Patents

Literature

98results about How to "Improve perfusion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

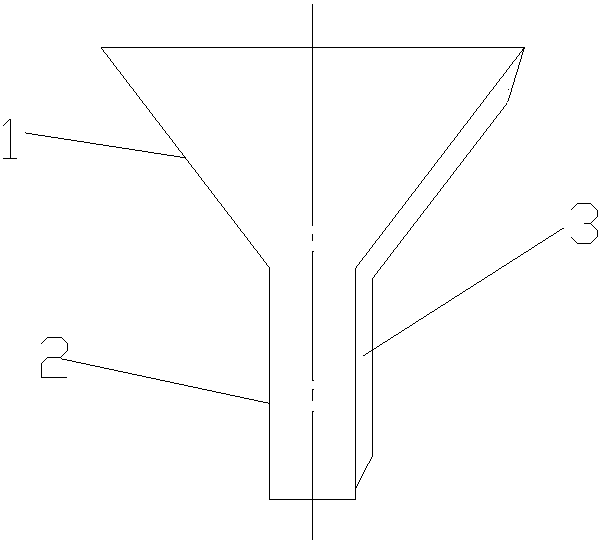

Dairy product filling and discharging structure capable of preventing fluid from dripping

InactiveCN106185762AIncrease perfusion rateImprove perfusion efficiencyLiquid bottlingEngineeringPiston

The invention discloses a dairy product filling and discharging structure capable of preventing fluid from dripping. The dairy product filling and discharging structure comprises a pipe body provided with a valve and a nozzle; an annular inner cavity is arranged in the pipe body and between the valve and the nozzle; one end, near the valve, of the inner cavity is enclosed, and one end, near the nozzle, of the inner cavity is unenclosed; the enclosed end of the inner cavity is fixedly provided with a drive rod facing the direction of the nozzle; and the drive rod is connected with an annular piston matched with the inner cavity. The dairy product filling and discharging structure capable of preventing the fluid from dripping provided by the invention aims at solving the problem that a residual dairy product is easy to drip into the filling system in the prior art, and therefore, the goals that waste of the dairy product is reduced, a sanitary condition of the filling system is improved, and meanwhile, the filling efficiency of the diary product is increased are achieved.

Owner:欧德机械成都有限公司

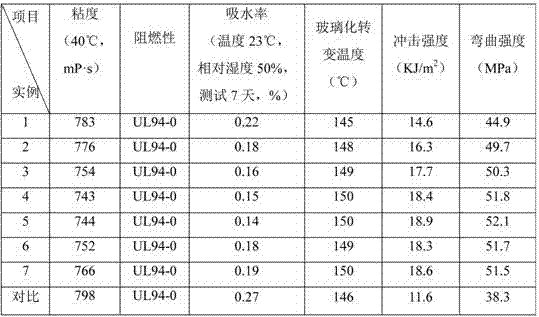

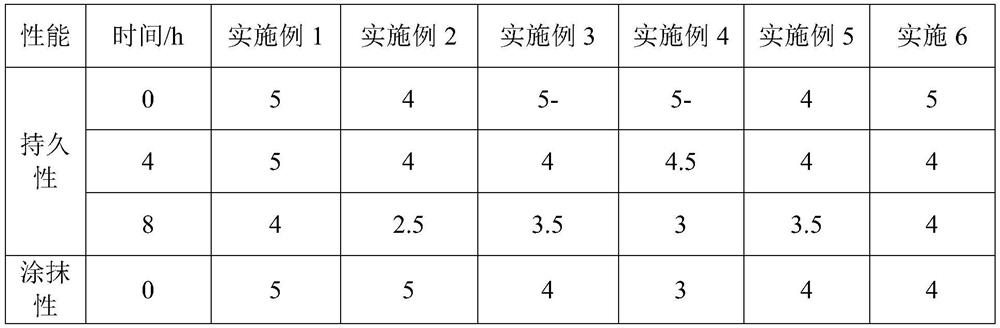

Environment-friendly anticorrosive coating and preparation method thereof

The invention belongs to the field of preparation of coatings and particularly relates to an environment-friendly anticorrosive coating and a preparation method thereof. The coating is prepared by mixing an oil paint component and a curing agent component in a weight ratio of 100 to (20-30). The oil paint component is prepared from the following components in percentage by weight: 55-70wt% of acrylic resin, 5-15wt% of tea stem powder, 10-15wt% of organic pigments, 3-5wt% of rosin, 10-15wt% of solvent and 2-5wt% of surfactant. The curing agent component is prepared from the following components in percentage by weight: 60-69wt% of curing agent, 30-39wt% of solvent and 0.05-1wt% of dehydrating agent, wherein the dehydrating agent is one or two of butyl ester, cyclohexanone and butyl cellosolve. The added tea stem powder can react with harmful gases such as formaldehyde and dimethylbenzene to form non-volatile harmless macromolecular chain substances, so as to effectively eliminate harmful gases in the atmosphere, so that the prepared coating is relatively environmentally friendly and pollution-free. Due to the design of a stepwise feeding device, the raw materials are fully and uniformly mixed, thereby improving the performance of the coating. Due to adoption of a discharging spill-proof hopper, the packaging process is simple, convenient and efficient.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

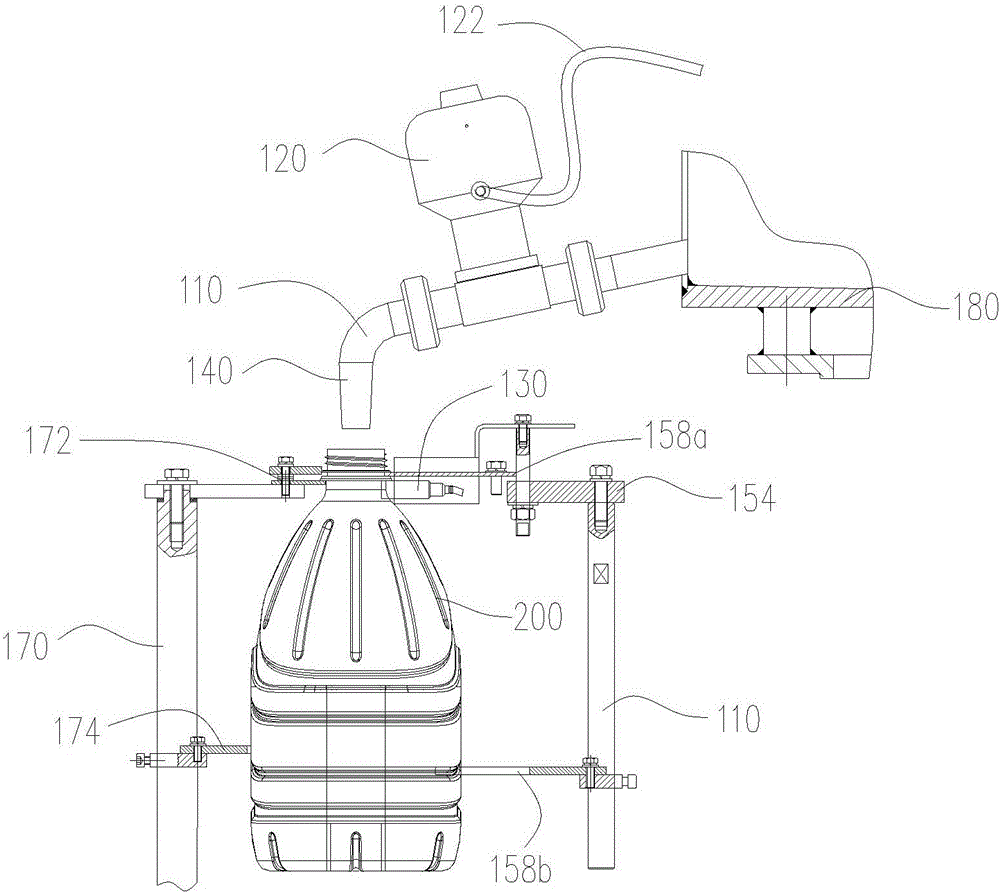

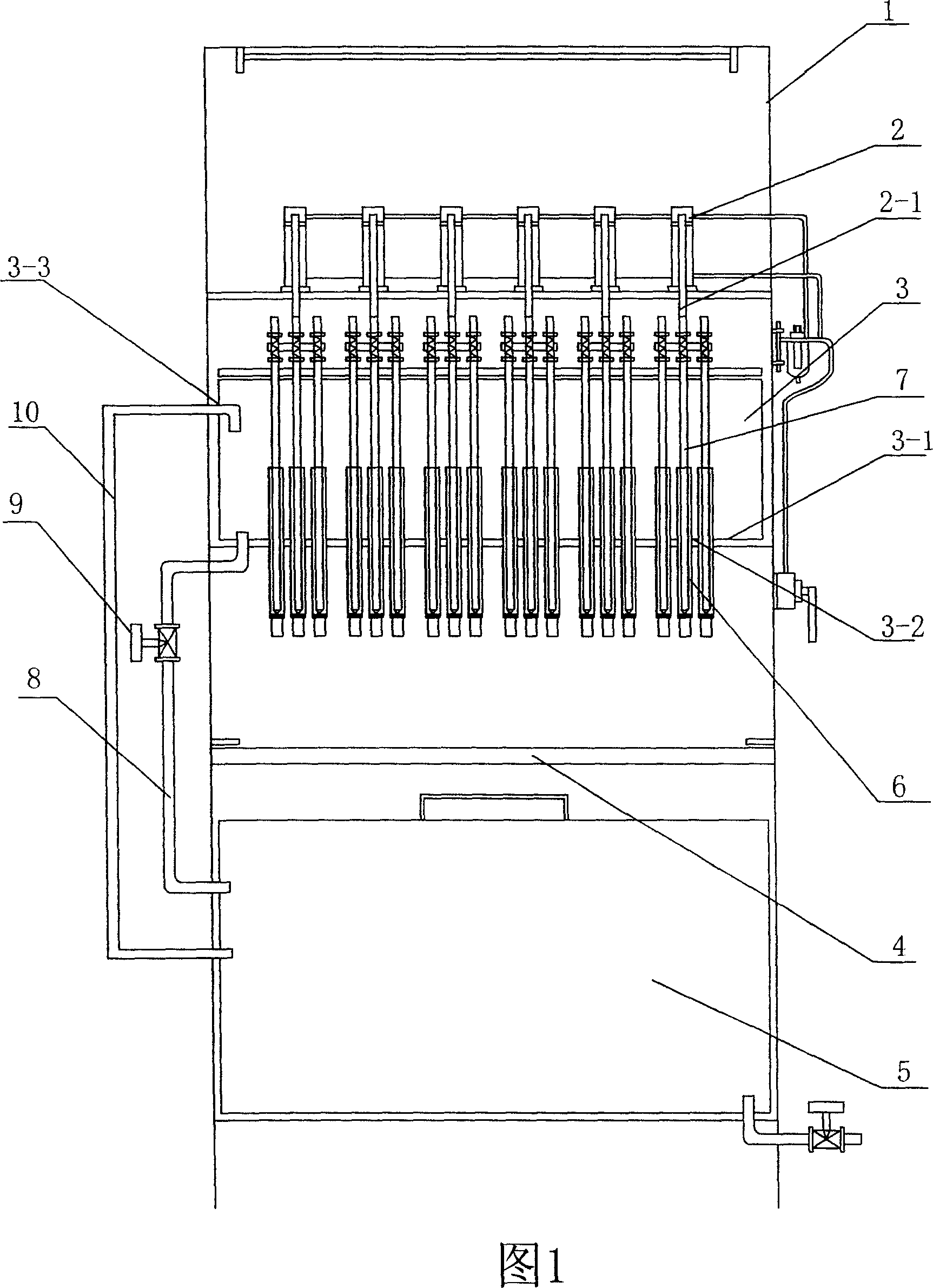

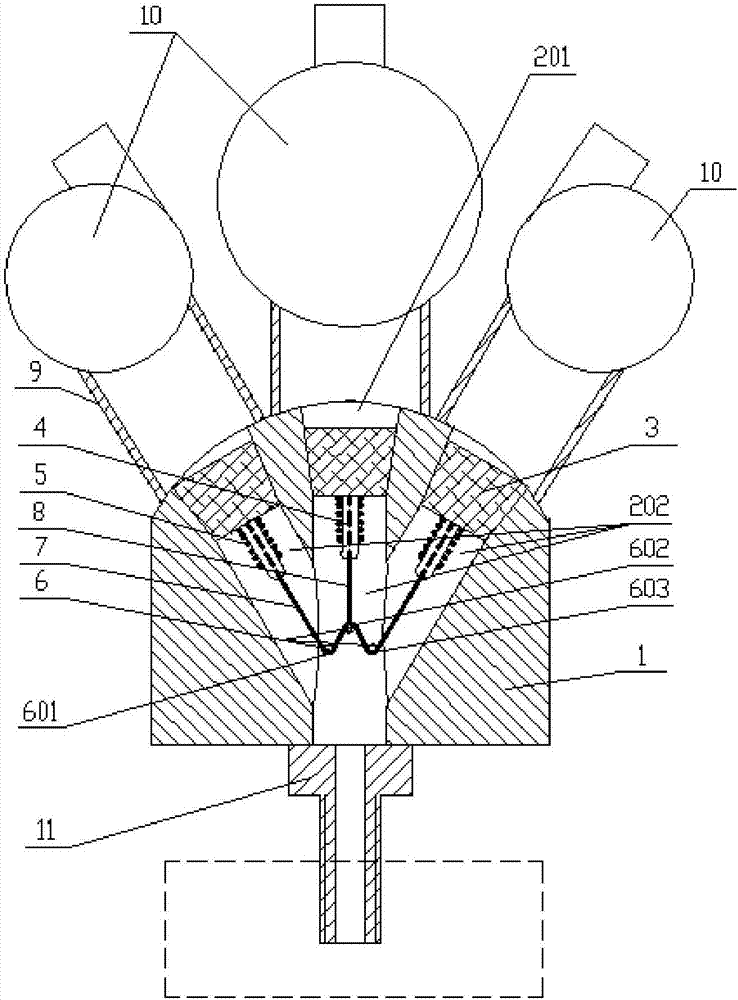

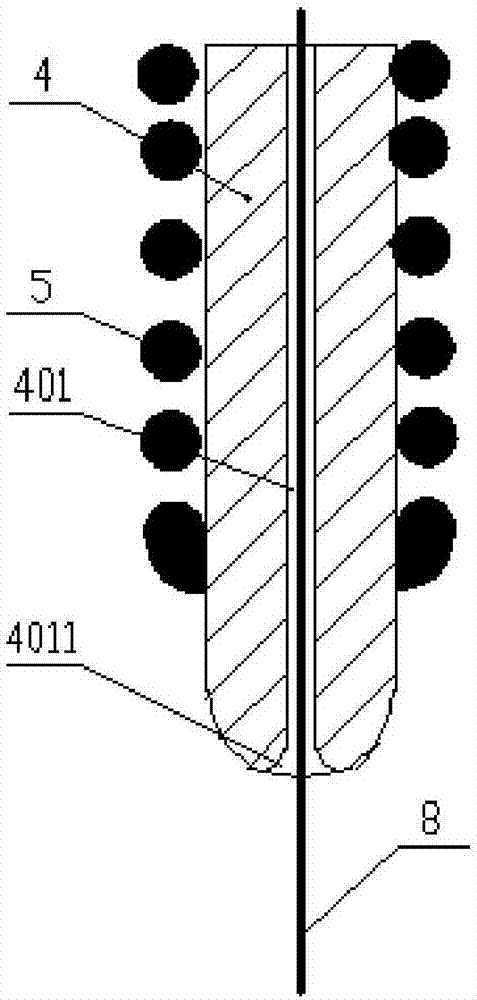

Double-loop oscillation perfusion-type biological reaction system

InactiveCN103194390AReduce consumptionReduce manufacturing costTissue/virus culture apparatusPerfusion CulturePeristaltic pump

The invention relates to a double-loop oscillation perfusion-type biological reaction system which is applied to co-culture of seed cells and biomaterials. The biological reaction system comprises a support perfusion culture device, a liquid storage bottle, a recovery bottle and peristaltic pumps, wherein the support perfusion culture device is internally provided with a plurality of supports for co-culture of seed cells and biomaterials; the liquid storage bottle is used for conveying a culture solution in the bottle to the supports; the recovery bottle is used for receiving the culture solution flowing from the support perfusion culture device through a liquid conveying pipe; the flowing direction of the liquid storage bottle and the flowing direction of the recovery bottle are controlled through respective three-way pipes, so that the liquid storage bottle and the recovery bottle are switched between a perfusion liquid-changing channel and a perfusion culture channel; the peristaltic pump is respectively arranged in the perfusion liquid-changing channel and the perfusion culture channel and used for controlling the flow velocity of a culture solution passing through the liquid conveying pipe. According to the double-loop oscillation perfusion-type biological reaction system, the combination between an oscillation method and the perfusion method is achieved, the seed cells inside the biomaterials are subjected to sufficient substance interchange and stress stimulation, the production efficiency of engineered tissues is improved and the requirements of large-scale classed culture can be met.

