Cutting machining device for mechanical part machining

A technology for cutting and processing mechanical parts, applied in the field of parts processing, can solve the problems of single function of supporting claws, easy loosening of fixing bolts of supporting claws, waste of time and other problems, and achieve the effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

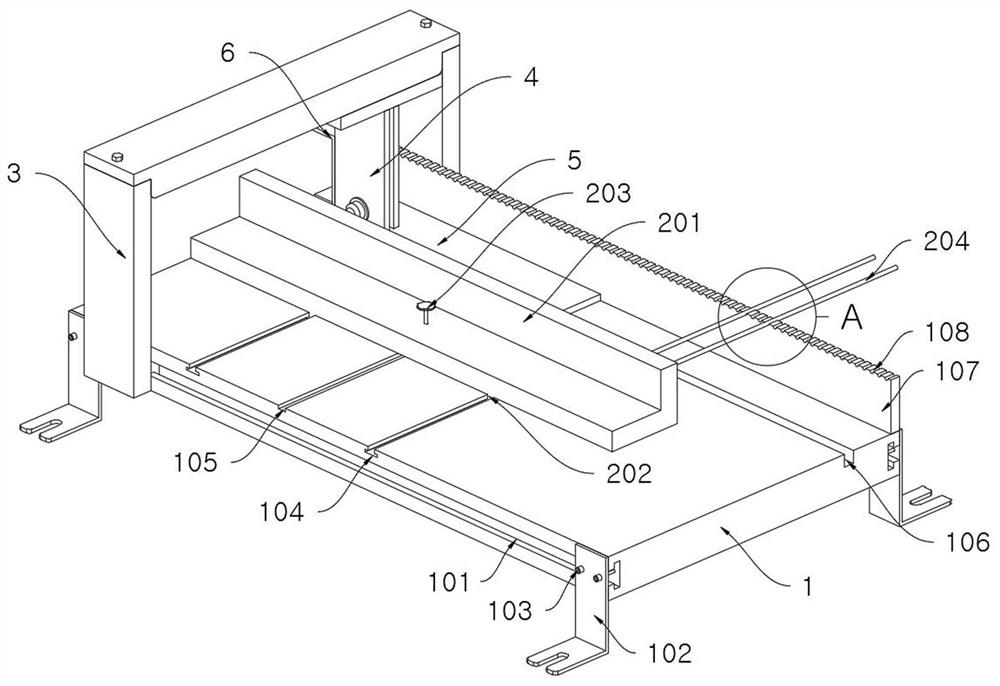

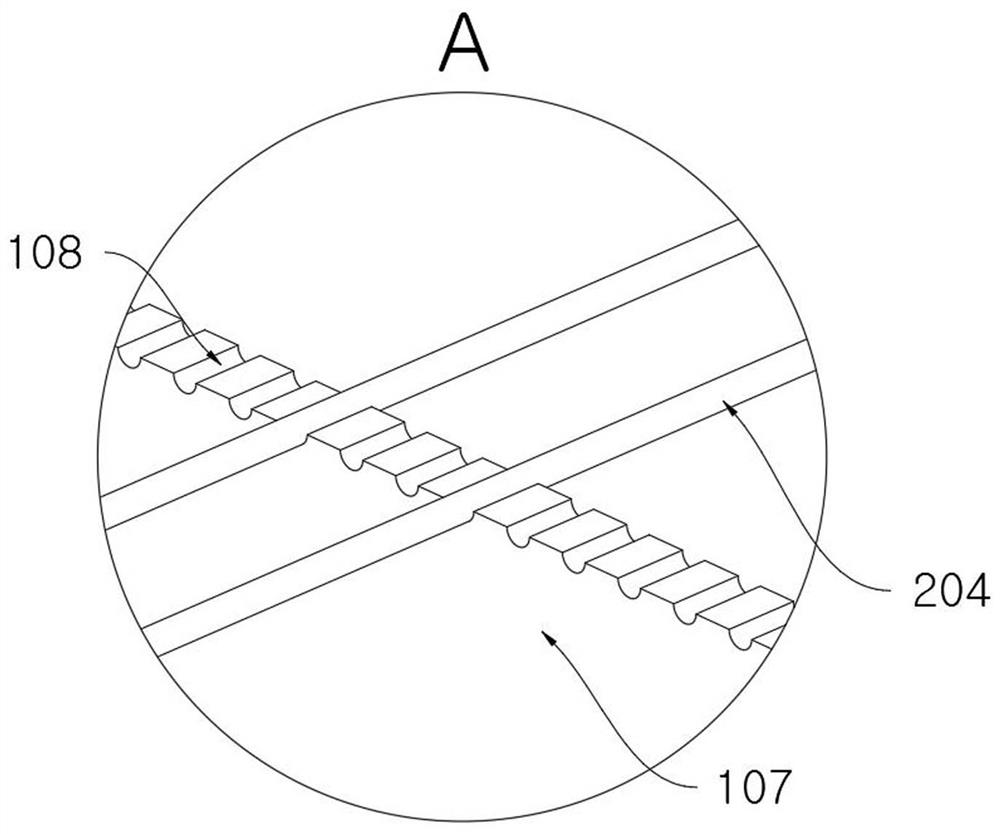

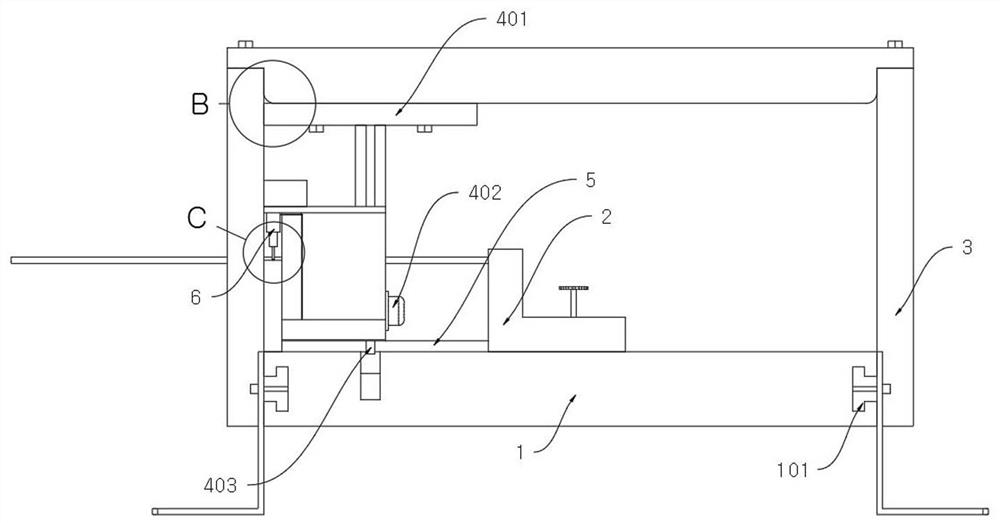

[0050] Example: Please refer to Figure 1 to Figure 12 :

[0051] The present invention proposes a cutting and processing device for processing mechanical parts, comprising: a main body seat 1, a fixing part 2, a mounting frame 3, a cutting part 4 and an application part 6; two sliding grooves A101 are symmetrically opened on the main body seat 1, And the top surface of the main body seat 1 is symmetrically provided with two sliding grooves B104; the top surface of the main body seat 1 is provided with an auxiliary groove 105, and a baffle plate 107 is welded on the main body seat 1; 202, locking bolt 203 and auxiliary rod A204, and the fixed plate 201 is an L-shaped plate-shaped structure; the bottom surface of the fixed plate 201 is symmetrically welded with two sliding protrusions 202, and the two sliding protrusions 202 are respectively slidably connected to the two The part 5 to be processed is clamped between the fixed plate 201 and the baffle plate 107; a locking bolt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com