Patents

Literature

125results about How to "Achieve scraping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

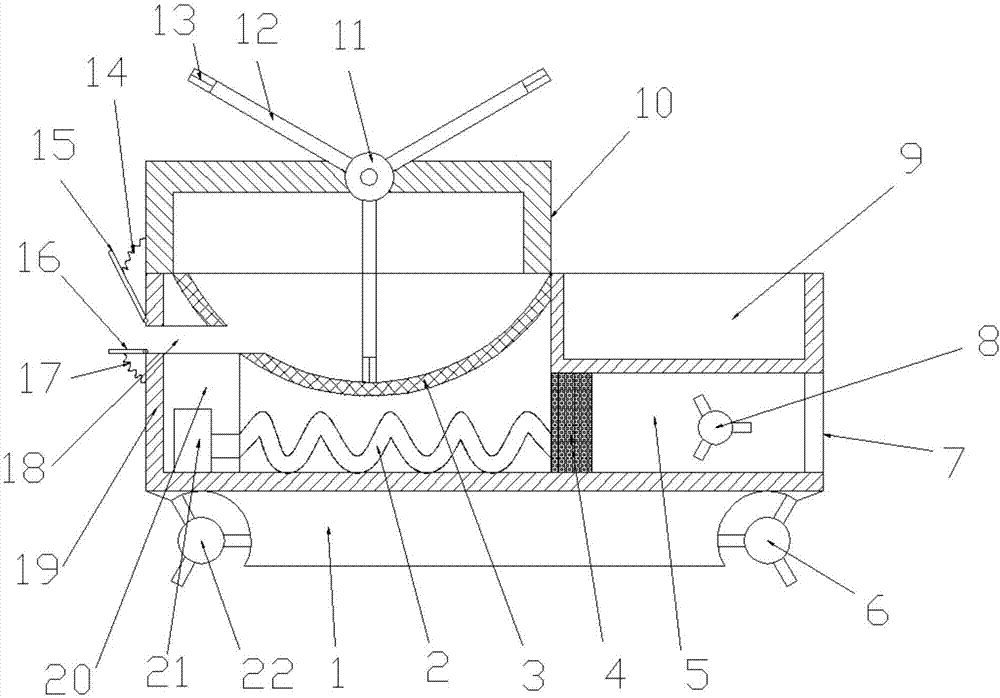

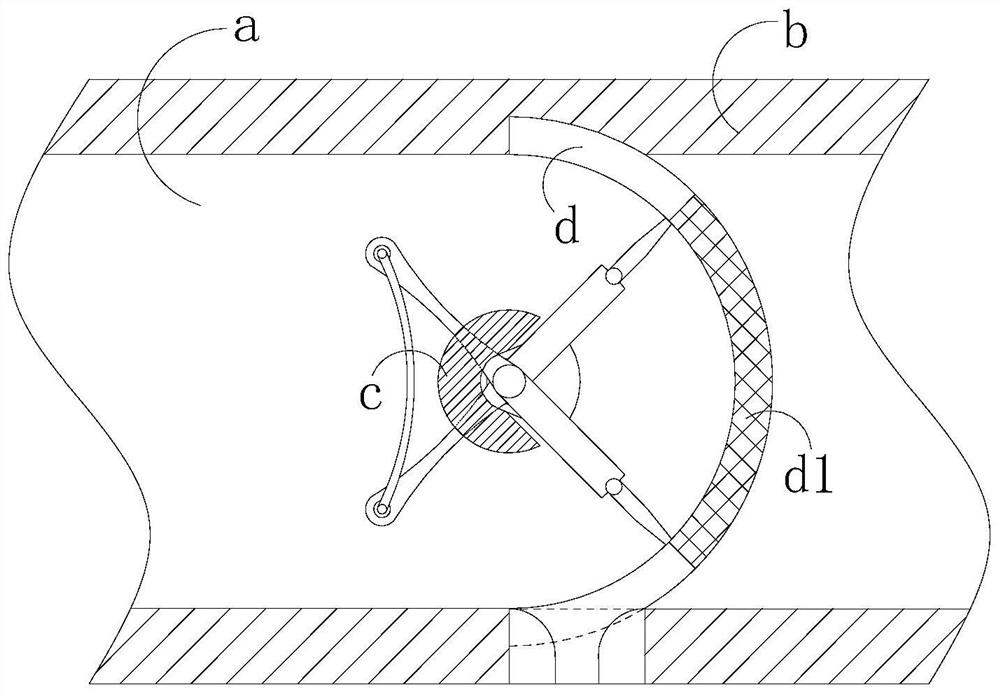

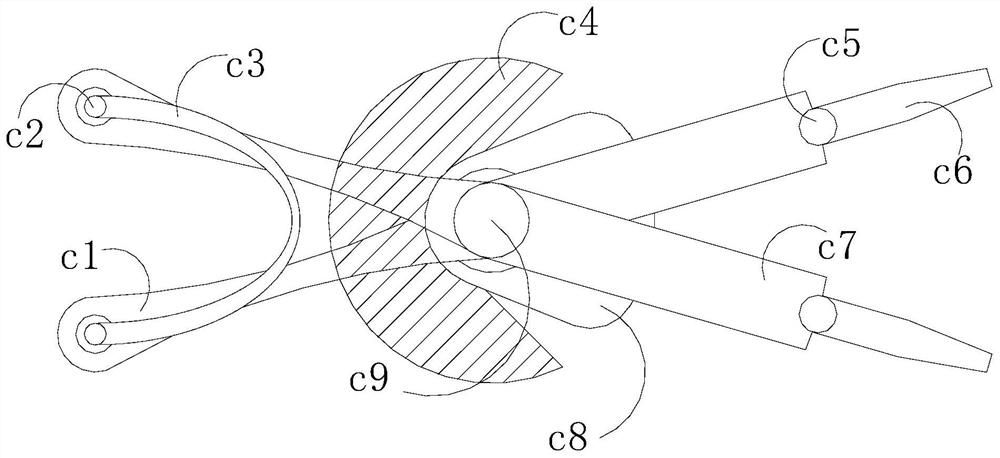

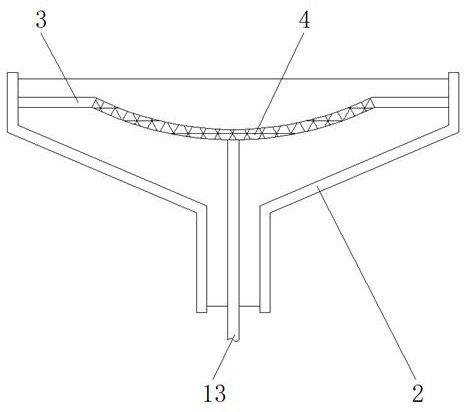

Water surface cleaning device for river courses

PendingCN107499466ANovel structureImprove garbage cleaning efficiencyWater cleaningWaterborne vesselsImpellerSewage treatment

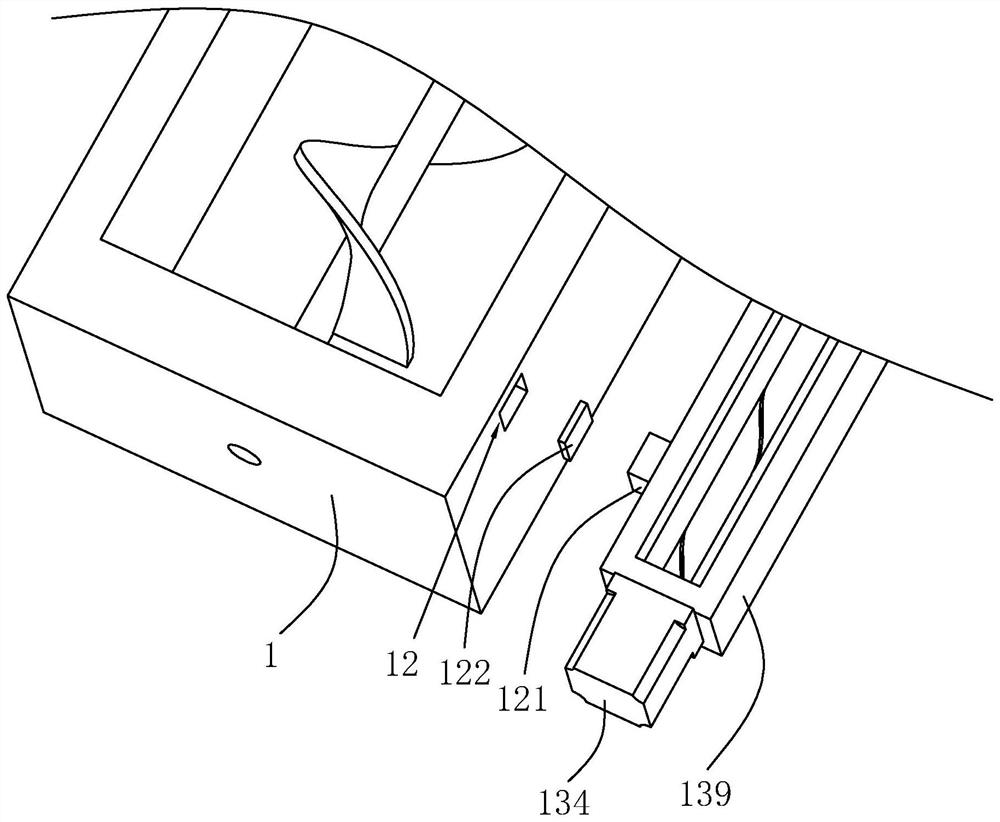

The invention discloses a water surface cleaning device for river courses. The device comprises a boat base, walking impellers are symmetrically arranged on the boat base in the left and right directions, a cabin is arranged above the boat base, an arc-shaped filtering screen is arranged inside the cabin horizontally, the left side of the filtering screen is provided with a water inlet pipeline transversely running through the filtering screen and the left side wall of the cabin, the left end of the water inlet pipeline stretches out of the left side wall of the cabin, the right end of the water inlet pipeline stretches into the filtering screen, and a supporting rack is arranged on the upper portion of the left side of the cabin; a turntable is arranged on the middle portion of the supporting rack and provided with a plurality of rotating rods in a central symmetry mode. The water surface cleaning device for the river courses is novel in structure, and capable of scraping off garbage on the water surface and achieving sewage treatment; through ingenious arrangement of the filtering screen and a scraper blade mechanism, the garbage cleaning efficiency is high, and meanwhile, through ingenuous arrangement of a sewage filtering device, the sewage treatment is achieved.

Owner:ZHENGZHOU UNIV

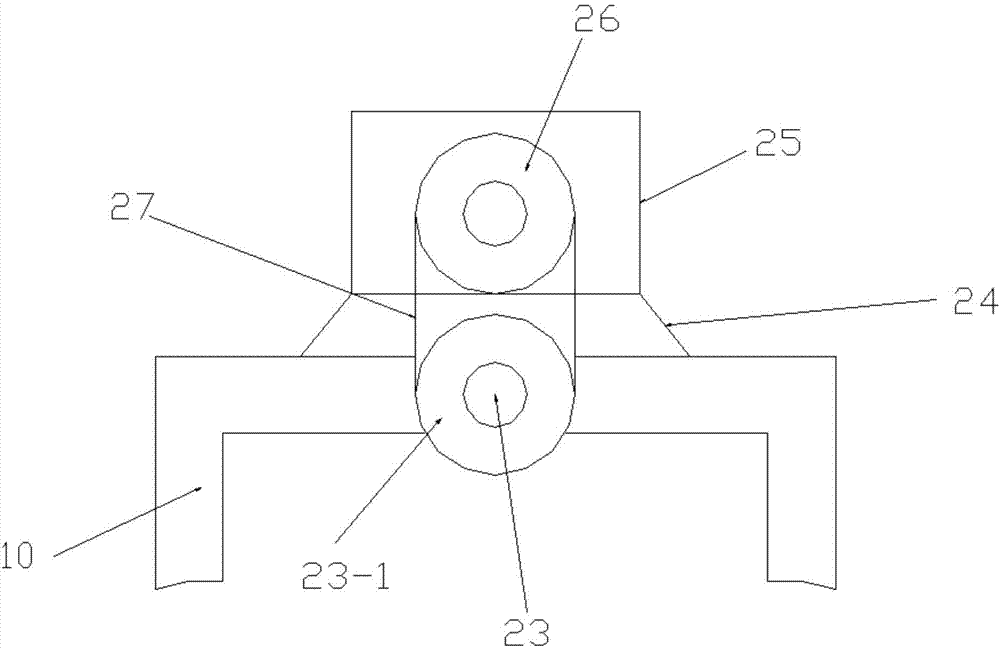

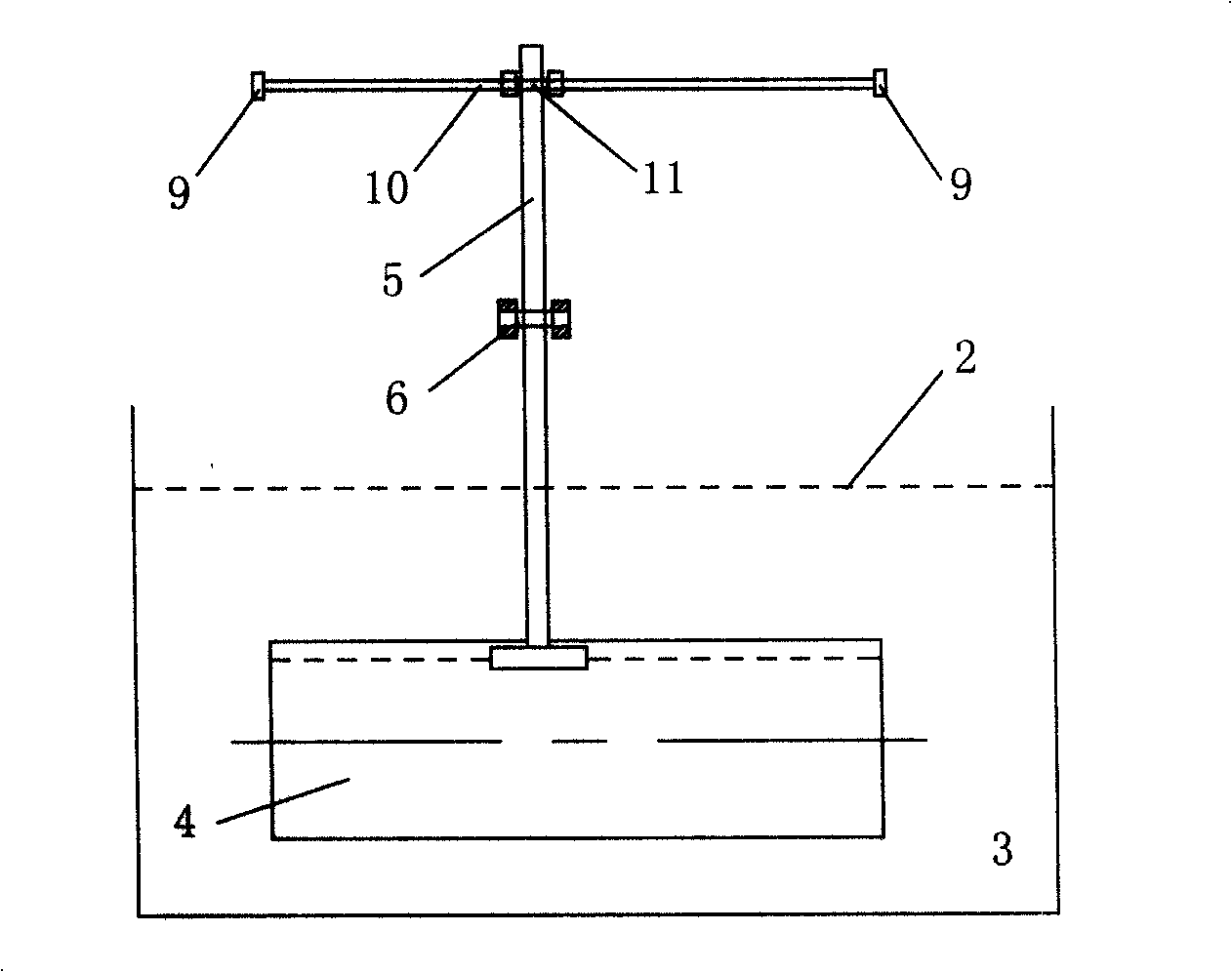

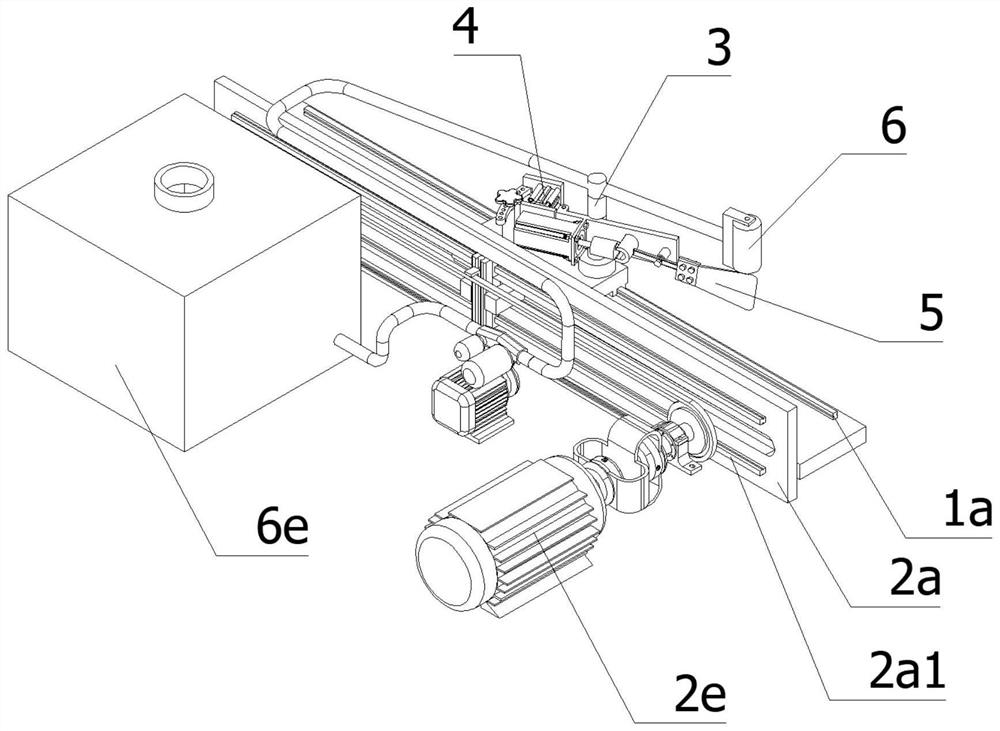

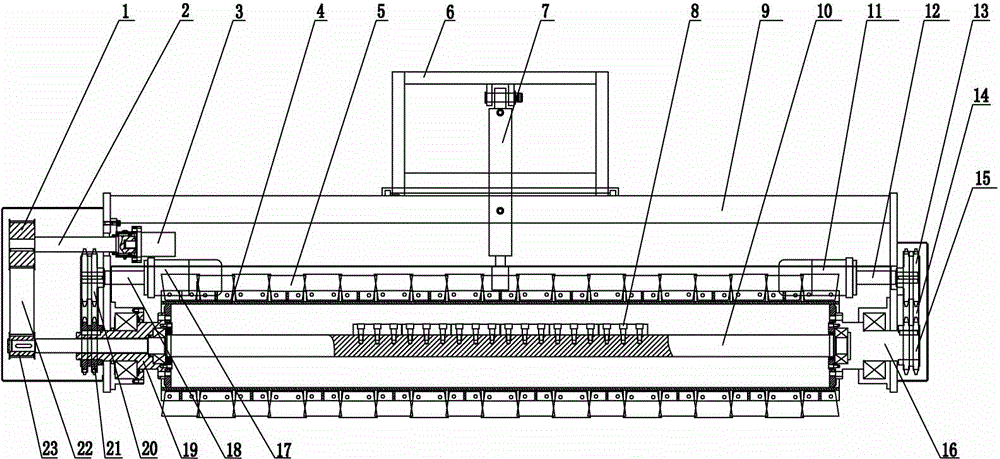

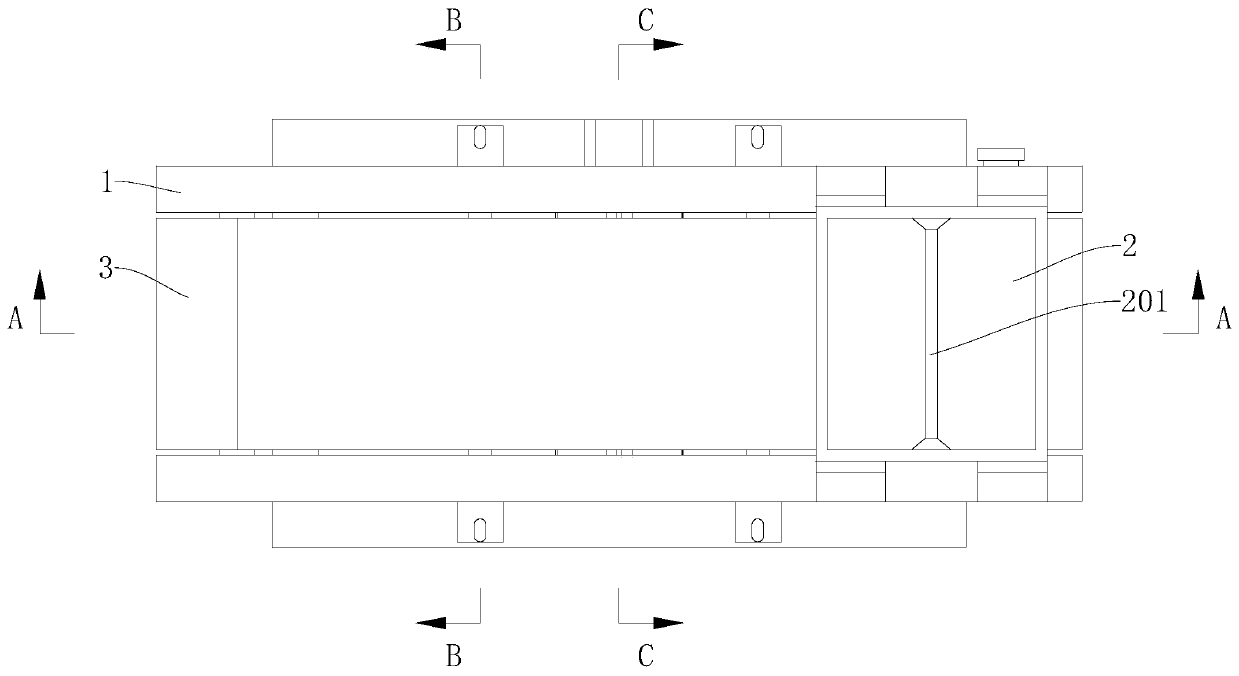

Method and device for detecting and clearing sink roll slagging

InactiveCN101255539AImprove efficiencyReduce wearHot-dipping/immersion processesSpeed/accelaration control using electric meansMoving speedEngineering

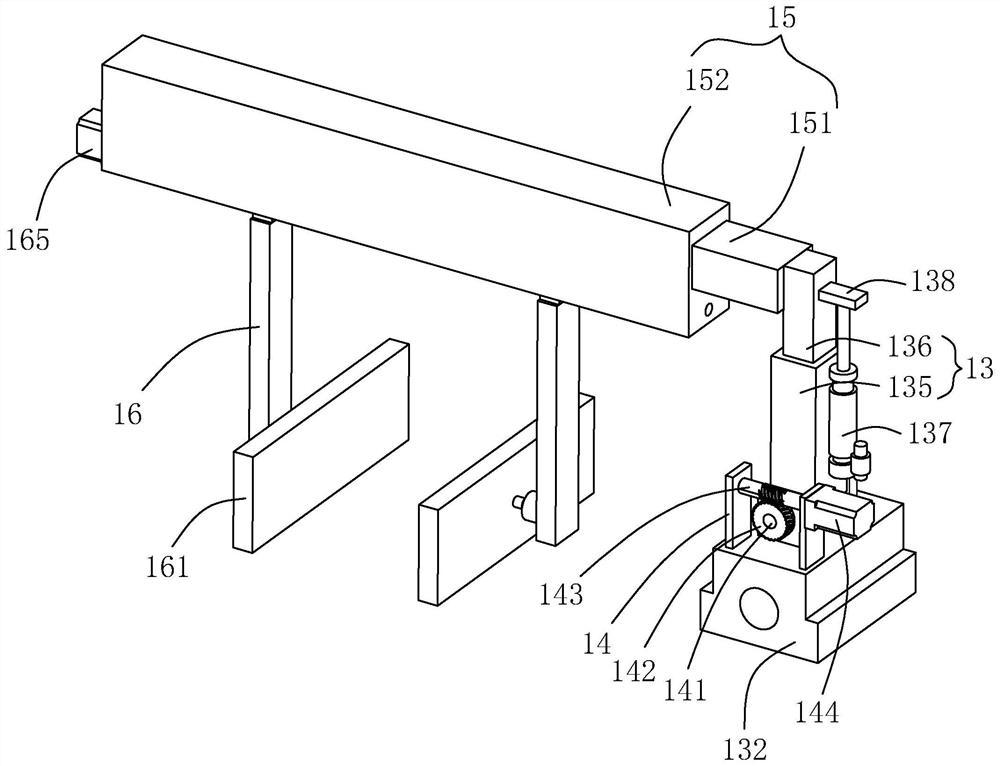

The present invention relates to a method for detecting and removing slagging of a sink roll in a cold rolling hot galvanizing device and a device therefor. The method for detecting and removing slagging is characterized in: the connecting end of a scraper rod and piston rod is equipped with a displacement sensor, and a top roll for transmitting strip belts is equipped with a revolution transmitter; the revolution transmitter measures the on-line speed of strip belts and transmits to a controller, the controller outputs the control speed of the scraper rod moving along the generatrix of the sink roll after calculation; the displacement sensor measures the vibration quantity and transmits to a controller, the vibration quantity is proportional to the thickness of the sink roll slagging, the controller outputs the control pressure of a scraper on the scraper rod to the sink roll, thus to removing the slagging on the sink roll. According to the invention, sensors are used for measuring the speed of the strip steel and the slagging speed of the sink roll, control the horizontal moving speed of the scraper and the pressure of the scraper to the sink roll, so that sink roll slagging is removed, and the abrasion of the sink roll and the scraper is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Vertical vibration concentrating machine

The invention discloses a vertical vibration concentrating machine which comprises a concentrating machine body. The surface of the right upper end of the concentrating machine body is provided with ashifting switch and a power line. The right side of the concentrating machine body is provided with a primary discharge outlet, a transmission box is arranged inside the left upper side of the concentrating machine body, a cam is rotationally connected with the interior of the transmission box through a motor, a guide plate is in sliding connection with the right surface of the cam, the middle ofthe guide plate is provided with a feeding separation port, flow guide plates are symmetrically arranged on the two sides of the middle of the guide plate, a sliding plate is fixedly connected to thesurface of the upper end of the flow guide plate, the concentrating machine body is in sliding connection with the outer surface of the left side of the sliding plate, a feeding hopper is fixedly connected to the surface of the right end of the sliding plate, a sliding way is rotationally connected with the interior of the right lower side of the concentrating machine body through a first rotating shaft, and a first vibration motor is arranged inside the left side of the concentrating machine body. According to the vertical vibration concentrating machine, ore raw materials are scattered on asieve plate by being divided into left and right portions, and ore slag on the surface of the sliding way is scratched away.

