Waste material pushing device used for seamless pipe material perforating machine

A perforator and seamless pipe technology, applied in the field of waste pushing devices, can solve the problems of unfavorable energy saving, downgrading and recycling, and large waste of process waste recycling, and achieve the effects of compact structure, convenient handling, strong operability and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

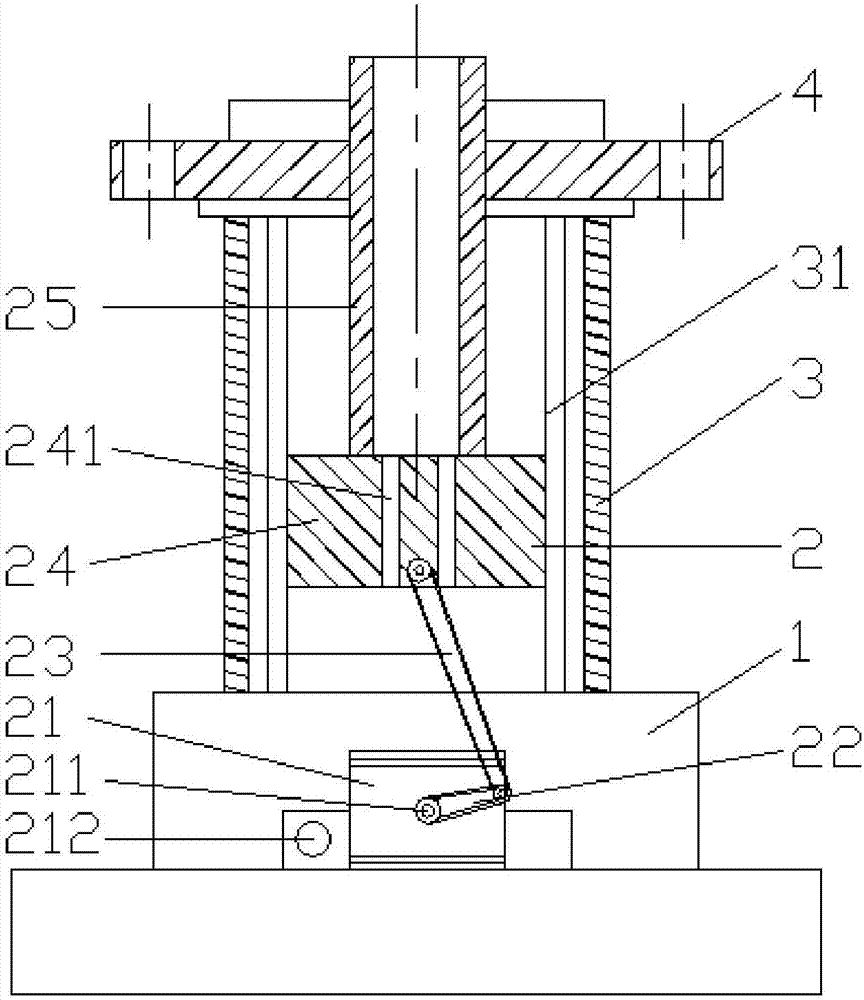

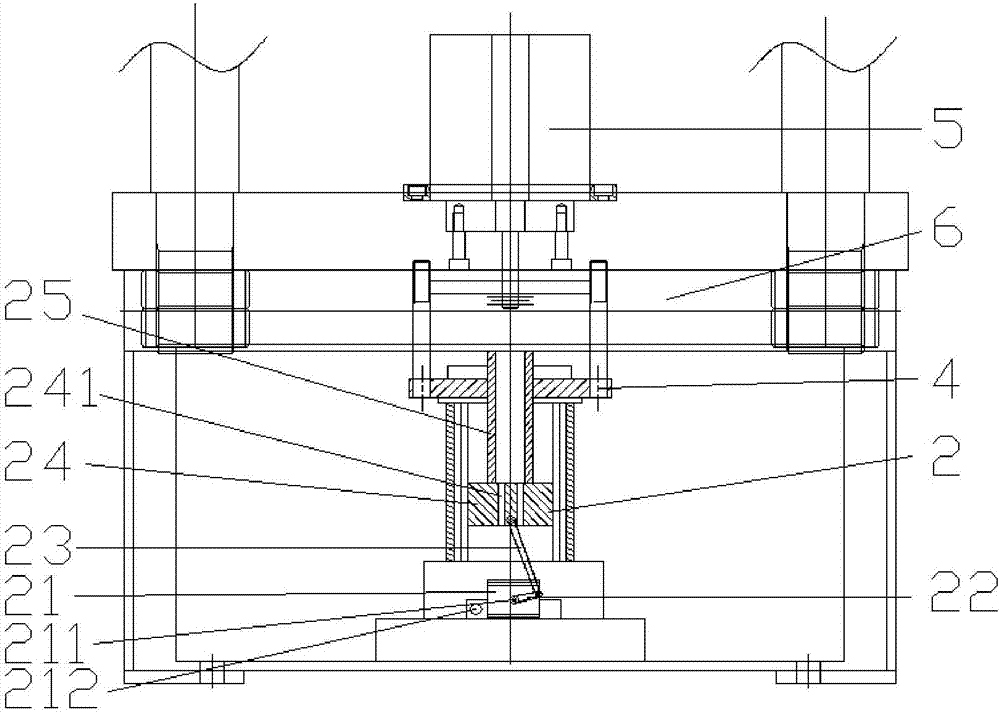

[0024] In order to more clearly illustrate the technical solutions in the embodiments of the present application or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art, and the drawings in the following description are only the application For some embodiments described in , those skilled in the art can also obtain other drawings based on these drawings without creative work.

[0025] Combine below Figure 1 ~ Figure 2 And specific embodiment, further clarifies the present invention.

[0026] A waste pushing device for a seamless pipe material punching machine, comprising a base 1, a pushing module 2, a supporting module 3, and a connecting module 4; the pushing module 2 and the supporting module 3 are fixed on the base 1, The connection module 4 is located at the top of the support module 3, and the inside of the support module 3 has a sliding frame 31; the pushing module 2 includes a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com