Manufacturing method for multilayer sole, and shoe

A production method and interlayer technology, which are applied to shoe soles, shoe-making machinery, footwear, etc., can solve the problems of poor structural connection strength, blurred sole layers, and poor decoration, and achieve good structural strength and wear resistance. Good continuity and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] The present invention is achieved in that a kind of manufacture method of multilayer sole is characterized in that, it comprises the steps:

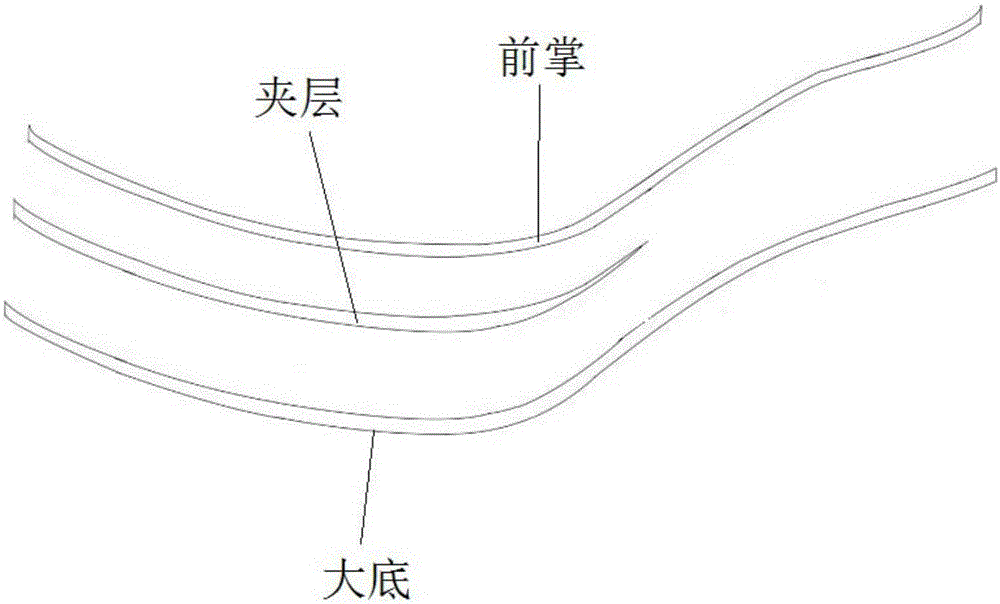

[0024] (1) According to the paper grid, widen the edging position and then cut the material to obtain the materials for the forefoot, interlayer and outsole required for the preparation of multi-layer soles, such as figure 1 As shown; this structure using split paste combination not only reduces the difficulty of production, improves production efficiency, but also saves production materials and reduces production costs.

[0025] (2) For the above-mentioned materials, first pour the edge, then spray the primer, and finally stick the protective film;

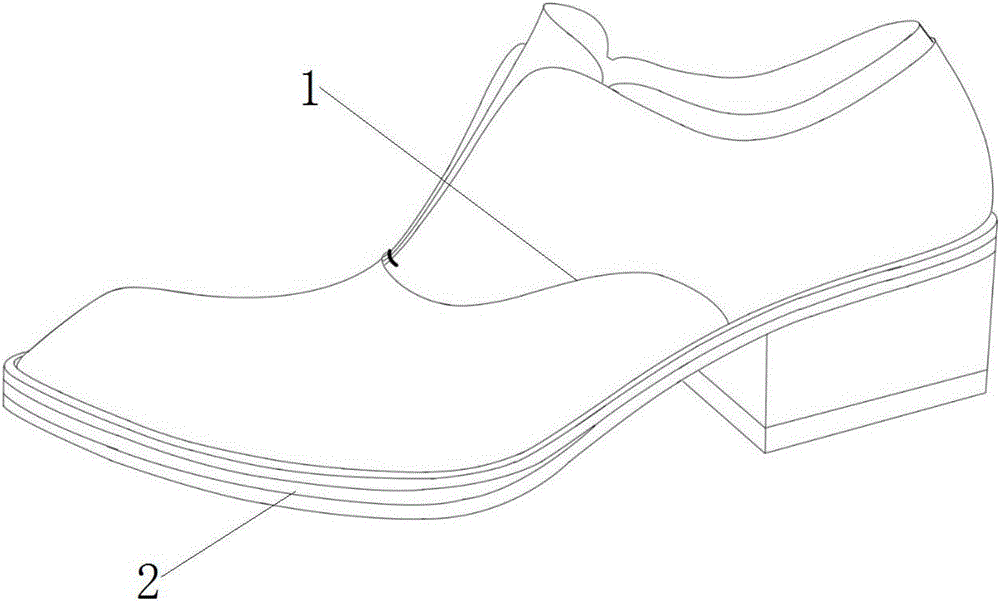

[0026] (3) rub glue on the above-mentioned materials, and then bond and combine the forefoot, interlayer and outsole to obtain the main model of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com