Process method for producing large-size LCD (Liquid Crystal Display) by adopting pouring mode

A process method and large-size technology, which is applied in the process field of large-size LCD production by perfusion method, to achieve accurate and fast perfusion process, improve perfusion efficiency, and avoid the effect of sealing side cavities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] A method for producing a large-size LCD by pouring, comprising the steps of:

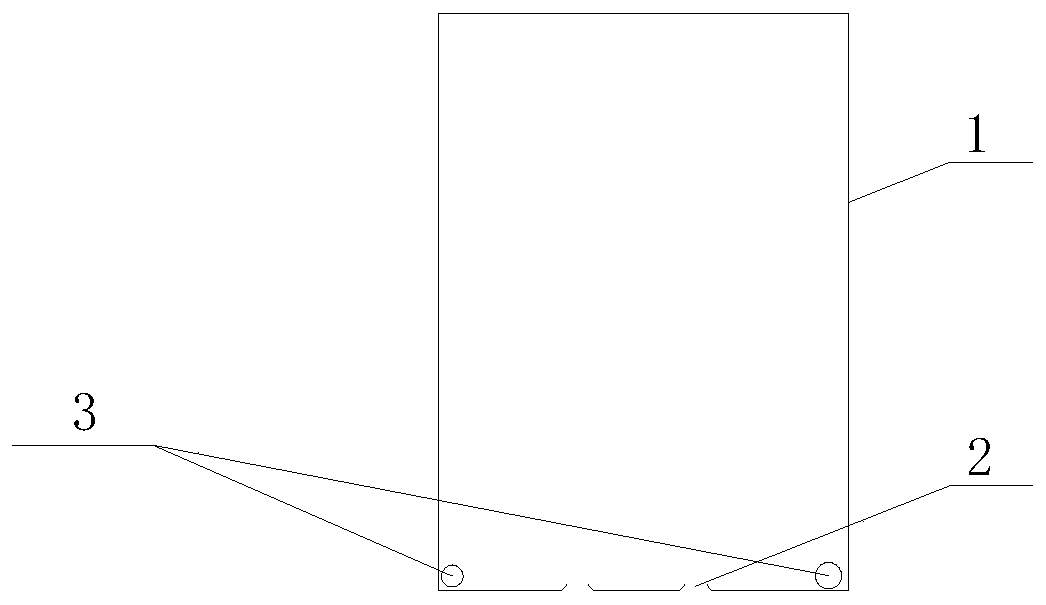

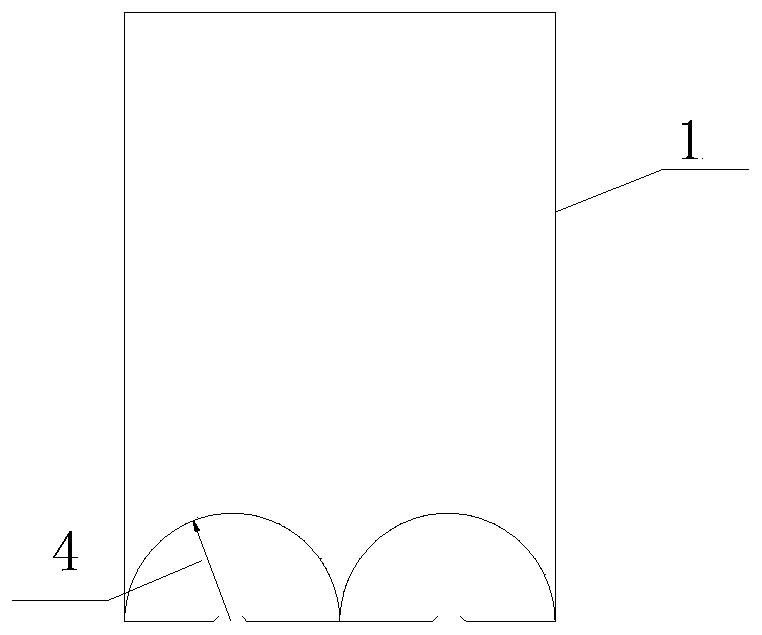

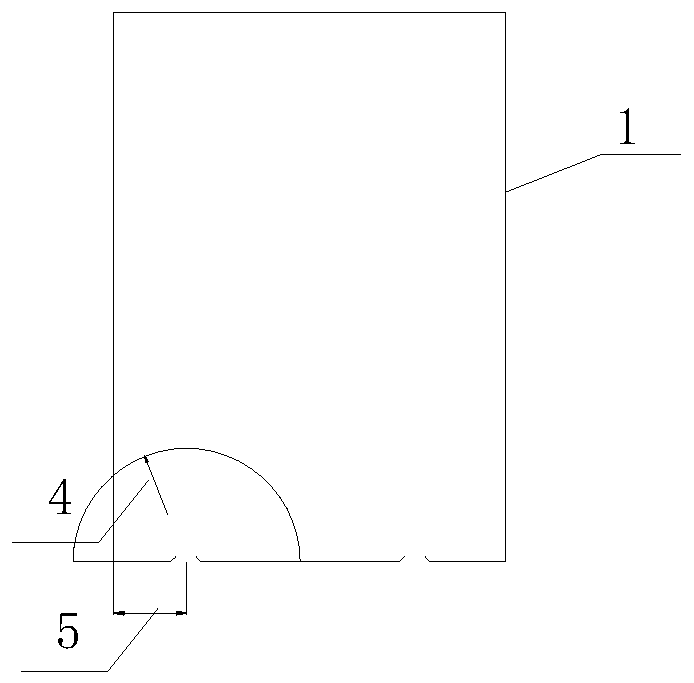

[0027] Step 1. Design the best sealing position: if image 3 As shown, the outermost sealing position is set at 2 / 3 of the pouring radius from the side.

[0028] Step 2. Pre-perfusion, record the hole position 6:

[0029] 1) First take 2 or 3 liquid crystal empty boxes, 2 to 3 grams of liquid crystals, and place them in the filling machine, and the filling machine is evacuated to <0.01Pa;

[0030] 2) The liquid crystal empty box falls and touches the liquid crystal. After the liquid crystal has risen by 5-10mm in the empty box, put the liquid crystal and the empty box being poured together in an oven at 55-65 degrees to expand the liquid crystal;

[0031] 3) After the liquid crystal is full, take out the full LCD, place it under the light tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com