Owner:NANFANG HOSPITAL OF SOUTHERN MEDICAL UNIV

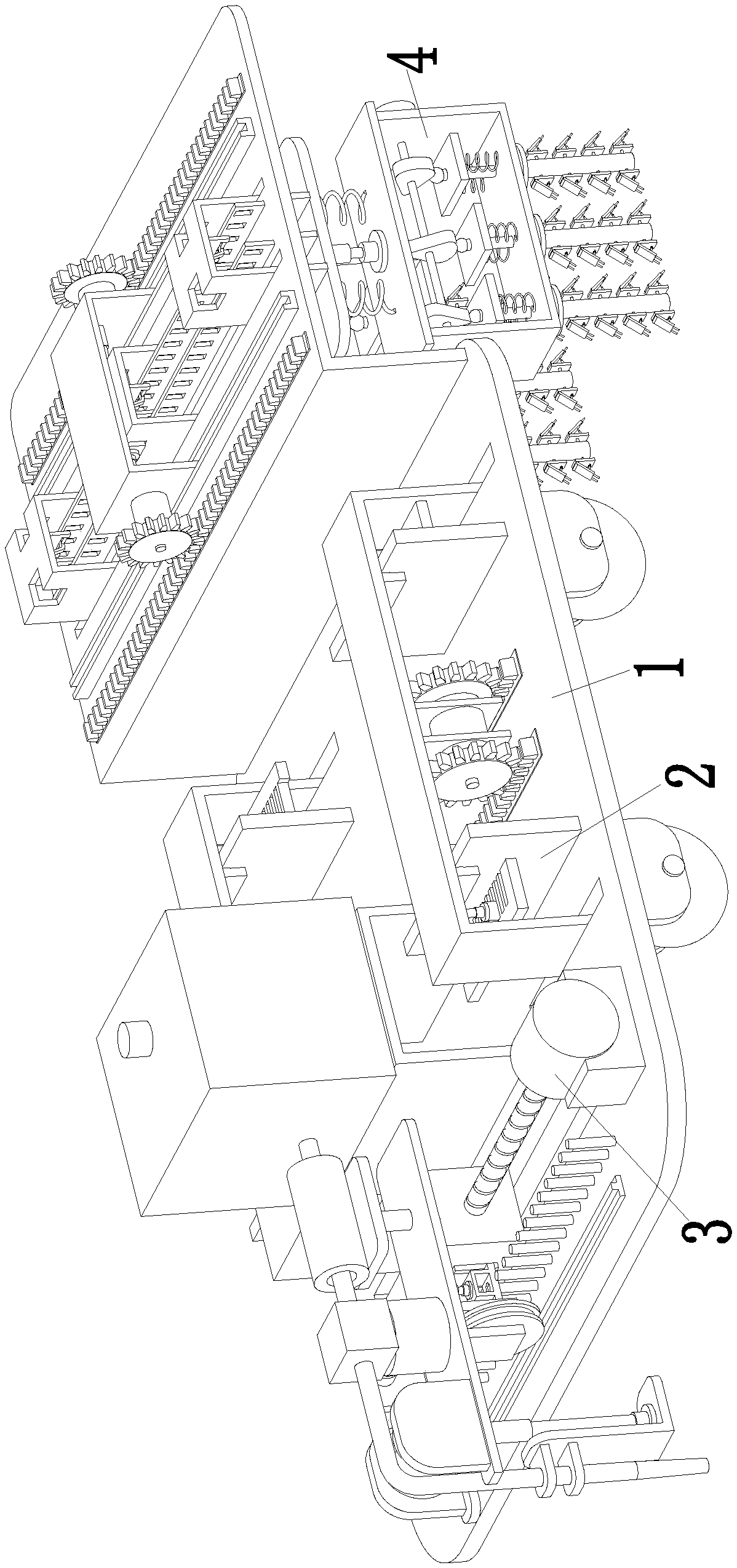

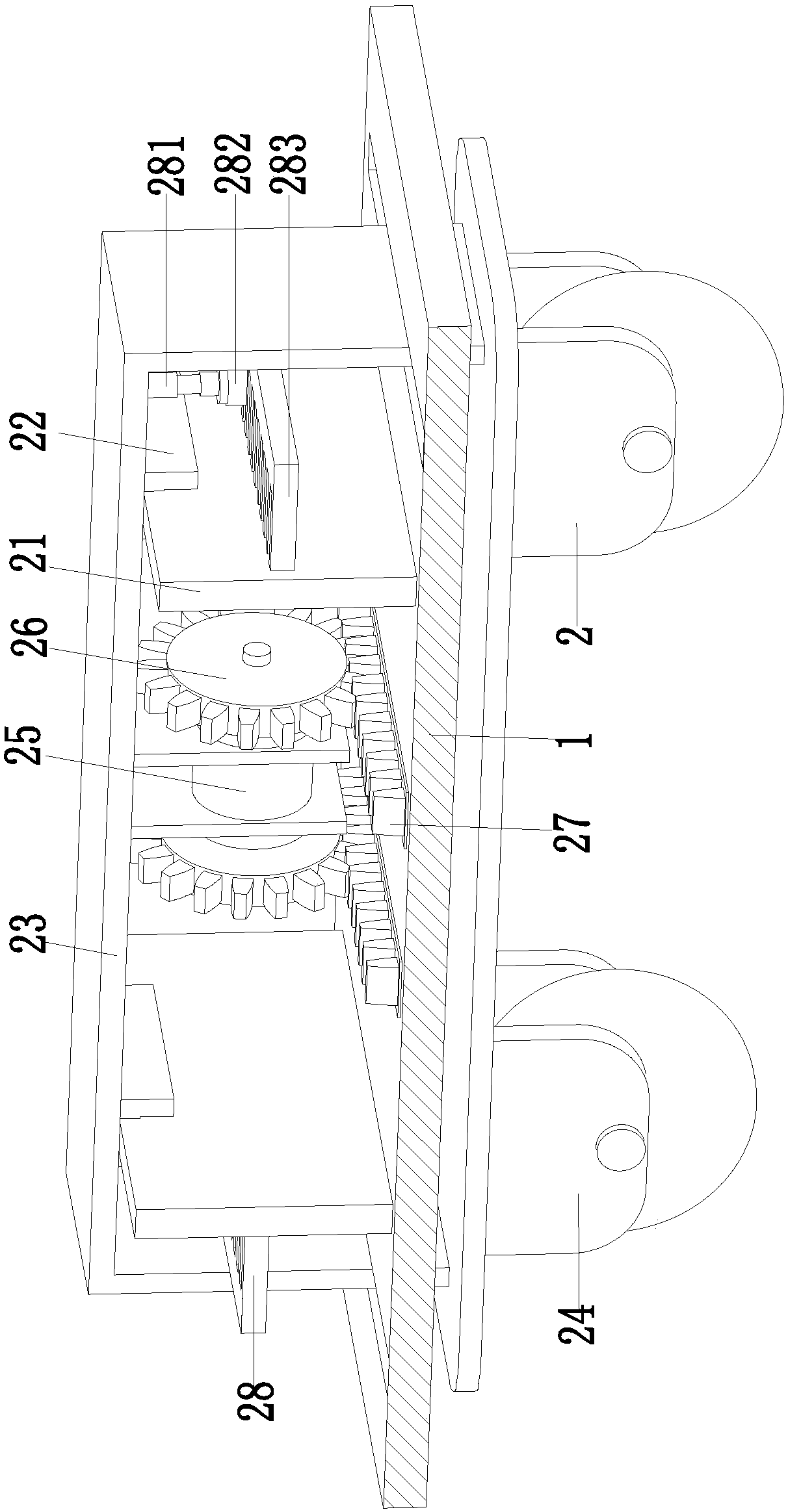

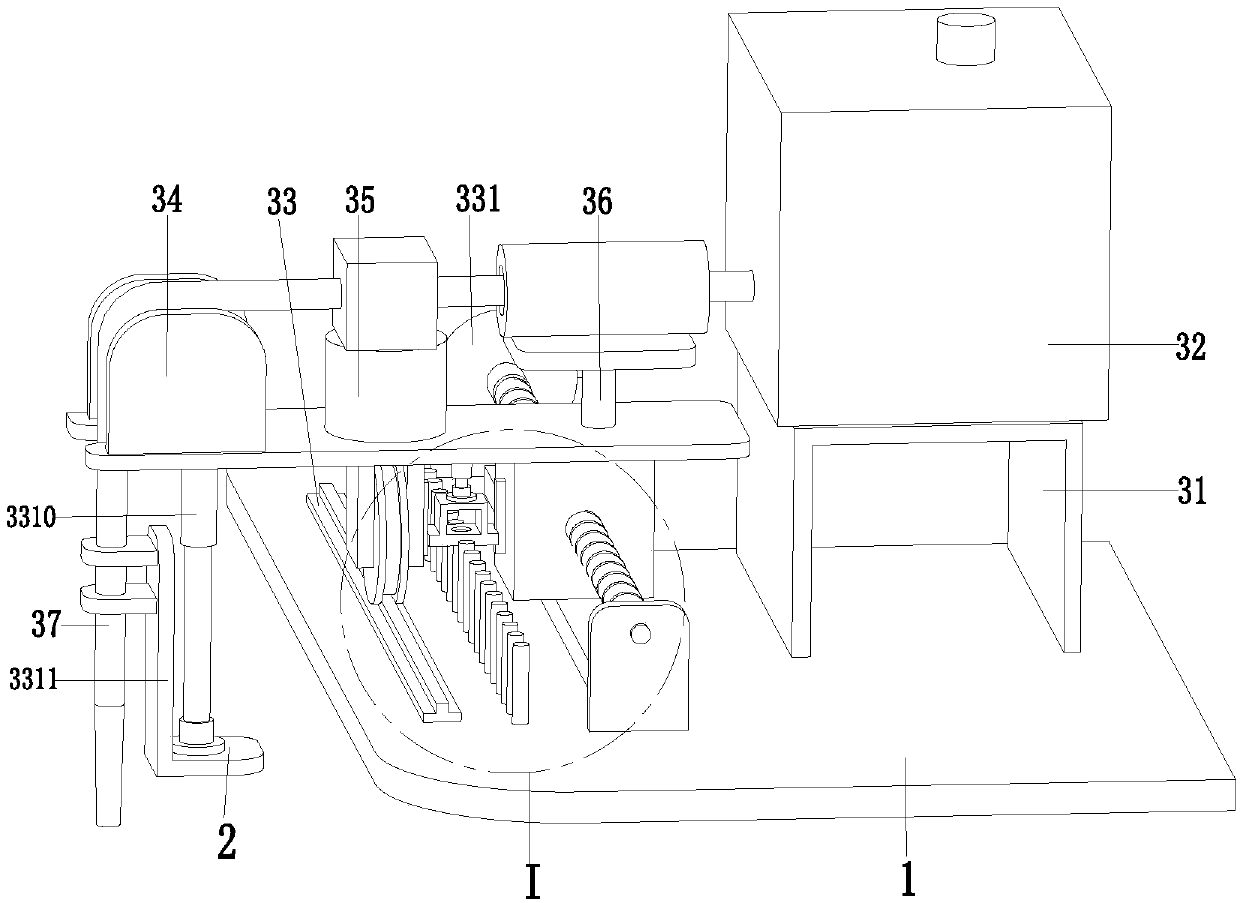

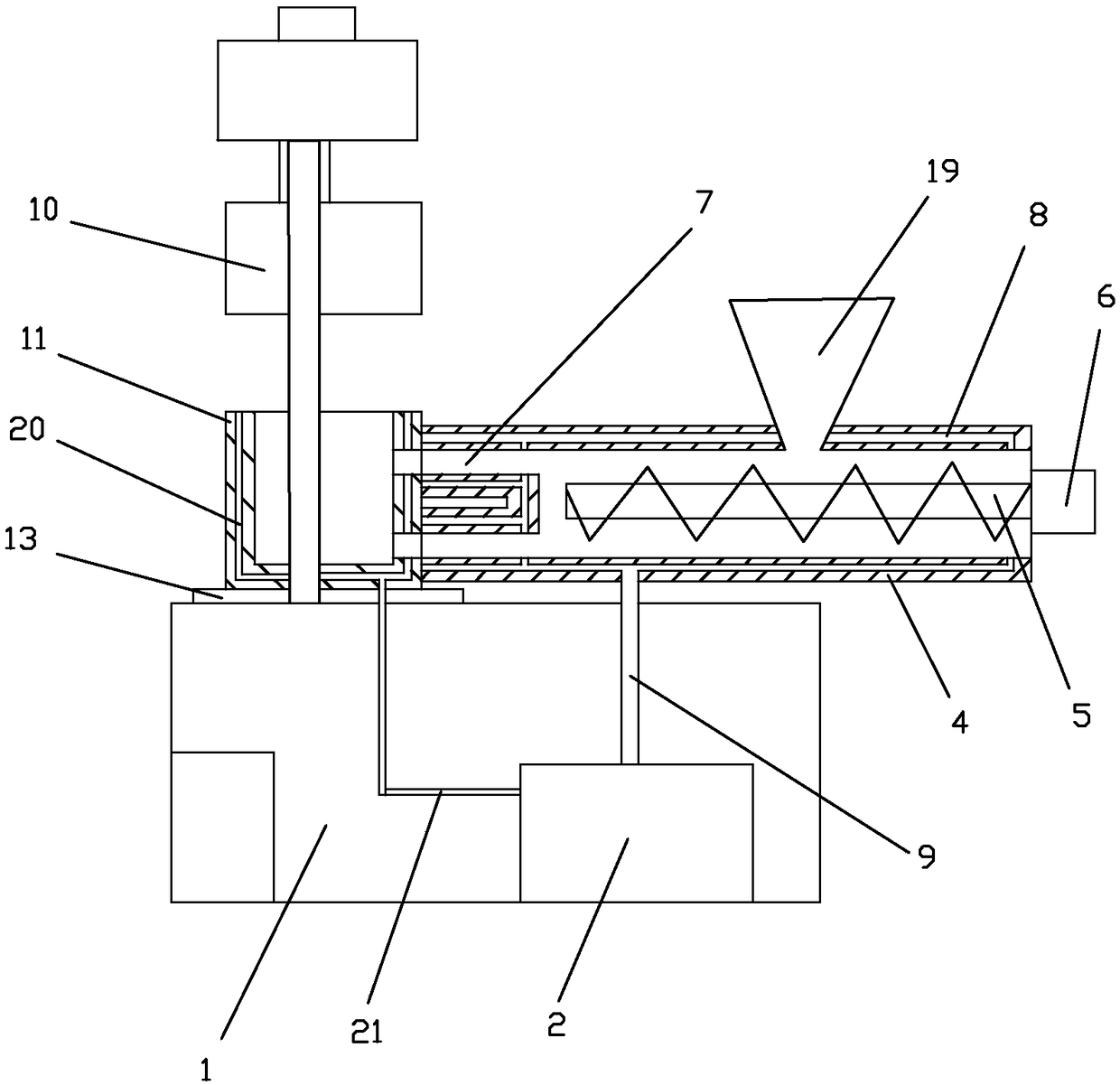

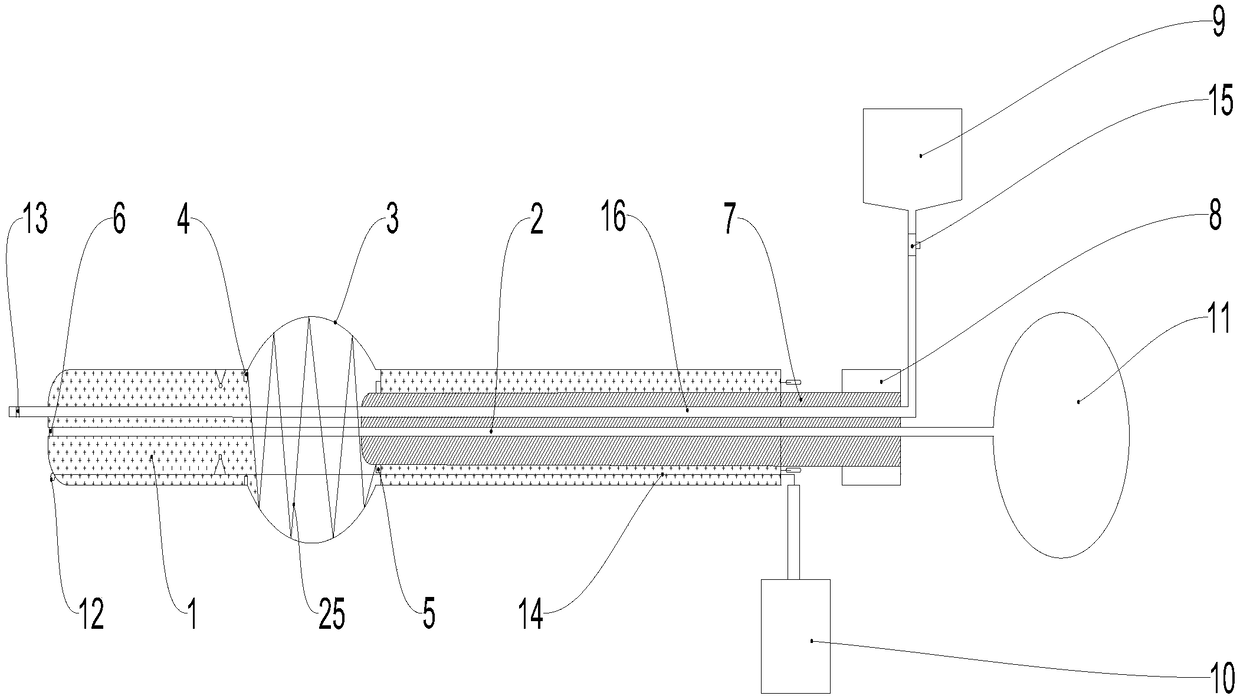

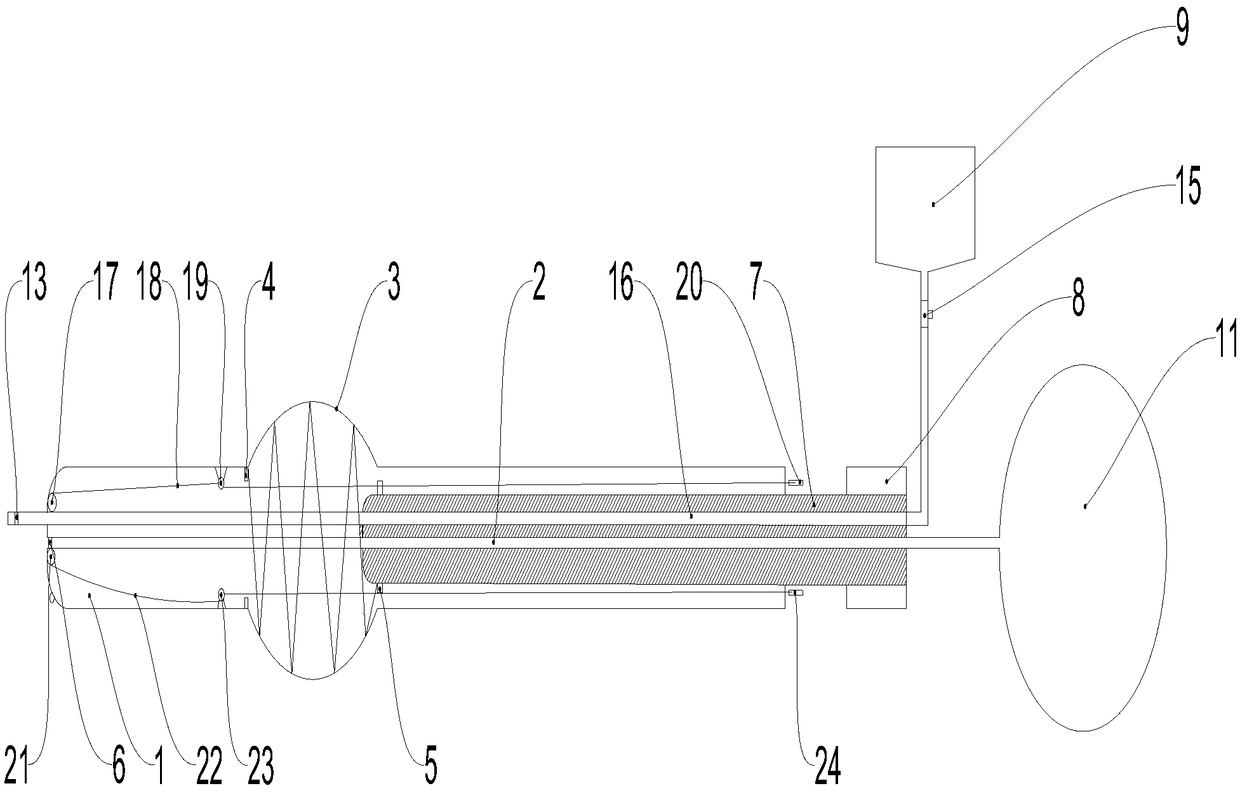

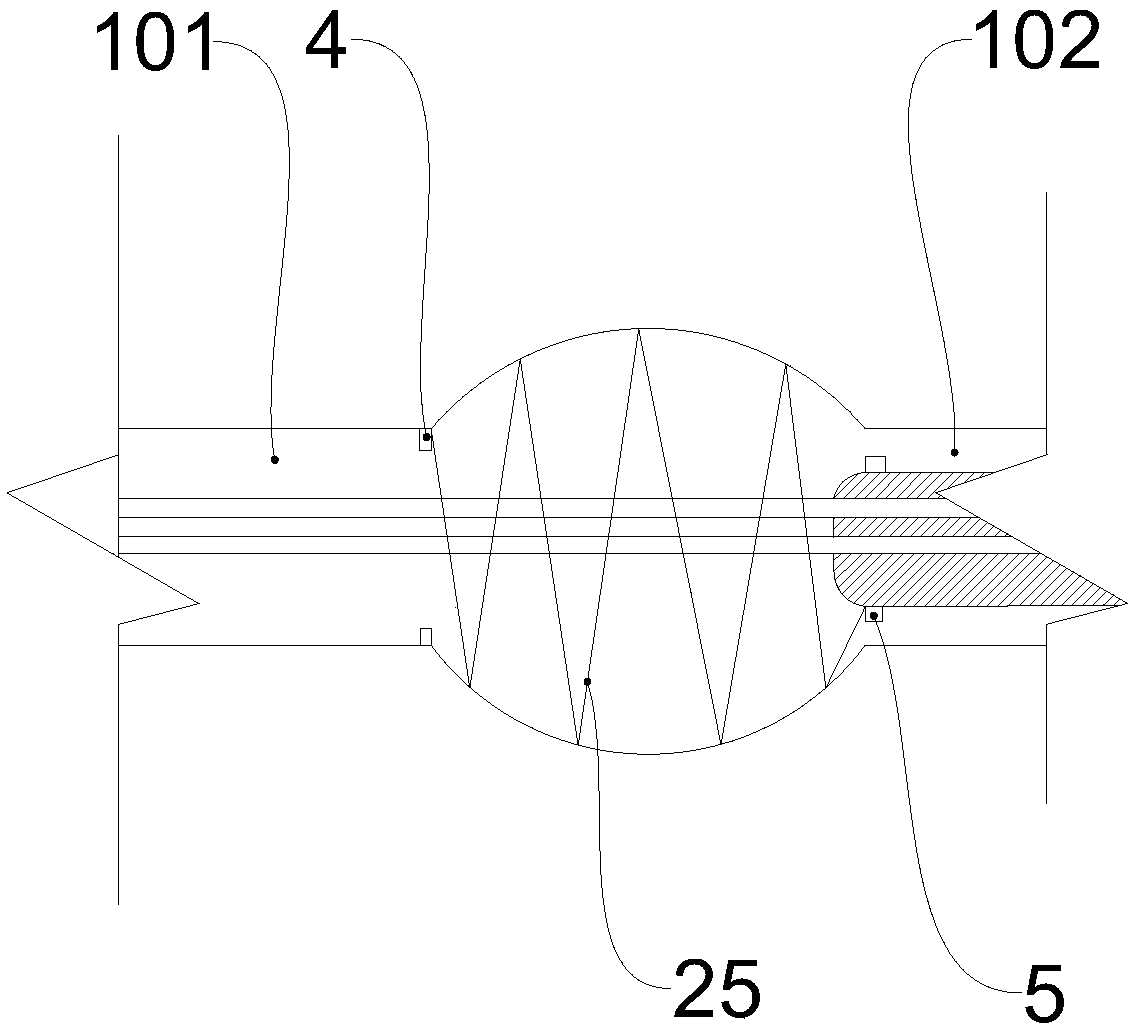

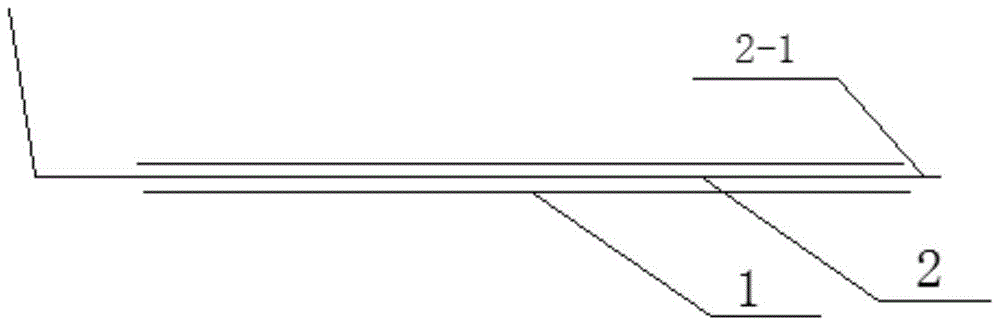

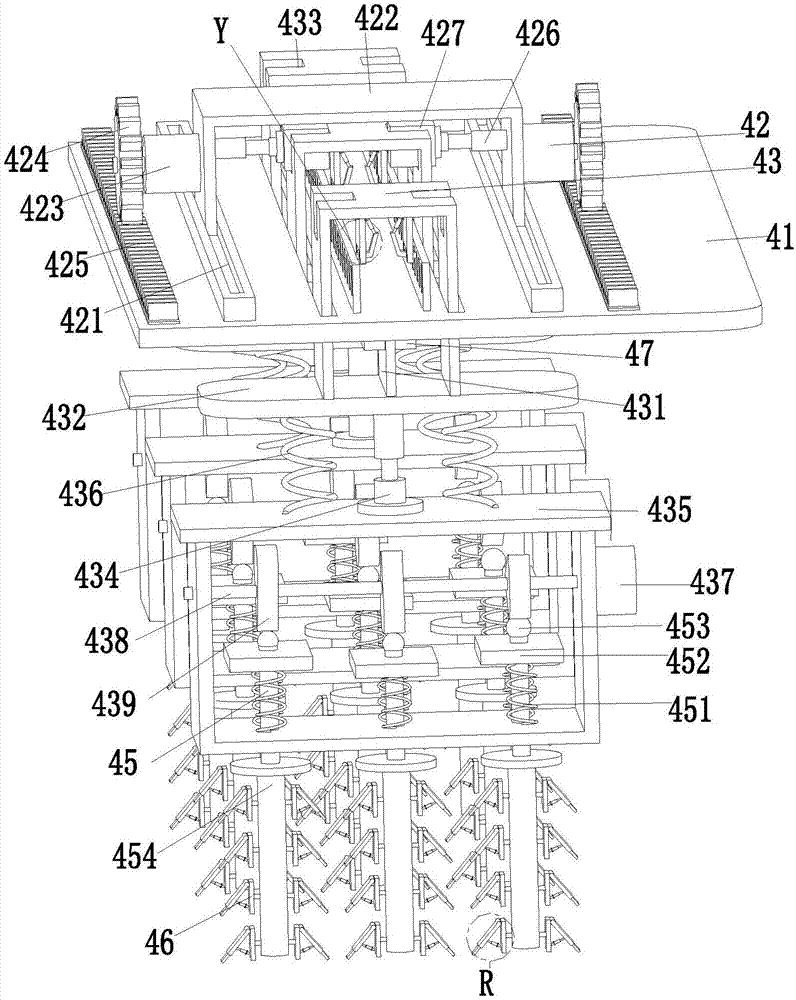

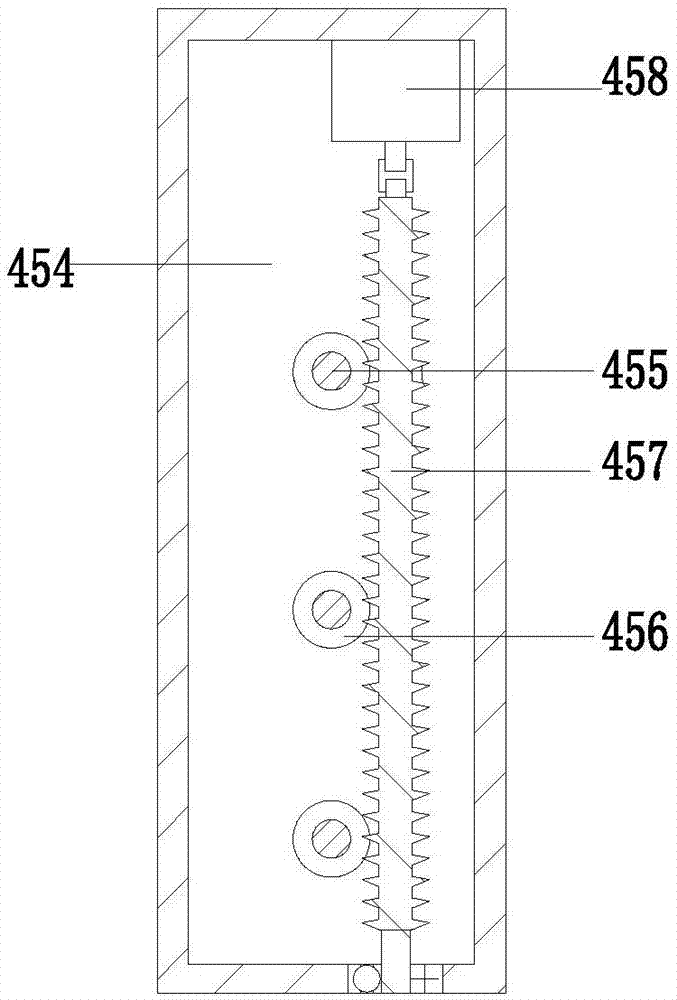

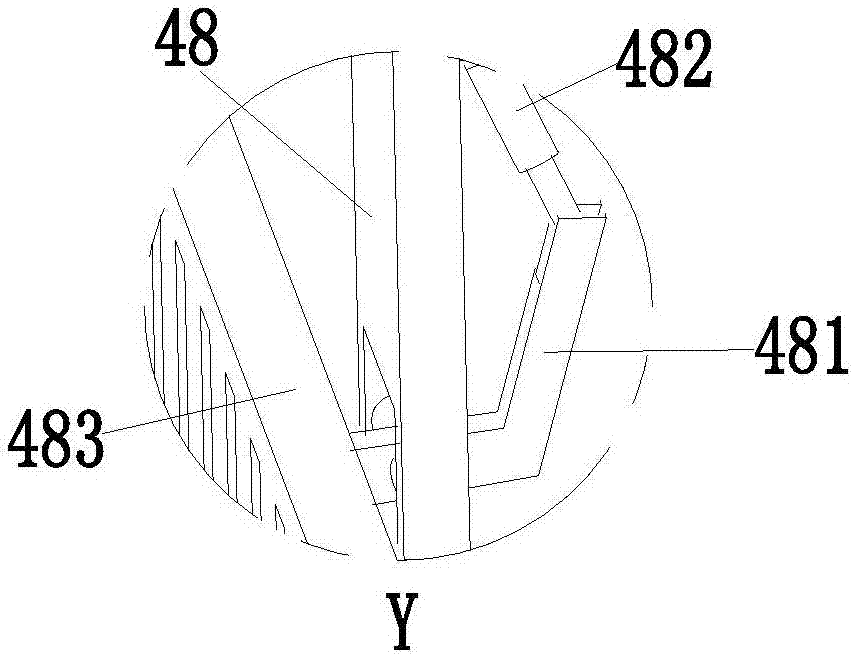

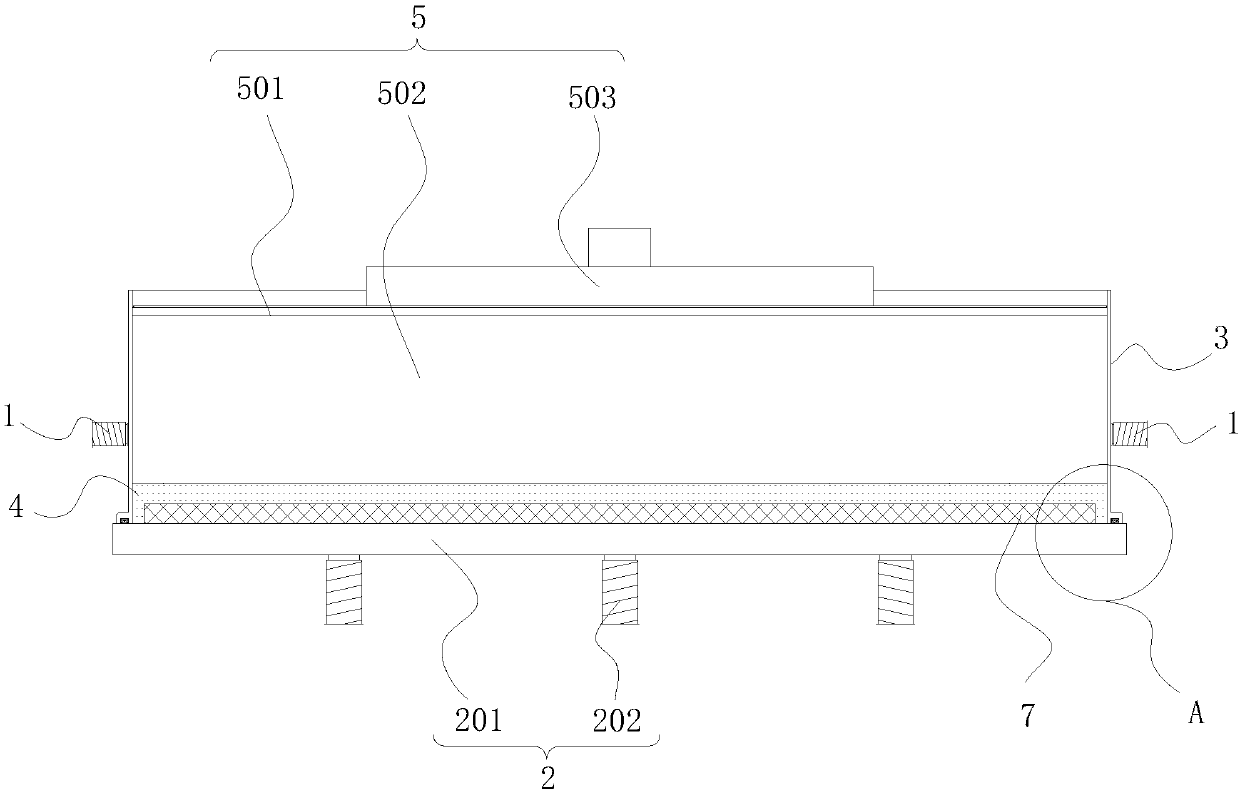

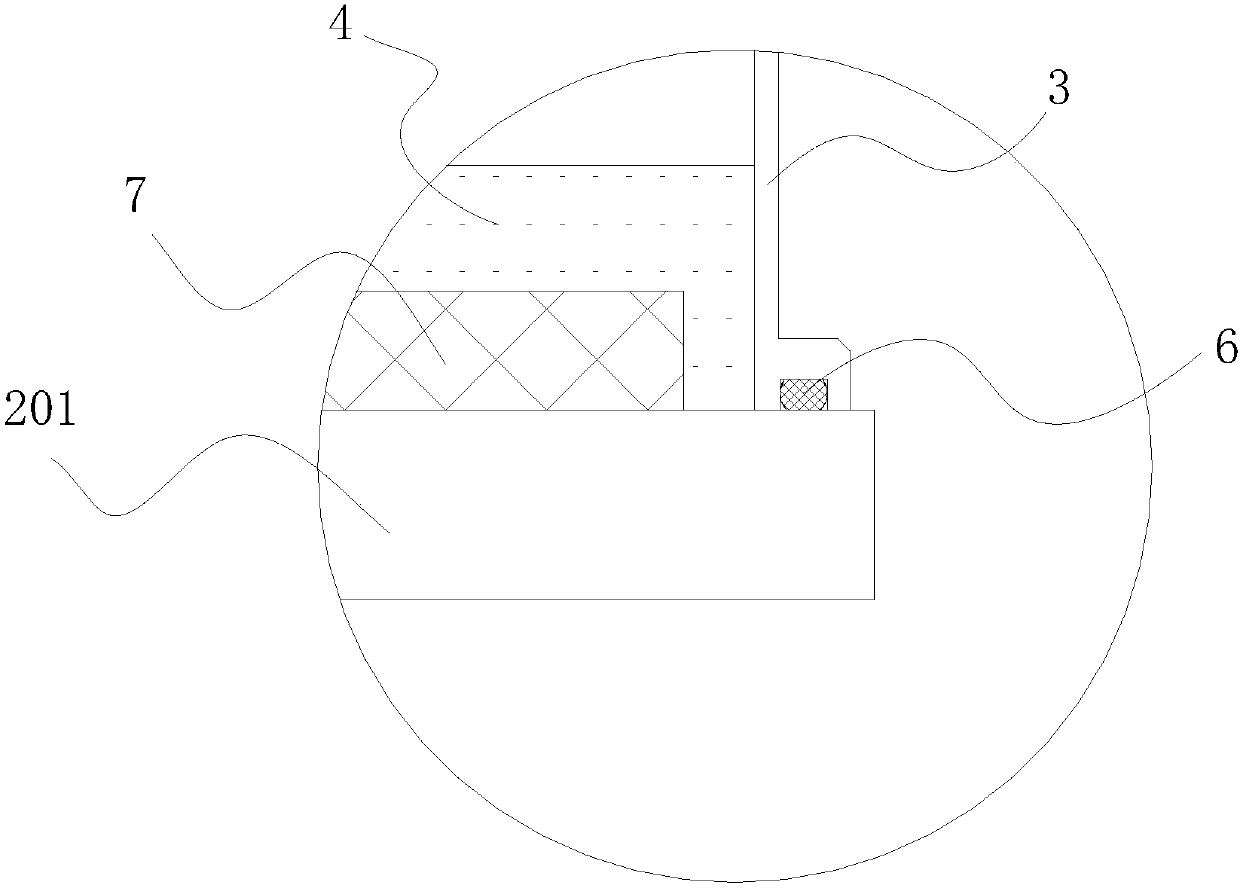

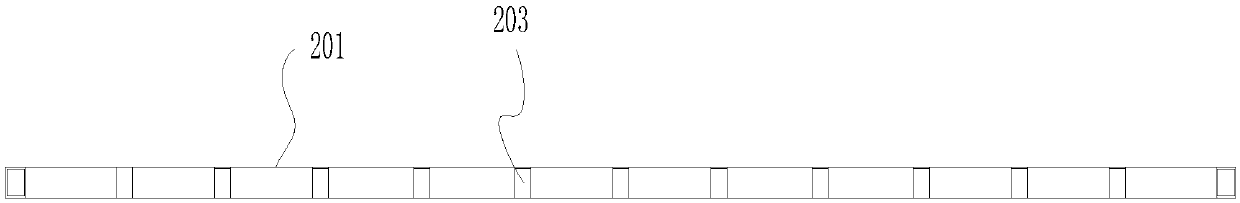

Reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine

InactiveCN107815972AStable jobThere is no security riskBridge erection/assemblyBridge materialsReinforced concreteEngineering

The invention relates to a reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine. The reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine comprises a base plate, wherein two pairs of movable regulating tanks are formed in the base plate, the two pairs of movable regulating tanks are symmetrically formed in the left side and the right side of the base plate, a movable regulating device is arranged in each pair of movable regulating tanks, a perfusion device is arranged at the front end of the base plate, a vibrating and compacting device is arranged at the rear end of the base plate, the perfusion device comprises a perfusion storage tank arranged on the base plate by virtue of a perfusion supporting frame, a discharging hole is formed in the lower side of the front end of the perfusion storage tank, and a perfusion regulating mechanism is arranged at the front end of the base plate. The reinforced concrete bridge cantilever bridge wet joint building and pouring intelligent machine provided by the invention can be used for solving the problems that concrete needs to be manually conveyed by virtue of existing movable equipment in an existing wet joint concrete pouring process, the poured concrete needs to be vibrated and compacted manually by virtue of existing vibrating equipment, a reinforcement cage needs to be avoided in a wet joint concrete pouring and vibrating process and the concrete can not be comprehensively vibrated by virtue of manpower.

