Patents

Literature

30results about How to "Shorten the perfusion time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

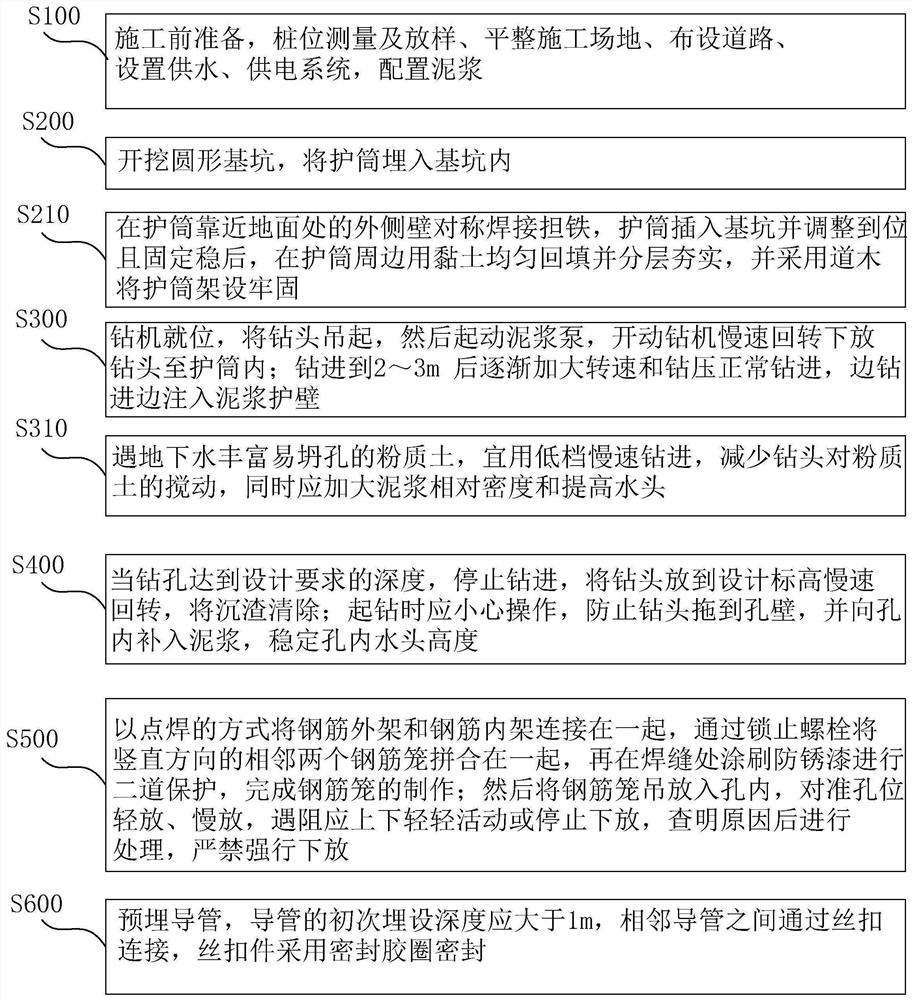

Construction process of floral tube dry filling piles

InactiveCN101713189AReduce labor intensityFew control parametersBulkheads/pilesResource utilizationWater table

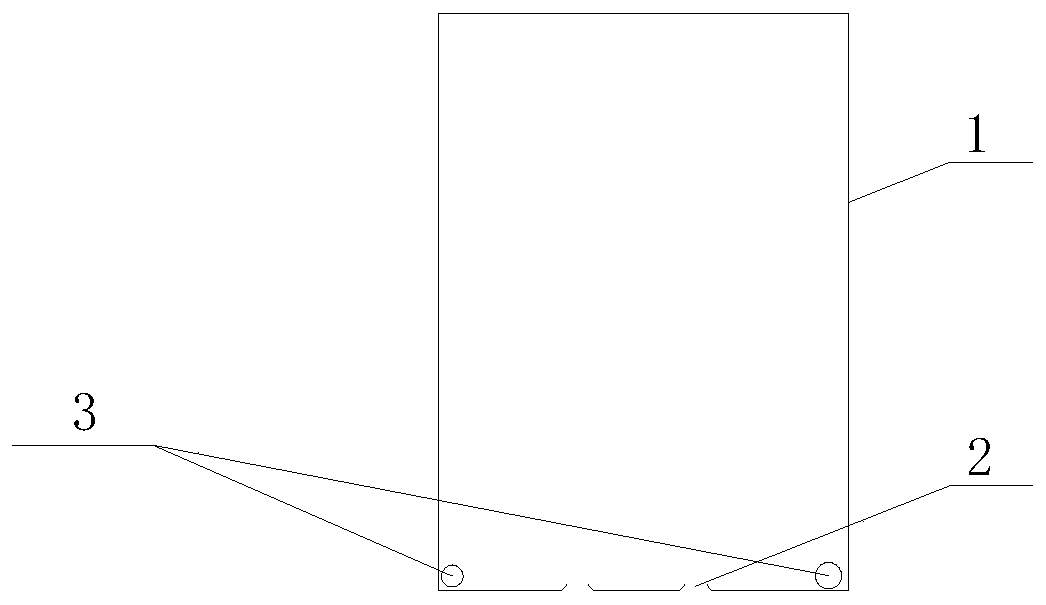

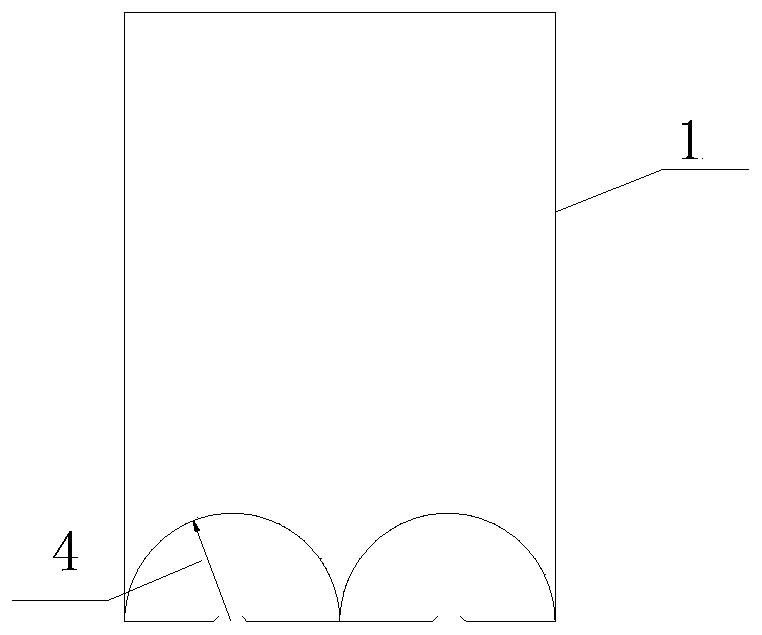

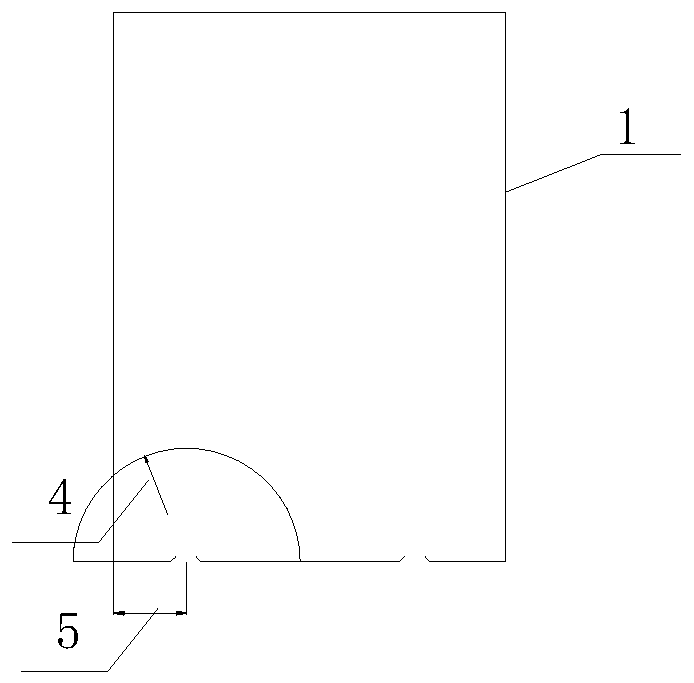

The invention relates to a construction process of floral tube dry filling piles with obvious engineering effect, low economic cost, high technical content and high resource utilization by improving the inherent characteristics of cement, soil strata, materials and the like. The process comprises the following steps of: (1) pore-forming process: 1, using dry pore-forming process for pore-forming piles above underground water level; 2, positioning a pore opening machine and a drill for pore-forming piles below underground water level; drilling in at low stroke and high rotary speed with clean water; reaching a drilling-in depth; lifting to a pore opening at unified stroke and high rotary speed with clean water; drilling into a pore bottom at unified stroke and high rotary speed with clean water; rotating at high speed and filling with cement mortar; and lifting to the pore opening at high rotary speed and low stroke after cement mortar returns to the pore opening; moving the drill; (2) the process of installation and pile molding by filling: adopting the following steps for installing pile pores and filling dry cement above or below water level: installing floral tubes; correcting the pore position of the floral tubes; filling the dry cement; and filling the dry cement to an elevation required by the design.

Owner:HENAN UNIVERSITY

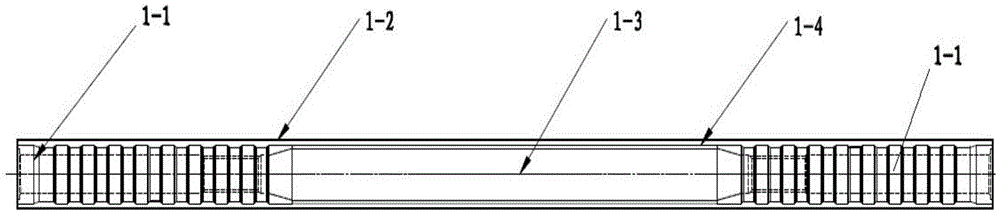

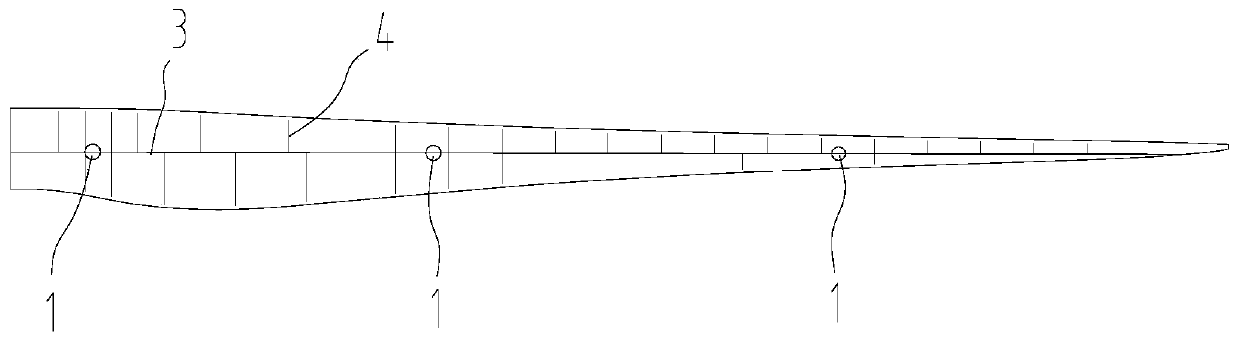

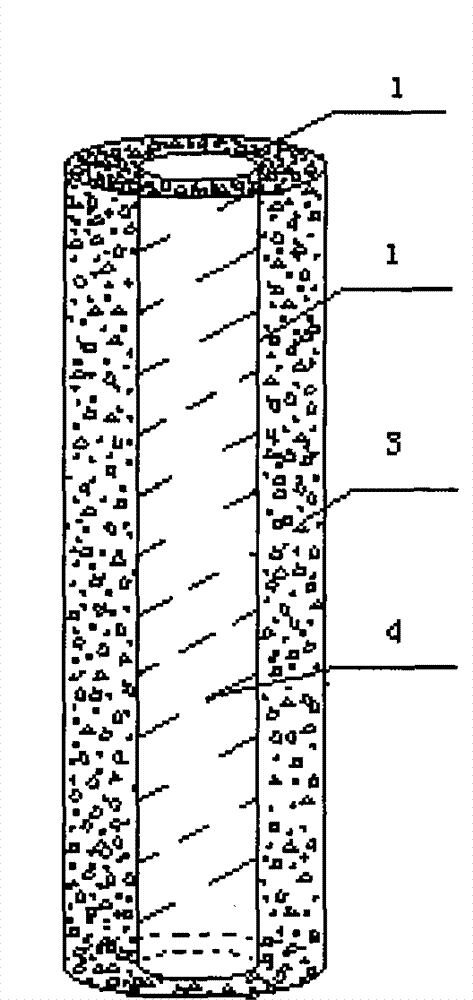

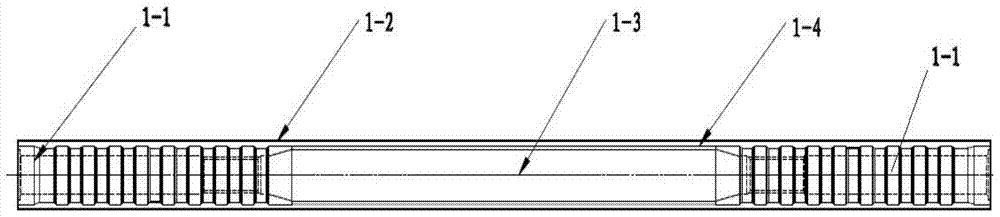

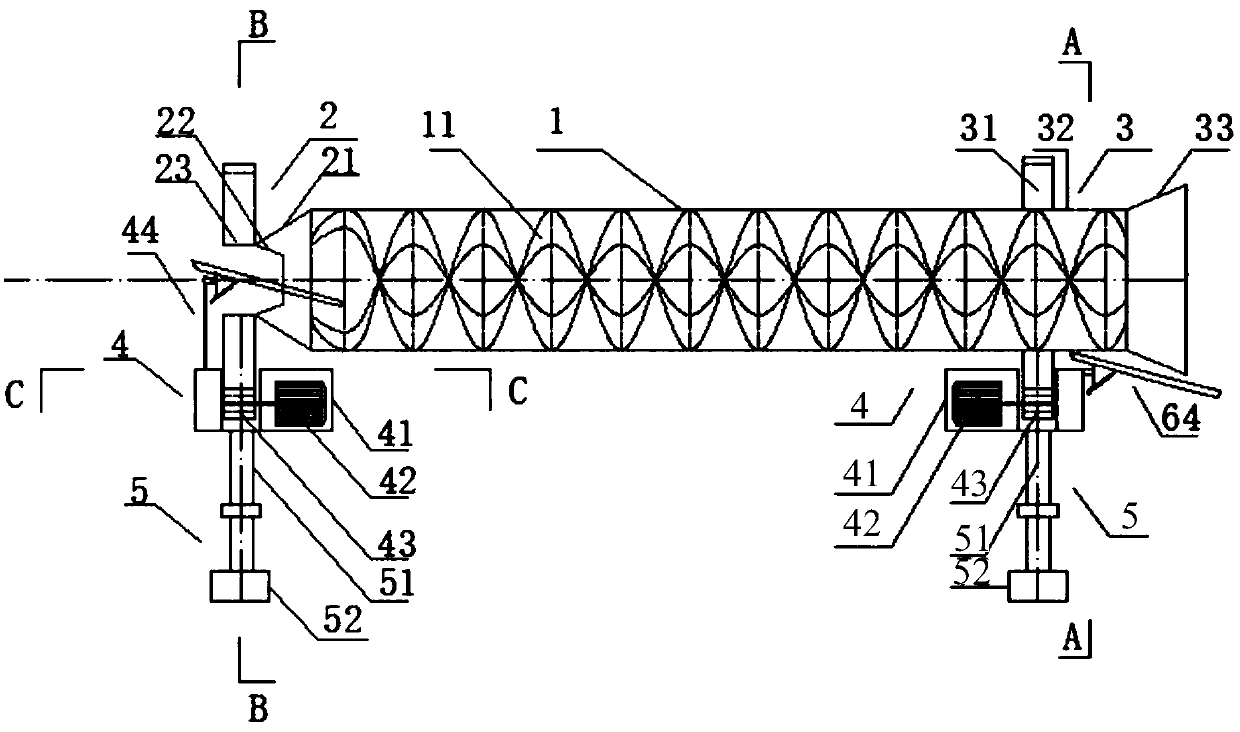

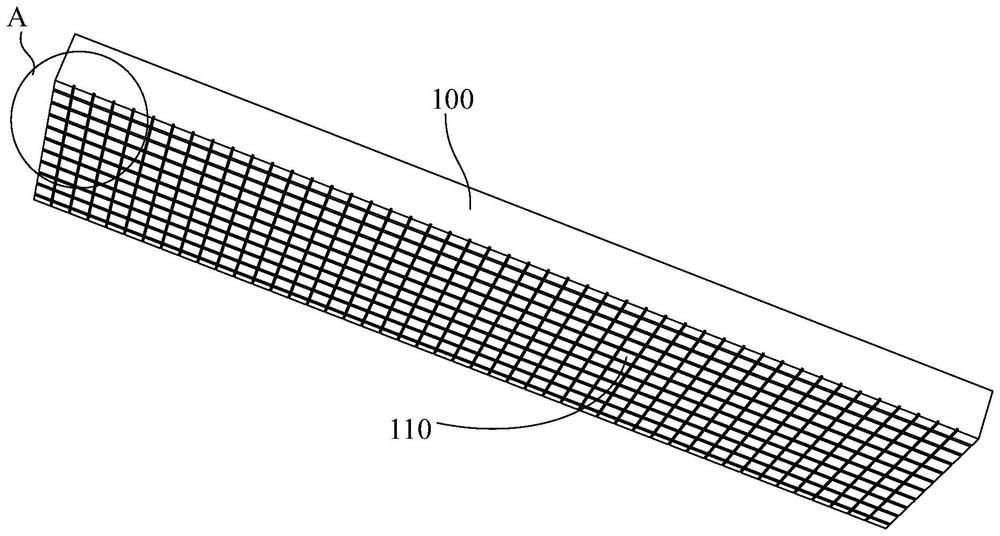

Pultrusion type embedded blade root connector for wind-driven generator blades and preparation method thereof

ActiveCN105465141AUnique strengthUnique Design FreedomFinal product manufactureNutsWind drivenEmbedded system

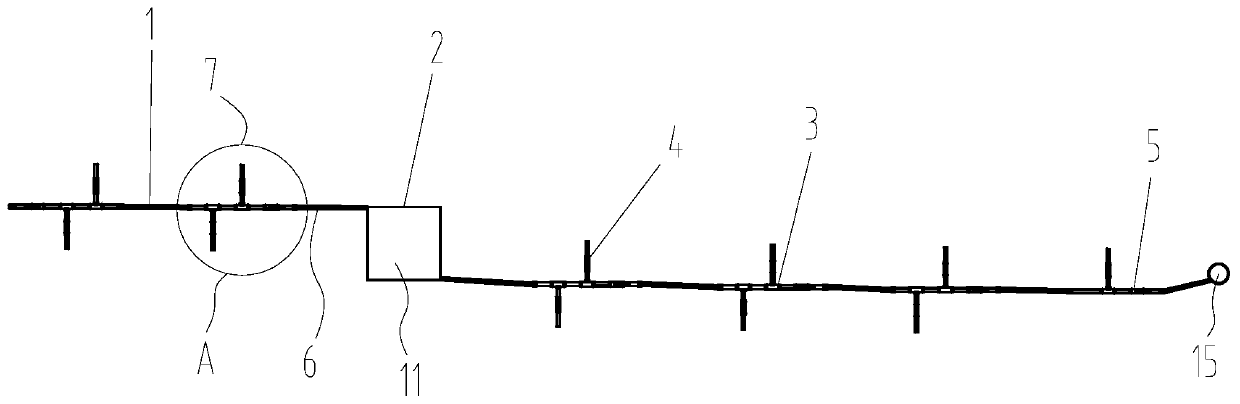

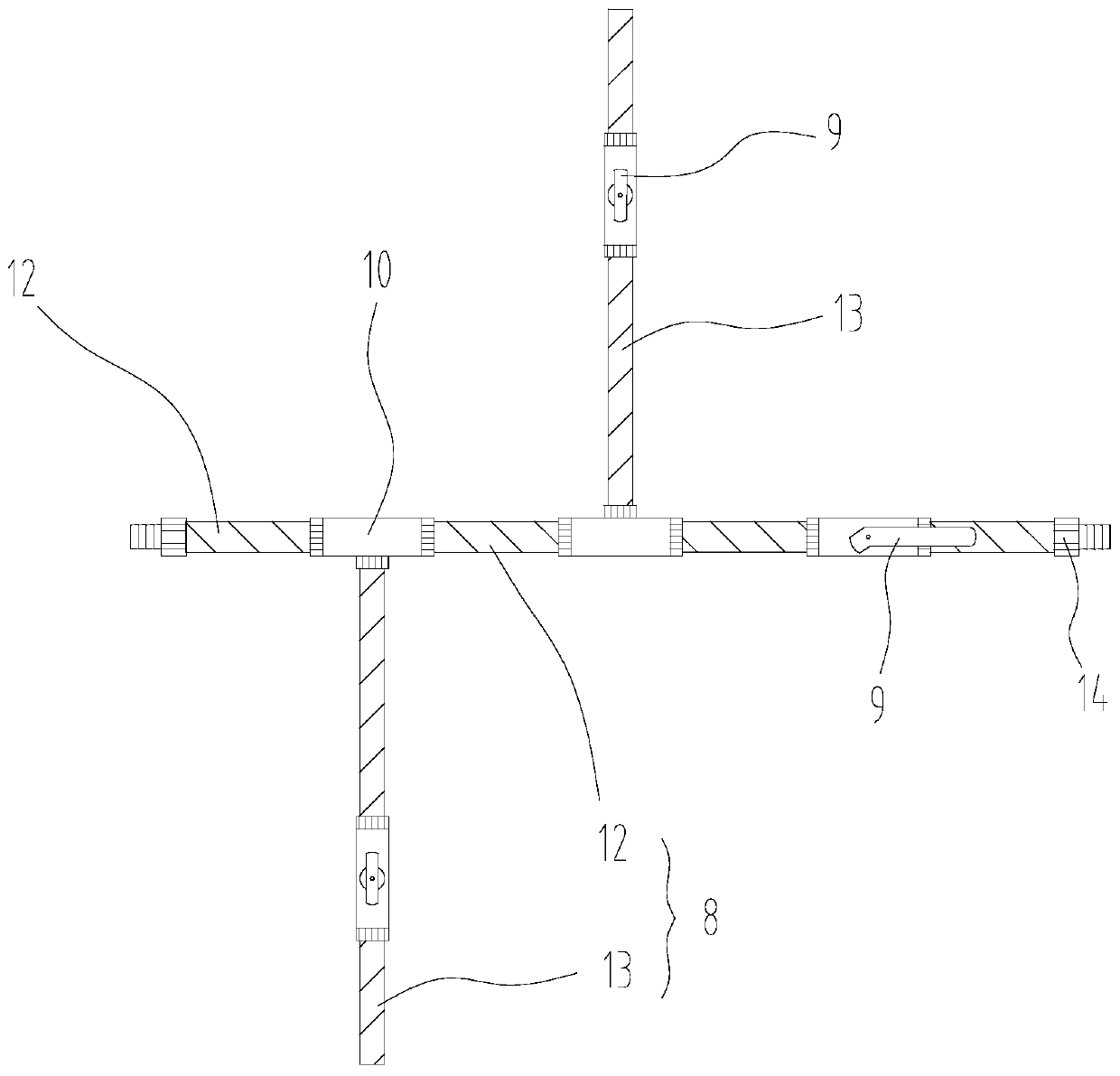

The invention discloses a pultrusion type embedded blade root connector for wind-driven generator blades and a preparation method thereof. The pultrusion type embedded blade root connector comprises blade root connector bodies (1-1), a light connector body (1-4) connected to the blade root connector bodies (1-1), light material (1-3) filling the light connector body (1-4), and a pultrusion type composite material part (1-2) wrapping the peripheries of the blade root connector bodies (1-1) and the periphery of the light connector body (1-4). The pultrusion type preparation method comprises the steps of part assembly, embedded type composite material pultrusion and finishing. The embedded blade root connector has the advantages that the appearance size is stable, the defect rate of products is low, the quality is continuously stable and reliable, locating is accurate, interfaces between different kinds of material are firmly bonded, and the mechanization level is high. The preparation method has the advantages that the time of occupying molds by the products can be shortened, the time of laying material can be shortened, the time of installing bolts can be shortened, the time of pouring and curing can be shortened, the production efficiency is high, and the labor cost is low.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

