Step-by-step tightening-type template limiting fastener

A technology of step-by-step tightening and formwork, which is applied to the joints of formwork/formwork/work frame, the preparation of building components on site, and construction, which can solve the problems of easy loss and easy fall of step-by-step tightening devices, so as to prevent Drop and lose, solve the effect of easy falling, and facilitate centralized collection and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

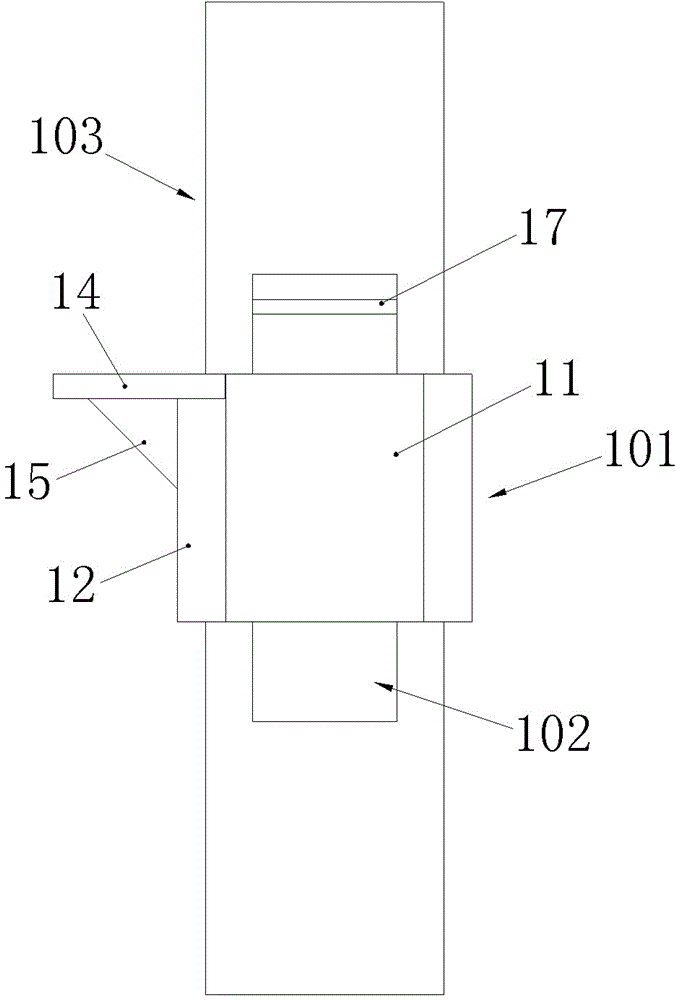

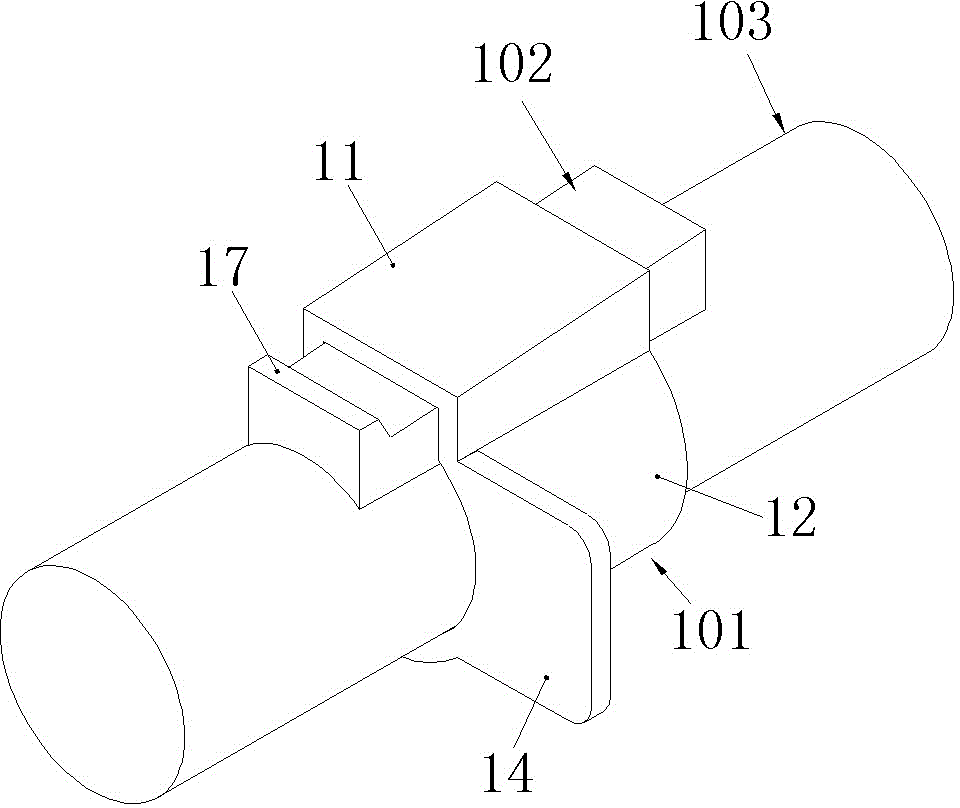

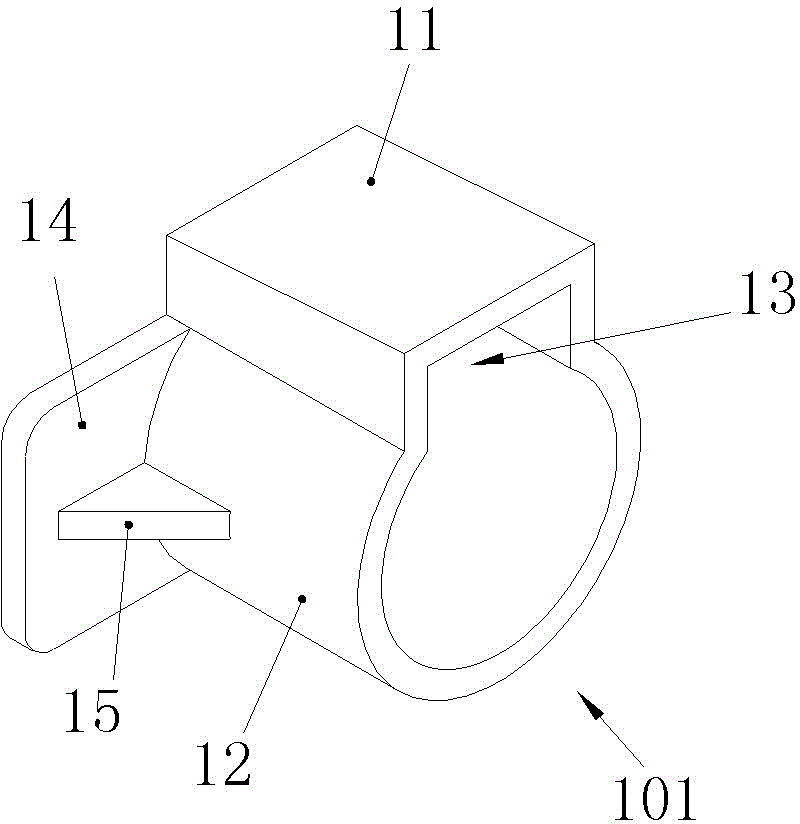

[0025] Examples of step-by-step formwork limit fasteners, such as Figure 1-6 As shown, the limit fastener in this embodiment is composed of a support sleeve 101 and an expansion block 102 . The support sleeve 101 includes a locking part 11 and a sliding sleeve part 12, wherein the cross section of the sliding sleeve part 12 is C-shaped, and the cross-section of the locking part 11 is U-shaped, and the locking part 11 and the sliding sleeve part 12 are arranged mouth to mouth. The U-shaped groove surrounded by the locking part 11 is a through groove through up and down, and the through groove forms a lock groove 13. The groove bottom surface of the lock groove 13 is a slope that gradually inclines toward the inner side of the support sleeve from back to front; in addition, the sliding sleeve The front end of the part 12 is provided with a side wing 14 for pressing the corresponding formwork forward, and the side wing 14 protrudes toward the radial periphery of the support slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com