Owner:陈跃勇

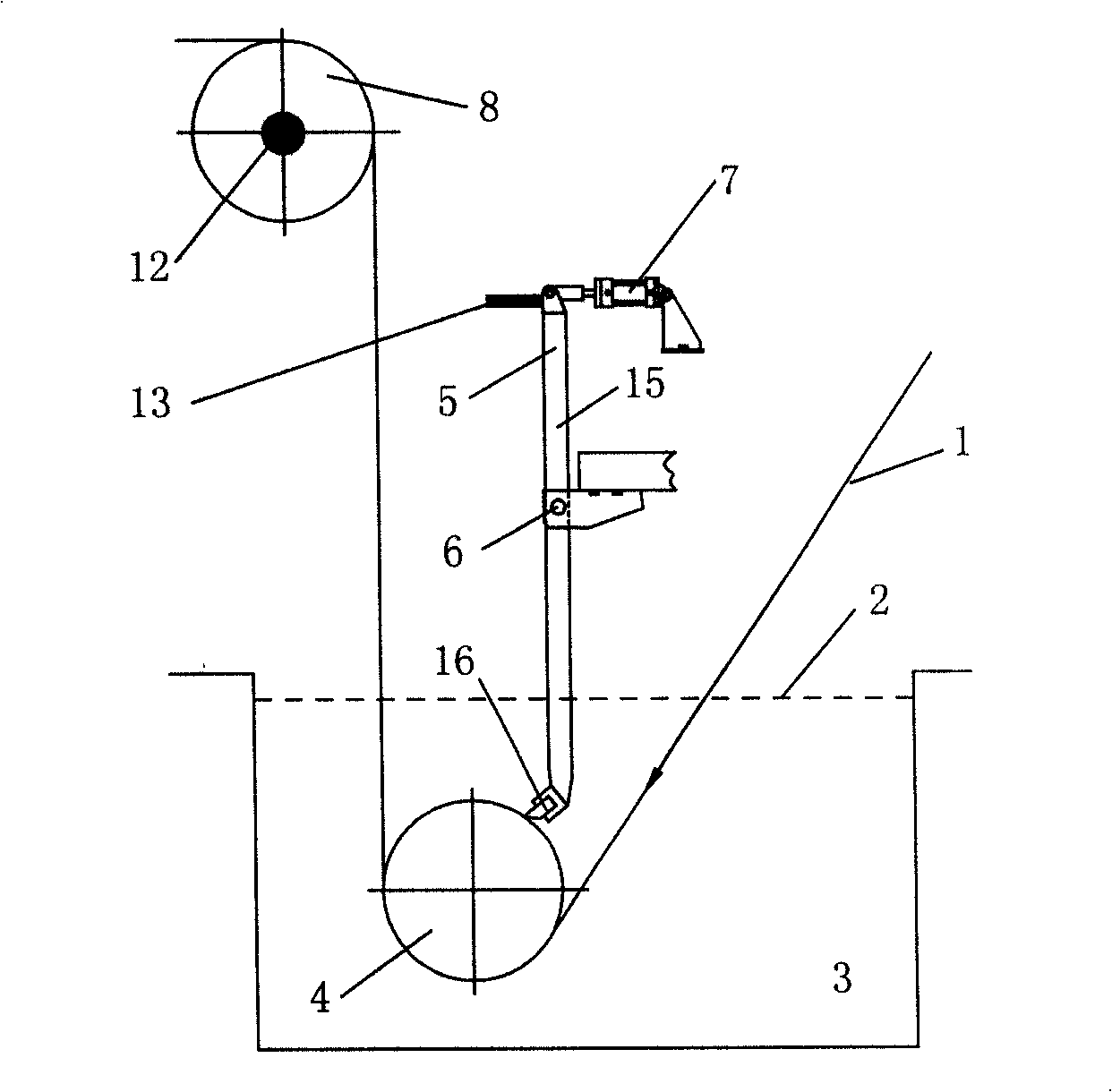

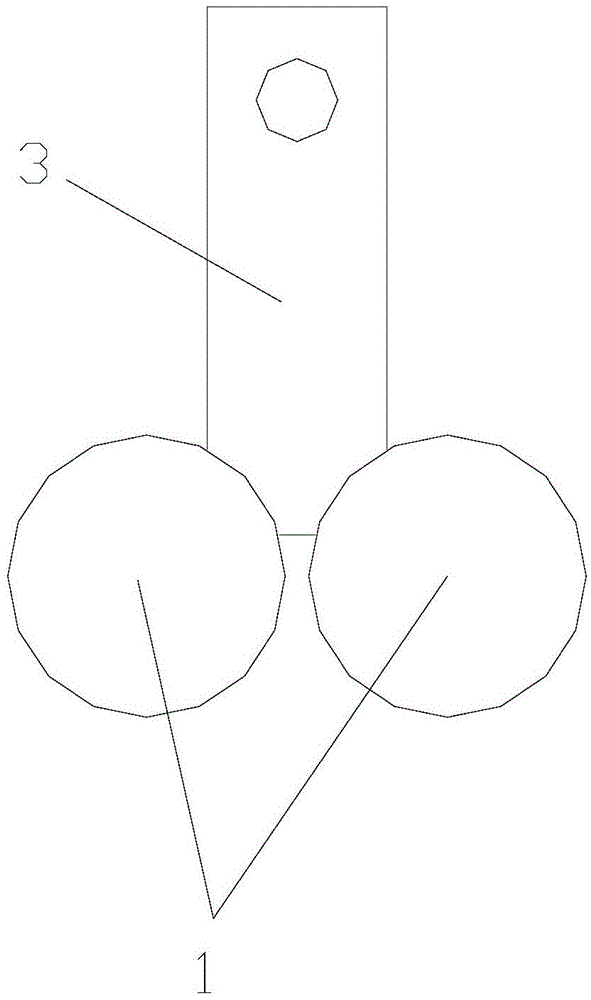

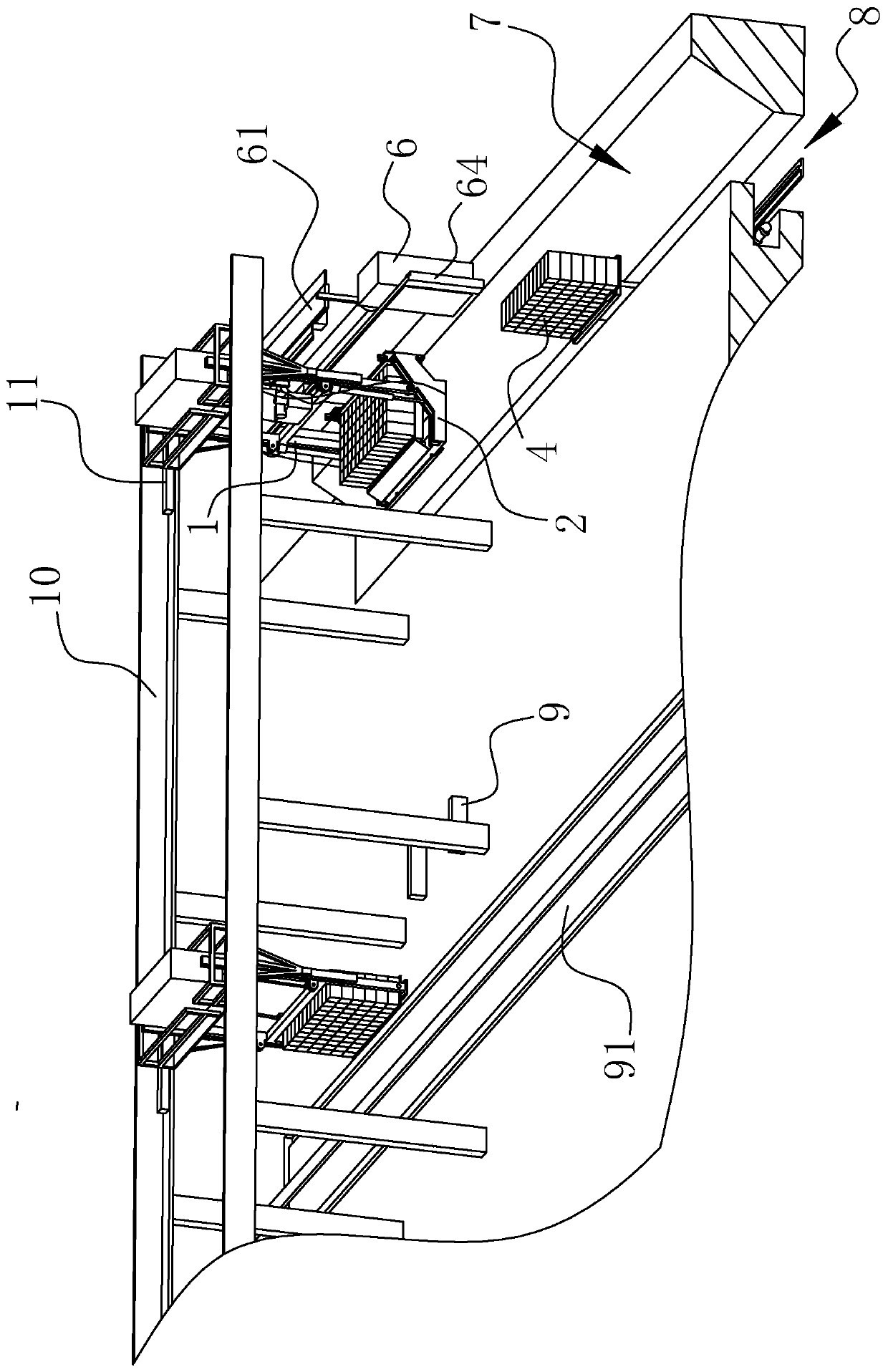

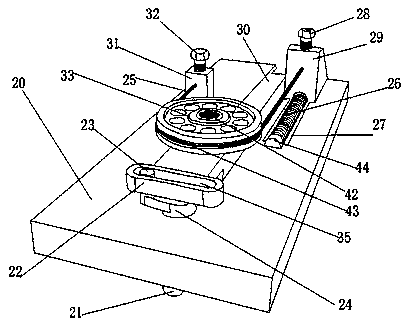

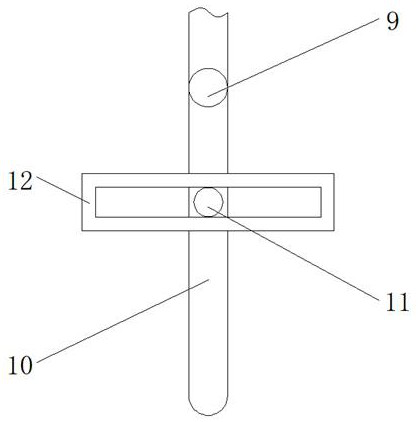

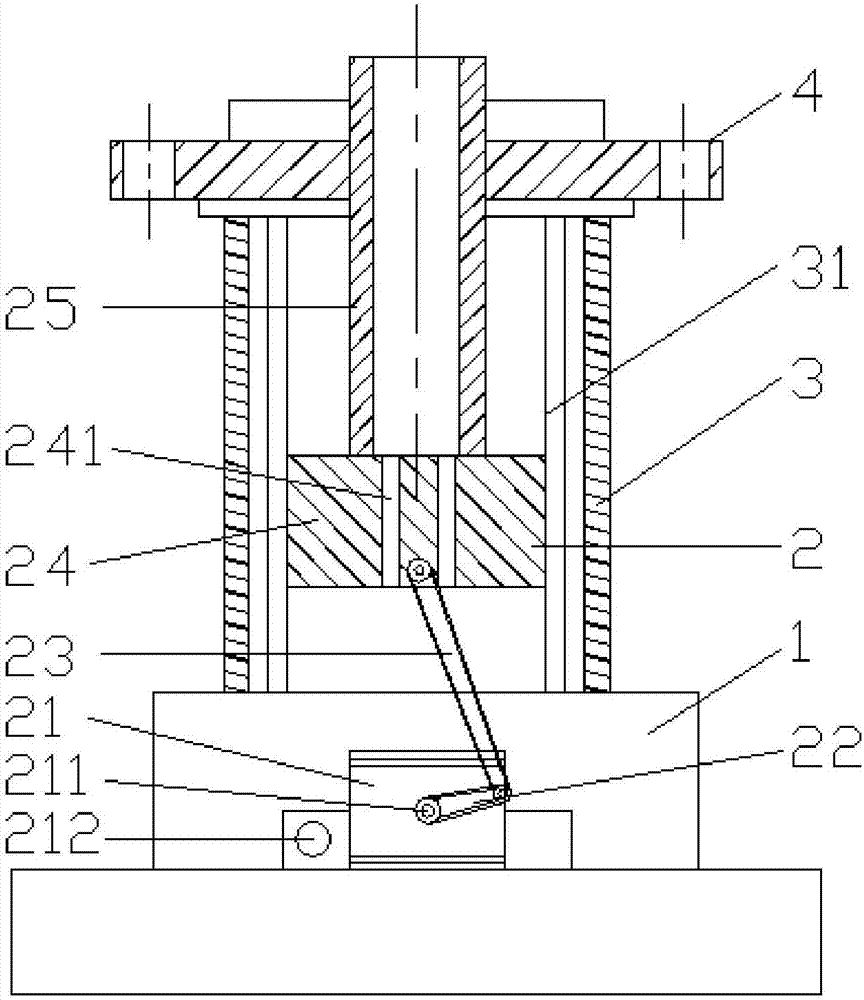

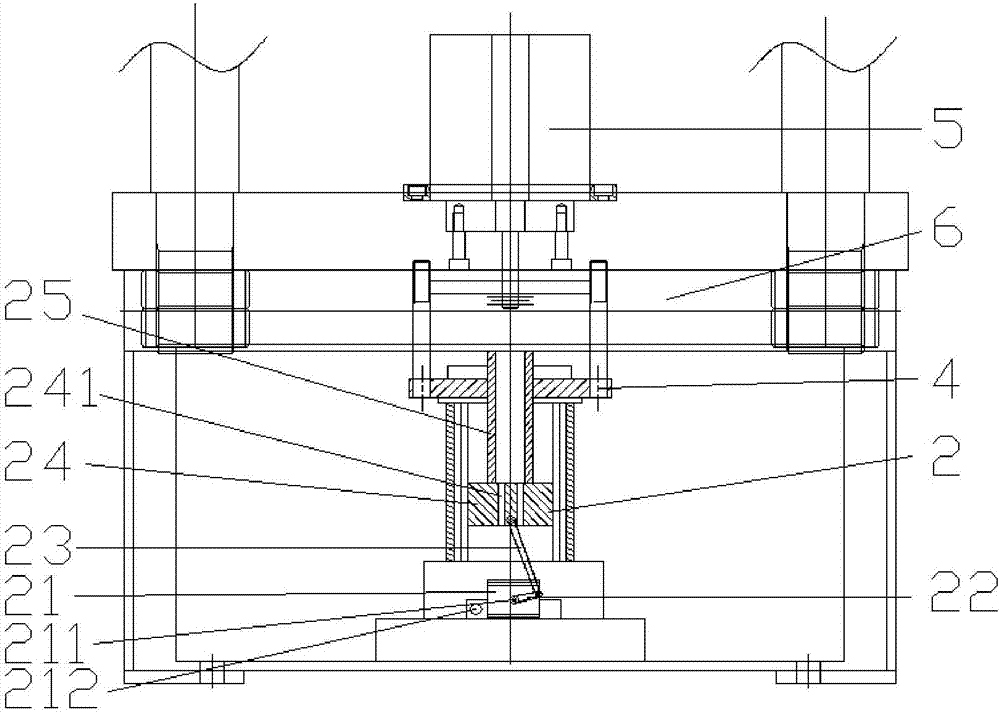

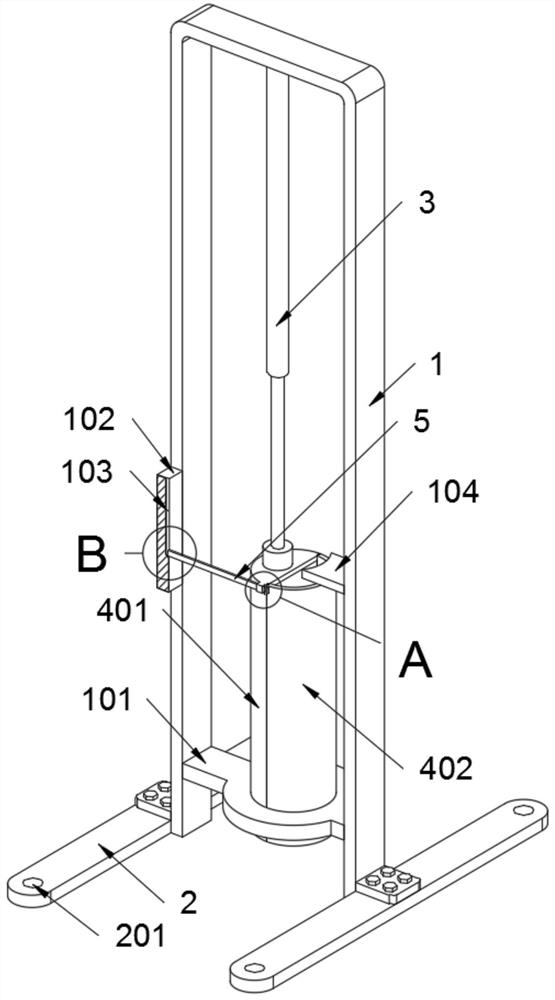

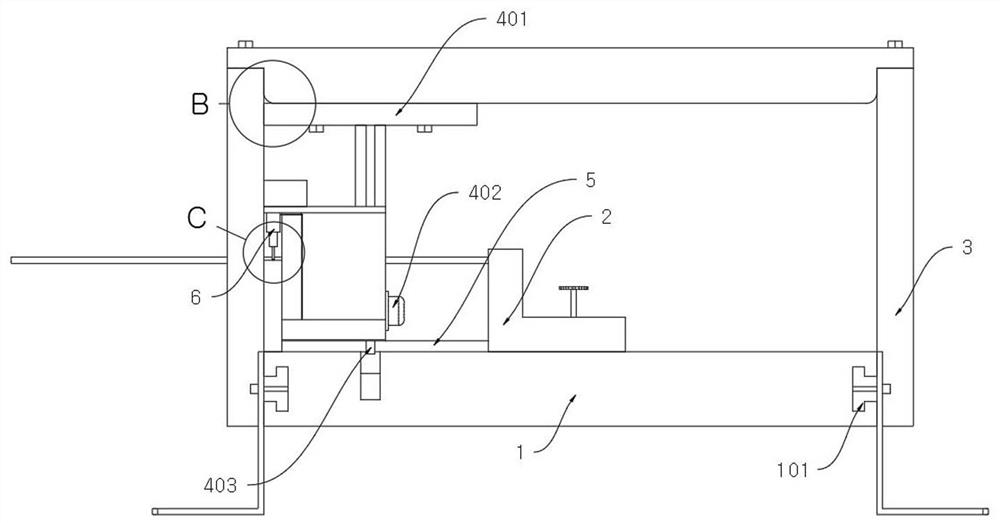

Long spiral drilling machine for efficient soil clearing

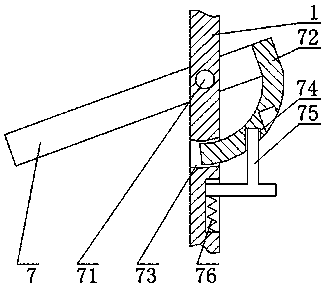

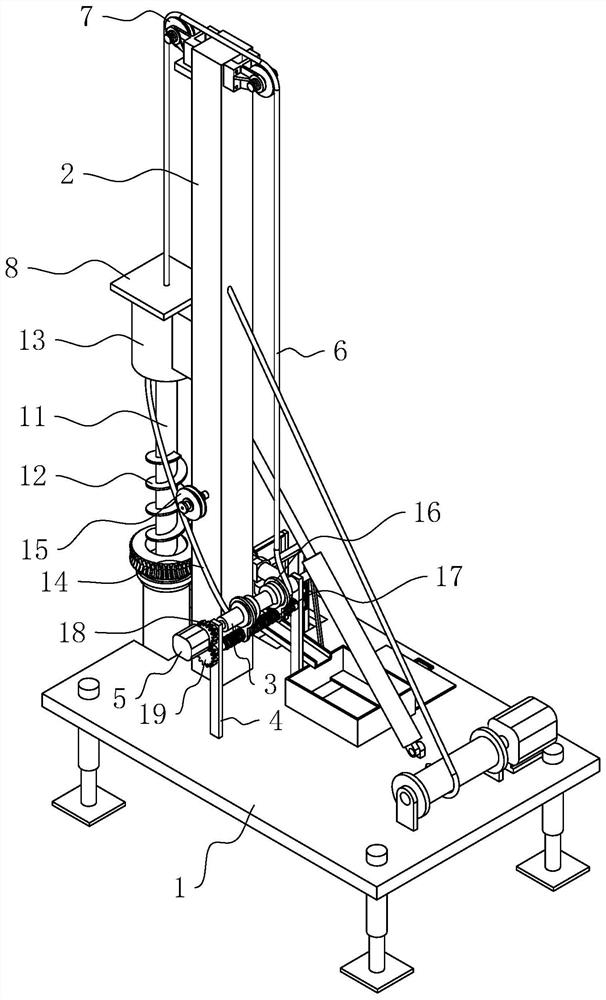

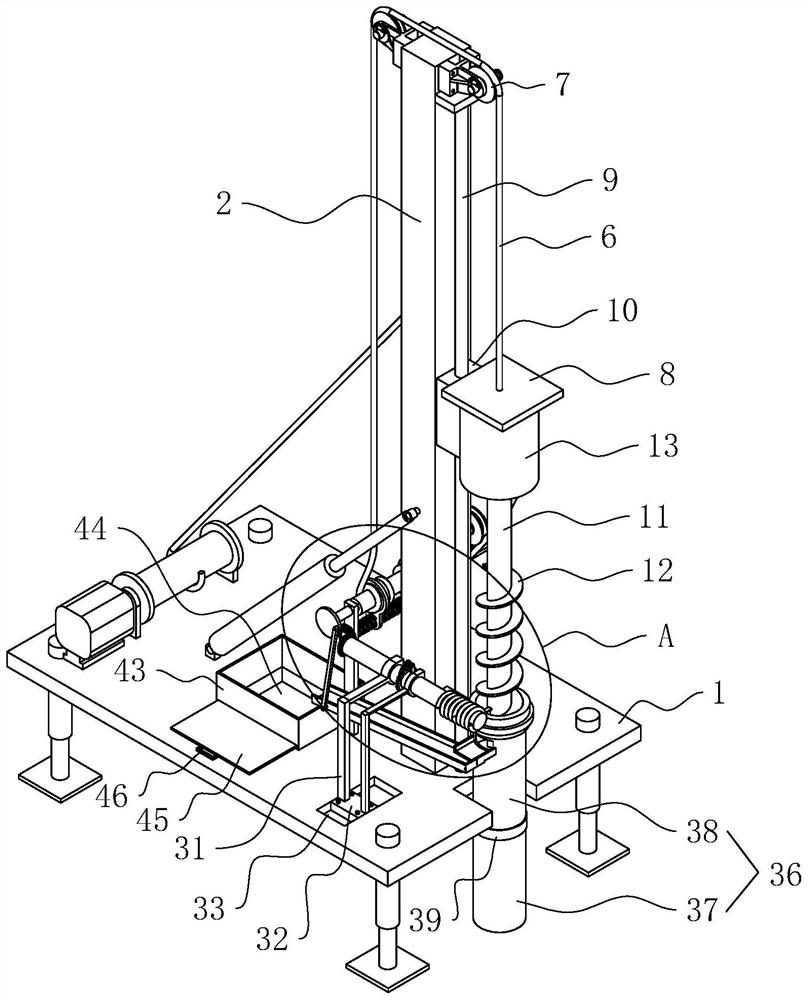

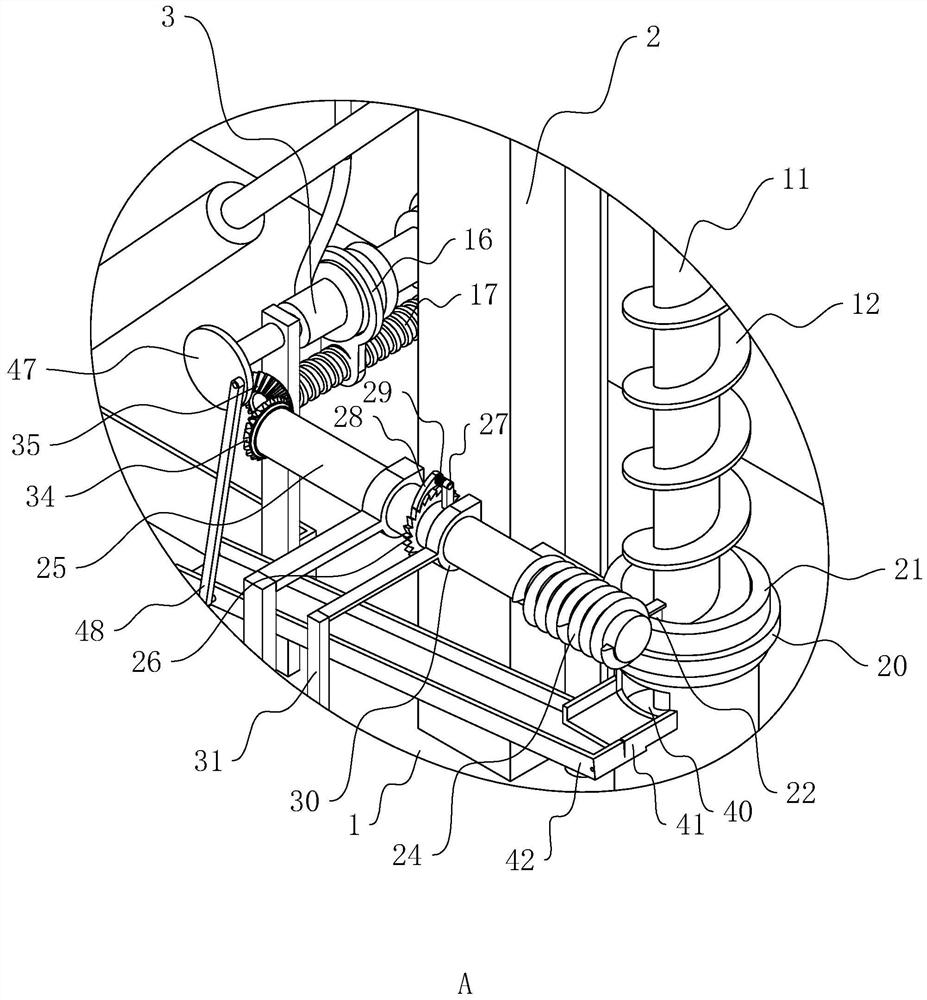

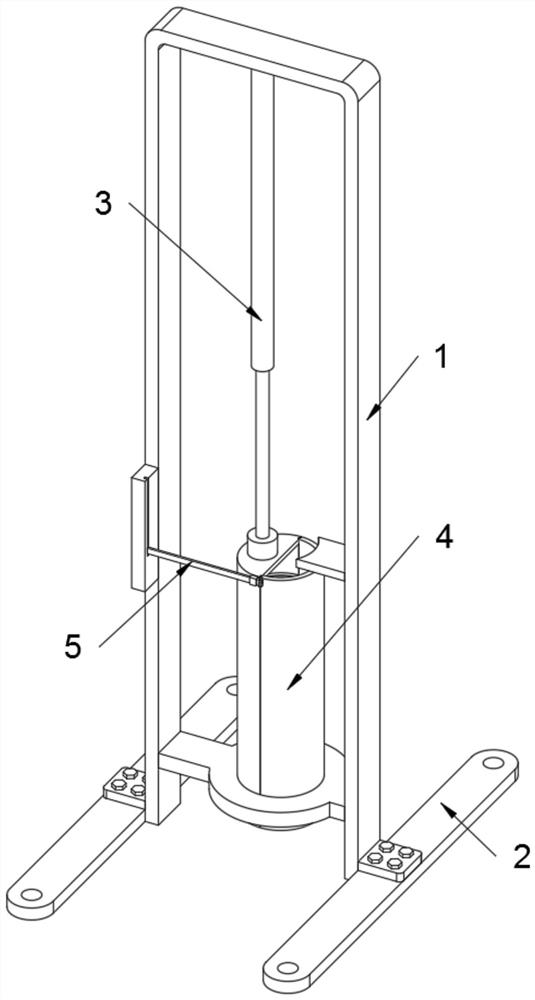

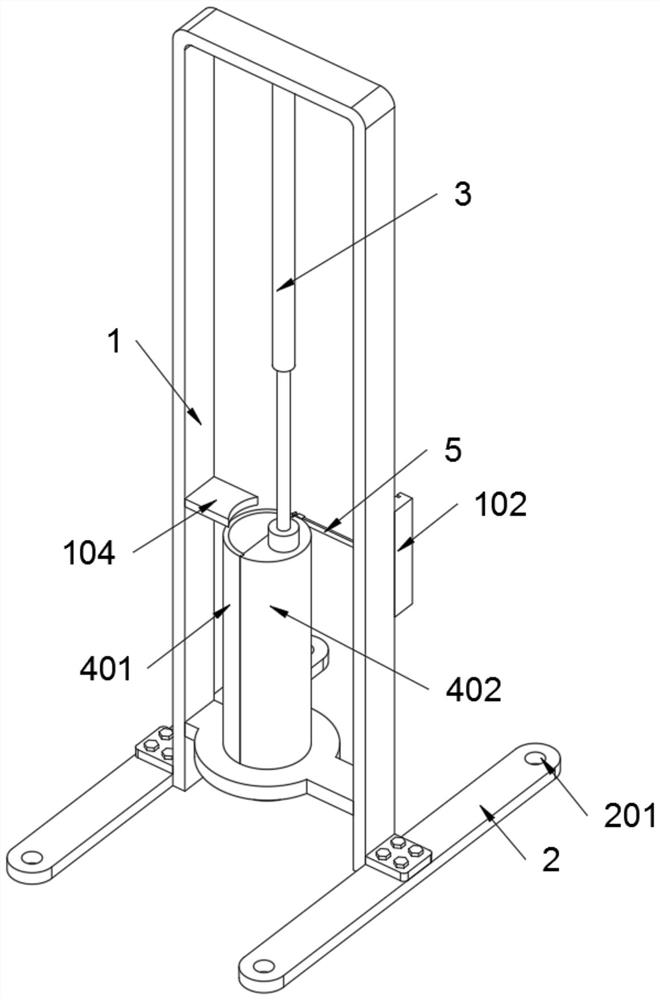

ActiveCN111827888AImprove drilling forceAchieve scrapingEarth drilling toolsDrilling rodsSpiral bladeAgricultural engineering

The invention relates to a long spiral drilling machine for efficient soil clearing. The long spiral drilling machine comprises a machine body, a stand column is installed on the machine body, a winding roller is rotatably connected to the machine body, a first motor for driving the winding roller to rotate is fixedly connected to the machine body, a first steel cable is fixedly connected to the winding roller in a winding manner, the end, far away from the winding roller, of the first steel cable passes around the upper end of the stand column and is fixedly connected with a power head, and the power head is in sliding connection with the stand column along the length direction of the stand column, the power head is rotatably connected with a drill rod which is vertically arranged downwards, a thread spiral blade is fixedly and spirally connected to the drill rod, the power head is provided with a second motor which is used for driving the drill rod to rotate, the winding roller is wound and fixedly connected with a second steel cable, the stand column is rotatably connected with a guide wheel, the end, far away from the winding roller, of the second steel cable is fixedly connected to the power head, and the winding directions of the first steel cable and the second steel cable are opposite. The long spiral drilling machine has the effect of improving the drilling force of the drill rod to a certain extent.

