Patents

Literature

74results about How to "Toughness to avoid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carburizing alloy steel, and preparation method and application thereof

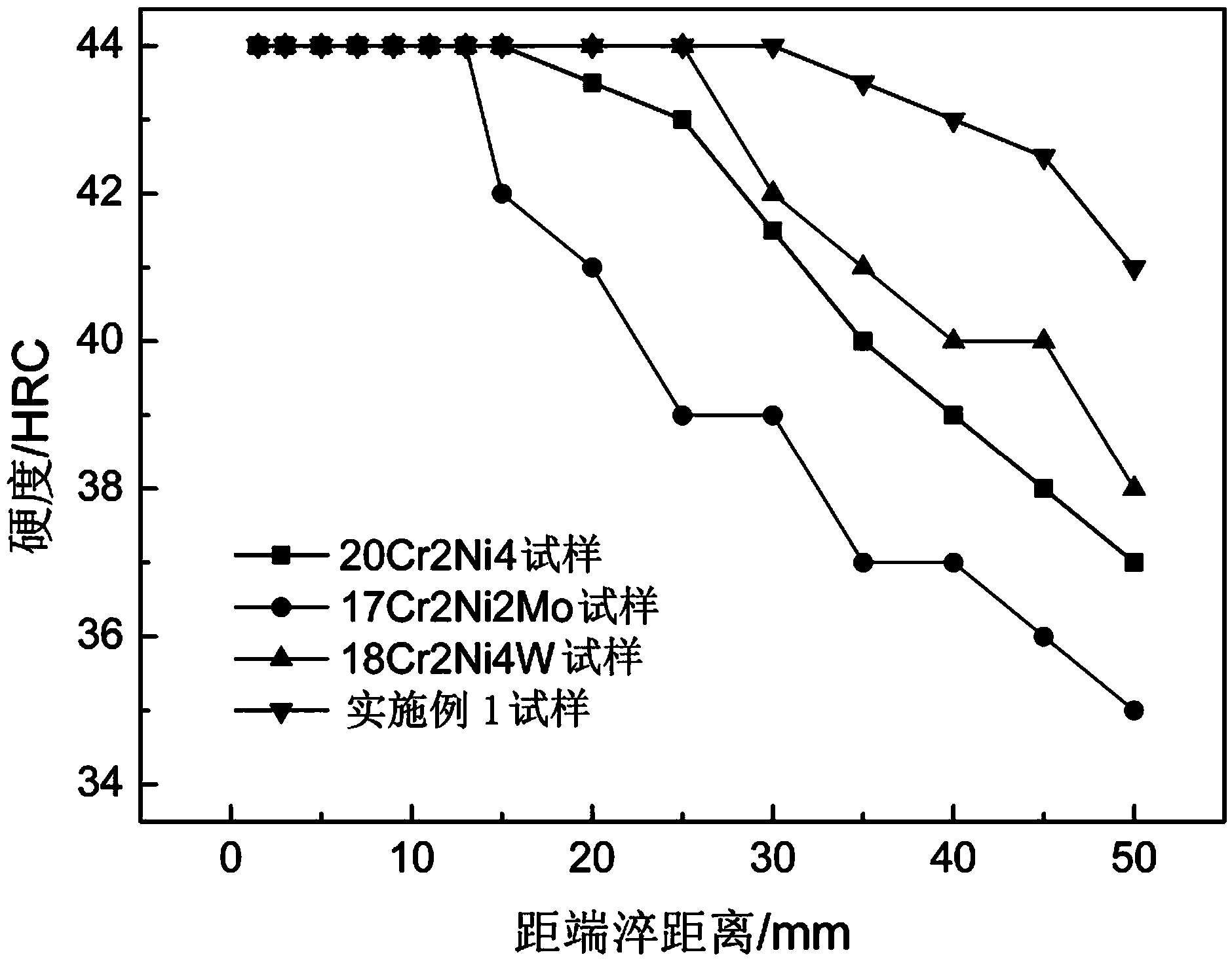

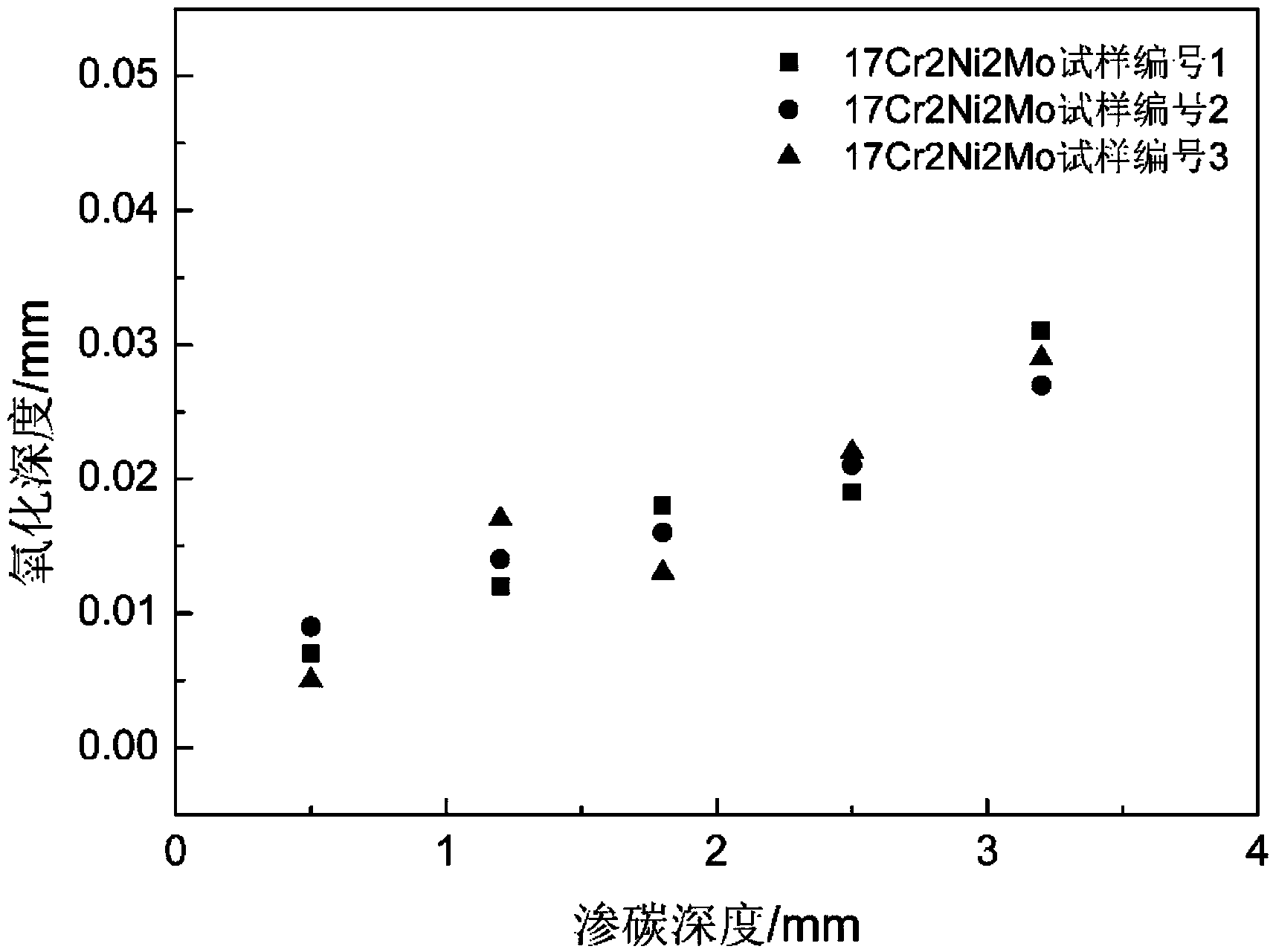

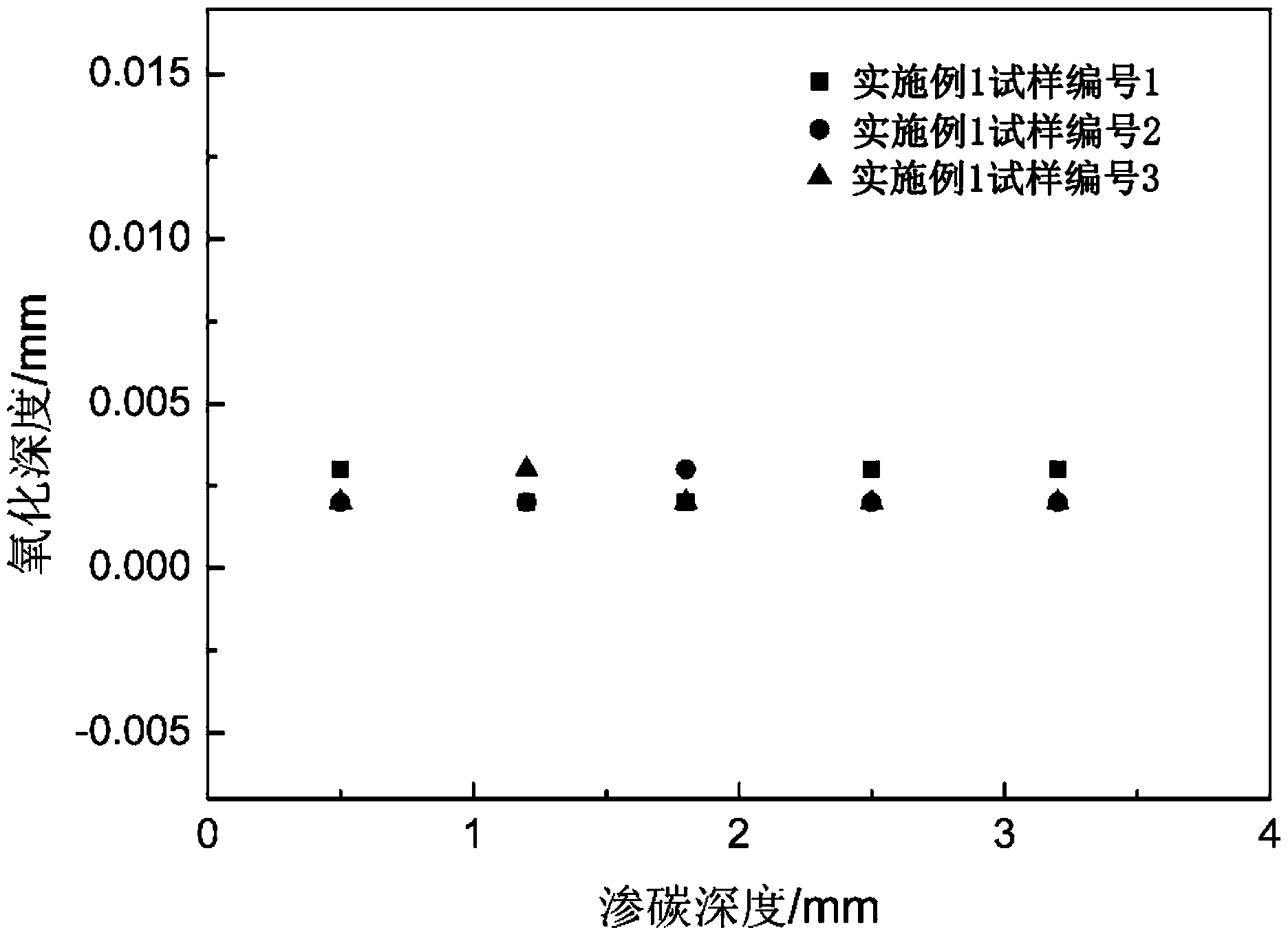

The invention relates to carburizing alloy steel, and a preparation method thereof. The alloy of the carburizing alloy steel comprises, by mass, 0.15%-0.25% of C, less than or equal to 0.30% of Si, 0.30%-1.20% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30%-1.50% of Cr, 2.80%-3.80% of Ni, 0.30%-1.00% of Mo, 0.01%-0.08% of Al, at least one selected from 0.05%-0.15% of V and 0.025-0.10% of Nb, and the balance being Fe and inevitable impurities. A mass percentage of V, Nb and Al meets an equation of V+Nb+Al <= 0.30%. The carburizing alloy steel provided by the invention has good anti-fatigue performance, excellent comprehensive properties, good hardenability, high yield ratio, extremely small internal oxidation and the characteristic of resisting grain growth at a high temperature, and is suitable for manufacturing heavy-duty gears.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

