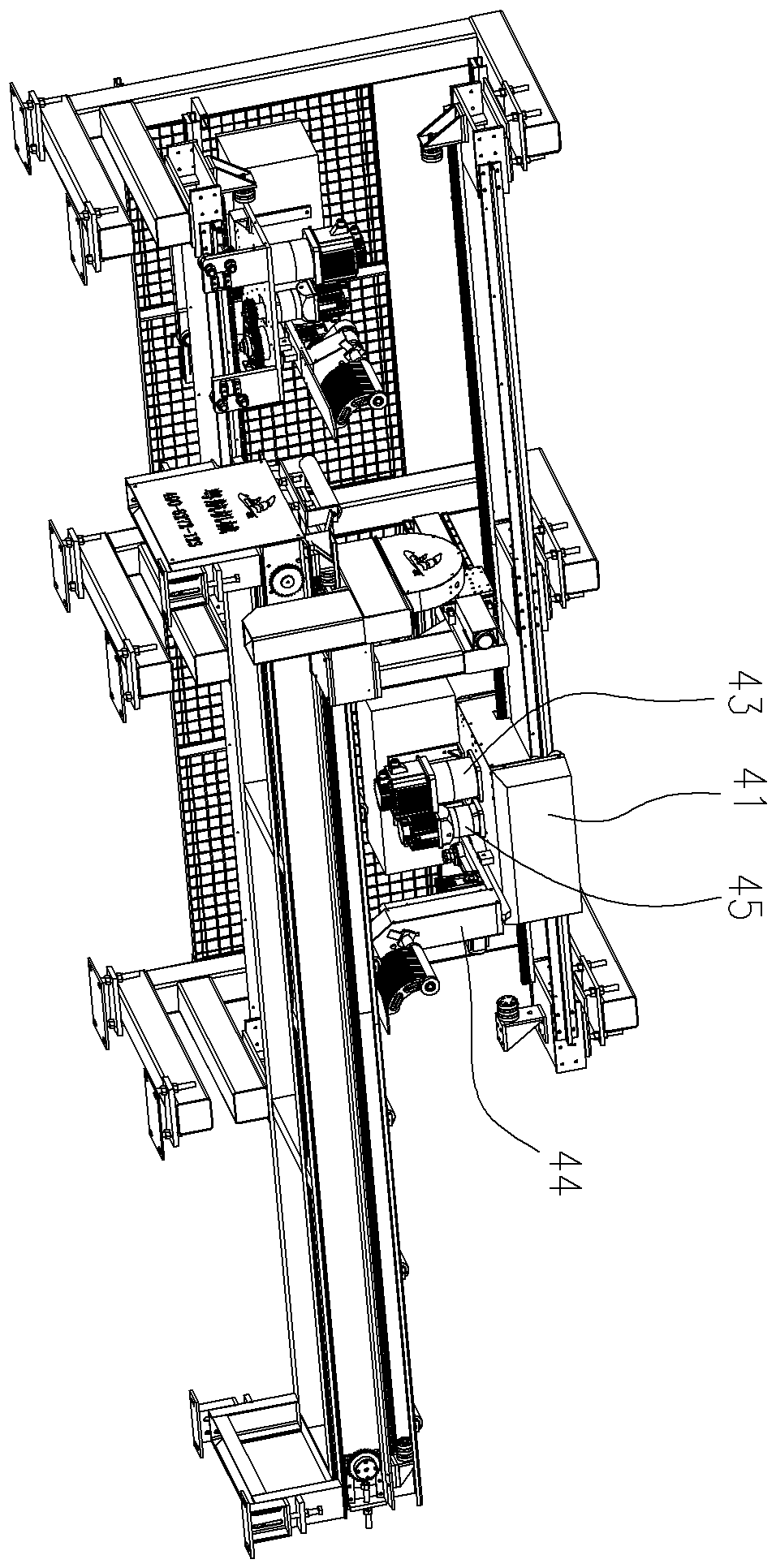

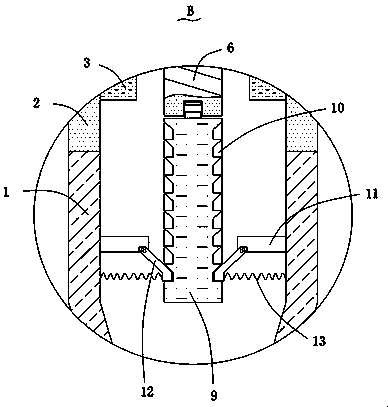

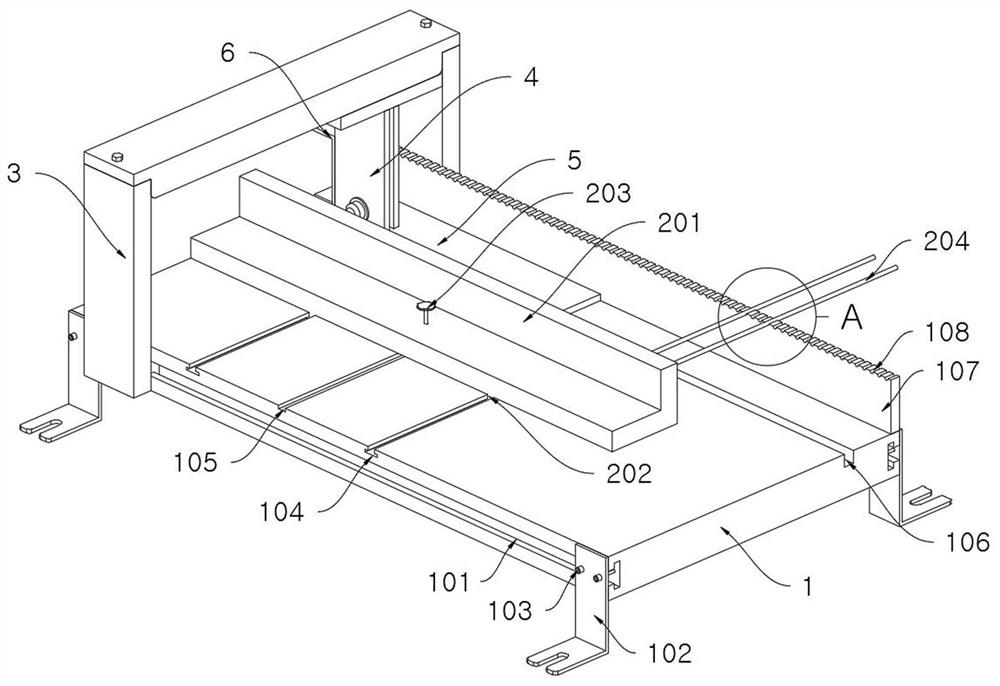

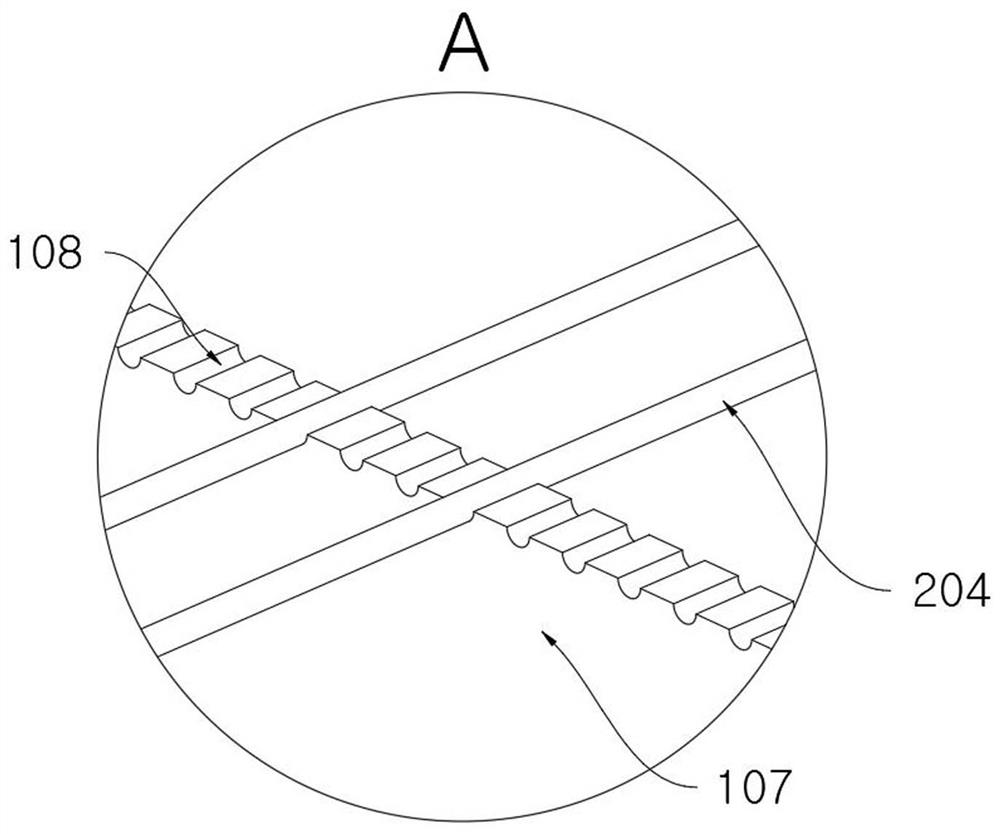

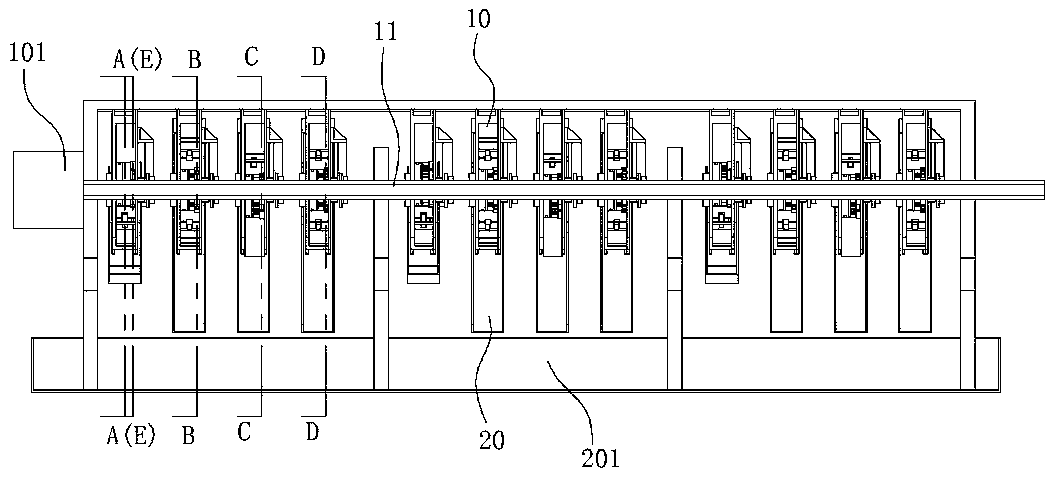

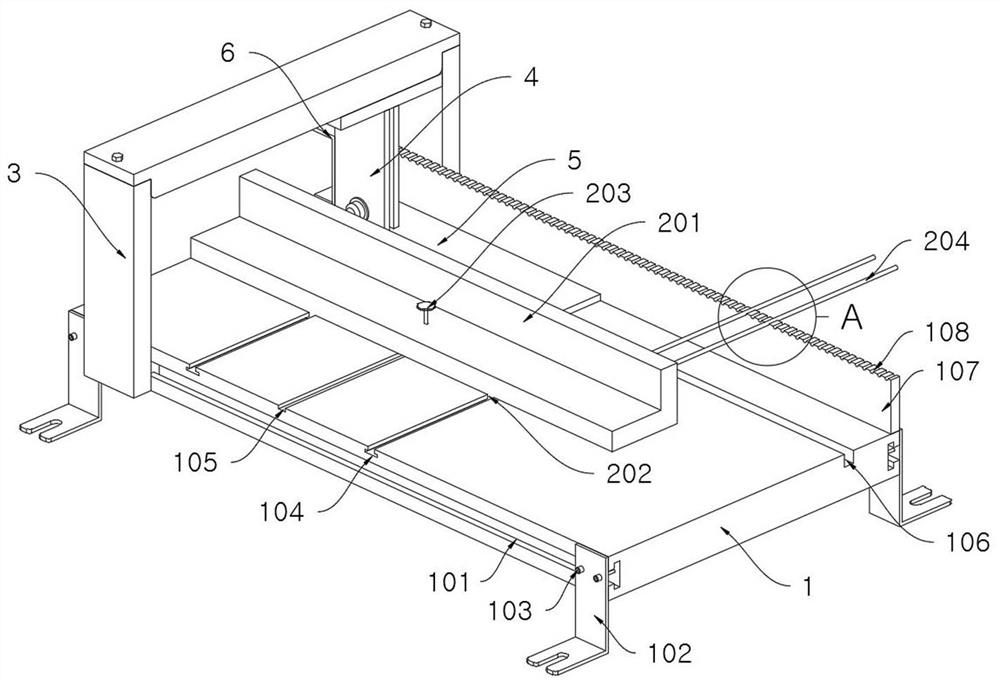

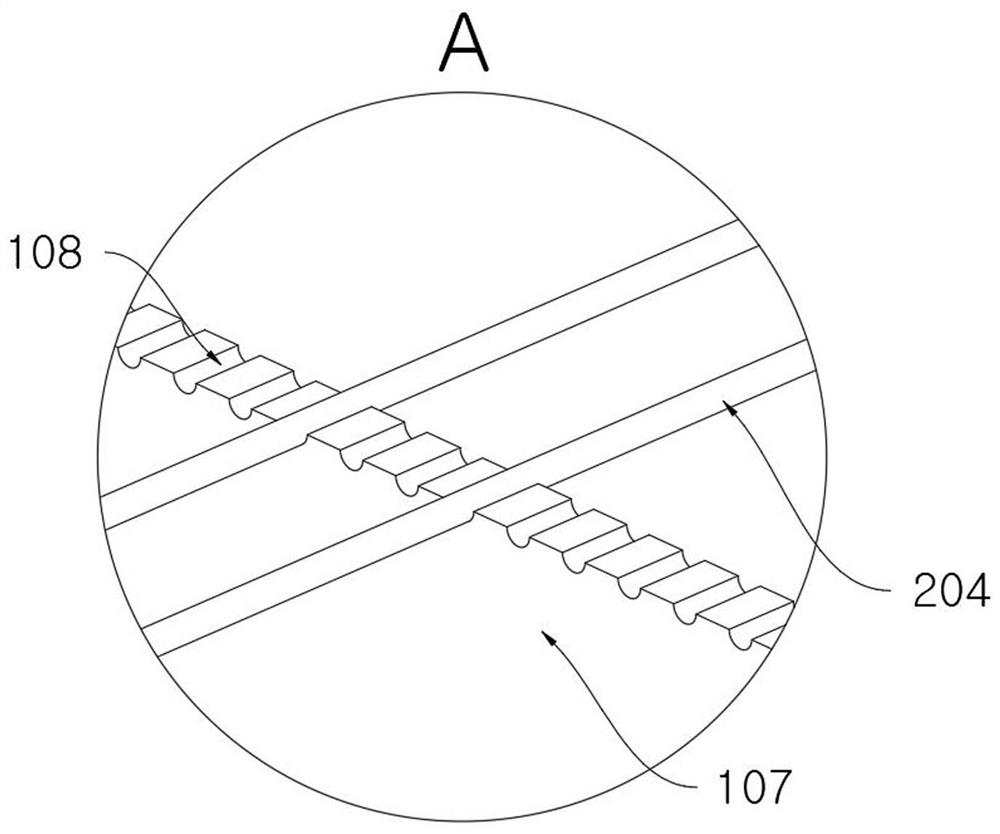

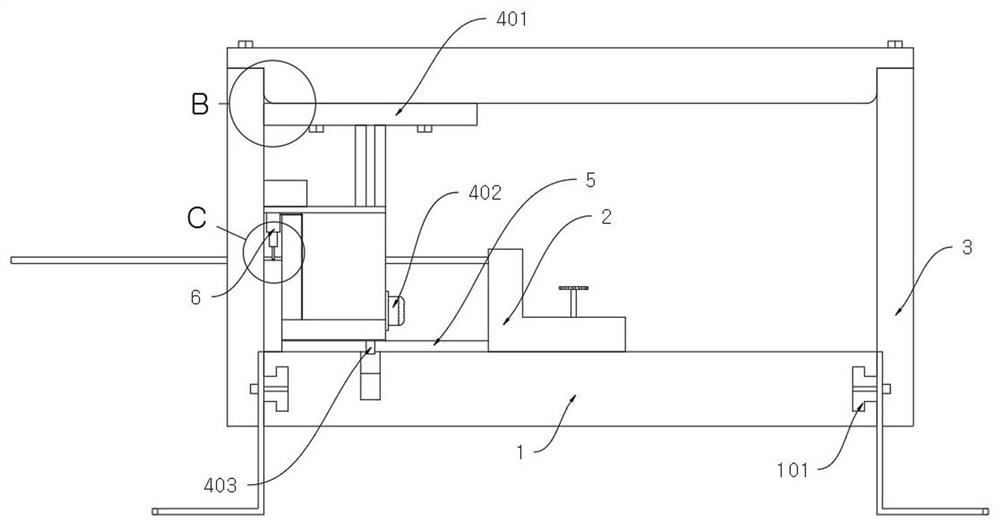

1000T pure-electric three-head tractor

The invention provides a 1000T pure-electric three-head tractor. The 1000T pure-electric three-head tractor comprises an upper layer guide rail unit, a lower layer guide rail unit, a roller frame, a first drawing head, a second drawing head and an automatic interruption saw; the middle part of the upper layer guide rail unit is provided with a first rack; the middle part of the lower layer guide rail unit is provided with a second rack; the first drawing head comprises a first drawing vehicle, a first driving gear and a first servo motor, wherein the first driving gear is arranged inside the first drawing vehicle and is engaged with the first rack; the first servo motor is reversely arranged at the bottom of the first drawing vehicle and is in transmission connection with the first drivinggear; the second drawing head comprises a second drawing vehicle, a second driving gear and a second servo motor, wherein the second driving gear is arranged inside the second drawing vehicle and isengaged with the second rack; and the second servo motor is reversely arranged at the top of the second drawing vehicle and is in transmission connection with the second driving gear. The 1000T pure-electric three-head tractor provided by the invention has the advantages of extremely high drawing speed, flexible start and braking, small inertia, relatively low running noise, stable performances, low fault rate and the like.

Owner:FOSHAN JINHANYUE HAIHANG MACHINERY EQUIP

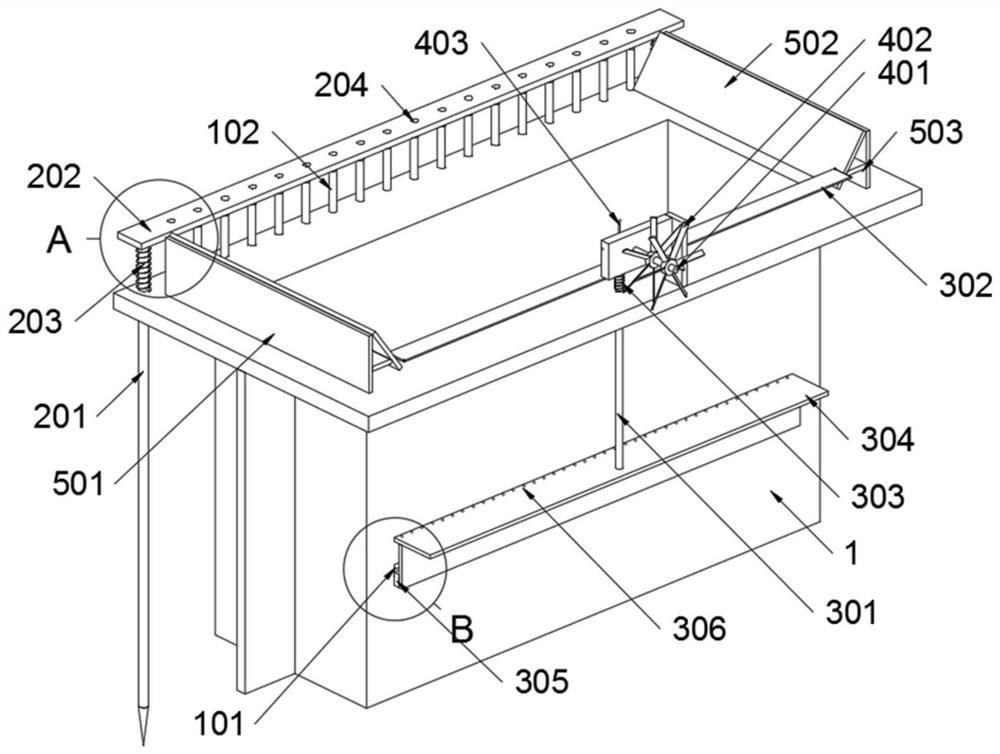

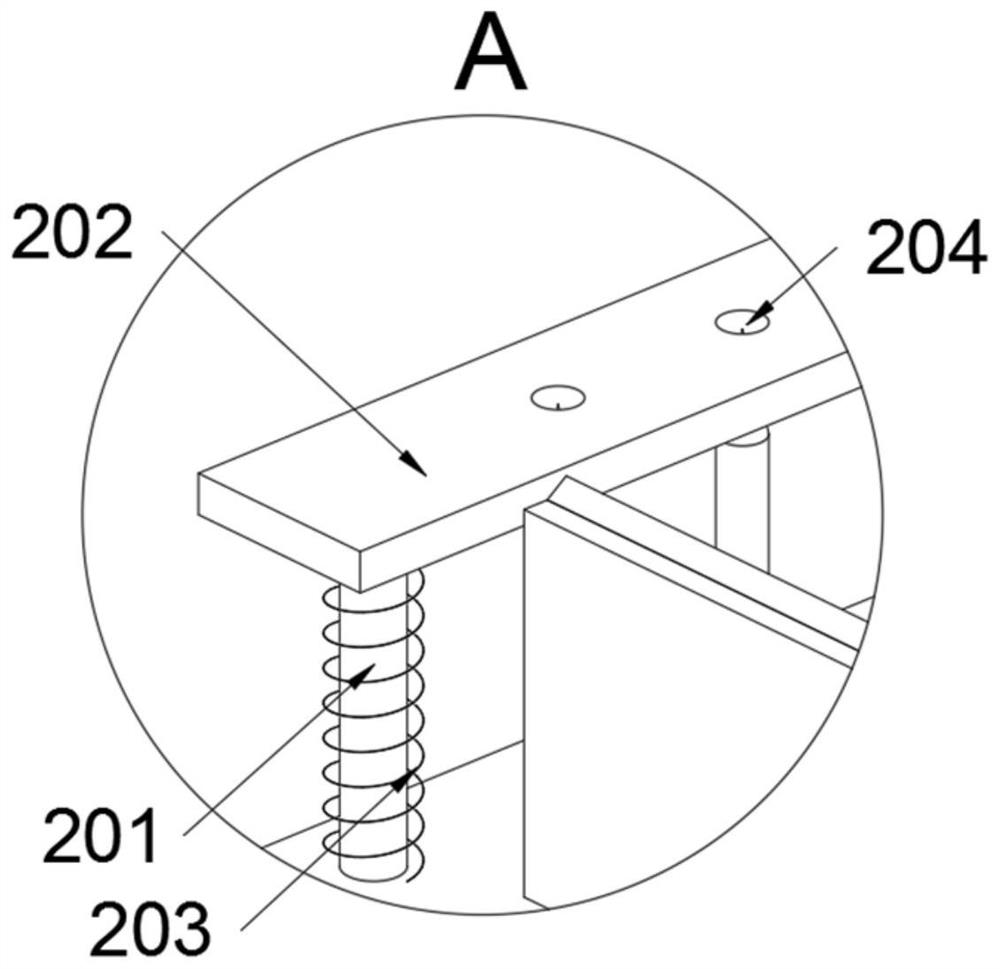

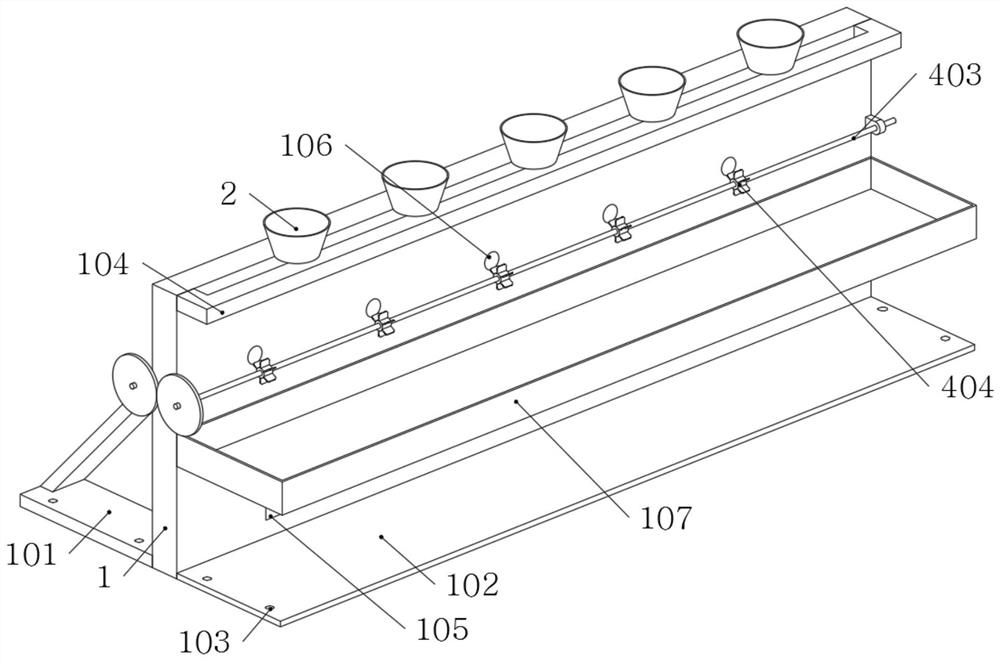

Planting device for wetland water quality protection

ActiveCN113079863ARealize continuous extrusionClean thoroughlySelf-acting watering devicesSustainable biological treatmentVegetationReciprocating motion

The invention provides a planting device for wetland water quality protection, and relates to the technical field of planting devices. The planting device solves the problems as follows: a protection structure is not provided, and personnel easily climb over the planting device to enter the wetland to damage the wetland or cause danger; automatic cleaning of a filter screen cannot be realized under the driving of natural wind power through the structural improvement; and the enhancement of the photosynthesis of the vegetation cannot be