Owner:吴秋敏

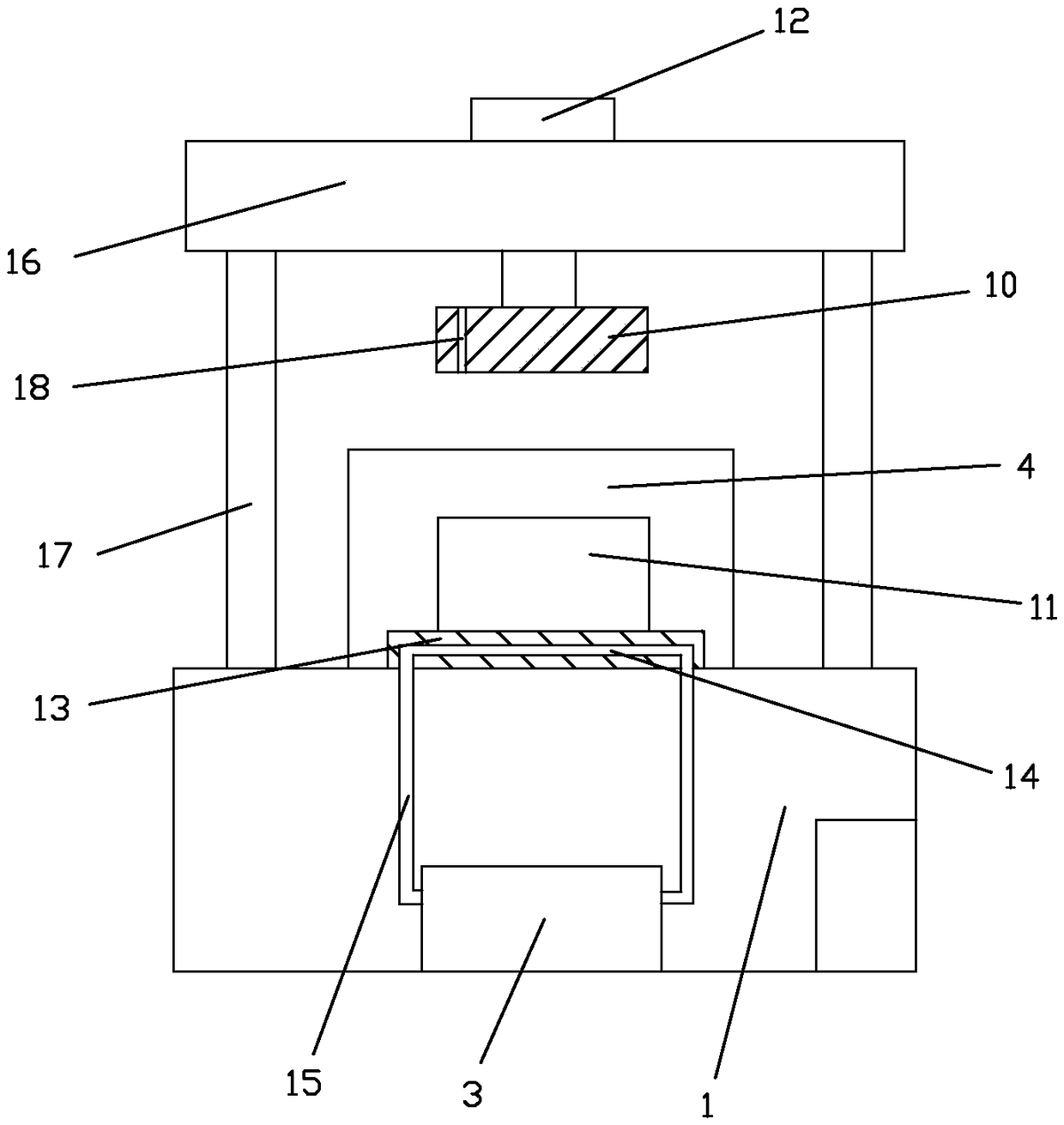

Injection molding machine

InactiveCN109228118AImprove cooling effectImprove perfusion efficiencyHeat conductingInjection molding machine

The invention discloses an injection molding machine. The injection molding machine comprises a machine seat, wherein an oil receiver and a water receiver are installed in the machine seat, an injection molding mechanism and a mold closing mechanism are installed above the machine seat, the injection molding mechanism comprises a heater and a threaded rod, the threaded rod is installed in the heater and connected with a servo motor, the heater is provided with two injection molding heads, the inner walls of the heater and the injection molding heads are provided with first cavities, and the first cavities are communicated with the oil receiver; the mold closing mechanism comprises an upper mold body and a lower mold body, the upper mold body is connected with a driving air cylinder, a moldcarrying disc used for installing the lower mold body is installed on the machine seat, a cooling pipeline is arranged in the mold carrying disc, and the cooling pipeline is communicated with the water receiver. The injection molding machine achieves injection through the two injection heads, has the high injection efficiency, and can avoid the situation that production cannot be operated becauseone injection head is abnormal. The injection molding heads are communicated with heat conducting oil, so that the situation that plastics is conveyed to the injection molding heads and cooled and solidified, and accordingly the injection molding heads are blocked is avoided. The mold carrying disc can be cooled through cooling water, thus the lower mold body is cooled, cooling of the plastic product is accelerated, and the production efficiency is improved.