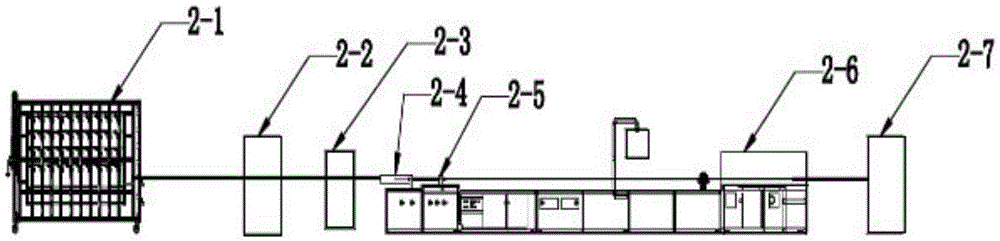

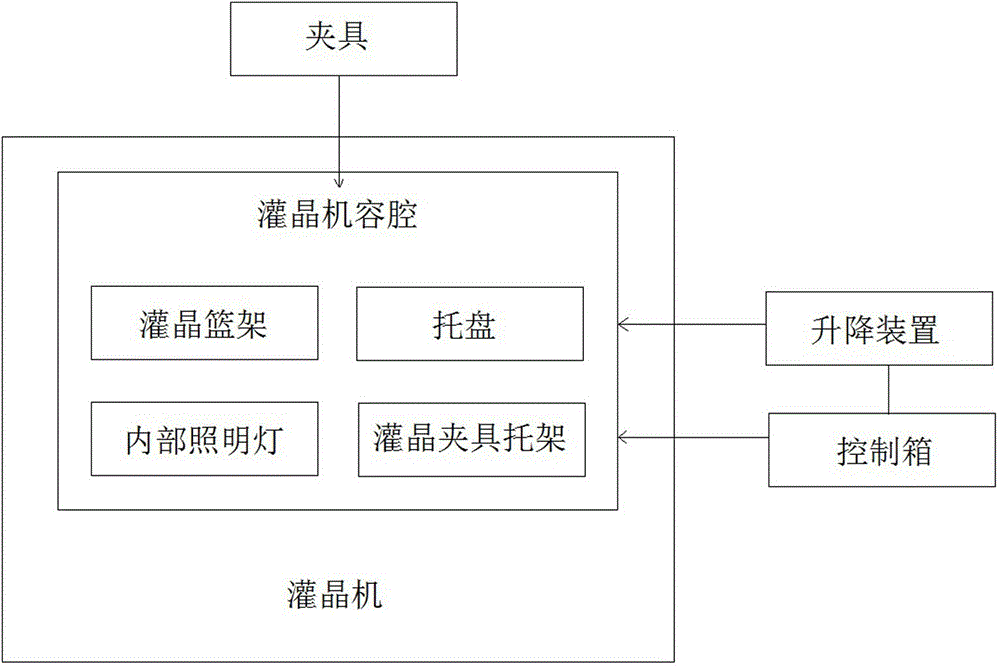

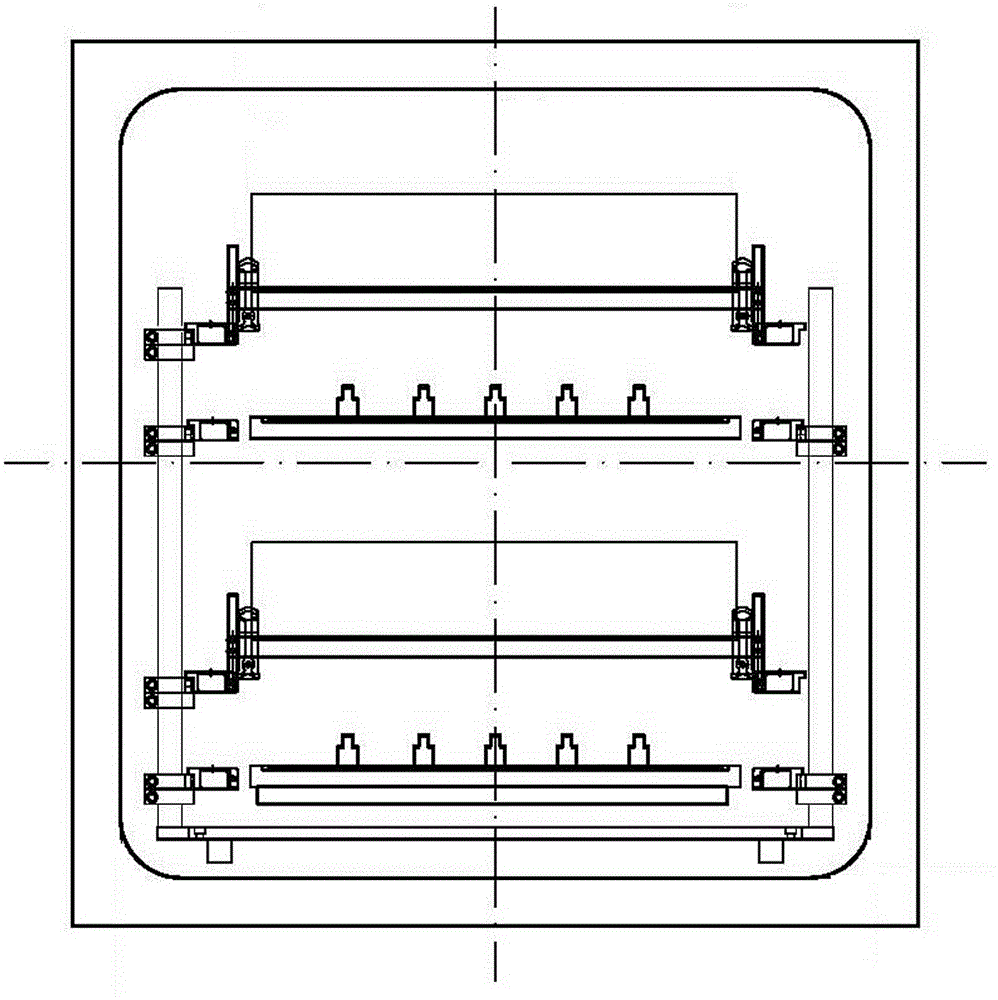

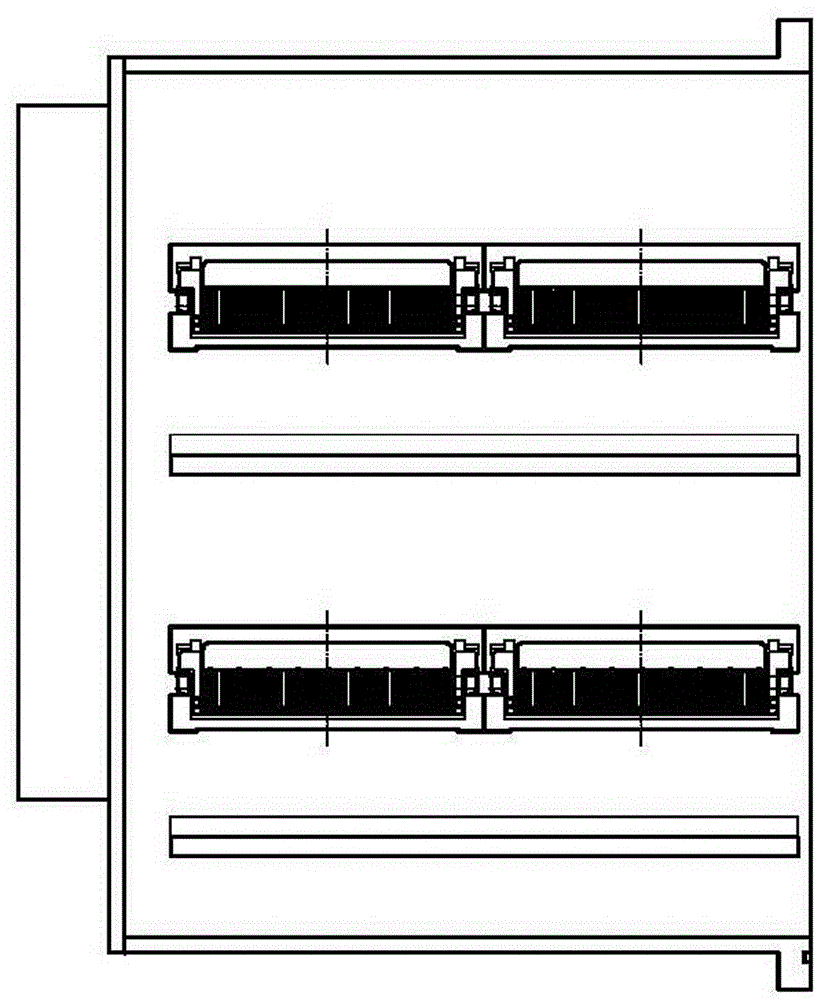

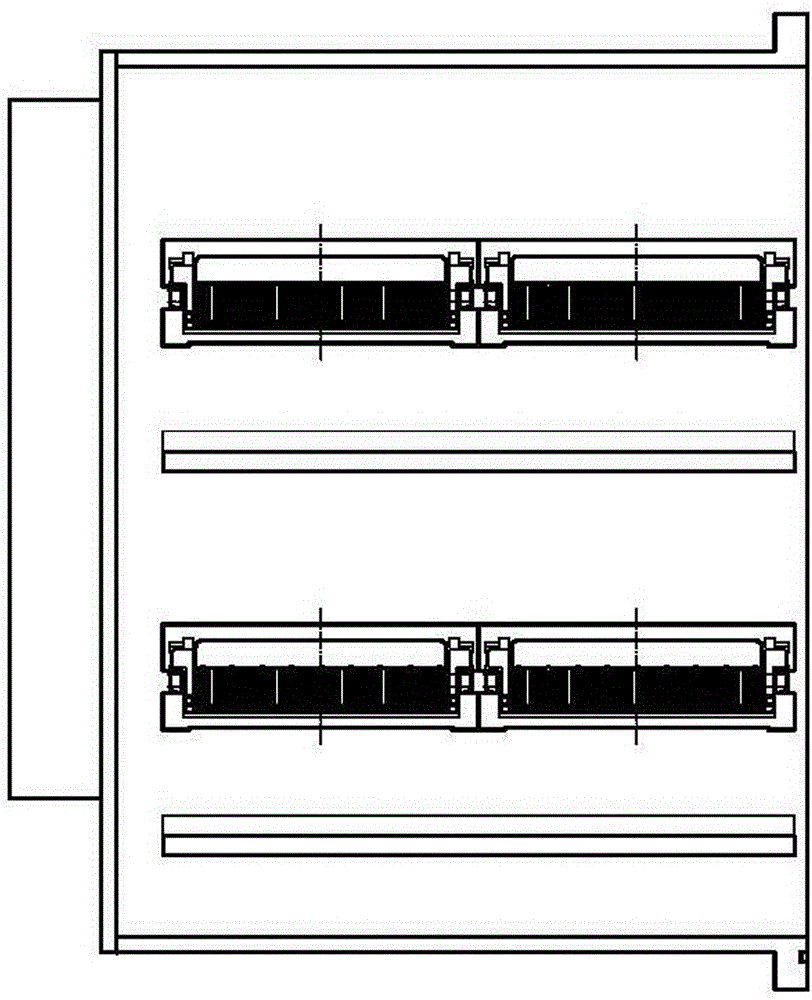

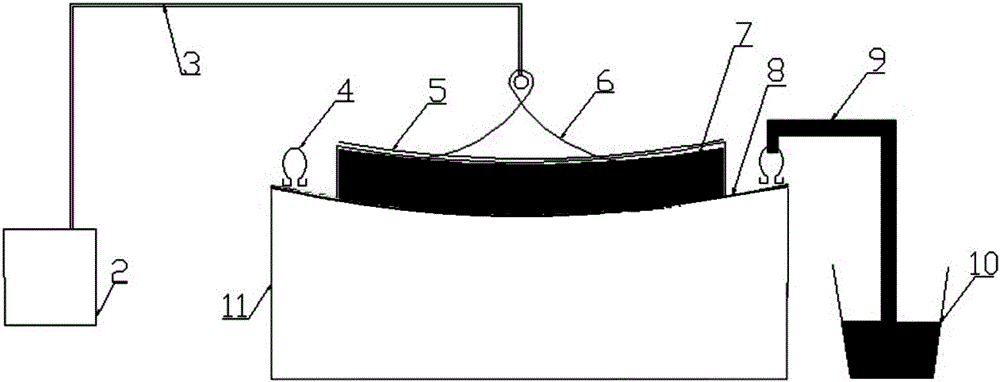

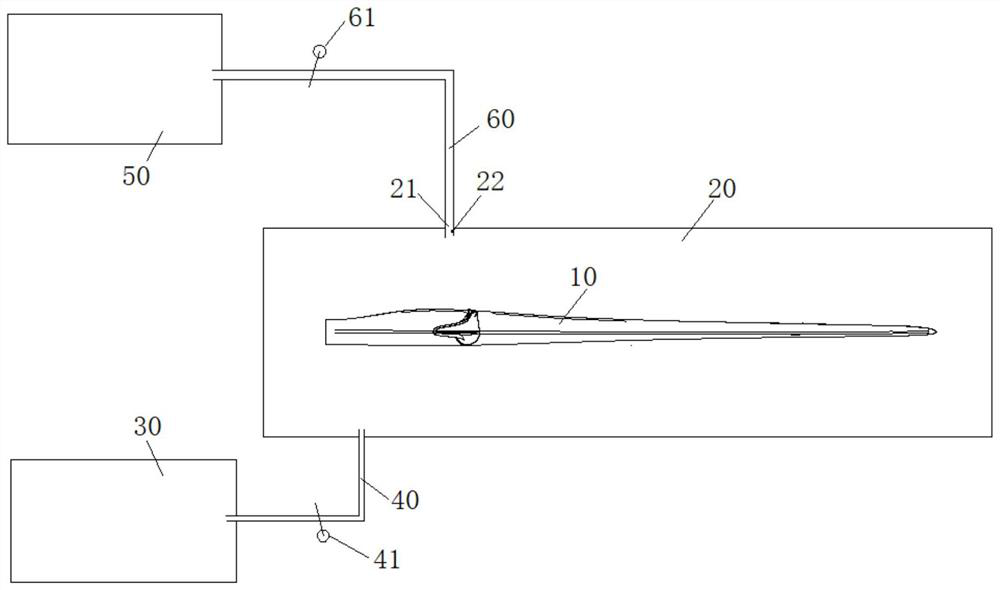

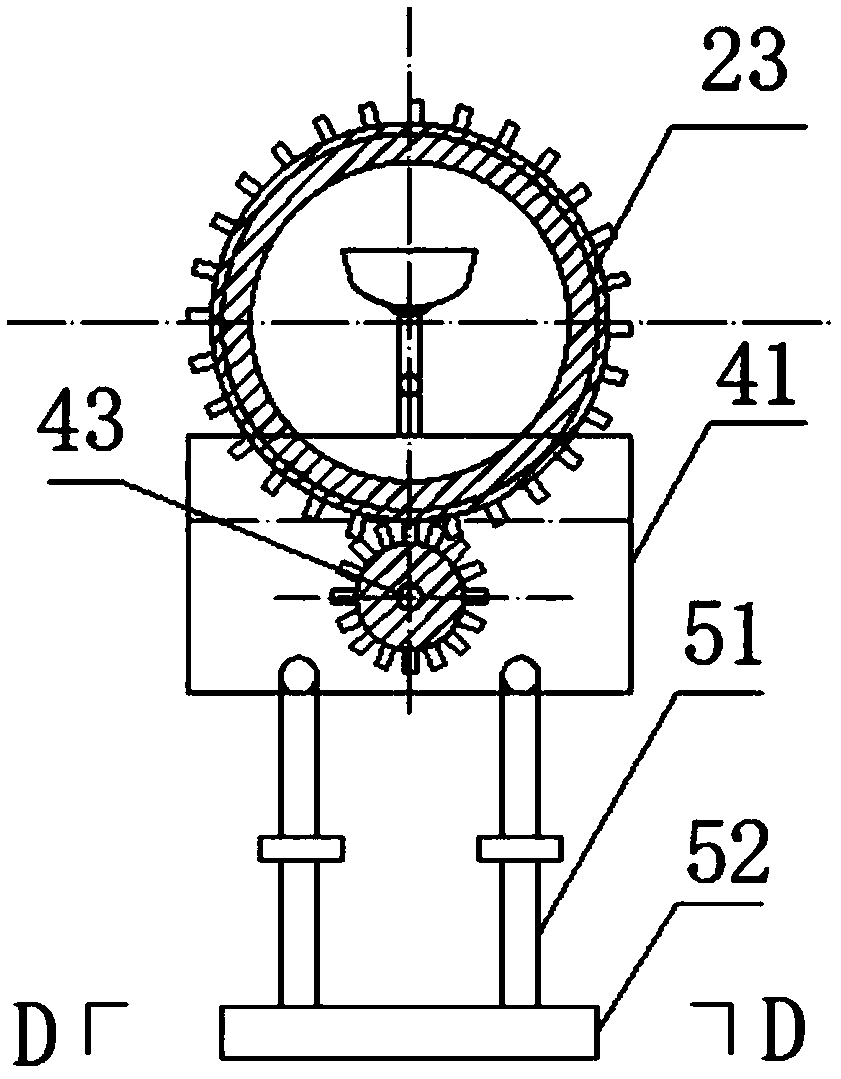

Crystal pouring device and method for flexible liquid crystal cell

InactiveCN104375335ASolve the inability to perfuseLow viscosityNon-linear opticsProduction rateEngineering

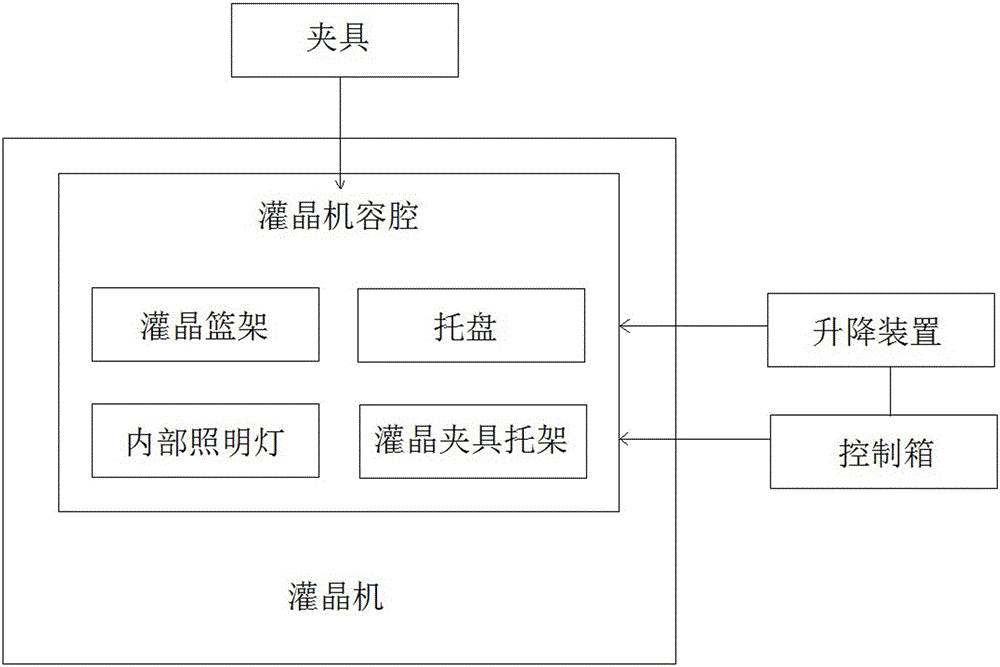

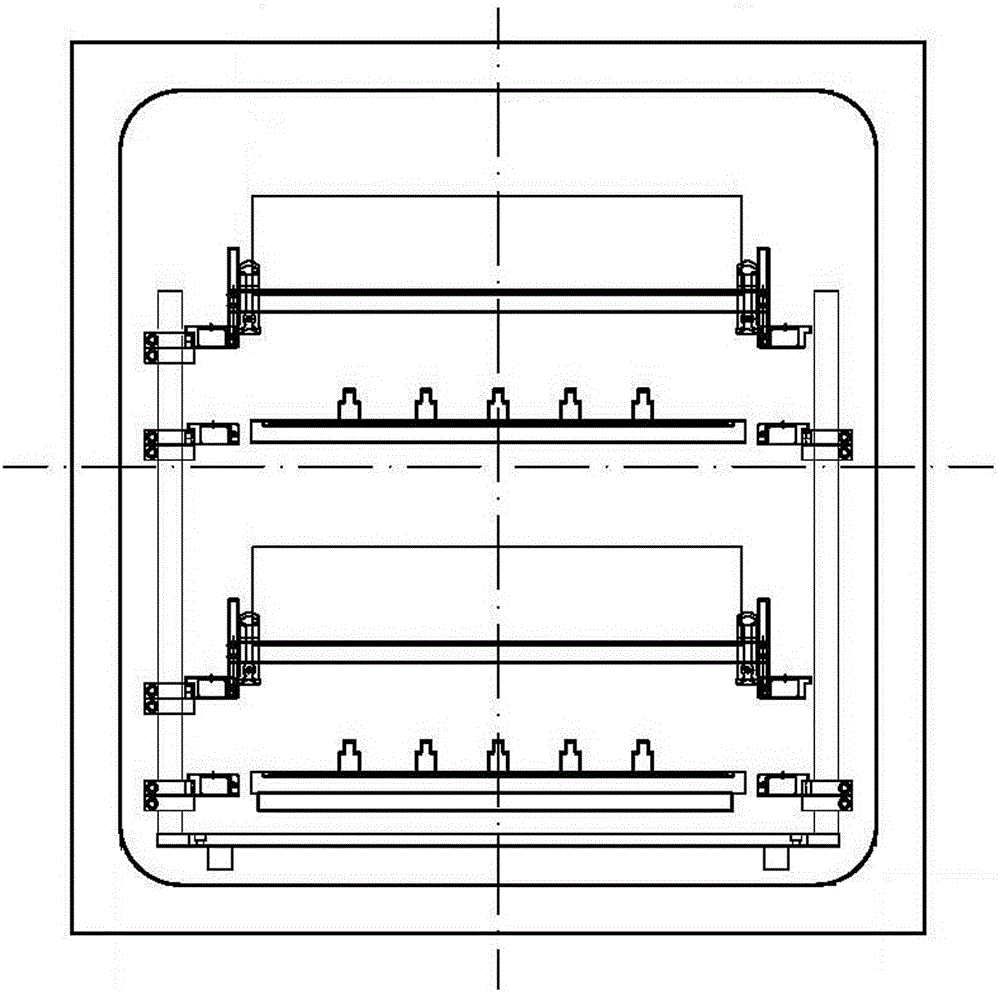

The invention discloses a crystal pouring device and method for a flexible liquid crystal cell. The device comprises a clamp, wherein the clamp is used for clamping the flexible liquid crystal cell into which crystal is to be poured and generating even surface pressure on the flexible liquid crystal cell. Before a crystal pouring machine is vacuumized, even surface pressure is generated on the surface of the flexible liquid crystal cell by means of the clamp, and liquid crystal is heated to reduce the viscosity of the liquid crystal. After the crystal pouring machine is vacuumized, the crystal pouring machine is in a pressure maintaining state to enable the interior vacuum degree of the flexible liquid crystal cell to be balanced, and then crystal pouring and inflation are conducted, so that pressure difference is prevented from being generated between the inside and outside of the flexible liquid crystal cell during vacuumization and cracking of the liquid crystal cell caused by expansion is avoided. The crystal pouring device and method for the flexible liquid crystal cell solve the problem that cracking of the liquid crystal cell can be caused by expansion due to the fact that pressure difference is generated between the inner surface and outer surface of the flexible liquid crystal cell during vacuumization for crystal pouring, productivity is increased, and production cost is reduced.