realized through the structural improvement. The planting device for wetland water quality protection comprises a box body, wherein the box body is of a rectangular box-shaped structure; the tail end of an elastic block is adhered to a seat plate, and the head end of the elastic block is in contact with a lens, so that the elastic resetting of the lens can be realized through the elastic block, and the photosynthesis of the vegetation can be enhanced through the lens; secondly, the initial position of the lens is inclined, and the inclination angle is 45 degrees; and the lens is in contact with a baffle plate, so that the reciprocating motion of the lens can be realized when the baffle plate reciprocates up and down, and the photosynthesis of the vegetation is further enhanced.

Owner:杨尧

Copper bus bar with high strength, high conductivity and high toughness and preparation method thereof

InactiveCN102034563BReduce energy consumptionReduce pickling processSingle bars/rods/wires/strips conductorsManufacturing extensible conductors/cablesLiquid cathodeLiquid copper

The invention relates to a copper bus bar with high strength, high conductivity and high toughness and a preparation method thereof. The copper bus bar is characterized in that the material comprises 99.96-99.998% of copper and silver, 0.002-0.02% of yttrium rare earth and 0-0.038% of impurities, wherein silver accounts for 0.0005-0.01% of copper and silver; and the copper master alloy containingthe yttrium rare earth is used as a modifier. The preparation method comprises the following steps: (1) melting a copper material: heating the cathode copper in a mains frequency core induction furnace to melt the cathode copper into liquid cathode copper; (2) modifying liquid copper: melting the modifier in the liquid cathode copper and fully mixing the modifier with the liquid cathode copper; (3) drawing a continuously cast copper bar upwards: causing a crystallizer of a continuous casting machine to stretch into the liquid cathode copper, condensing the liquid cathode copper into the copper bar in the crystallizer and drawing the copper bar upwards by means of two pairs of drawing roll mechanisms in the continuous casting machine to lead the copper bar to a take-up machine via a wheel frame; (4) continuously extruding the copper bar at medium temperature and carrying out anti-oxidation cooling; and (5) carrying out draw forming: putting copper bus bar blanks on a drawing machine, carrying out draw forming on the copper bus bar blanks.

Owner:福州市广福有色金属制品有限公司

Textile machine for cutting gauze

ActiveCN112575569ARealize continuous cuttingAchieve absorptionSevering textilesDirt cleaningAssembly lineManufacturing engineering