Owner:鹤山市金利源五金塑料制品有限公司

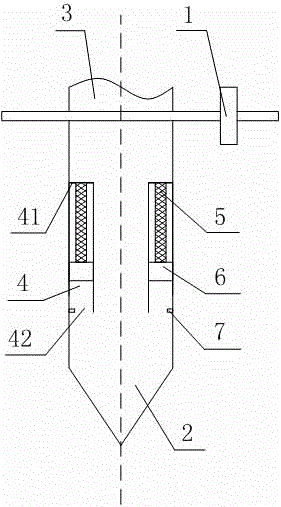

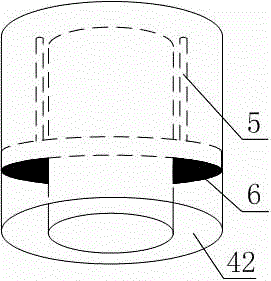

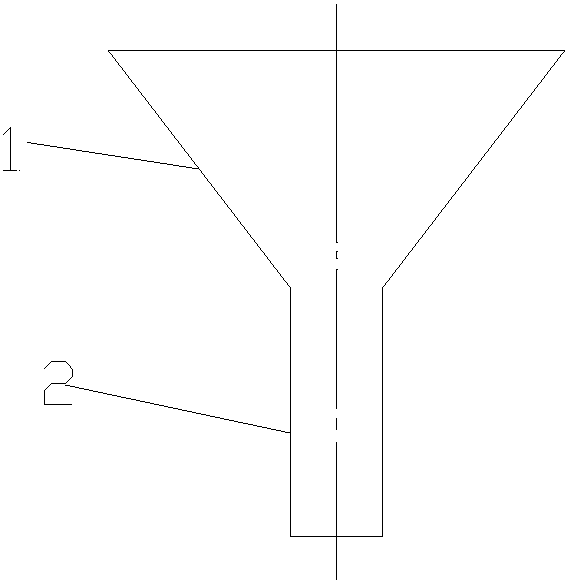

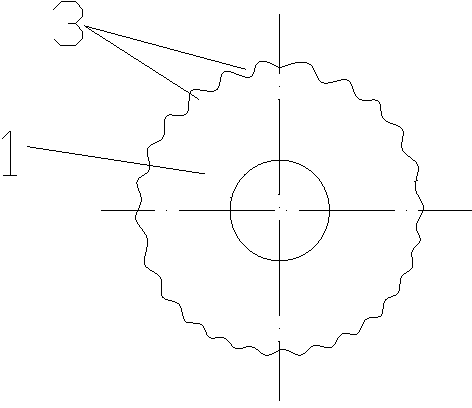

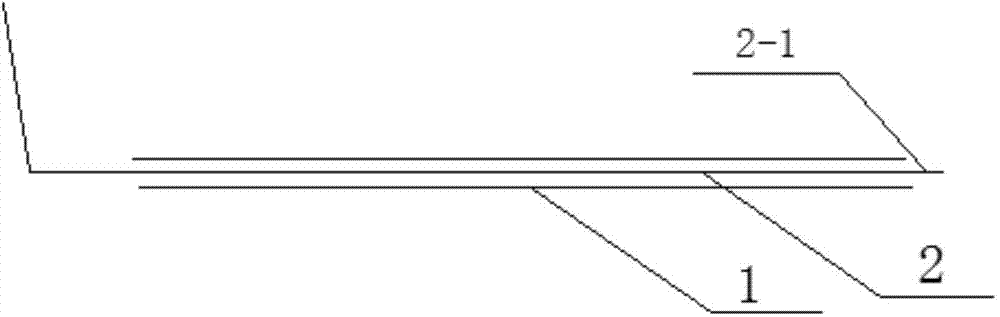

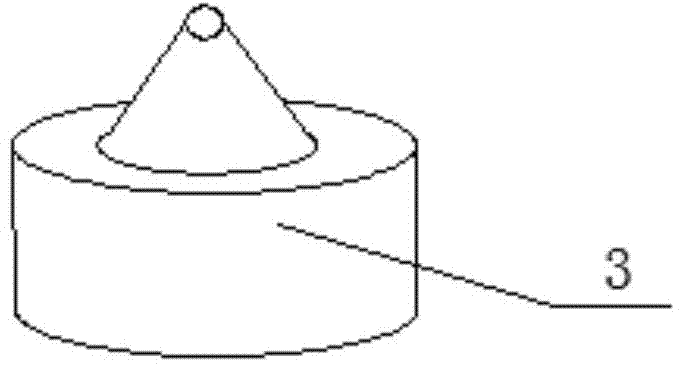

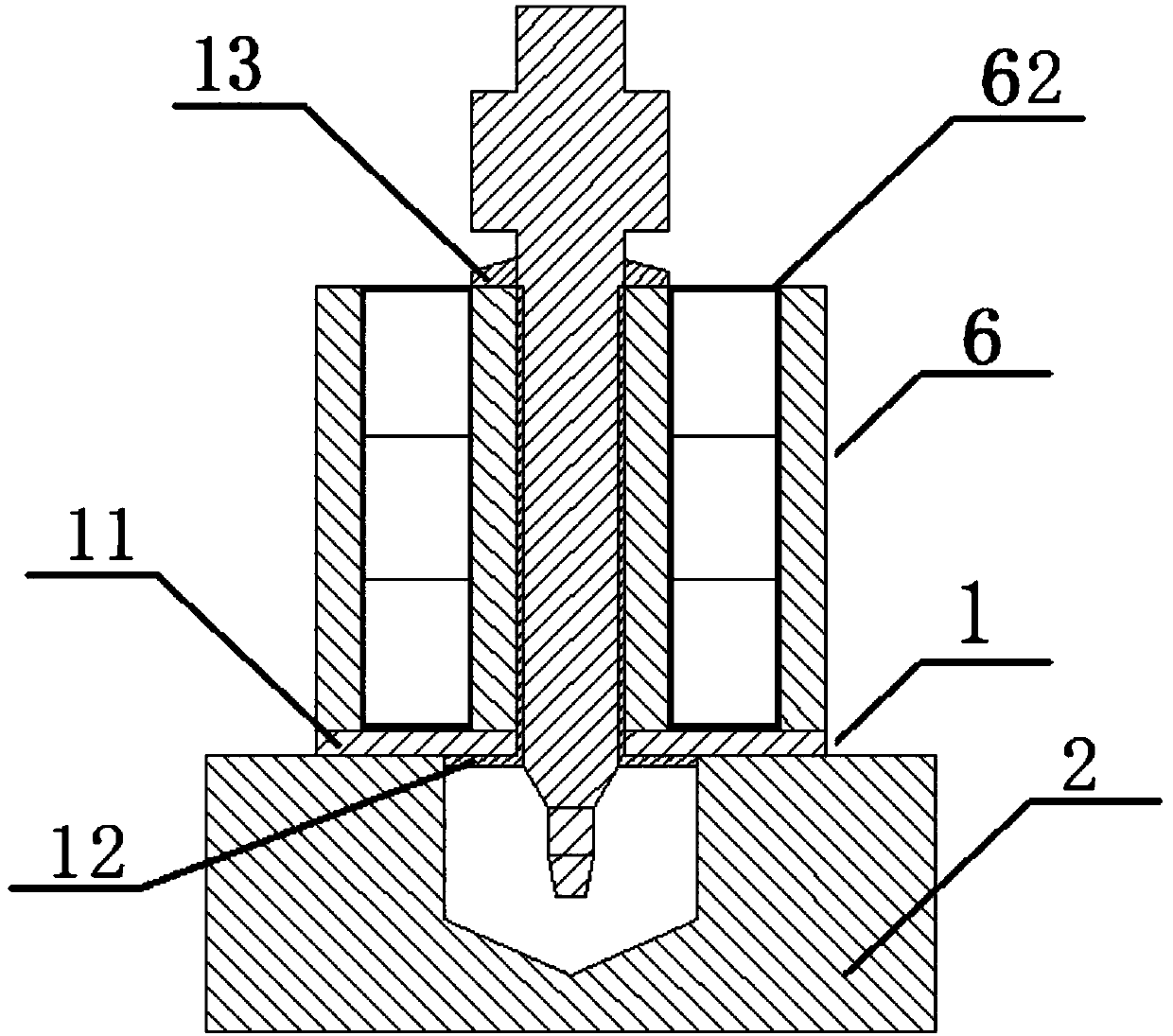

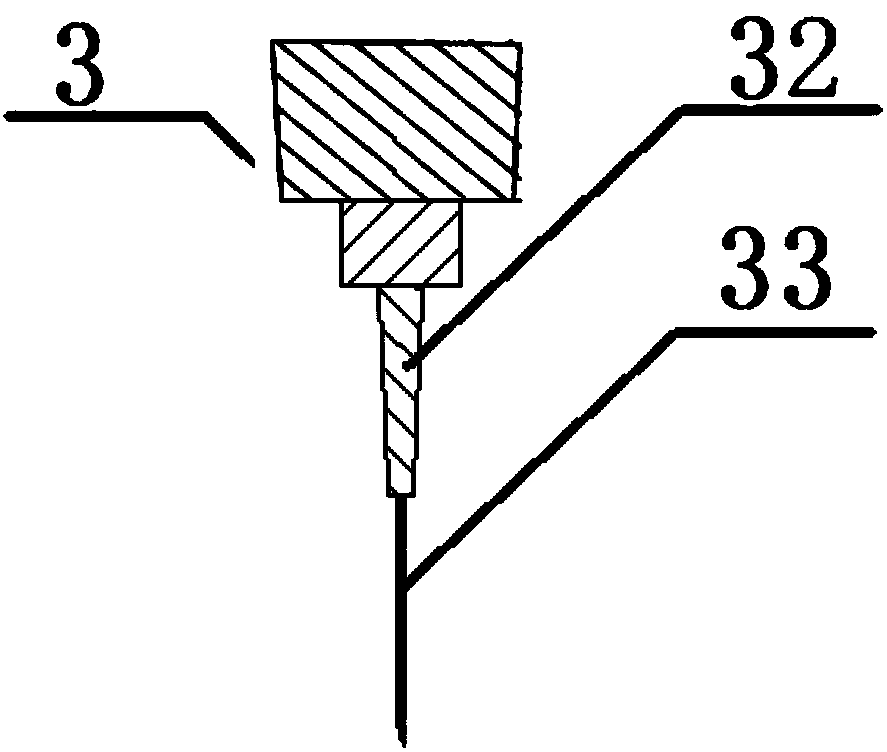

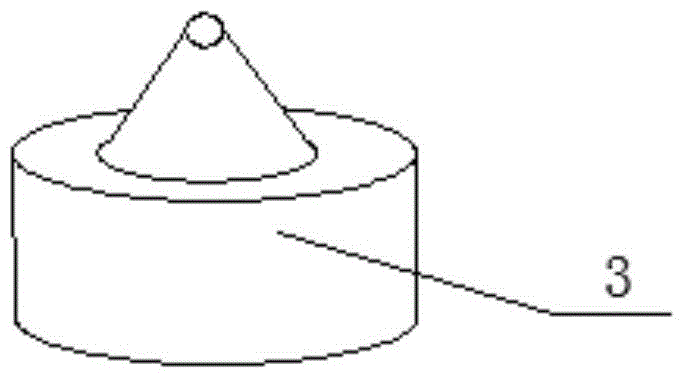

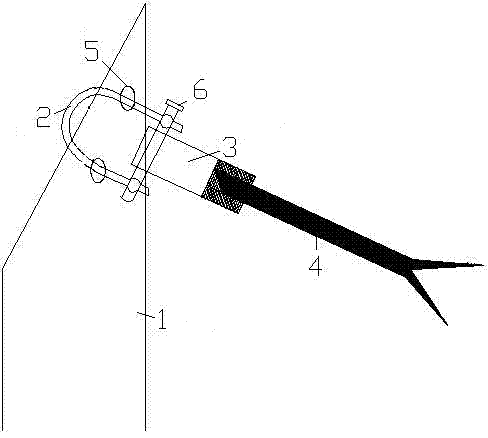

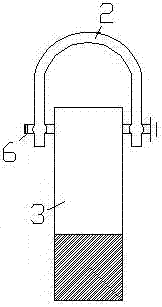

Supplied-liver quickly-fixed perfusion device for liver transplant

ActiveCN104770361AAvoid artificial differencesGuaranteed one-wayDead animal preservationLiver transplantsPerfused liver

The invention relates to the medicine field, especially relates to a perfusion device, which can rapidly carry out connection and perfusion when obtaining a supplied liver in an organism (liver) transplant operation, and specifically relates to a supplied-liver quickly-fixed perfusion device for liver transplant. The perfusion device comprises a puncture guiding device and a connecting ring for connecting a perfusion pipe. The puncture guiding device is a puncture steel wire, a contractible and magnetic ring is arranged on the top end of the steel wire, the top end of the connecting ring is in a conical shape, the bottom of the connecting ring is connected to a perfusion pipe, a unidirectional valve is arranged in the bottom of the connecting ring, the top of the connecting ring is made of an iron-containing material, the top of the connecting ring is matched with the contractible ring, and the top of the connecting ring and the contractible ring absorb on each other through magnetic force. The operation of the device is simple, practicable, and pertinent. The device is mainly used to carry out rapid perfusion when obtaining a supplied liver in a liver transplant operation, and is capable of rapidly and effectively performing liver perfusion so as to obtain a high quality liver.

Owner:ZHEJIANG UNIV

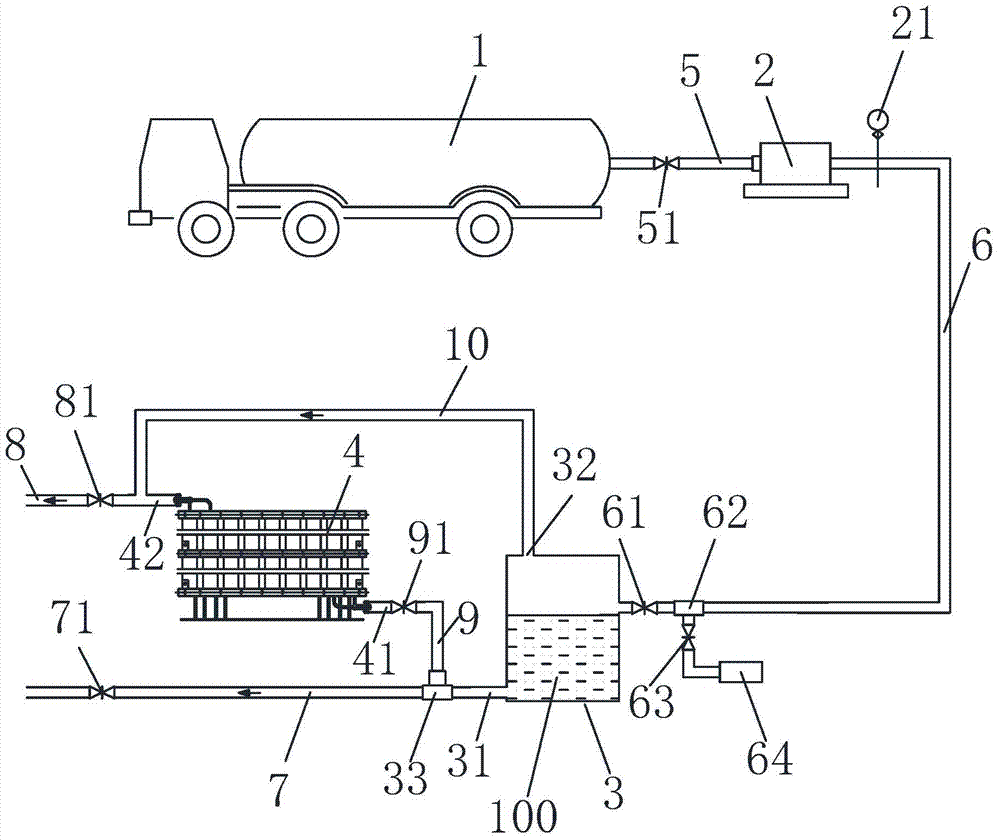

Mine liquid nitrogen fire preventing and extinguishing system and using method thereof

InactiveCN104747226AAvoid cloggingImprove perfusion efficiencyDust removalFire preventionLiquid nitrogen containerBuffer tank

The invention discloses a mine liquid nitrogen fire preventing and extinguishing system. The system comprises a liquid nitrogen container tank vehicle, a low-temperature liquid pump, a buffer tank and a liquid nitrogen gasification device. The liquid nitrogen container tank vehicle is connected with the low-temperature liquid pump through a conveying hose. The conveying hose is provided with a first control valve. The low-temperature liquid pump is connected with the buffer tank through a thermal insulation pipe. The thermal insulation pipe is provided with a vacuum valve. A second control valve is arranged between the vacuum valve and the buffer tank. The vacuum valve is connected with a low-temperature vacuum pump. The bottom of the buffer tank is provided with a buffer tank bottom opening. The buffer tank bottom opening is connected with a liquid nitrogen injection pipe. The liquid nitrogen injection pipe is provided with a third control valve. The buffer tank bottom opening is further connected with a conveying pipe. The conveying pipe is connected with an input opening of the liquid nitrogen gasification device and provided with a fourth control valve. An output opening of the liquid nitrogen gasification device is connected with a gaseous nitrogen injection pipe. The gaseous nitrogen injection pipe is provided with a fifth control valve. The invention further discloses a using method for preventing and extinguishing fire through the mine liquid nitrogen fire preventing and extinguishing system.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