Owner:SINOFLEX OPTOELECTRONICS CHUZHOU

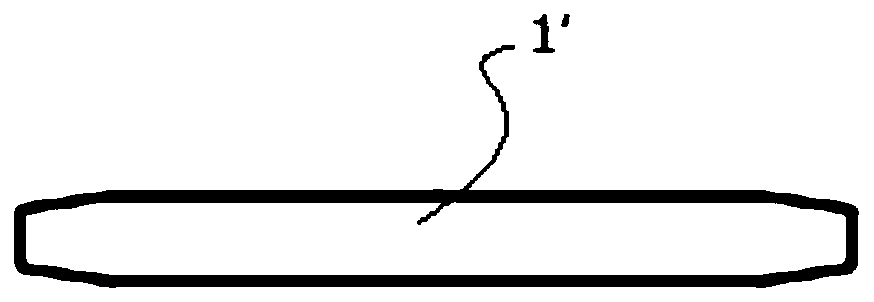

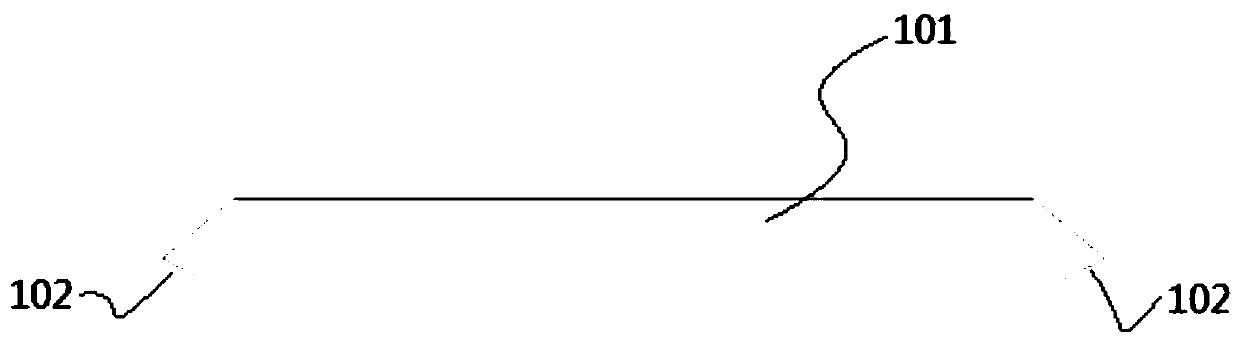

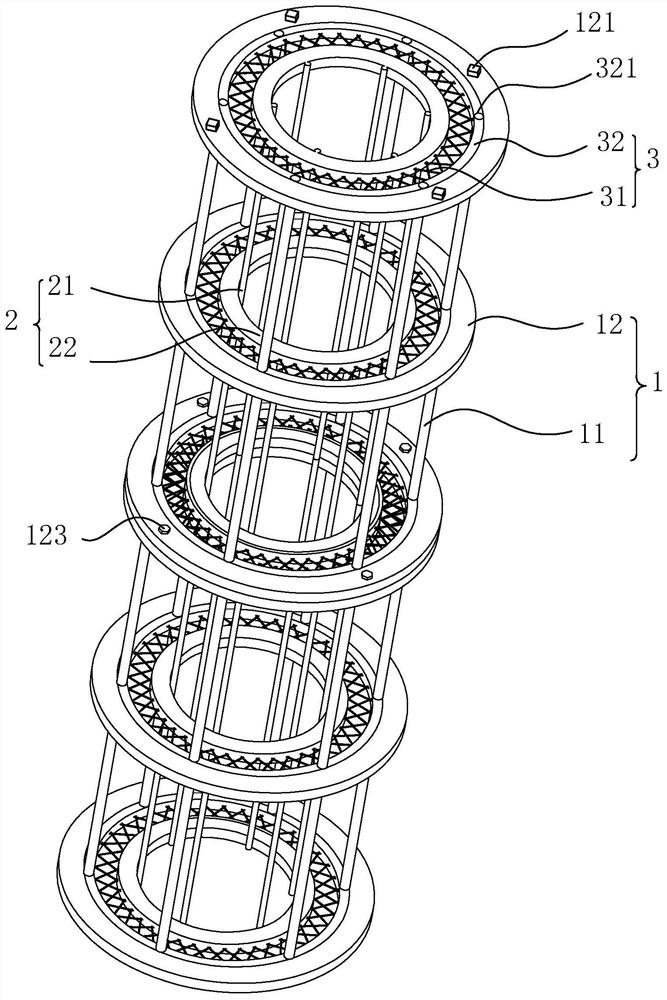

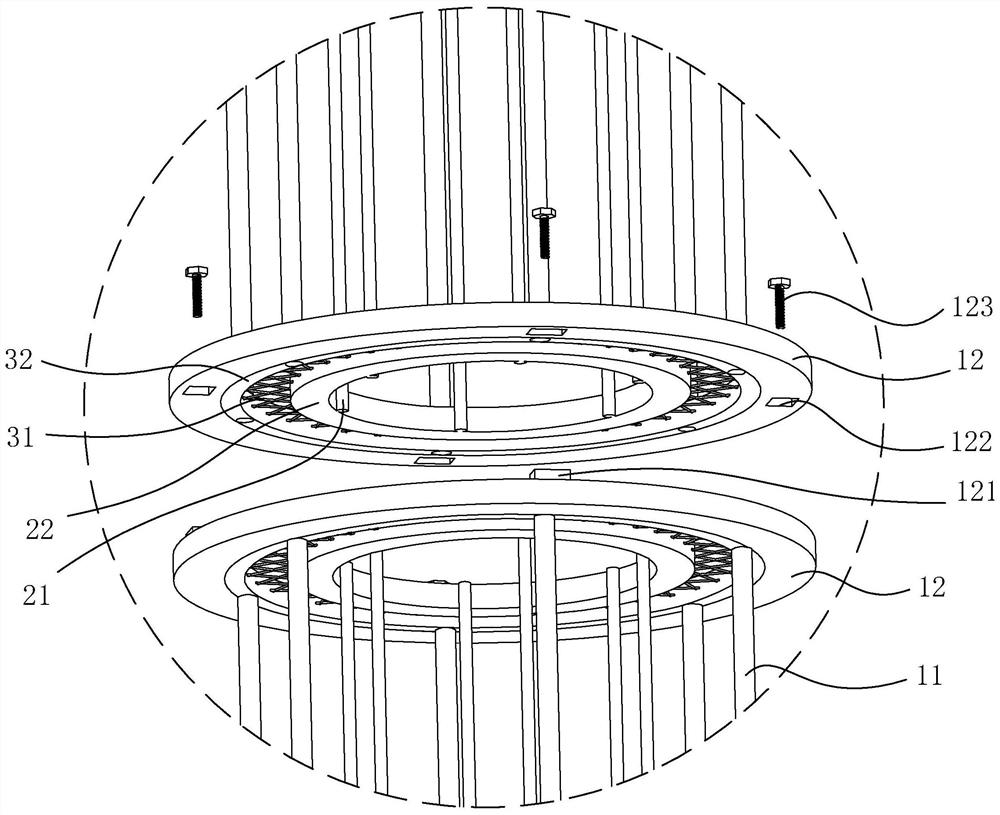

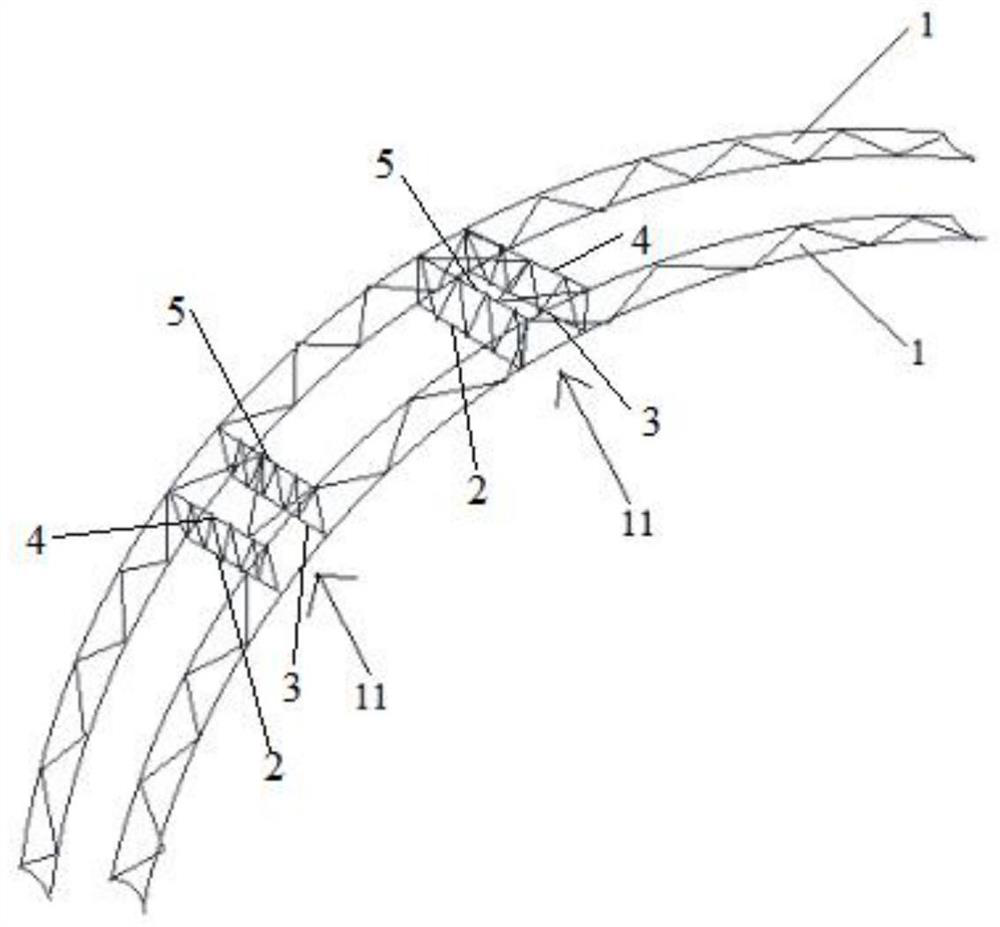

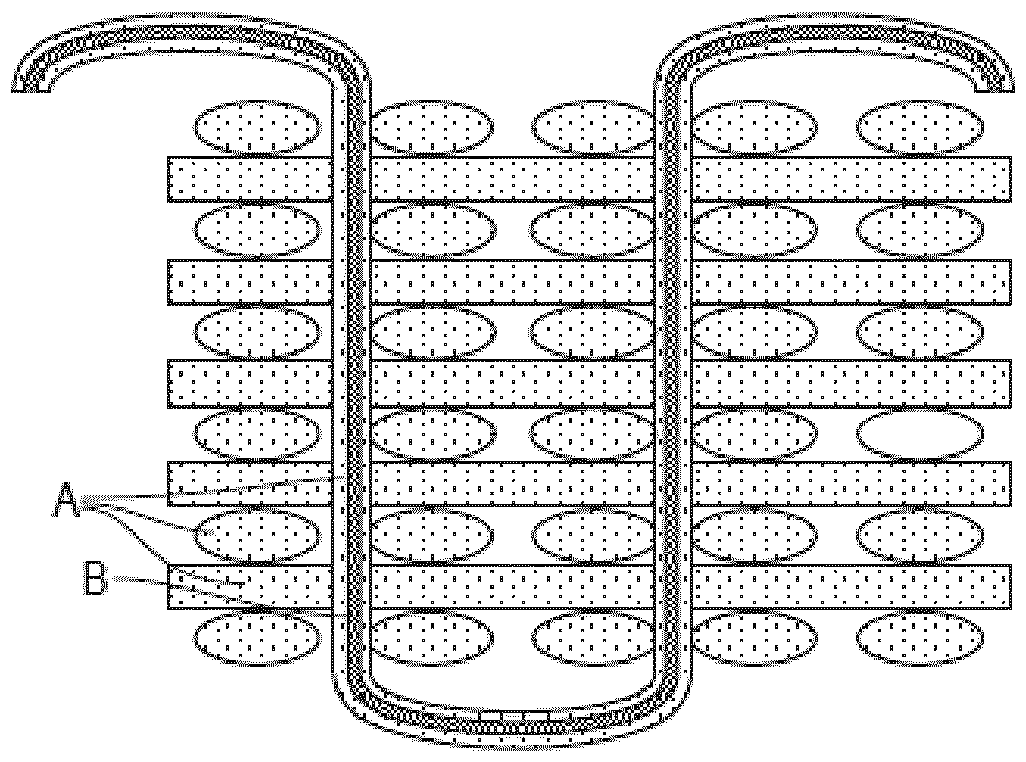

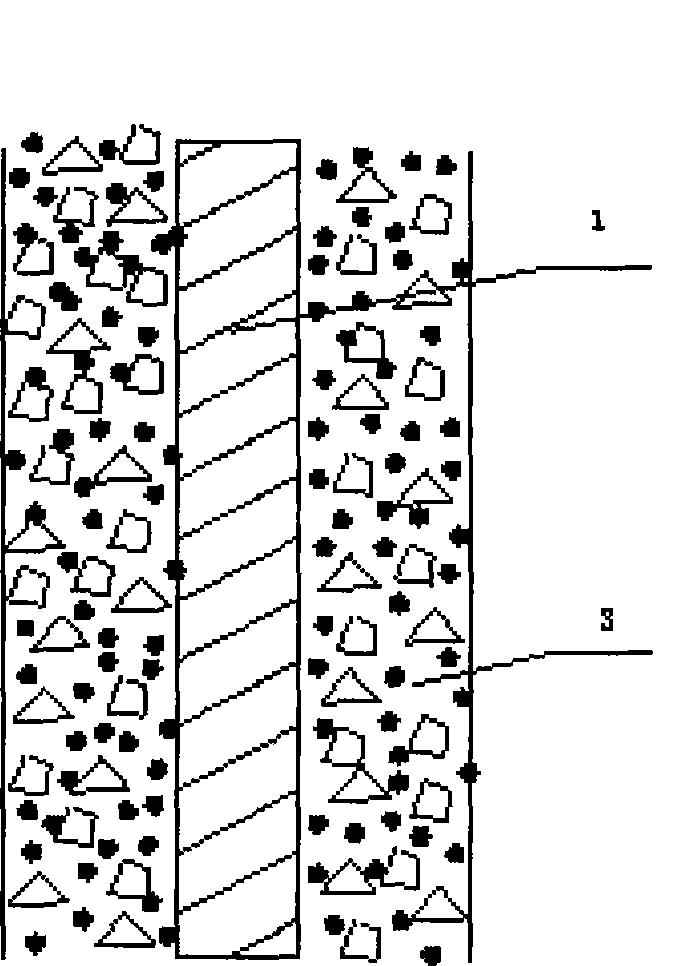

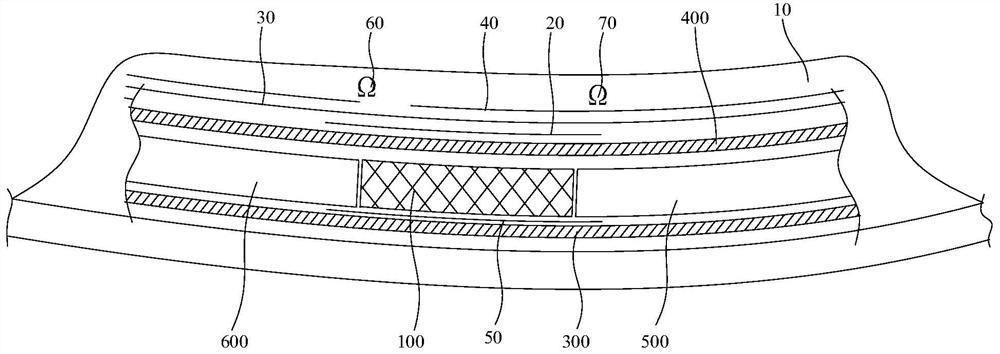

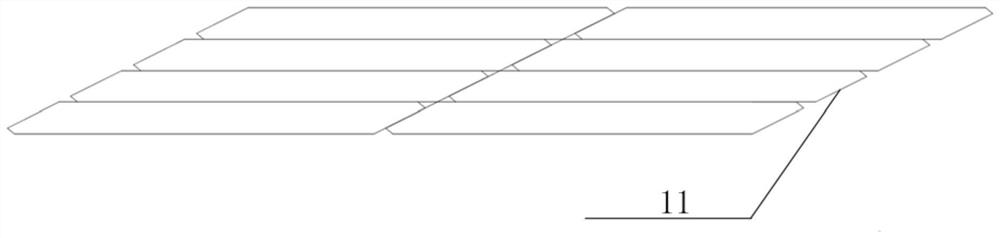

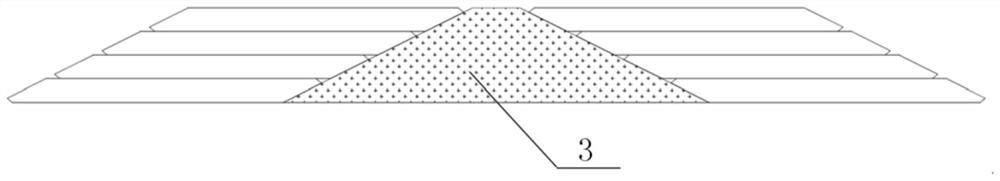

Bearing structure member used for wind power blade and preparation method thereof

InactiveCN111255639AIncrease bonding areaAvoid stiffnessWind motor combinationsMachines/enginesStructural engineeringUltimate tensile strength

The invention discloses a bearing structure member used for a wind power blade and a preparation method thereof. The bearing structure member is formed by stacking a plurality of pultrusion sheet layers with the same arrangement, and the edges at the two sides are aligned; the pultrusion sheet layers are formed by arranging even number of trapezoidal pultrusion sheets, and the trapezoidal pultrusion sheet is provided with at least one chamfer; the upper and lower edges of the adjacent two pultrusion sheets of each layer are arranged oppositely, horizontally aligned, the side walls of the adjacent trapezoidal pultrusion sheets are closely arranged and connected, and the connection part of the adjacent trapezoidal pultrusion sheets is formed with a diagonal seam between layers. According tothe invention, a weak straight joint is in a vertical section by designing the trapezoidal pultrusion sheet with a trapezoidal cross section and a stacking method to ensure the alignment of the beveled edges of the edge sheet, and the adhesion area of two adjacent pultrusion sheets of each layer is increased, the overall bearing capacity of a sheet structure is improved, and the problem that rectangular cross-section sheets form vertical straight joint when being stacked to reduce the rigidity and strength of the sheet structure is overcome.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