Owner:淮北悯农生物科技有限公司

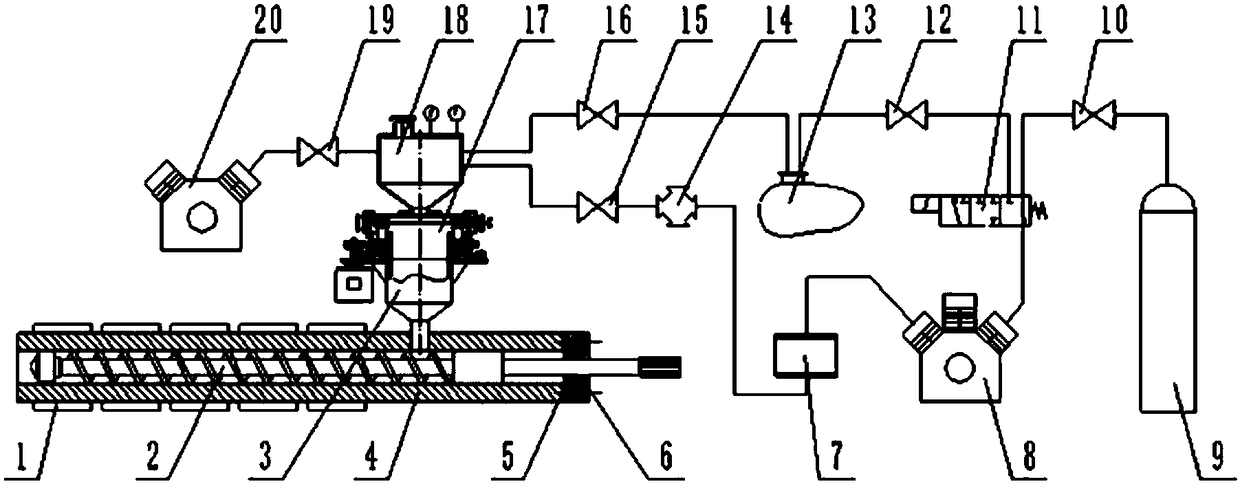

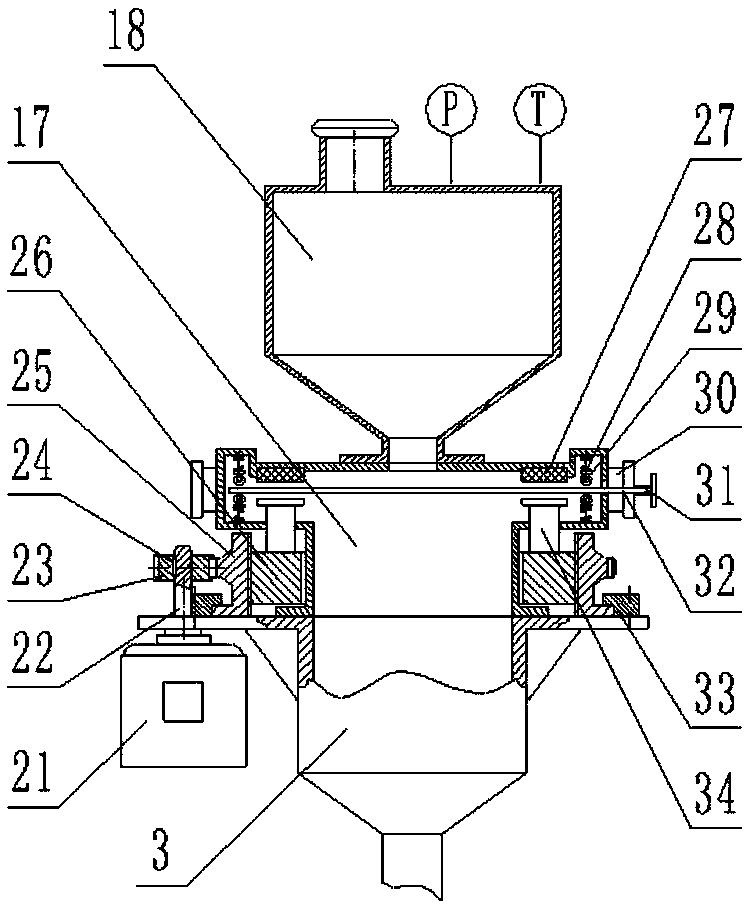

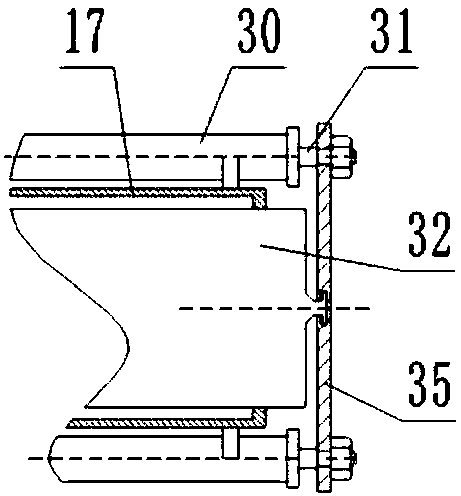

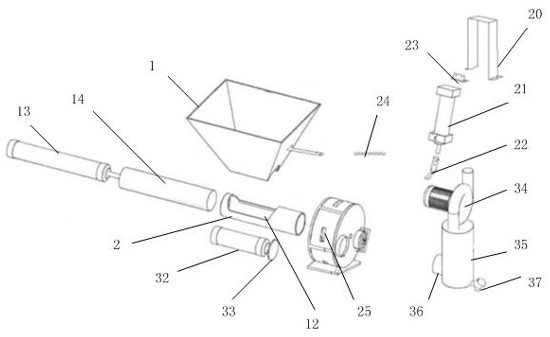

Kettle-pressure extrusion integrated micro-foaming extrusion forming device and kettle-pressure extrusion integrated micro-foaming extrusion forming method

InactiveCN108312413AImprove performanceRealize continuous extrusionFlat articlesMotor driveGas cylinder

The invention discloses a kettle-pressure extrusion integrated micro-foaming extrusion forming device and a kettle-pressure extrusion integrated micro-foaming extrusion forming method. The kettle-pressure extrusion integrated micro-foaming extrusion forming device mainly consists of a material feeding system, a gas feeding system and an extrusion system; the material feeding system is connected with a material feeding device of a machine barrel of the extrusion system; the gas feeding system provides the material feeding system with supercritical gas; and the material feeding system mainly consists of a storage hopper, a motor, a motor driving shaft, a gear, a key, a transmission piece, a pressure piece, a sealing barrel, a permeating kettle, a sealing gasket, a spring, a roller, a gas cylinder, a gas cylinder pull rod, a sealing plate, a limiting block and a pressure rod. A granular raw material is permeated, so that the penetrating time is shortened substantially, continuous extrusion of micro-foaming products is achieved, and the production efficiency is improved; the granular raw material is subjected to supercritical gas permeating through the permeating kettle, so that technological parameters are controlled accurately, the foaming quality is higher, and the property of the product is better; and the gas after being permeated can be recycled in a working process, so thata use ratio of the gas is increased compared with that in the traditional kettle-pressure foaming method.

Owner:BEIJING UNIV OF CHEM TECH

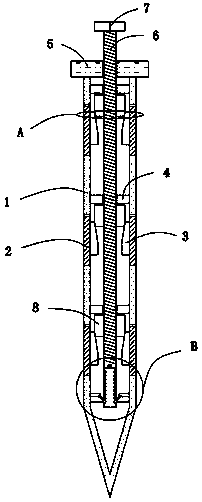

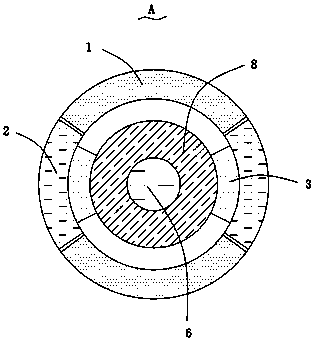

Expansion anchor rod

The invention provides an expansion anchor rod which comprises a shell, multiple anchor blocks, multiple extruding blocks, a tail block, a screw rod, a rotating block and multiple circular truncated cone blocks. The multiple anchor blocks are evenly arranged on the two sides of the shell. The multiple extruding blocks are fixedly installed on the multiple anchor blocks correspondingly, and the multiple extruding blocks are located in the shell. The tail block is fixedly installed at the top end of the shell. The screw rod is installed on the tail block in a threaded manner, and the bottom endof the screw rod extends into the shell. The rotating block is located above the tail block, and the rotating block is fixedly connected with the top end of the screw rod. The multiple circular truncated cone blocks are fixedly arranged on the outer side of the screw rod in a sleeving manner, and the multiple circular truncated cone blocks are located in the shell. The expansion anchor rod has thebeneficial effects that use is convenient, stability is good, and the anchor rod can be prevented from disengaging from a hole.

Owner:铜陵市弘润机电有限责任公司

Cutting machining device for mechanical part machining

ActiveCN113695683AAchieve installationAchieve cleanupPositioning apparatusMaintainance and safety accessoriesMechanical componentsStructural engineering

The invention provides a cutting machining device for mechanical part machining, and relates to the technical field of part machining. The cutting machining device comprises a main body seat, a fixing part, a mounting frame, a cutting part and a smearing part; two sliding grooves A are symmetrically formed in the main body seat, and two sliding grooves B are symmetrically formed in the top end face of the main body seat; supporting claws and a sliding arm are arranged in a matched mode, so that limiting of the sliding arm can be achieved, specifically, due to the fact that the left end face of the sliding arm makes contact with the supporting claw at the left side, after the sliding arm slides rightwards by 50 cm, the right end face of the sliding arm makes contact with the supporting claw, sliding limiting of the sliding arm can be achieved through the supporting claws, and the problem that the clamping quality is affected due to the fact that a gap is too large when a clamping structure is used for a long time is solved; and the problems that supporting claw fixing bolts are easy to loosen, and the function of the supporting claws is single are solved.