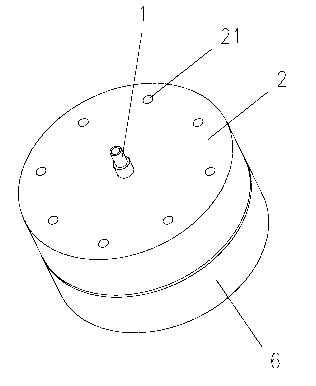

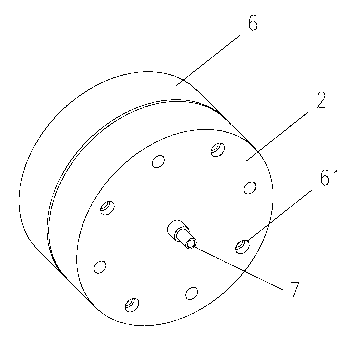

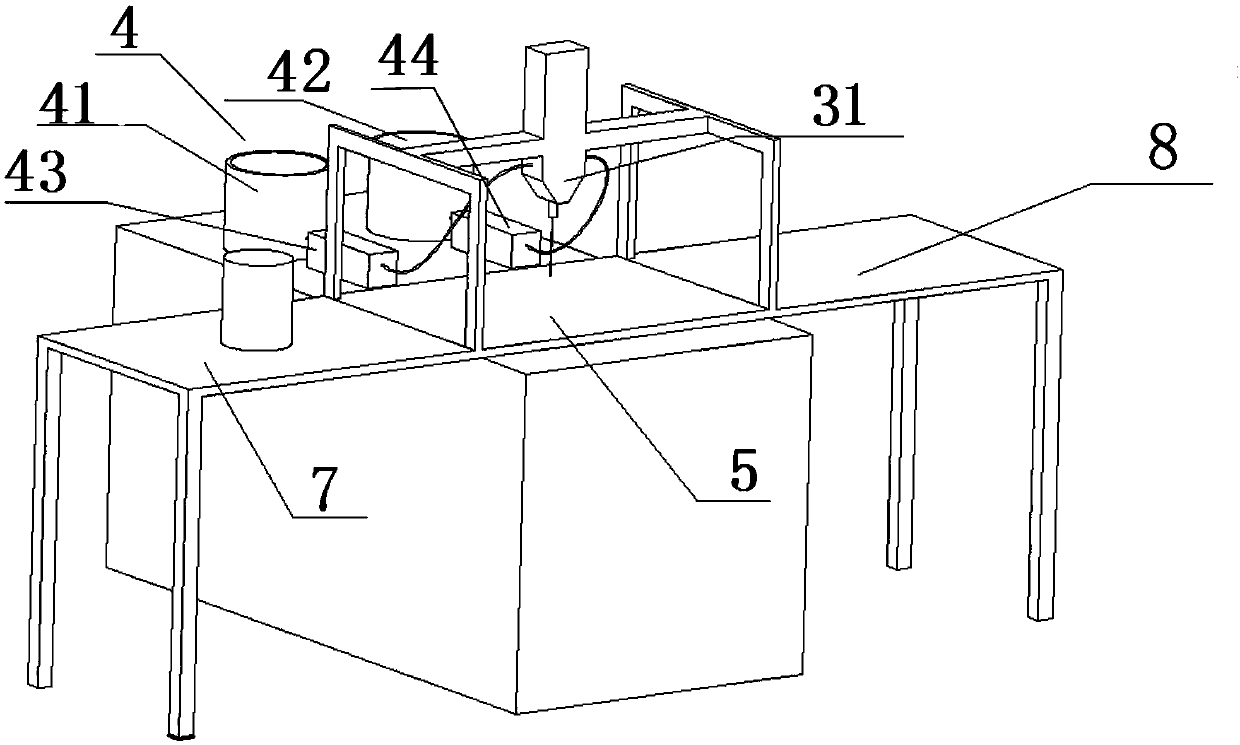

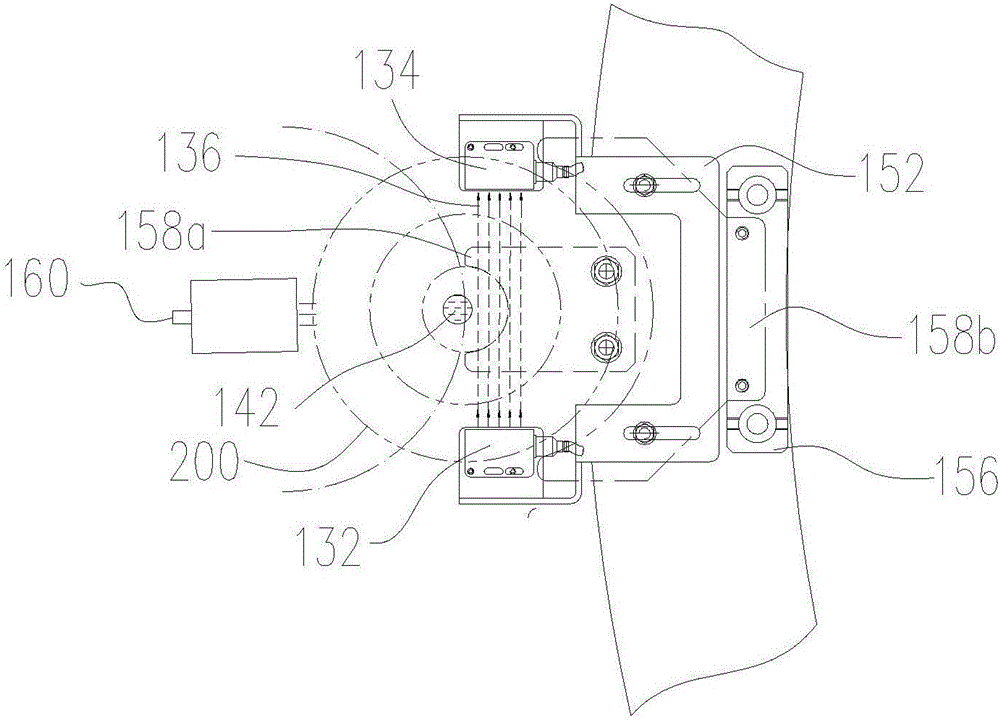

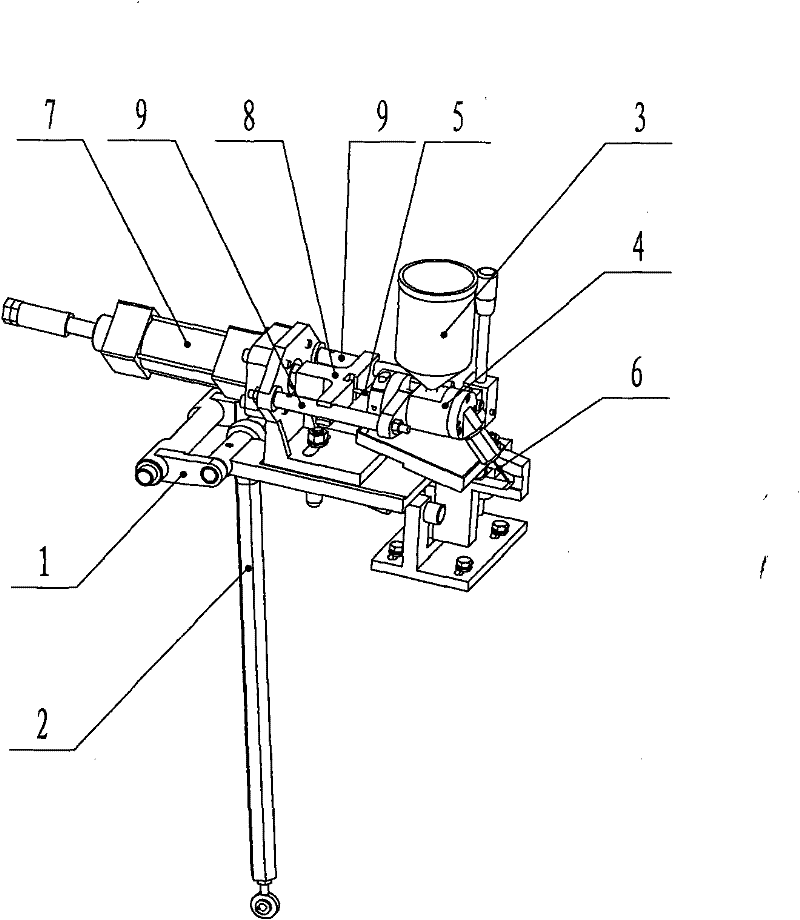

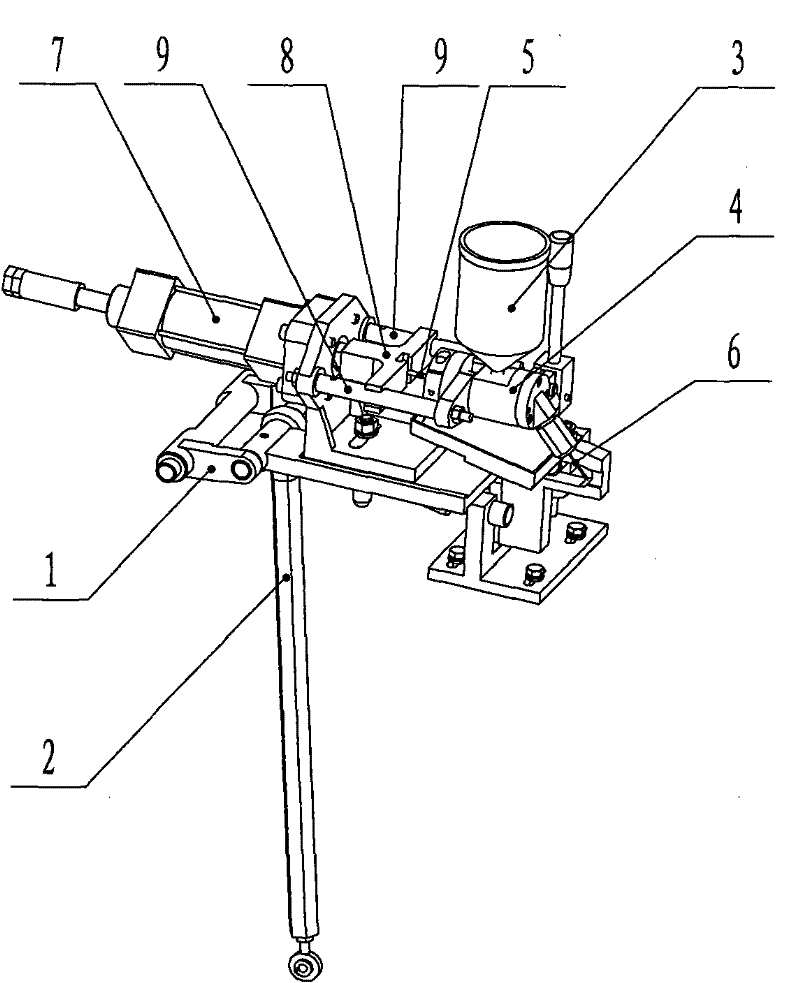

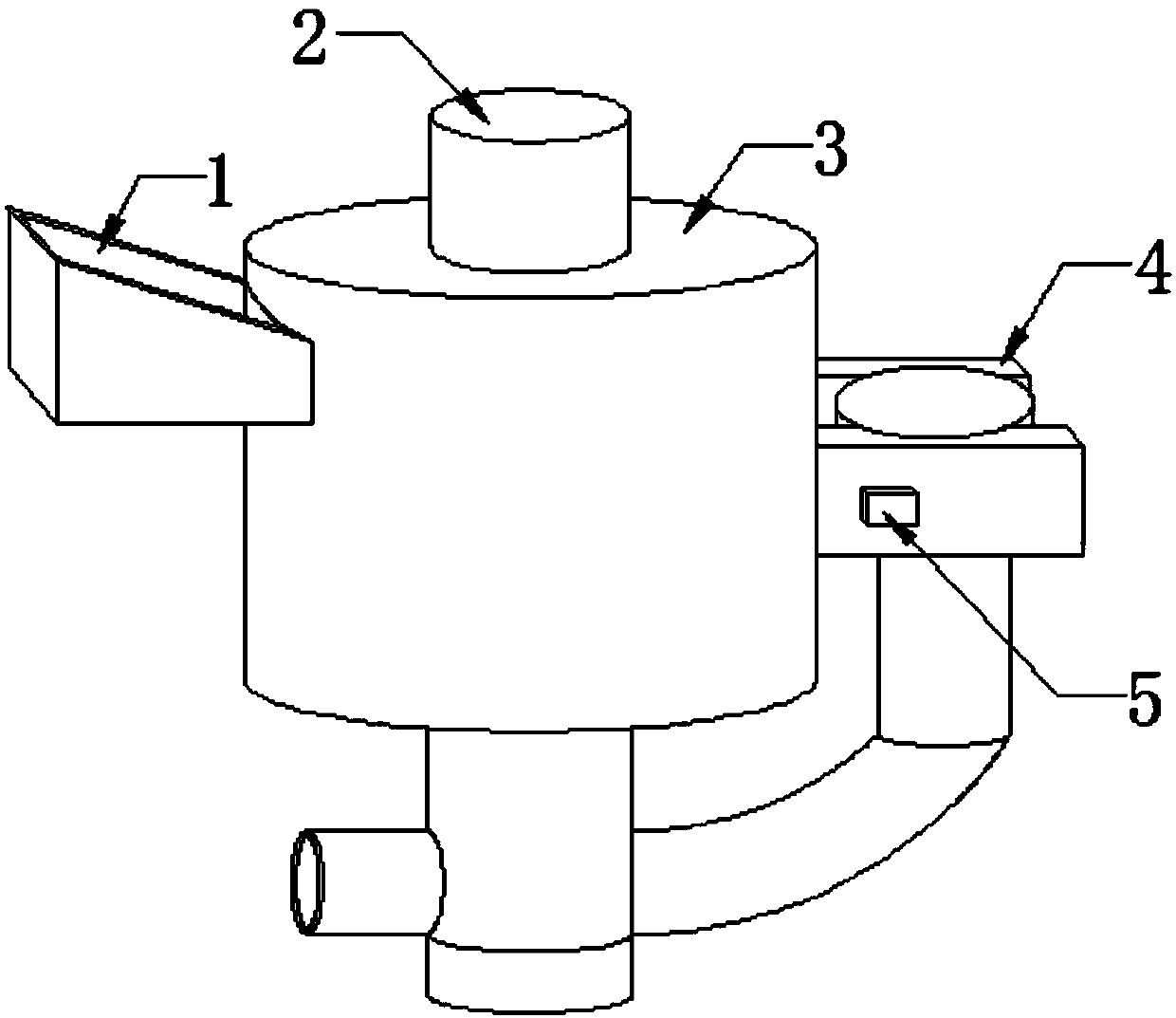

Glue filling device of permanent-magnet synchronous-motor rotor assembly and flue filling method of glue filling device

PendingCN107565773AHigh precisionImprove perfusion efficiencyLiquid surface applicatorsManufacturing stator/rotor bodiesRotor magnetsPermanent magnet synchronous motor

The invention discloses a glue filling device of a permanent-magnet synchronous-motor rotor assembly and a flue filling method of the glue filling device. The glue filling device comprises a rotor assembly fixing device, a positioning fixture, a glue filling device body, a glue storing device and a glue filling device stand. The glue filling method includes the steps of 1), adjusting the positioning fixture in position; 2), fixedly installing a front end plate on the positioning fixture; 3), fixing the rotor assembly to the front end plate and a rotor support through a positioning tooling; 4),starting a triaxial manipulator; 5), driving the triaxial manipulator to move to a glue filling point according to relative positions of the glue filling point in a magnetic steel notch in the rotorassembly and the positioning point; 6), driving a first transfer pump and a second transfer pump to fill glue liquor to a glue mixture tube and an injection needle for glue filling. With the method, precision in glue filling can be effectively improved, glue filling efficiency can be effectively improved, and the glue filling method is simple in operation.

Owner:NANJING YUEBO ELECTRIC DRIVE SYST CO LTD

Alveolar lavage fluid collector

PendingCN108888818ARealize the collectionSolve absorptionCannulasEnemata/irrigatorsAlveolar lavage fluidEngineering

The invention relates to the field of medical instruments, in particular to an alveolar lavage fluid collector. The alveolar lavage fluid collector comprises an outer single-cavity pipe with an opening in the tail end, an inner single-cavity pipe, a water suction pipe, a perfusion pipe and a retractable mechanism control device; the inner single-cavity pipe is disposed in the outer single-cavity pipe, a cavity is formed between the inner single-cavity pipe and the outer single-cavity pipe, the top of the outer single-cavity pipe is used for being inserted into the body of a patient, the innersingle-cavity pipe penetrates through the tail end of the outer single-cavity pipe to be connected to the retractable mechanism control device, and the water suction pipe is disposed in an inner cavity of the inner single-cavity pipe; one end of the water suction pipe sequentially penetrates through the inner single-cavity pipe and the outer single-cavity pipe and is communicated with the top of the outer single-cavity pipe. The end, away from the outer single-cavity pip, of the water suction pipe sequentially penetrates through the inner single-cavity pipe and the retractable mechanism control device and extends out of the retractable mechanism control device to be communicated with a negative pressure collector.

Owner:GUIZHOU PROVINCIAL PEOPLES HOSPITAL

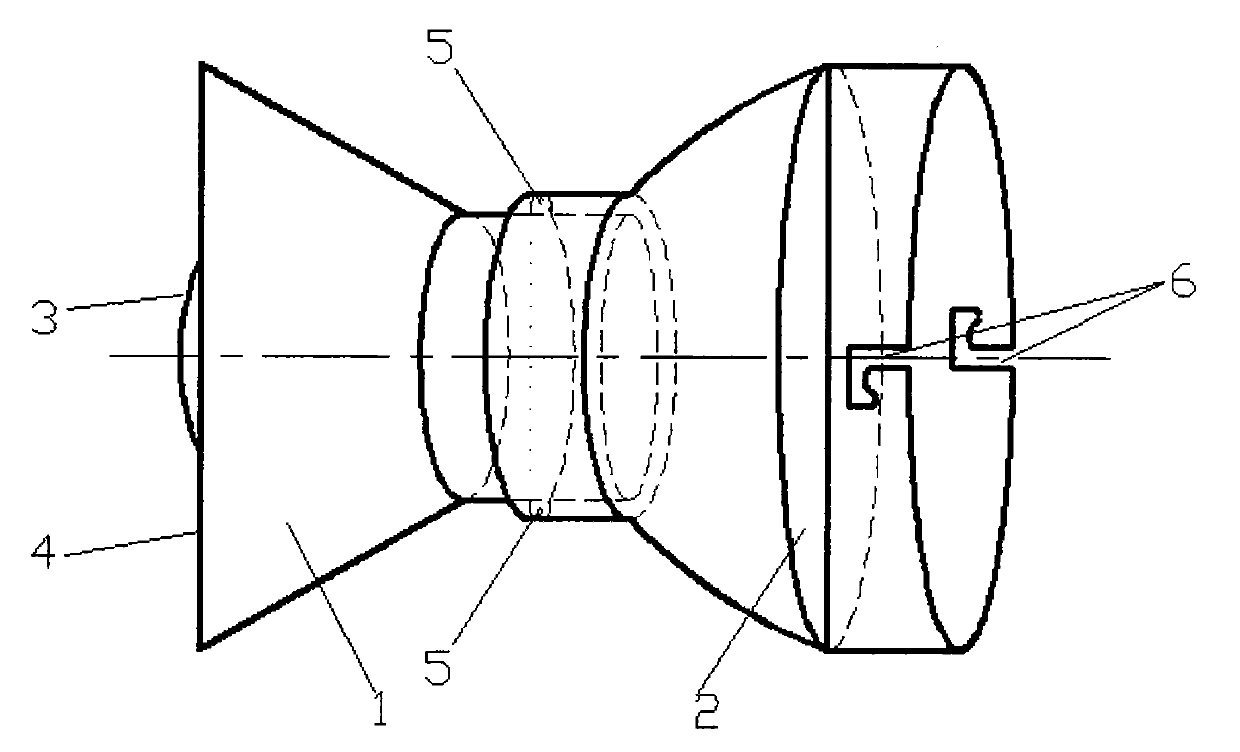

Donor Liver Rapid Fixed Perfusion Device in Liver Transplantation

ActiveCN104770361BAvoid artificial differencesGuaranteed one-wayDead animal preservationOrgan transplantationSplit liver transplantation

The invention relates to the medicine field, especially relates to a perfusion device, which can rapidly carry out connection and perfusion when obtaining a supplied liver in an organism (liver) transplant operation, and specifically relates to a supplied-liver quickly-fixed perfusion device for liver transplant. The perfusion device comprises a puncture guiding device and a connecting ring for connecting a perfusion pipe. The puncture guiding device is a puncture steel wire, a contractible and magnetic ring is arranged on the top end of the steel wire, the top end of the connecting ring is in a conical shape, the bottom of the connecting ring is connected to a perfusion pipe, a unidirectional valve is arranged in the bottom of the connecting ring, the top of the connecting ring is made of an iron-containing material, the top of the connecting ring is matched with the contractible ring, and the top of the connecting ring and the contractible ring absorb on each other through magnetic force. The operation of the device is simple, practicable, and pertinent. The device is mainly used to carry out rapid perfusion when obtaining a supplied liver in a liver transplant operation, and is capable of rapidly and effectively performing liver perfusion so as to obtain a high quality liver.

Owner:ZHEJIANG UNIV

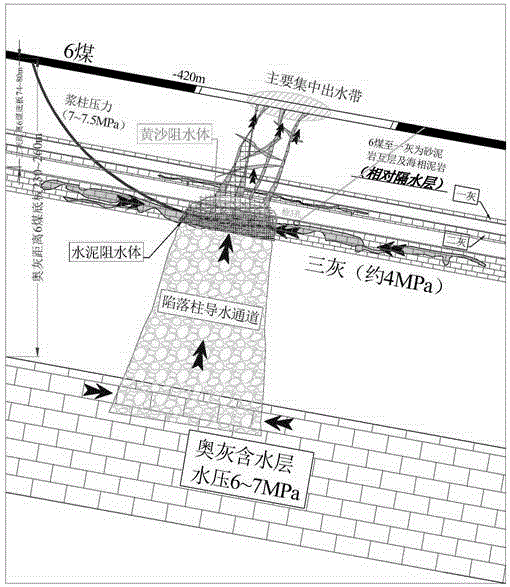

Difficult mining coal seam bottom plate thin layer limestone high-pressure strong aquifer karst fissure aggregate perfusion method

InactiveCN106593489AEffective surgeEffective blockingUnderground chambersTunnel liningKarstThin layer

The invention discloses a difficult mining coal seam bottom plate thin layer limestone high-pressure strong aquifer karst fissure aggregate perfusion method. The difficult mining coal seam bottom plate thin layer limestone high-pressure strong aquifer karst fissure aggregate perfusion method comprises the following steps that (1) aggregates are perfused at an opening of a drilling horizontal section, and aggregate perfusion is stopped after hole sealing of the aggregates; (2) hole sweeping is conducted, and then mixed slurry is perfused; (3) grouting is continued after an orifice device is added at a drilling opening, and cement slurry is injected; and (4) the cement slurry is injected to the opening, and when an orifice is at the normal pressure, perfusion is continued for 1 h. By adopting the technical scheme, the aggregate perfusion technology can rapidly fill large karst fissures; by means of the filling mode, a water resistant body is formed after aggregate filling, the filling process is shortened, and meanwhile, the defect that the perfusion plugging aggregates cannot reach the fissures easily due to repeated hole sweeping in the prior art is effectively overcome; the perfusion efficiency is improved; working face extraction is ensured; the water burst phenomenon is avoided; and the mining safety is ensured.

Owner:HUAIBEI MINING IND

Quantitative filling device and quantitative filling method

ActiveCN105060217AHigh filling accuracyQuick responseFilling without pressureBiomedical engineeringTransmitter

The invention relates to a quantitative filling device and a quantitative filling method. The quantitative filling device comprises a filling pipe, a switching valve, a photoelectric detection device and a controller. The filling pipe is provided with a water outlet. The switching valve is communicated with the filling pipe. The photoelectric detection device comprises a light source transmitter and a receiver, wherein the light source transmitter and the receiver are arranged oppositely. The light source transmitter and the receiver are both arranged below the water outlet. The controller is electrically connected with the photoelectric detection device and the switching valve. After a container reaches the quantitative liquid level, the valve can be quickly closed through the quantitative filling device, the filling accuracy is high, and the response is quick; meanwhile, the anti-interference capacity of the photoelectric detection device is high, and cost is low; and the application occasions of the quantitative filling device can be effectively guaranteed, the reliability of the quantitative filling device can be improved, and the service life of the quantitative filling device can be prolonged.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

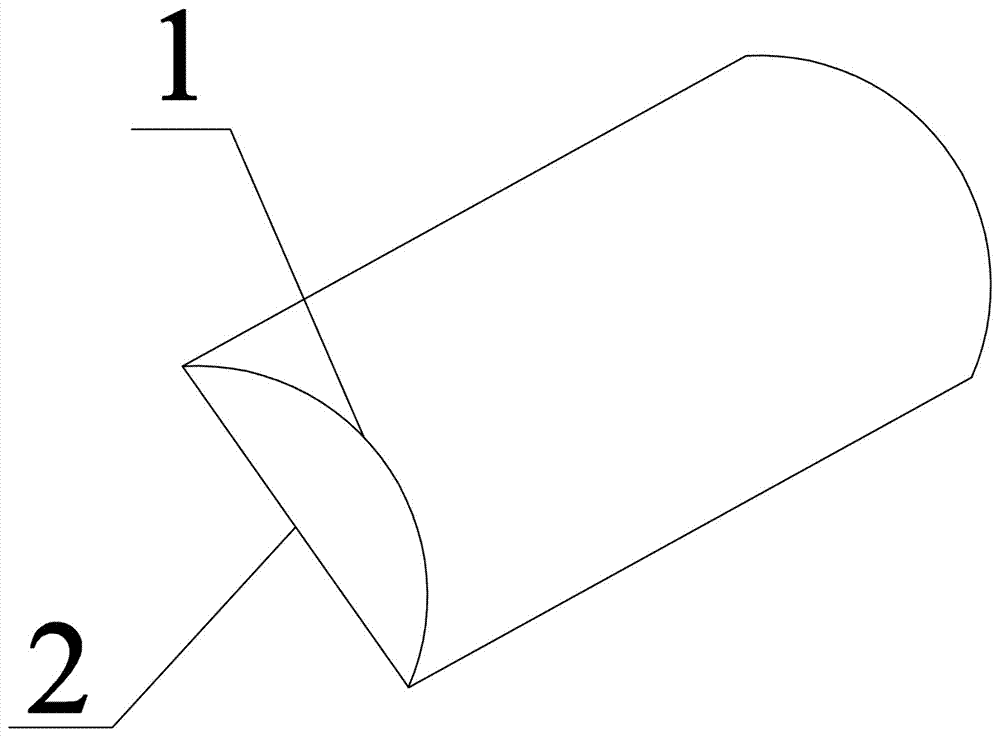

A potting process of metallized polypropylene film dielectric capacitor

InactiveCN105820512BUniform perfusionStable flowThin/thick film capacitorStacked capacitorsDielectricEpoxy

The invention discloses an injection process for a metalized polypropylene film dielectric capacitor .The injection process includes the following steps that an injection head for an epoxy resin filling adhesive is closely attached to the inner wall of a capacitor shell, the epoxy resin filling adhesive flows downwards along the inner wall of the capacitor shell, the level of the epoxy resin filling adhesive rises gradually, the position of the injection head shifts upwards constantly, and finally injection is completed .An injection tube serves as the injection head, and the outer wall of the injection tube is defined by an arc outer wall and a planar outer wall .The epoxy resin filling adhesive is prepared from, by weight, 45-60 parts of epoxy resin, 10-18 parts of polyester resin, 5-10 parts of a fire retardant, 30-45 parts of a filling material, 30-45 parts of a diluent, 0.5-1.5 parts of a defoaming agent, 22-35 parts of a curing agent and 0-1.5 parts of a curing accelerator .The epoxy resin filling adhesive is uniformly injected without bubbles inside, the injection process is simple, and the injection efficiency is high.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Bridge wet joint cast-in-place concrete automatic vibration compacting device

InactiveCN107964879AImprove work efficiencyThere is no security riskBridge erection/assemblyStructural engineering

Owner:吴丹

Novel pouring gun head for silicone joint material of concrete expansion joint

InactiveCN104195932ALarge amount of glueNot easy to mixRoads maintainenceRailway track constructionExpansion jointUltimate tensile strength

