Thin cast-in-place concrete thin plastering component and construction process thereof

A construction technology and concrete structure technology, which is applied in the field of construction engineering, can solve the problems of mortar falling, reduce raw materials, etc., and achieve the effects of reducing plastering labor, improving project quality, and preventing hollowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

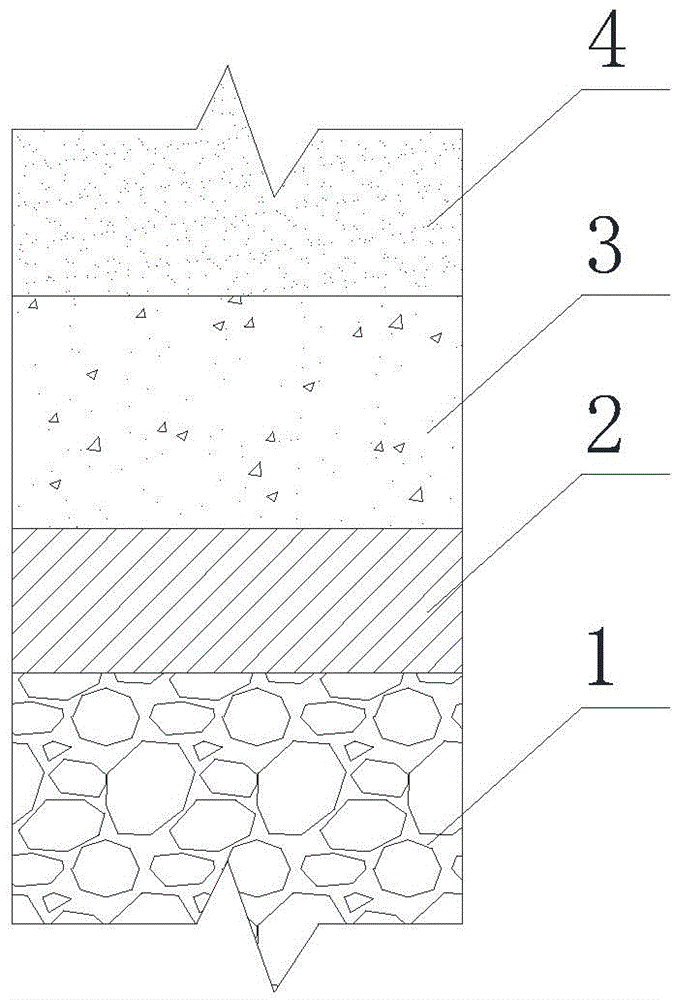

[0029] A construction technique for thin cast-in-place concrete thin plastering components, which comprises the following steps:

[0030] (1), make concrete structure layer 1;

[0031] (2), coating interface agent: after the concrete structure layer 1 is stable, coat interface agent on the concrete structure layer to form interface agent layer 2, the thickness of interface agent layer 2 is 2mm, and described interface agent is made of cement: water: building Glue: sand: retarder is mixed according to the weight ratio of 1:0.5:0.15:0.1:0.03;

[0032] (3), coating anti-cracking mortar: after 48 hours after the construction of the interface agent, coat the anti-cracking mortar with a thickness of 3-5mm on the interface agent to form the anti-cracking mortar layer 3, and the anti-cracking mortar is based on the gray-to-water ratio of 1 : The ratio of 0.3 is mixed with 0.05 anti-cracking agent;

[0033] (4), coating surface layer 4: coating surface layer 4 on the anti-cracking mo...

Embodiment 2

[0036] A construction technique for thin cast-in-place concrete thin plastering components, which comprises the following steps:

[0037] (1), make concrete structure layer 1;

[0038] (2), coating interface agent: after the concrete structure layer 1 is stable, coat interface agent on the concrete structure layer to form interface agent layer 2, the thickness of interface agent layer 2 is 1mm, and described interface agent is made of cement: water: building Glue: sand: retarder is mixed according to the weight ratio of 1:0.4:0.1:0.15:0.01;

[0039] (3), coating anti-cracking mortar: after 48 hours after the construction of the interface agent, coat the anti-cracking mortar with a thickness of 3-5mm on the interface agent to form the anti-cracking mortar layer 3, and the anti-cracking mortar is based on the gray-to-water ratio of 1 : The ratio of 0.2 is mixed with 0.03 anti-cracking agent;

[0040] (4), coating surface layer 4: coating surface layer 4 on the anti-cracking mo...

Embodiment 3

[0043] A construction technique for thin cast-in-place concrete thin plastering components, which comprises the following steps:

[0044] (1), make concrete structure layer 1;

[0045] (2), coating interface agent: after the concrete structure layer 1 is stable, coat interface agent on the concrete structure layer to form interface agent layer 2, the thickness of interface agent layer 2 is 3mm, and described interface agent is made of cement: water: building Glue: sand: retarder is mixed according to the weight ratio of 1:0.6:0.15:0.05:0.05;

[0046] (3), coating anti-cracking mortar: after 48 hours after the construction of the interface agent, coat the anti-cracking mortar with a thickness of 3-5mm on the interface agent to form the anti-cracking mortar layer 3. The anti-cracking mortar is based on the gray-to-water ratio of 1 : The ratio of 0.4 is mixed with 0.08 anti-cracking agent;

[0047] (4), coating surface layer 4: coating surface layer 4 on the anti-cracking morta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com