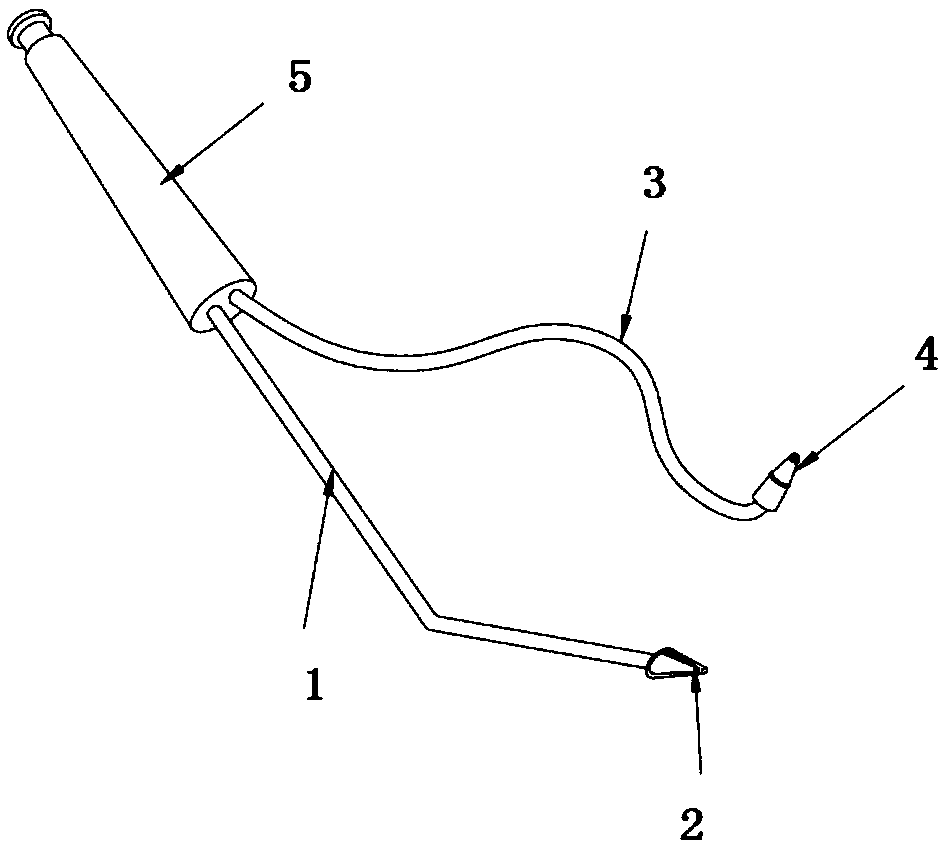

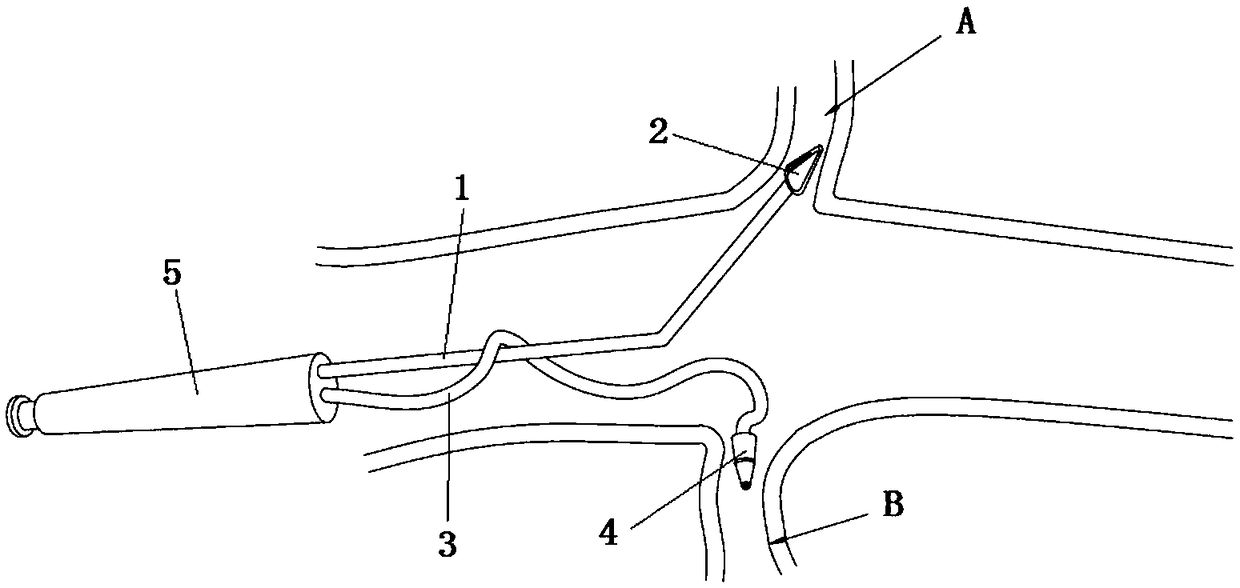

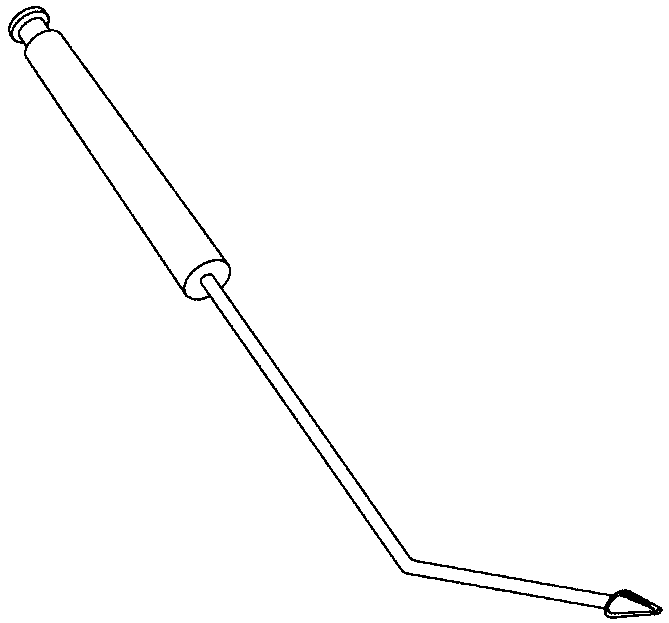

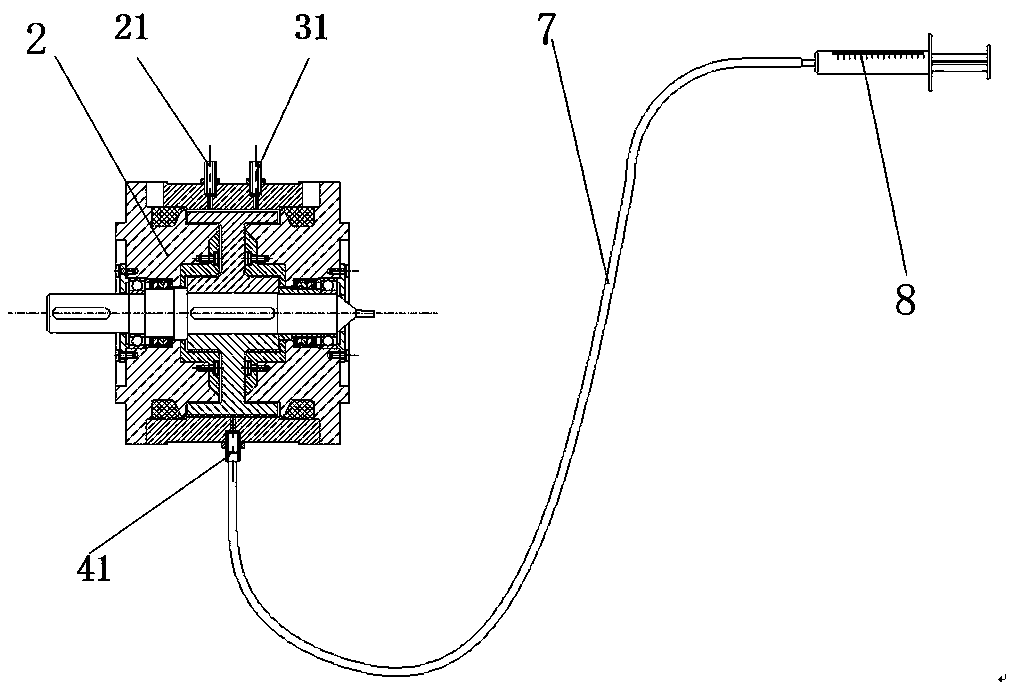

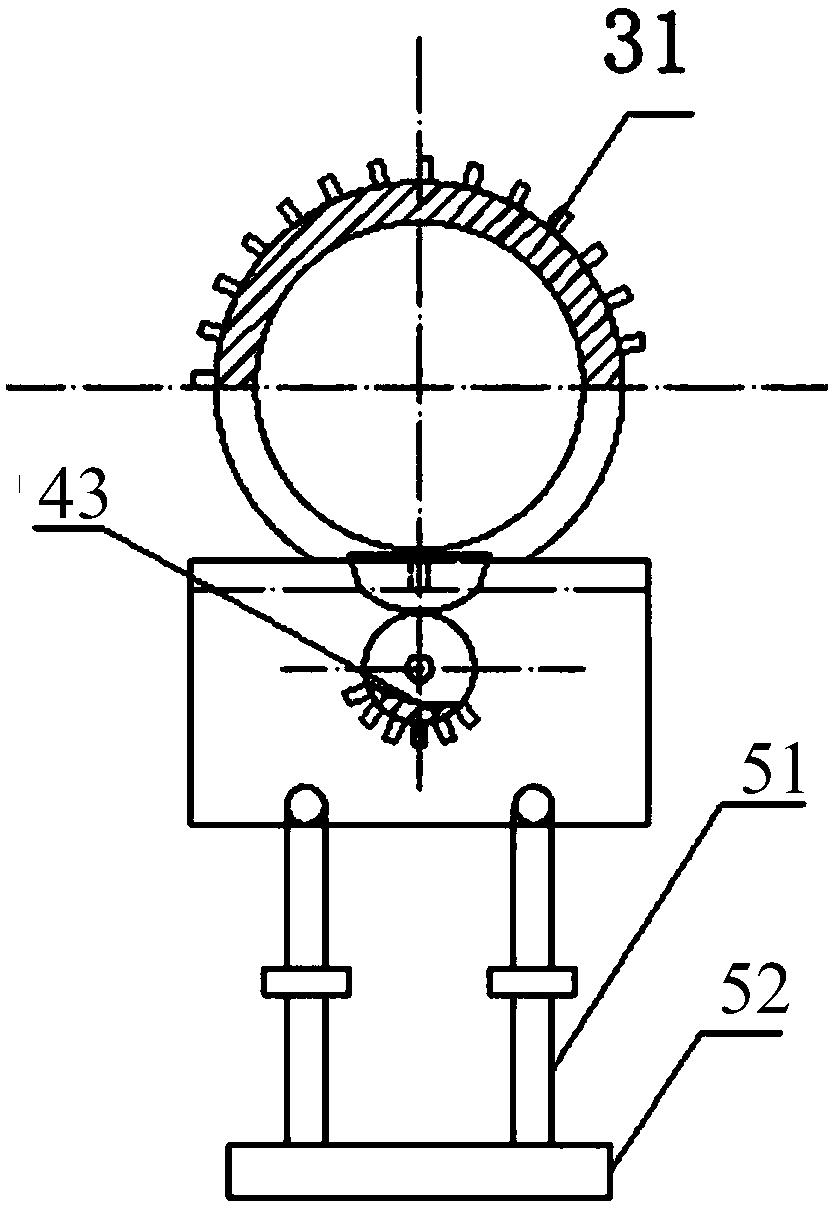

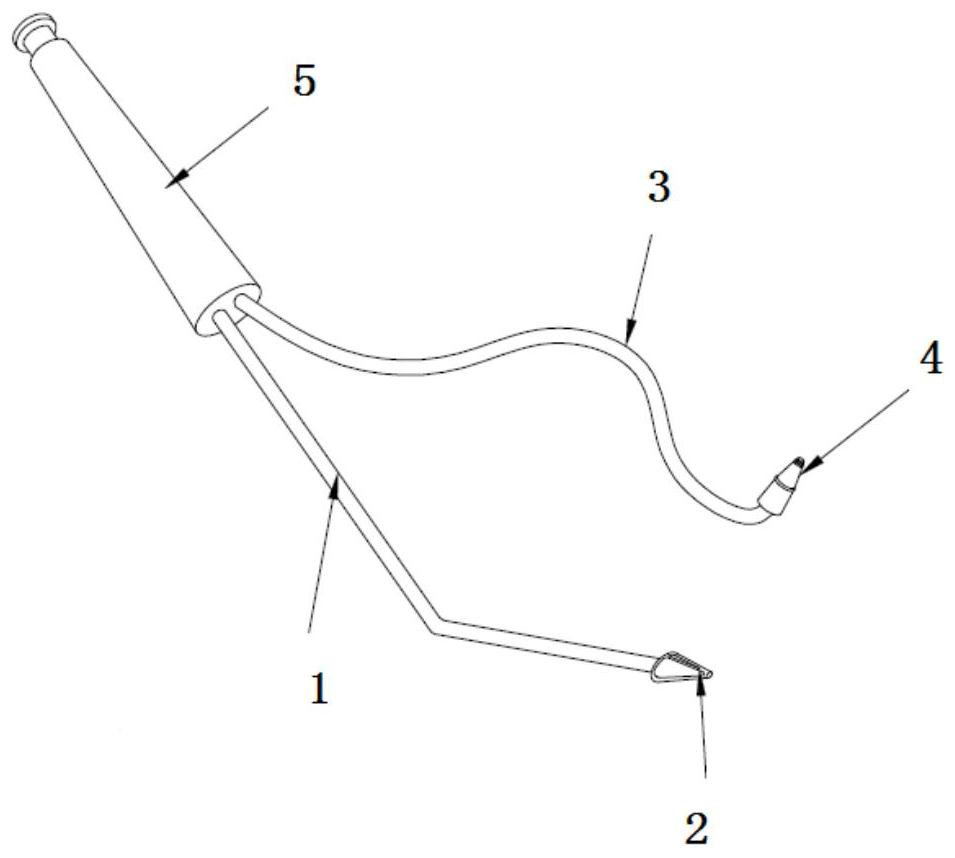

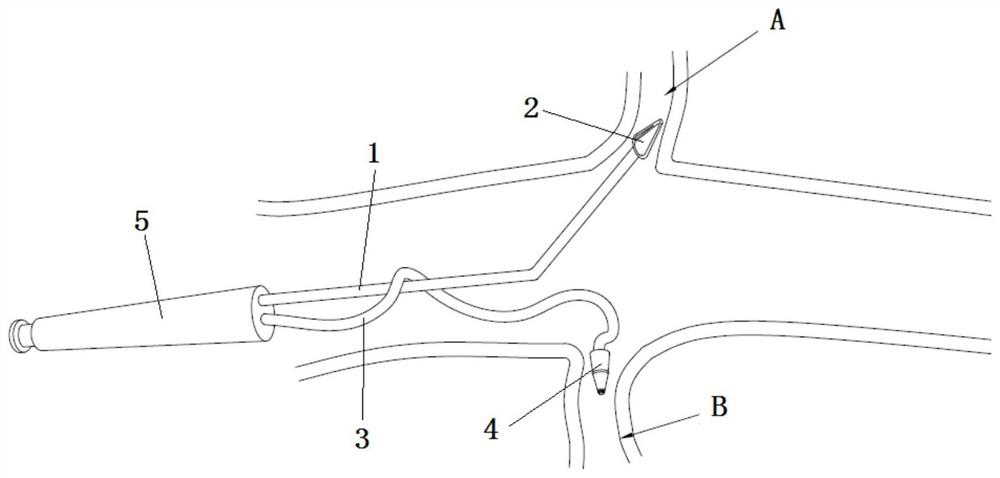

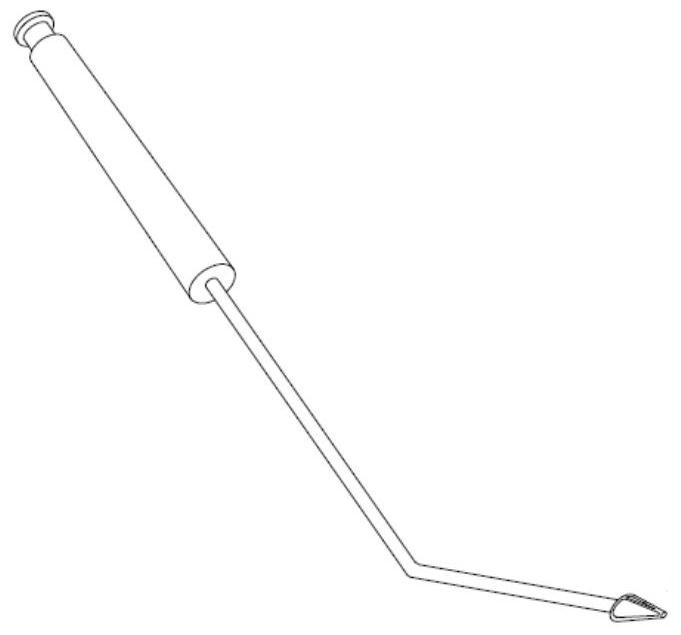

Dual-head coronary artery direct perfusion tube

ActiveCN109200443AShorten the perfusion timeShorten operation timeMulti-lumen catheterCoronary arteriesHigh density

The invention relates to the technical field of medical devices, in particular to a dual-head coronary artery direct perfusion tube, which is composed of a handle, a left coronary artery perfusion head, a hard connecting rod, a high-density right coronary artery perfusion head and a soft perfusion tube. As that weight of the right coronary artery perfusion head is several time of that of the leftcoronary artery perfusion head, the right coronary artery perfusion head can be naturally lowered to the right coronary artery orifice and position under the action of gravity. As that double-headed coronary artery direct perfusion tube of the invention is use, the left coronary artery and the right coronary artery can be simultaneously perfusion, the perfusion time is shortened by half, the wholeoperation time is greatly shorten, the operation risk can be reduced, and great benefits are brought to the patients. The double-headed coronary artery direct perfusion tube of the invention can simultaneously perfusion the left coronary artery and the right coronary artery, thus shortening the perfusion time by half.

Owner:DALIAN CORVIVO MEDICAL CO LTD

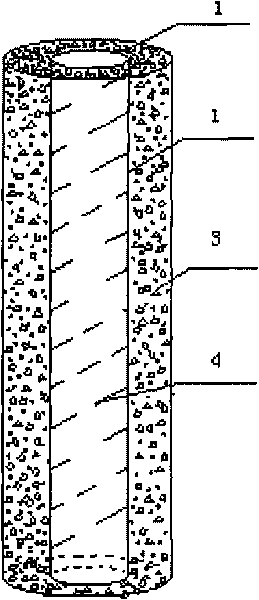

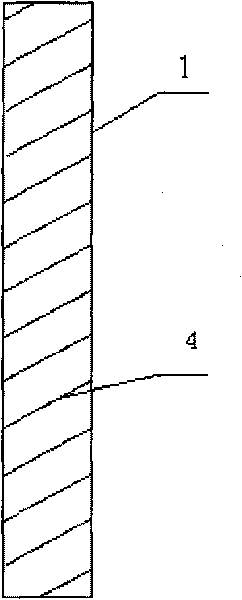

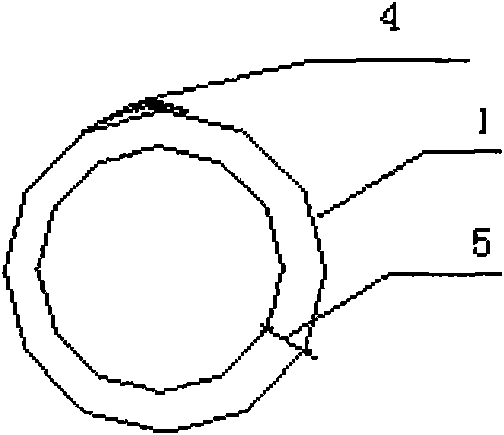

Reinforcement cage structure for karst area pile foundation and pile foundation construction method

InactiveCN112211187AImprove radial compressive strengthEnhanced axial compressive strengthBuilding reinforcementsBulkheads/pilesRebarSteel plates

The invention relates to a reinforcement cage structure for a karst area pile foundation, and relates to the technical field of building construction. The structure comprises a reinforcing steel bar outer frame and a reinforcing steel bar inner frame; the reinforcing steel bar outer frame comprises a plurality of outer main reinforcements and a plurality of outer hoop steel plates fixedly connected with the peripheries of the outer main reinforcements; the reinforcing steel bar inner frame comprises a plurality of inner main reinforcements and a plurality of inner hoop steel plates fixedly connected with the peripheries of the inner main reinforcements; and reinforcing rib frames are arranged on the side walls, away from the inner main reinforcements, of the outer hoop steel plates and located between the reinforcing steel bar outer frame and the reinforcing steel bar inner frame. The reinforcement cage structure for the karst area pile foundation and a pile foundation construction method have the advantages that the overall structural strength of the reinforcement cage is effectively improved, and therefore the foundation pile construction quality is improved.

Owner:福建新华夏建工集团有限公司

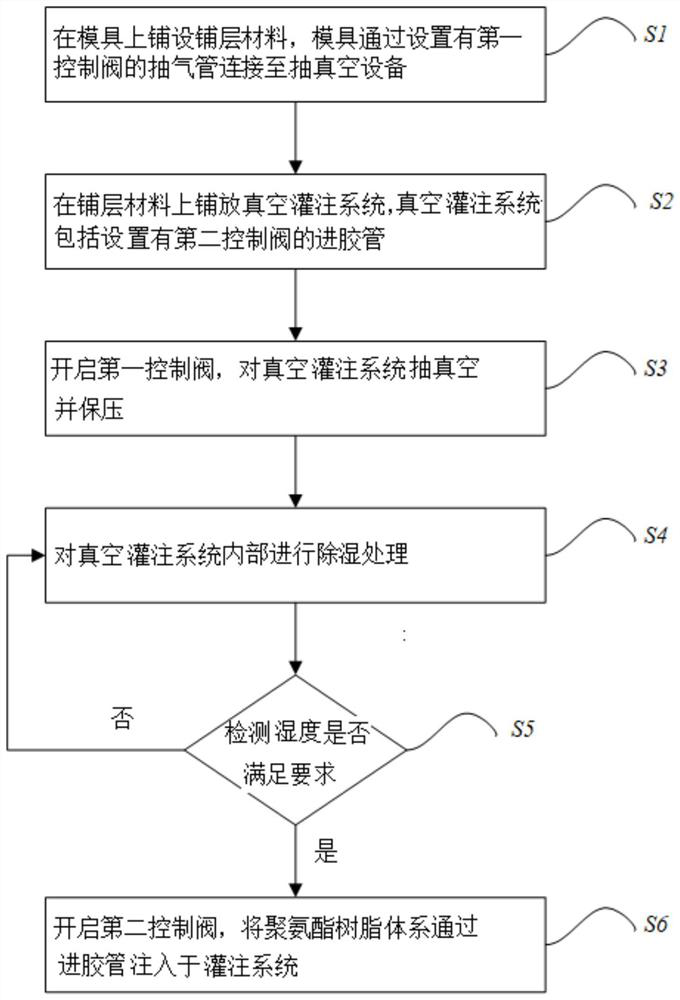

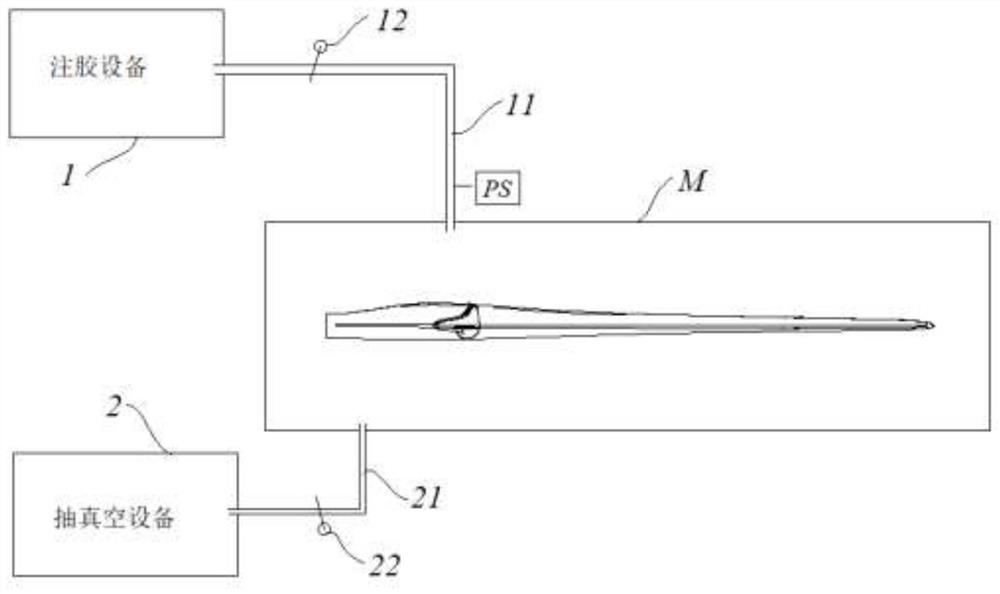

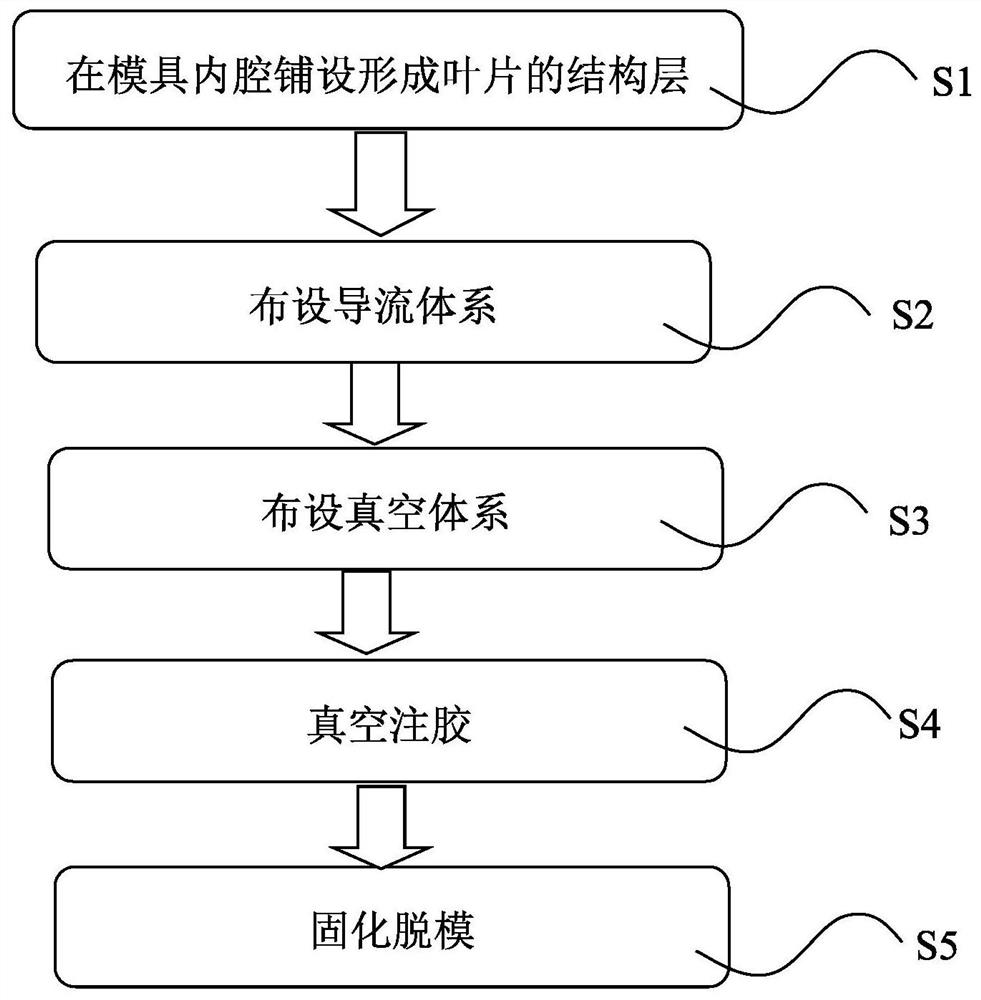

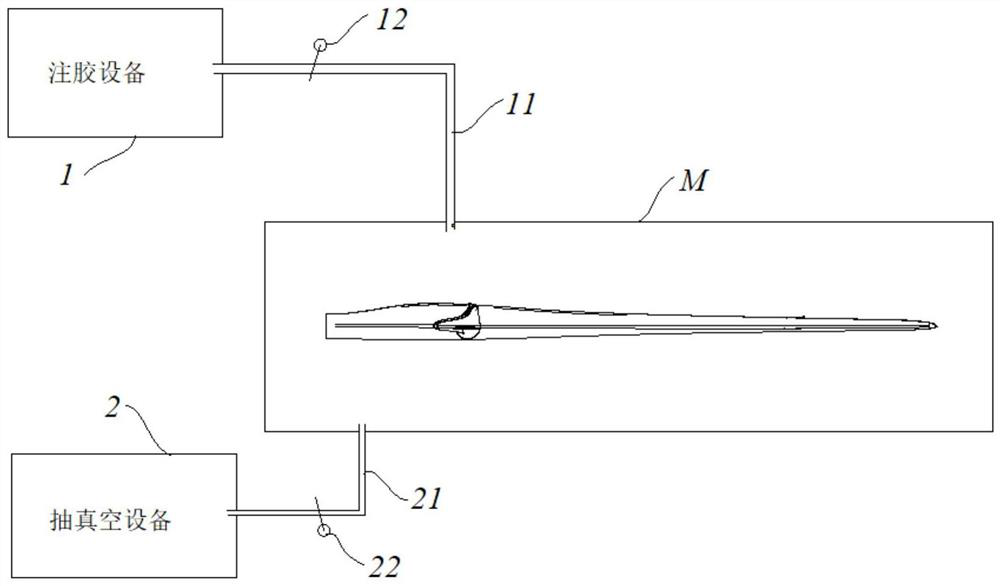

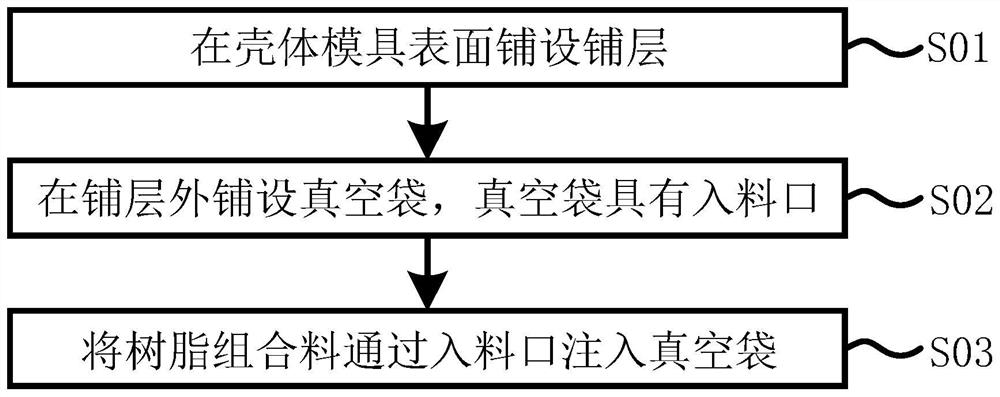

Blade forming method and blade

PendingCN114654764AShorten the perfusion timeIncrease productivityDomestic articlesEngineeringControl valves

