Perfusion structure of transformer

A transformer and magnetic core technology, applied in the field of transformers, can solve problems such as transformer inductance drop, and achieve the effects of improving efficiency, solving inductance drop, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

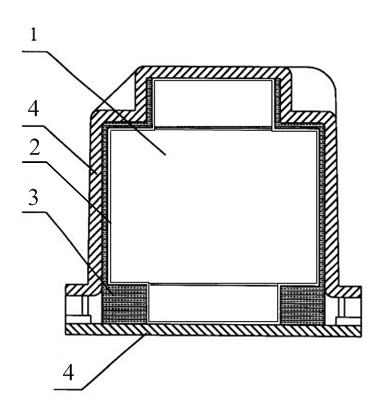

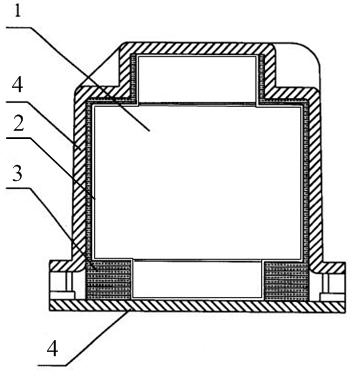

[0011] Such as figure 1 As shown, the present invention includes a magnetic core 1 and a casing 4, and the magnetic core 1 is installed in the casing 4 (the casing 4 is divided into an upper casing and a lower casing). A layer of silica gel layer 2 is coated on the surface of the magnetic core 1, which can reduce the influence of epoxy stress, and then the epoxy layer 3 is poured between the silica gel layer 2 and the shell 4 to increase the withstand voltage of the transformer. For the silica gel layer 2 coated in the present invention, it is better to select silica gel with lower fluidity.

[0012] After testing, the transformer adopting the structure of the present invention has only 30% drop in inductance, qualified withstand voltage, and can meet the performance requirements of the transformer.

[0013] What is described above is only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com