Shell-type encapsulated capacitor epoxy filling mechanism

A capacitor and epoxy technology, used in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of low work efficiency and low perfusion accuracy, and achieve the effects of ensuring quality and pass rate, improving perfusion accuracy and high perfusion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

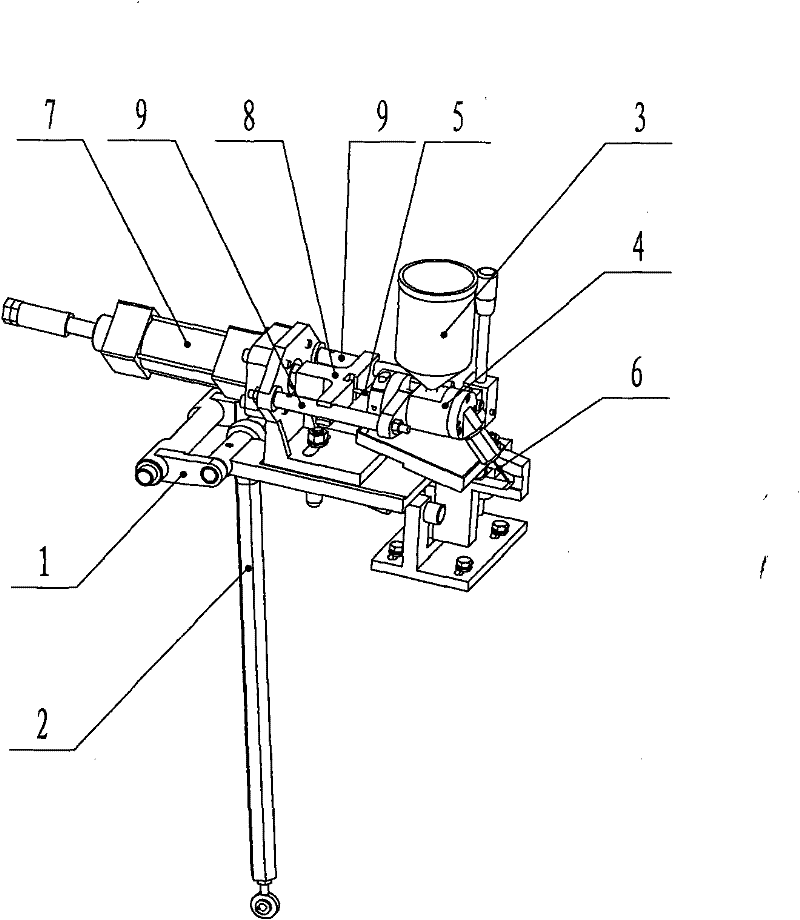

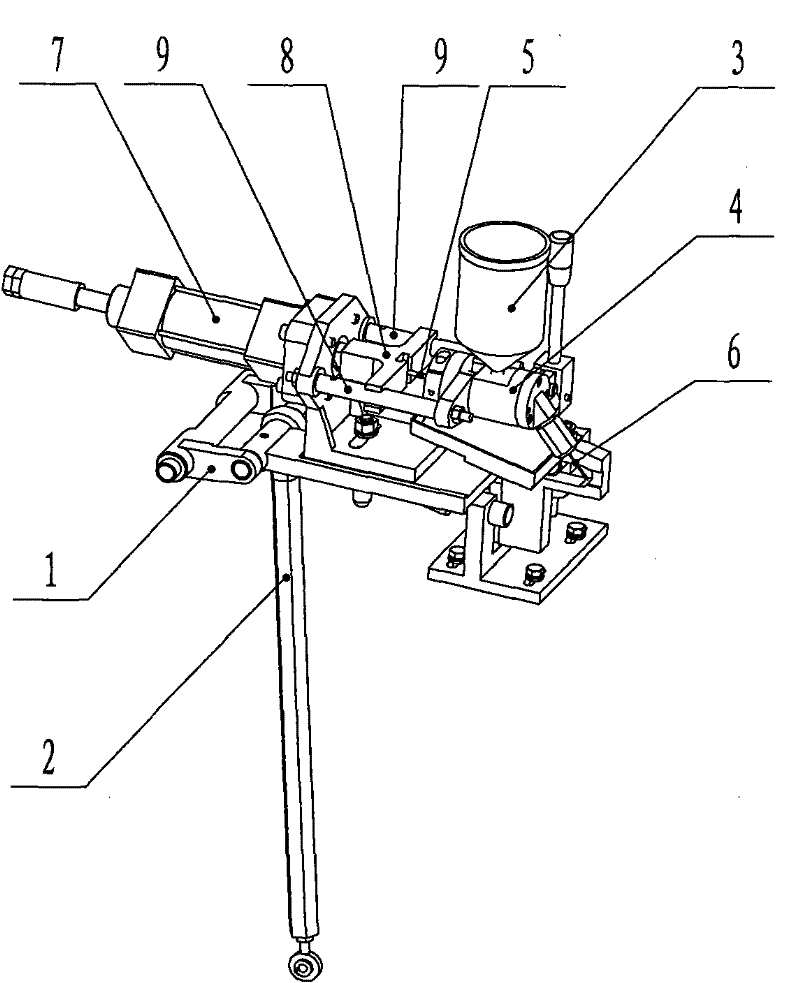

[0010] Epoxy filling mechanism for shell-type encapsulated capacitors, including a base 1, a connecting rod 2 hinged to the base 1, an epoxy storage cup 3, and a syringe; 5. And the needle tube 6 located at the front end of the cylinder 4 and connected to the inner cavity of the cylinder 4; the base 1 is fixed with a cylinder 7, the front end of the cylinder 7 is connected with a connecting block 8, and the rear end of the push rod 5 is vertically fixed to the connecting block 8. On the front surface, the epoxy storage cup 3 communicates with the inner cavity of the cylinder body 4 of the syringe; a guide rod 9 is arranged between the cylinder body 4 and the cylinder 7, and the two ends of the guide rod 9 are fixed to the cylinder body 4 and the cylinder 7 respectively, and the connecting block The 8 sides are supported on the guide rod 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com