The invention relates to a novel pouring gun head for a silicone joint material of a concrete expansion joint. The novel pouring gun head for the silicone joint material of the concrete expansion joint comprises a pouring head and a base, wherein the pouring head is connected with the base, and the base is connected with a glue gun. The novel pouring gun head has the characteristics of being uniform in pouring and being difficultly mingled with bubbles; pouring and surface concave scrapping of a joint material can be simultaneously realized, and the pouring quality and the pouring efficiency are remarkably improved. The pouring head is connected with the base by adopting a bayonet and the base is connected with the glue gun by adopting a bayonet, thus the novel pouring gun head is easy to disassemble, brings convenience in immediately cleaning a glue material inside, and can be repeatedly used. The problems of poor construction quality, low pouring efficiency, large labor intensity and the like of an existing joint material are solved, and the novel pouring gun head is suitable for constructing joint materials in the fields of high-speed railways, expressways, airfield runways and the like.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Bearing structure member used for wind power blade and preparation method thereof

InactiveCN111255639AIncrease bonding areaAvoid stiffnessWind motor combinationsMachines/enginesStructural engineeringUltimate tensile strength

The invention discloses a bearing structure member used for a wind power blade and a preparation method thereof. The bearing structure member is formed by stacking a plurality of pultrusion sheet layers with the same arrangement, and the edges at the two sides are aligned; the pultrusion sheet layers are formed by arranging even number of trapezoidal pultrusion sheets, and the trapezoidal pultrusion sheet is provided with at least one chamfer; the upper and lower edges of the adjacent two pultrusion sheets of each layer are arranged oppositely, horizontally aligned, the side walls of the adjacent trapezoidal pultrusion sheets are closely arranged and connected, and the connection part of the adjacent trapezoidal pultrusion sheets is formed with a diagonal seam between layers. According tothe invention, a weak straight joint is in a vertical section by designing the trapezoidal pultrusion sheet with a trapezoidal cross section and a stacking method to ensure the alignment of the beveled edges of the edge sheet, and the adhesion area of two adjacent pultrusion sheets of each layer is increased, the overall bearing capacity of a sheet structure is improved, and the problem that rectangular cross-section sheets form vertical straight joint when being stacked to reduce the rigidity and strength of the sheet structure is overcome.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

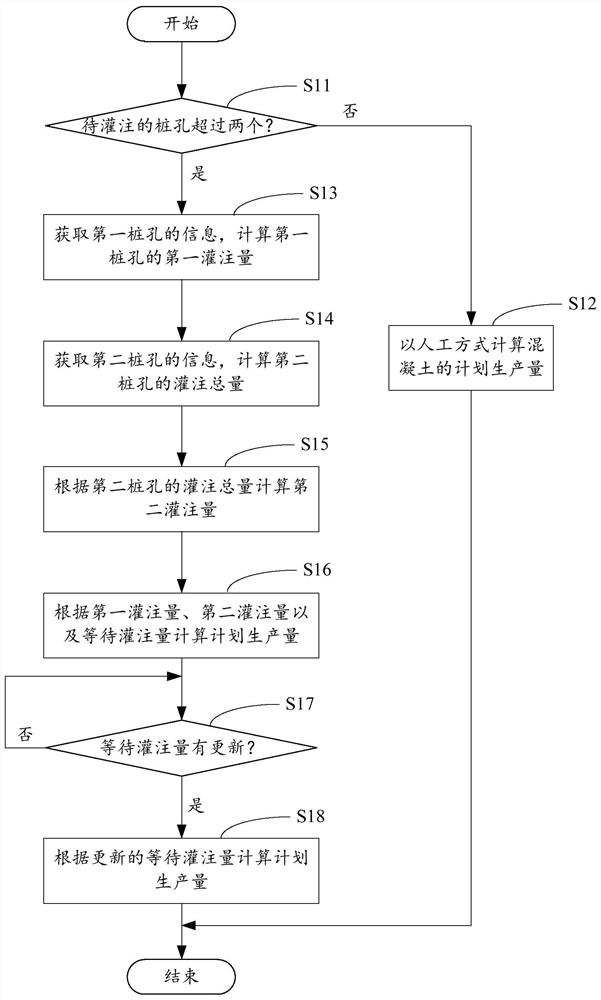

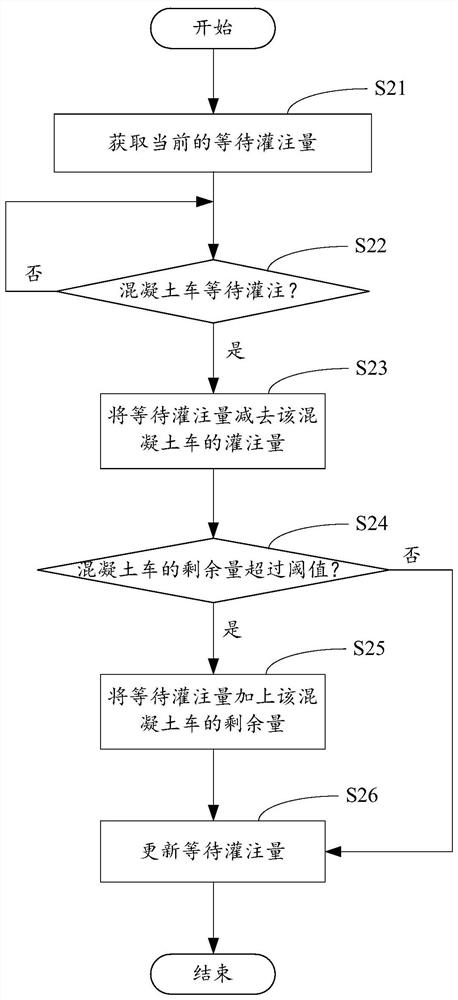

Concrete mixing plant control method, computer device and computer readable storage medium

PendingCN113392443AAvoid wastingEnsure control methodsGeometric CADDesign optimisation/simulationMechanical engineeringIndustrial engineering

The invention provides a concrete mixing plant control method, a computer device and a computer readable storage medium. The method comprises the steps: acquiring the information of a first pile hole capable of being poured currently, and calculating the first pouring amount of the first pile hole; acquiring the information of a second pile hole capable of being poured within the target prediction time, calculating the total pouring amount of the second pile hole, and calculating the second pouring amount of the second pile hole, wherein the second pouring amount is the preset proportion of the total pouring amount of the second pile hole; according to the first pouring amount, the second pouring amount and the waiting pouring amount, calculating the planned production amount of the planned concrete. The invention further provides a computer device for implementing the method and a computer readable storage medium. A certain volume of concrete can be produced in advance, the continuity of pile hole construction is ensured, and a large amount of concrete cannot be wasted.

Owner:GUANGZHOU ENG CO LTD OF CHINA RAILWAY 19TH BUREAU GRP

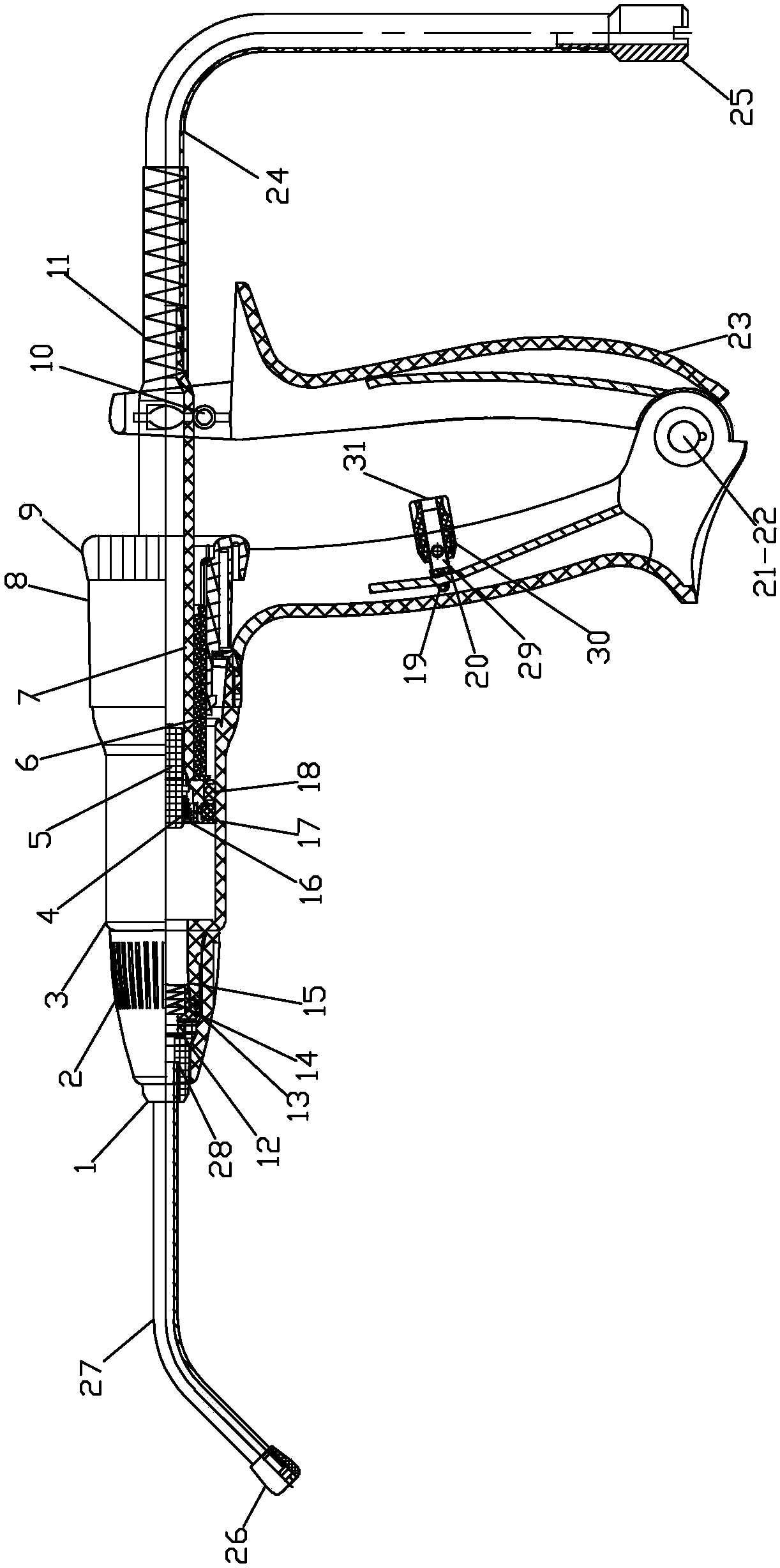

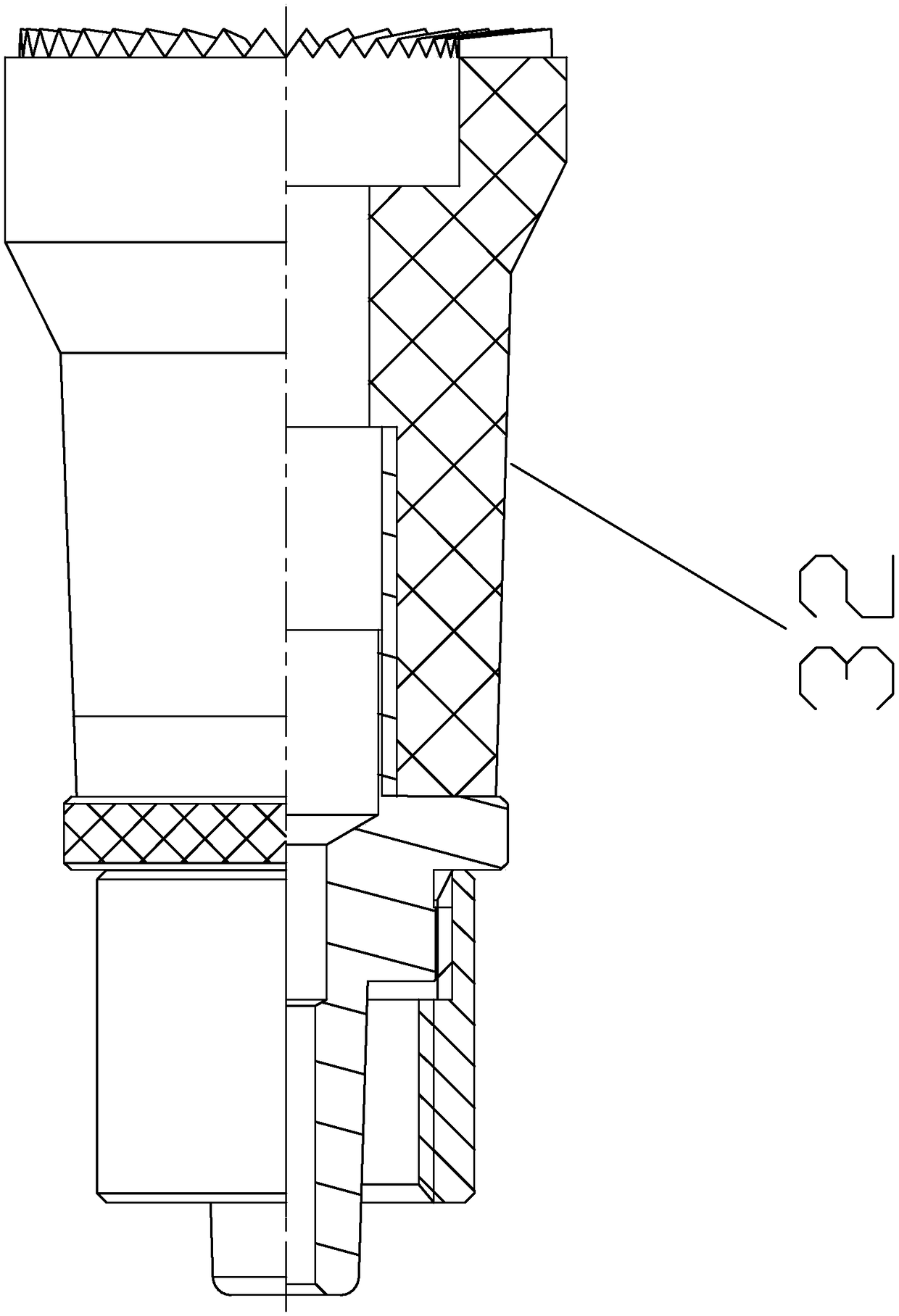

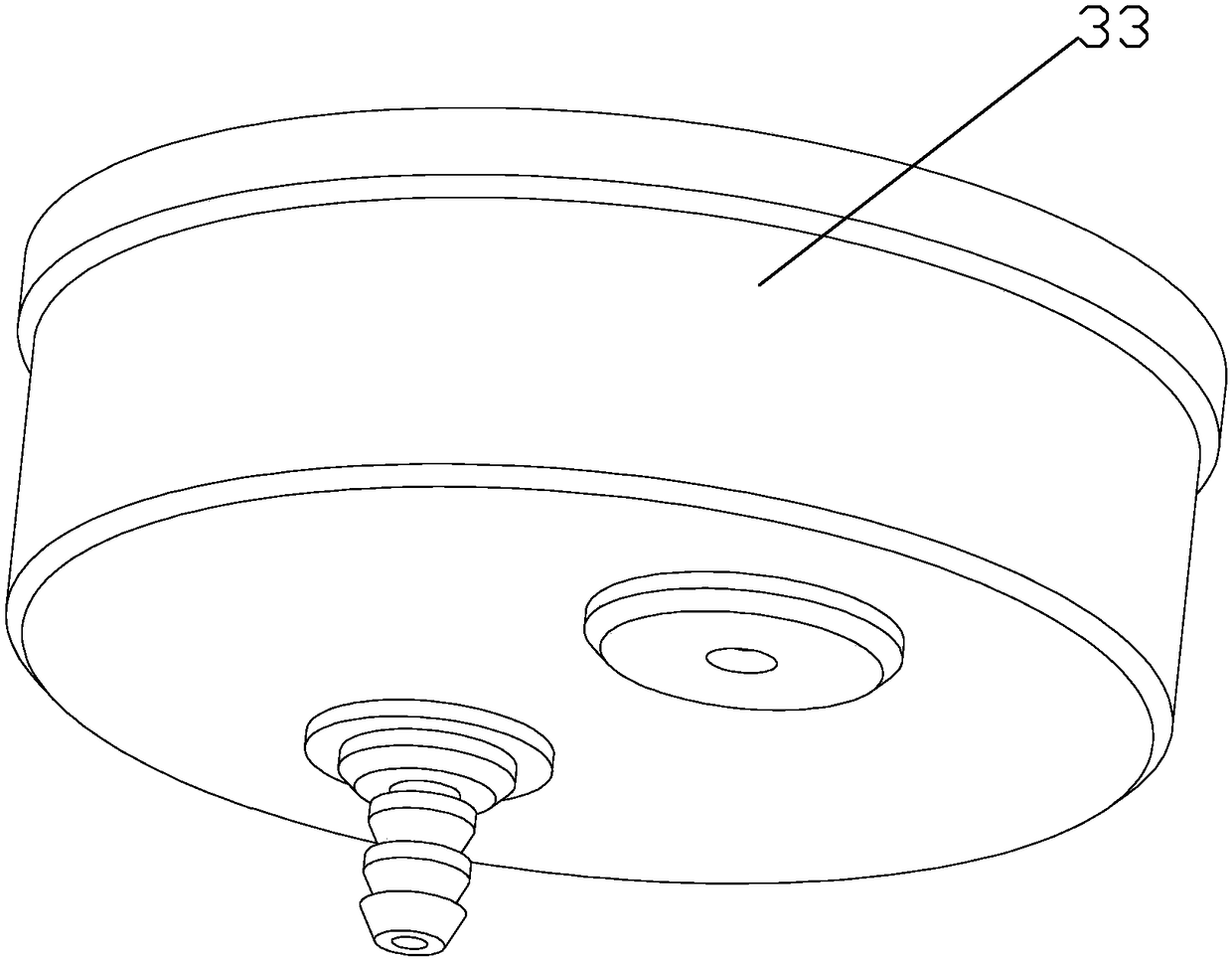

Continuous medicine filling injector

PendingCN108433849AImprove the lubrication effectFit firmlyVeterinary instrumentsGraduated cylinderSpray nozzle

The invention relates to a continuous medicine filling injector which comprises a handle assembly. The handle assembly is connected with a volume cylinder. One end of the volume cylinder is connectedwith a medicine filling pipe assembly or an injecting head assembly. The other end of the volume cylinder is connected with a piston assembly. The piston assembly is connected with a liquid absorptionassembly. The medicine filling pipe assembly comprises an elbow pipe. One end of the elbow pipe is connected with a spraying nozzle. The other end of the elbow pipe is connected with an elbow pipe connector. The elbow pipe connector is connected with the volume cylinder through a fixing nut. The liquid absorption assembly comprises a liquid absorption rubber pipe. One end of the liquid absorptionrubber pipe is connected with a piston assembly. The other end of the liquid absorption rubber pipe is connected with a liquid absorption connector or a liquid storage cylinder connecting end shield.The continuous medicine filling injector is made of high-quality plastic and an anti-corrosion metal material and has the advantages of being diversified in function, adjustable in elastic force, convenient to operate, accurate in dosage, firm, durable, comfortable in hand feel, light in weight, high in filling efficiency, stable in chemical performance and the like.

