Refrigerant filling method for outdoor unit of air conditioner

An air conditioner outdoor unit and outdoor unit technology, which is applied in air conditioning systems, refrigerators, heating methods, etc., can solve the problem of low refrigerant perfusion speed, etc., and achieve the effect of increasing the perfusion speed, improving the efficiency of operation and production, and improving the perfusion accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

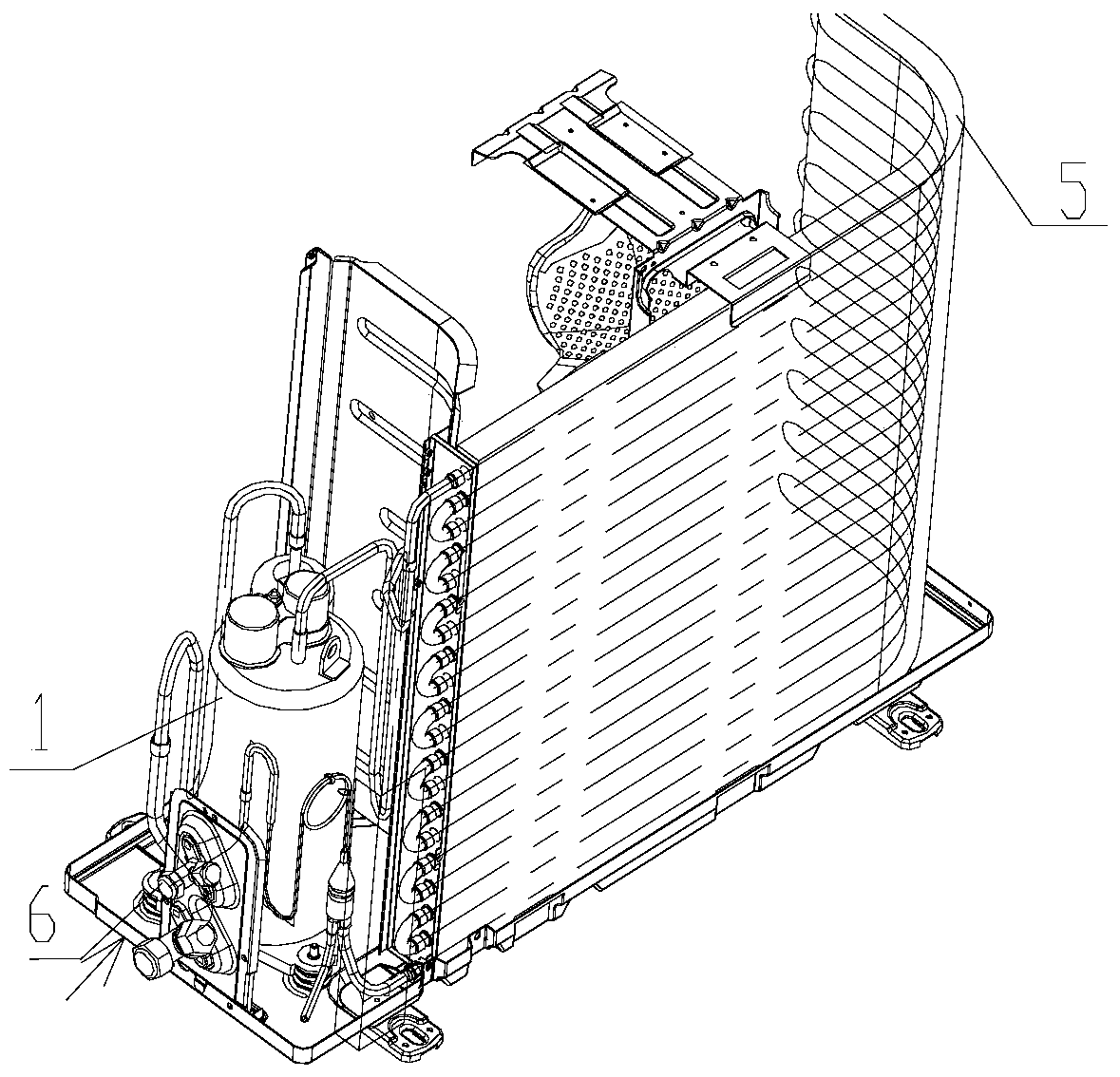

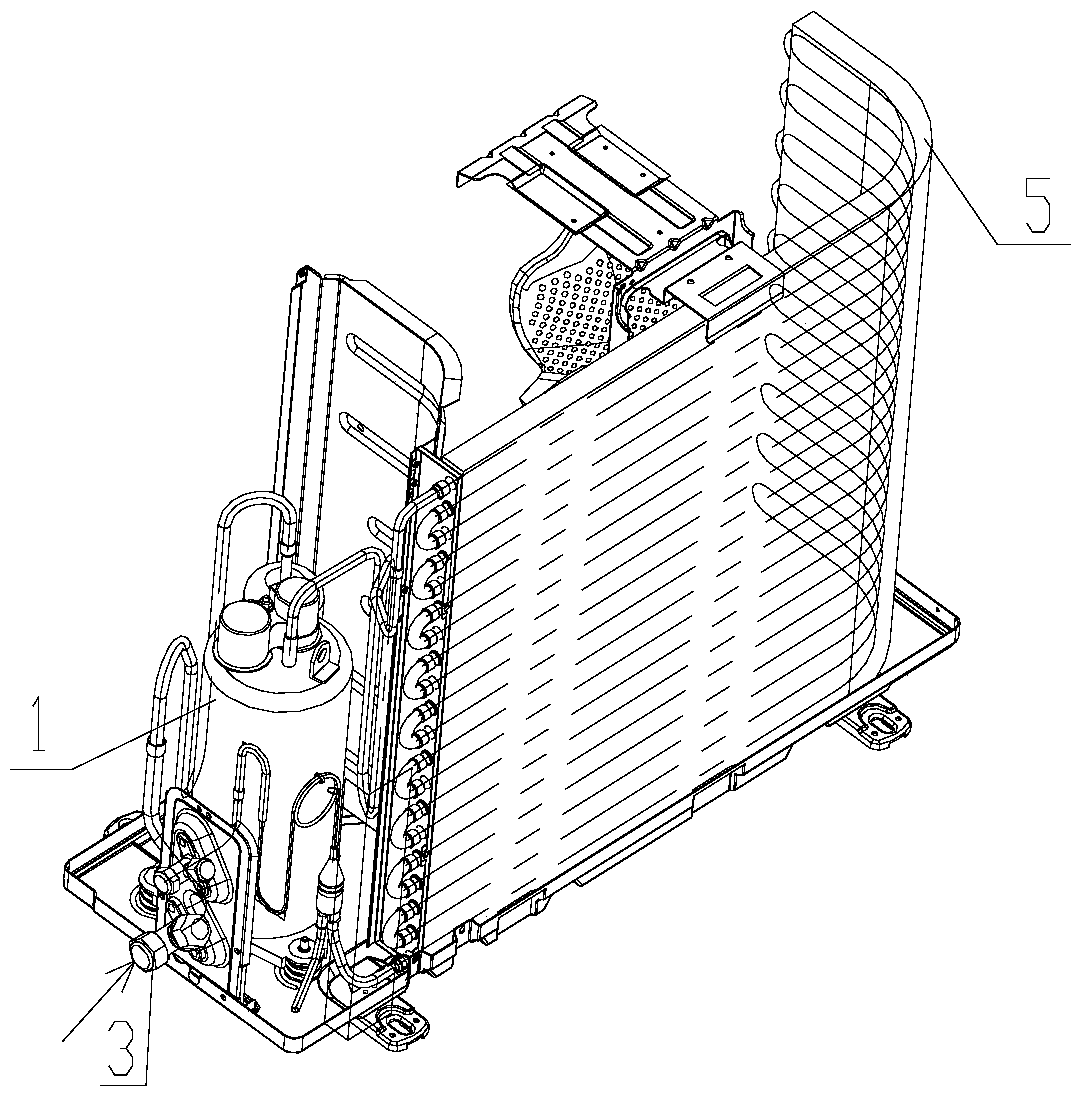

