Cleaning device for chips on bottom surface of concrete masonry block

A technology for concrete blocks and cleaning devices, which is applied in the direction of cleaning methods using tools, transportation and packaging, cleaning methods and utensils, etc., which can solve problems that affect processing, cannot clean chips, and the bottom surface of concrete blocks is not clean, etc., to achieve convenience Recycling and separation methods save labor and are beneficial to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

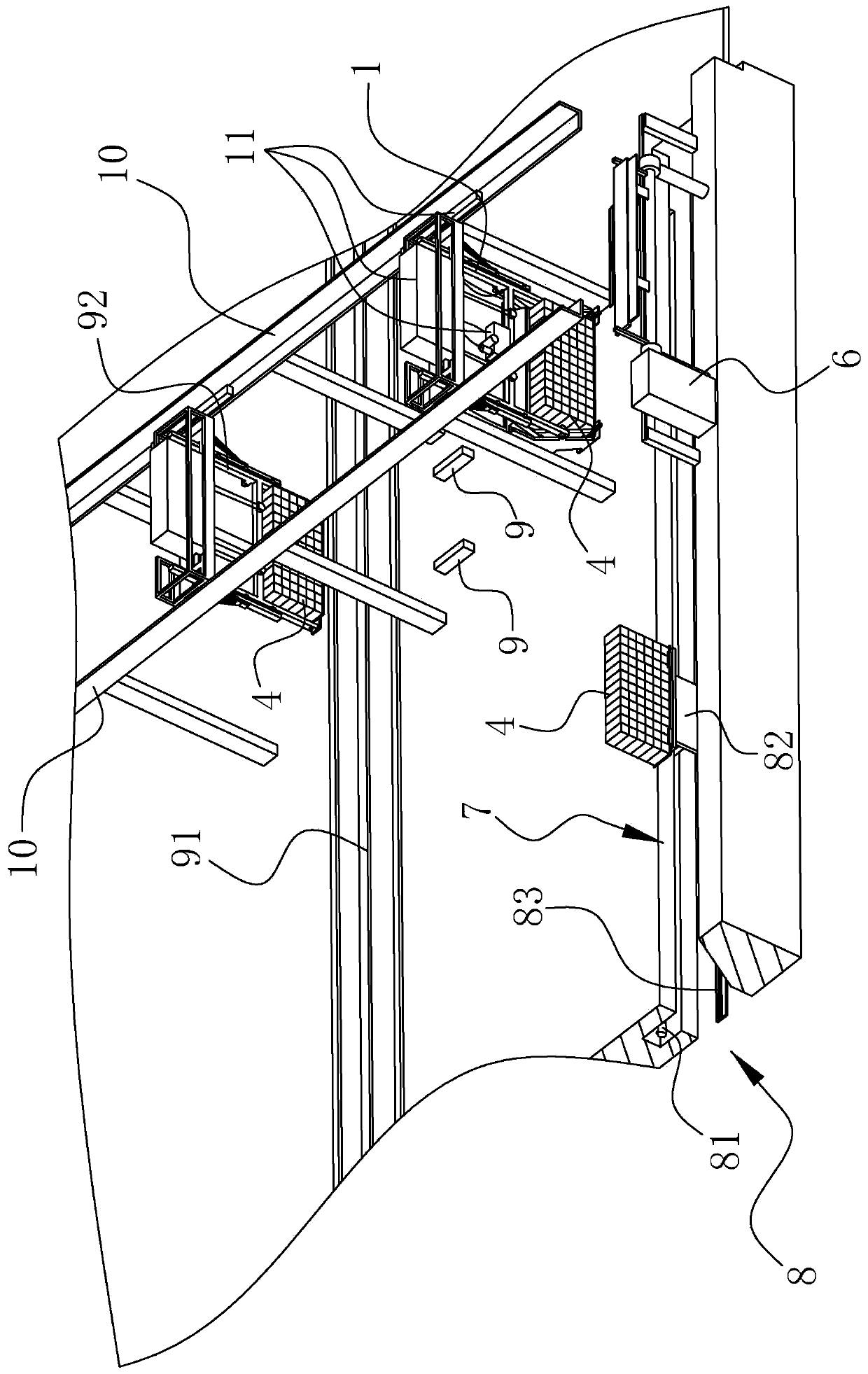

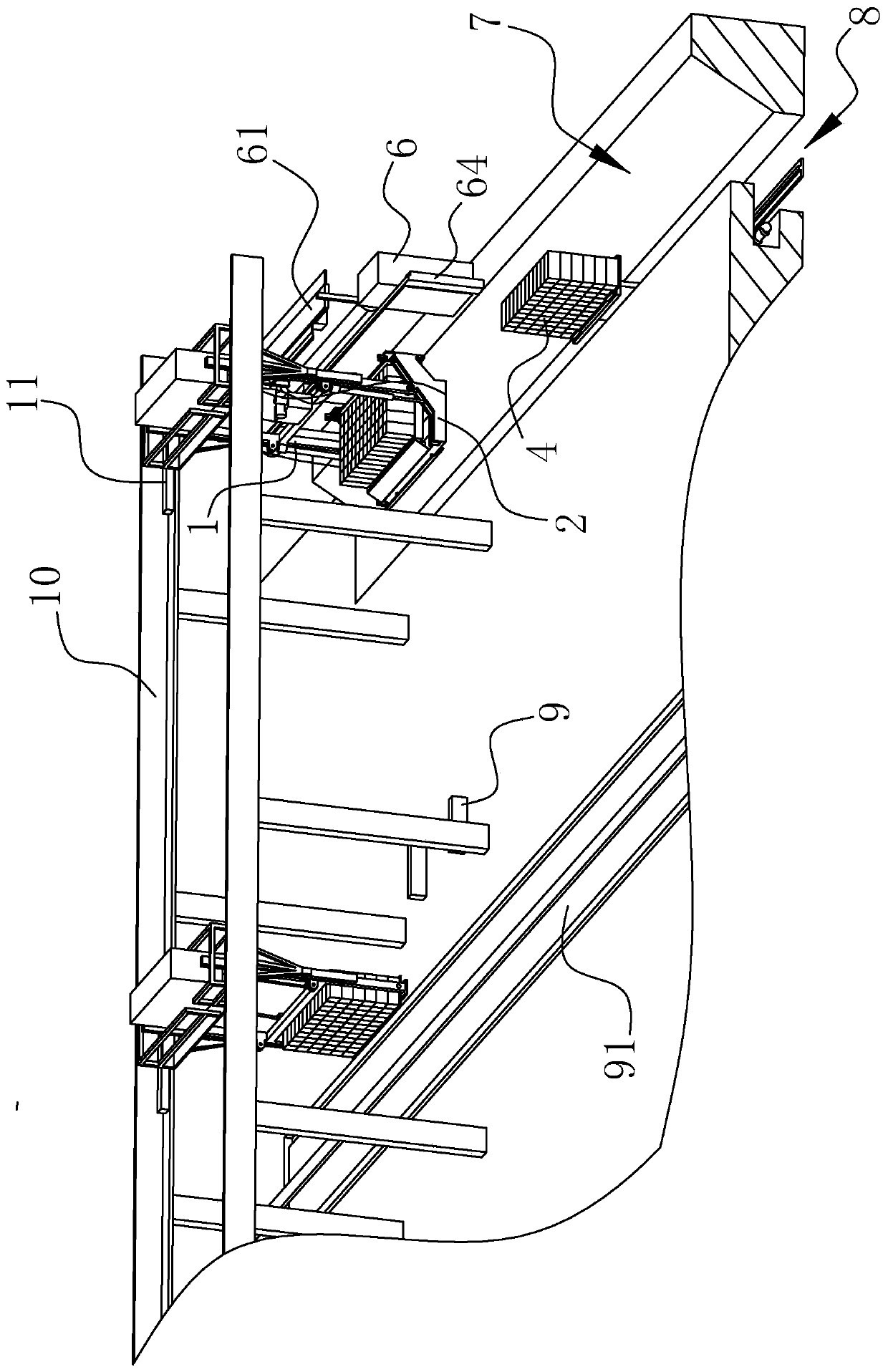

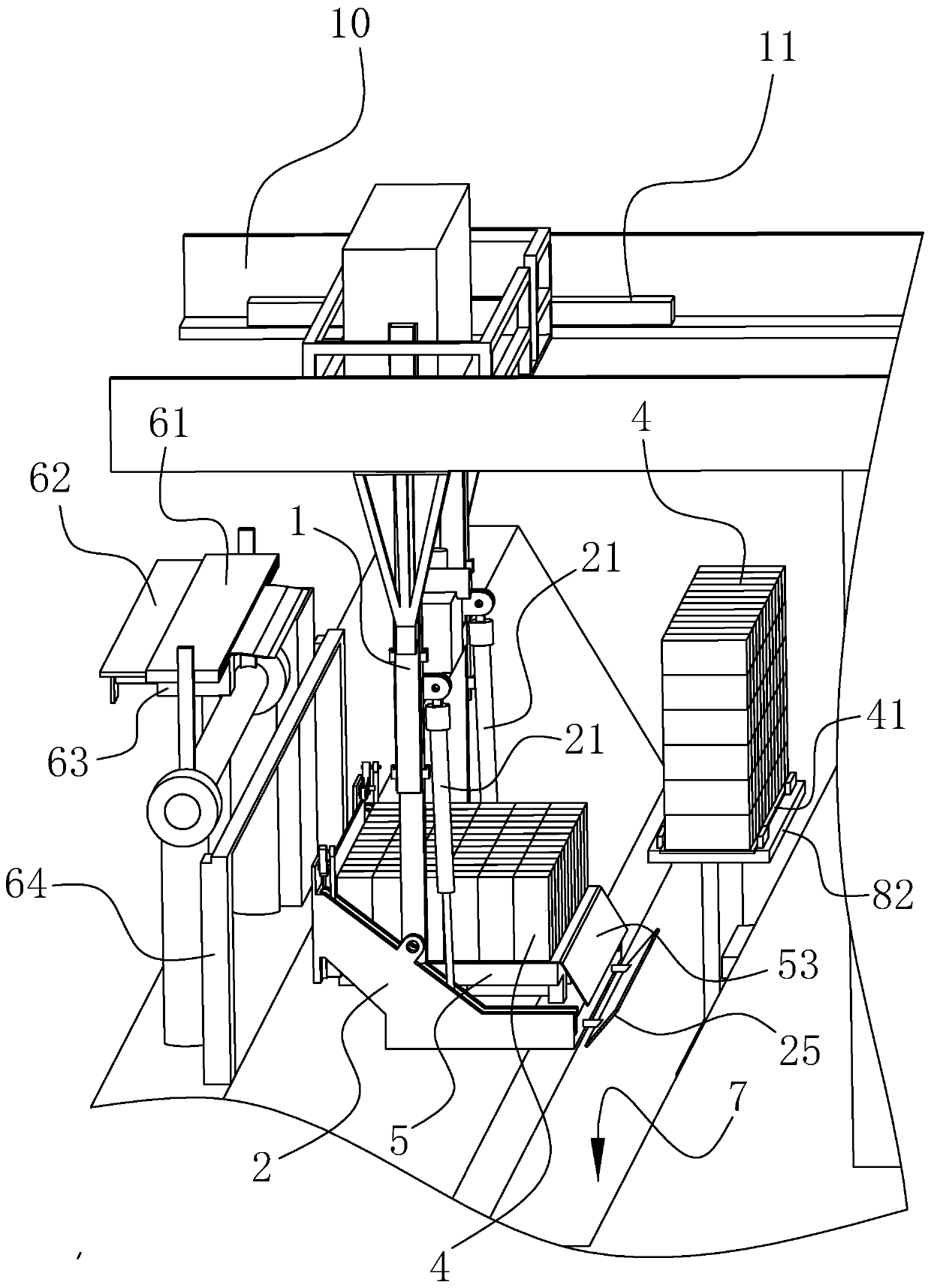

[0026] Such as Figure 1 to Figure 10 As shown, the cleaning device for chips on the bottom surface of concrete blocks in this embodiment includes a placement plate 41 capable of supporting concrete blocks cut and formed by steel wires, a moving frame 1 that can drive the placement plate 41 to move, and a drive that can drive the moving frame 1. The device 11 is provided with a rotating part that can drive the concrete block 4 and the placing plate 41 to rotate at the bottom of the mobile frame 1, and a clamping mechanism that can clamp the placing plate 41 is provided on the rotating part, and can be placed between the rotating part and the placing plate 41. After the plate 41 rotates to the horizontal plane, it drives the concrete block 4 to move so that the bottom surface of the concrete block is separated from the placement plate 41. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com