Owner:江西中恒地下空间科技有限公司

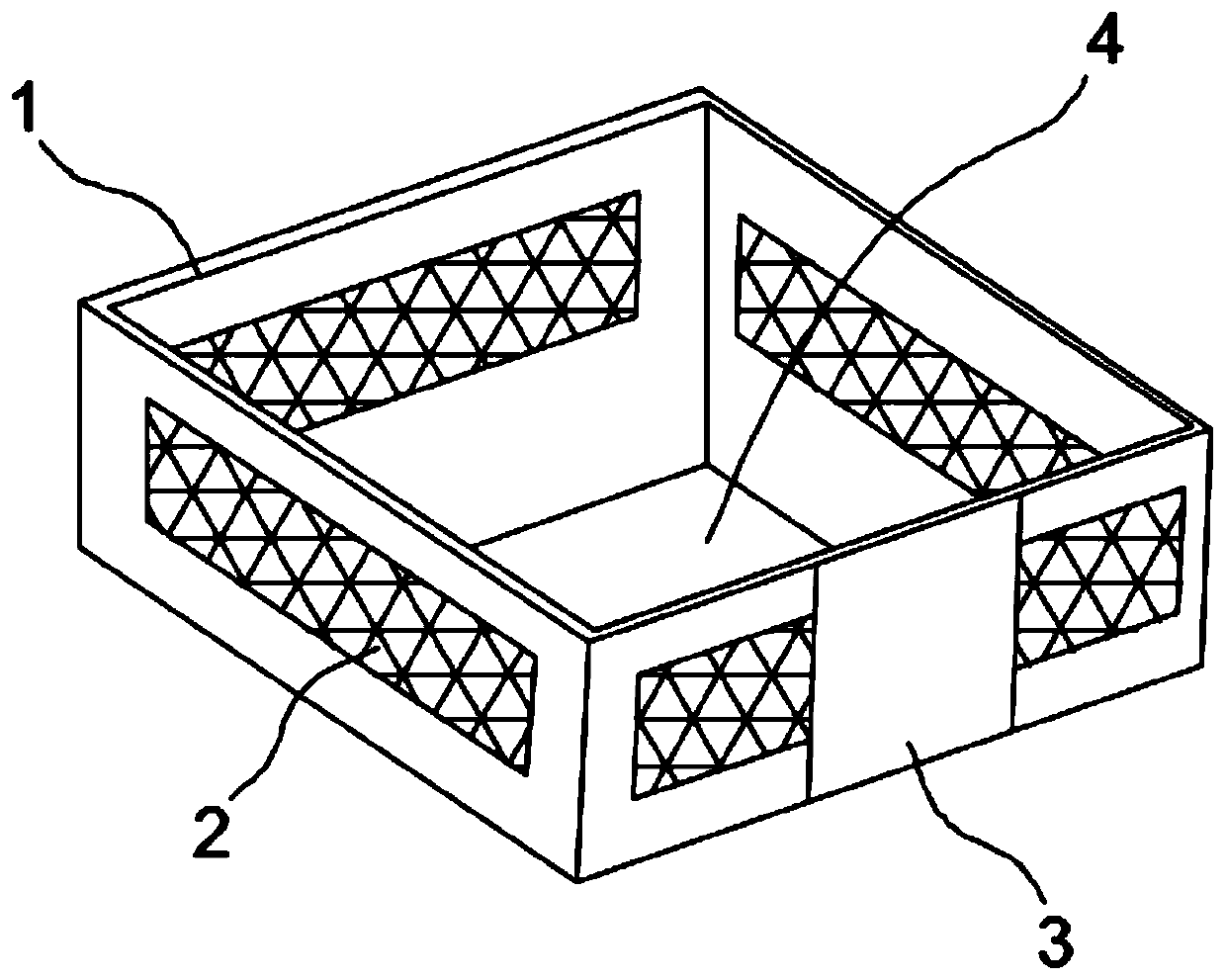

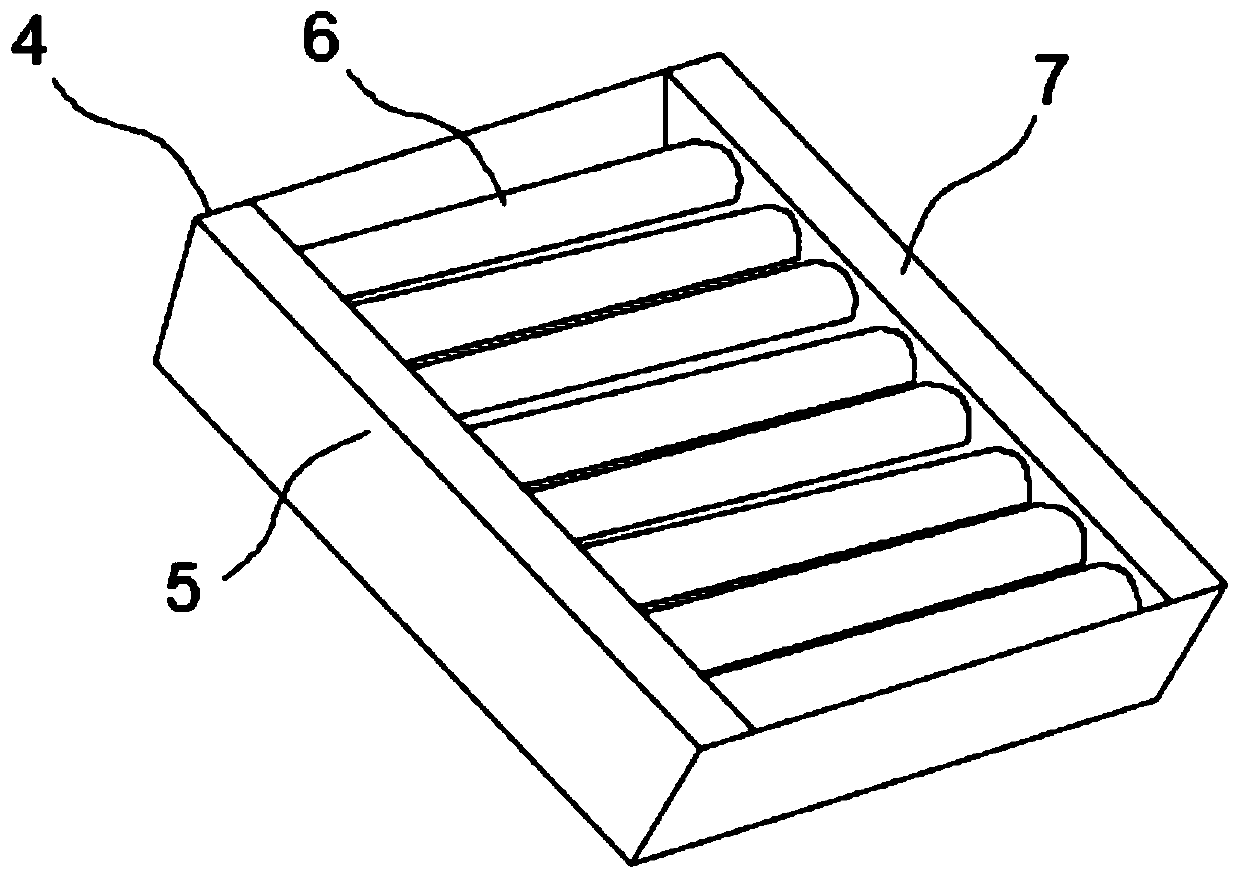

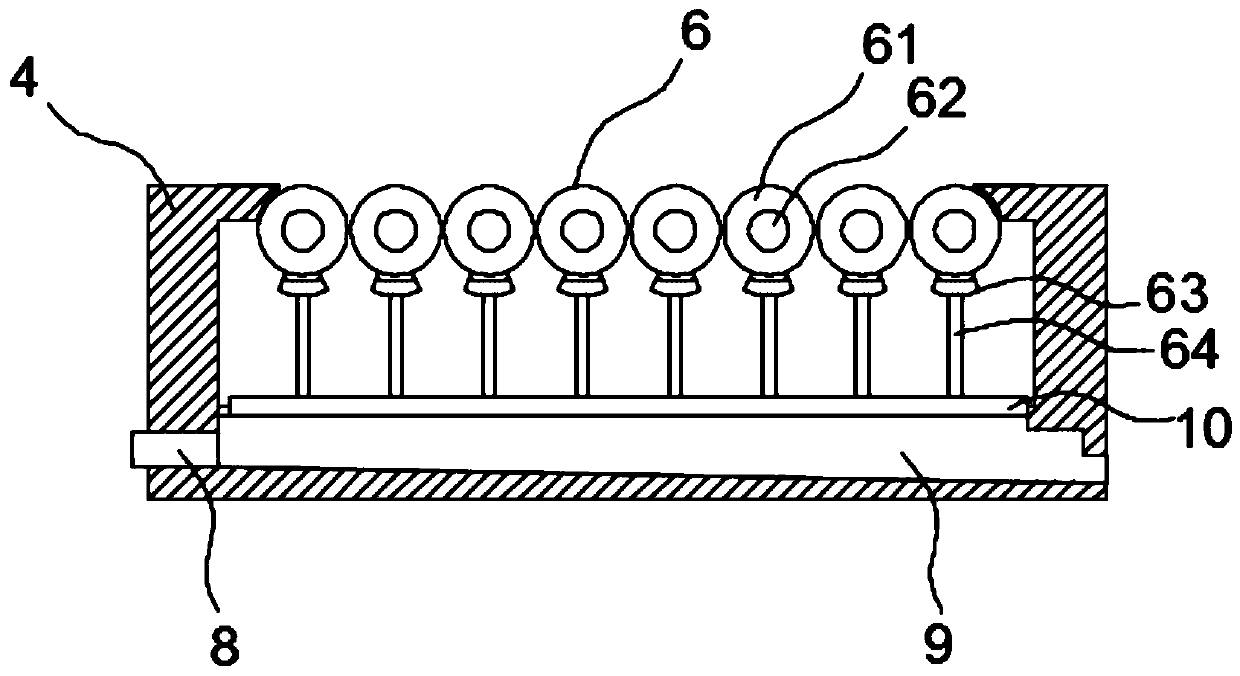

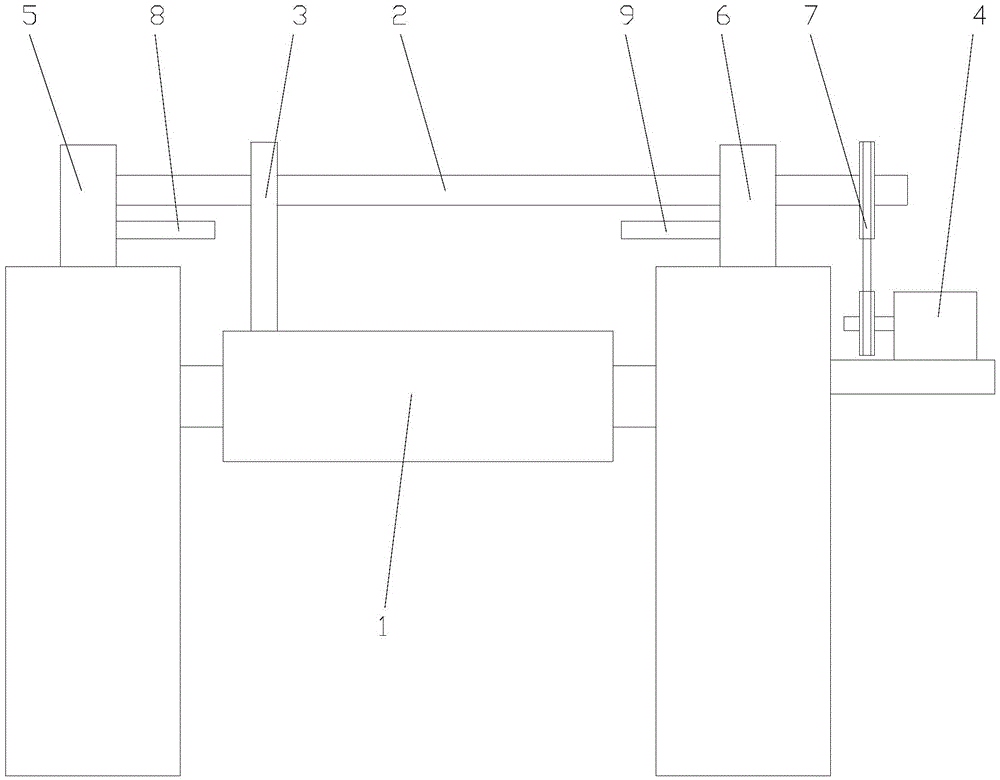

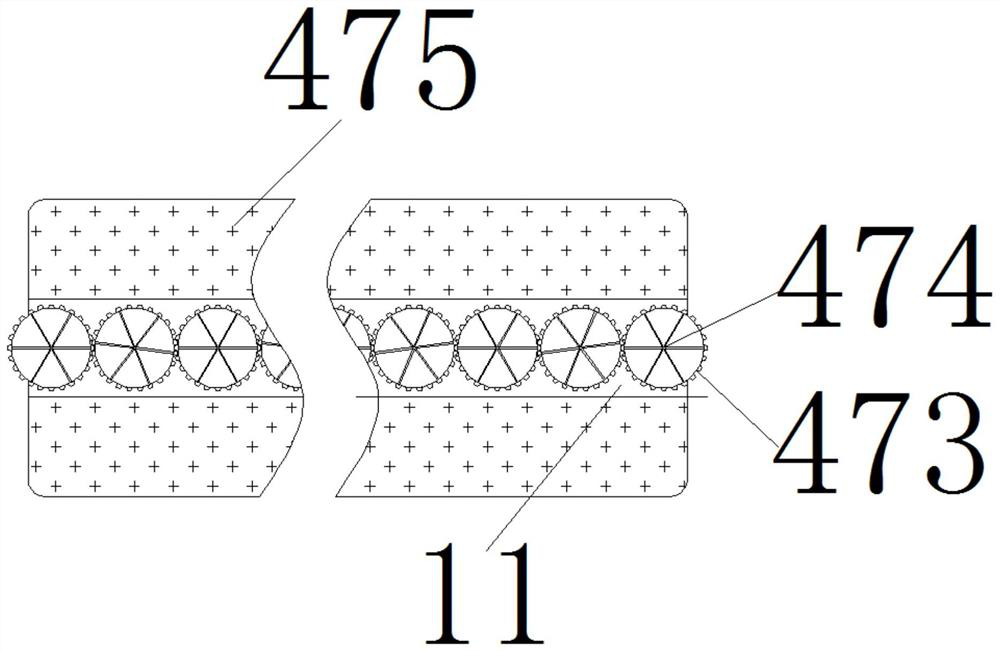

Ecological breeding circle for breeding cattle

ActiveCN110741953AIncrease exerciseImprove meat fiberPasturing equipmentAnimal housingEngineeringZoology

The invention discloses an ecological breeding circle for breeding cattle, which belongs to the field of agriculture and animal husbandry and comprises a bottom plate and a rotating roller group, wherein the rotating roller group is mounted on the bottom plate; the rotating roller group consists of a plurality of unit rotating rollers arranged side by side, and cleaning structures are arranged onthe bottom plate at the bottom of the rotating roller group; a power box is mounted on the bottom plate on one side of the rotating roller group, a plurality of groups of power devices are arranged inside the power box, and a plurality of unit rotating rollers arranged side by side are controlled in blocks; and the power devices can control a plurality of the unit rotating rollers which are arranged side by side to perform local rotation in blocks, so that excrement on the surface of the power devices can be rotated to the cleaning structures to be cleaned, cattle do not need to be driven outof the circle to be cleaned, the cleaning effect is good, and integral cleaning of local excrement is not needed, and energy waste is avoided; and at the same time, the rotation of the unit rotating rollers can promote the movement of cattle, so as to improve the meat quality.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

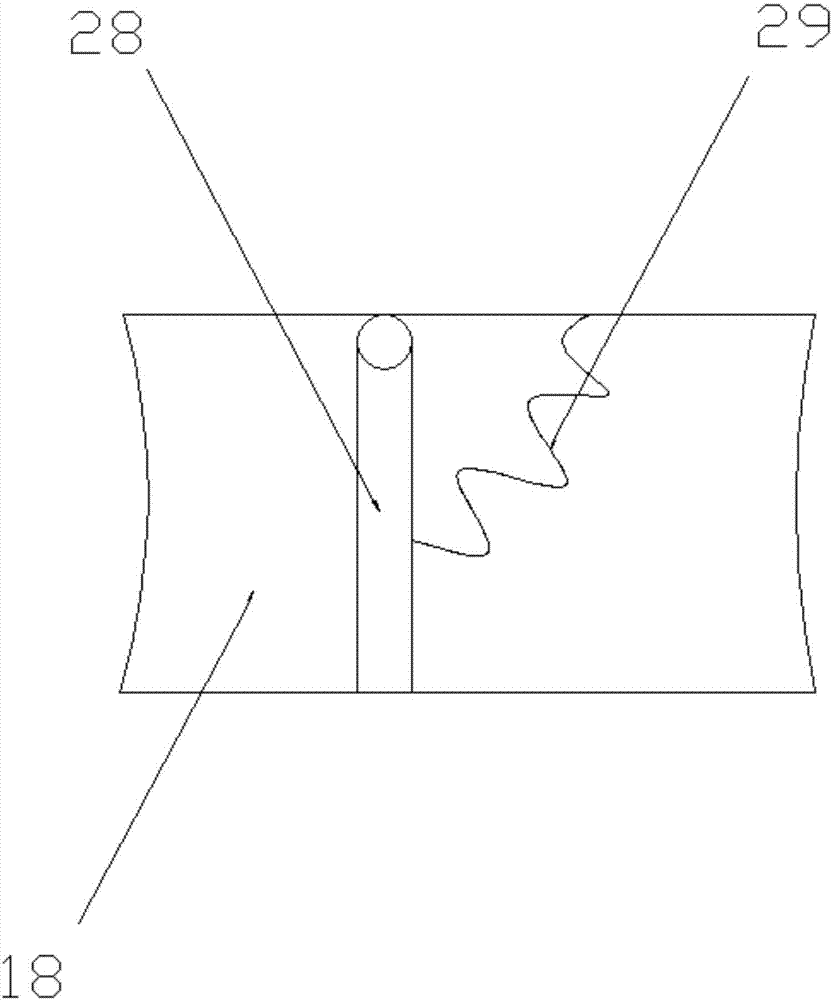

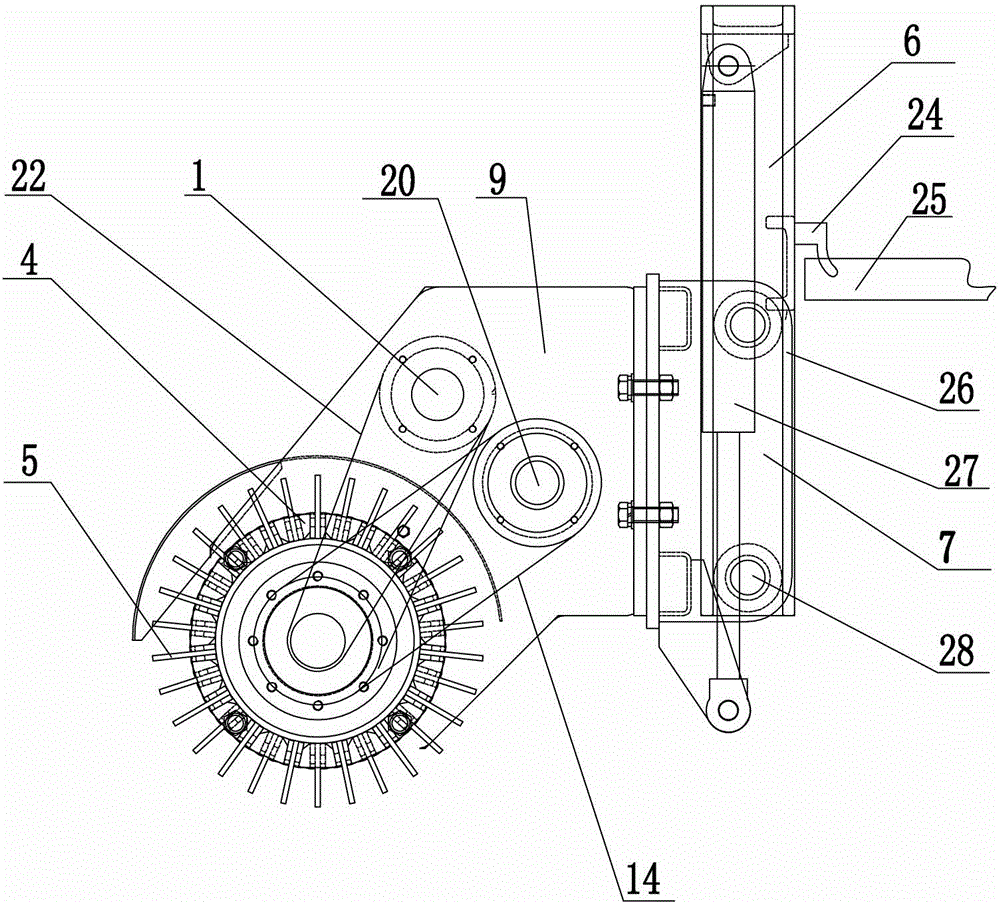

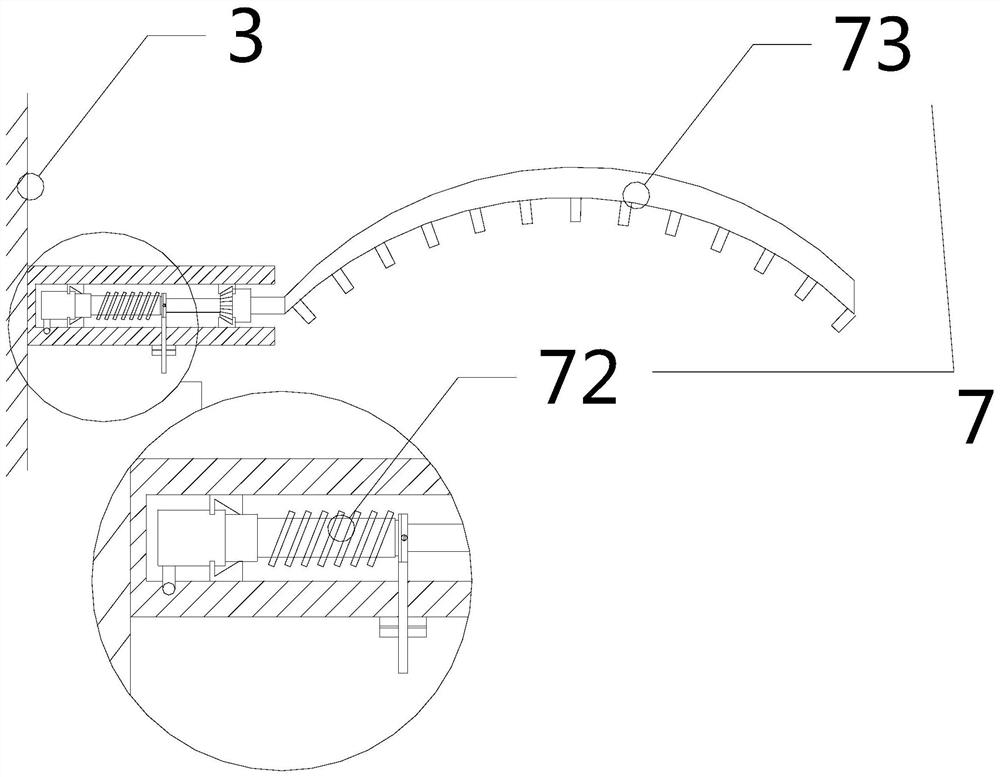

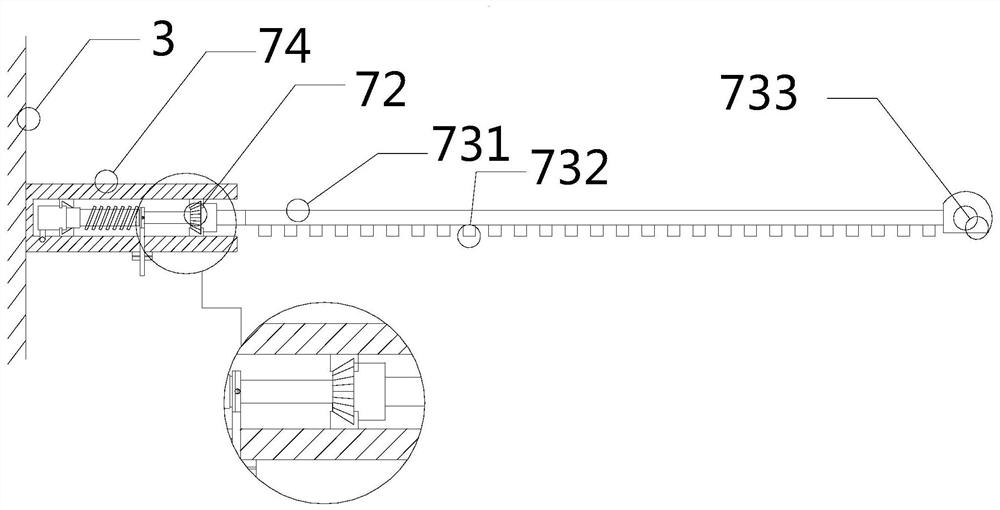

Scraper device of open rubber refining machine

The invention discloses a scraper device of an open rubber refining machine. The scraper device comprises a lead screw, a scraper and a drive motor, wherein the lead screw is parallel to a pressure roll of the rubber refining machine; the scraper is matched with the lead screw through threads; the drive motor is arranged on a machine frame of the rubber refining machine; a left supporting plate and a right supporting plate which are rotationally matched with the two ends of the lead screw are also arranged on the machine frame of the rubber refining machine, and the motor is in transmission connection with the lead screw through a belt wheel transmission device; the scraper device further comprises a left proximity switch and a right proximity switch respectively arranged on the left supporting plate and the right supporting plate for controlling the drive motor to reverse. The scraper device of the open rubber refining machine has the benefits that the scraper is controlled by the drive motor, the proximity switches and the lead screw to do reciprocating motion in the axial direction of the pressure roll of the rubber refining machine, thereby automatically scraping stranded rubber on the pressure roll; the working efficiency is high; the problem that the stranded rubber influences the product quality is solved.

