Hot stripping pliers for ribbon fiber

A ribbon-shaped optical fiber and stripping forceps technology, which is applied in the field of optical fiber stripping devices, achieves the effects of stable clamping, reduced skill requirements, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

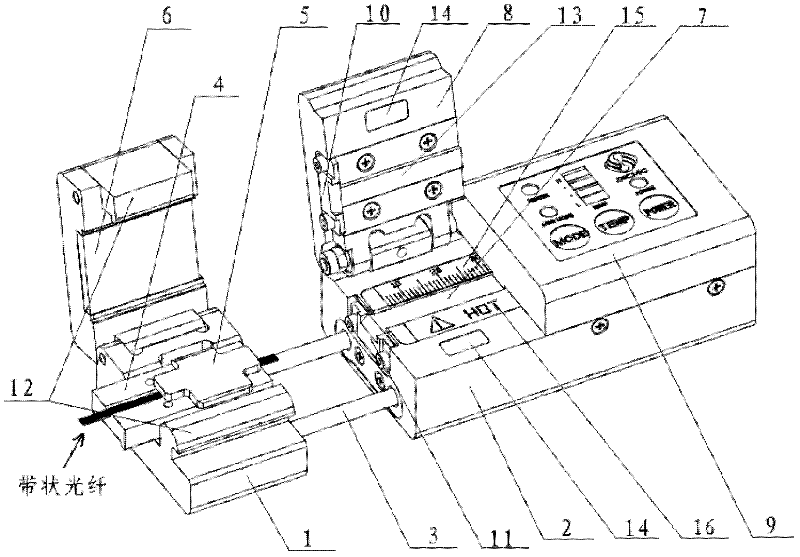

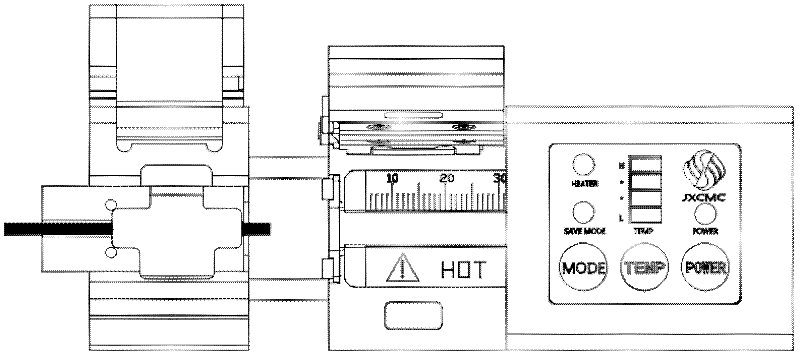

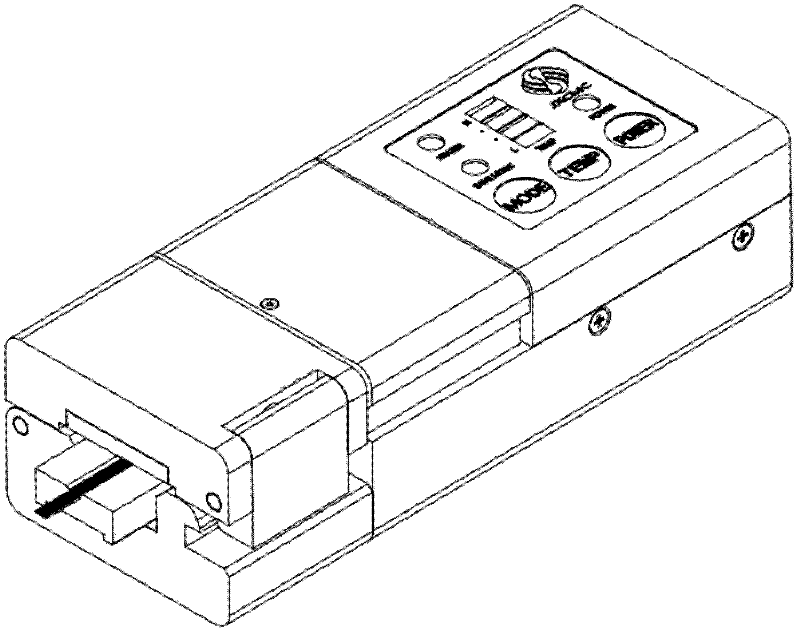

[0021] Such as figure 1 As shown, a strip-shaped optical fiber thermal stripper includes a left base 1 and a right base 2, the left end of the right base 2 is equipped with a linear bearing 3, the left base 1 is slidably mounted on the linear bearing 3, and the left base 1 is hinged with a left cover Plate 6, the bottom plate 4 is installed in the left base 1, the pressure block 5 is installed in the left cover plate 6, and the left cover plate 6 can be attracted to each other when it is tightly closed on the left base 1; the heating plate is installed on the left side of the right base 2 7. A heating system connected to the heating sheet 7 is installed on the right side, and an operation panel 9 connected to the heating system is installed. The right base 2 is hinged with a middle cover plate 8 that can be tightly closed on the heating sheet 7. The right base 2 The upper blade 10 and the lower blade 11 that are cut in half are installed on the left end of the middle cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com