The invention relates to a blade forming method and a blade, and the blade forming method comprises the following steps: laying a laying material on a mold, and connecting the mold to vacuumizing equipment through an exhaust pipe provided with a first control valve; laying a vacuum infusion system on the laying material, wherein the vacuum infusion system comprises a glue inlet pipe provided with a second control valve; a first control valve is opened, and the vacuum infusion system is vacuumized and subjected to pressure maintaining; dehumidification treatment is conducted on the interior of the vacuum infusion system; detecting the internal humidity of the vacuum infusion system; and when the humidity in the vacuum infusion system meets the requirement, the second control valve is opened, and the polyurethane resin system is injected into the vacuum infusion system through the glue inlet pipe. According to the method, a polyurethane resin system with relatively low viscosity at room temperature is adopted for pouring and forming the blade, so that the pouring time of the blade can be shortened, the production efficiency of the blade can be improved, and the material cost of the blade can be reduced.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

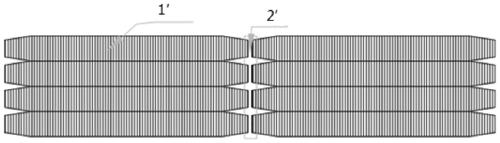

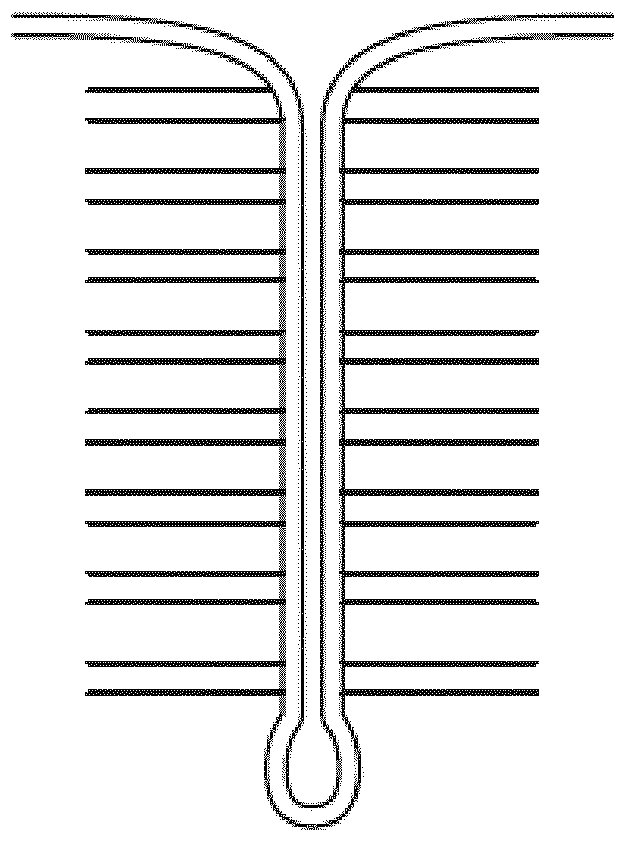

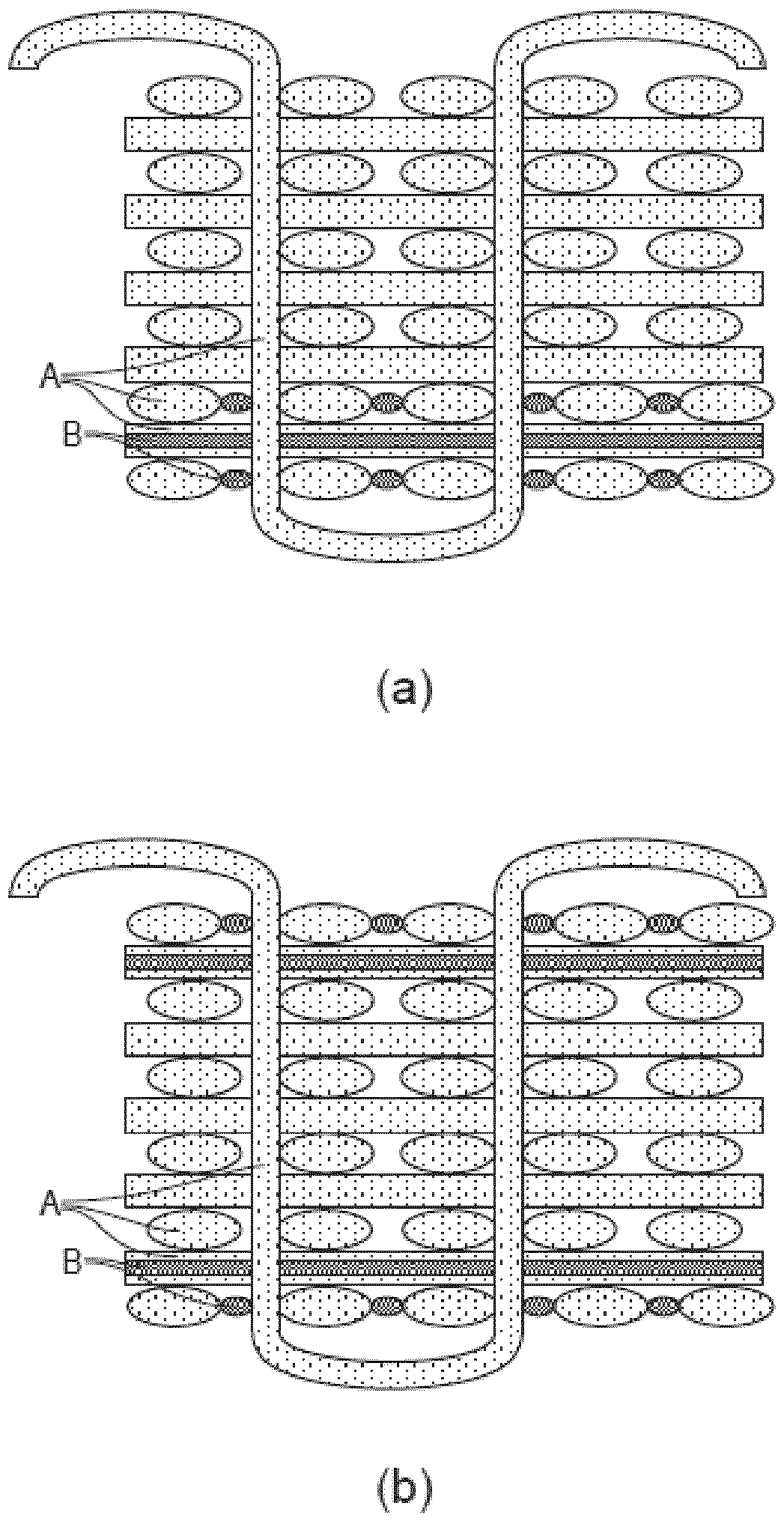

Vein type perfusion adapter tube and perfusion method

The invention discloses a vein type perfusion adapter tube and a perfusion method. The vein type perfusion adapter tube sequentially comprises a glue perfusion opening, a buffer channel, a main flow channel, secondary flow channels and a glue outlet; the buffer channel is arranged between the glue perfusion opening and the main flow channel; the secondary flow channels are distributed in a vein form and connected to the main flow channel; the tail of the main flow channel is provided with the glue outlet; and the glue perfusion opening, the buffer channel, the main flow channel, the secondaryflow channels and the glue outlet are all connected through steel wire spiral tubes. According to the vein type perfusion adapter tube disclosed by the invention, by virtue of a vein type shaft and aglue perfusion tube which is arranged chordwise, the glue is mainly injected through a chordwise flow channel so that the perfusion time is obviously reduced; waste of glue is reduced; and the vein type perfusion adapter tube has less the glue perfusion openings than a traditional perfusion system.

Owner:中材科技(萍乡)风电叶片有限公司

A kind of filling device and filling method of flexible liquid crystal cell

The invention discloses a crystal-filling device and a crystal-filling method of a flexible liquid crystal cell. The crystal-filling device includes a clamp, and the clamp clamps a flexible liquid crystal cell to be filled and produces Uniform surface pressure. Before the filling machine is evacuated, a uniform surface pressure is generated on the surface of the flexible liquid crystal cell by using a fixture to heat the liquid crystal to reduce the viscosity of the liquid crystal. balance, and then fill the crystal with gas, so that the pressure difference between the inside and outside of the flexible liquid crystal cell can be avoided during the vacuum process, and the liquid crystal cell can be avoided from swelling and cracking. The crystal filling device of the flexible liquid crystal cell and the crystal filling method thereof of the present invention solve the problem that the liquid crystal cell is bulged, cracked and damaged due to the pressure difference generated on the inner and outer surfaces of the flexible liquid crystal cell during the vacuuming process of filling the crystal, and the productivity is low, and the production cost.

Owner:SINOFLEX OPTOELECTRONICS CHUZHOU

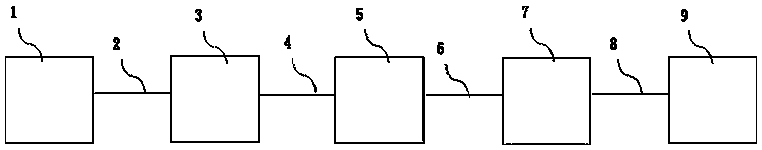

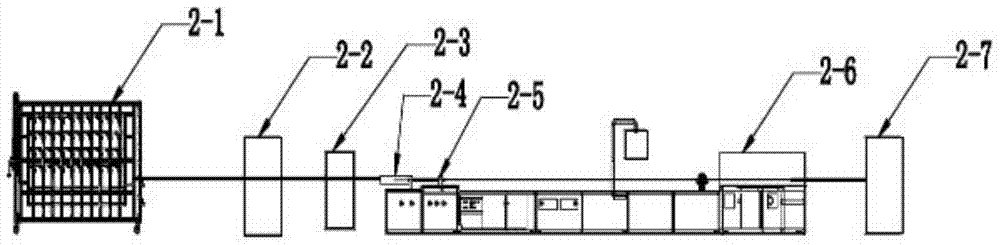

Automatic shoe pad production assembly line

InactiveCN108839364AGood production stabilityImprove efficiencyDomestic footwearContinuous productionAssembly line

The invention discloses an automatic shoe pad production assembly line. The automatic shoe pad production assembly line comprises a pour machine, a foaming mold, a sheet cutter, a rubber coating laminator and a cloth sticking machine; the pour machine is connected with the foaming mold through a pour hose, the foaming mold is connected with the sheet cutter through a first conveying belt, the sheet cutter is connected with the rubber coating laminator through a second conveying belt, the sheet cutter is connected with the cloth sticking machine through a third conveying belt, the pour machinecomprises a material cylinder, a refrigerating machine and a pour machine head, the refrigerating machine is connected with the material cylinder, the material cylinder is connected with the pour machine head, the foaming mold comprises a foaming mold body and a heating device, the foaming mold is provided with an exhaust system, and the pour machine head is connected with the foaming mold body through the pour hose. The automatic shoe pad production assembly line has the beneficial effects of being high in production stability, high in efficiency, good in product quality, small in pollution,low in loss, and capable of reducing cost, achieving automatic continuous production and improving the production efficiency.

Owner:东莞依科聚合物有限公司

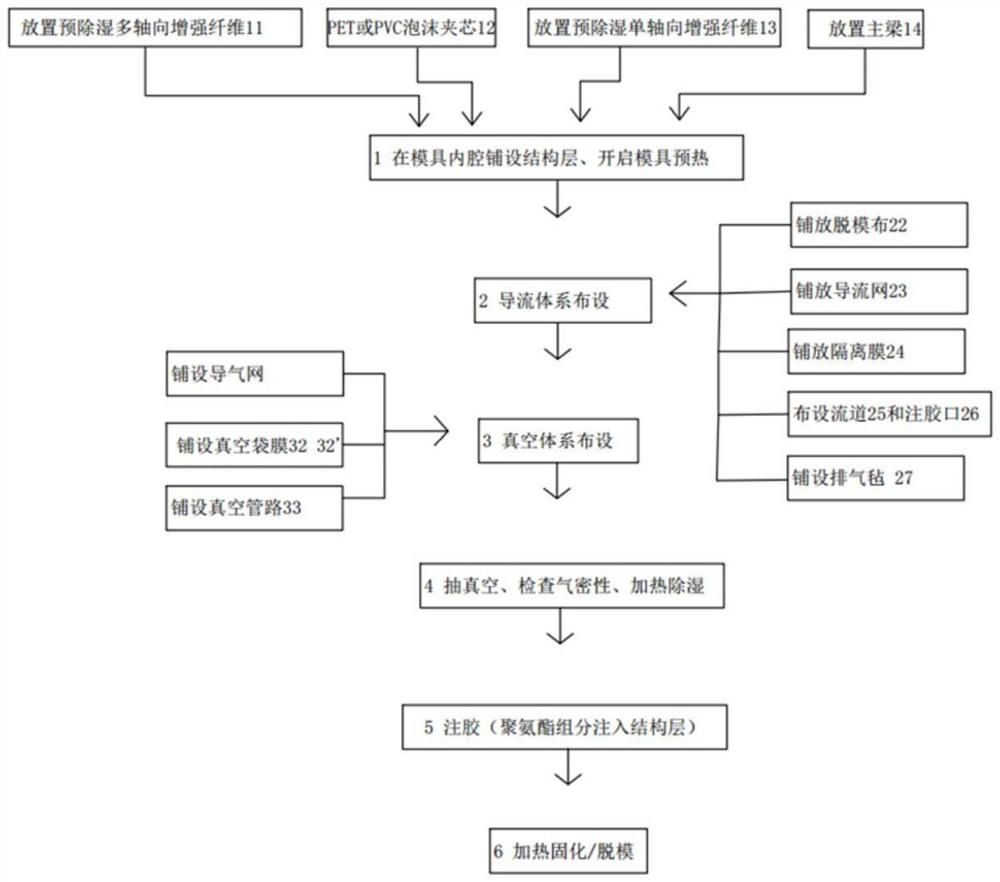

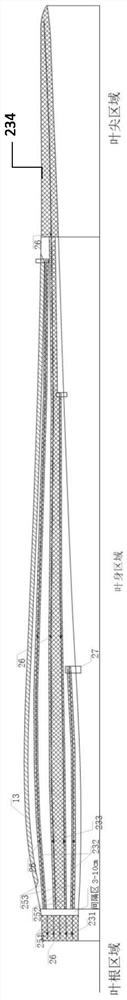

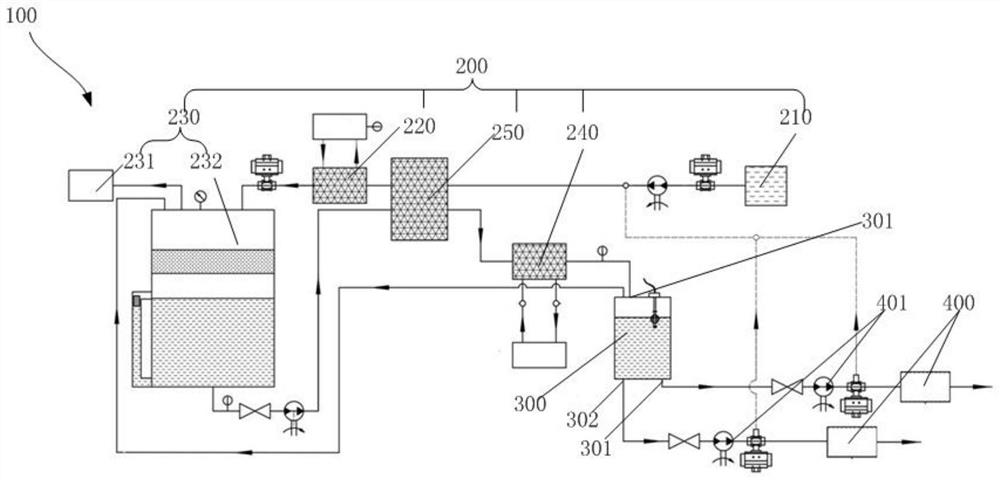

Blade perfusion process method and perfusion system

PendingCN113492542AReduced risk of curingReduce exposureDomestic articlesSurgeryMechanical engineering

The invention discloses a blade perfusion process method and a perfusion system. The process method sequentially comprises the following steps that a structural layer for forming a blade is laid in an inner cavity of a mold; the mold comprises a blade root area, a blade body area and a blade tip area; a flow guide system is arranged above the structural layer, the flow guide system comprises a plurality of flow channels, the flow channels are arranged in the blade root area, the blade body area and the blade tip area respectively, and the flow channels in the blade root area and the flow channels in the blade body area are not in communication; a plurality of gel injection openings are formed in the flow channels; a vacuum system is arranged, and a vacuum environment is provided for the inner cavity of the mold; vacuum gel injecting is carried out; and curing and demolding are carried out. The risk of resin gel curing in the glue injection process can be reduced, the blade forming stability is improved, the contact with personnel and air outside water in the gel process is reduced, the use amount of resin and a flow guide net is saved, the environment is protected, resources are saved, the perfusion time is shortened, and gel injection of all areas is accurately controlled.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