Owner:CHONGQING HAISHAN RUBBER CHEM

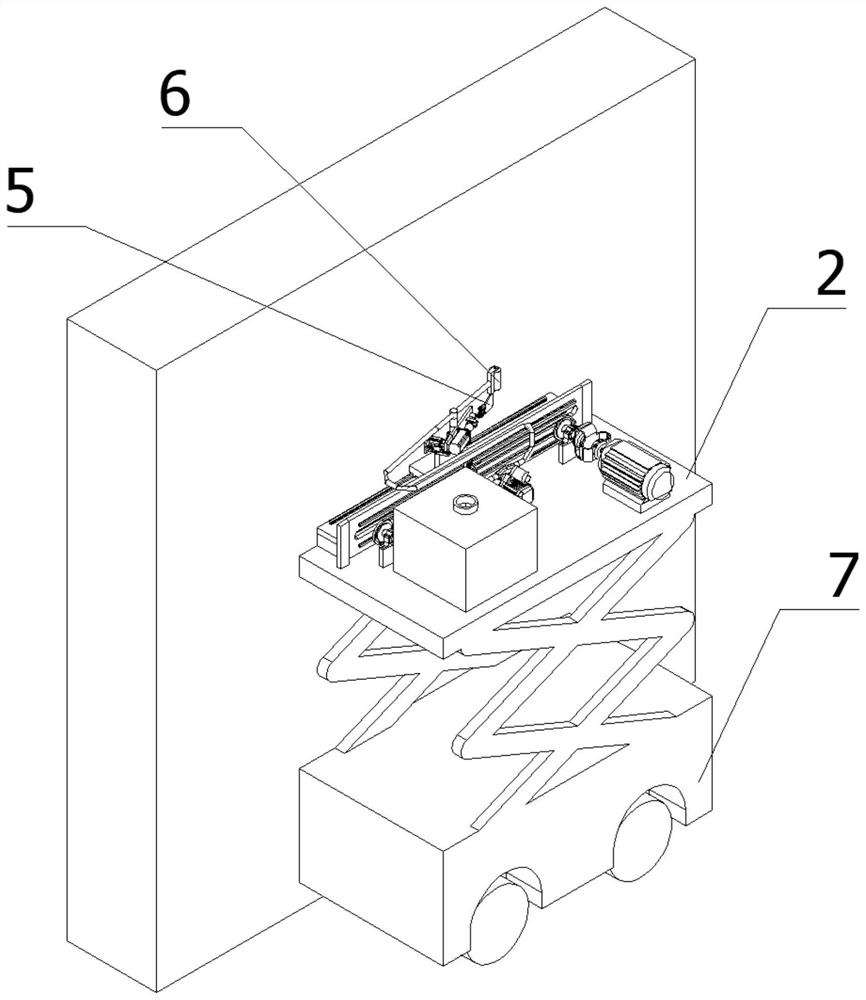

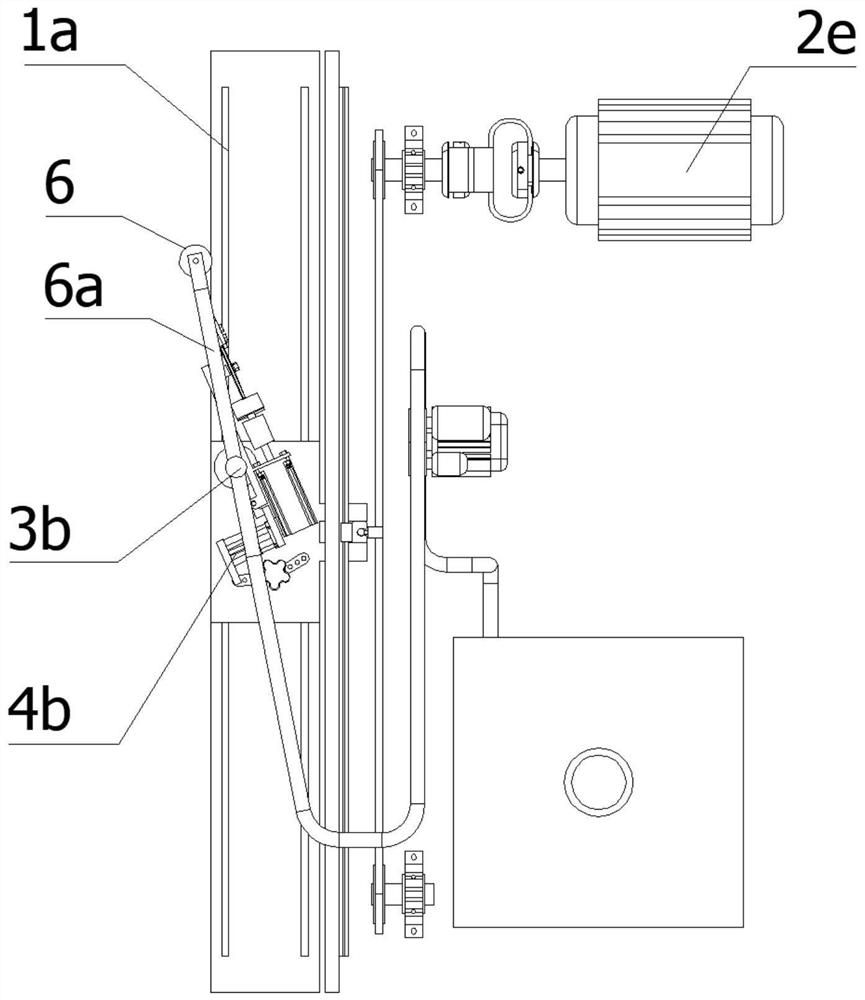

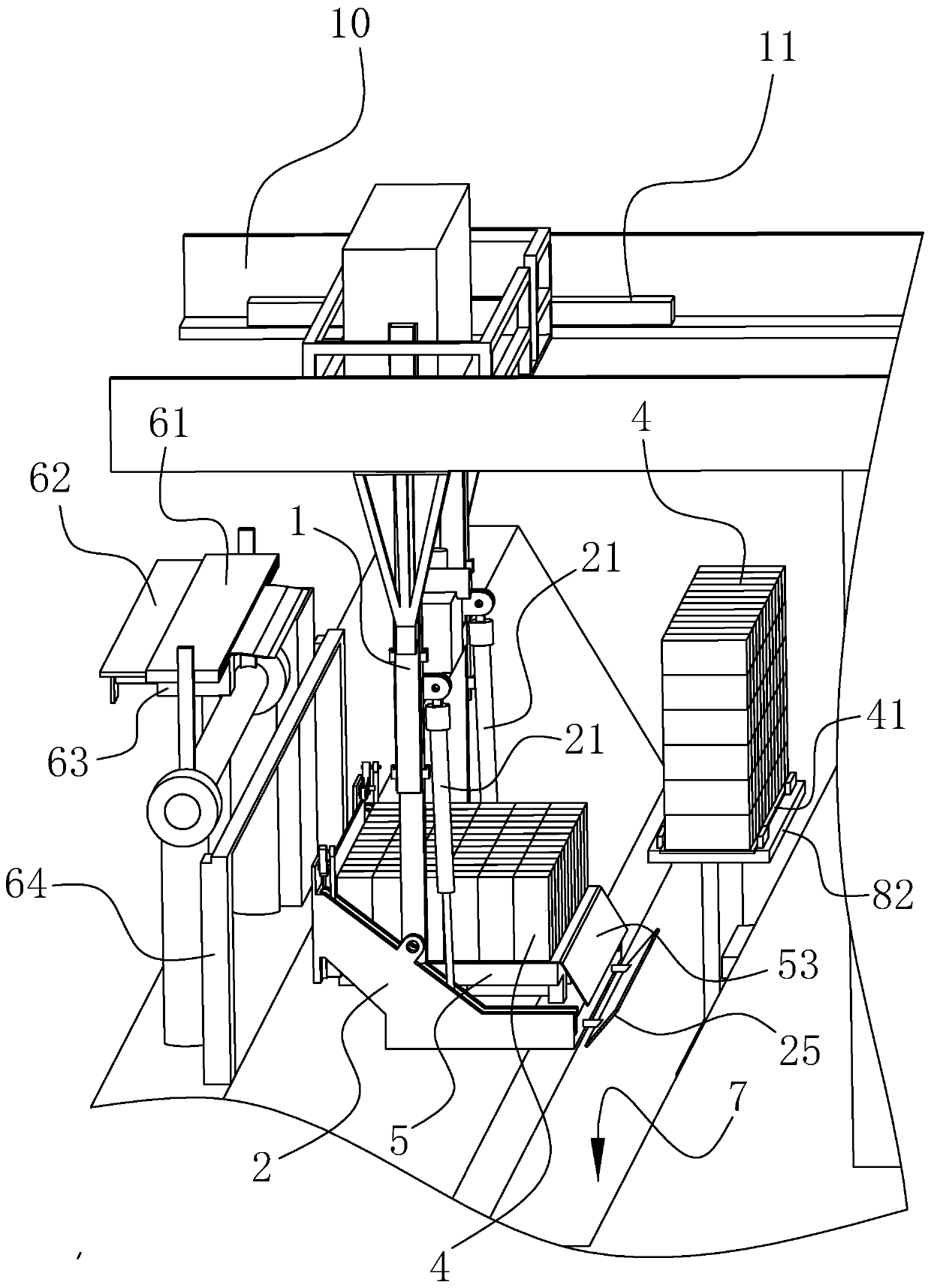

Building wall surface automatic painting robot and method

ActiveCN112031347ARealize automatic paintingAchieve scrapingBuilding repairsStructural engineeringMechanical engineering

The invention relates to the field of building equipment, in particular to a building wall surface automatic painting robot. The robot is characterized by comprising a walking mechanism capable of walking along a preset route, a supporting plate supported on the walking mechanism in a manner of moving up and down, a rolling brush rotatably supported on the supporting plate along the vertical axis,used for painting a wall surface to be painted and capable of moving back and forth in the painting direction relative to the supporting plate and moving back and forth in the direction close to or far away from the wall surface so as to be in contact with the wall surface when the wall surface is painted, two first sliding rails arranged in parallel, supported on the supporting plate and extending in the painting direction, a first sliding block supported on the first sliding rails in a sliding mode in the painting direction, a hollow rod rotatably arranged on the first sliding block along the vertical axis, a coating box and a pump, wherein a U-shaped structure is arranged at one end of the hollow rod, the two ends of the rolling brush are rotatably supported on the two sides of the U-shaped structure respectively, at least the middle part of the U-shaped structure is of a hollow structure communicated with the interior of the hollow rod, a plurality of openings are formed in one side, facing the rolling brush, of at least the middle part of the U-shaped structure, the coating box is used for storing the prepared coating, the other end of the hollow rod is communicated with thecoating box through a hose, and the pump is arranged on the hose and used for conveying the coating in the coating box to the rolling brush. The robot can achieve automatic painting of the wall surface.

Owner:HEBEI TIANXIN CONSTR GRP CO LTD

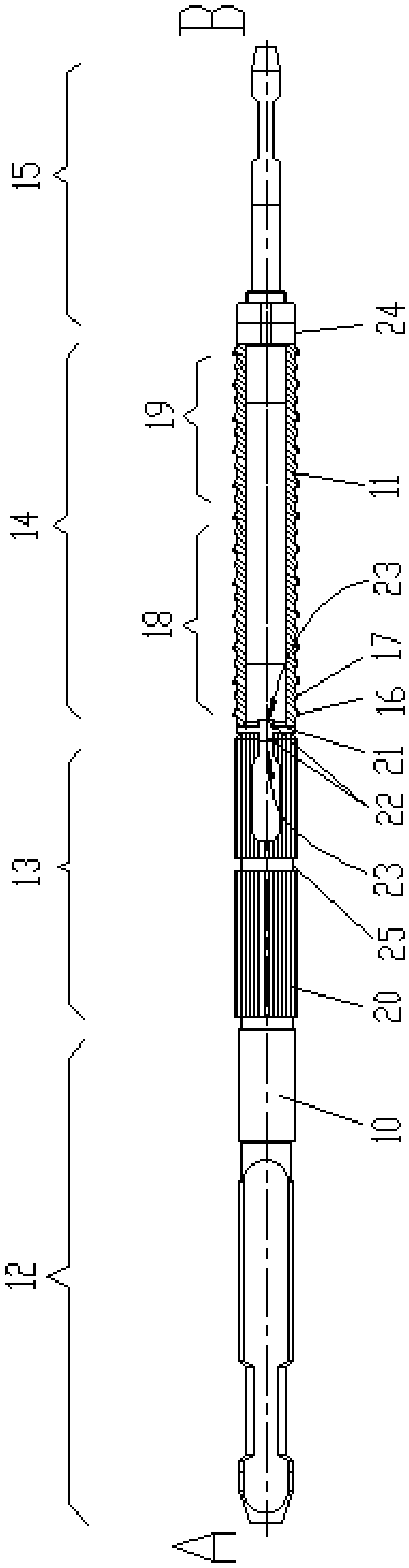

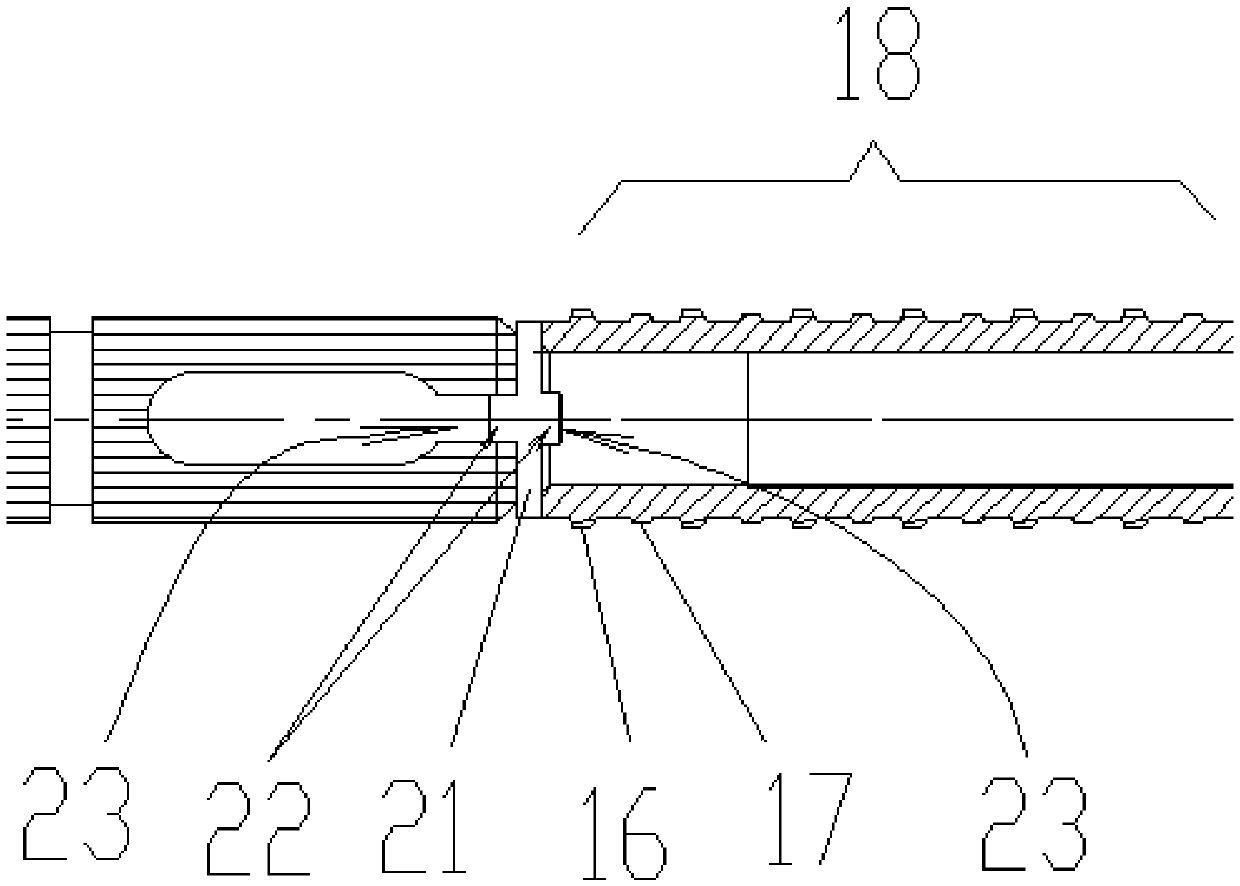

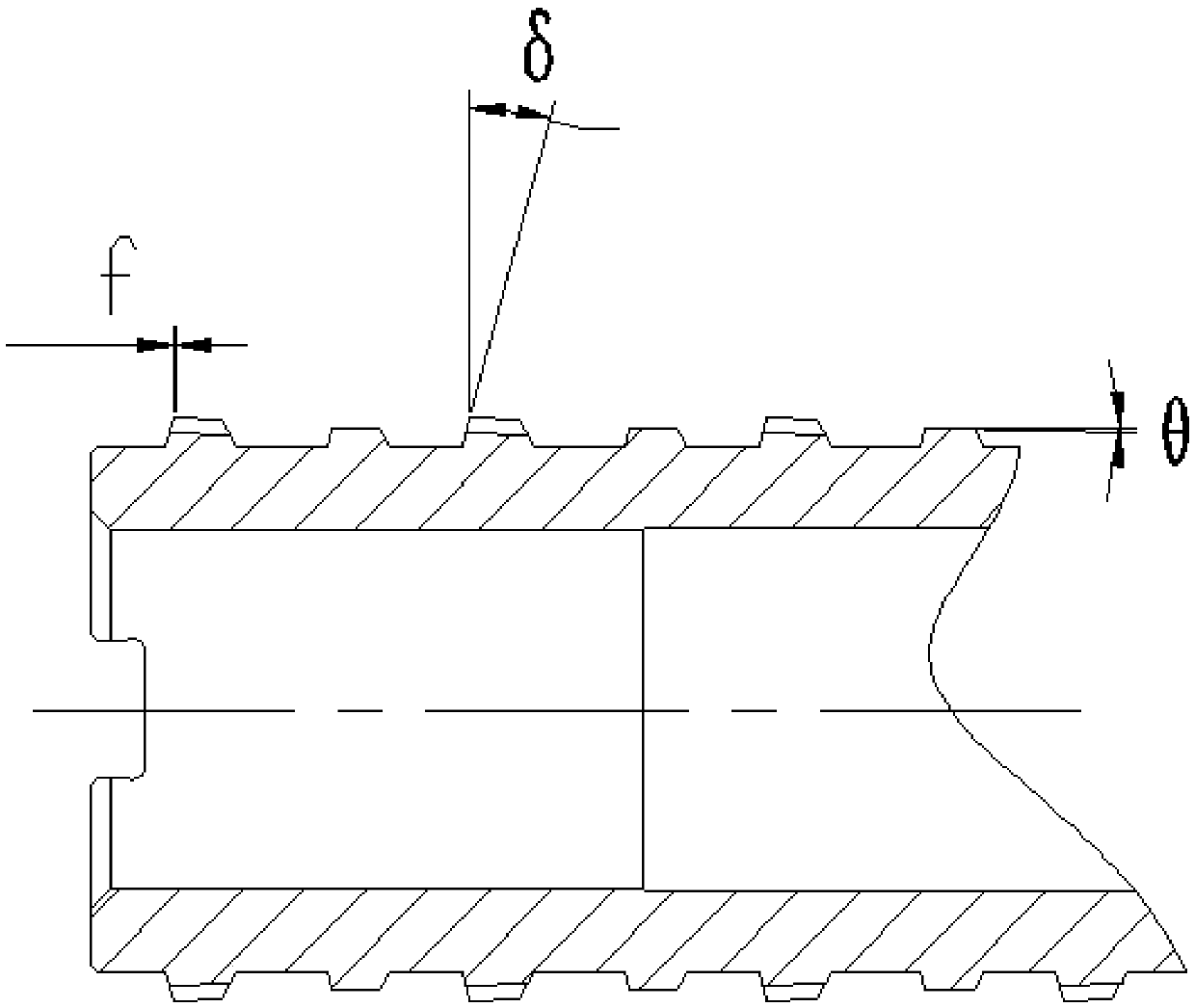

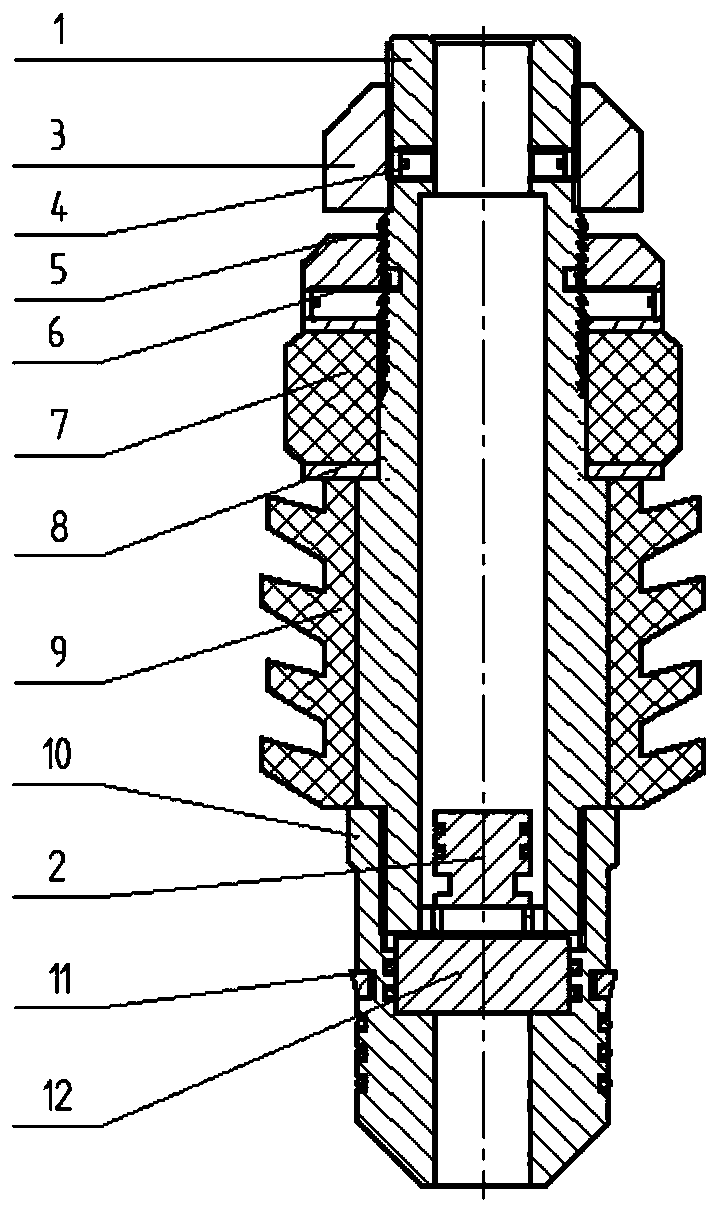

Scraping broaching tool for hard tooth face spline hole

PendingCN108672806AImprove broaching conditionsImprove broaching qualityBroaching toolsEngineeringMetal cutting

The invention relates to the technical field of metal cutting tools and discloses a scraping broaching tool for a hard tooth face spline hole. The scraping broaching tool comprises a broaching tool rod and a sleeve type hard alloy broaching tool. The broaching tool rod is provided with a front end handle section, a guide locating section, a broaching section and a tail end handle section sequentially in the direction from the front end to the rear end of the scraping broaching tool. The outer circle of the broaching section is sleeved with the sleeve type hard alloy broaching tool. The sleevetype hard alloy broaching tool is sleeved with spline teeth for machining the spline two side faces in the spline hole and the spline top face, and circle cutting teeth for machining the inner circlein the spline hole. The multiple spline teeth and the multiple circle cutting teeth are arranged sequentially alternately in the axial direction. The multiple spline teeth and circle cutting teeth, close to the front end of the scraping broaching tool, in thew spline teeth and the circle cutting teeth are cutting teeth with rise per tooth, and the multiple spline teeth and circle cutting teeth, close to the rear end of the scraping broaching tool, in the spline teeth and the circle cutting teeth are correction tooth without rise per tooth. Trough the scraping broaching tool, high-precision broaching of the hard tooth face spline hole is improved.