Owner:ZHEJIANG KANGRUI APP TECH CO LTD

Shell-type encapsulated capacitor epoxy filling mechanism

The invention relates to the capacitor epoxy encapsulation technology, in particular to a shell-type encapsulated capacitor epoxy filling mechanism. The invention solves the problem that manual capacitor epoxy filling is low in working efficiency and filling capacity precision. The mechanism comprises a base, a connecting rod hinged with the base, an epoxy storage cup and an injector, wherein theinjector comprises a cylinder body, a push rod sleeved in the cavity of the cylinder body and a needle tube arranged at the front end of the cylinder body and communicated with the cavity of the cylinder body; a cylinder is fixedly installed on the base; a connecting block is connected at the front end of the cylinder; the rear end of the push rod is vertically fixed on the front surface of the connecting block; and the epoxy storage cup is communicated with the cavity of the cylinder body of the injector. The mechanism is suitable for the epoxy filling link in the capacitor manufacturing process, can be used in capacitor encapsulation equipment in a mating manner and can be applied to raw material quantitative filling occasions in an extended manner.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

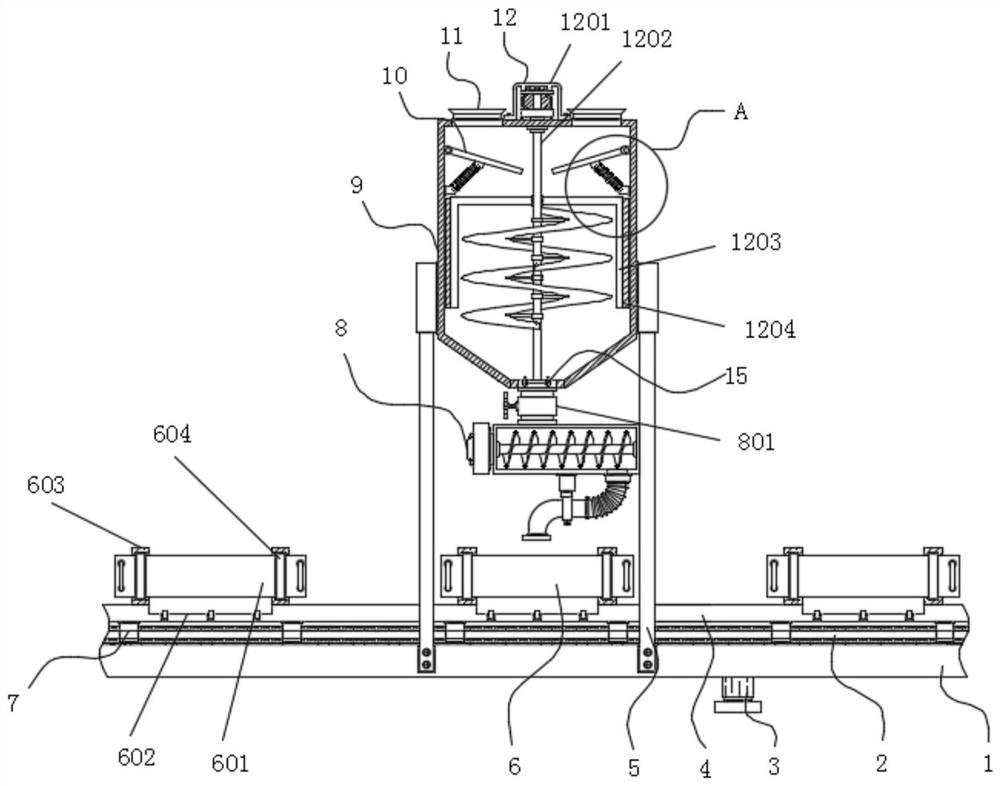

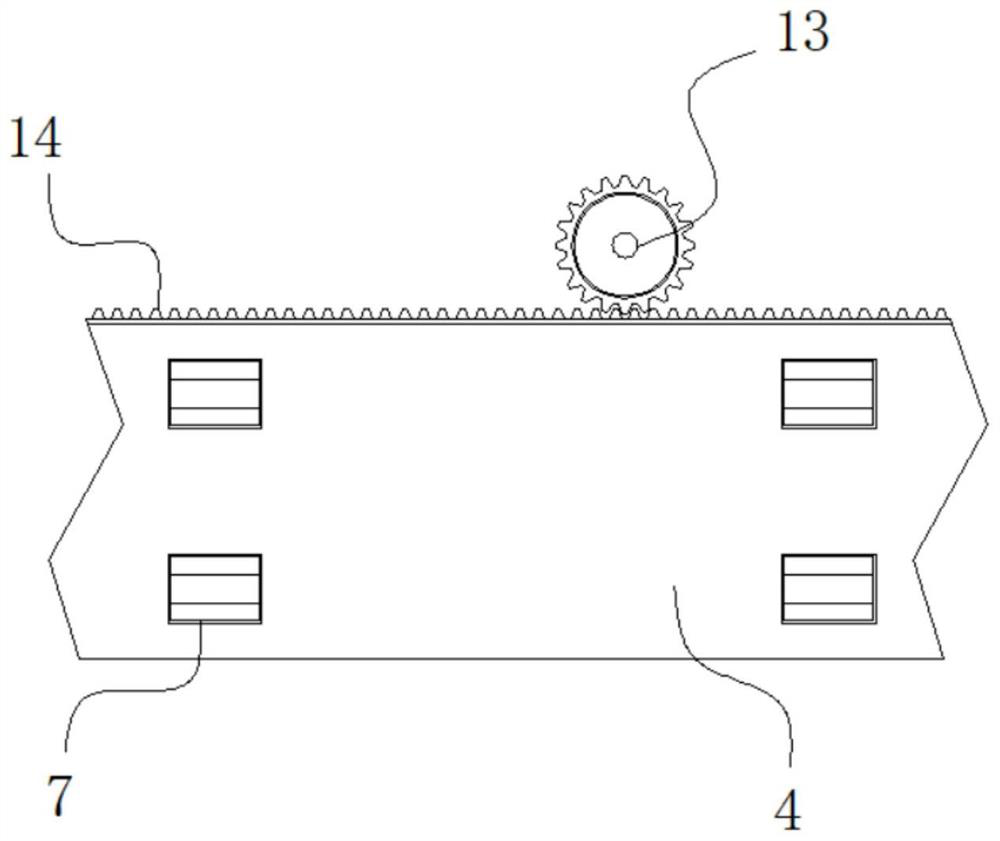

Anti-blocking concrete pipe pile material making and pouring device

PendingCN112976275AEasy to limit and disassembleEasy to useDischarging apparatusFeeding arrangmentsBuilding materialStructural engineering

The invention discloses an anti-blocking concrete pipe pile material making and pouring device, and particularly relates to the technical field of building material processing. The anti-blocking concrete pipe pile material making and pouring device comprises a base, a transmission plate and a material making tank. The transmission plate is arranged at the top end of the base, supporting columns are fixedly connected to the two sides of the two ends of the base correspondingly, and the material making tank is fixedly connected to the top ends of the supporting columns. And a structure convenient for limiting and taking is arranged at the top end of the transmission plate. By arranging a variable frequency motor, a stirring rod, a wall scraping frame and a scraping plate, during use, the variable frequency motor is started, the variable frequency motor can drive the stirring rod to rotate, the stirring rod stirs and mixes raw materials for material making, and after material making is completed, the stirring rod continues to stir concrete materials, so that layering of the concrete materials is avoided. And meanwhile, the scraping plate on one side of the wall scraping frame can scrape off the concrete materials attached to the inner side wall of the material making tank, so that the concrete materials in the material making tank are fully utilized, the interior of the material making tank can be conveniently cleaned, and the practicability is high.

Owner:解正祥

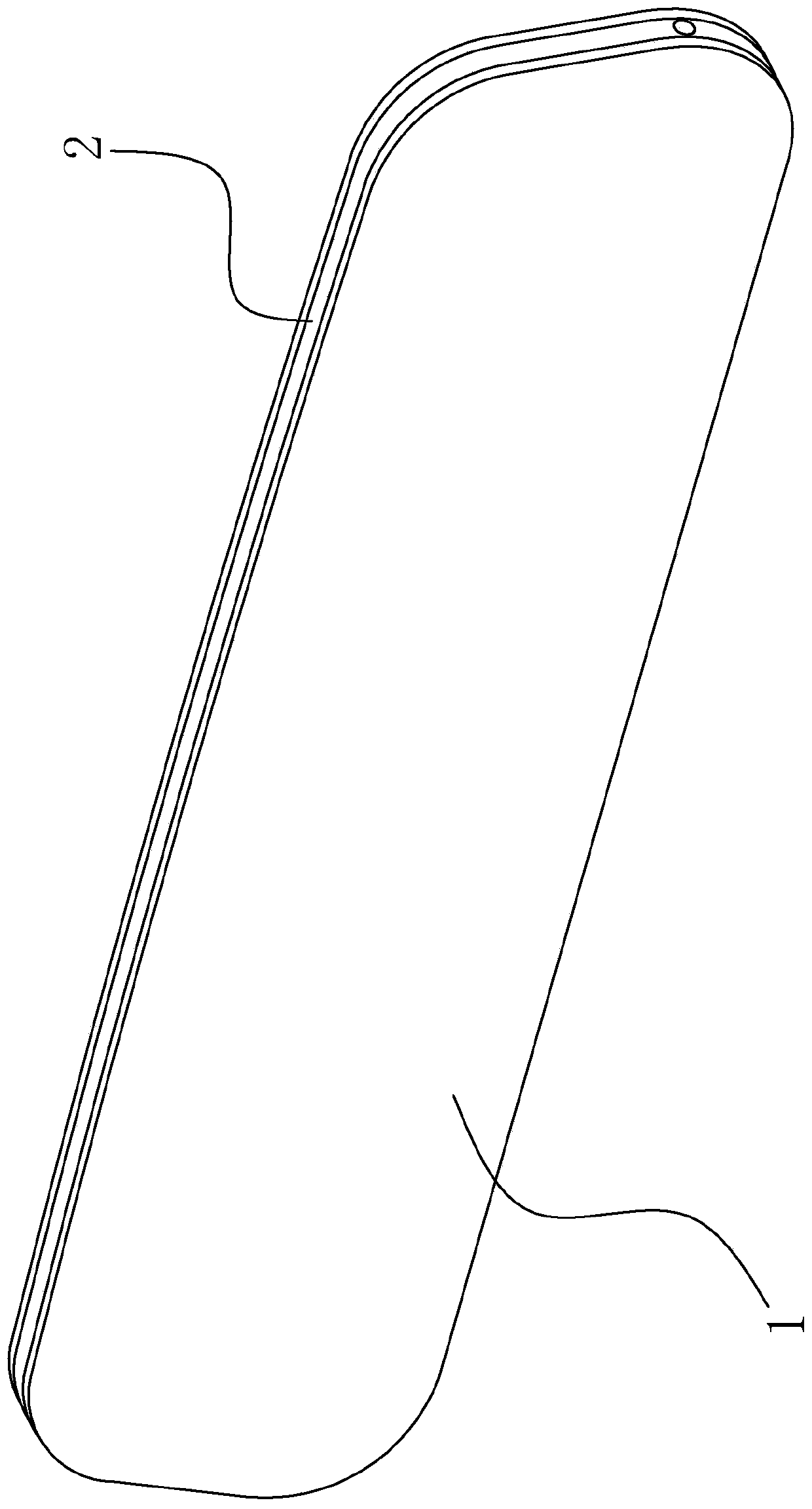

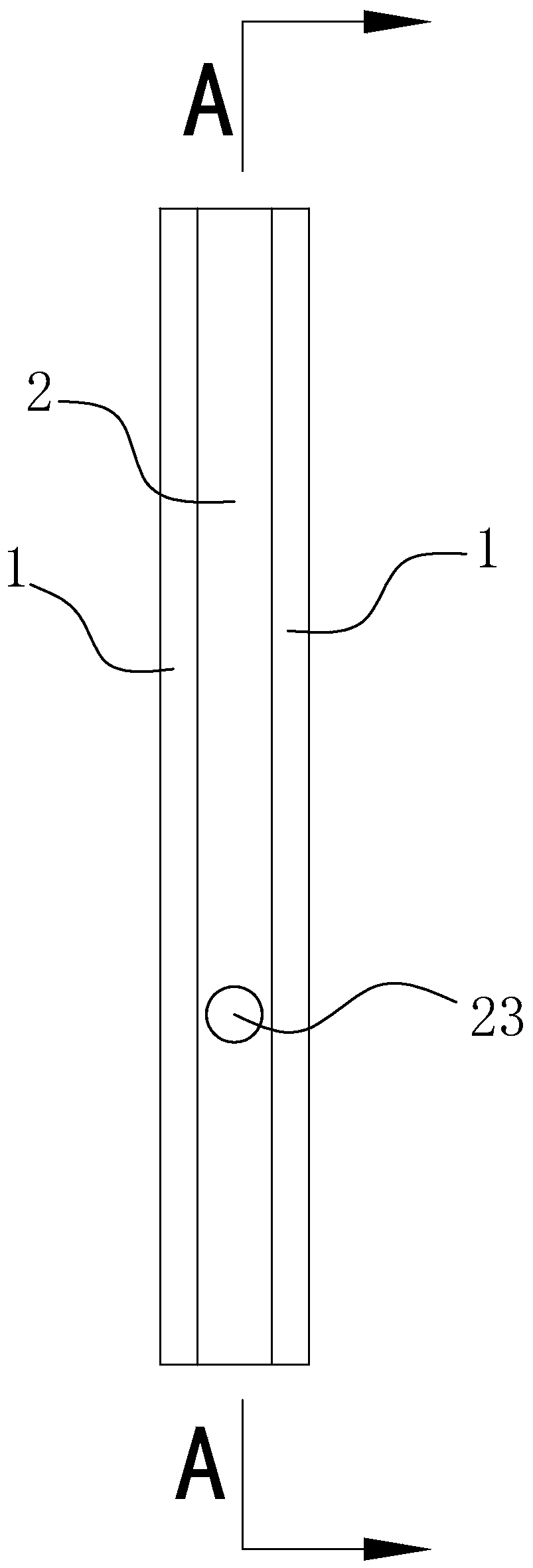

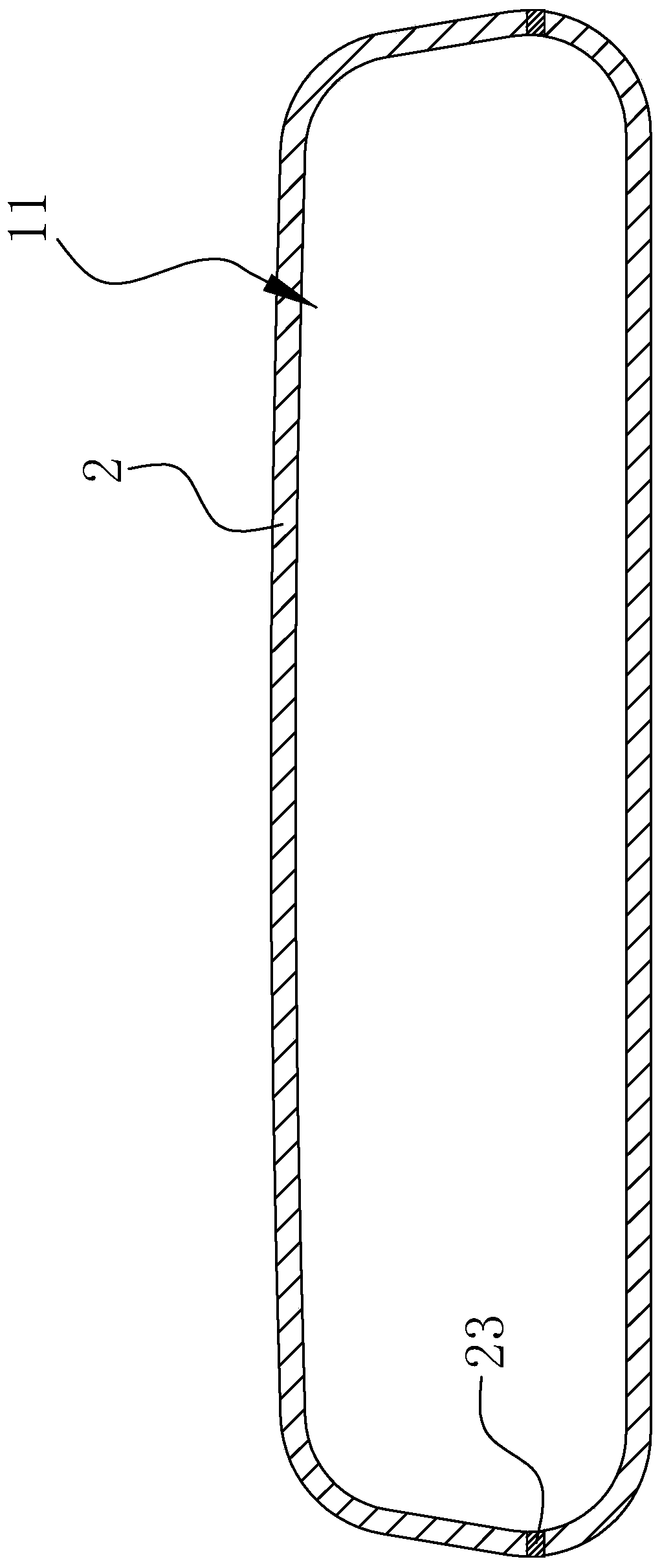

Method for conveniently pouring electrochromic liquid into electrochromic rearview mirror

The invention discloses a method for conveniently pouring an electrochromic liquid into an electrochromic rearview mirror. The method comprises the steps that a glass shell is manufactured, wherein the glass shell is formed by bonding a front glass substrate and a rear glass substrate through epoxy resin glue on the periphery of the front glass substrate and the periphery of the rear glass substrate, a liquid inlet opening is formed in one end of the glass shell, and a liquid outlet opening is formed in the other end of the glass shell; the electrochromic liquid is vacuumized to eliminate airin the electrochromic liquid before pouring; and in a normal-pressure environment, the liquid inlet opening is soaked in the electrochromic liquid, the electrochromic liquid flows into an inner cavityof the glass shell from the liquid inlet opening in a suction or pressure injection mode, and when the electrochromic liquid reaches the liquid outlet opening, the liquid inlet opening and the liquidoutlet opening are sealed and closed by using colloid. The method has the advantages that the electrochromic liquid can be filled in a normal-pressure environment, the filling operation is simple, and the manufacturing is convenient.

Owner:ATRA PLASTICS SHANGHAI

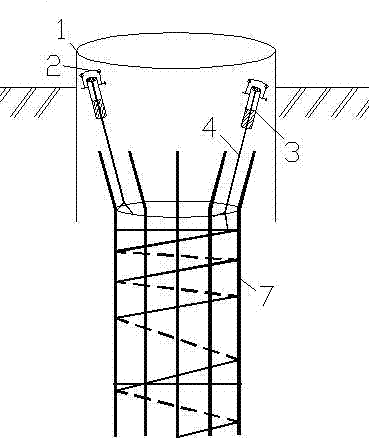

Anti-floating method and device for bored concrete pile reinforcement cage

The invention relates to an anti-floating method and device for a bored concrete pile reinforcement cage. The anti-floating method is characterized in that the technological process is as follows: before starting to drill a hole, taking the center of a pile position as the center of a circle, confirming the position of a steel pile casing on the soil according to the radius of the steel pile casing of the anti-floating device of the bored concrete pile reinforcement cage, after placing the steel pile casing, applying pressure for embedding the steel pile casing into the soil, and then starting to drill the hole; after forming the hole in a bored concrete pile, placing the reinforcement cage into the hole; penetrating a U-shaped lock catch into the reserved hole in the steel pile casing; using a bolt to connect the U-shaped lock catch with a connecting loop bar; inserting the tail part of a fork rod into the connecting loop bar; clamping the head of the fork rod on a top hoop of the reinforcement cage, and then starting to pour concrete; when the concrete is about to be poured to the pile top position, detaching the bolt on the U-shaped lock catch; taking down the connecting loop bar, the steel fork rod and the U-shaped lock catch; continuing pouring the concrete to the designed elevation, and pulling out the steel pile casing. According to the anti-floating method and device provided by the invention, the floating of the reinforcement cage while pouring the concrete can be effectively avoided.

Owner:HUBEI CENT SOUTH EXPLORATION & FOUND ENG

Eyeliner based on hectorite lipophilic thickener and preparation method thereof

ActiveCN112545924AGood dispersionEvenly distributedCosmetic preparationsMake-upCapric triglyceridesPhysical chemistry

The invention discloses an eyeliner based on hectorite lipophilic thickener and a preparation method thereof, the eyeliner comprises a lipophilic thickener, the lipophilic thickener is based on hectorite-based, and is a compound composed of propylene carbonate, caprylic / capric triglyceride and hectorite by weight percentage, the hectorite is selected from at least one of distearylamine hectorite,selammonium chloride hectorite and quaternary ammonium salt-18 hectorite. The invention further discloses a method for preparing the eyeliner based on hectorite thickener. The thickener used in the invention is based on the oleophylic characteristic of hectorite, and has excellent dispersing performance in an oily environment, so that the toner is uniformly distributed, the color and the brightness of the product are improved, the appearance of the product is smooth, the pouring in the production process is smoother, and the pouring efficiency is improved.

Owner:原田(苏州)技术研发有限公司

Upper-pressing-lower-sucking-type slurry injection structure of automatic plate production line

The invention relates to the technical field of foam plate slurry injection, in particular to an upper-pressing-lower-sucking-type slurry injection structure of an automatic plate production line. Theupper-pressing-lower-sucking-type slurry injection structure comprises a material injection device and a vacuum sucking device; the vacuum sucking device comprises a vacuum plate and a vacuum suckingpipe which is connected to the vacuum plate; baffle plates which are hermetically connected with the vacuum plate are arranged on the vacuum plate; the vacuum plate and the baffle plates jointly forma material injection pool of which the opening is upward; the material injection device communicates with the material injection pool; and a downwards-pressing component is hermetically arranged on the inner walls of the baffle plates. By adopting the upper-pressing-lower-sucking-type slurry injection structure of the automatic plate production line, the amount of slurry absorbed in various partsof a plate is consistent; and the speed and efficiency of slurry injection are improved; the slurry can uniformly permeate the whole plate, so that the problem of descending of the yield and fireproof performance of foam plates is avoided.