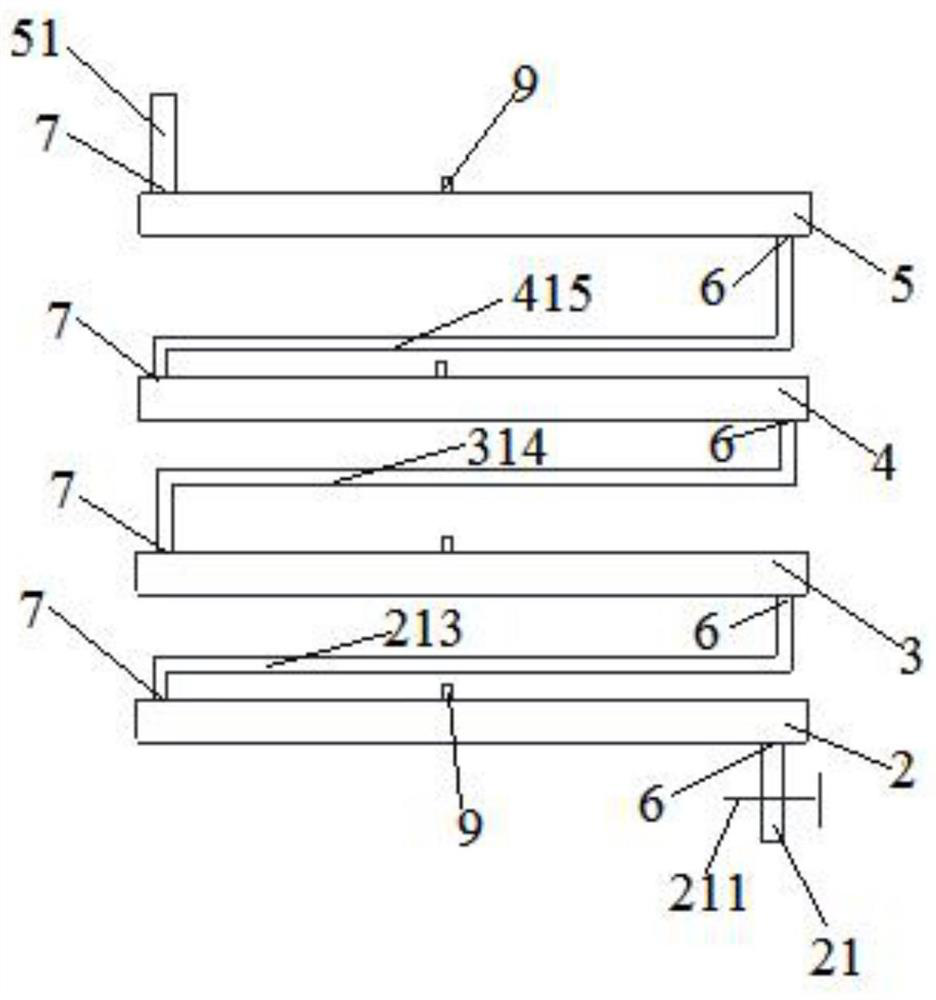

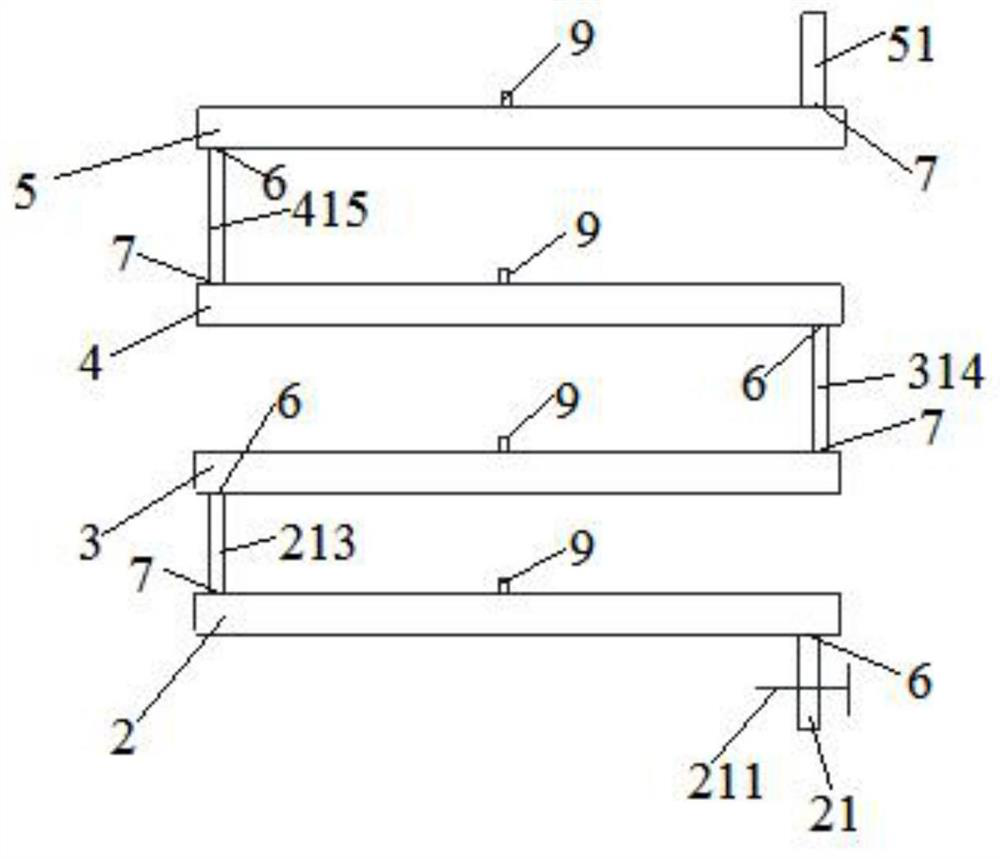

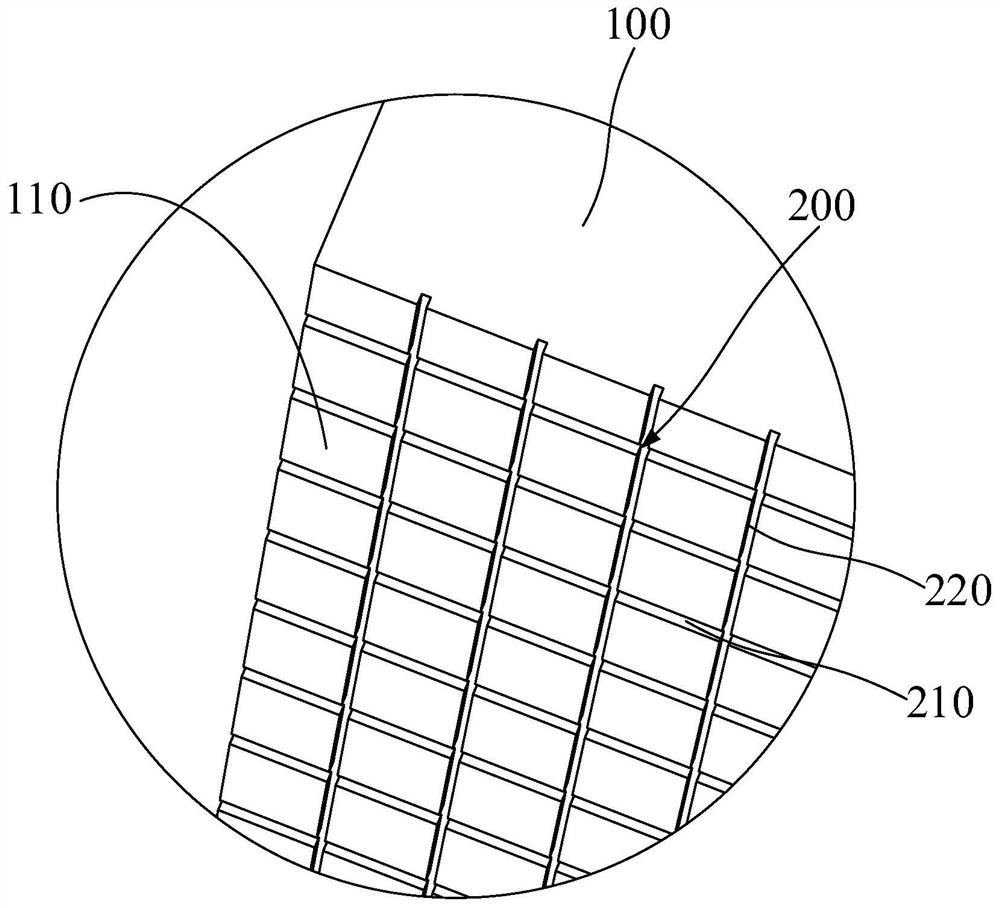

Unidirectional cloth manufacturing system and layout method thereof

The invention relates to the technical field of manufacturing parts of wind power blades, and discloses an unidirectional cloth manufacturing system and a layout method thereof.The unidirectional cloth manufacturing system comprises a mold body used for laying an unidirectional cloth structure layer and a feeding system, injection guiding openings are formed in the upper surface of the mold body, and the mold body is communicated with the feeding system through the injection guiding openings; the unidirectional cloth manufacturing system further comprises a vacuum system used for extracting air from the unidirectional cloth structure layer laid on the mold body, the unidirectional cloth structure layer comprises a lower layer auxiliary material layer, a body unidirectional cloth material layer and an upper layer auxiliary material layer which are sequentially arranged from bottom to top and laid on the mold body, multiple air extracting openings are formed in the upper layer auxiliary material layer, and the vacuum system is connected with the unidirectional cloth structure layer through the air extracting openings.Perfusion time of unidirectional cloth is shortened, it can be ensured that unidirectional cloth different in thickness and type can be infiltrated well, production efficiency and product quality of wind power blades are improved and ensured, and the unidirectional cloth manufacturing system is suitable for producing main beam unidirectional cloth, different in type and length, of wind power blades.

Owner:JILIN CHONGTONG CHENGFEI NEW MATERIAL +1

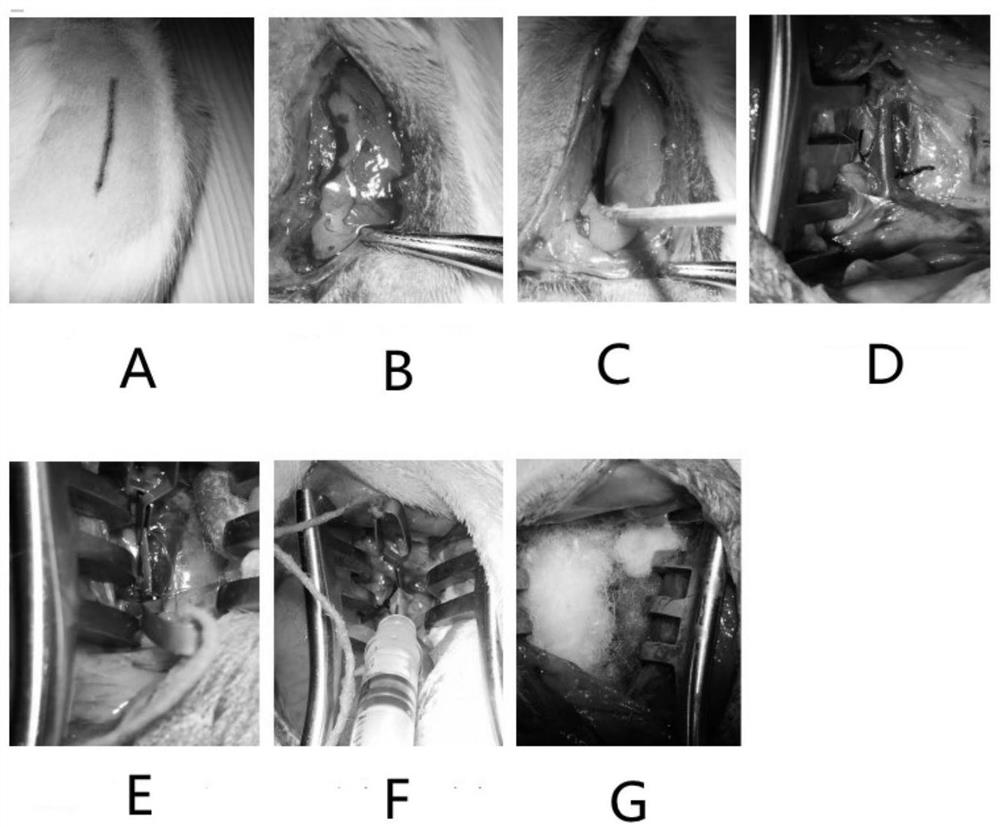

Rat infrarenal abdominal aortic aneurysm model constructed through retroperitoneal approach and construction method

The invention relates to the technical field of biological and medical technologies, in particular to a rat infrarenal abdominal aortic aneurysm model constructed through a retroperitoneal approach and a construction method. The operation is relatively simple, risks caused by the abdominal approach can be avoided, pressurized perfusion is not adopted, the perfusion time is shortened to 20 min, lower limb ischemia does not occur, the tumor formation rate is not affected, damage to blood vessels is extremely small, bleeding can be stopped through local compression after perfusion is finished, and the operation success rate is remarkably increased; The construction method comprises the following steps: S1, performing fasting for 12 hours before an operation of a rat, anesthetizing the rat with pentobarbital sodium according to 40-50mg / kg, taking a right side lying position after satisfaction of anesthesia, conventionally preserving skin, performing disinfecting, taking a connecting line from the lower part of a left side posterior axillary line costal margin to the root of a thigh as an incision with the length of 3-3.5 cm, cutting the skin, subcutaneous tissue and muscles layer by layer to see the retroperitoneal fat tissue, finding a potential gap between the peritoneum and lumbar dorsal muscles along the fat tissue, separating the gap by a cotton swab to reach the aorta abdominalis, and separating the aorta abdominalis from the inferior vena cava.

Owner:川北医学院 +1

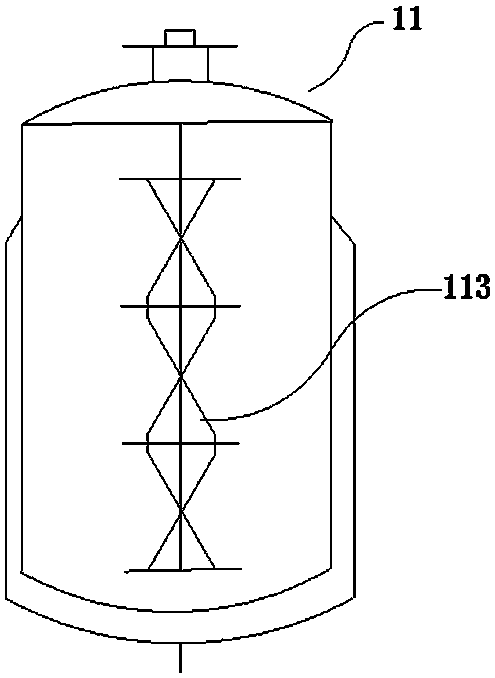

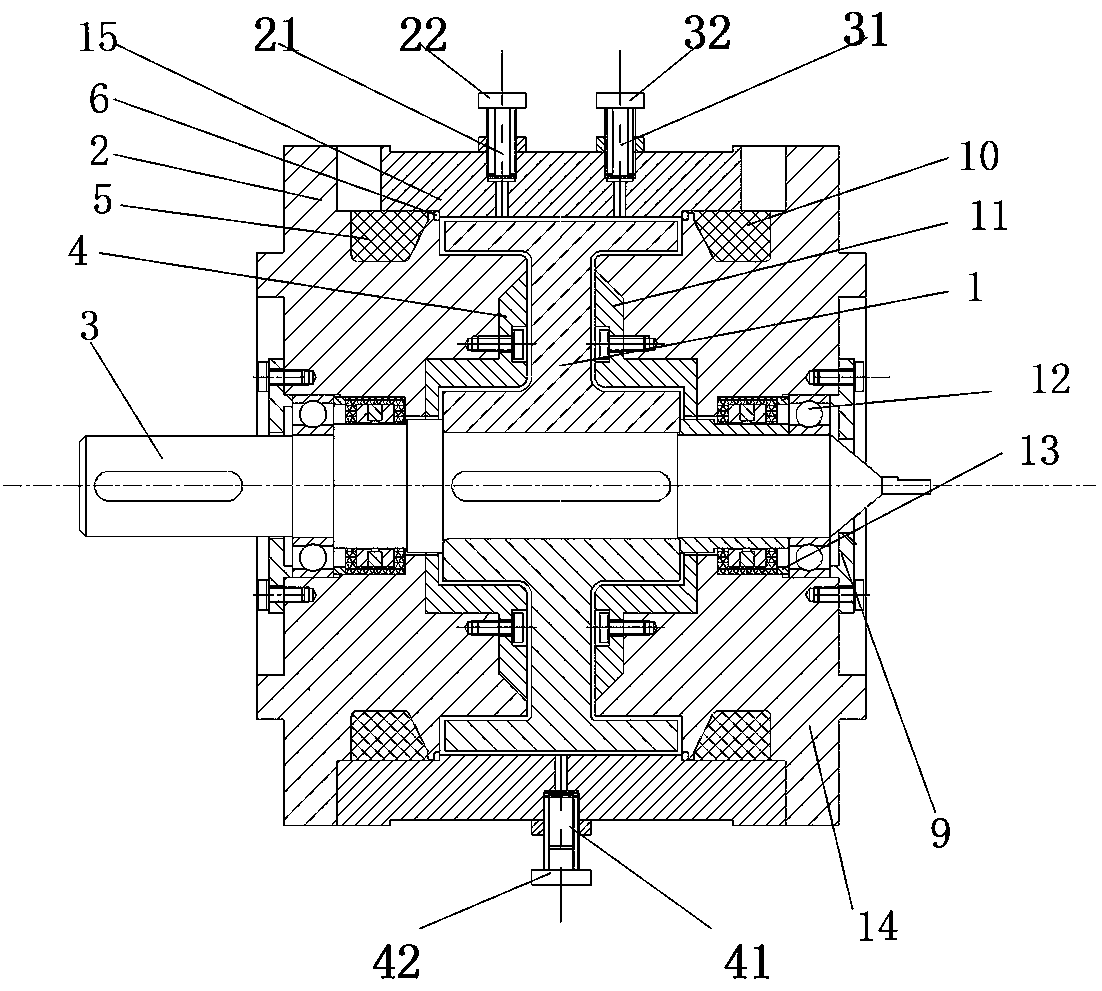

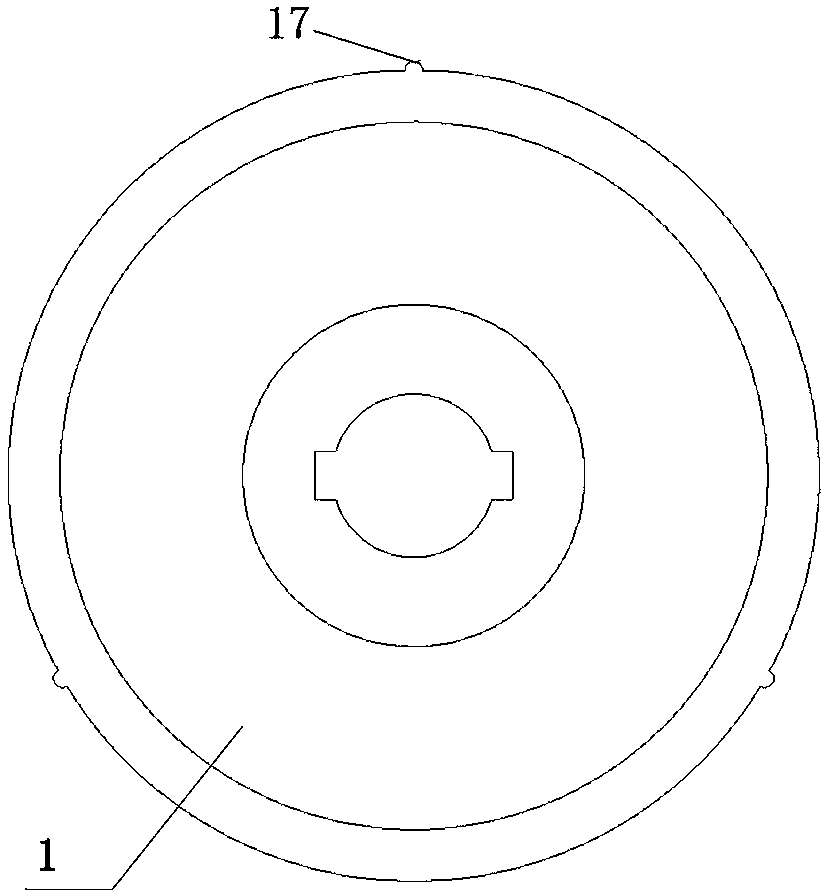

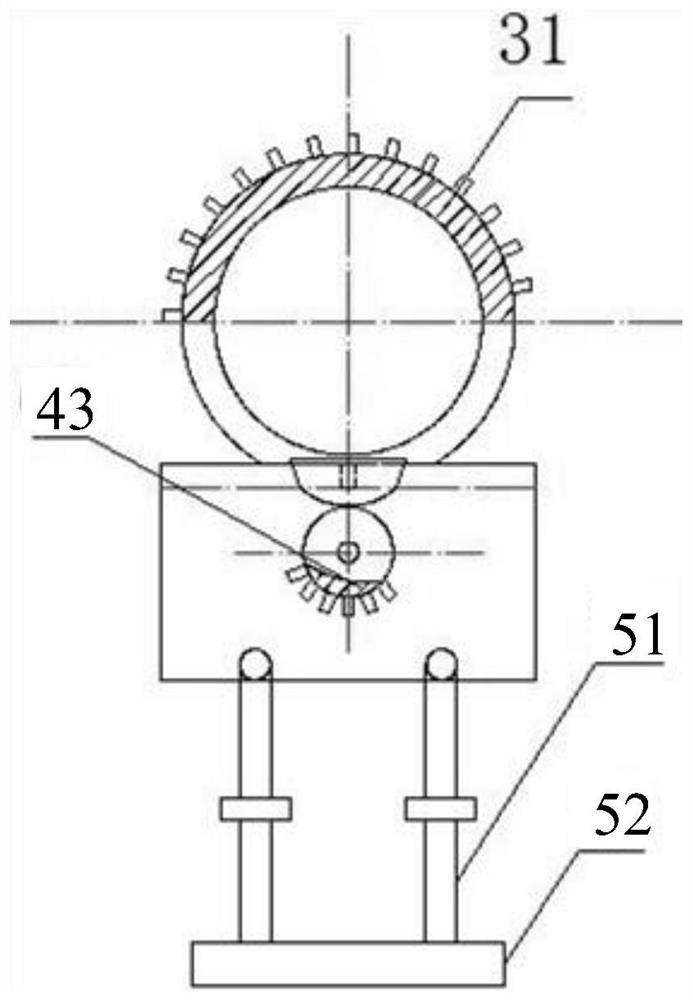

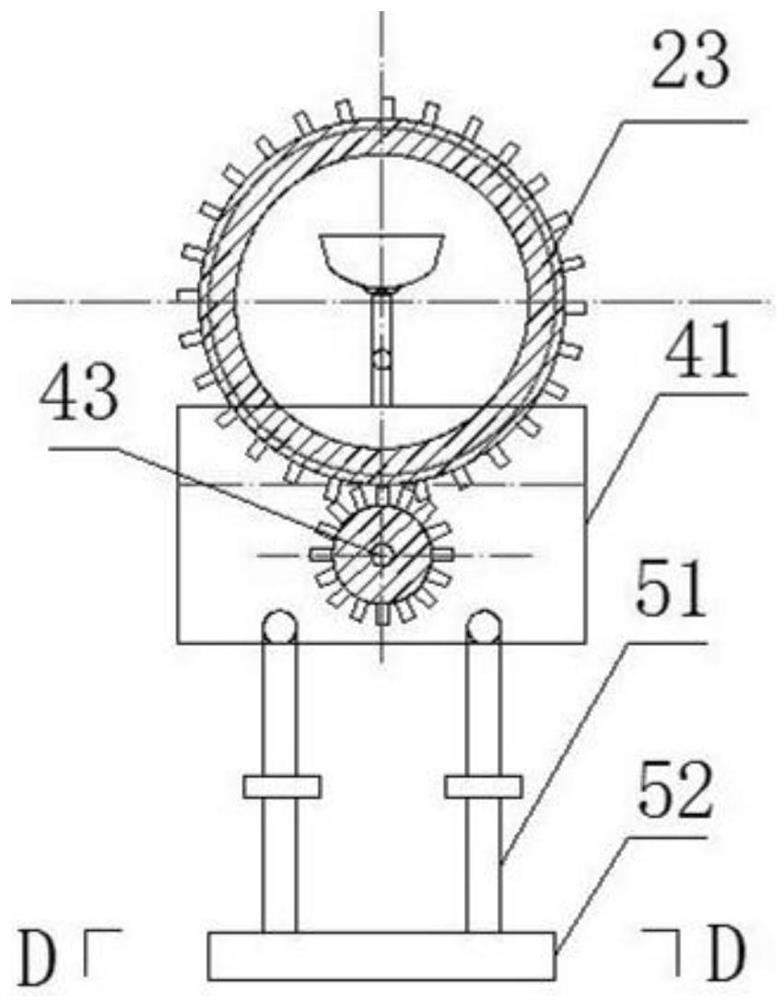

Magnetorheological damper and magnetorheological fluid perfusion method

PendingCN108980260AOptimize locationOptimize quantitySpringsNon-rotating vibration suppressionDrive shaftEngineering

The invention relates to a magnetorheological damper and a magnetorheological fluid perfusion method. The magnetorheological damper includes a rotor, and the rotor is connected to a transmission shaftby a key. A front end cover and a rear end cover are respectively arranged on the front and rear sides of the rotor, and the outer part of the rotor is provided with an outer casing, the front end cover and the rear end cover and the outer casing are fixed together to form a stator; the front end cover and the rear end cover are distributed in the axial direction of the transmission shaft; the front end cover and rear end cover are internally correspondingly wound with a front excitation coil and a rear excitation coil, a front isolation magnetic ring is set between the front end cover and the front side face of the rotor, and a rear isolation magnetic ring is set between the rear end cover and the rear side face of the rotor; the outer casing is provided with at least three liquid injection holes, each liquid injection hole is sealed by a sealing cover. According to the magnetorheological damper and the magnetorheological fluid perfusion method, the magnetorheological damper is provided with at least three perfusion holes in an appropriate position. On the basis of the existing technical scheme, the position and number of the perfusion holes are optimized, at least one perfusionhole can be used as an exhaust hole in the process of liquid injection is ensured, and design of the position of the perfusion holes is reasonable.

Owner:713 RES INST OF CHINA SHIPBUILDING IND CORP

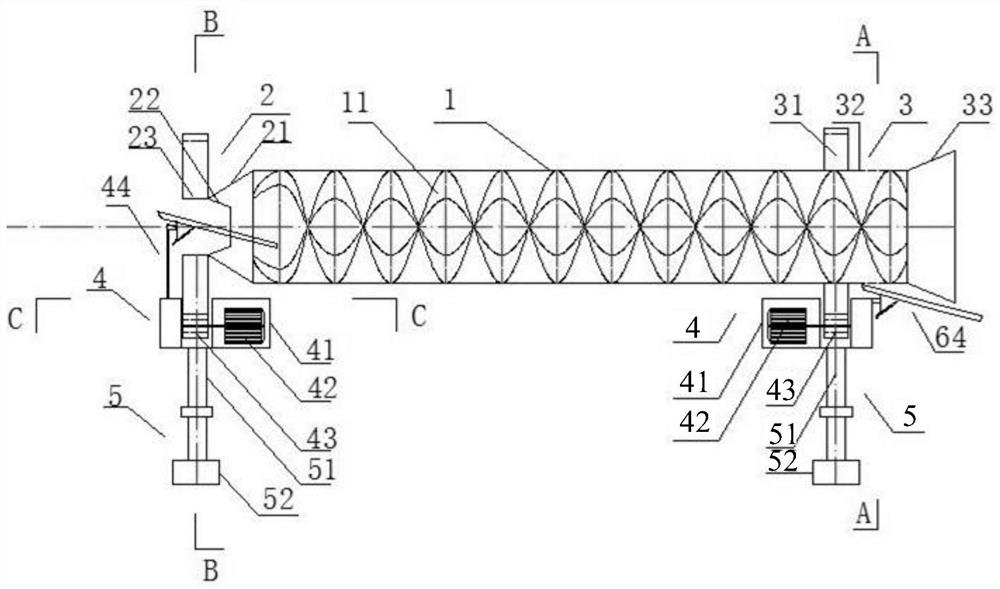

A concrete conveying device

ActiveCN109653206BAchieve continuous perfusionShorten the perfusion timeFoundation engineeringSpiral bladeArchitectural engineering

The invention discloses a concrete conveying device, which comprises: a transportation pipe body and at least two supporting control components, wherein a plurality of spiral blades are arranged in the transportation pipe body; the spiral blades realize that concrete is maintained in an agitating state and cannot flow out the transportation pipe body when the transportation pipe body rotates clockwise, and the concrete flows out of the transportation pipe body when the transportation pipe body rotates counterclockwise; and the at least two supporting control components are respectively disposed at the feeding end and the discharging end of the transportation pipe body to control the clockwise rotation and the counterclockwise rotation of the transportation pipe body and adjust the inclination angle of the transportation pipe body, thereby realizing conveying and agitation of the concrete. The concrete conveying device realizes continuous pouring of the concrete, promotes the reductionof concrete pouring time, makes the super-pouring amount of the concrete easy to control, saves the labor and reduces the waste of the concrete.