Owner:如东中灿机械有限公司

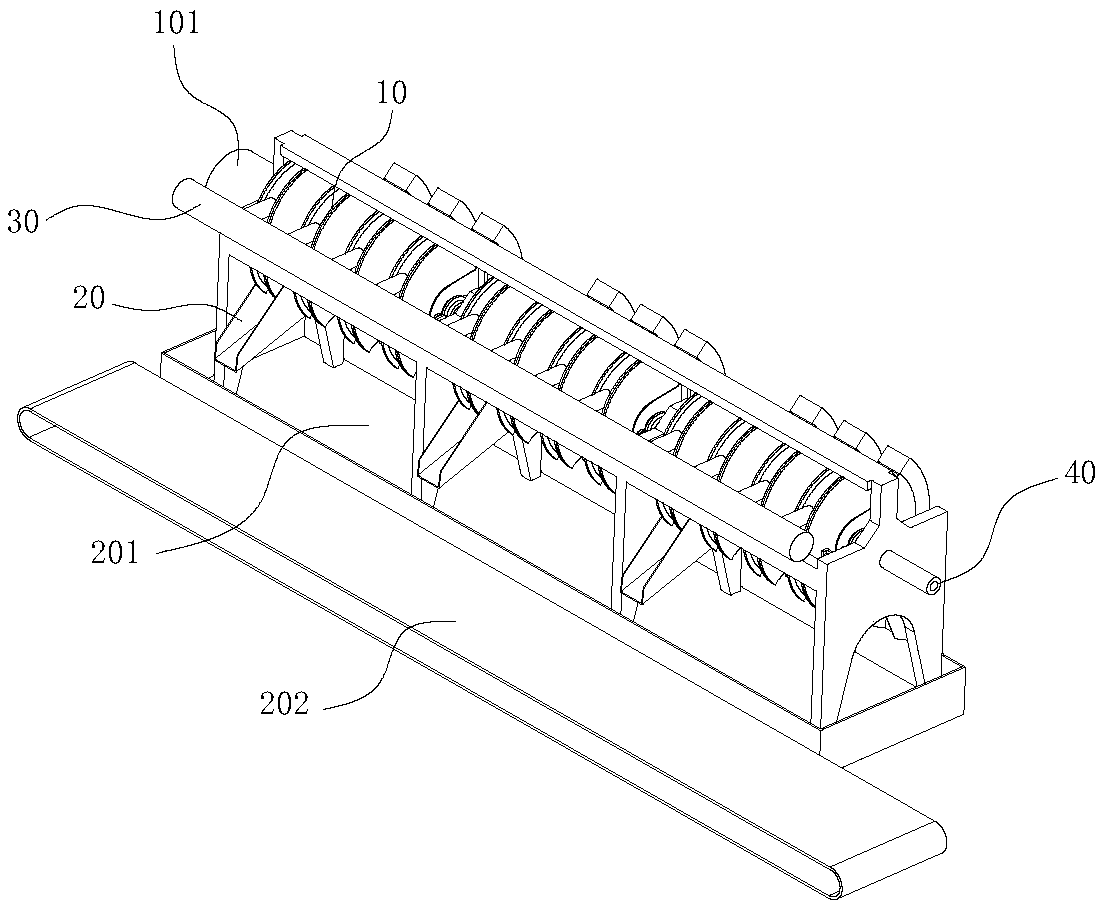

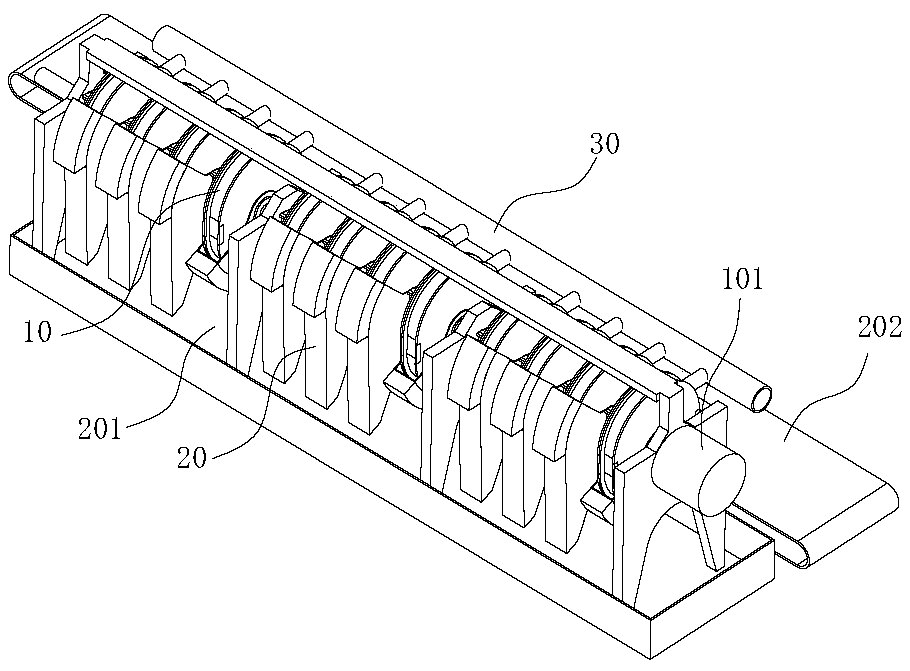

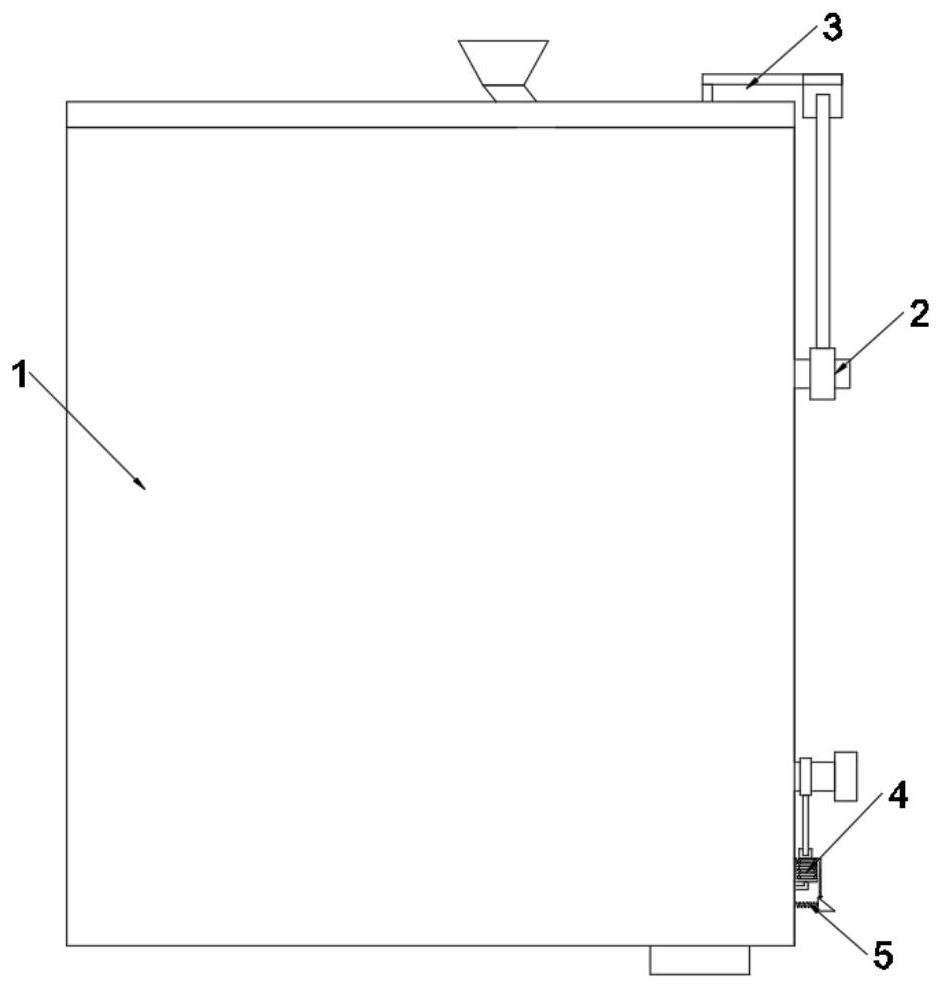

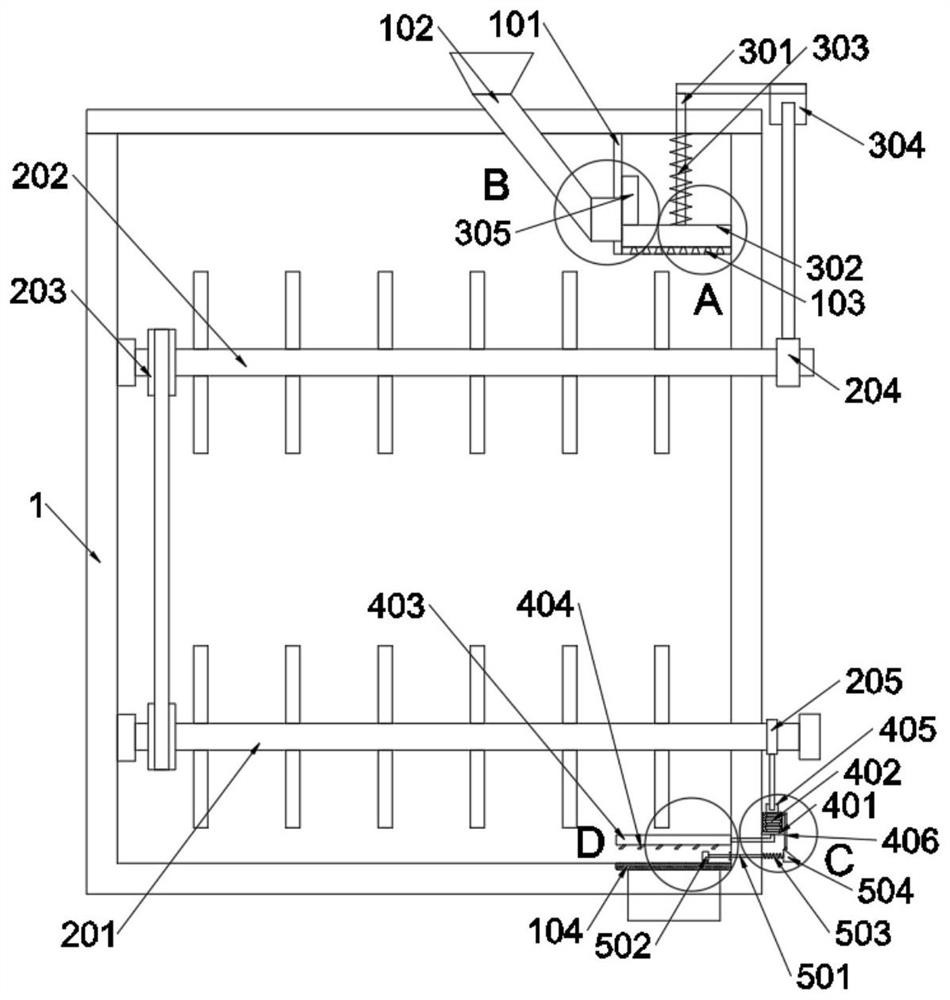

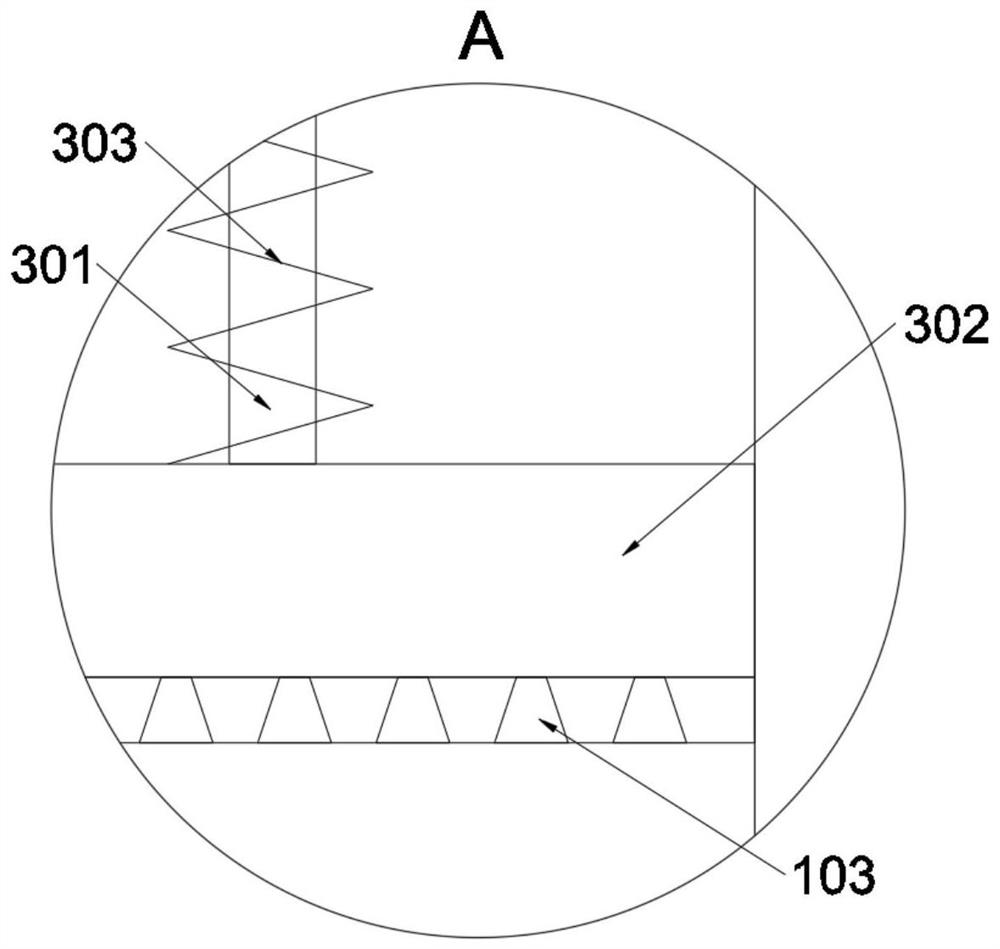

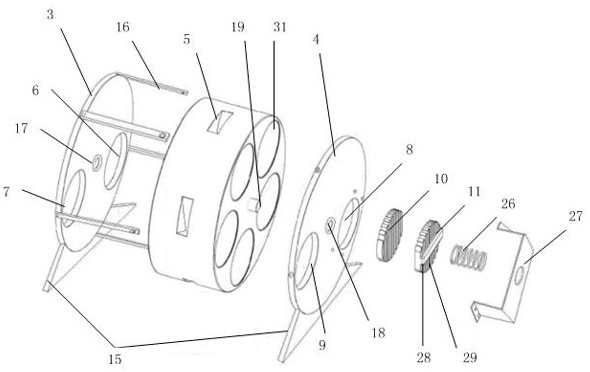

Sludge dewatering system

InactiveCN111574017ARealize continuous extrusionRealize continuous dehydration operationSludge treatment by de-watering/drying/thickeningSlagMechanical engineering

The invention belongs to the technical field of sludge treatment and specifically relates to a sludge dewatering system. The sludge dewatering system comprises a feeding pipe, a dewatering mechanism,a liquid discharging pipeline and a slag discharging device, wherein the feeding pipe communicates with a feeding port of the dewatering mechanism, the dewatering mechanism is used for squeezing sludge, the liquid discharging pipeline communicates with a liquid discharging hole of the dewatering mechanism, and the slag discharging device is located at a slag discharging port of the dewatering mechanism and collects dewatered sludge. Continuous extrusion of sludge in a shell is achieved through revolution and rotation of an arc triangle, so continuous dehydration operation of the sludge is achieved, and the dehydration efficiency of the sludge is improved. The slag discharging device is arranged to be of a movable structure, a material guiding groove moves to a position below the slag discharging hole and is used for guiding sludge to fall towards a conveying belt during slag discharging; and when slag discharging is not conducted, the material guiding groove is removed from the position below the slag discharging hole, and overflowing water drips into a water receiving groove, so secondary mixing of the overflowing water, water and the sludge is effectively avoided.

Owner:安徽清蓝环保工程有限公司

Plant extract purification and low-temperature concentration equipment based on cosmetic preparation

InactiveCN112237762AAchieve smashAchieve hammer crushingRotary stirring mixersTransportation and packagingProcess engineeringBiology

The invention provides plant extract purification and low-temperature concentration equipment based on cosmetic preparation, relates to the technical field of cosmetic production equipment, and solvesthe problem that linkage work of multiple procedures cannot be realized through one electric appliance element through structural improvement, and a problem that multiple cleaning of the filter screen cannot be realized through linkage in the mixing process due to structural improvement. The equipment based on cosmetic preparation comprises a box body; a mixing structure is installed in the box body, and a smashing and juice discharging structure is further installed in the box body. Juice discharge holes are formed in the bottom end surface of the crushing box in a rectangular array shape, and the juice discharge holes are of conical hole structures, so that the anti-blocking capability of the juice discharge holes can be improved; fourthly, the stop block is welded on the extrusion head, is in contact with the head end of the feeding pipe and forms a shielding structure of the extrusion head, so plant fragments entering from the feeding pipe can be prevented from entering the position above the extrusion head.

Owner:穆艺茂

Wet garbage extrusion device

ActiveCN112092436AEffective squeezeRealize continuous extrusionPressesEngineeringProcess engineering

The invention provides a wet garbage extrusion device. The wet garbage extrusion device comprises a supporting frame, and an extrusion mechanism, a circulating filter pressing structure and a pushingmechanism which are arranged on the supporting frame; an extrusion channel and a discharge channel are formed in the circulating filter pressing structure; and the extrusion mechanism is used for extruding the wet garbage materials into the extrusion channel for extrusion. According to the wet garbage extrusion device, wet garbage materials can be fully extruded.

Owner:杭州纯友科技发展有限责任公司

Extraction equipment for cosmetic essence

InactiveCN112497808ARealize continuous extrusionSqueeze out the juiceRotary stirring mixersTransportation and packagingBiotechnologyEngineering

The invention provides cosmetic extraction equipment for cosmetic essence, relates to the technical field of cosmetic processing, and solves the problems that continuous extrusion of plant fragments cannot be implemented in a linkage manner for implement extrusion and discharge of plant juice while stirring and mixing are carried out through structural improvement, and injection type mixing cannotbe implemented for improving rapid mixing of extruded juice while extrusion is carried out. The extraction equipment for the cosmetic essence comprises a barrel body; a mixing structure is mounted onthe barrel body; and an extrusion structure is further mounted on the barrel body. A sliding rod B is welded to an extrusion head, the sliding rod B is in sliding connection with a baffle, and the sliding rod B is sleeved with an elastic piece B used for elastic resetting of the baffle; the baffle and the extrusion head jointly form an injection structure, so that liquid pushing can be implemented when the extrusion head extrudes the plant fragments, thereby implementing rapid mixing of the extruded juice.