Owner:SICHUAN UNIV

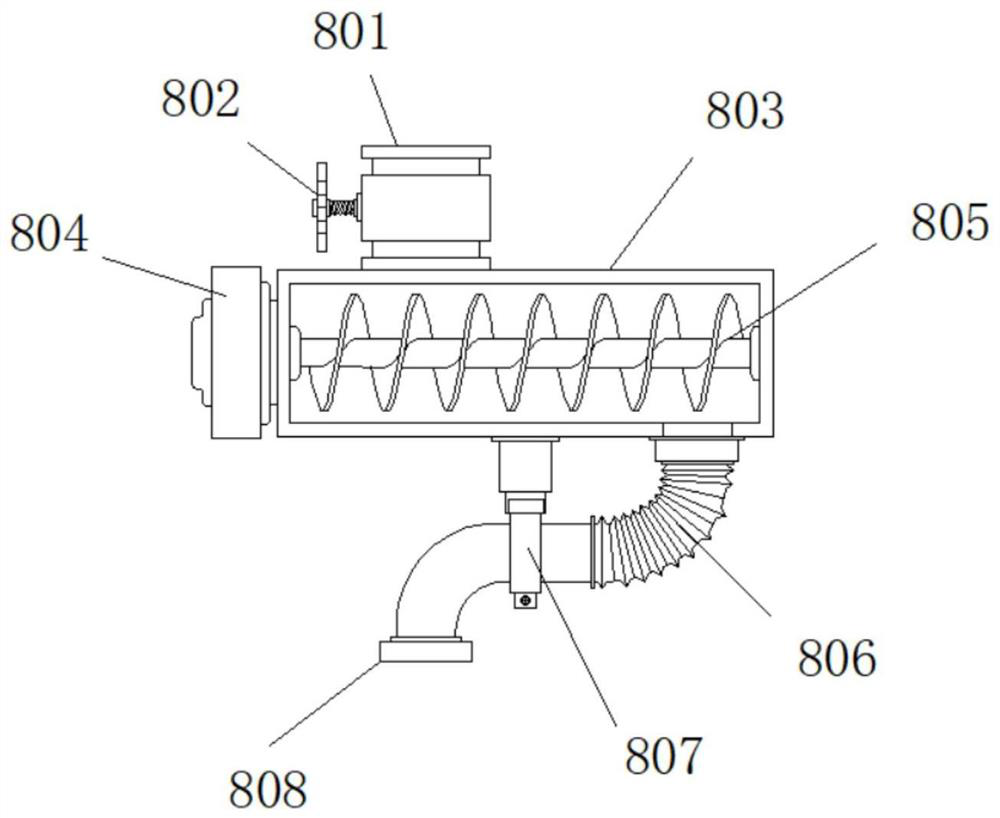

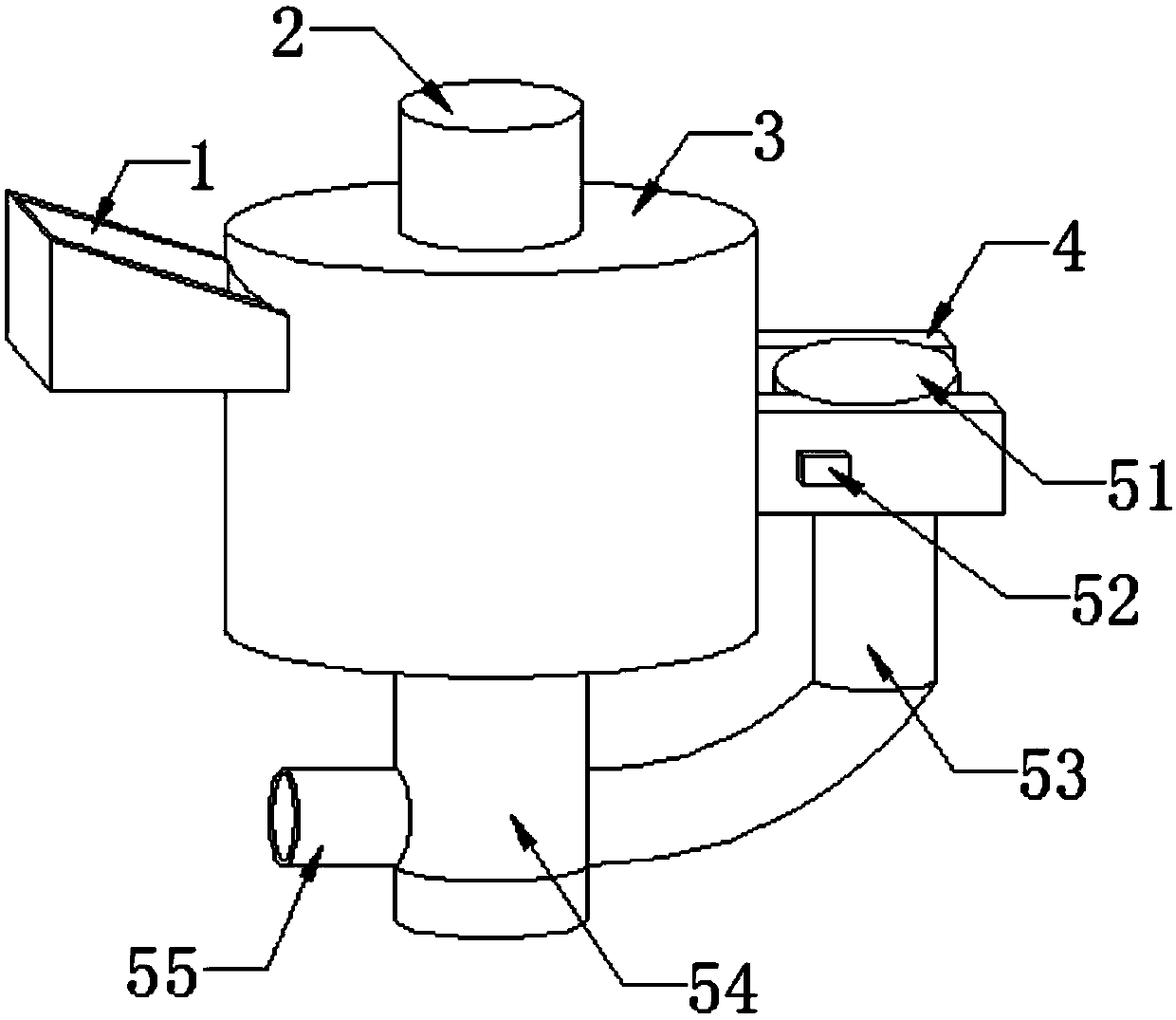

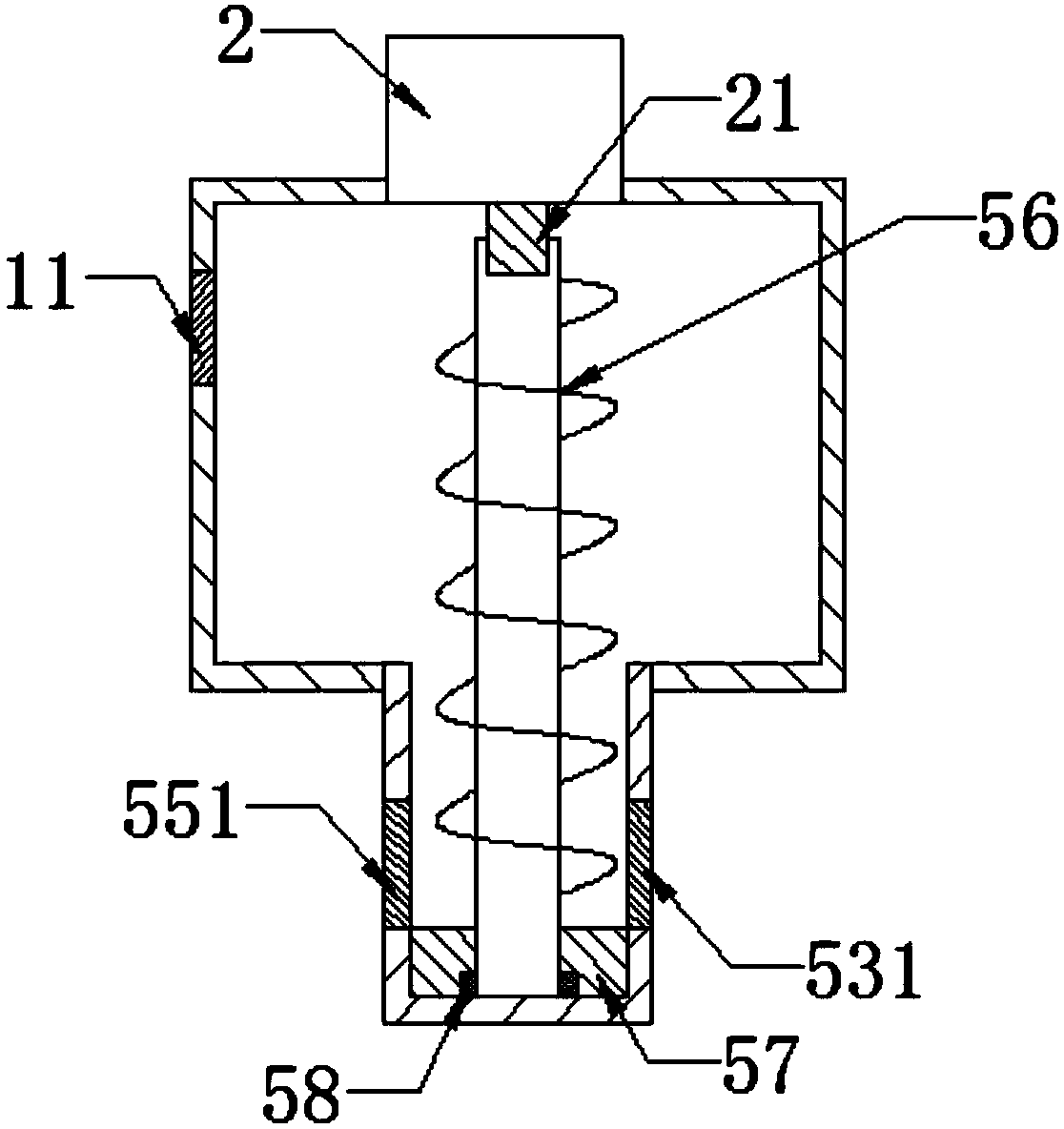

Cement perfusion apparatus for construction machinery

InactiveCN109653503ASolve the problem of poor perfusionRapid perfusionBuilding material handlingArchitectural engineeringControl switch

The invention provides a cement perfusion apparatus for construction machinery. The cement perfusion apparatus for the construction machinery comprises a pouring port, a motor, a perfusion box, a fixed bracket, a gas pressurizing pump, a control switch, a pressurizing pipe, a connecting pipe, a perfusion pipe, a spiral rod, a fixed plate and a bearing, wherein the upper end surface of the perfusion box is provided with the motor, the left side of the perfusion box is provided with the pouring port, the right end surface of the perfusion box is fixedly provided with the fixed bracket, the spiral rod is installed on the middle position inside the perfusion box, the lower end surface of the spiral rod is provided with the bearing, the lower end surface of the perfusion box is provided with the connecting pipe, the fixed plate is installed at the inner lower side of the connecting pipe, the left end surface of the connecting pipe is connected with the perfusion pipe, the right end surfaceof the connecting pipe is connected with a pressurizing pipe, the upper end surface of the pressurizing pipe is provided with the gas pressurizing pump, and the front end surface of the fixed bracketis provided with the control switch. By adopting the cement perfusion apparatus for the construction machinery, the problems of poor perfusion effect of the original cement perfusion apparatus for theconstruction machinery can be solved. The cement perfusion apparatus for the construction machinery is reasonable in structure, convenient in use and good in perfusion effect.

Owner:ANQING RUIXIA MECHINERY CO LTD

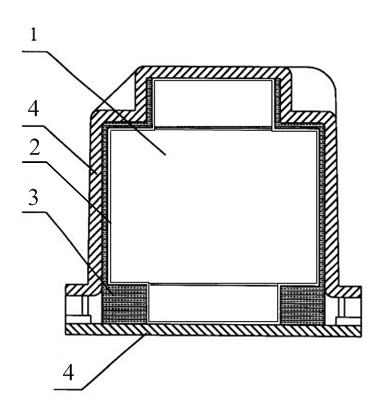

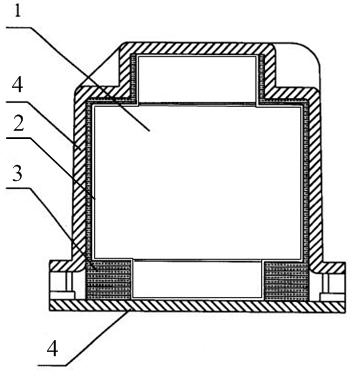

Perfusion structure of transformer

InactiveCN102682964ASolve the fallImprove perfusion efficiencyTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerEngineering

The invention provides a perfusion structure of a transformer, comprising a magnetic core and a housing, wherein the magnetic core is mounted in the housing; the magnetic core is coated with a silica gel layer; and an epoxy layer is perfused between the silica gel layer and the housing. The perfusion structure of the transformer well solves the problem that inductance value of the transformer drops after perfusion by means of the mutual characteristics of the magnetic core, the silica gel and the epoxy layer; and therefore, the perfusion efficiency and yield are improved, the product cost is decreased and the product volume is reduced.

Owner:WUXI JINGLEI ELECTRONICS

Pre-curing perfusion method for wind power blade without flow guide net

ActiveCN109822947AIncreased permeability and strike rateImprove perfusion efficiencyDomestic articlesMoving speedElectricity

The invention discloses a pre-curing perfusion method for a wind power blade without a flow guide net. The pre-curing perfusion method for the wind power blade without the flow guide net comprises seven steps of cleaning a mould, laying the demoulding cloth, laying the outer skin cloth layer, beam mounting, laying core materials, laying the inner skin, laying other auxiliary materials, and filling. According to the pre-curing perfusion method for the wind power blade without the flow guide net, PVC core material with chordwise linear grooves with the width and the depth of 2.0 mm and the spacing of 20+ / -2 mm arranged on the outer surface chordwise or light wood core materials with chordwise linear grooves with the width of 1.2 mm, the depth of 1.5 mm and the spacing of 20+ / -2 mm arranged on the outer surface chordwise are adopted, so that when pouring, resin is directly poured into the linear grooves, the permeability of the poured resin is obviously improved, and the poured resin consumption is reduced. The flow guide net is not needed to be laid in the grooved area of the core materials. During pouring, the resin is directly poured into the core material grooves, which can significantly improve the moving speed of the poured resin, significantly reduce the consumption of the auxiliary materials, further effectively reduce the production cost, shorten the production cycle of the wind power blade, and improve the production efficiency and economic benefits.

Owner:SINOMATECH JIUQUAN WIND POWER BLADE CO LTD

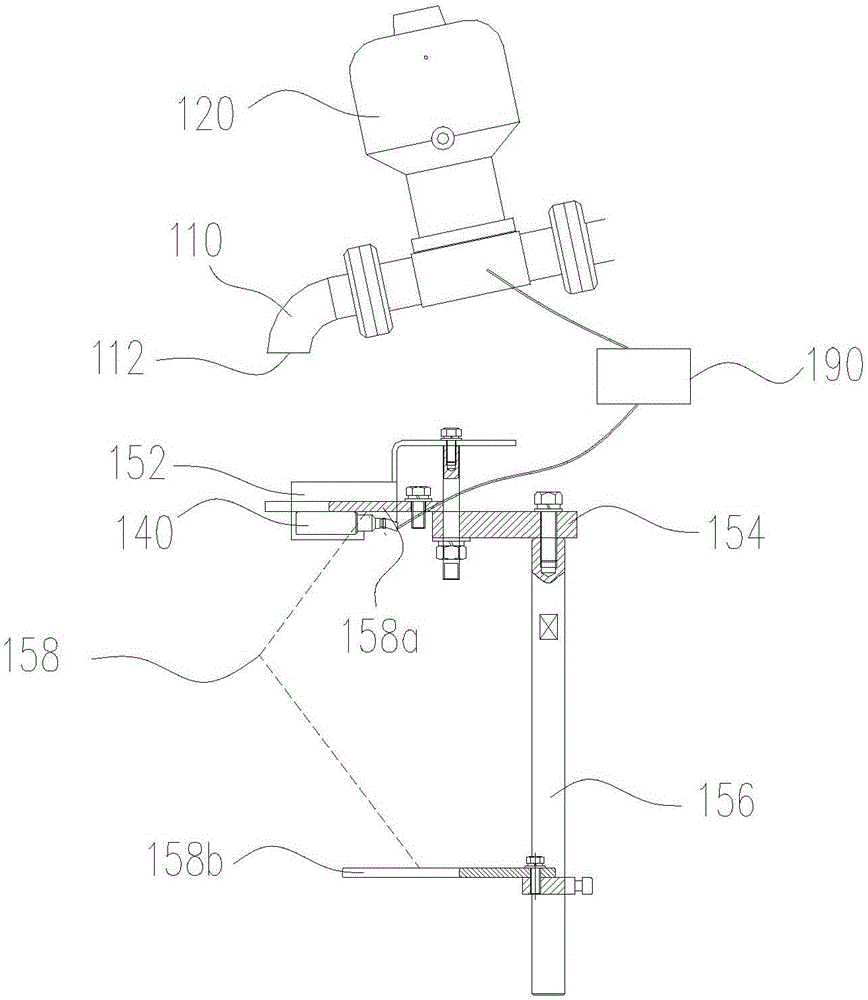

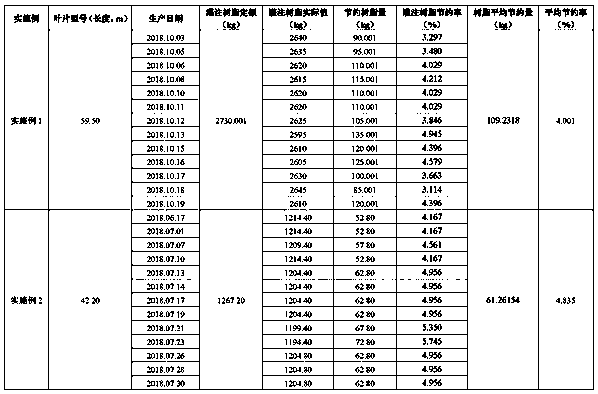

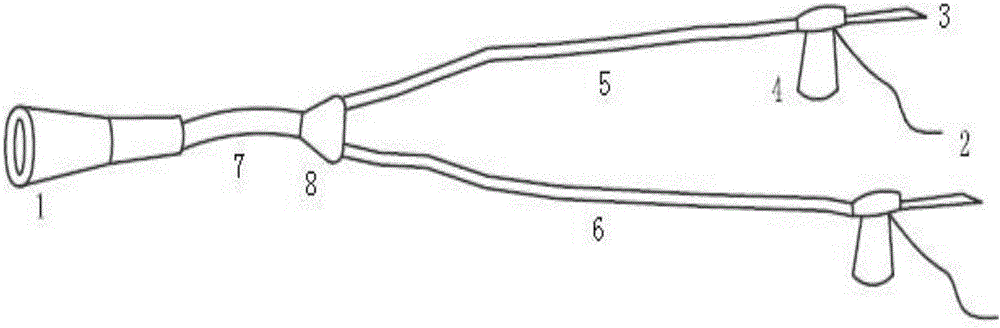

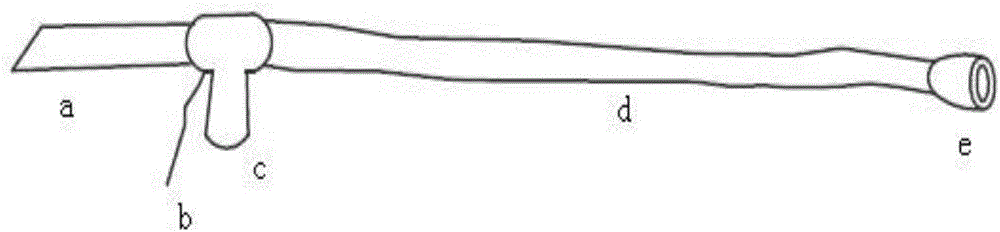

Filling and acquiring devices for extracting hematopoietic stem cells from placenta

ActiveCN105695302AReduce damageImprove survival rateCell dissociation methodsBioreactor/fermenter combinationsFirst FillHematopoietic cell

The invention provides a filling device and an acquiring device for extracting hematopoietic stem cells (HSC) from a placenta. The filling device comprises a filling inlet, a T-joint, a first filling needle and a second filling needle, wherein one end of the filling inlet is connected with the inlet end of the T-joint, the first outlet end of the T-joint is connected with the first filling needle, and the second outlet end of the T-joint is connected with the second filling needle. The acquiring device comprises a catheter and an acquisition needle, wherein one end of the catheter is connected with the acquisition needle, and the acquisition needle is provided with a fixing device. By the adoption of double syringe needles, the filling needles can be fixed for placenta filling, contact between HSC and the external environment is avoided all through the process of separating and extracting HSC from the placenta, and the contamination rate is reduced greatly; furthermore, continuous filling can be achieved, and filling efficiency is improved greatly.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

Pressurization type mechanical glue-pouring machine

InactiveCN101145607AImprove perfusion efficiencyReduce colloid wasteCell component detailsSyringeEngineering

A compression-type mechanical glue dispenser is provided, which relates to the mechanical equipment for producing lead-acid accumulators, particularly the technique of glue dispensing equipment. A cylinder and a glue storage box are both provided on a frame. The cylinder is arranged above the glue storage box. The bottom plate of the glue storage box is provided with a through hole. A syringe-like acid cup is vertically equipped on and hermetically connected with the through hole. A pusher is equipped inside the syringe-like acid cup, and the top end of the pusher is connected with a piston rod of the cylinder. The inventive glue dispenser has the advantages that the efficiency of glue dispense is high; since the syringe-like acid cup is sized according to the glue consumption, to completely avoid the overflow of glue, reduce the waste of glue and improve the glue dispersion quality; and the operator can rapidly and easily complete the glue dispense operation by controlling the cylinder.

Owner:江苏华富能源有限公司

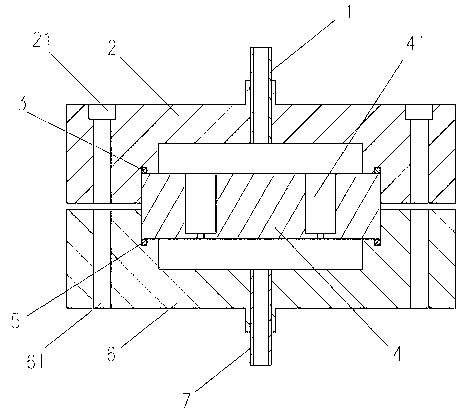

Multifunctional valve

InactiveCN106917883ALarge openingIncrease perfusion rateOperating means/releasing devices for valvesMultiple way valvesNatural stateBilateral symmetry

The invention discloses a multifunctional valve. Three communicated flow passages are arranged in a valve main body of the multifunctional valve; each flow passage comprises a conical hole and a cylindrical hole, wherein one flow passage is positioned on the axial line of the valve main body; the other two flow passages are in bilateral symmetry by using the flow passage positioned on the axial line as the symmetry axis; an identical conical piston is arranged in each flow passage; a fixing rod is arranged in the cylindrical hole; a spring sleeves a rod body at the section, coaxial with the cylindrical hole, of the fixing rod; the upper end of the spring is connected with the piston; the other end of the spring is welded at the surface of the fixing rod; three pulleys are arranged in the flow passage at the crossed and converged part of the three flow passages; a first elastic rope bypasses the three pulleys; the middle is connected with a second elastic rope connected with the small end surface of the piston positioned in the middle; in a natural state, the first elastic rope and the second elastic rope freely and straightly extend. The multifunctional valve has the advantages that the pressure intensity of each container after the filling can be enabled to be maintained in the identical range; the automatic regulation and flow division can also be realized; the filling efficiency is accelerated.

Owner:秦朝东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com