Owner:SHANGHAI MARITIME UNIVERSITY

Process method for producing large-size LCD (Liquid Crystal Display) by adopting pouring mode

ActiveCN111290180AThe perfusion process is accurate and fastShorten the perfusion timeNon-linear opticsPhysicsLiquid-crystal display

The invention discloses a process method for producing a large-size LCD (Liquid Crystal Display) by adopting a pouring mode. The process method comprises the following steps of: designing an optimal sealing position, wherein the outermost sealing position is 2 / 3 of a pouring radius from the side edge; carrying out pre-pouring, specifically, putting 2 or 3 empty liquid crystal boxes and 2-3 g of liquid crystals into a pouring machine, and putting the liquid crystals and the empty box which is being poured into a drying oven at the temperature of 55-65 DEG C to expand the liquid crystals after the liquid crystals are expanded by 5-10 mm in the empty boxes; and recording a cavity position S after the liquid crystals are fully expanded; and carrying out formal batch pouring, specifically, putting 30-40 empty boxes in batch and 7-10 g of liquid crystals into the pouring machine, waiting until the liquid crystals are expanded for 5-10mm in the empty boxes, moving the empty boxes for expanding the liquid crystals and the liquid crystals into the drying oven at the room temperature of 23 DEG C to expand the liquid crystals, waiting until the liquid crystals are expanded to exceed 10-15 mmof the cavity position S of appearing in the pre-pouring process, and moving the liquid crystals and the empty boxes for expanding the liquid crystals into the drying oven at the temperature of 55-65DEG C until the liquid crystals are fully expanded. The process method can avoid sealing side cavities, the formal pouring process can be accurate and rapid by utilizing the cavity position obtained by pre-pouring, the pouring time is shortened, and the pouring efficiency is improved.

Owner:亚世光电(集团)股份有限公司

A pouring method of concrete in the cross brace tube between arch ribs of steel pipe bridge

ActiveCN112709148BShorten the perfusion timeImprove securityBridge erection/assemblyBuilding material handlingSlurryPipe

The invention relates to a pouring method of concrete in a cross-stay tube between arch ribs of a steel pipe bridge. The two ends of the brace tube, wherein, the hole at the bottom of the brace tube is a grouting hole, and the hole at the top of the brace tube is a grout hole; step 2, the first brace tube The grout hole is connected to the grouting hole of the second brace pipe with a pump pipe ..., and the grout hole of the n-1th brace pipe is connected to the grouting hole of the nth brace pipe hole; step 3, connect the concrete delivery pump pipe with the grouting hole of the first cross-bracing pipe, perform concrete pouring, and stop pumping when the concrete flowing out of the grouting hole of the n-th cross-bracing pipe contains aggregate , close the valve of the pump pipe, the pouring of one horizontal support pipe assembly is completed, and the concrete pouring of the next horizontal support pipe assembly is performed. The pouring method can effectively shorten the construction period and improve the safety of construction and environment.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Products comprising reinforcing fibres and shape memory alloy wires and methods of making thereof

InactiveCN110809514AGood penetration resistanceGood interlayer propertiesProtective equipmentLayered productsFiberShape-memory alloy

A three-dimensional (3D) preform comprising reinforcing fibres and shape memory alloys (SMA) wires and a composite material comprising a polymer matrix with a 3D- preform embedded therein, wherein the3D-preform comprises reinforcing fibres and shape memory alloy (SMA) wires.

Owner:QINETIQ LTD

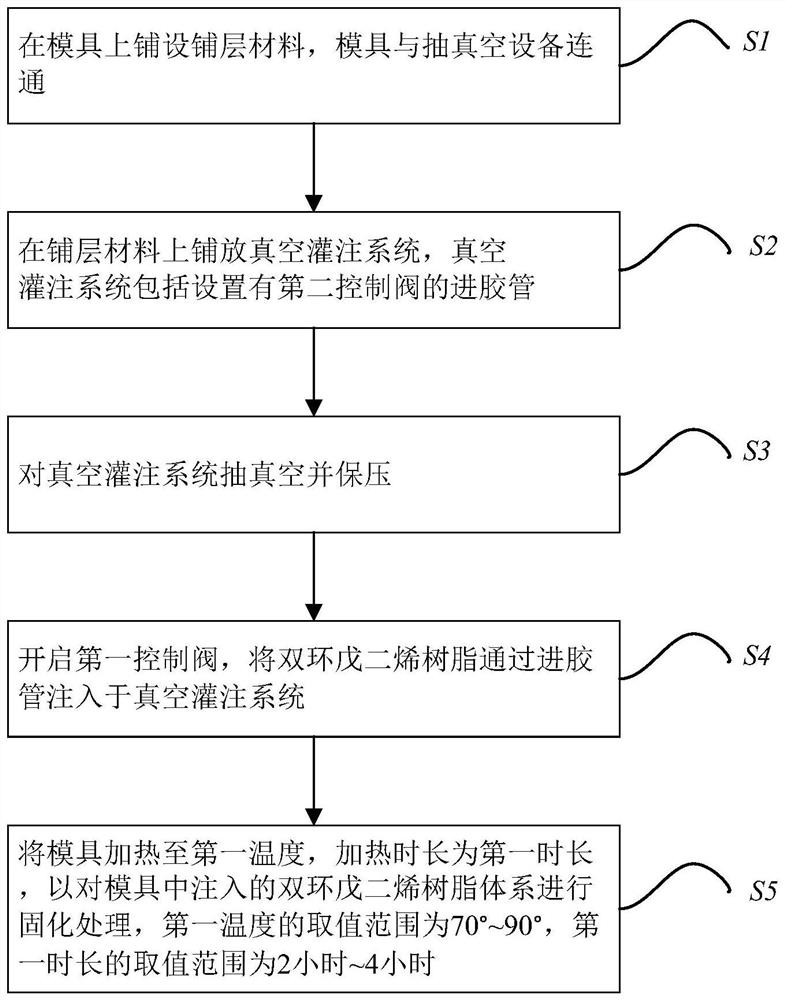

Blade forming method and blade

PendingCN114654765AShorten the perfusion timeShorten the curing timeDomestic articlesControl valvesDicyclopentadiene

The invention relates to a blade forming method and a blade. The forming method comprises the steps that a layering material is laid on a mold, and the mold is communicated with vacuumizing equipment; laying a vacuum infusion system on the laying material, wherein the vacuum infusion system comprises a glue inlet pipe provided with a second control valve; vacuumizing the mold and maintaining the pressure; opening a second control valve, and injecting the dicyclopentadiene resin system into the vacuum infusion system; the mold is heated to the first temperature, the heating duration is the first duration, the dicyclopentadiene resin system poured into the mold is subjected to curing treatment, the value range of the first temperature ranges from 70 DEG C to 90 DEG C, and the value range of the first duration ranges from 2 hours to 4 hours. According to the method, the shell, the web or the beam cap of the blade is formed by pouring the dicyclopentadiene resin system with relatively low viscosity at room temperature, and post-curing is not needed after pouring forming, so that the pouring time and the curing time of the blade can be shortened, the production efficiency of the blade can be improved, and the material cost of the blade can be reduced.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

Construction process of floral tube dry filling piles

InactiveCN101713189BReduce labor intensityFew control parametersBulkheads/pilesResource utilizationWater table

Owner:HENAN UNIVERSITY

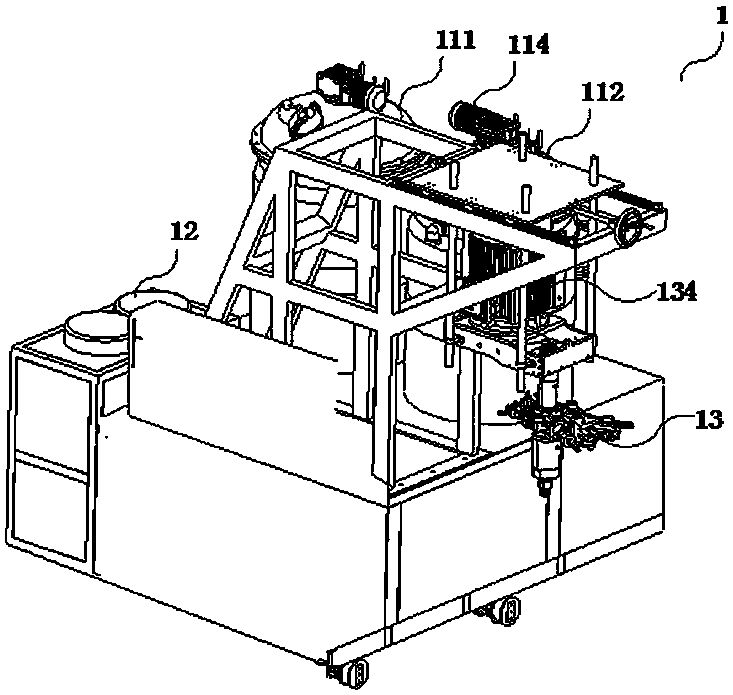

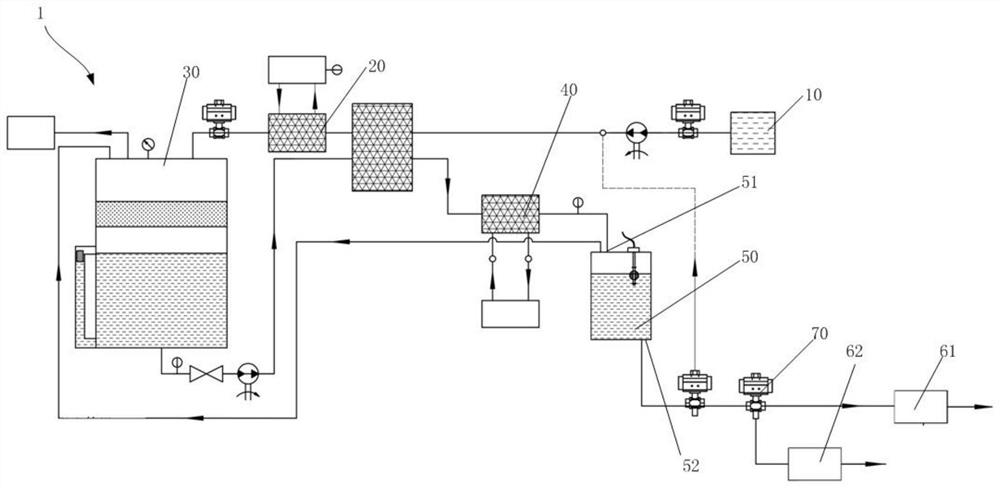

automatic perfusion method

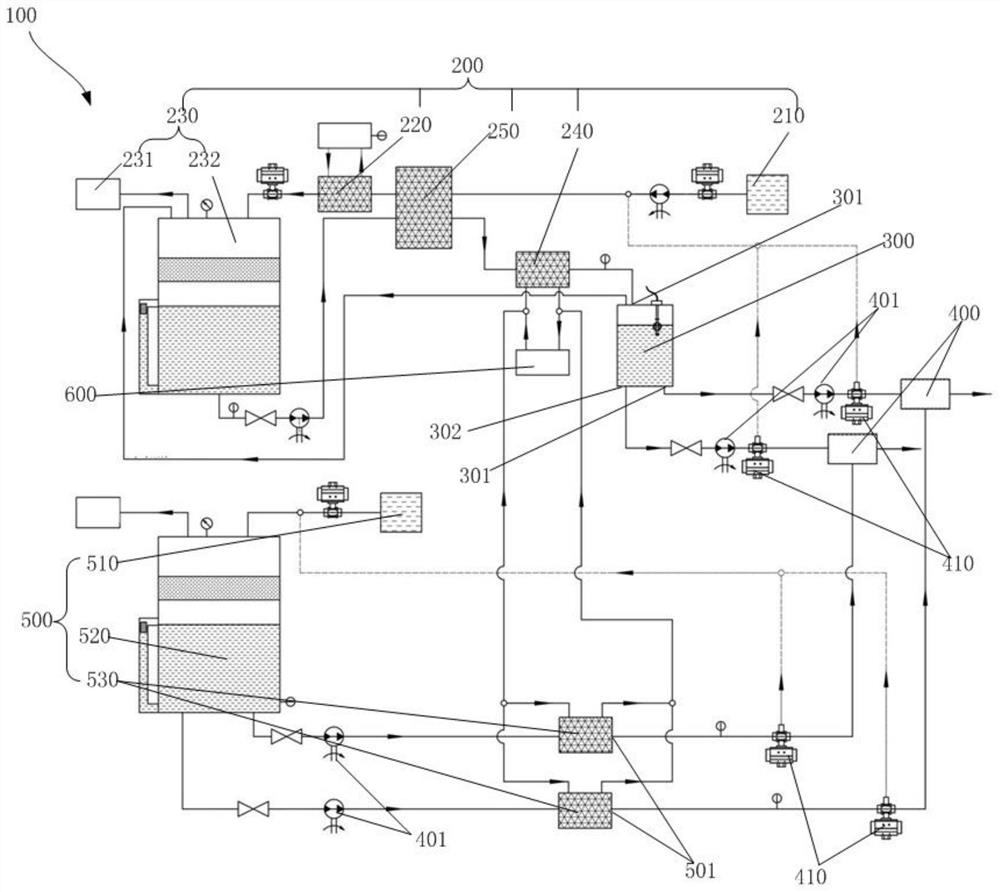

ActiveCN111331879BImprove work efficiencyShorten the perfusion timeProcess engineeringMechanical engineering

Automatic filling equipment comprises a first defoaming cooling device for material defoaming cooling treatment and a buffering device. The buffering device is provided with a buffering feeding port and at least two buffering discharging ports. The buffering feeding port is connected with the first defoaming cooling device. The buffering device receives materials obtained after defoaming cooling treatment and outputs the materials through the buffering discharging port. The provided automatic filling equipment can output multiple strands of materials at the same time, material flow and pressure can be adjusted, filling can be conducted at the same time, the production efficiency is improved, and the product quality is improved.

Owner:SINPA INDAL AUTOMATION

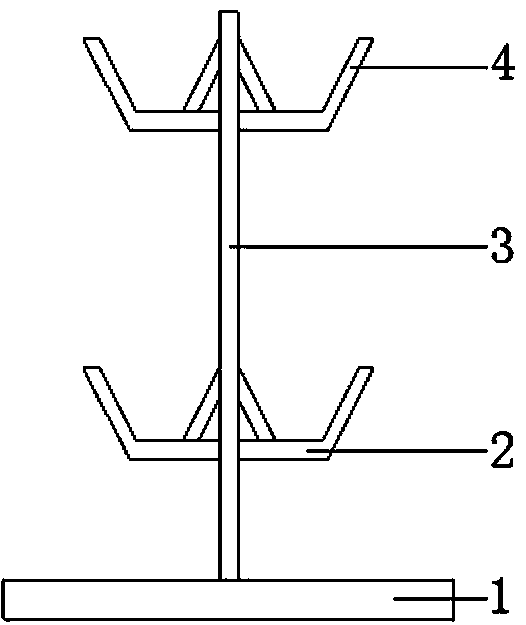

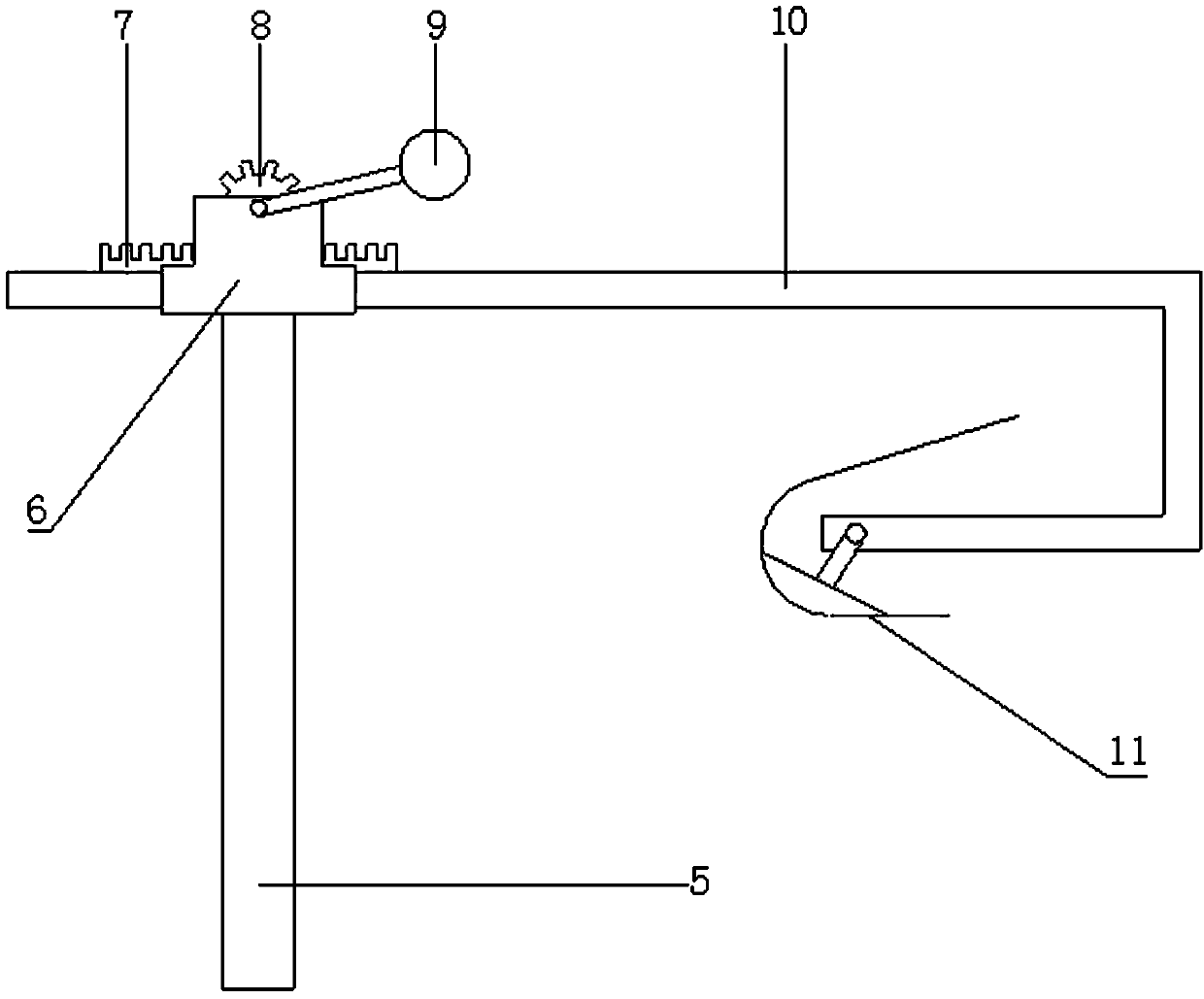

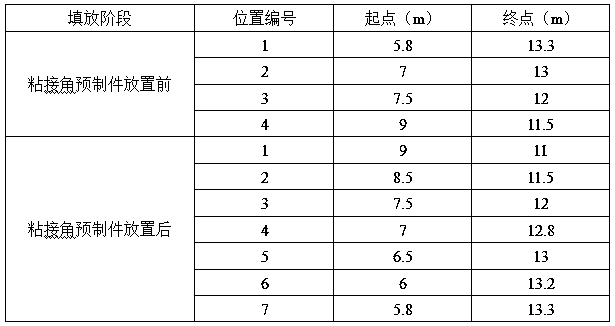

Adhesive Corner Prefabrication and Integrated Infusion Molding Process

ActiveCN108044957BEasy to controlEasy to identifyDomestic articlesMechanical engineeringMaterials science

The invention provides a bonding corner prefabricating and integrated filling forming process. The bonding corner prefabricating and integral filling forming process comprises the steps of manufacturing a bonding corner mold, prefabricating a bonding corner, carrying out skin forming and carrying out integrated filling. According to the bonding corner prefabricating and integral filling forming process, in a blade forming process, the bonding corner prefabricating and skin forming integrated filling technology is adopted, due to the fact that a bonding corner prefabricated part is manufacturedin advance, the defect of a bonding corner is easy to control and recognize, and the found defect can be maintained effectively in time; moreover, a bonding corner cloth layer does not need to be coated with resin and soaked again in a filling process, so that the filling time is effectively shortened, the use amount of filling resin is reduced, the production cost is reduced while the productionefficiency is improved, and the product percent of pass is improved; due to the fact that the bonding corner defect is recognized in a prefabricating stage, the defect maintenance phenomenon can notbe found again during subsequent-stage circulation, secondary maintenance at a main forming stage is avoided, and the blade circulation time is shortened; and therefore, the production efficiency is improved, and a considerable popularization prospect and potential practical value are achieved.