Owner:JIANGYIN SAITE PRECISION TOOL

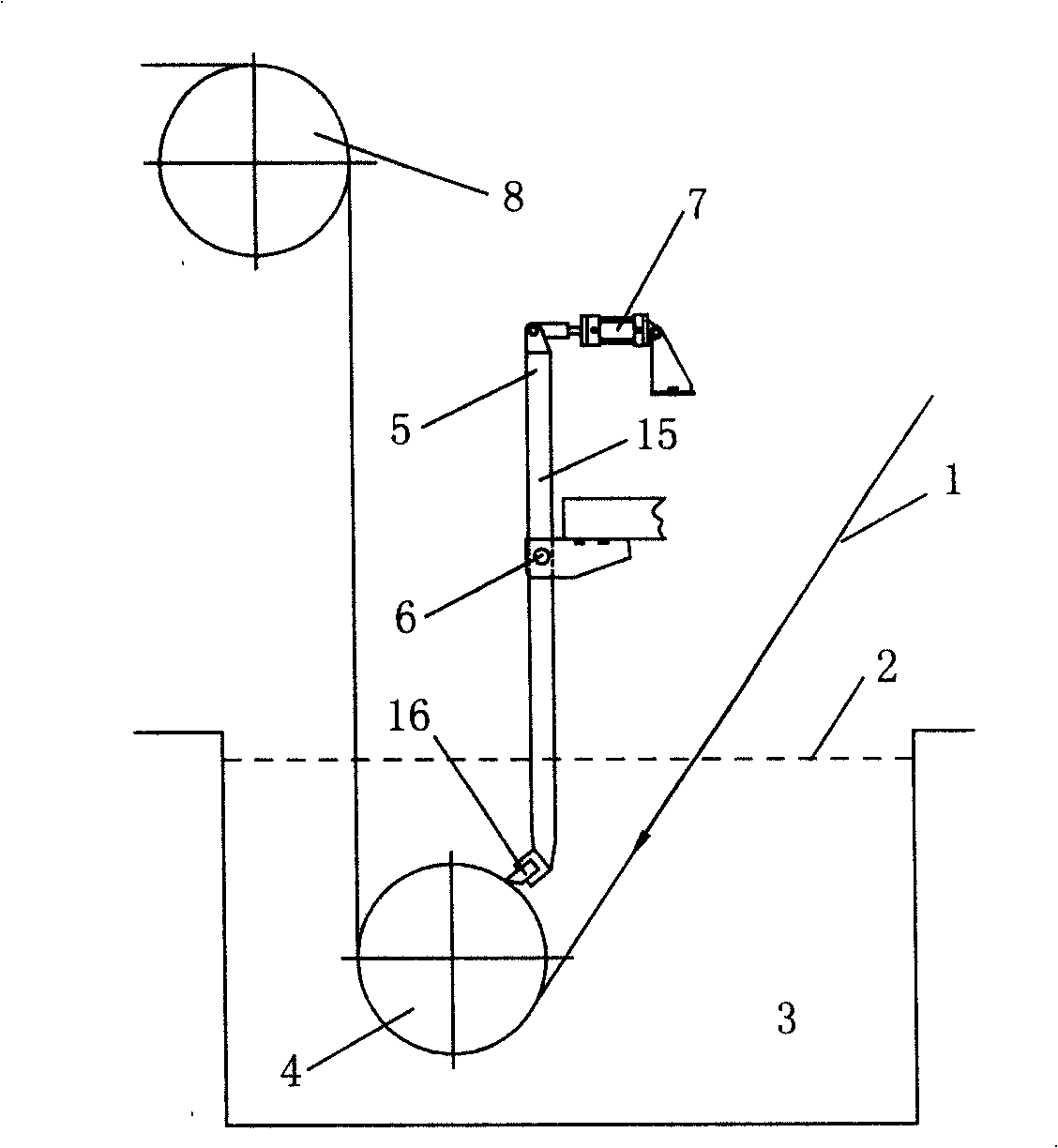

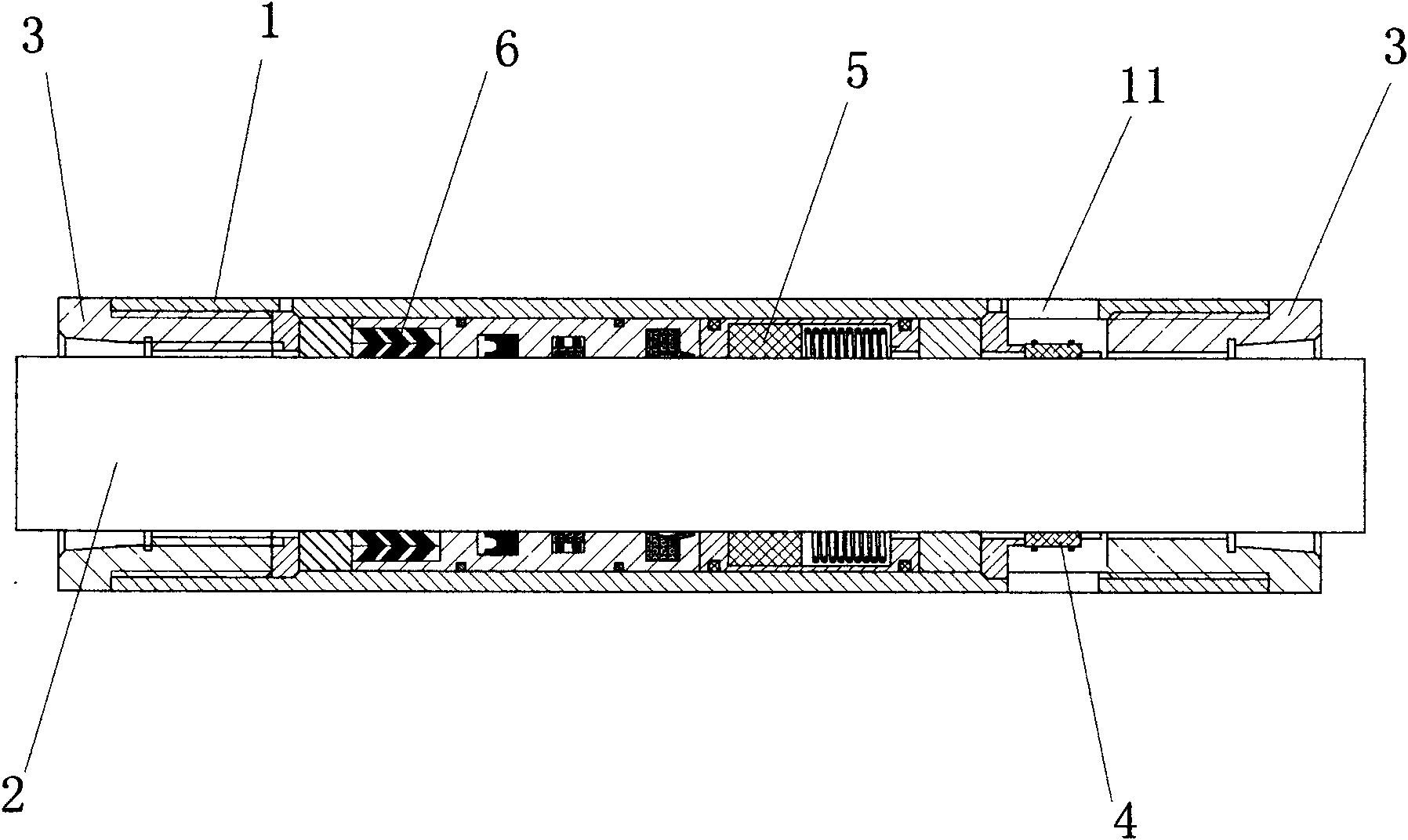

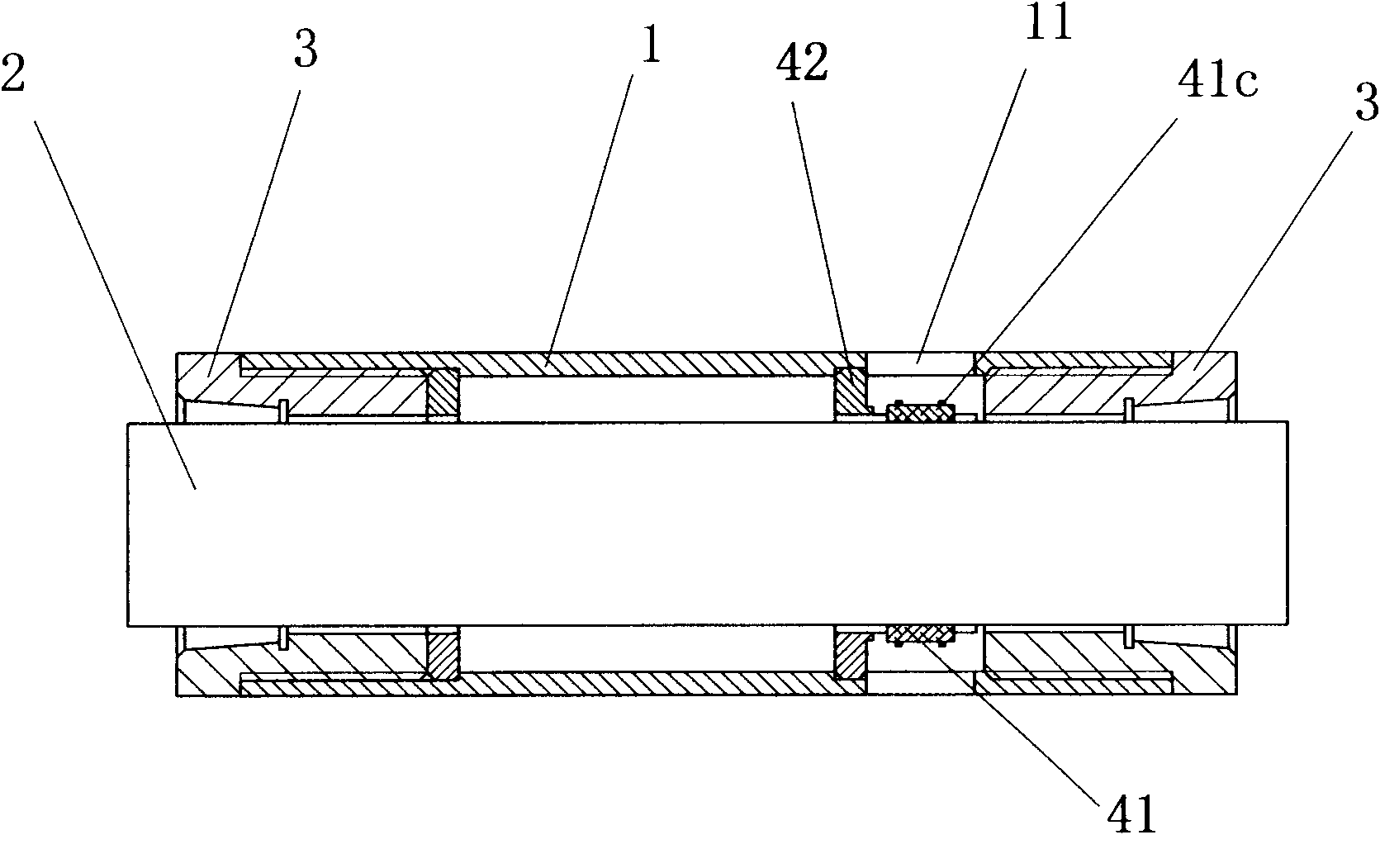

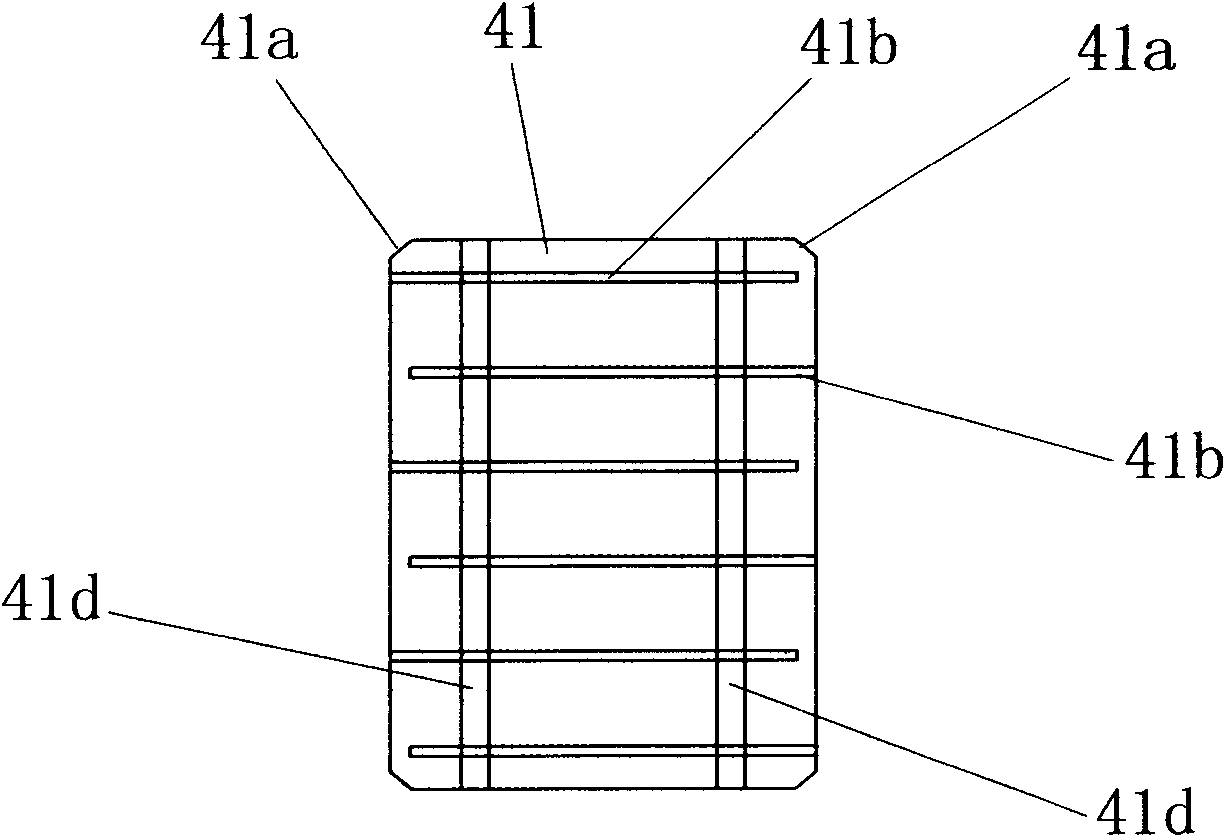

Protector of underground oil extraction machine

InactiveCN101949278AEnsure work quality and efficiencyAchieve scrapingFluid removalPetroleumEngineering

The invention relates to a protector of an underground oil extraction machine, which comprises an outer pipe, a connecting rod and adapters arranged at both ends of the outer pipe, wherein a decontamination unit, a filter unit and a sealing unit are arranged between the outer pipe and the connecting rod; the filter unit comprises a framework, a filter layer of a flexible structure is arranged in the framework, the inner diameter of the filter layer is slightly smaller than the pore diameter of both ends of the framework and is in interference fit with a connecting shaft, and one end of the filter layer is also provided with a flexibility compensation mechanism. By arranging the decontamination unit, the filter unit and the sealing unit between the outer pipe and the connecting rod, the invention realizes the scraping of dust on the connecting shaft and ensures the favorable fit between the shaft and holes after abrasion; by using the filter layer of a flexible structure, the invention effectively filter off silts or other metal particles in crude oil; and by using the dynamic / static seal structure design, the invention further avoids the inflow of the silts and other harmful substances in the crude oil and ensures the working quality and efficiency of the equipment.

Owner:佛山市顺德区精艺动力科技有限公司

Icebreaking roller

The invention belongs to the technical field of deicing equipment, and in particular relates to an icebreaking roller which comprises a connecting rack, a roller rack, a rolling device and a vibrating device which are arranged on an icebreaking automobile, wherein the rolling device comprises an icebreaking roller body, a rotating sleeve and a connecting short shaft; and the vibrating device comprises a main vibrating shaft. The icebreaking roller is characterized in that the main vibrating shaft is rotationally connected with the icebreaking roller body; the main vibrating shaft is connected with the vibrating motor through a small synchronous pulley and a large synchronous pulley; the icebreaking roller body is connected with a driving motor through chain transmission; and the roller rack is connected with the connecting rack on the icebreaking automobile through a lifting device. The icebreaking roller provided by the invention has a floating vibration function, the icebreaking roller lightly touches the ground all the time, the ice on the road is transversely scraped and grinded by an impacting force generated by the main vibrating shaft, and power sources of vibration and rolling are separated, so that the icebreaking roller is high in overload bearing capability, good in icebreaking effect and high in breaking efficiency.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

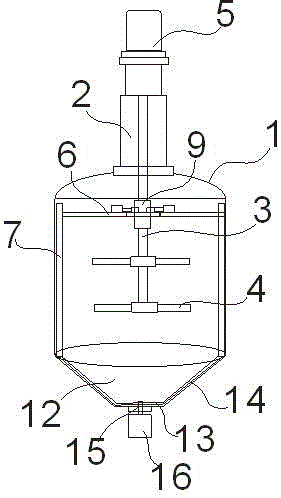

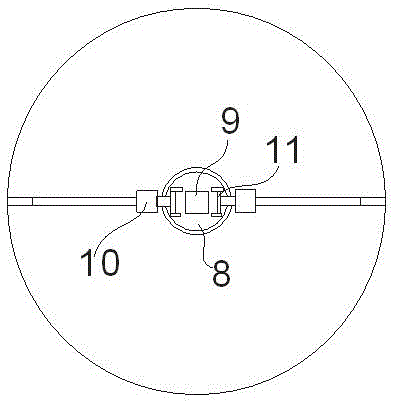

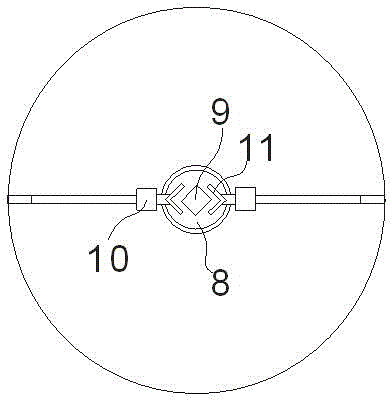

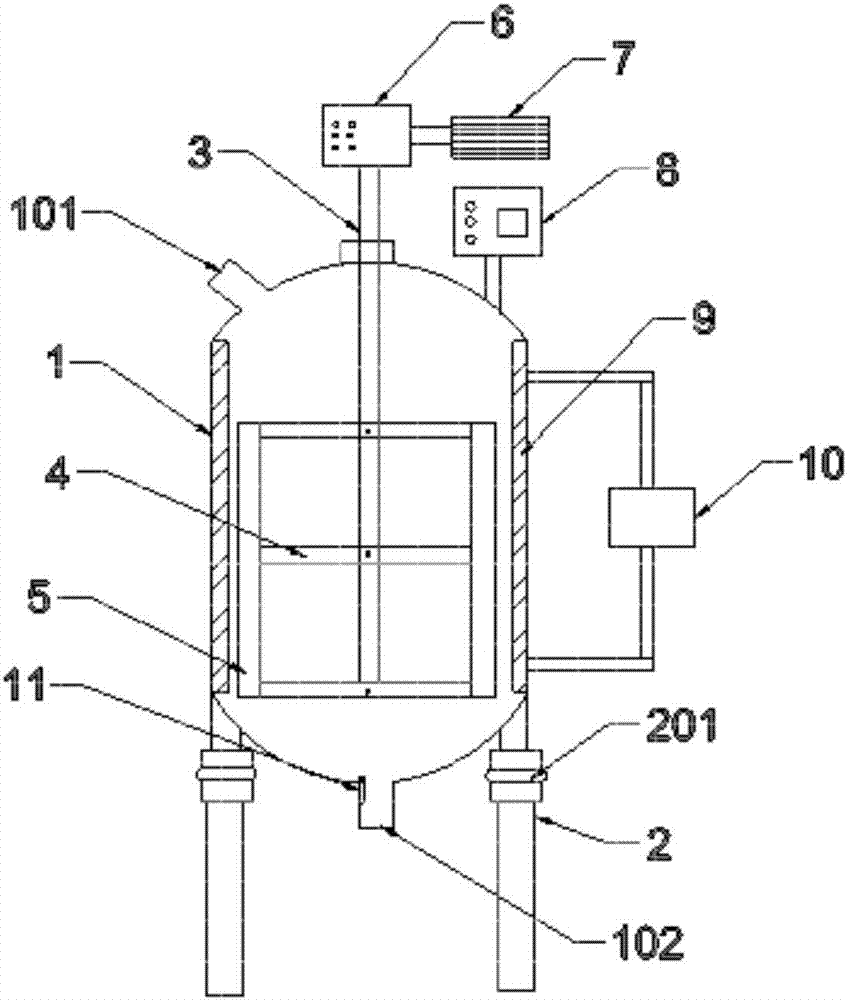

Reaction kettle for production of dyestuff

InactiveCN106512906AAchieve scrapingChemical/physical/physico-chemical stationary reactorsLocking mechanismBiochemical engineering

The invention relates to the field of chemical production equipment, in particular to a reaction kettle for production of dyestuff. The reaction kettle comprises a reaction tank body, a stirrer, an inner side wall scraping device and a tank bottom scraping device, wherein the reaction tank body is provided with a conical tank bottom; the stirrer is arranged in the middle of the reaction tank; the inner side wall scraping device is used for scraping the inner side wall of the reaction tank body; and the tank bottom scraping device is used for scraping a tank bottom. By a locking mechanism, when the side wall of the reaction tank requires to be scraped, a stirring bar is locked with a scraper blade and drives the scraper blade, and therefore, scraping of the side wall of the reaction tank is realized.

