Fabric with high penetration rate, and preparation method and application of fabric

A speed and fabric technology, applied in knitting, mechanical equipment, warp knitting, etc., can solve the problems of whitening of perfusion, long perfusion time of blade root, etc., and achieve the effect of increased perfusion speed, short perfusion time and high soaking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

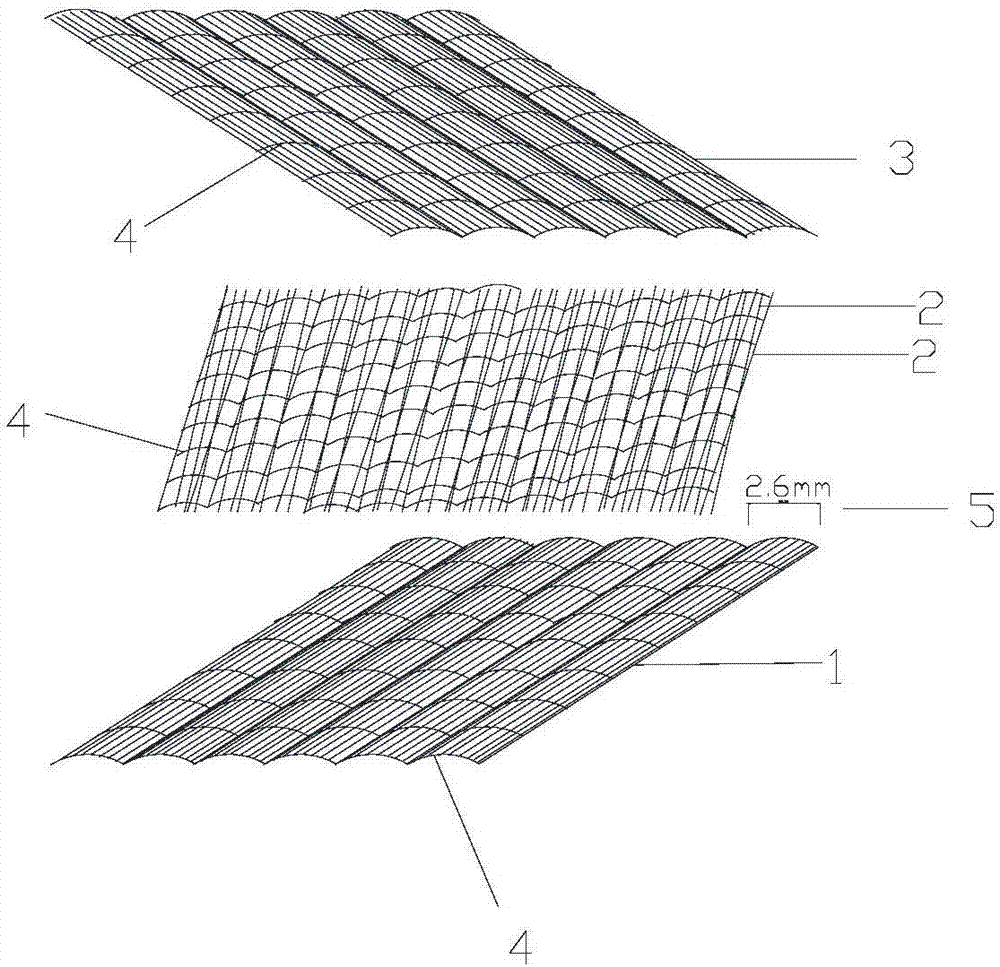

[0043] A fabric with a high soak-through rate, such as figure 2 As shown, including +45° weft yarn 1, 90° weft yarn 2, -45° weft yarn 3 and 0° warp yarn 4, the +45° weft yarn, 90° weft yarn, and -45° weft yarn are bound together by 0° warp yarn, 0 ° The sewing stitch length 5 when the warp is bound is 2.6mm. Wherein, the arrangement angle of 90° weft yarn 2 is 88-92°, for example, 90° weft yarn 2 can follow 90°, 88°, 90°, 92°, 90°, 90°, 88°, 92°, and so on Arranged in the same way, there is a cross section between a part of the adjacent 90° weft yarn 2; the 90° weft yarn layer is sandwiched between the +45° weft yarn layer and the -45° weft yarn layer. It can be seen that the 90° weft yarn 2 of the present invention is only a name, and its laying angle is not limited to the 90° direction.

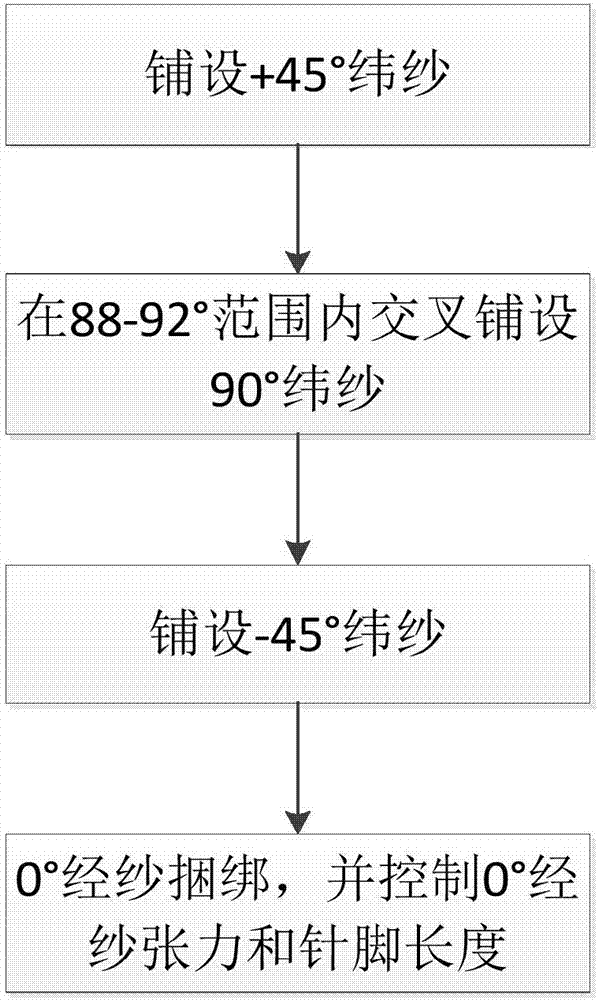

[0044] Such as figure 1 Shown, the preparation method of the fabric with high soaking rate in the present embodiment, comprises the following steps successively:

[0045] A. Laying +45...

Embodiment 21

[0059] A fabric with a high soaking rate, different from Example 1, in step D of its preparation method, when binding +45° weft yarn 1, 90° weft yarn 2 and -45° weft yarn 3 with 0° warp yarn 4 , control the tension of warp 4 at 0° to 19cN.

[0060] In this embodiment, the blade plant takes 3.9 hours to fill the shell, and at the same time, the root of the blade does not turn white.

Embodiment 22

[0062] A fabric with a high soaking rate, different from Example 1, in step D of its preparation method, when binding +45° weft yarn 1, 90° weft yarn 2 and -45° weft yarn 3 with 0° warp yarn 4 , control the tension of warp 4 at 0° to 15cN.

[0063] In this embodiment, the blade plant takes 3.8 hours to fill the shell, and at the same time, the root of the blade does not turn white.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com