Owner:SINOMATECH JIUQUAN WIND POWER BLADE CO LTD

A kind of pultrusion pre-embedded blade root connector for wind power generator blade and preparation method thereof

ActiveCN105465141BShorten molding timeShorten the timeFinal product manufactureNutsWind drivenTurbine blade

The invention discloses a pultrusion type embedded blade root connector for wind-driven generator blades and a preparation method thereof. The pultrusion type embedded blade root connector comprises blade root connector bodies (1-1), a light connector body (1-4) connected to the blade root connector bodies (1-1), light material (1-3) filling the light connector body (1-4), and a pultrusion type composite material part (1-2) wrapping the peripheries of the blade root connector bodies (1-1) and the periphery of the light connector body (1-4). The pultrusion type preparation method comprises the steps of part assembly, embedded type composite material pultrusion and finishing. The embedded blade root connector has the advantages that the appearance size is stable, the defect rate of products is low, the quality is continuously stable and reliable, locating is accurate, interfaces between different kinds of material are firmly bonded, and the mechanization level is high. The preparation method has the advantages that the time of occupying molds by the products can be shortened, the time of laying material can be shortened, the time of installing bolts can be shortened, the time of pouring and curing can be shortened, the production efficiency is high, and the labor cost is low.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

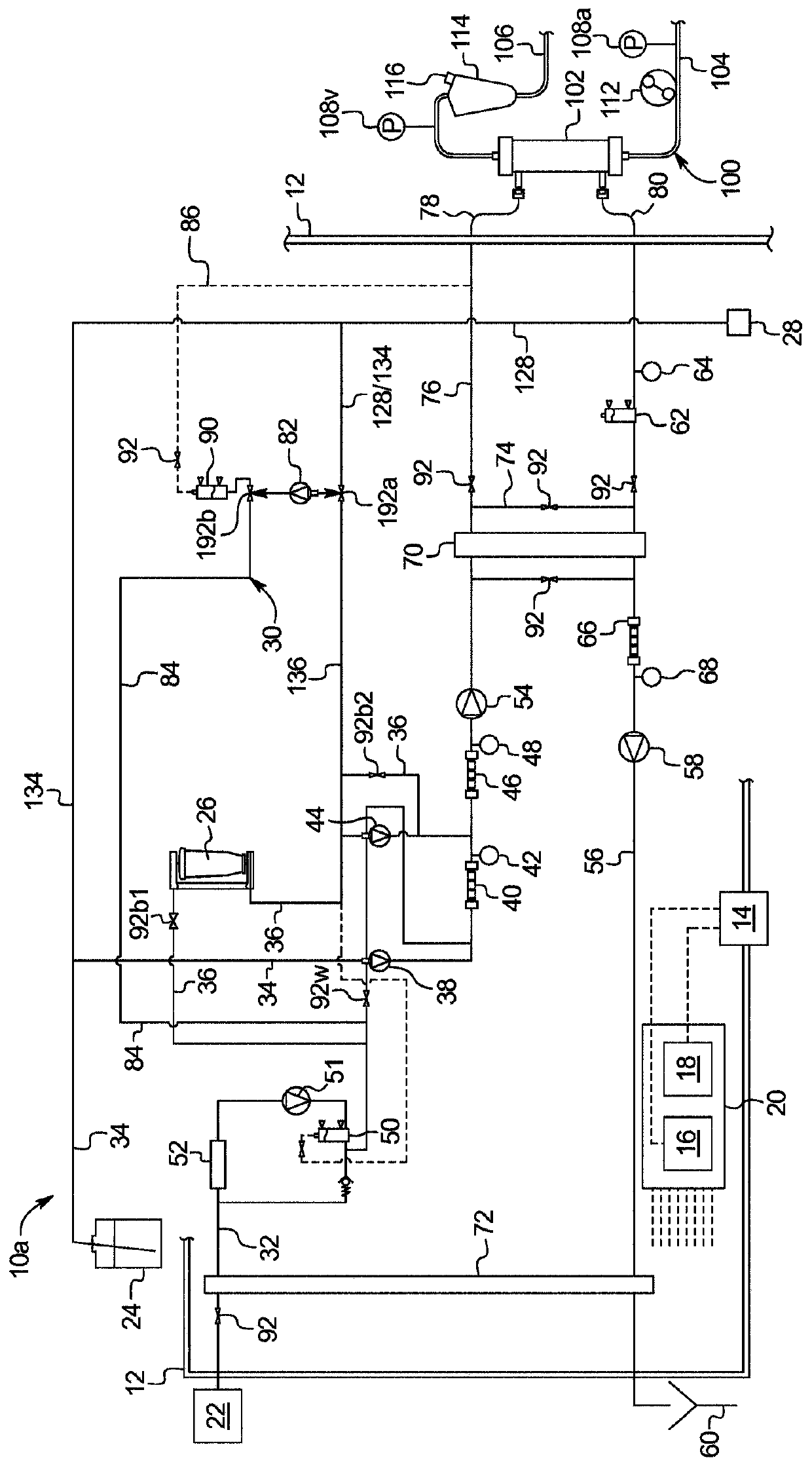

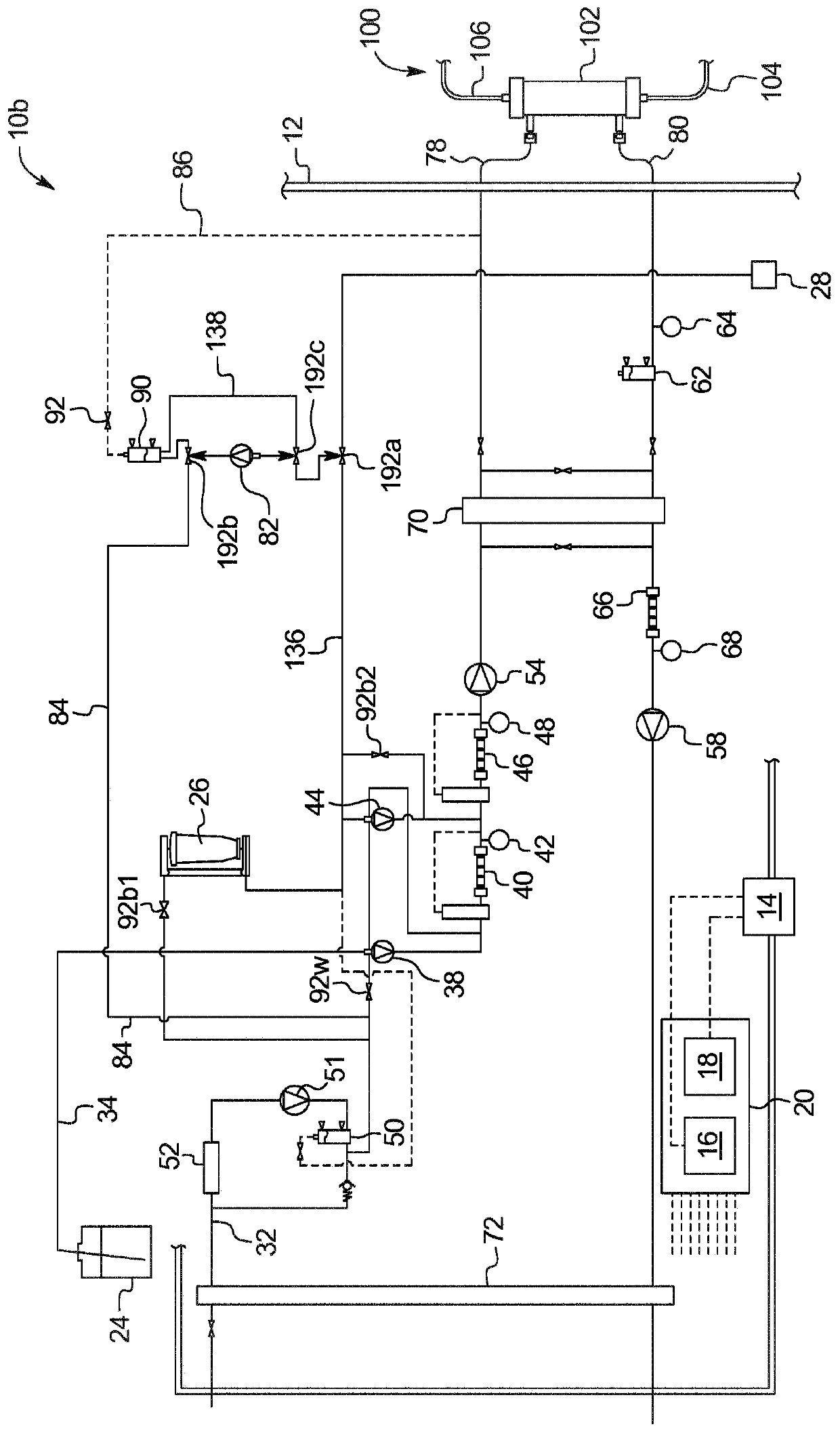

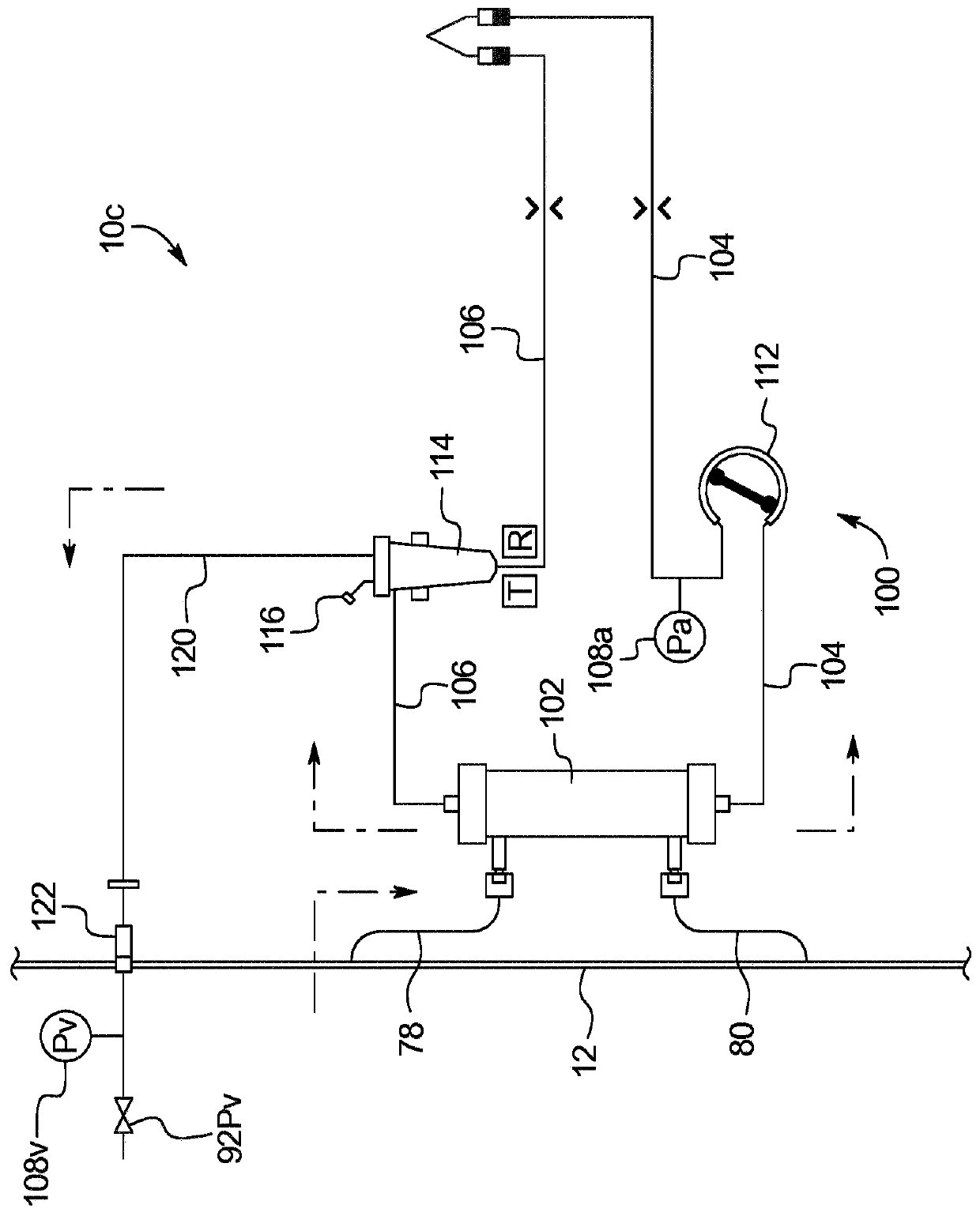

Dialysis system having carbon dioxide generation and prime

PendingCN111511418AEasy to primeRelatively cheap perfusion for improved perfusionOther blood circulation devicesInorganic active ingredientsDialysis fluidIntensive care medicine

An extracorporeal therapy system includes: (i) a dialysis fluid circuit including dialysis fluid preparation structure configured to prepare a dialysis fluid for an extracorporeal therapy treatment; (ii) a blood circuit including a blood filter for use during the extracorporeal therapy treatment; (iii) a blood pump operable to pump blood through the blood circuit and blood filter; and (iv) a control unit operable with the dialysis fluid preparation structure and the blood pump, the control unit programmed to prepare a gas generation fluid different than the dialysis fluid for the extracorporeal therapy treatment, wherein the gas generation fluid generates carbon dioxide ("CO2") gas, and wherein the CO2 gas is used to prime the blood circuit including the blood filter.

Owner:GAMBRO LUNDIA AB

Resin composite material, preparation method, blade shell and wind generating set

PendingCN114311753AShort curing timeImprove production efficiencyDomestic articlesEpoxyPolymer science

The embodiment of the invention provides a resin composite material, a preparation method, a blade shell and a wind generating set, the resin composite material comprises polydicyclopentadiene resin and a catalyst, and the weight ratio of the catalyst to the polydicyclopentadiene resin is 0.001%-0.5%. When the resin composition provided by the embodiment of the invention is used for preparing the blade of the wind generating set, the polydicyclopentadiene resin system is low in viscosity at room temperature, so that the filling speed is very high, and the preparation time of the blade of the wind generating set can be effectively shortened. The weight of the blade can be reduced; and the polydicyclopentadiene resin does not need to be post-cured, the curing time is short, and the preparation efficiency of the blade can be further improved. In addition, the cost of the polydicyclopentadiene resin is lower than that of epoxy resin and polyurethane resin systems. Therefore, the resin composite material provided by the embodiment of the invention not only can effectively improve the preparation efficiency of the blade of the wind generating set, but also can effectively reduce the manufacturing cost of the blade.

Owner:JIANGSU GOLDWIND SCI & TECH CO LTD

Concrete conveying device

ActiveCN109653206AAchieve continuous perfusionShorten the perfusion timeFoundation engineeringSpiral bladeEngineering

The invention discloses a concrete conveying device, which comprises: a transportation pipe body and at least two supporting control components, wherein a plurality of spiral blades are arranged in the transportation pipe body; the spiral blades realize that concrete is maintained in an agitating state and cannot flow out the transportation pipe body when the transportation pipe body rotates clockwise, and the concrete flows out of the transportation pipe body when the transportation pipe body rotates counterclockwise; and the at least two supporting control components are respectively disposed at the feeding end and the discharging end of the transportation pipe body to control the clockwise rotation and the counterclockwise rotation of the transportation pipe body and adjust the inclination angle of the transportation pipe body, thereby realizing conveying and agitation of the concrete. The concrete conveying device realizes continuous pouring of the concrete, promotes the reductionof concrete pouring time, makes the super-pouring amount of the concrete easy to control, saves the labor and reduces the waste of the concrete.

Owner:SHANGHAI MARITIME UNIVERSITY

Main beam applied to wind power blade, wind power blade and forming method thereof

PendingCN113844058AUniform flow velocitySpeed up the flowMachines/enginesWind energy generationYarnEngineering

The invention discloses a main beam applied to a wind power blade, the wind power blade and a forming method thereof. The main beam is provided with a lower surface which is placed downwards when the wind power blade is formed; a plurality of first grooves are formed in the lower surface of the main beam; the first grooves extend from the end portion of one end of the main beam to the end portion of the other end of the main beam. According to the main beam of the wind power blade, the structure is adopted; the structural defects such as the dry yarn defect caused by resin wrapping of the wind power blade can be avoided; and compared with forming of the traditional main beam, the forming period of the wind power blade can be shortened; and the structural performance can be enhanced.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

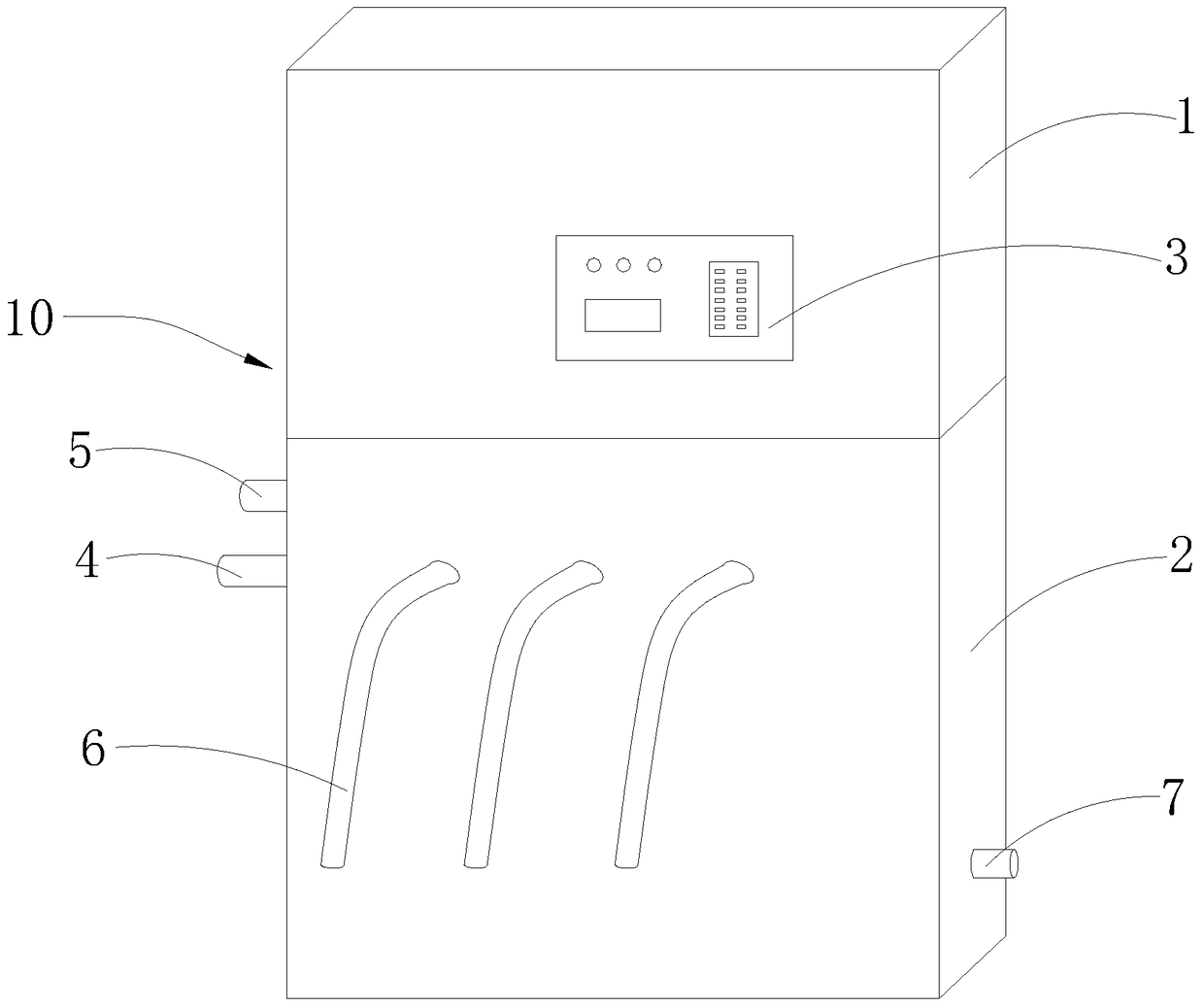

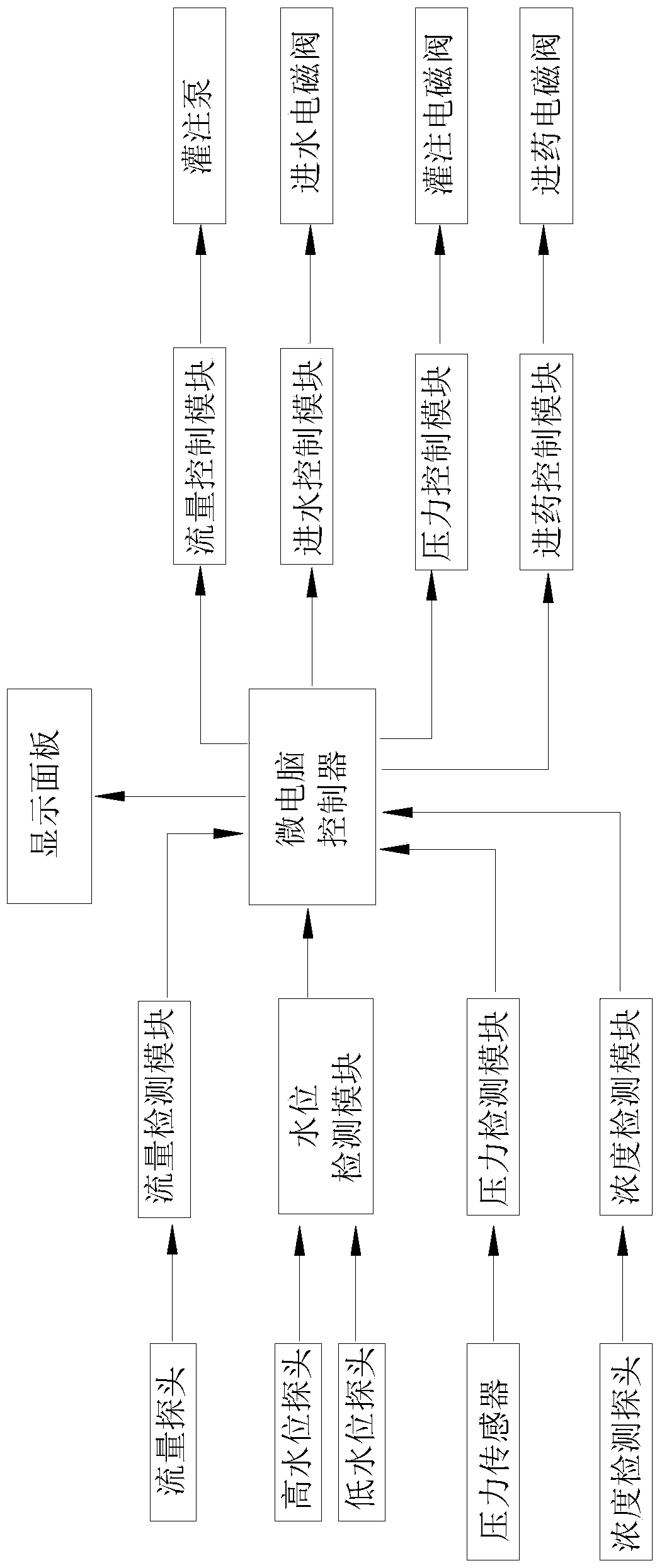

Microcomputer automatic perfusion system

The invention discloses a microcomputer-based full-automatic perfusion system comprising an operation platform and a perfusion box. The perfusion box comprises an upper box body and a lower box body which have independent cavities, a water inlet pipe and a liquid medicine inlet pipe which are communicated with the cavity of the lower box body, multiple perfusion pumps of which the liquid inlet ends are communicated with the cavity of the lower box body, and perfusion pipes which are connected to the liquid outlet ends of the perfusion pumps respectively. The perfusion system further comprises a microcomputer controller and a plurality of module units which are arranged in the cavity of the upper box body, and a display panel which is arranged on the surface of the upper box body and is electrically connected with the output end of the microcomputer controller. The perfusion system of the invention has a simple structure, needs no manual operation, realizes full-automatic operation in the perfusion process, can carry out perfusion on a plurality of bodies at the same time, and effectively improves the working efficiency.

Owner:江苏日升恒隆科教设备有限公司

A double-headed coronary direct perfusion tube

ActiveCN109200443BShorten the perfusion timeShorten operation timeMulti-lumen catheterCoronary arteriesSurgical risk

The invention relates to the technical field of medical devices, and specifically discloses a double-head coronary artery direct perfusion tube, which is composed of a handle, a left coronary artery perfusion tip, a hard connecting rod, a high-density right coronary artery perfusion tip, and a soft perfusion tube. The weight of the right coronary perfusion head is several times that of the left coronary perfusion head, and it can naturally hang and be positioned at the right coronary artery under the action of gravity. When the double-ended coronary artery direct perfusion tube of the present invention is used, the left and right coronary arteries can be perfused simultaneously, the perfusion time is shortened by half, the entire operation time is greatly shortened, the operation risk can be reduced, and great benefits are brought to the patient.

Owner:DALIAN CORVIVO MEDICAL CO LTD

Laying method of the main beam of the wind power blade and its core material and plate

ActiveCN110500242BAvoid structural strengthPromote formationFinal product manufactureMachines/enginesAcute angleUltimate tensile strength

The invention discloses a main beam of a wind power blade, and a laying method of a core material and plates of the main beam of the wind power blade. The main beam comprises the first core material and the plates. The laying method includes the following steps that (1) the first core material is laid, at least one side of the first core material is provided with an oblique surface, and an acute angle is formed between the oblique surface and the bottom surface of the first core material; and (2) the plates are laid layer by layer on the side of the oblique surface, the plates are provided with first side surfaces which are oblique, and the first side surfaces of the plates are fit with the oblique surface. Firstly, the core material is positioned and laid, then the plates are fit with theedge of the core material to be laid layer by layer , thus the effect that the plates are fully tightly fit with the edge of the core material can be guaranteed, and mismatching of the plates is avoided. The problem that seams are formed during stacking of the plates, and consequently the structural rigidity and strength of the plates are lowered is avoided, meanwhile the problem of defects and risks that rich resin exists at the interface of the plates and the core material, and mismatching of the plates of the main beam occurs is solved, the method is easy to implement, operation is convenient for workers, and the production efficiency can be improved.

Owner:SHANGHAI ELECTRIC WIND POWER GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com