Dairy product filling and discharging structure capable of preventing fluid from dripping

A dairy product filling and discharging technology, which is applied in the field of dairy product filling and discharging structure, can solve problems such as easy dripping of residual dairy products in the filling system, and achieve the effects of increasing speed, improving filling efficiency, and improving sanitary conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

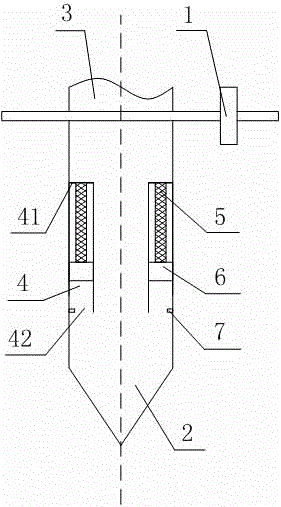

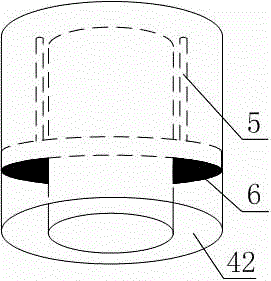

[0019] Such as figure 1 and figure 2 The milk product filling and discharging structure shown to prevent fluid dripping includes a pipe body 3 provided with a valve 1 and a nozzle 2. Inside the pipe body 3, an annular One end of the inner cavity 4 close to the valve 1 is closed, and one end close to the nozzle 2 is open. The closed end 41 of the inner cavity 4 is fixed with a driving rod 5 facing the direction of the nozzle 2. The driving rod 5 is connected with An annular piston 6 matching the inner chamber 4; the drive rod 5 is an electric push rod; the open end 42 of the inner chamber 4 is provided with a baffle 7 that blocks the outward movement of the piston 6; the piston 6 For rubber stoppers.

[0020] In the present invention, an annular inner chamber 4 is provided in the discharge pipe body 3 of the dairy product filling system. The inner chamber 4 is located between the valve 1 and the nozzle 2. The end of the inner chamber 4 close to the valve 1 is closed and clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com