Alkalescent diatom ooze wall material and preparation method thereof

A weakly alkaline and diatom mud technology, which is applied in the preparation of weakly alkaline diatom mud wall materials and the field of weakly alkaline diatom mud wall materials, can solve problems such as inconvenient construction, inability to transmit light, and uneven mixing. Achieve the effect of increasing operability, strong operability, and increasing penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

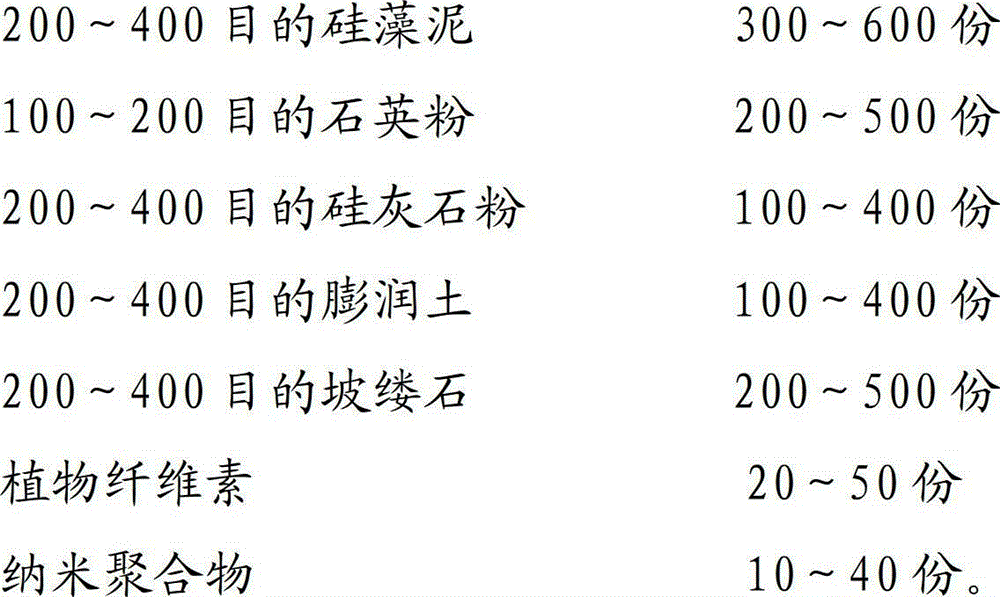

[0042] The weakly alkaline diatom mud wall material comprises wall material powder and water, and the wall material powder includes the following components by weight in grams:

[0043]

[0044] The preparation method comprises the following steps:

[0045] (1) Weigh the components of the wall material powder in parts by weight, and mix them evenly with a mixer;

[0046] (2) Weighing water, the weight ratio of the wall material powder to water is 1:0.9;

[0047] (3) Add 75% of the wall material powder mixed in step (1) to the water prepared in step (2), and stir with a mixer for 2 to 5 minutes until uniform;

[0048] (4) Add the remaining wall material powder, stir with a mixer for 1 to 3 minutes, and mix the wall material powder and water into a paste without hanging.

Embodiment 2

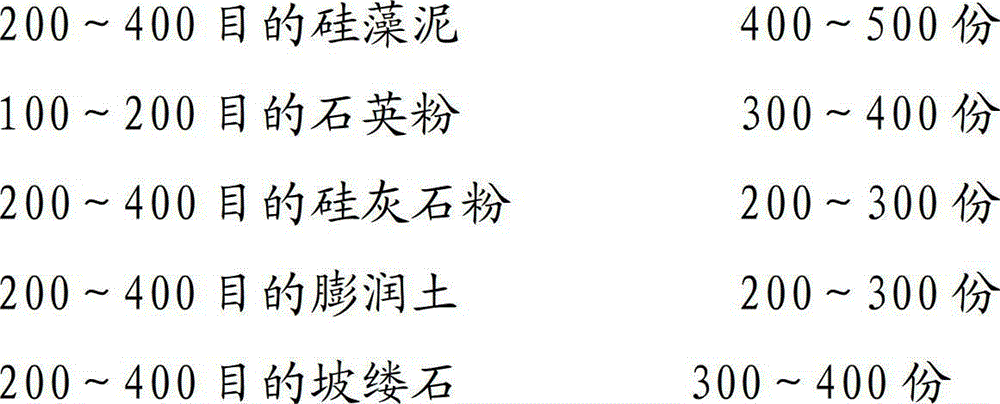

[0050] The weakly alkaline diatom mud wall material comprises wall material powder and water, and the wall material powder includes the following components by weight in grams:

[0051]

[0052] The preparation method comprises the following steps:

[0053] (1) Weigh the components of the wall material powder in parts by weight, and mix them evenly with a mixer;

[0054] (2) Weighing water, the weight ratio of the wall material powder to water is 1:1.0;

[0055] (3) Add 80% of the wall material powder mixed in step (1) to the water prepared in step (2), and stir with a mixer for 2 to 5 minutes until uniform;

[0056] (4) Add the remaining wall material powder, stir with a mixer for 1 to 3 minutes, and mix the wall material powder and water into a paste without hanging.

Embodiment 3

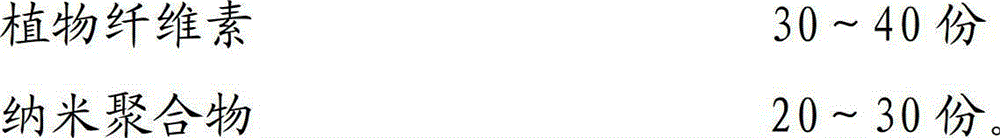

[0058] The weakly alkaline diatom mud wall material comprises wall material powder and water, and the wall material powder includes the following components by weight in grams:

[0059]

[0060]

[0061] The preparation method comprises the following steps:

[0062] (1) Weigh the components of the wall material powder in parts by weight, and mix them evenly with a mixer;

[0063] (2) Weighing water, the weight ratio of the wall material powder to water is 1:1.1;

[0064] (3) Add 85% of the wall material powder mixed in step (1) to the water prepared in step (2), and stir with a mixer for 2 to 5 minutes until uniform;

[0065] (4) Add the remaining wall material powder, stir with a mixer for 1 to 3 minutes, and mix the wall material powder and water into a paste without hanging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com