Owner:天津兆博化工有限公司

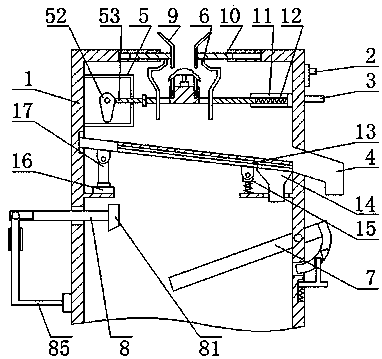

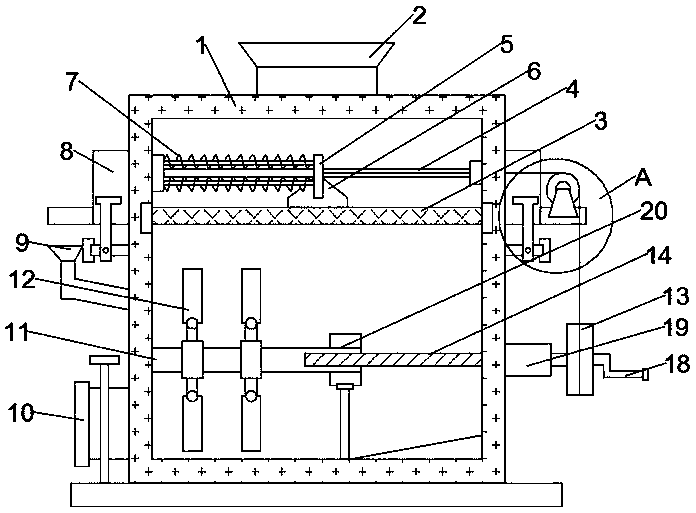

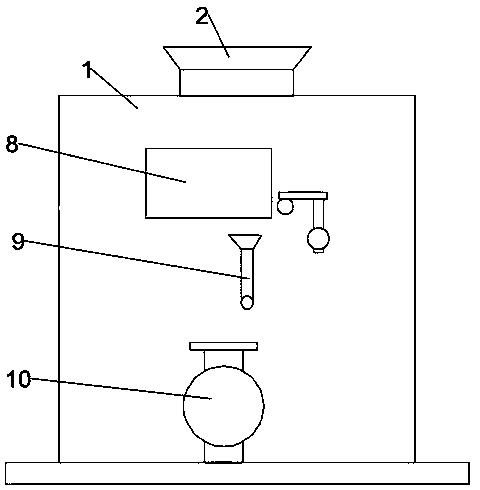

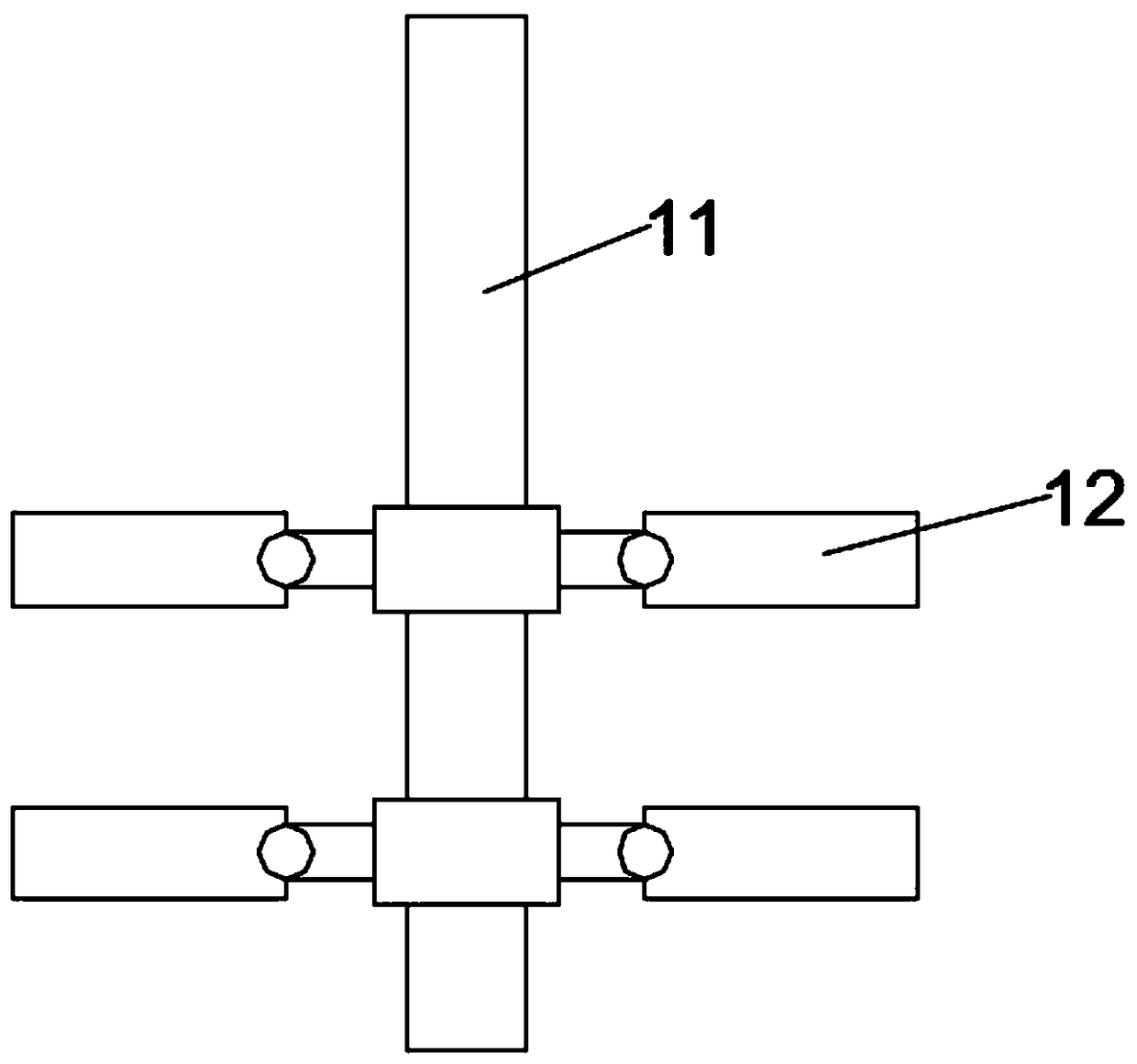

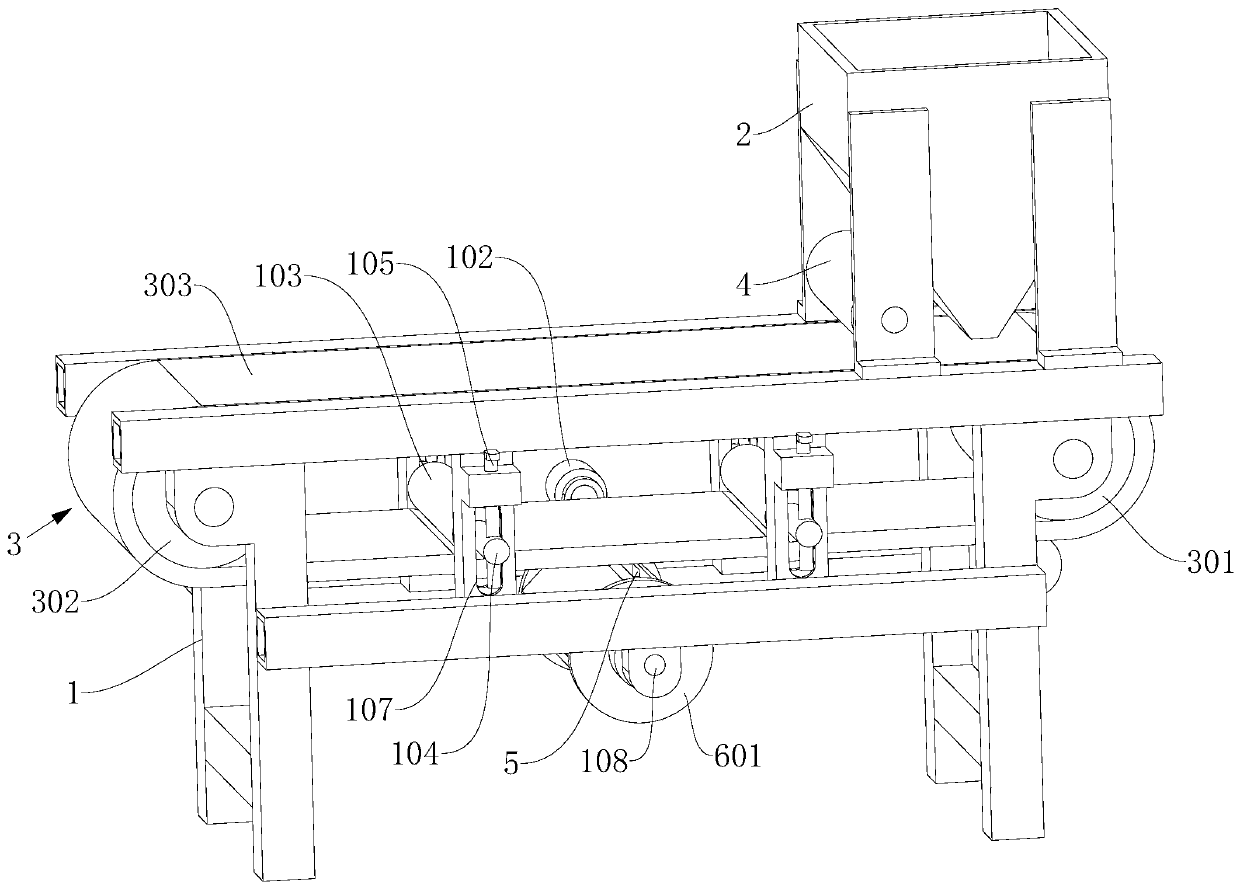

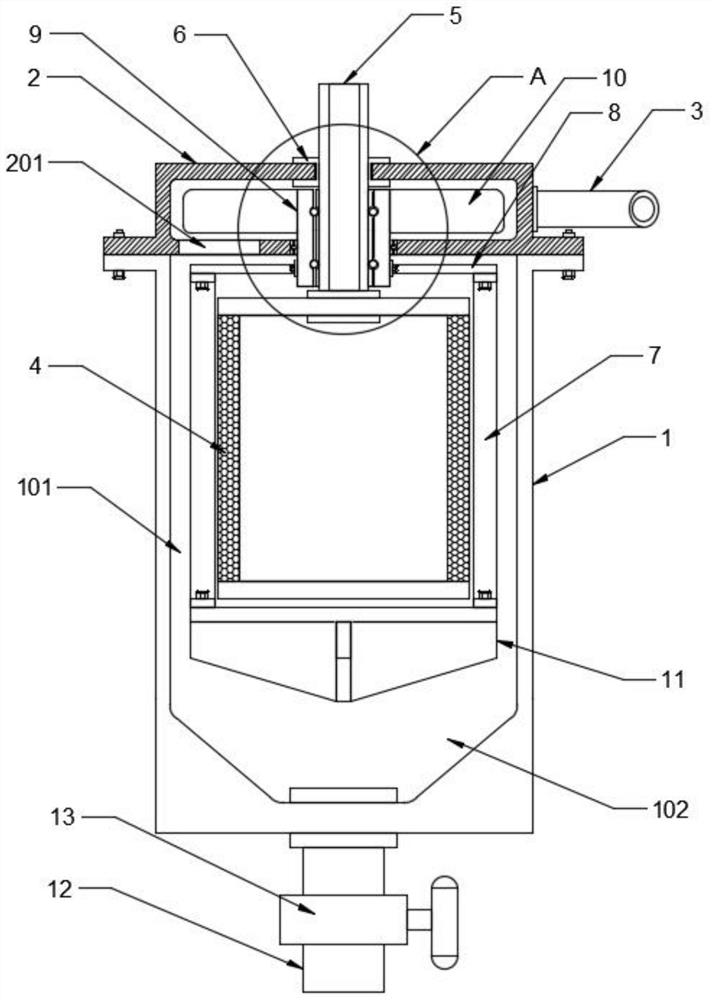

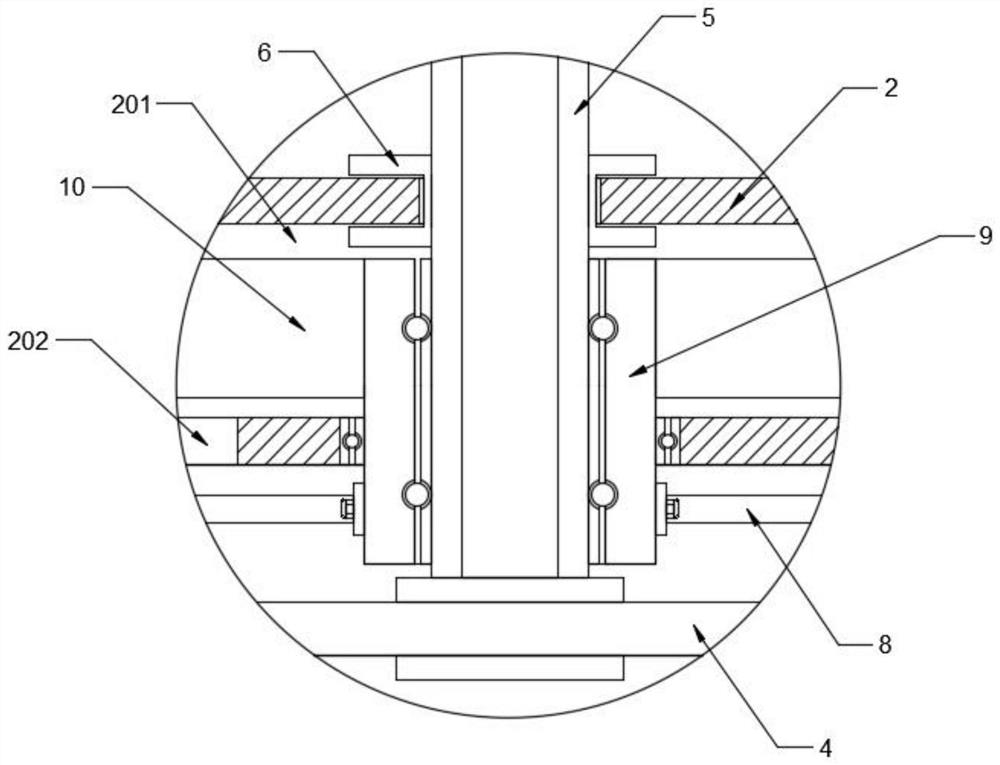

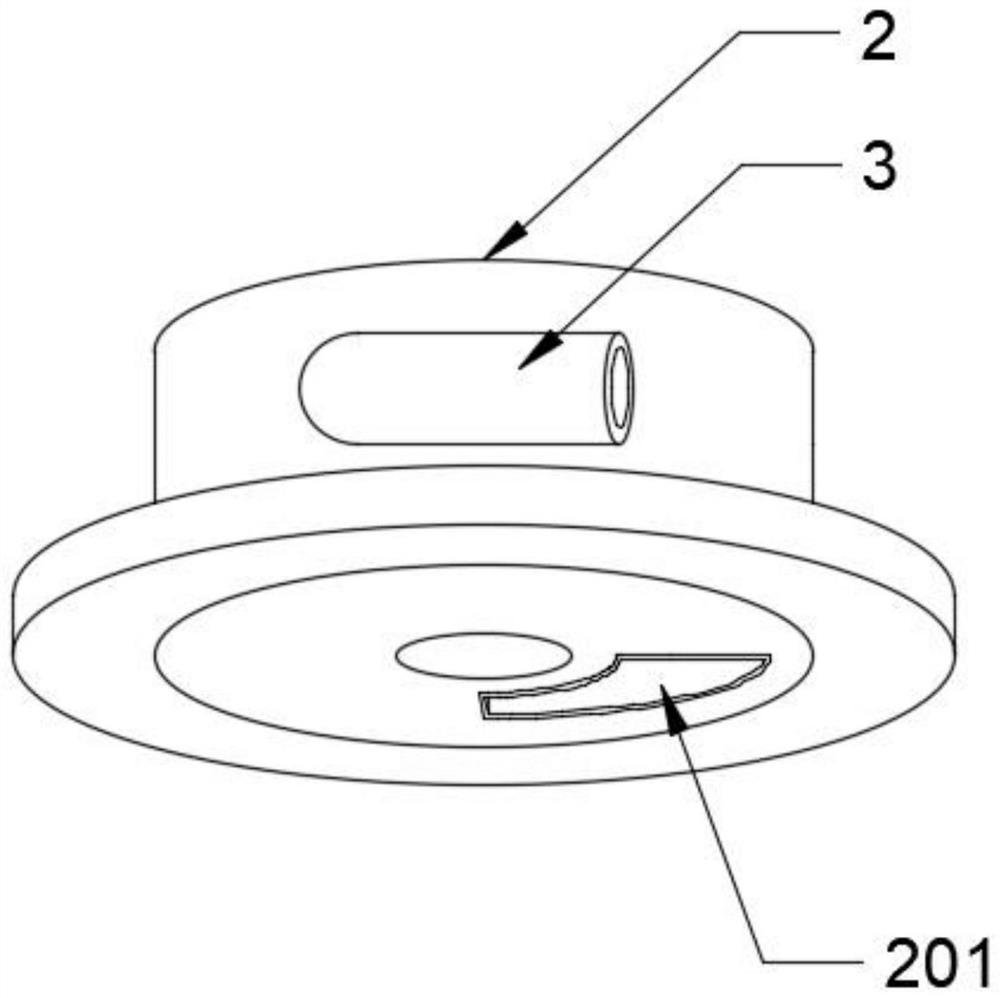

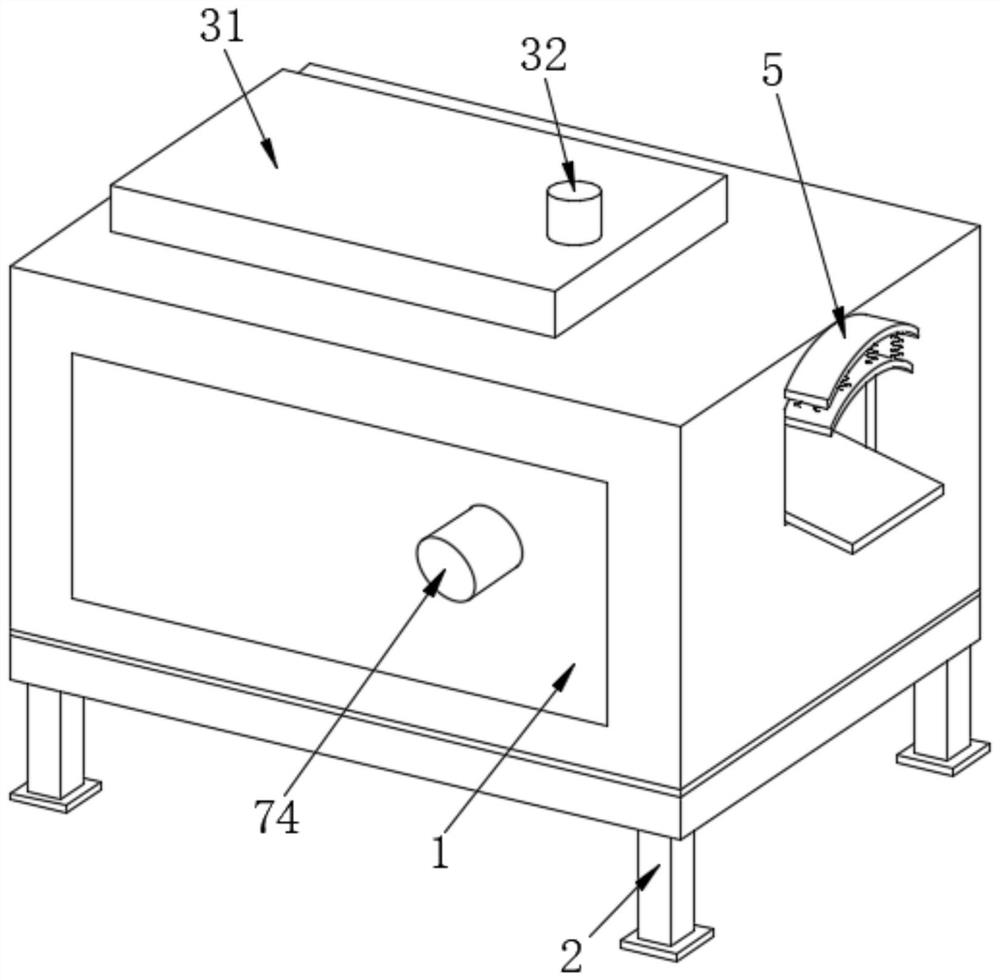

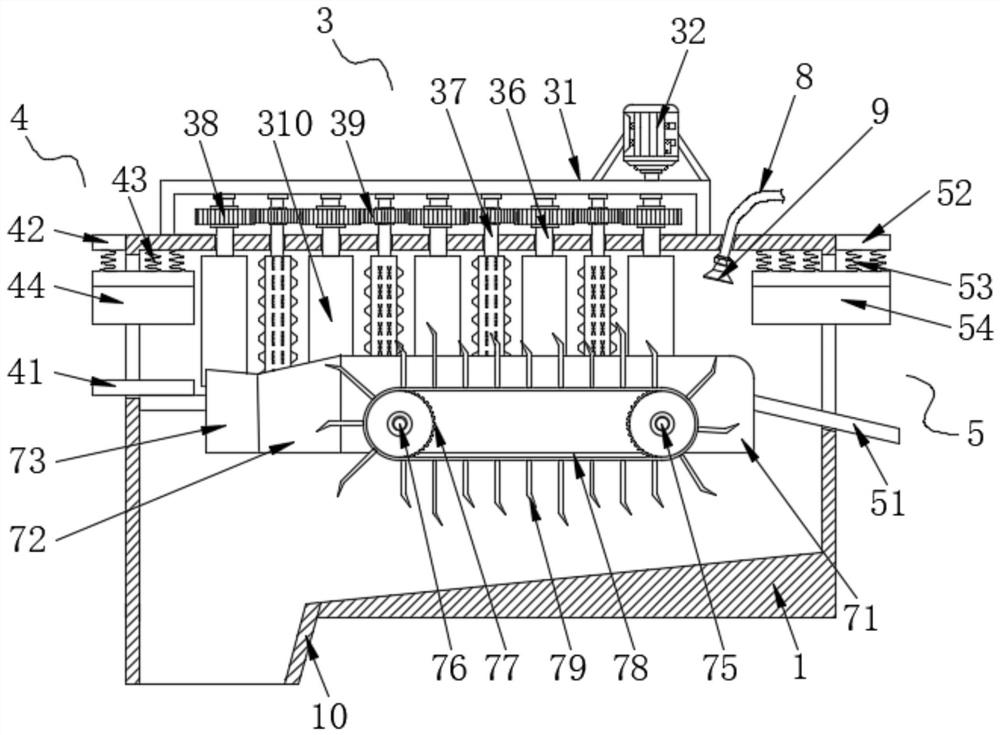

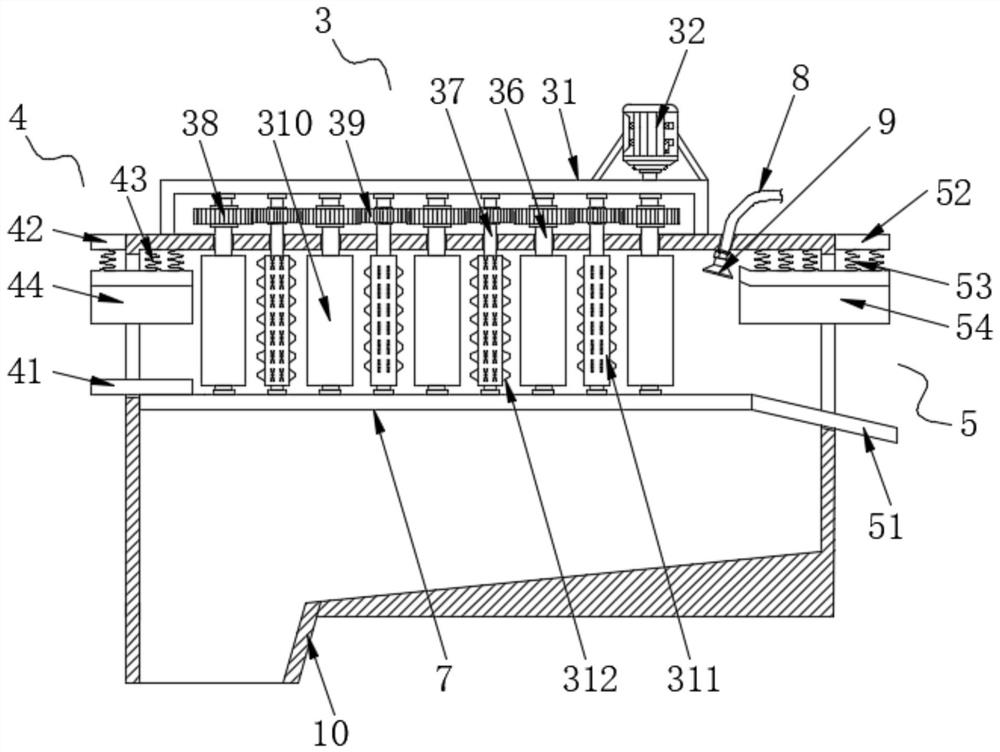

Anti-clogging sewage filtering treatment device

PendingCN109319980AGuaranteed buffer resetAchieve scrapingTreatment involving filtrationMultistage water/sewage treatmentSlagSewage

The invention discloses an anti-clogging sewage filtering treatment device, and belongs to the technical field of environmental protection equipment, solving the problem that the sewage treatment efficiency is affected due to clogging of filter screens caused by the fact that impurities are liable to leave on the surfaces of the filter screens during sewage treatment by existing devices. The anti-clogging sewage filtering treatment device is characterized by comprising a casing, a filter screen, a cleaning plate and a winding wheel; an inlet is arranged in the middle of the upper surface of the casing, and is communicated with the inner cavity of the casing; a discharge outlet is arranged at the bottom of the left side wall of the filter screen; a bearing block is arranged in the middle ofthe right side wall of the filter screen; the winding wheel is arranged on the right side of the bearing block; slag discharge ports are arranged at the tops of two side walls of the casing, and thelower edges of the slag discharge ports are on the same horizontal line with the filter screen. The anti-clogging sewage filtering treatment device has the advantages that sewage treatment can be carried out quickly; the impurities in sewage can be filtered out, and clogging in the sewage treatment process can be avoided.

Owner:张静

Food flattening machine

ActiveCN110844532AImprove sugar scraping effectAchieve scrapingCleaningLoading/unloadingEngineeringSugar

The invention provides a food flattening machine, and belongs to the technical field of food processing equipment. The food flattening machine comprises a supporting frame, a hopper, an annular conveying member, an extrusion roller, a scraper, a sleeve and a driving mechanism, wherein the hopper is used for containing puffing objects, a discharging port is formed in the lower portion of the hopper, an annular conveying member is located below the hopper and is used for conveying the puffing objects to the next process, the extrusion roller is rotationally arranged on the supporting frame and is positioned above the annular conveying member, the scraper is positioned below the annular conveying member and is in contact with the sugar layer on the annular conveying member, the sleeve is rotationally arranged on the supporting frame, the axis of the sleeve is perpendicular to the conveying direction of the annular conveying member, the sleeve is provided with a first sliding groove whichis in sliding fit with the scraper, and the driving mechanism is used for driving the scraper to reciprocate in the radial direction of the sleeve. According to the food flattening machine, the firstsliding groove which is in sliding fit with the scraper is formed in the sleeve, so that sugar on the scraper is cleared, and therefore the sugar scraping effect of the scraper is improved.

Owner:沧州五谷食尚食品科技有限公司

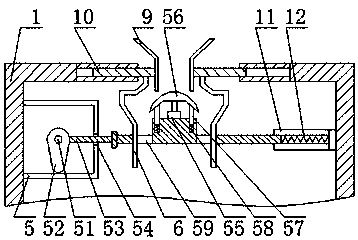

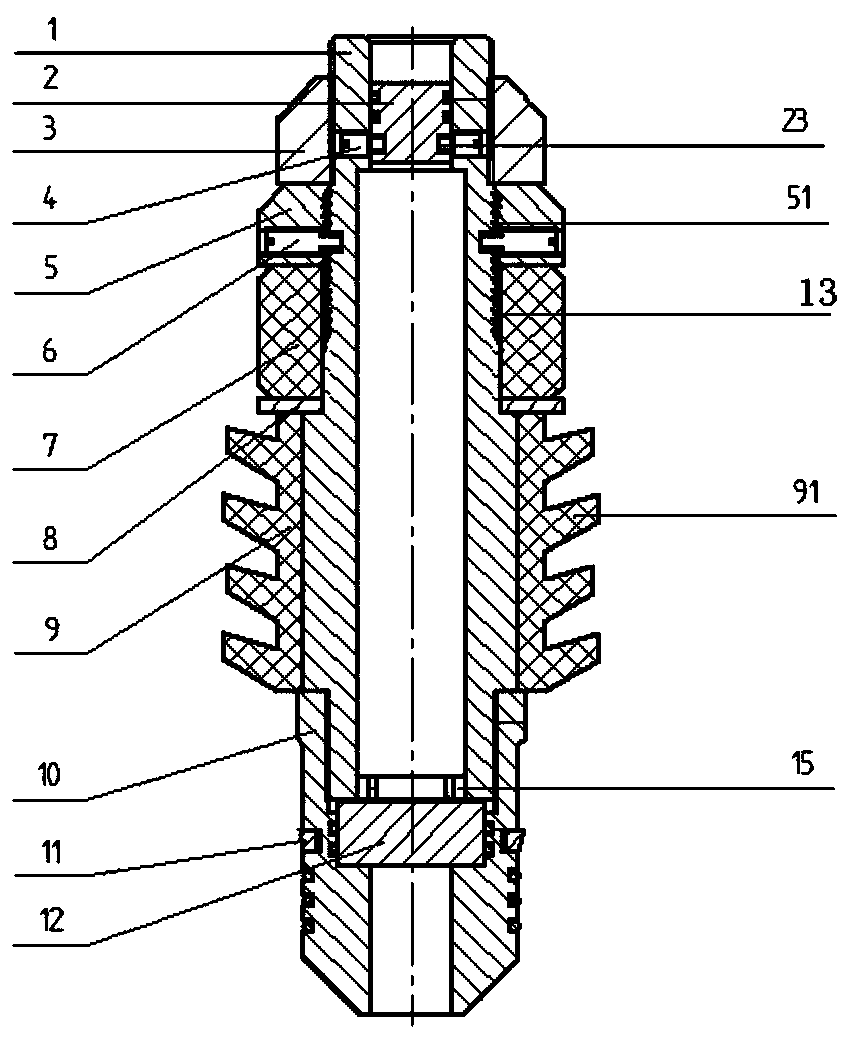

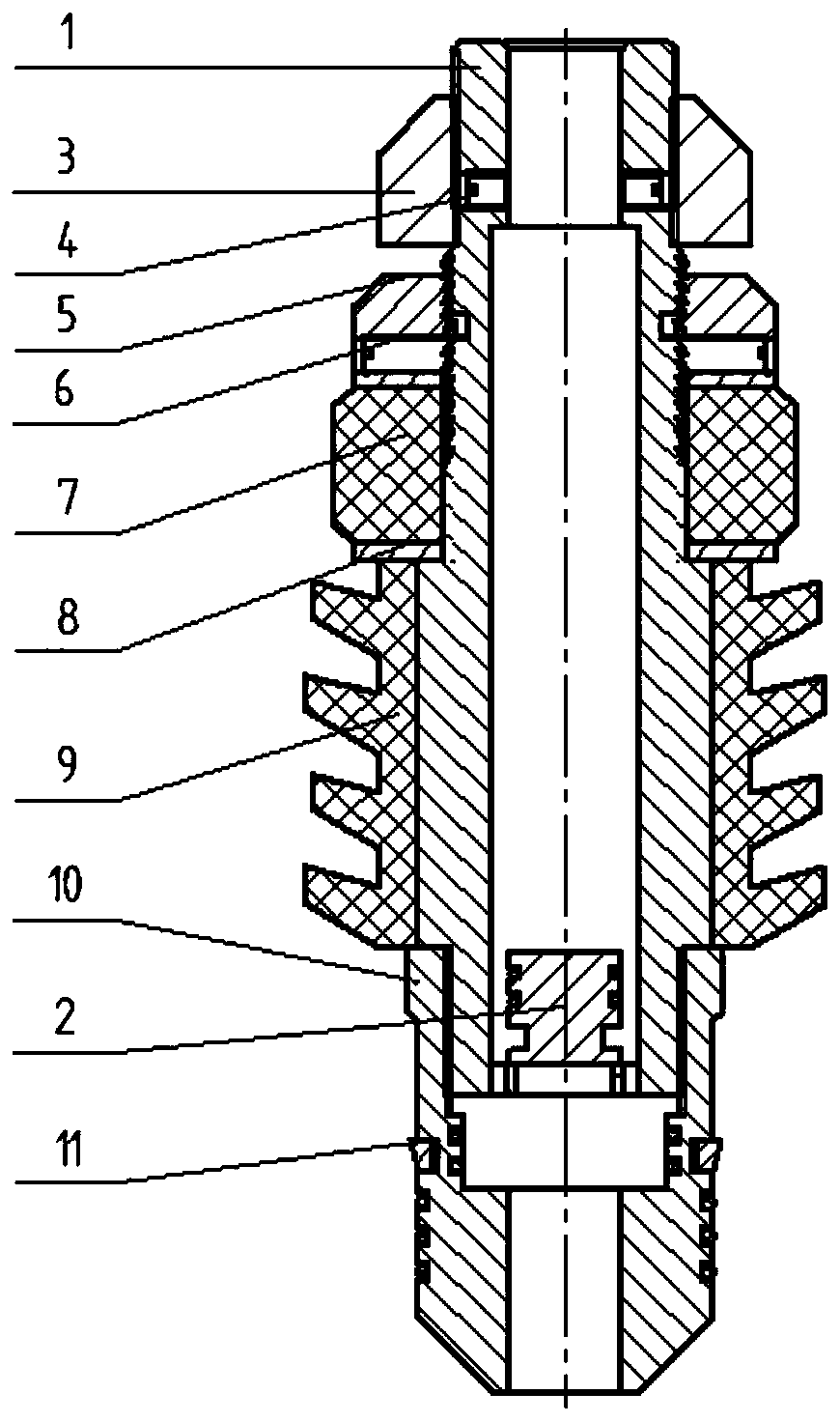

Controllable dissolvable well cementation rubber plug

The invention provides a controllable dissolvable well cementation rubber plug. The controllable dissolvable well cementation rubber plug comprises a core shaft, a sealing core body, a locking cap, aliquid cylinder, a rubber barrel, a rubber cup, a sealing body and a dissolvable core body, wherein the core shaft is of a hollow barrel-shaped structure; the sealing core body is arranged in one endof the core shaft; the sealing body sleeves the outer side of the other end of the core shaft; a cavity is formed between the inner part of the sealing body and the end part of the core shaft; the dissolvable core body is arranged in the cavity; the rubber cup, the rubber barrel, the liquid cylinder and the locking cap sleeve in sequence from the outer side of the core shaft at one end of the sealing body to the outer side of the other end of the core shaft. According to the controllable dissolvable well cementation rubber plug provided by the invention, well cementation can be finished; aftera sleeve is subjected to a pressure test, the dissolvable core body is dissolved and a channel between a shaft and a stratum is established, so that perforation operation is avoided.