Owner:莱西市星脉先进材料技术中心

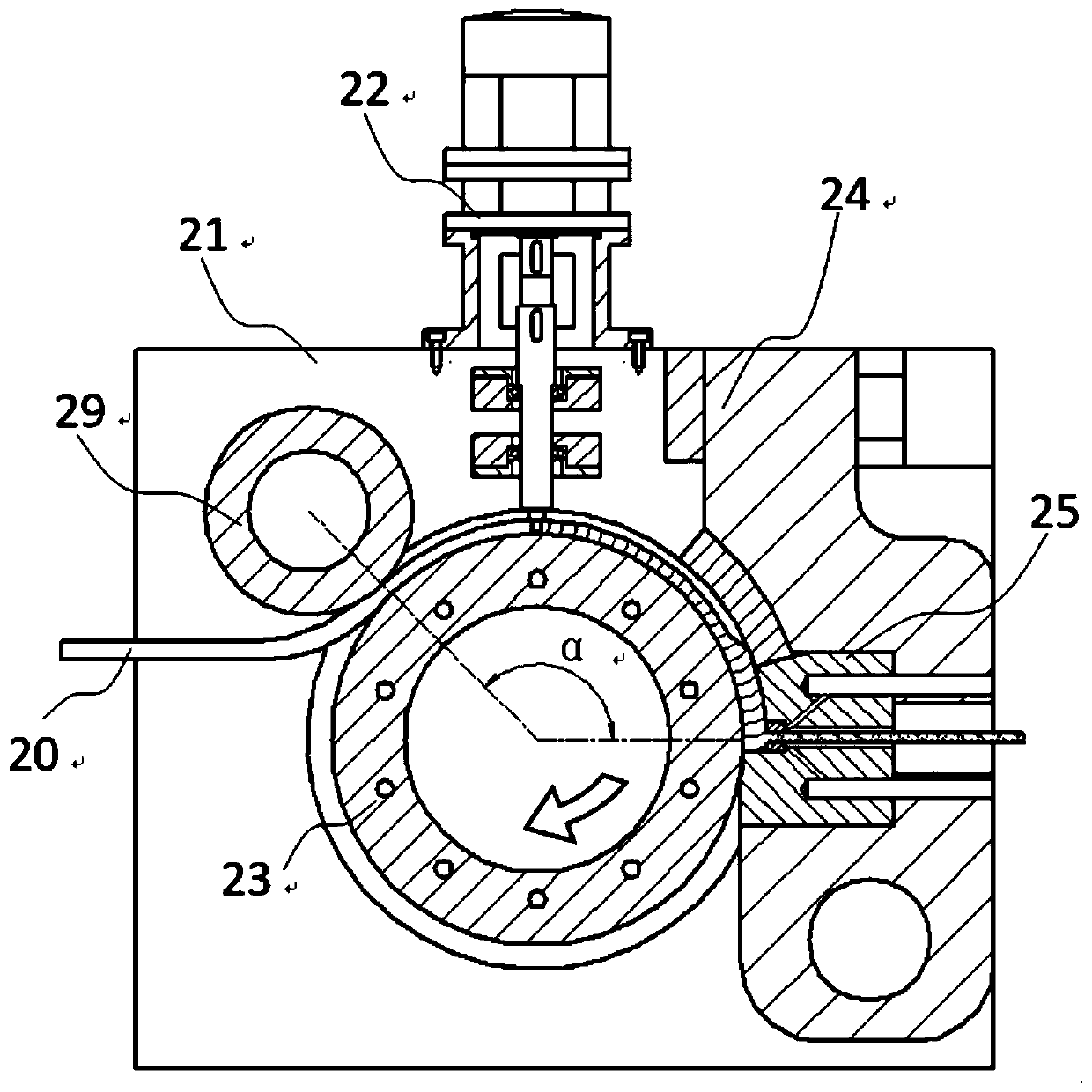

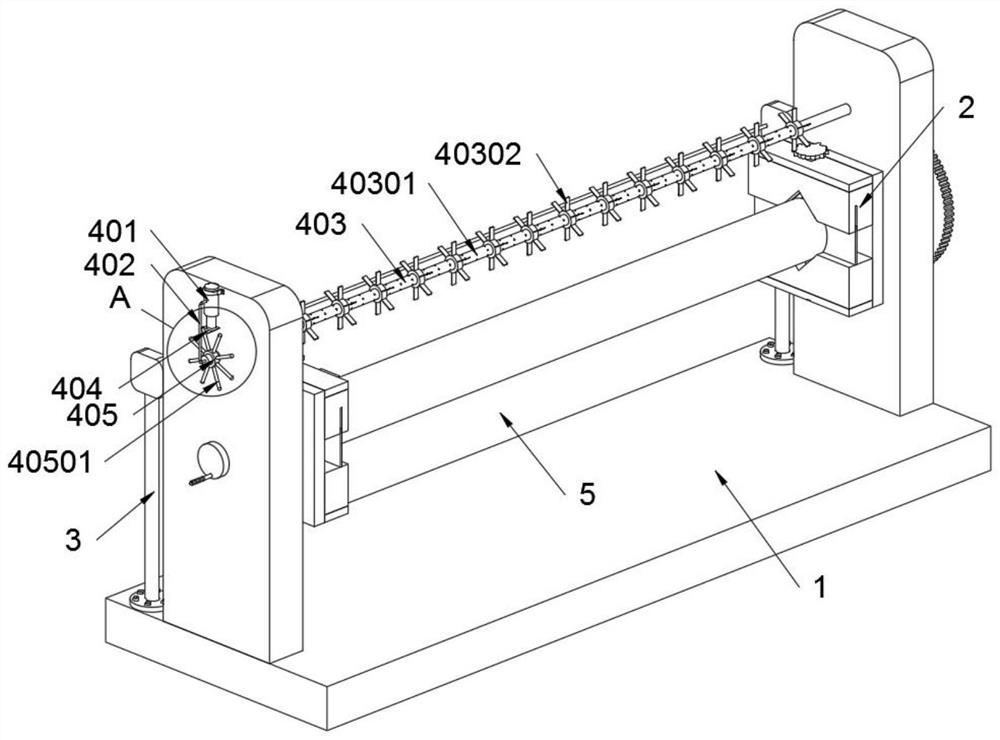

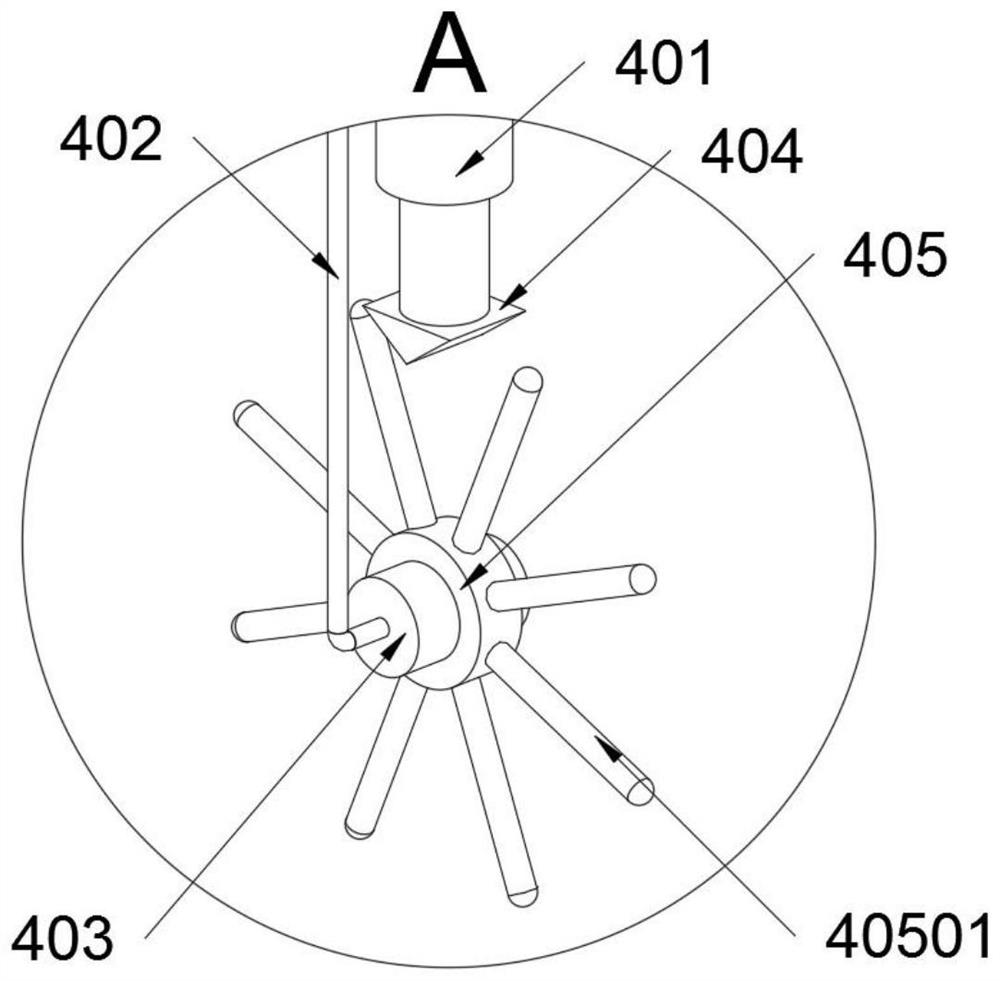

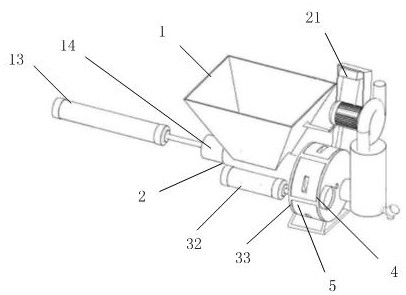

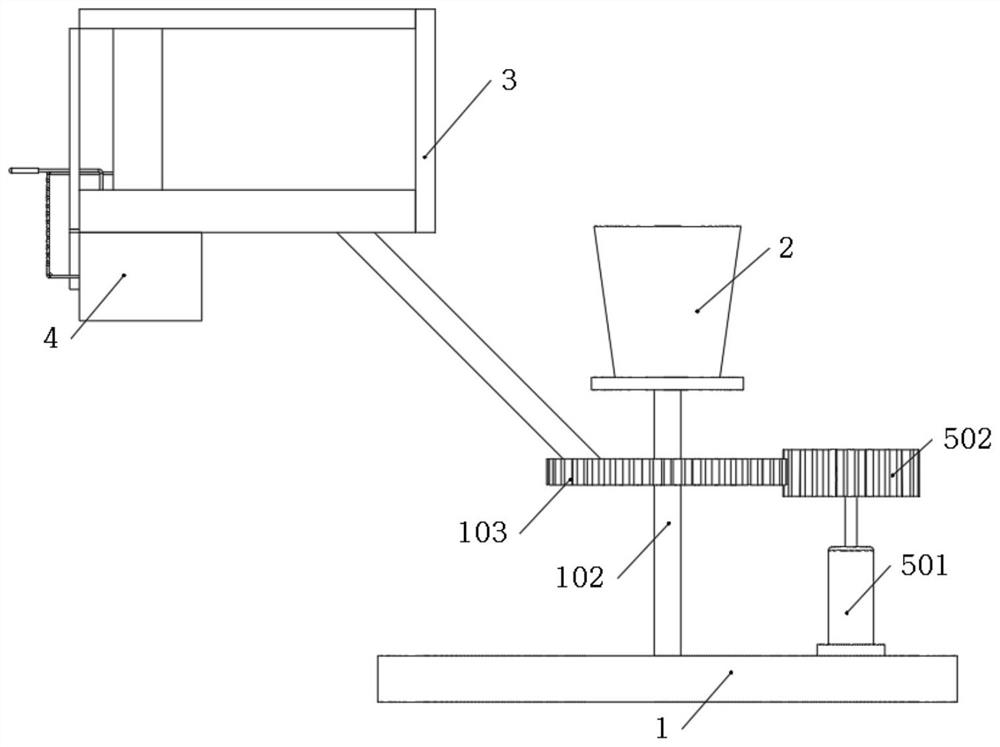

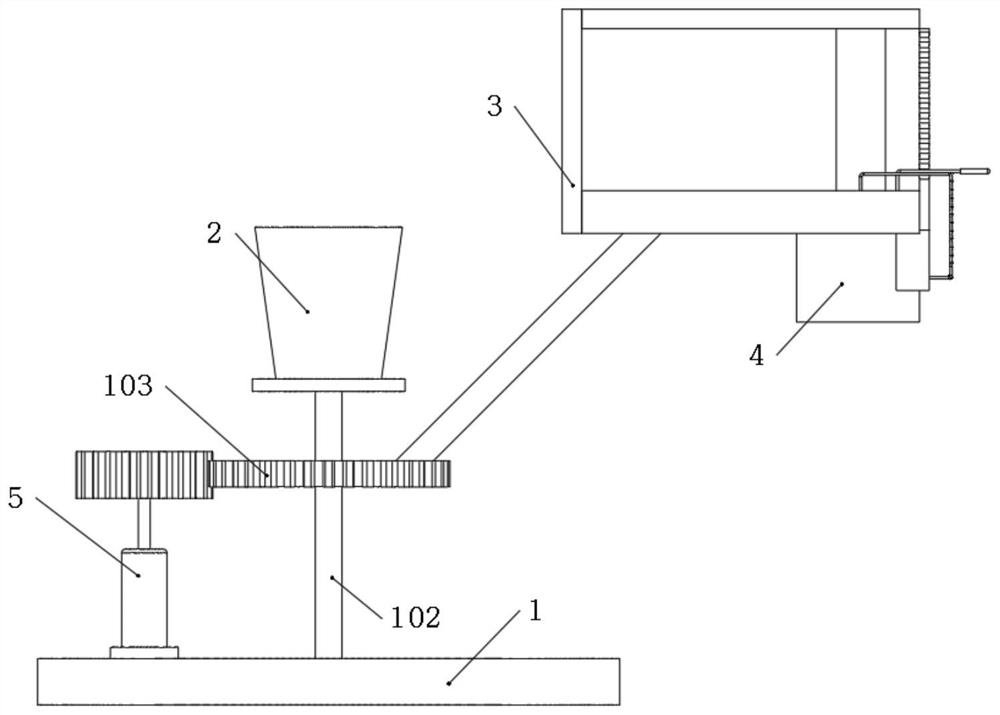

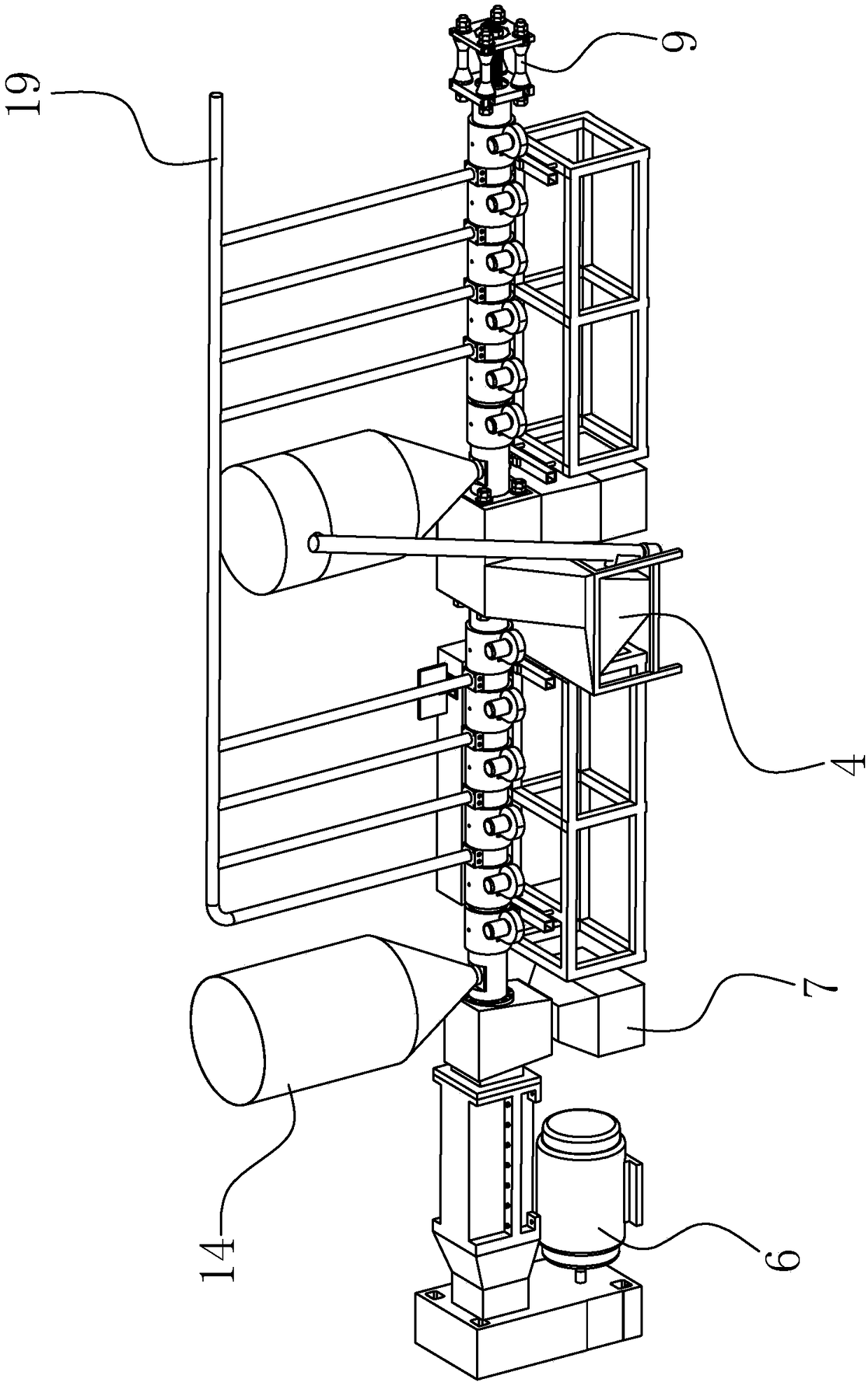

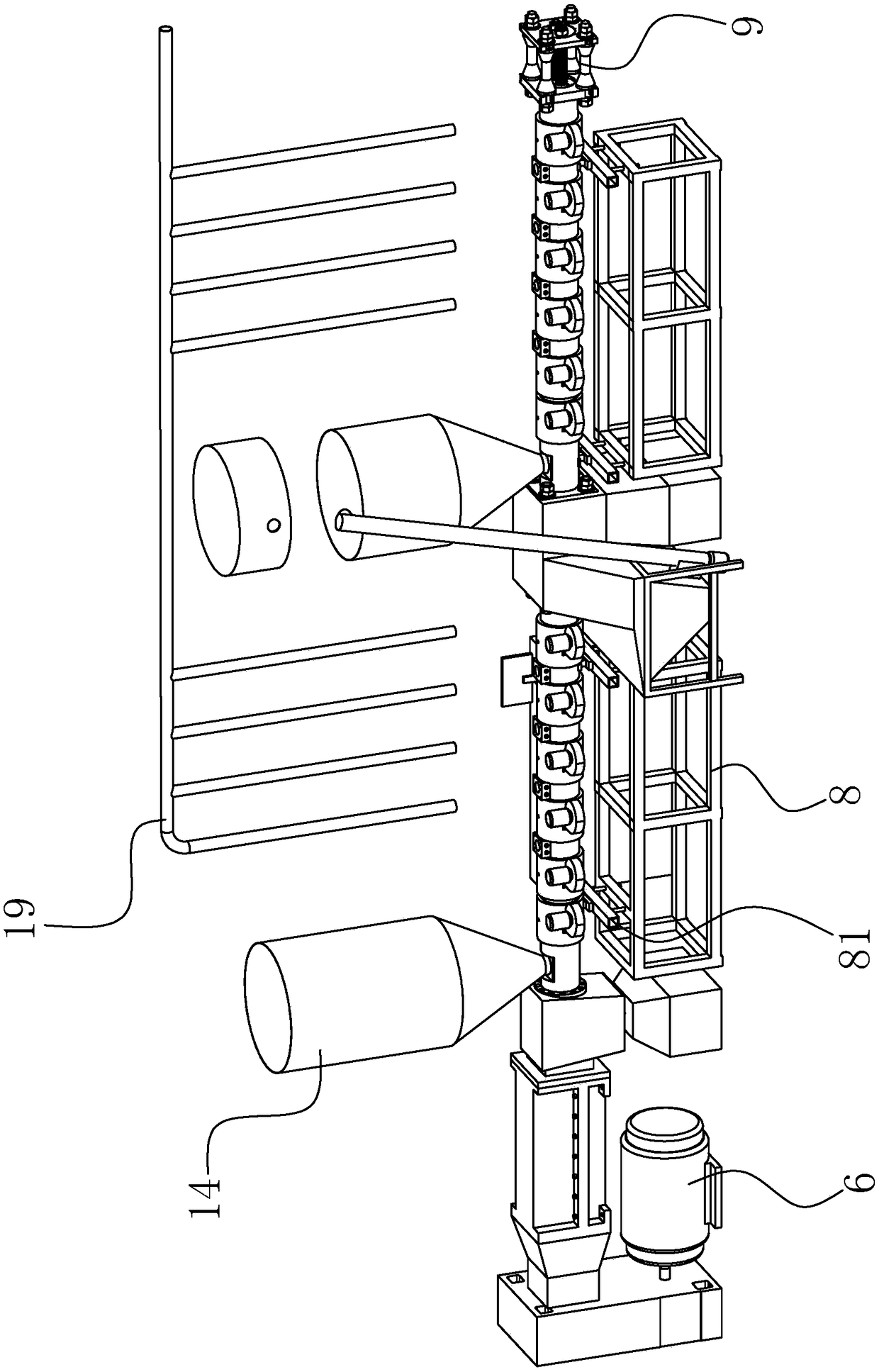

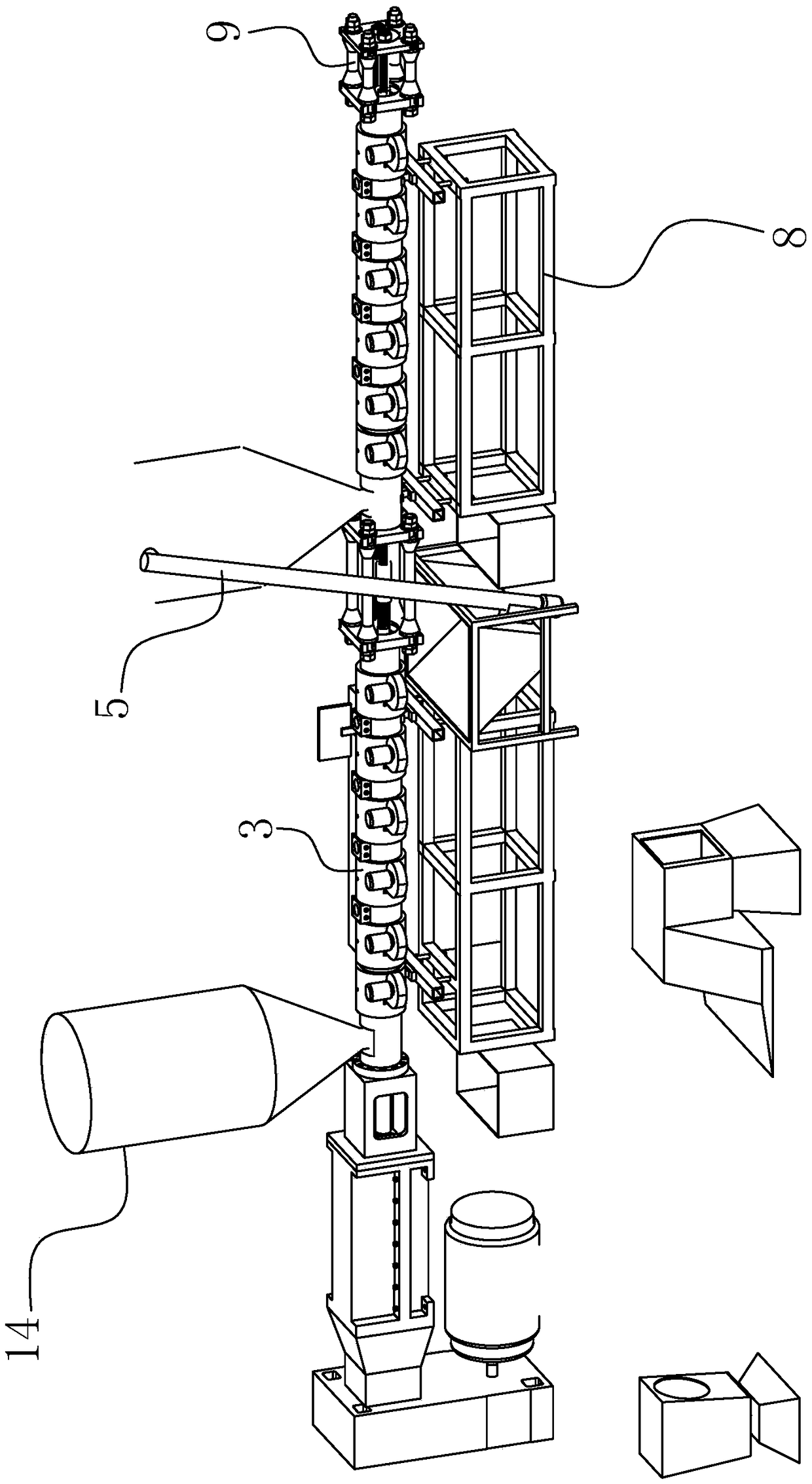

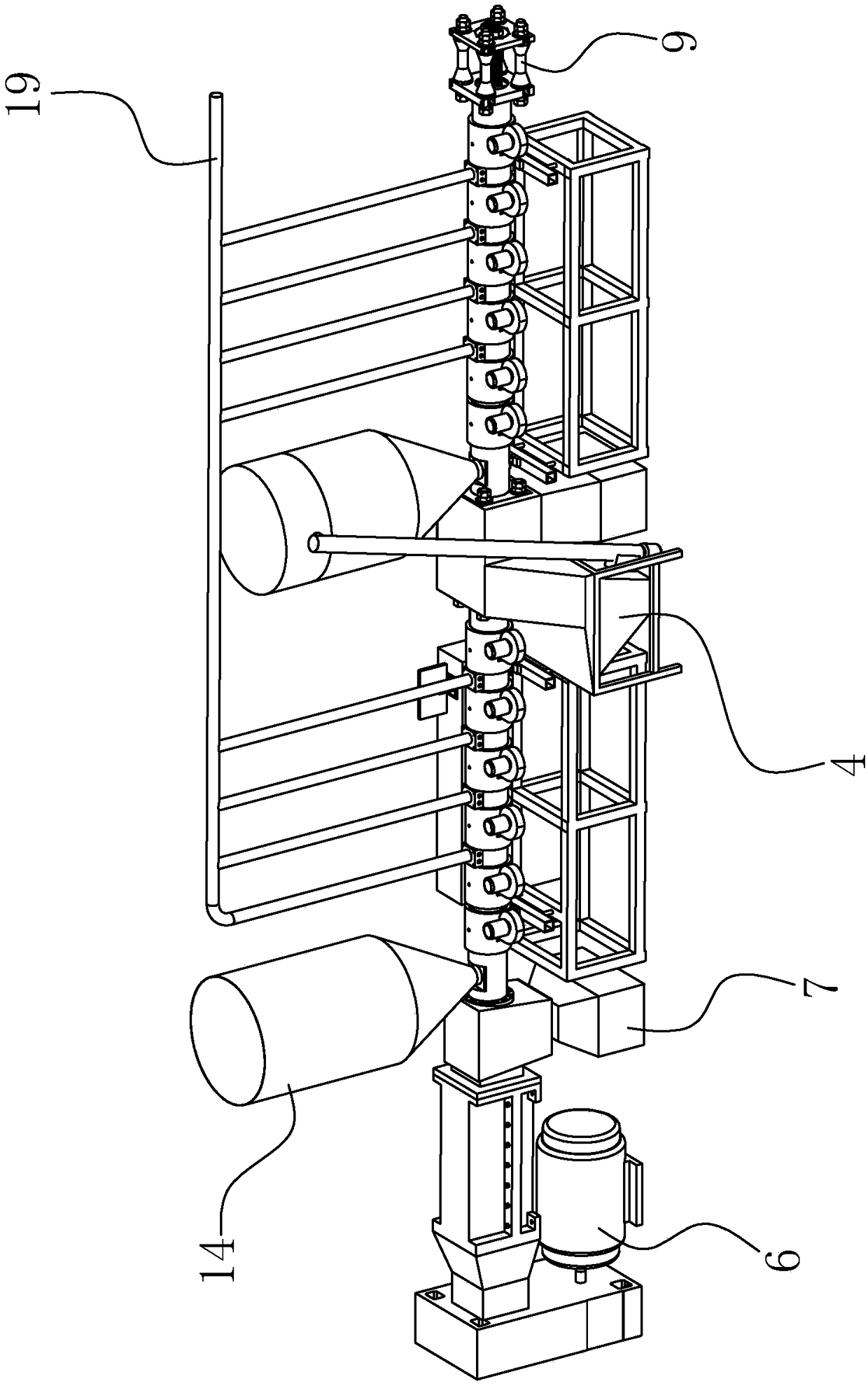

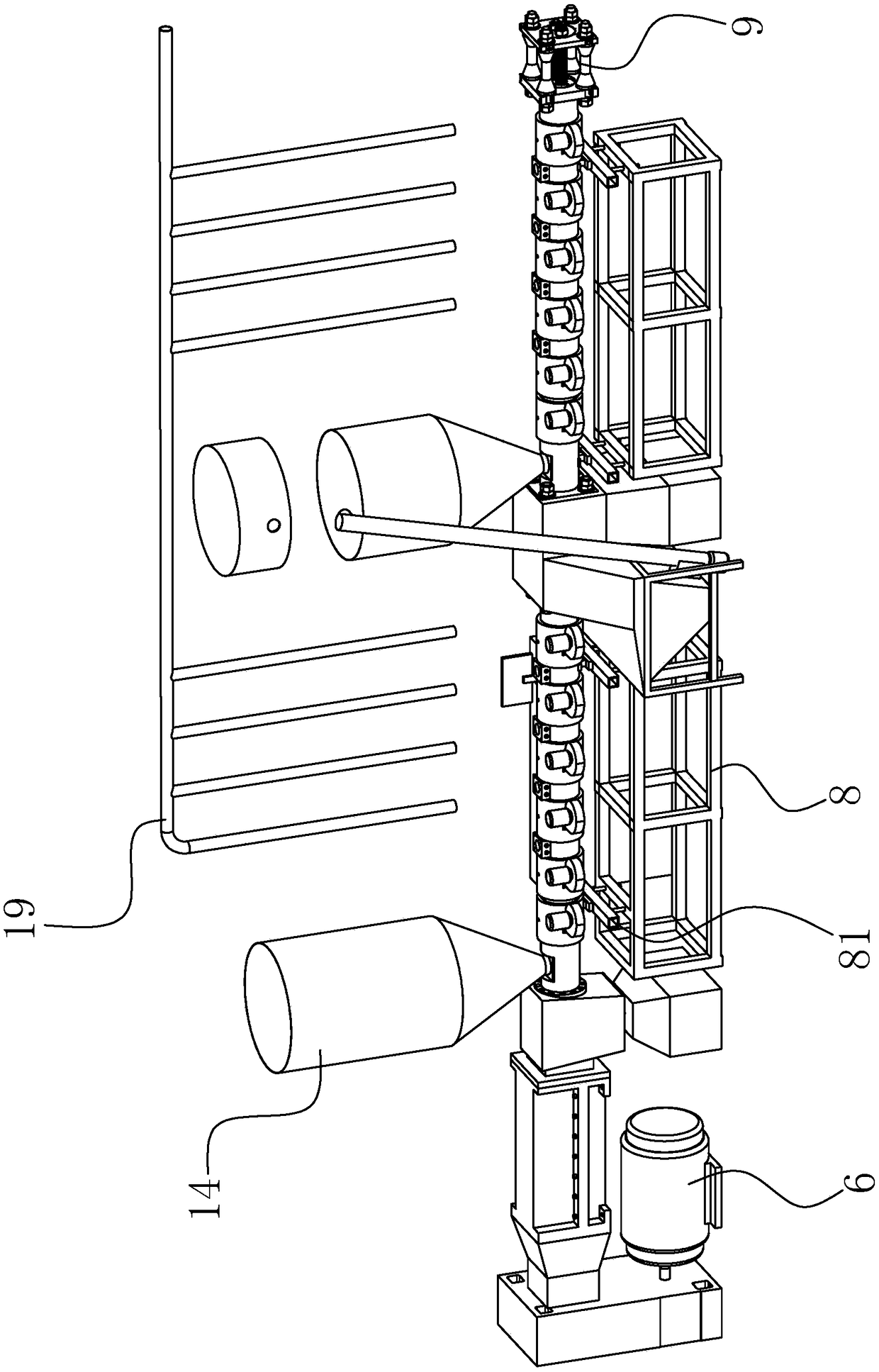

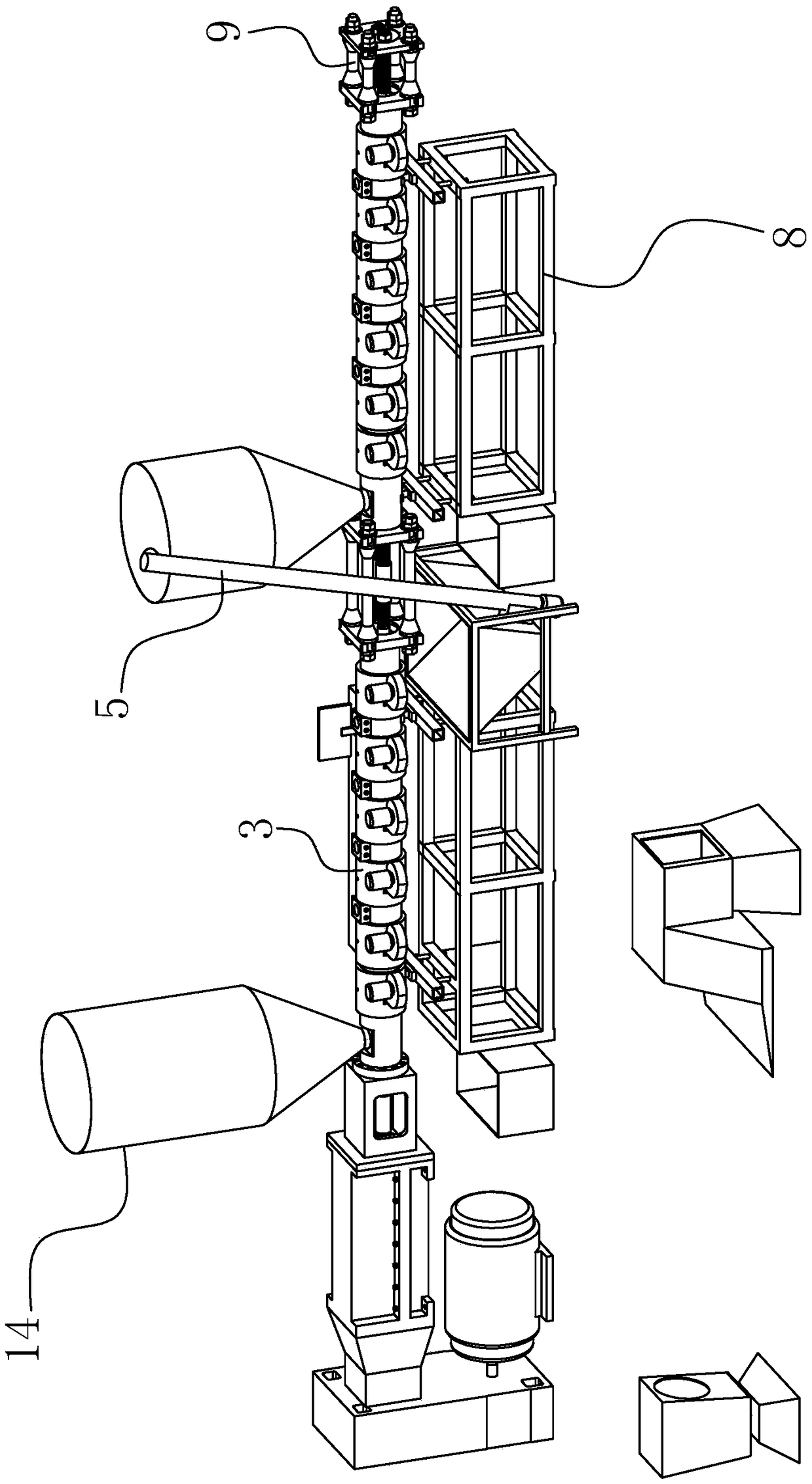

Alloy rod high-throughput continuous preparation device

PendingCN110883336AEnable high-throughput productionSimple structureTurbinesOther manufacturing equipments/toolsRotational axisElectric machinery

The invention discloses an alloy rod high-throughput continuous preparation device, and belongs to the technical field of material preparation. The device comprises a continuous extruder, a rotating wheel type feeding device, a powder mixing device, a rotating shaft I, an outer shell I, a storage bin I, a funnel I, a cylindrical powder mixer, a stirrer, a motor, a connecting part, a rotating shaftII, a rotating shaft III, a storage bin II, a funnel II 1, a funnel III and an outer shell II; alloy rods extruded by the rotating wheel type feeding device have gradient component change to realizehigh-throughput preparation of the alloy rods; the alloy rods extruded by the powder mixing device also have gradient component change to realize high-throughput preparation of the alloy rods; and thedevice can realize high-throughput preparation of alloys with three or more elements, is simple in structure, convenient to operate and less in occupied space, and greatly improves the production efficiency.

