Pre-curing perfusion method for wind power blade without flow guide net

A wind turbine blade and pre-curing technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems that are not conducive to the penetration of perfusion resin, prolong the production cycle of blades, increase the use of diversion nets, etc., so as to shorten the layer laying. time, enhance market competitiveness, and improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

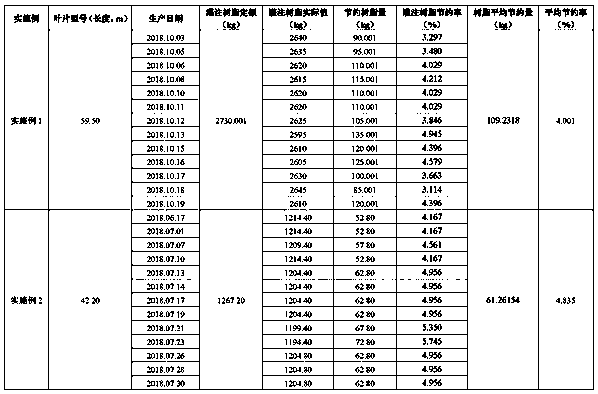

[0023] Example 1: Pre-cured perfusion production of megawatt-class wind power blades with a length of 59.50 m

[0024] (1) Mold cleaning: clean the surface of the mold, use a film cleaner to remove oil and stains, take a clean degreasing gauze with a length of 0.8m-1.5m and knead it into a ball, moisten it with a release agent, and clean the distance between the front and rear edges of the mold cavity In the 300mm area of the inner edge, apply the release agent evenly on the surface of the mold in a spiral circle.

[0025] (2) Laying the release cloth: After the release agent is applied, lay the release cloth from the root of the blade to the tip of the blade. When laying, turn 20mm out of the parting surface, and leave the rest in the mold cavity, confirm After the release cloth is smooth and wrinkle-free, it is fixed by spraying glue.

[0026] (3) Lay the outer skin cloth layer: Lay five layers of outer skin cloth in sequence, and the laying direction of each layer is fro...

Embodiment 2

[0031] Example 2: Pre-cured perfusion production of megawatt wind power blades with a length of 42.20 m

[0032] (1) Mold cleaning: clean the surface of the mold, use a film cleaner to remove oil and stains, take a clean degreasing gauze with a length of 0.8m-1.5m and knead it into a ball, moisten it with a release agent, and clean the distance between the front and rear edges of the mold cavity In the 300mm area of the inner edge, apply the release agent evenly on the surface of the mold in a spiral circle.

[0033] (2) Laying the release cloth: After the release agent is applied, lay the release cloth from the root of the blade to the tip of the blade. When laying, turn 20mm out of the parting surface, and leave the rest in the mold cavity, confirm After the release cloth is smooth and wrinkle-free, it is fixed by spraying glue.

[0034](3) Lay the outer skin cloth layer: Lay five layers of outer skin cloth in sequence, and the laying direction of each layer is from the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Lap width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com