Owner:PETROCHINA CO LTD

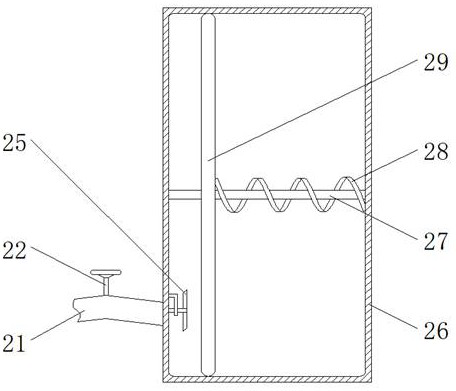

Self-cleaning geothermal heating filtering device

InactiveCN112169409AExtended service lifeAvoid gatheringStationary filtering element filtersGeothermal heatingWater flow

The invention discloses a self-cleaning geothermal heating filtering device. The self-cleaning geothermal heating filtering device comprises a device shell, a filtering mechanism and a cleaning mechanism, wherein the filtering mechanism and the cleaning mechanism are installed in the device shell. The device is provided with a cover body with a columnar cavity, a water inlet pipe tangentially communicated with the columnar cavity of the cover body, a communicating hole, a water outlet pipe communicated with a filter cartridge and a precipitation cavity, so that water flow forms rotational flowoutside the filter cartridge to scour the surface of the filter cartridge while filtering, impurities are prevented from gathering on the surface of the filter cartridge; the service life of the filter cartridge is prolonged while the filtering effect is ensured; by arranging a scraper, an impeller plate, a rotary drum and a connecting rod, kinetic energy of water is used for driving the impellerplate to rotate, the impeller plate drives the scraper to rotate, scaling on the surface of the filter cartridge is scraped off through the scraper, the filtering effect is improved, and the self-cleaning effect is improved; meanwhile, the impeller plate mounted at the lower end of the scraper is utilized to increase the flow velocity of rotational flow and accelerate precipitation aggregation and precipitation.

Owner:湖南达道新能源开发有限公司

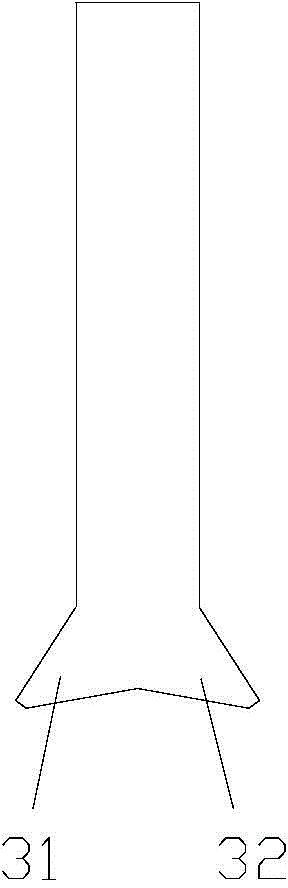

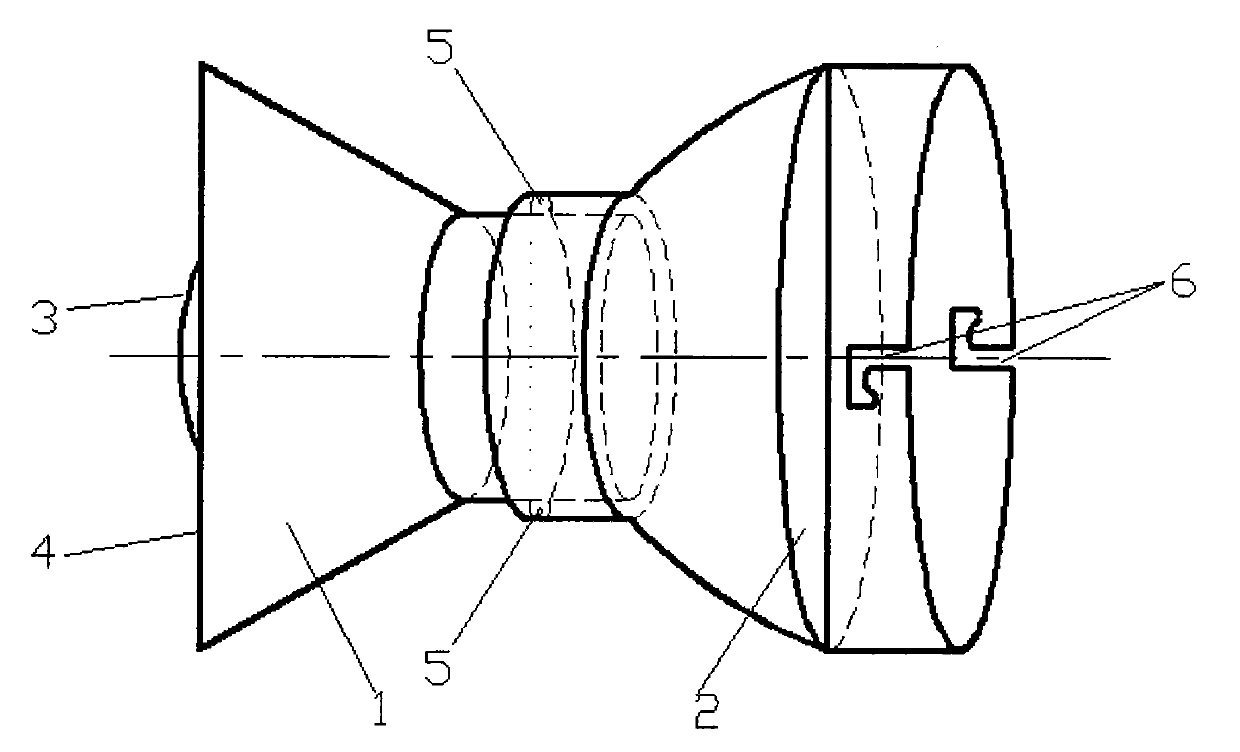

Novel pouring gun head for silicone joint material of concrete expansion joint

InactiveCN104195932ALarge amount of glueNot easy to mixRoads maintainenceRailway track constructionExpansion jointUltimate tensile strength

The invention relates to a novel pouring gun head for a silicone joint material of a concrete expansion joint. The novel pouring gun head for the silicone joint material of the concrete expansion joint comprises a pouring head and a base, wherein the pouring head is connected with the base, and the base is connected with a glue gun. The novel pouring gun head has the characteristics of being uniform in pouring and being difficultly mingled with bubbles; pouring and surface concave scrapping of a joint material can be simultaneously realized, and the pouring quality and the pouring efficiency are remarkably improved. The pouring head is connected with the base by adopting a bayonet and the base is connected with the glue gun by adopting a bayonet, thus the novel pouring gun head is easy to disassemble, brings convenience in immediately cleaning a glue material inside, and can be repeatedly used. The problems of poor construction quality, low pouring efficiency, large labor intensity and the like of an existing joint material are solved, and the novel pouring gun head is suitable for constructing joint materials in the fields of high-speed railways, expressways, airfield runways and the like.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

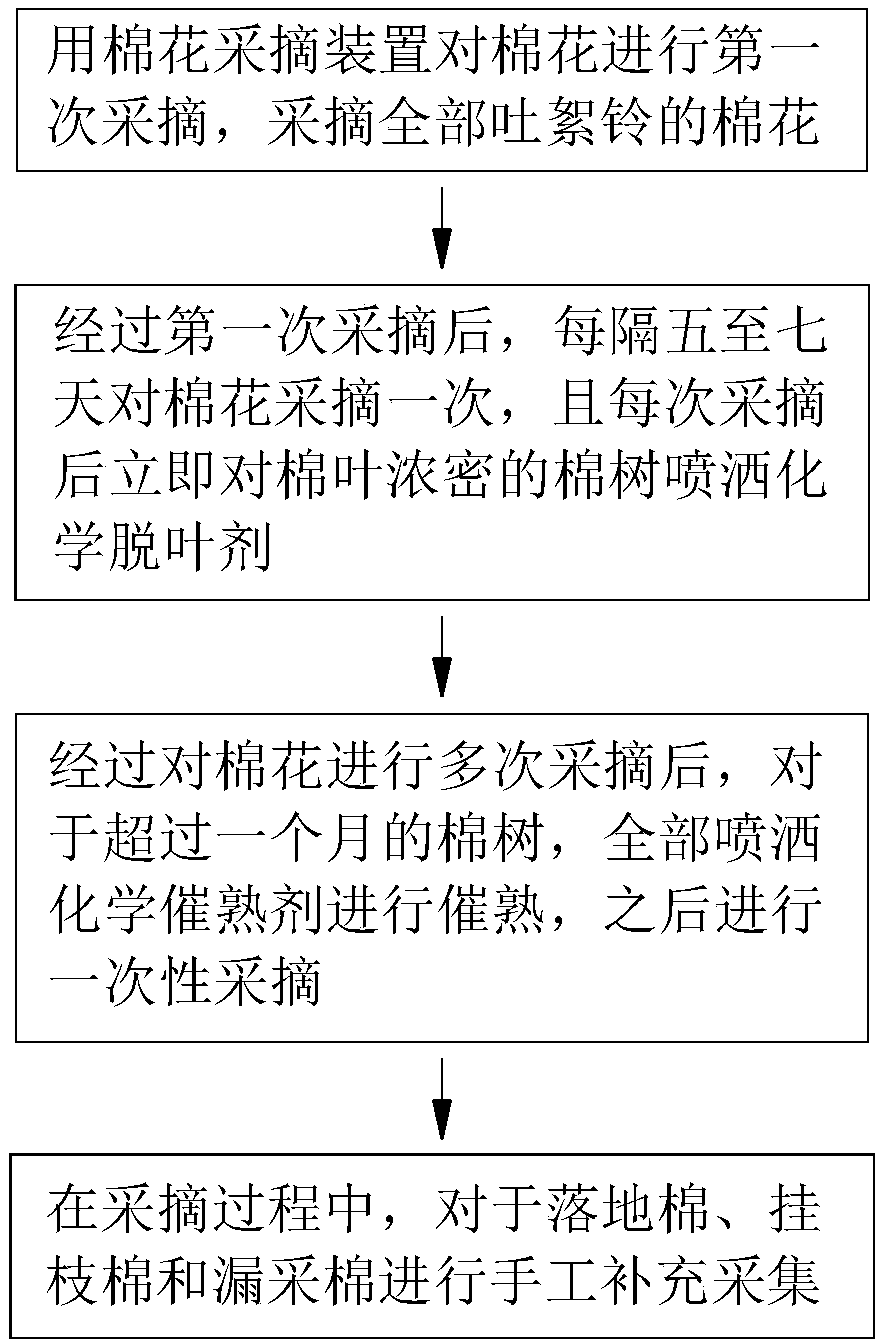

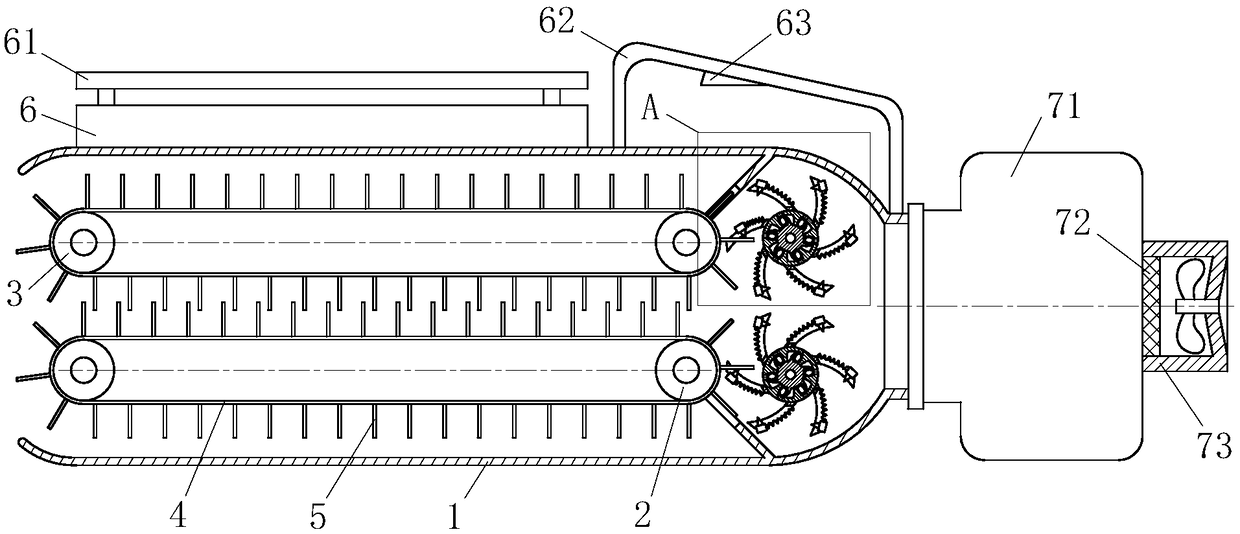

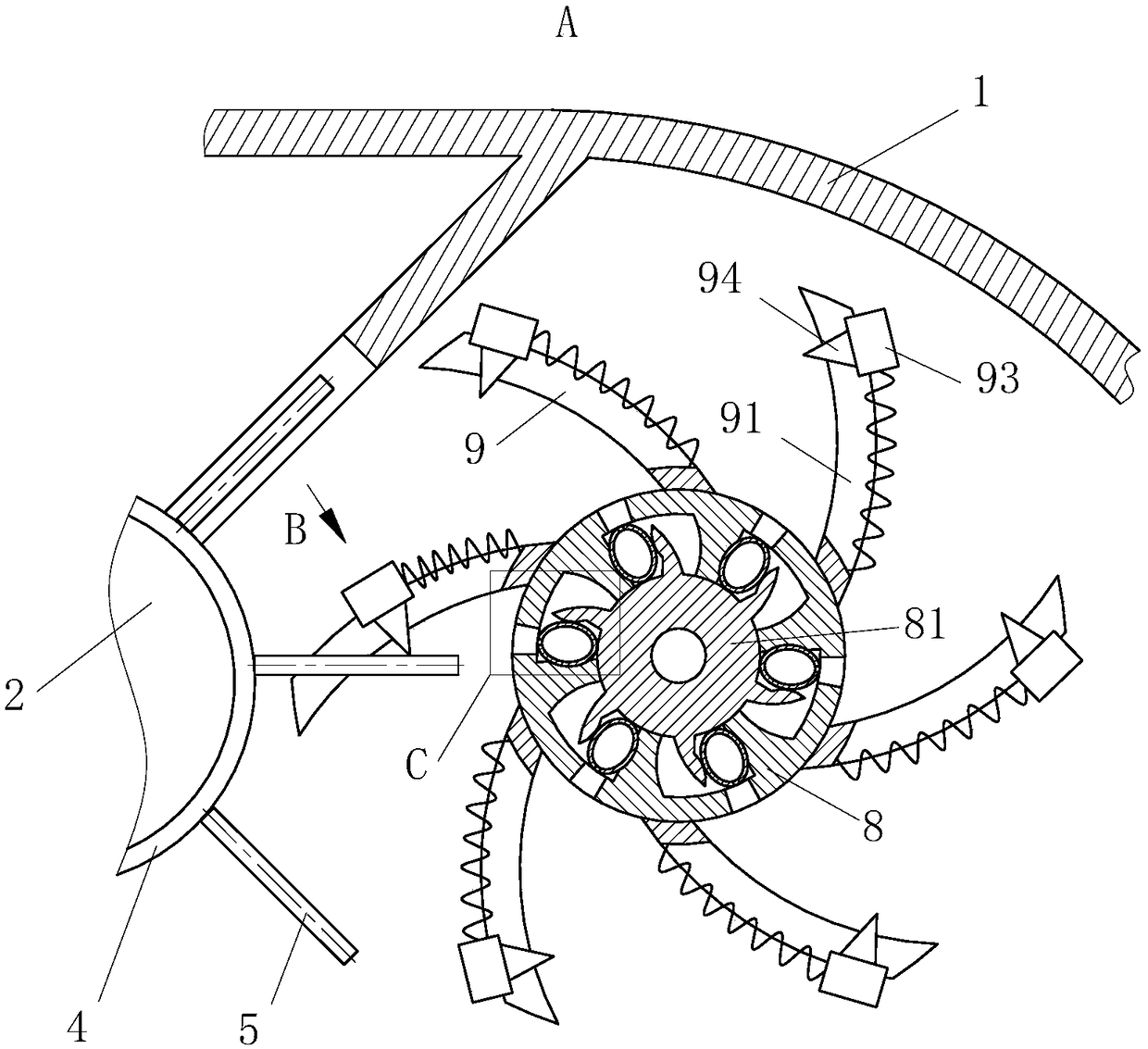

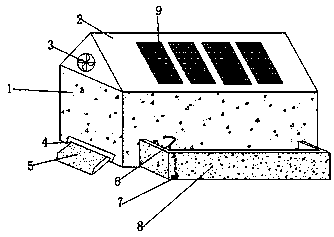

Method for picking cotton in mountainous area

The invention belongs to the technical field of agricultural production, in particular to a method for picking cotton in a mountainous area. A cotton picking device used in the method comprises a machine shell, a driving cylinder, a driven cylinder, a steel belt, a steel needle, a battery pack, a solar panel, a handle, a control switch, a cotton collecting box, a filter sheet, a fan, a cotton picking roller and cotton picking blades. A set of the cotton picking blades is fixedly connected to the cylindrical surface of the cotton picking roller; a set of first rectangular grooves is formed in the cotton picking blades, and the cotton picking blades are used for removing cotton on the steel needle. The cotton picking roller is arranged on the right side of the driving cylinder, a set of thecotton picking blades are fixedly connected with the cylinder surface of the cotton picking roller, and the cotton picking roller is rotated, so that the cotton picking blades are driven to remove thecotton on the steel needle, the situations that the steel needle brings the cotton out of the machine shell and causes scattering of the cotton and unnecessary trouble, and the picking efficiency isinfluenced are prevented, and the cotton without cotton leaves is sucked by the fan on the right to be brought into the cotton collecting box.

Owner:浏阳市月亮岛农业科技开发有限公司

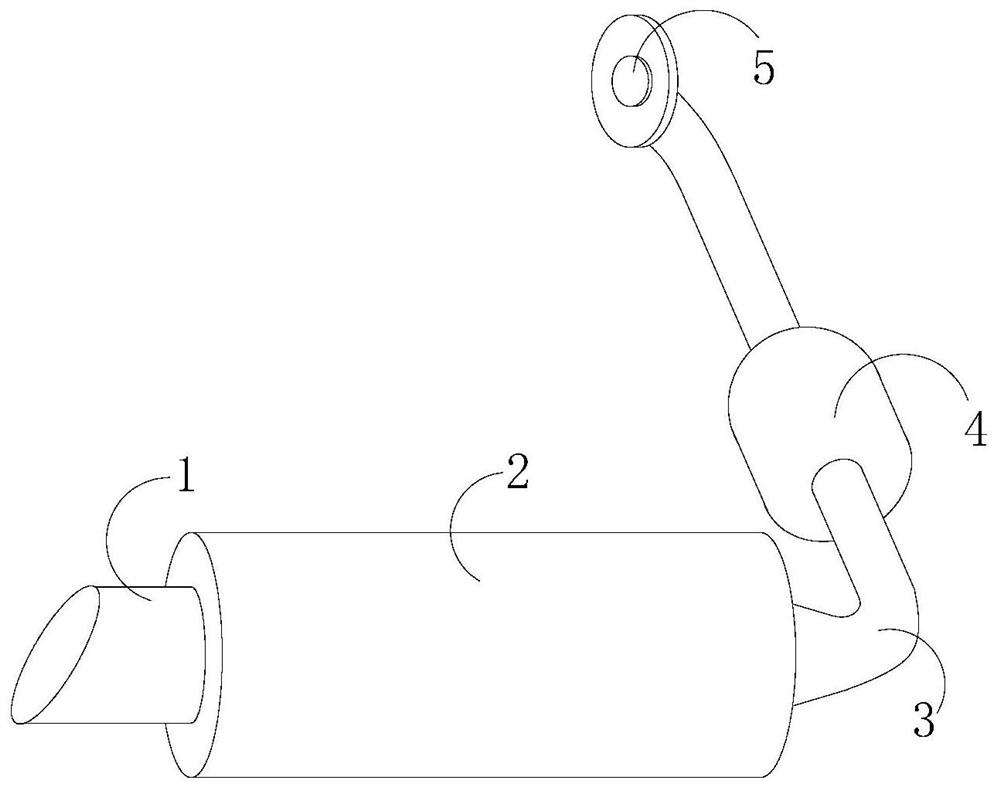

Exhaust pipe for diesel mining machinery

InactiveCN112610320ANormal exhaustAchieve scrapingExhaust apparatusSilencing apparatusThermodynamicsMechanical engineering

The invention discloses an exhaust pipe for diesel mining machinery. The exhaust pipe structurally comprises an output end, a pipeline, a connecting pipe, a transition pipe and a connecting end, the output end is in communication with the pipeline, the pipeline is connected with the transition pipe through the connecting pipe, and the transition pipe is in communication with the connecting end. The exhaust pipe has the beneficial effects that a soft layer is arranged in the pipeline, and along with the accumulation of the amount of smoke in the pipeline, the soft layer can be sunken inwards to deform under the pressure of smoke, two movable plates are pulled to rotate oppositely around a center shaft, a scraper moves along a filter screen to scrape impurities intercepted on the filter screen, and therefore the pipeline can exhaust normally, the impurities in the smoke can be intercepted to the maximum extent while the exhaust pipe works normally, and other elements in the equipment are effectively prevented from being damaged due to high temperature caused by smoke accumulation.

Owner:张主民

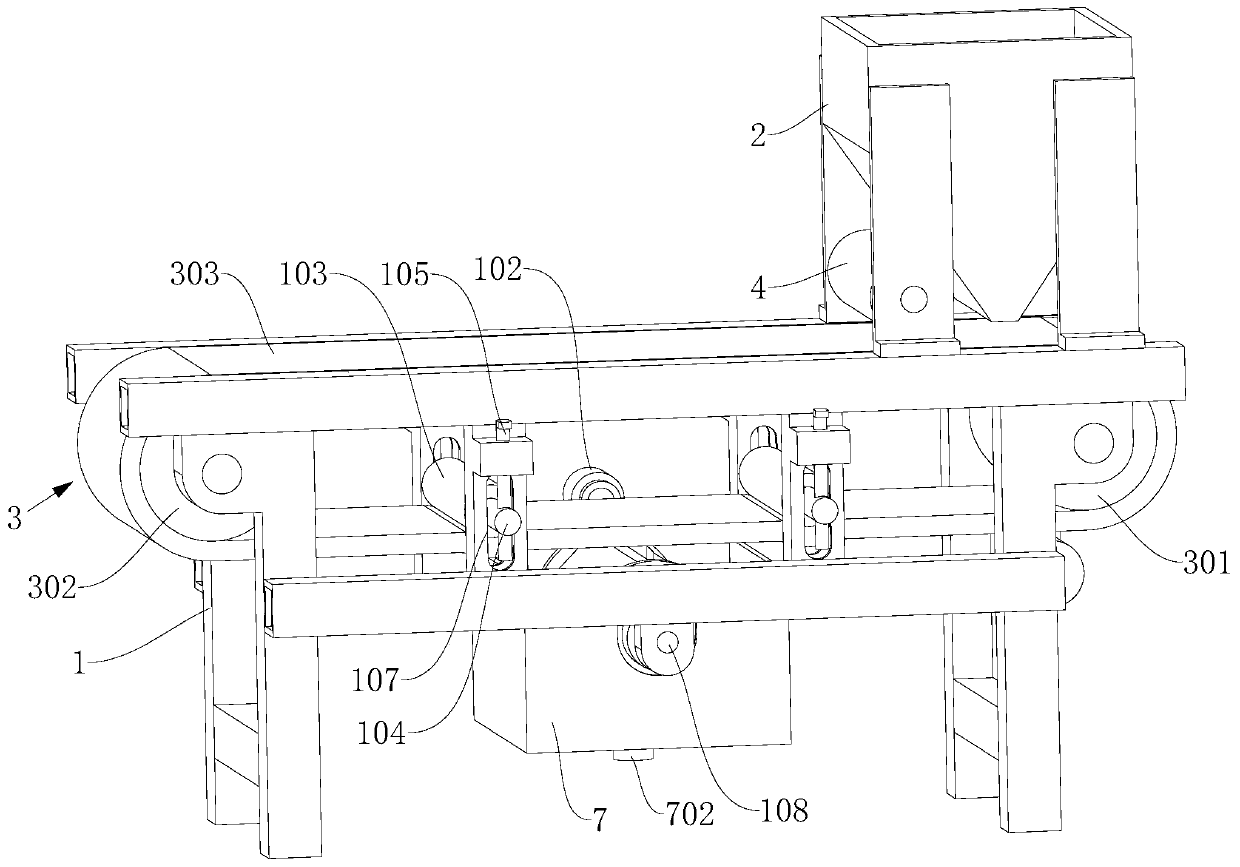

Cleaning device for chips on bottom surface of concrete masonry block

InactiveCN110815540AEasy to cleanIngenious designAuxillary shaping apparatusCleaning using toolsNumerical controlSurface cleaning

The invention discloses a cleaning device for chips on the bottom surface of a concrete masonry block. The cleaning device for the chips on the bottom surface of the concrete masonry block comprises aplacement plate, a movable frame and a drive device for the movable frame, wherein a rotary part capable of driving the concrete masonry block and the placement plate to rotate is arranged at the bottom of the movable frame; a clamping mechanism capable of clamping the placement plate and a separation mechanism capable of driving the concrete masonry block to move to separate the bottom surface of the concrete masonry block from the placement plate after the rotary part and the placement plate rotate towards the horizontal plane are arranged on the rotary part; and the drive device, the rotary part, the clamping mechanism and the separation mechanism are connected with a numerical control circuit in a controller through a circuit separately. The cleaning device for the chips on the bottomsurface of the concrete masonry block has the following advantages: the cleaning device is ingenious in structural design, a direct force on the concrete masonry block is not required, so that damageto the structure of the concrete masonry block is avoided, and meanwhile, the separation method is labor-saving and low in energy consumption; and the chips on the placement plate can be manually scraped off after the concrete masonry block is separated from the placement plate, the automation of surface cleaning for the placement plate can further be realized through a cleaning mechanism, and agood cleaning effect and high cleaning efficiency are achieved.