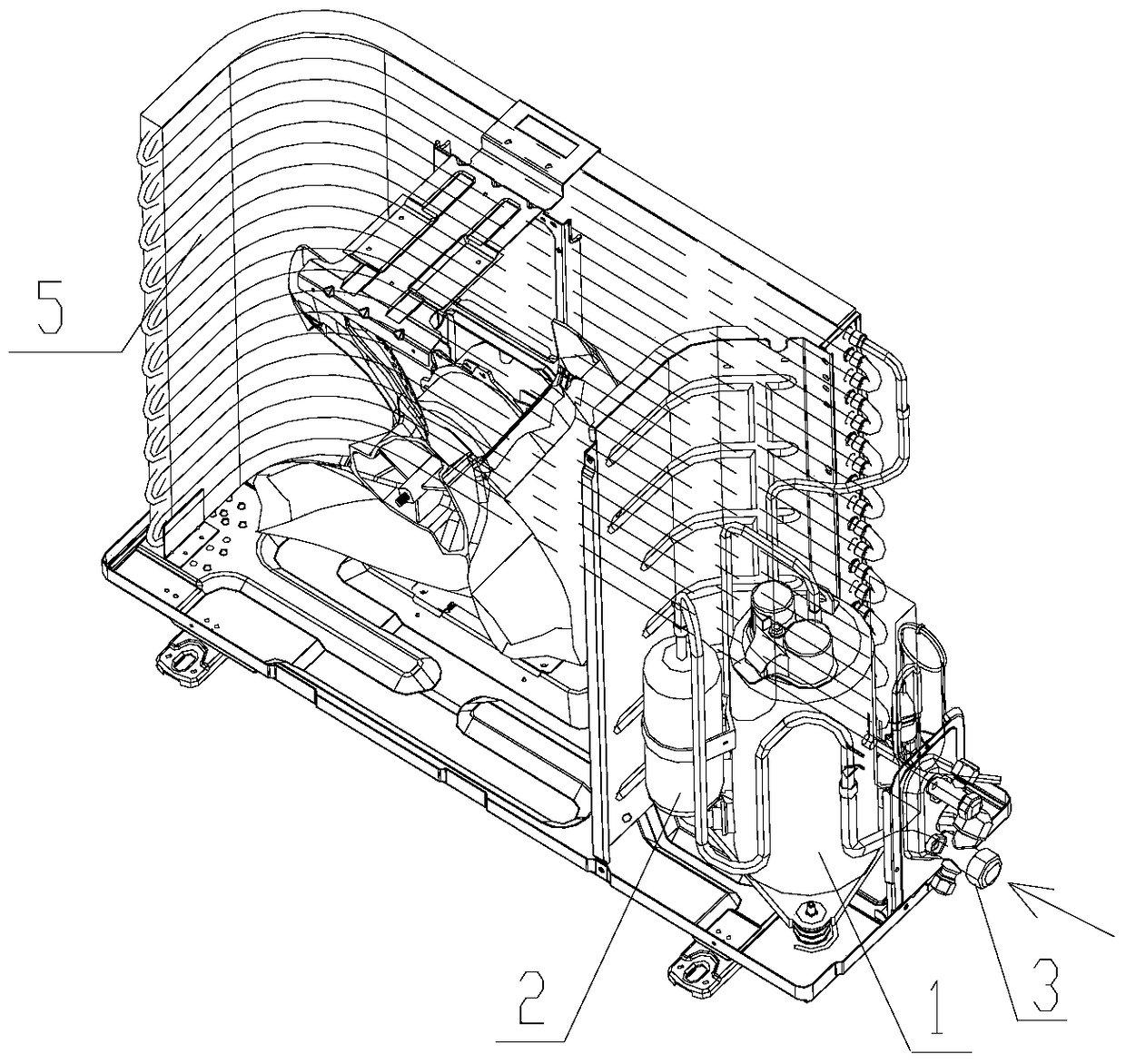

[0029] Such as Figure 2-7 As shown, the present invention provides an air-conditioning system, which includes a compressor 1 having a discharge chamber and a suction chamber, and a liquid storage tank 2 communicating with the suction chamber of the compressor 1. The air flow upstream end of the discharge chamber of the compressor 1 is also provided with a discharge valve plate, and the air conditioning system also includes the refrigerant required for filling the air conditioning system into the discharge chamber of the compressor 1 and / or the large valve structure of the suction cavity3. There are two valves, one large and one small, on the outdoor unit of the air conditioner. The large valve and the small valve are relative terms of pipe diameter. (Usually, at present, the outer diameter of the copper pipe of the small valve of the company's household air conditioner is D6 (mm), and the large valve has specifications such as D9.52, D12, D18, and D24 (mm). This specificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com