Scraping broaching tool for hard tooth face spline hole

A technology of spline hole and hard tooth surface, applied in the field of metal cutting tools, can solve the problems of difficult machining of hard tooth surface, reduced gear precision, tooth deformation, etc., to improve broaching conditions, improve overall strength, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

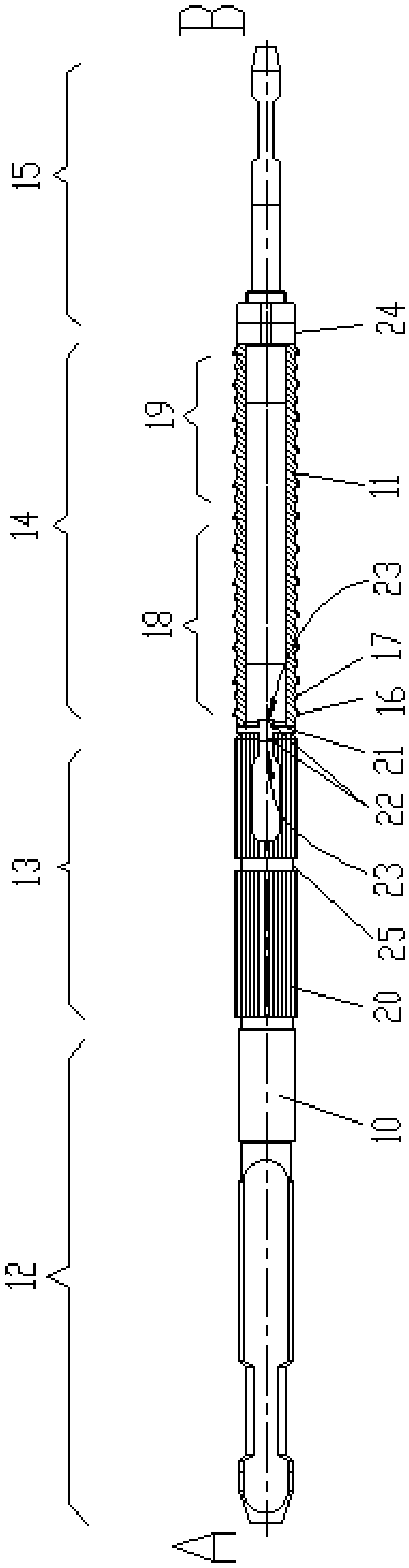

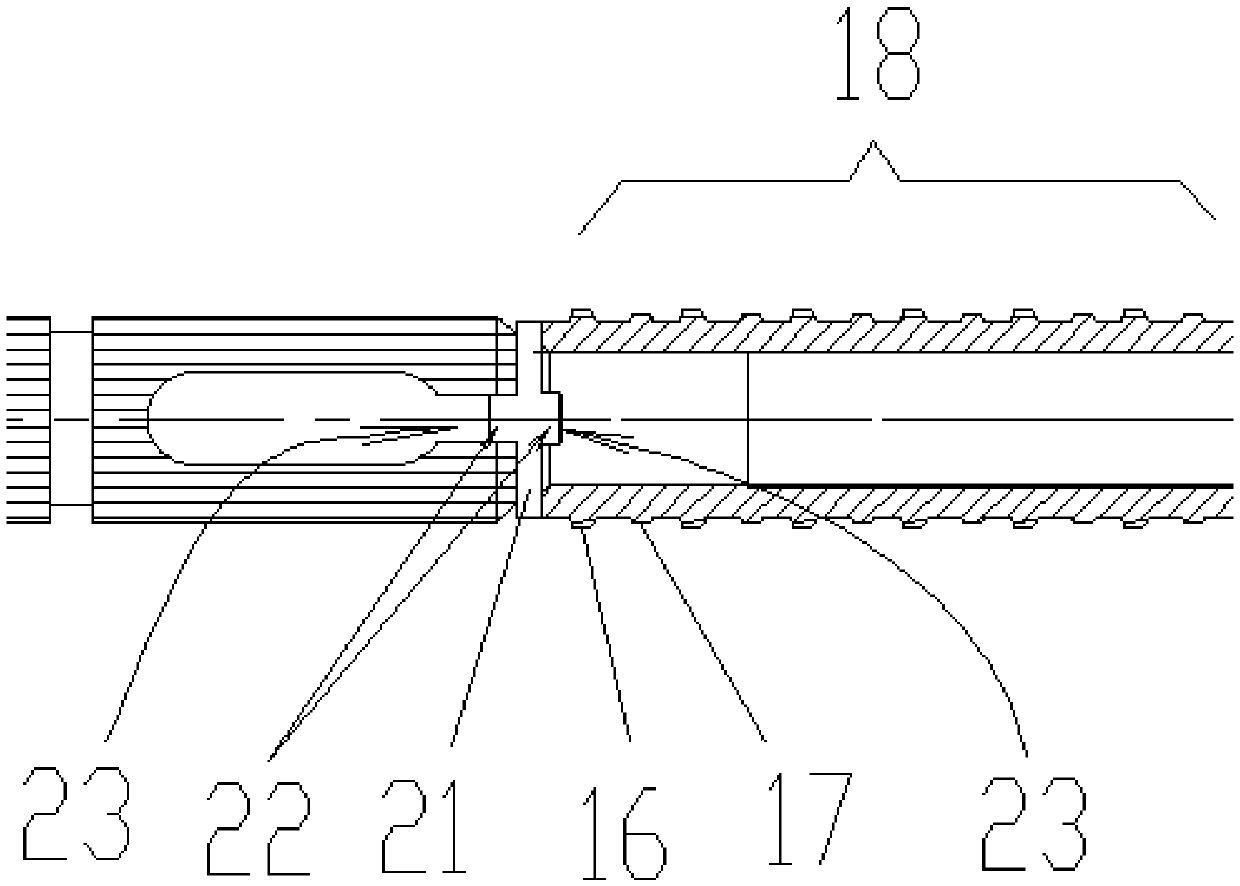

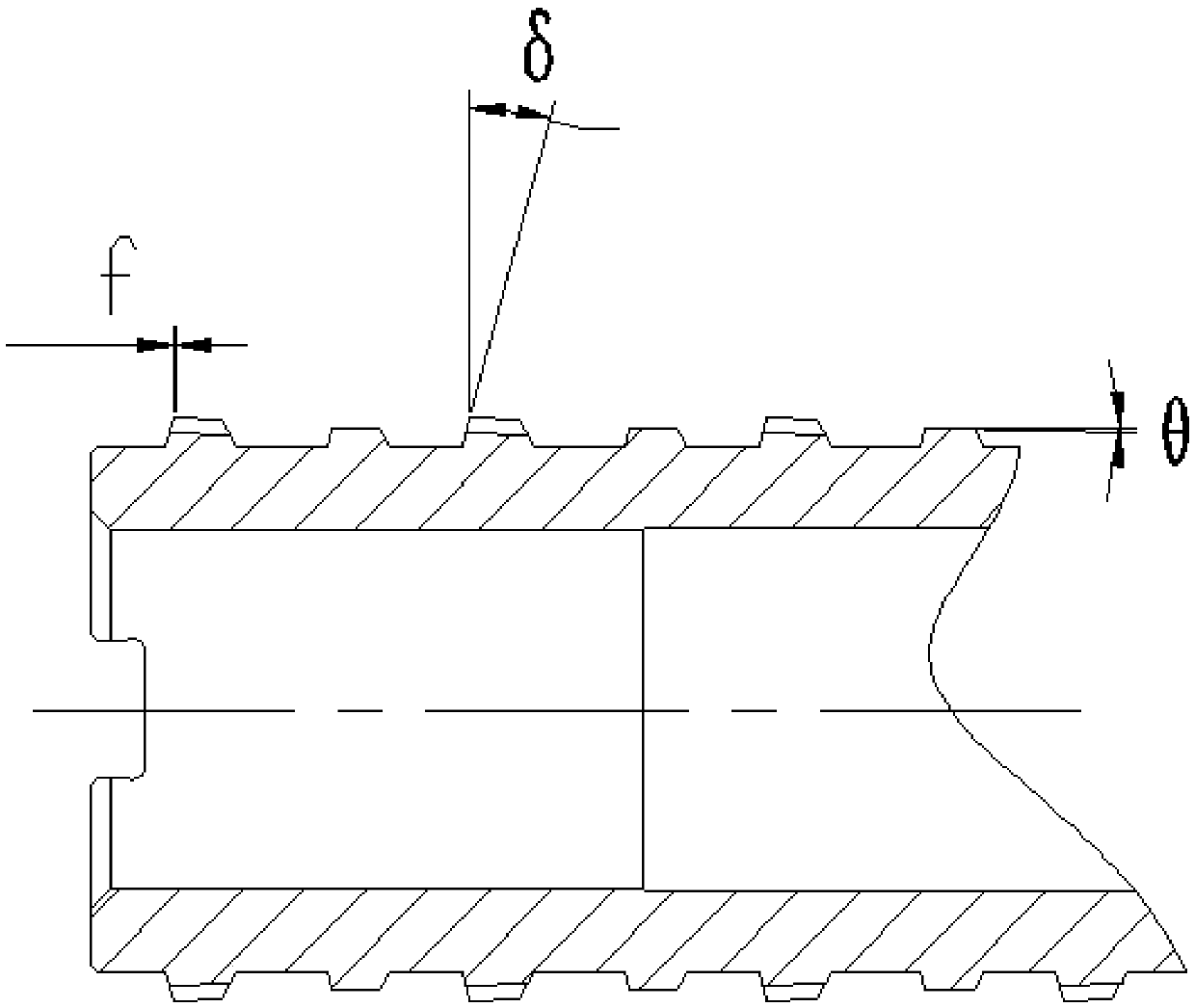

[0032] Such as Figures 1 to 4 Shown is an embodiment of a scraping broach of a hard tooth surface spline hole of the present invention, comprising a broach bar 10, a sleeve type cemented carbide broach 11 connected with the broach bar 10, the broach The rod 10 is sequentially provided with a front end shank section 12, a guide positioning section 13, a broaching section 14, and a tail end shank section 15 according to the direction from the front end A to the back end B of the scraping broach. The sleeve type cemented carbide broach 11 is set on the circle, and the sleeve type carbide broach 11 is provided with spline teeth 16 for processing the two sides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com