Owner:KUNMING UNIV OF SCI & TECH

Deinsectization device applied to plant protection

PendingCN113575541AContinuous water spray cleaningImprove capture efficiencyCleaning using toolsCleaning using liquidsVerminLight source

The invention provides a deinsectization device applied to plant protection, relates to the technical field of deinsectization devices, and solves the problems that although an existing device can attract pests through a light source, most of light source attraction structures of the existing device are fixed, and the light source attraction structures cannot capture the pests through structural improvement. The deinsectization device applied to plant protection comprises a base, the base is fixedly connected to the ground, and a flowerpot is placed on the base; a mosquito eradication part is mounted on the base, and a cleaning part is mounted on the mosquito eradication part; and a driving part is mounted on the base. A cleaning block is sleeved in a cleaning base, and a mosquito killing lamp is sleeved with the cleaning block, so that the mosquito killing lamp can be wiped and cleaned when the cleaning base moves up and down; due to the fact that a groove is formed in a containing base B, the cylindrical hole communicated with a water storage box is further formed in the groove, and the mosquito killing lamp is located in the groove, sewage generated after the mosquito killing lamp is cleaned can be prevented from being scattered.

Owner:BEIHUA UNIV

Aluminum strontium alloy production process

The invention belongs to the technical field of production of aluminum strontium alloys, and discloses an aluminum strontium alloy production process. The aluminum strontium alloy production process comprises the steps of batching, smelting, casting and extrusion-forming. The aluminum strontium alloy production process is characterized in that the extrusion forming process comprises the following steps of 1) arranging an excess material cavity between a straight-tube-shaped forming mold and a bar accommodating cavity, wherein the excess material cavity takes the shape of a frustum, the diameter of the bottom surface of the frustum is 30 mm, the taper of the frustum is 1 / 3, the excess material cavity and the forming mold are coaxial, and the bottom surface of the excess material cavity is close to the forming mold; and 2) putting an aluminum strontium bar, formed through casting, into the excess material cavity, extruding the aluminum strontium bar to form a wire rod through the forming mold, and putting another bar to continue extruding when the remaining height of the bar is 10-20 mm. According to the aluminum strontium alloy production process, the technical problems that the existing production process cannot implement continuous extrusion and the efficiency is low are solved.

Owner:重庆庆龙新材料科技有限公司

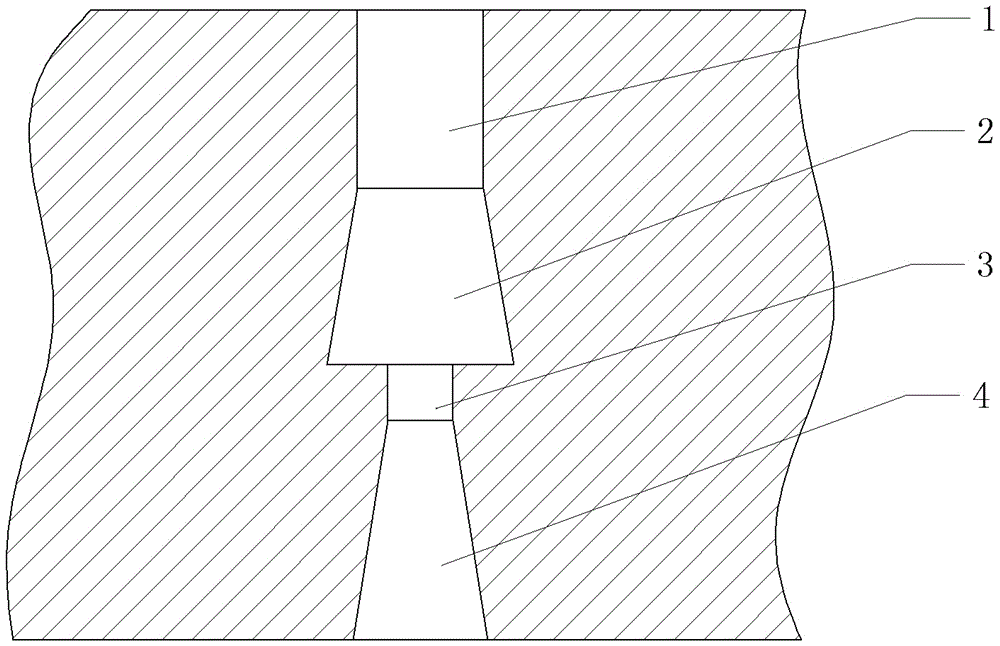

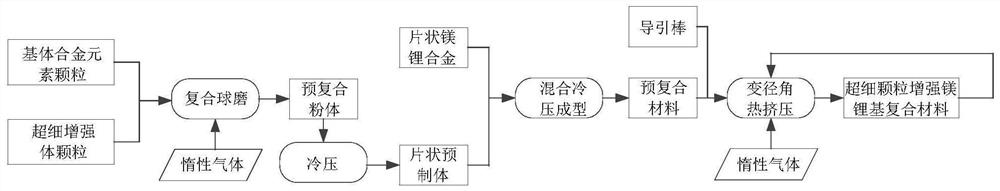

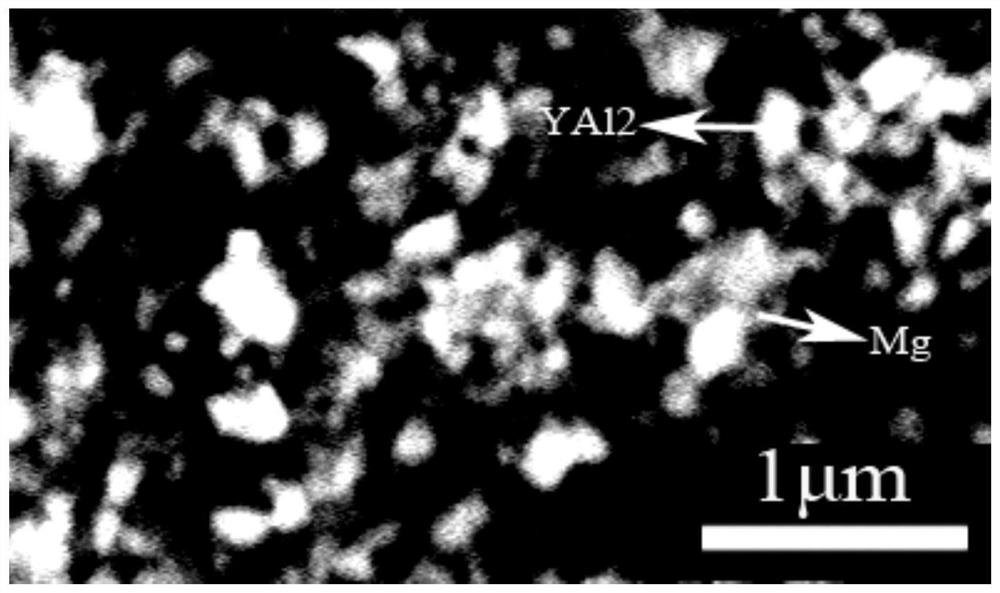

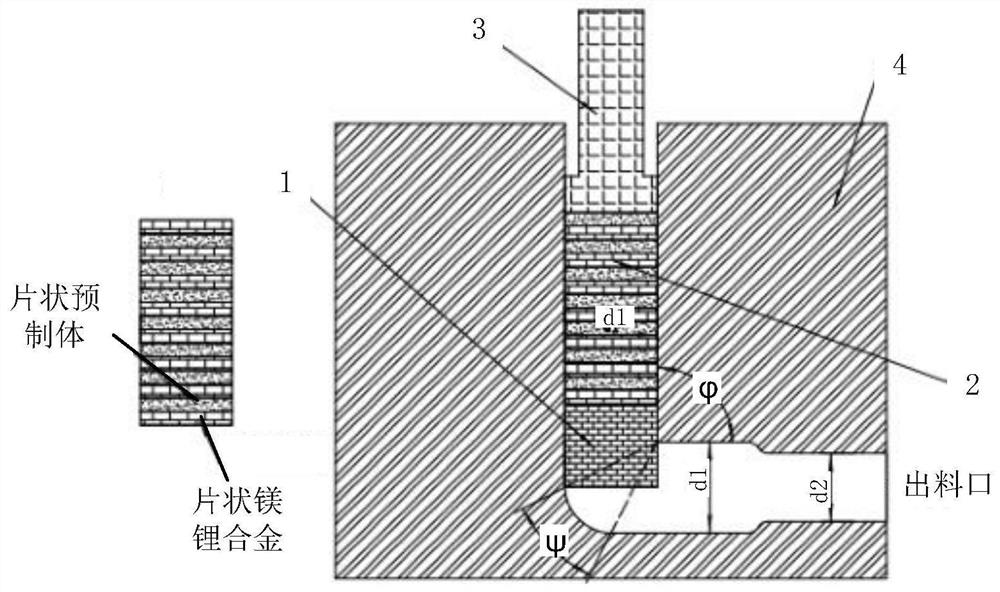

High-volume-fraction ultrafine particle enhanced Mg-Li base composite material and preparing method thereof

PendingCN111730059AGood particle dispersionReduce reunionTransportation and packagingMetal-working apparatusPlasticitySemi solid

The invention discloses a high-volume-fraction ultrafine particle enhanced Mg-Li base composite material and a preparing method thereof, and belongs to the technical field of composite materials and preparing of the composite materials. The preparing method comprises enhanced body surface modification, flaky body forming through cold pressing, mixing cold-pressing forming with a flaky Mg-Li alloyand other procedures. Then under guidance of a guiding bar, multi-pass variable diameter angle hot extrusion is conducted, and an Mg-Li base composite material is obtained. By means of the high-volume-fraction ultrafine particle enhanced Mg-Li base composite material and the preparing method thereof, material forming and deforming are integrated, through variable diameter angle extrusion, the flaky Mg-Li alloy and an enhanced body prefabricated body are subjected to upsetting, shearing, drawing and other large-plasticity deformation, enhanced body particles are evenly distributed in the Mg-Lialloy, the content of the enhanced body is high, and the enhanced Mg-Li base composite material with the particle volume fraction being 10%-30% can be prepared. The Mg-Li base composite material is directly extruded and formed in a solid state or a semi-solid state. Compared with a traditional stirring casting technology, the operation process is short, energy is saved, and industrial production is facilitated.

Owner:山东源航超轻材料研究院有限公司

Cutting and processing device for processing mechanical parts

ActiveCN113695683BAchieve fixationAchieve clampingPositioning apparatusMaintainance and safety accessoriesMechanical componentsStructural engineering

The invention provides a cutting and processing device for processing mechanical parts, which relates to the technical field of parts processing and includes: a main body seat, a fixing part, a mounting frame, a cutting part and a coating part; two sliding grooves are symmetrically opened on the main body seat A, and two sliding grooves B are symmetrically opened on the top surface of the main body seat; through the cooperative setting of the supporting claw and the sliding arm, the limit of the sliding arm can be realized, as follows: due to the left end surface of the sliding arm and the left supporting claw Contact, and when the sliding arm slides 50cm to the right, the right end surface of the sliding arm contacts the supporting claw on the right side, so that the sliding limit of the sliding arm can be realized through the supporting claw, which solves the problem that the clamping structure will cause excessive gap when used for a long time , affecting the clamping quality; the fixing bolts of the supporting claws are easy to loosen, and the supporting claws have a single function.

Owner:如东中灿机械有限公司

Pollution-free and environmentally friendly vinasse treatment device

PendingCN109228482AAutomatic forward conveying smoothlyEfficient separationBy-product recoveryPressesAlcoholEngineering

The invention discloses a pollution-free and environmentally friendly vinasse treatment device. The device comprises a sealing extruding structure composed of a cylinder and a threaded rod, the end portion of the threaded rod extends out of the end portion of the cylinder and is connected with a threaded rod driving mechanism, and a feeding inlet is formed in one end of the cylinder; a dischargingoutlet is formed in the other end of the cylinder, heating devices capable of heating the cylinder are distributed on the portion, between the feeding inlet and the discharging outlet, of the outer wall of the cylinder, gas exhausting holes used for gas in an inner cavity of the cylinder to be exhausted are distributed in the top of the cylinder, and the gas exhausting holes are communicated witha gas sucking device through a pipeline. The device has the advantages that moisture in vinasse can be efficiently extruded out, in the moisture extruding process, vinasse residues are conveyed awayfrom the cylinder, and the extruding efficiency is improved; moisture and ethyl alcohol which are extruded from the vinasse entering the cylinder only can be exhausted from openings in the two ends ofthe cylinder or the discharging outlet, or the moisture and the ethyl alcohol are heated to become steam and volatile ethyl alcohol so as to be exhausted from the gas exhausting holes, therefore it is only required that collecting device are placed at corresponding positions, the moisture and ethyl alcohol can be prevented from spilling, or waste gas can be prevented from being exhausted directly, and the device is green, environmentally friendly and pollution-free.

Owner:浙江华业塑料机械股份有限公司

Pollution-free and environmentally friendly vinasse treatment method

ActiveCN109228481AAutomatic forward conveying smoothlyEfficient separationBy-product recoveryPressesAlcoholEngineering

The invention discloses a pollution-free and environmentally friendly vinasse treatment method. The method is characterized by comprising the following steps that step one, vinasse is conveyed into aninner cavity of a cylinder of a vinasse treating device for extrusion; step two, a twin screw in the vinasse treating device extrudes the vinasse and conveys the vinasse to a discharging outlet of the vinasse treating device, the vinasse treating device extrudes and heats the vinasse synchronously, and in the extruding process, the generated steam and the volatilized ethyl alcohol are exhausted from the a gas exhausting hole of the vinasse treating device; step three, a gas sucking device absorbs and recovers the exhausted steam and the volatilized ethyl alcohol; step four, the dehydrated vinasse is conveyed to a dehydrated residue collecting device from the discharging outlet for recycling. The method has the advantages that the extruding effect is good; moisture and ethyl alcohol whichare extruded from the vinasse entering the cylinder only can be exhausted from openings in the two ends of the cylinder or the discharging outlet, or the moisture and the ethyl alcohol are heated to become gases so as to be exhausted from the gas exhausting hole, therefore it is only required that collecting device are placed at corresponding positions, the moisture and the ethyl alcohol can be prevented from spilling, or waste gas can be prevented from being exhausted directly, and the method is green, environmentally friendly and pollution-free.

Owner:浙江华业塑料机械股份有限公司

Pipeline anti-corrosion treatment method

InactiveCN112589632AImplement automatic conversionRealize continuous extrusionGrinding carriagesGrinding machinesMechanical engineeringTriangular prism

The invention provides a pipeline anti-corrosion treatment method, and relates to the technical field of pipeline anti-corrosion treatment. The problems that removal of residues attached to the outerwall of a pipeline cannot be synchronously achieved after polishing operation is accomplished, displacement of a polishing structure cannot be synchronously achieved in the pipeline rotary polishing achieving process through the structural improvement, and quick clamping and collision protection of an adjusting structure cannot be achieved are solved. According to the pipeline anti-corrosion treatment method, a pipeline anti-corrosion treatment facility comprises a body base. Two clamp structures are installed on the body base, a polishing structure is further installed on the body base, and apipeline is clamped on the clamp structures. Due to the facts that poke rods make contact with a stress block, and the stress block is of a triangular prism structure, when a poke base drives the poke rods to rotate, continuous extrusion of an elastic telescopic bottle can be achieved. A spray pipe is connected to a connecting pipe and located at the position 5cm above the pipeline, and thereforewhen the elastic telescopic bottle is extruded, pneumatic removal of the polishing residues on the pipeline can be achieved through the spray pipe.

