Laying method of the main beam of the wind power blade and its core material and plate

A laying method and technology of wind power blades, which are applied in wind power generation, mechanical equipment, wind turbines, etc., can solve the problems of reducing the rigidity and strength of the plate structure, and achieve the effect of speeding up the manufacturing speed, improving the perfusion efficiency and effect, and facilitating the operation of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

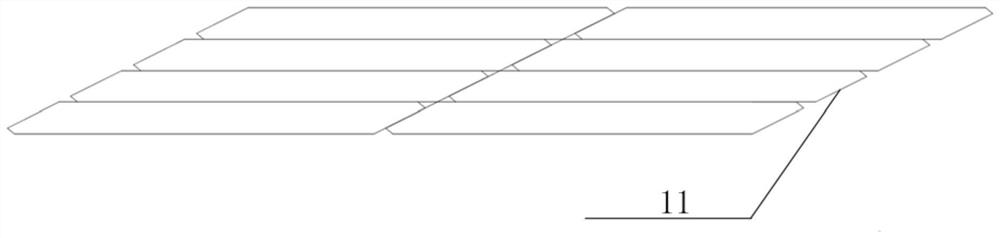

[0058] Using a section such as figure 1 The shown parallelogram plate 1 is used to make the main girder of the wind power blade, which is laid using the first laying method of the present invention. The main girder of the wind turbine blade is obtained by stacking a plurality of parallelogram plates 1 to form a multi-layer structure, and then pouring resin with the core material. The structure formed after the parallelogram plates 1 are stacked is as follows: figure 2 As shown, the stacked parallelogram sheet 1 will form an inwardly concave edge ( figure 2 edge of the sheet structure 11).

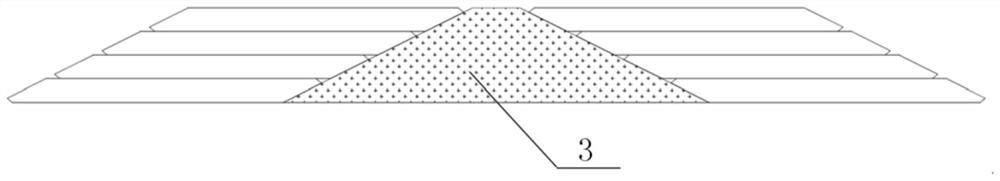

[0059] see image 3 Firstly, the first core material 3 is positioned and laid in the blade shell, and then the parallelogram plates 1 on both sides of the first core material 3 are laid. When the parallelogram plate 1 is stacked, it is close to the slope of the first core material 3 . When laying the parallelogram plate 1 on both sides of the first core material 3, the number of laye...

Embodiment 2

[0062] The main girder of the wind power blade is made of the trapezoidal plate 2, and the laying method 1 of the present invention is still used for laying. The main girder of wind turbine blades is made by pouring resin after laying multiple plates and core materials in corresponding molds. The structural form of the trapezoidal plate 2 is as follows Figure 8 shown. The structure formed after the trapezoidal plates 2 are stacked is as follows Figure 9 As shown, when the trapezoidal plates 2 are stacked, one of the two adjacent trapezoidal plates 2 is placed in reverse, and the contacting sides of the adjacent trapezoidal plates 2 are combined in a mosaic form and superimposed layer by layer. After the trapezoidal plates 2 are stacked, an inwardly concave edge will be formed ( Figure 9 edge of the sheet structure 21).

[0063] The main girder stacking form of embodiment 2 is as follows Figure 10 As shown, the first core material 3 is first positioned and laid in the ...

Embodiment 3

[0067] The laying method 1 is used for laying, and the implementation steps of integral pouring of the main beam and the shell are as follows:

[0068] 1. Determine the size of the trapezoidal first core section in the middle of the plate according to the blade design, including the length of the upper and lower sides, thickness and angle;

[0069] 2. Determine the location of the centerline of the main beam in the blade shell according to the blade design;

[0070] 3. According to the positioning of the center line of the main beam in the shell, lay the first core material in the shell so that the center of the first core material is aligned with the center line of the main beam;

[0071] 4. Lay the main beam plate on both sides of the first core material. When laying the plate, the number of layers of the plate on both sides of the first core material should be consistent, that is, lay the first layer of plate on one side of the first core material first, and then lay the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com