Novel pouring gun head for silicone joint material of concrete expansion joint

A caulking material and concrete technology, which is applied in the field of new-type concrete expansion joint silicone caulking material pouring gun heads, can solve the problems of bubble inclusion in the adhesive layer, time-consuming and laborious, small diameter of the gun muzzle, etc. quality, the effect of improving perfusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described as follows with reference to accompanying drawing in conjunction with specific embodiment:

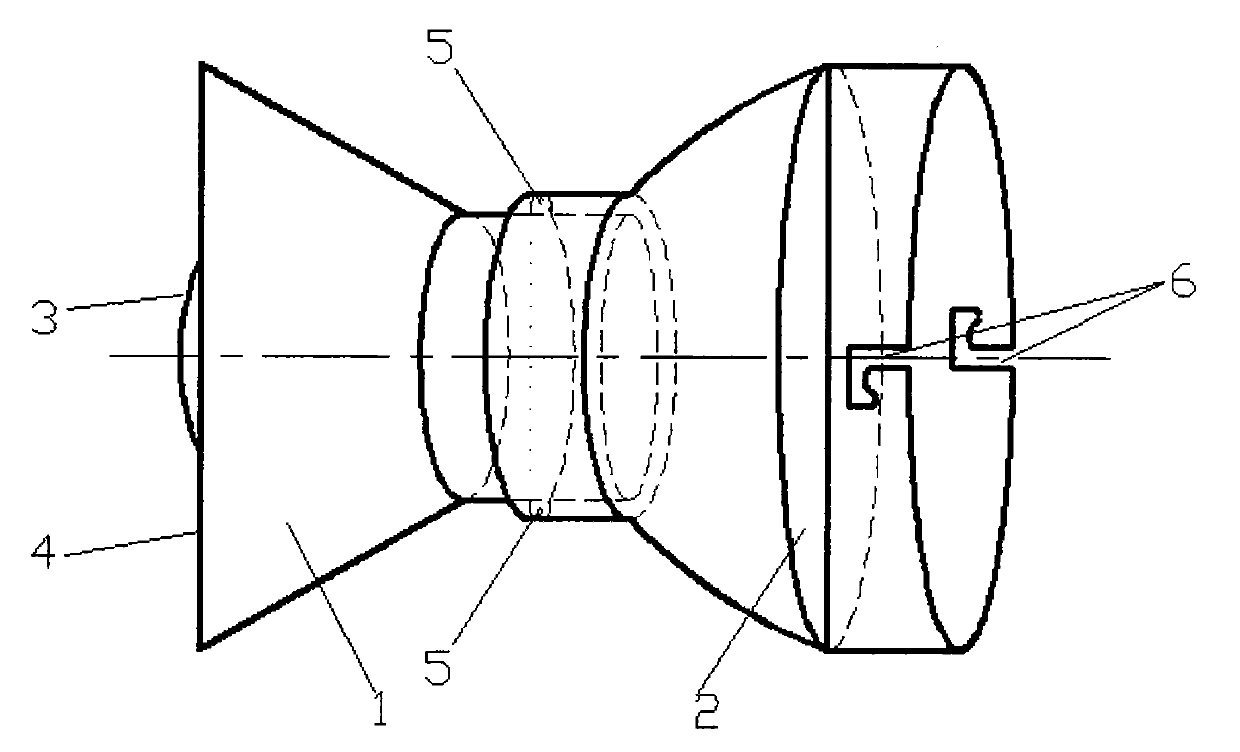

[0022] As shown in the accompanying drawings, the present invention consists of two parts, a pouring head (1) and a base (2). The filling head is made of plastic injection molding, the front end is a flat structure, the glue nozzle (3) is a convex arc, the two sides of the glue nozzle (3) are flat scrapers (4), and the tail is provided with two bayonets (5 ), the filling head (1) is connected to the base (2) through the quick-connect bayonet (5); The outer diameter of the tail is consistent, and the tail has a functional bayonet slot (6).

[0023] When pouring the silicone caulking material for concrete expansion joints, first connect the pouring head and the base through the bayonet, put the soft-packed single-component silicone caulking material into the glue gun, and then connect the entire pouring gun head to the glue gun ; Hold the glue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com