Owner:舟山弘业环保材料有限公司 +1

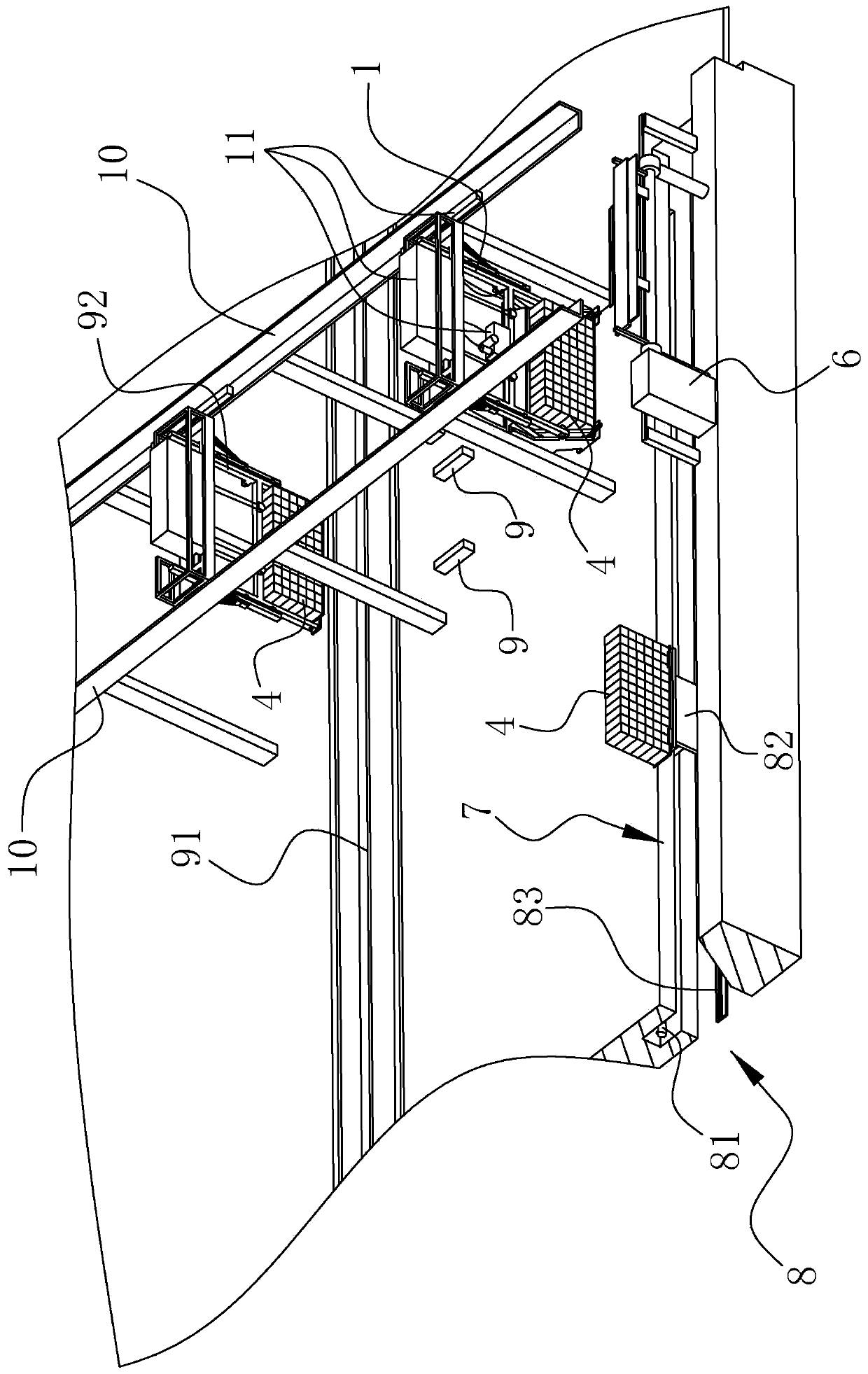

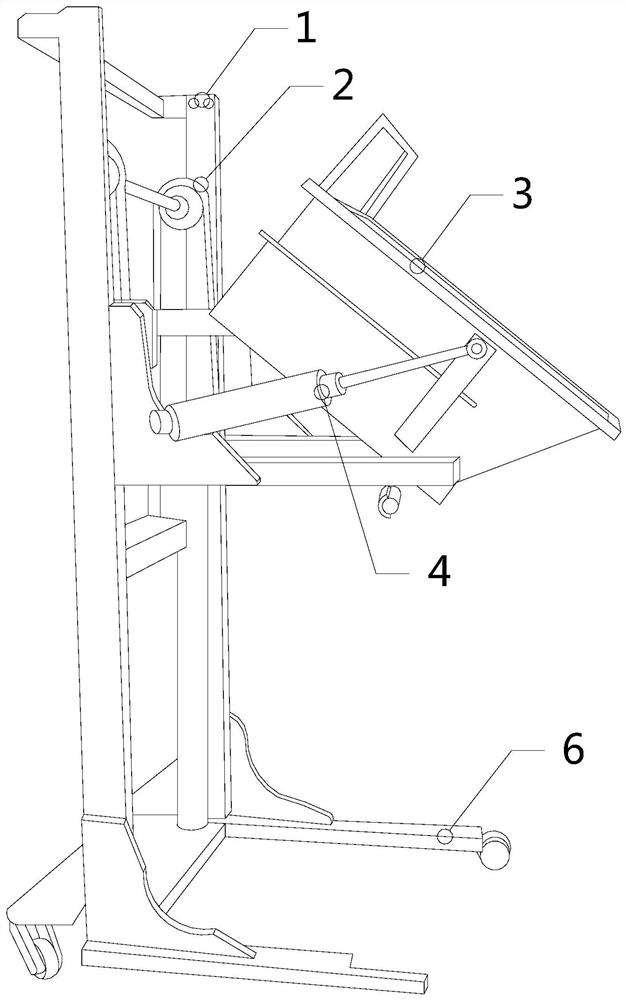

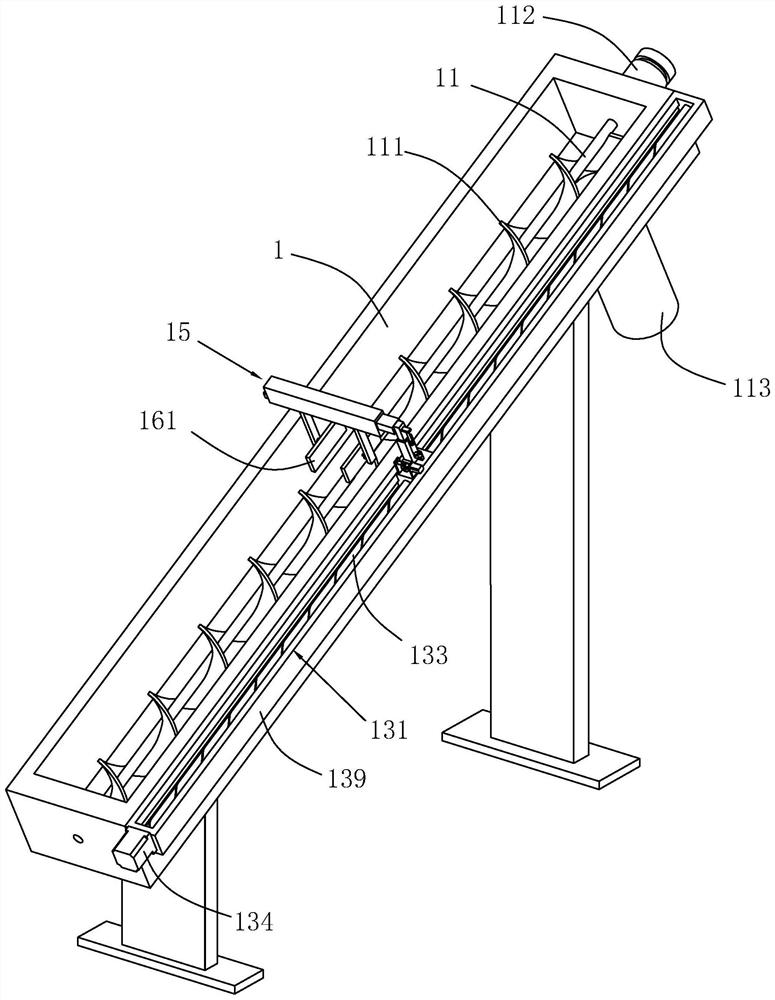

Material lifter for building construction

InactiveCN111977397AAvoid bouncing up and downWeight increaseBottle emptyingLoading/unloadingArchitectural engineeringFriction force

The invention discloses a material lifter for building construction. The material lifter structurally comprises a support, conveying belts, a hopper, telescopic rods, a bottom frame and a dischargingtongue plate, wherein the support is vertically mounted on the bottom frame, the support and the bottom frame are vertically welded, the hopper is movably mounted on the support, the telescopic rods are mounted on two sides of the hopper, the conveying belts are mounted on the two sides of the hopper, the conveying belts and the hopper are mechanically connected, the discharging tongue plate is mounted at the bottom of the hopper, and a motor is arranged at the bottom of the hopper. According to the material lifter, a heavy block and a balance stabilizing structure fix a scraping plate, the weight of the tail end of the scraping plate is enhanced, the tail end of the scraping plate is not warped, the scraping plate and the bottom end face of the hopper are completely attached, the scrapingplate does not float, sawteeth are staggered up and down in the moving process of the scraping plate, so that the friction force contact with the scraping plate is increased, and therefore the purpose that the clearing is more clean is achieved; and in addition, at the outmost, a heavy block can be removed to make the scraping plate bounce up from bottom to top, a gap is formed, and when the scraping plate moves left and right, building materials can be removed more smoothly.

Owner:柏先琼

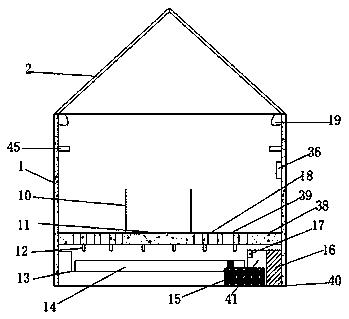

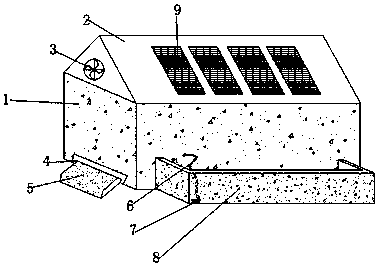

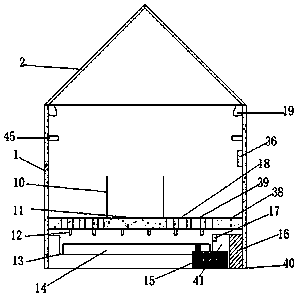

Heat-insulating henhouse for chick farming

InactiveCN108990806AAvoid harmAutomatic cleaningTemperature control using plurality of sensorsAnimal housingSprayerEngineering

The invention discloses a heat-insulating henhouse for chick farming and belongs to the technical field of farming facilities. The heat-insulating henhouse for chick farming comprises walls, a roof, exercise grounds and flat grounds, wherein dung discharging openings are formed below left side faces of the walls, a plurality of solar panels are fixedly connected with the roof, disinfecting sprayers are fixedly connected to the two sides of each wall, pedestrian ways are arranged at middle parts of the exercise grounds, stable breeding coops are arranged at the two sides of each exercise ground, dirt leaking holes are formed in the stable breeding coops, a plurality of water spray pipes are arranged on lower surfaces of the exercise grounds, pushing devices are fixedly connected with rightfront sides of surfaces of the flat grounds, scrapers are fixedly connected with front sides of the pushing devices, and dirt receiving flutes are fixedly connected with the surfaces of the flat grounds. Through arranging the pushing devices and employing the scrapers, chicken dung in the dirt receiving flutes can be scraped; and meanwhile, the water spray pipes are used for thoroughly cleaning the interior of the dirt receiving flutes, so as to achieve the aim of cleaning up the chicken dung and avoiding harmful gases resulting from chicken dung accumulation.

Owner:赵敏

Concentrated desalting device and desalting method for industrial high-salinity wastewater treatment

InactiveCN113105048AImprove desalination efficiencyAvoid cloggingTreatment involving filtrationMultistage water/sewage treatmentDesalinationProcess engineering

The invention discloses a concentrated desalting device for industrial high-salinity wastewater treatment and a desalting method.The concentrated desalting device comprises a treatment tank, a motor, a heating element, a discharge port and a valve, a liquid inlet is fixed to the top of the treatment tank, a steam outlet pipe is fixed to one side of the treatment tank, and an output shaft of the motor is rotationally connected with a movable cylinder; and a stirring rod is fixed to the end of a connecting shaft, a sleeve block is arranged on the outer side of a fixed block in a sleeving mode, a transmission shaft is connected to the end of a movable cylinder, a heating element is installed in a first valve plate in an embedded mode, and a discharging opening is formed in the lower corner of the treatment tank. According to the concentrated desalting device and desalting method for treating the industrial high-salinity wastewater, the wastewater can be kept in a flowing state all the time in the desalting process of the industrial high-salinity wastewater, and other fixed substances contained in the wastewater can be treated, so that the desalting efficiency is improved; and and meanwhile, salt adhering to the interior of the pipeline can be cleaned, and the blocking phenomenon is avoided.

Owner:刘建光

Multifunctional emulsification tank

InactiveCN107970832AAchieve scrapingSimple and fast operationRotary stirring mixersTransportation and packagingElectricityBiochemical engineering

Owner:成都尚智恒达科技有限公司

Heat preservation chicken coop for chicken breeding

The invention discloses a heat preservation chicken coop for chicken breeding, and belongs to the technical field of breeding facilities. The chicken coop comprises a wall body, a roof and a movable ground. An excrement discharging opening is arranged under the left side face of the wall body. Multiple solar energy panels are fixedly connected to the roof. Disinfection sprays are fixedly connectedto two sides of the wall body. A pavement is arranged in the middle part of the movable ground. Captivity grooves are arranged in two sides of the movable ground. Waste leaking holes are arranged inthe captivity grooves. Multiple water spraying pipes are arranged on the lower surface of the movable ground. A pushing device is fixedly connected to the front side on the right of the surface of a flat ground. A scrapping plate is fixedly connected to the front side of the pushing device. A waste collection groove is fixedly connected to the surface of the flat ground. By setting the pushing device and combining use of the scrapping plate, scrapping of chicken manure in the waste collection groove is achieved; and by using the water spraying pipes to thoroughly clean the interior of the waste collection groove, thereby achieving an objective of cleaning the chicken manure and preventing the chicken manure to be piled to generate dangerous gas.

Owner:徐松

Automatic fish killing machine

The invention discloses an automatic fish killing machine. The automatic fish killing machine comprises a box body, wherein supporting legs are fixedly connected to the four corners of the bottom of the box body, a conveying mechanism is arranged in the box body, an inlet assembly is arranged on the left side of the box body, an outlet assembly is arranged on the right side of the box body, supporting plates are fixedly connected to the front face and the back face of the inner wall of the box body, and a belly cutting mechanism is arranged between the two supporting plates. The invention relates to the technical field of automatic fish killing machines. According to the automatic fish killing machine, fish body conveying and fish scale scraping can be performed at the same time through one power source, the energy utilization rate is increased, resources are saved, the machine is more environmentally friendly, maw cutting and scale removing work can be performed at the same time in the conveying process, the overall size of the machine is reduced, internal organs, fish scales and sewage can be conveniently collected, and follow-up treatment is facilitated; and a transition plate is combined with front and rear fixing plates for use, so that the fish maws can be always opened in the process of cutting the maws, and favorable conditions are provided for cleaning viscera by a cleaning plate.

Owner:湖北国启生态农业有限公司

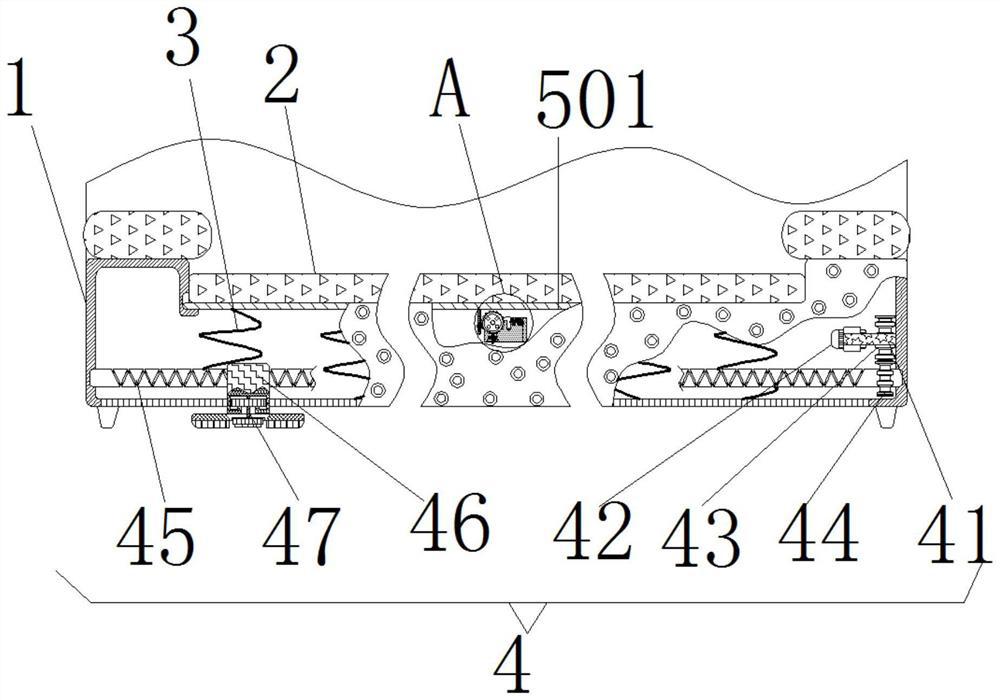

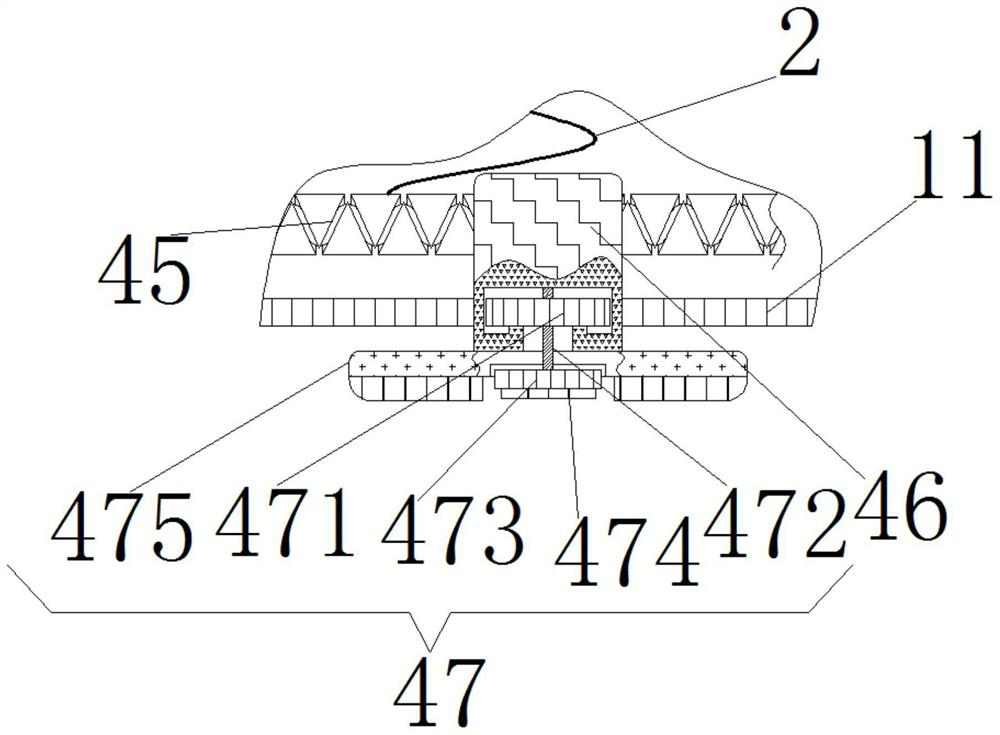

Intelligent sofa bottom ground automatic cleaning device

InactiveCN113693395AGuaranteed cleanlinessAchieve scrapingCarpet cleanersFloor cleanersCushionElectrical and Electronics engineering

The invention relates to the technical field of intelligent sofa control, and discloses an intelligent sofa bottom ground automatic cleaning device which comprises a shell, a soft cushion is placed outside the shell, a first spring for increasing the elasticity of a sofa is fixedly connected into the shell, and a sweeping device for cleaning the ground is movably connected into the shell. A trigger device for controlling the start-stop state of the sweeping device is movably connected to the interior of the shell, a lead screw rotates to drive a sliding block to move back and forth, and then a sweeping brush fixedly connected with the sliding block can be driven to move back and forth to clean the ground. A scraper rotates back and forth with a gear, and solid sticky substances which are difficult to directly sweep off on the ground can be scraped off, so that the bottom of the sofa can be kept clean.

Owner:徐宏

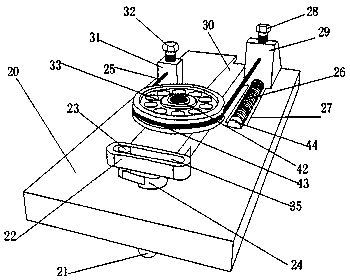

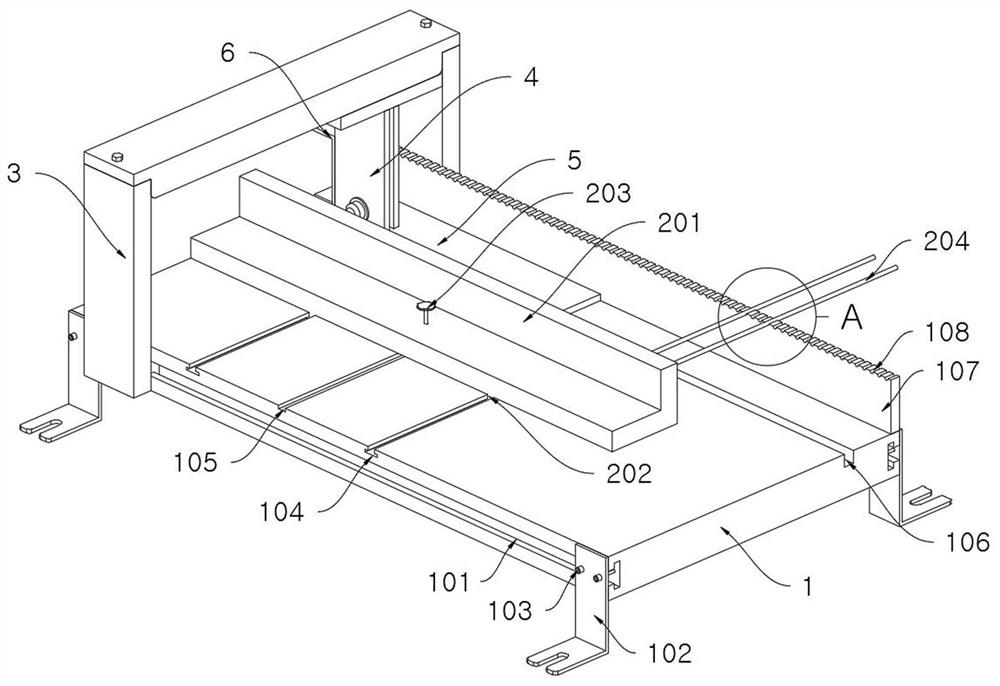

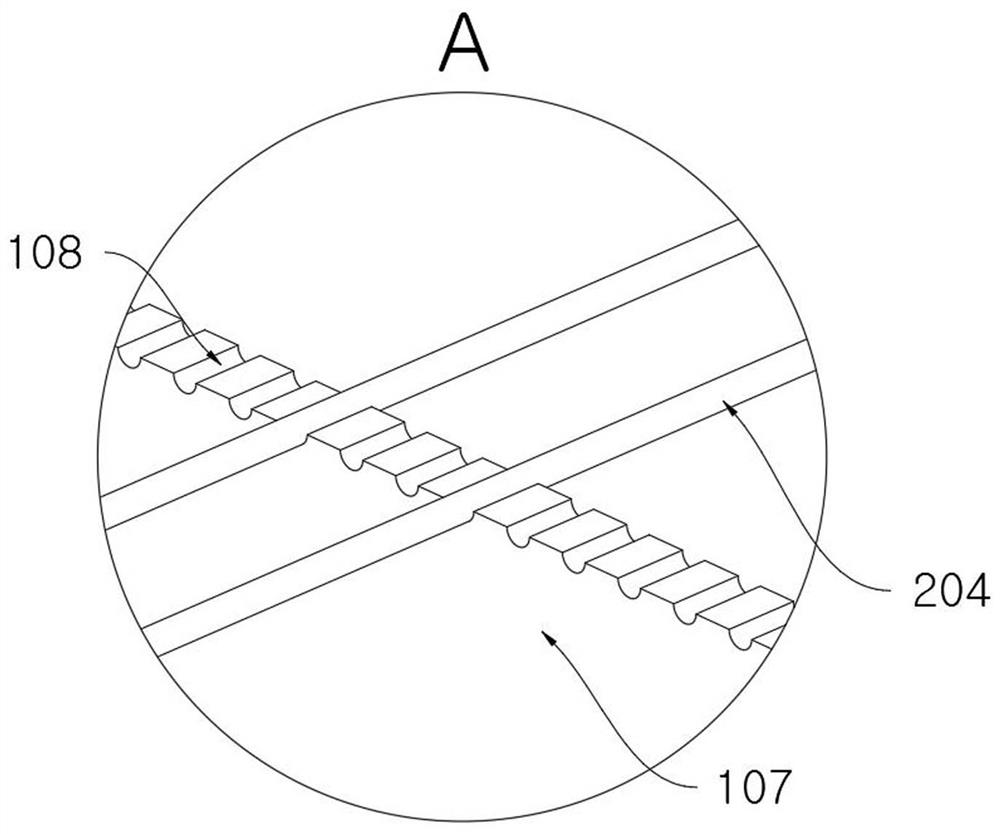

Waste material pushing device used for seamless pipe material perforating machine

The invention discloses a waste material pushing device used for a seamless pipe material perforating machine which comprises a base, a material pushing module, a supporting module and a connecting module. The material pushing module and the supporting module are fixed above the base. The connecting module is located at the upper portion of the supporting module. A sliding frame is arranged on the inner side of the supporting module. The material pushing module comprises a motor, a first connecting rod, a second connecting rod, a sliding block and a material pushing pipe. A slider-crank mechanism is composed of the first connecting rod, the second connecting rod and the sliding block. The sliding block is located in the sliding frame. The motor is provided with a rotating shaft, and the material pushing pipe is connected with the upper portion of the sliding block. The waste material pushing device is compact in structure and convenient to use, the cost of the slider-crank mechanism is relatively low, waste materials automatically fall to the base, treatment is convenient, in addition, continuous adjustment on the rotating shaft can be achieved through a speed adjusting switch, the waste material pushing process is fully automatic, and high operability and applicability are achieved.

Owner:HENAN HUIFENG TUBE IND

A feeder for concrete processing

Owner:新兴栈(绵阳)建材有限公司

Soil sampling device for preventing disturbance damage to soil sample layer during sampling separation

PendingCN111649977AAchieve scrapingAchieve complete and non-destructive extractionWithdrawing sample devicesHollow article cleaningSoil scienceMechanical engineering

The invention provides a soil sampling device for preventing disturbance damage to a soil sample layer during sampling separation, relates to the field of soil sampling, and solves the problem that disturbance to a soil sample cannot be reduced by adopting a pricking type sampling structure so as to improve the sampling precision. When samples are taken out of the sampling barrel, most of the samples are taken out by adopting a crushing method, so that complete reservation of the soil samples cannot be realized, and the storage and reservation of the samples are influenced. The invention discloses a soil sampling device for preventing disturbance damage to a soil sample layer during sampling separation. The soil sampling device comprises a frame body adjusting groove and a sampling cylinder B, the frame body is of a concave structure, and two fixing bases are fixedly connected to the frame body through bolts. When the sampling cylinder B moves upwards by 10cm along with the electric telescopic rod, the top end surface of the sampling cylinder B is in contact with the top end surface of the shifting plate, and when the sampling cylinder B continuously moves upwards along with the electric telescopic rod, the sampling cylinder B is in a dismounting state, so that the sampling cylinder B can be automatically dismounted through the contraction of the electric telescopic rod.

Owner:LINYI UNIVERSITY

Cutting machining device for mechanical part machining

ActiveCN113695683AAchieve installationAchieve cleanupPositioning apparatusMaintainance and safety accessoriesMechanical componentsStructural engineering

The invention provides a cutting machining device for mechanical part machining, and relates to the technical field of part machining. The cutting machining device comprises a main body seat, a fixing part, a mounting frame, a cutting part and a smearing part; two sliding grooves A are symmetrically formed in the main body seat, and two sliding grooves B are symmetrically formed in the top end face of the main body seat; supporting claws and a sliding arm are arranged in a matched mode, so that limiting of the sliding arm can be achieved, specifically, due to the fact that the left end face of the sliding arm makes contact with the supporting claw at the left side, after the sliding arm slides rightwards by 50 cm, the right end face of the sliding arm makes contact with the supporting claw, sliding limiting of the sliding arm can be achieved through the supporting claws, and the problem that the clamping quality is affected due to the fact that a gap is too large when a clamping structure is used for a long time is solved; and the problems that supporting claw fixing bolts are easy to loosen, and the function of the supporting claws is single are solved.

Owner:如东中灿机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com