Owner:莱西市盈德装备技术中心

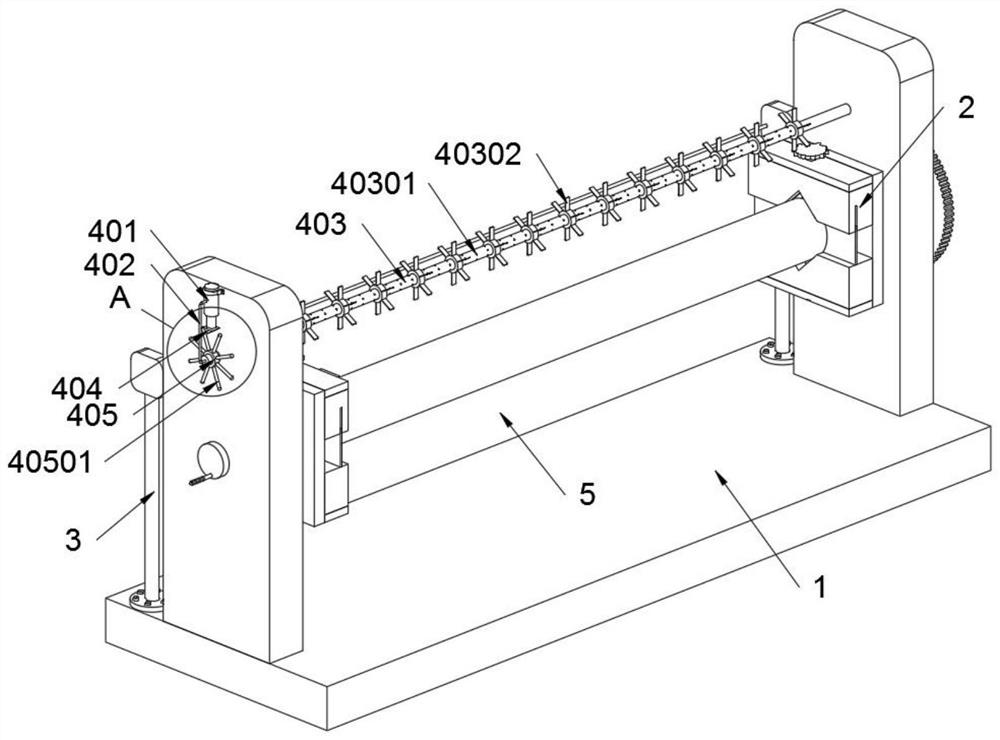

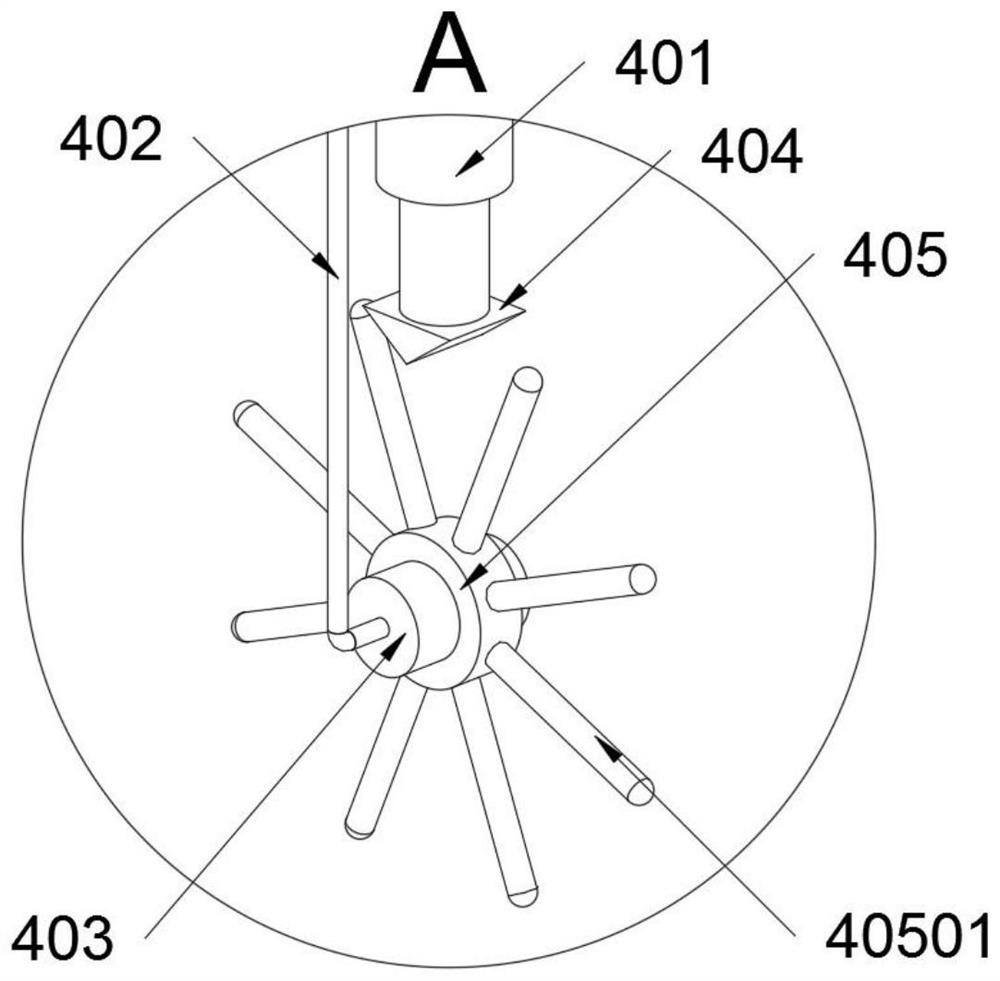

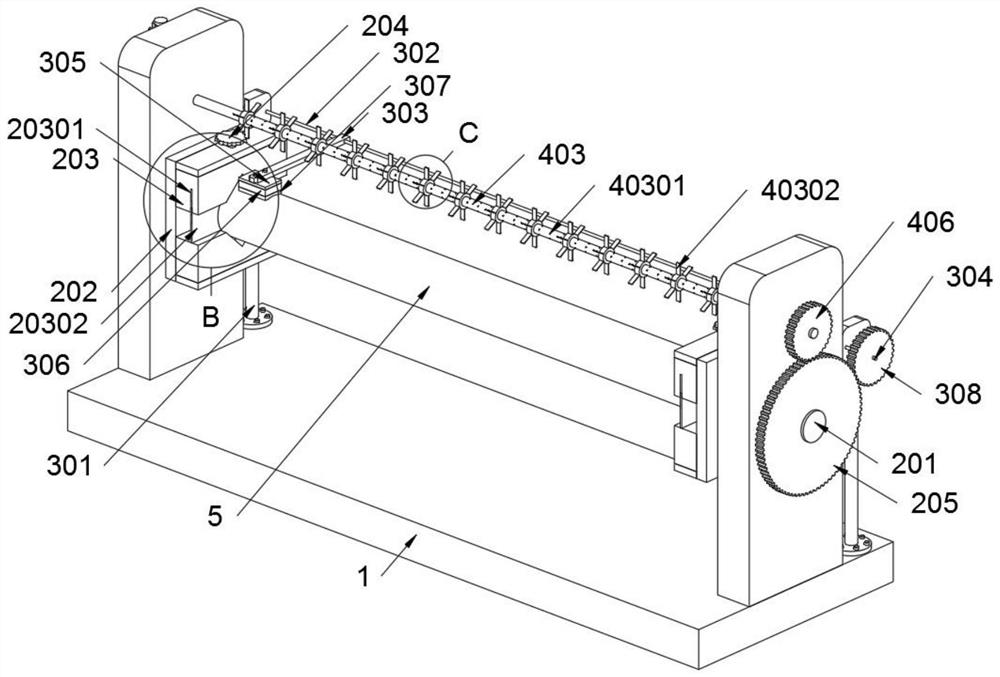

Mechanical continuous threshing device for agricultural harvesting

PendingCN114532076AIncrease vibration frequencyImprove threshing effectSaving energy measuresThreshersAgricultural engineeringAgriculture

The invention provides a mechanical continuous threshing device for agricultural harvesting, and relates to the technical field of threshing devices, the mechanical continuous threshing device comprises a shell, a threshing part, a screening part, a driving part and a cleaning part; two fixed seats are symmetrically welded on the shell; the two fixing seats are each of a rectangular plate-shaped structure, and two fixing bolts are connected to each fixing seat in an inserted mode. Four elastic telescopic rods A are mounted on the bottom end face of the top plate, and a mounting seat is mounted at the head ends of the four elastic telescopic rods A; the mounting seat is of a concave structure, and stop levers are welded on the mounting seat in a linear array shape; the blocking rod is of a cylindrical rod-shaped structure, protrusions A are welded to the blocking rod in a linear array shape, and the protrusions A form a retarding structure when the sunflowers move, so that the threshing effect is improved, and the problems that firstly, the sunflowers move fast during threshing, the threshing effect is not obvious enough, and repeated threshing needs to be conducted are solved; and secondly, the problem that residues are doped in the seeds during threshing is solved.

Owner:山东琨福农业科技有限公司

Yellow River ecological slope wall with water and soil loss prevention and landscape ornamental effect

PendingCN113668451APrevent soil from washing outAchieve clean upReceptacle cultivationMarine site engineeringEcologyLeaf blade

The invention provides a Yellow River ecological slope wall with water and soil loss prevention and landscape ornamental effect, relates to the technical field of slope walls. The problem that a filter screen needs to be manually cleaned after being blocked and cannot be cleaned by water flow driving force through structural improvement is solved. The Yellow River ecological slope wall with the water and soil loss prevention and the landscape ornamental effect comprises a wall body; the wall body is fixed on the ground, and potted plants are placed on the wall body; and five cleaning parts are installed on the wall body, and a driving part is installed on the wall body. The wall body is fixedly connected with a collecting box through a bolt, and the collecting box is of a rectangular box-shaped structure; and the collecting box is aligned with a path of a water column at a through hole B, so that the water column sprayed out of the through hole B can be jetted into the collecting box after passing through blades and can overflow gradually after the collecting box is full, and finally the situation that soil on the front side of the wall is scattered due to too strong jet flow is prevented.

Owner:徐雁飞

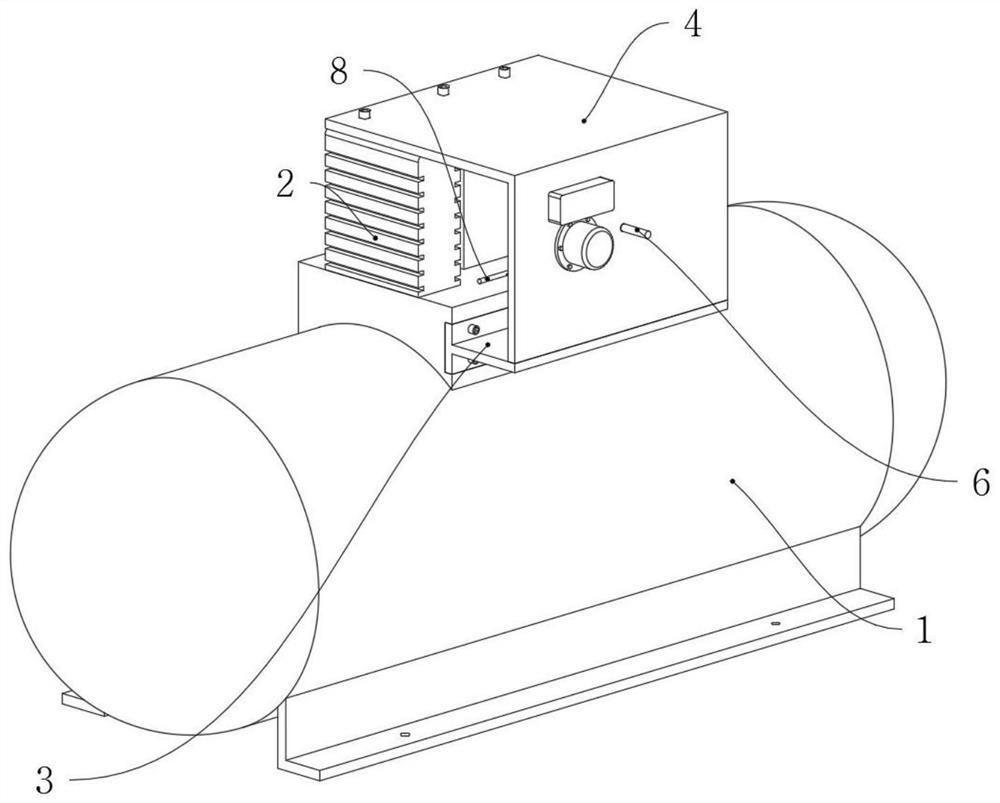

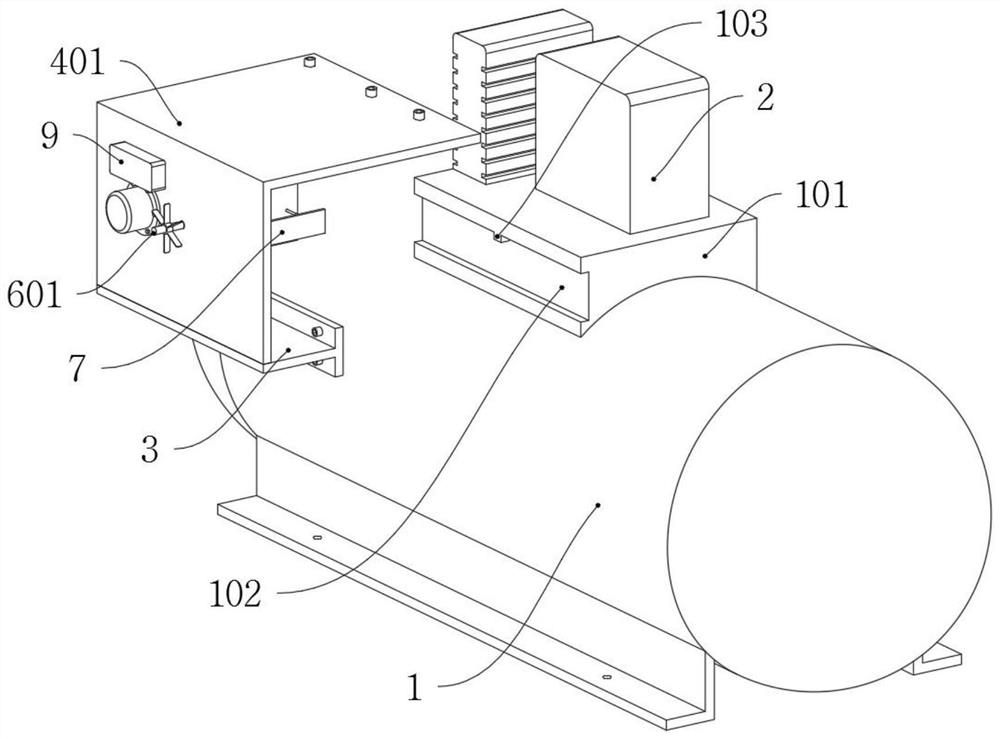

Cooling device of air compressor head and control method of cooling device

ActiveCN114046239ARealize wind coolingImprove cooling effectPositive displacement pump componentsPump controlImpellerGear wheel

The invention provides a cooling device of an air compressor head and a control method of the cooling device, and relates to the technical field of air compressors, the cooling device comprises an air compressor main body, a cooling part, a first heat dissipation part, a transmission part, an auxiliary part, a second heat dissipation part and a control box; a mounting seat A is welded on the air compressor main body, and a clamping groove is formed in the mounting seat A; and a fixed seat is clamped in the clamping groove, and is fixedly connected with the mounting seat A through a bolt. Due to the fact that a stress rod is installed on an elastic piston bottle B, the head end of the stress rod is of an arc-shaped structure, and the head end of the stress rod makes elastic contact with a gear A, when the gear A rotates, continuous extrusion of the stress rod can be achieved, air injection cooling at a spray hole B is achieved, namely heat on an air compressor head is taken away through the action of airflow, and the problems that an existing device can only achieve wind power cooling through rotation of an impeller, the cooling effect is not obvious enough, and heat dissipation structures cannot be mutually linked are solved.

Owner:江苏巨风机械制造有限公司

Environment-friendly casting crude sand screening device based on part casting process

The invention provides an environment-friendly casting crude sand screening device based on a part casting process, relates to the technical field of casting auxiliary equipment, and solves the problem that high-frequency auxiliary vibration screening cannot be realized while vibration screening is performed through structural improvement. And automatic blockage clearing of the sieve pores cannot be realized while screening is carried out. The environment-friendly casting crude sand screening device based on the part casting technology comprises a box body. The box body is of a rectangular box-shaped structure. Through the arrangement of the frame, the auxiliary rods are welded to the frame in the rectangular array shape, the auxiliary rods welded in the rectangular array shape are aligned to the screen holes formed in the rectangular array shape, and when the screening frame moves downwards, the auxiliary rods penetrate through the screen holes, and therefore sand clamped in the screen holes can be cleaned.

Owner:河北金栋机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com