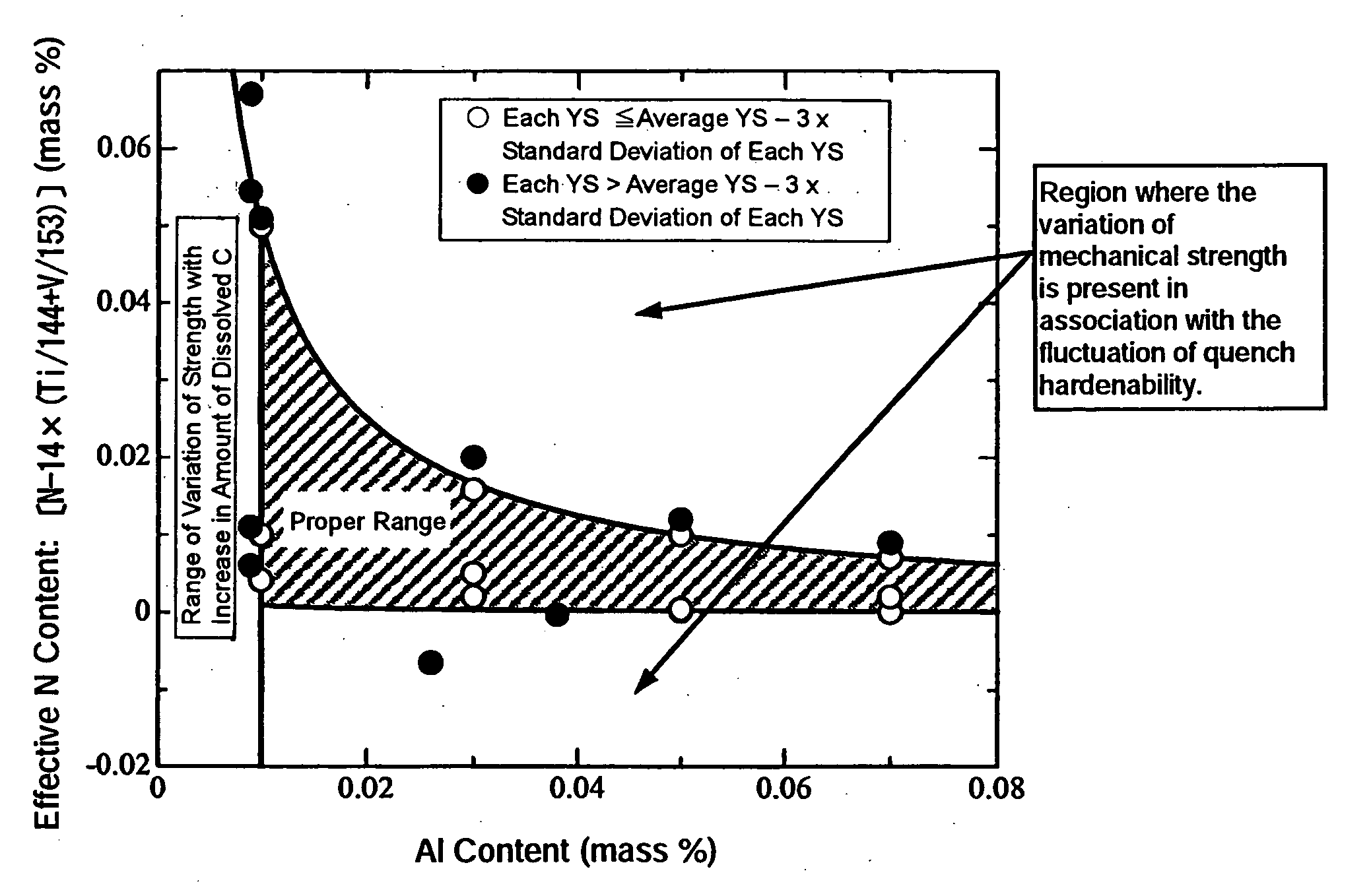

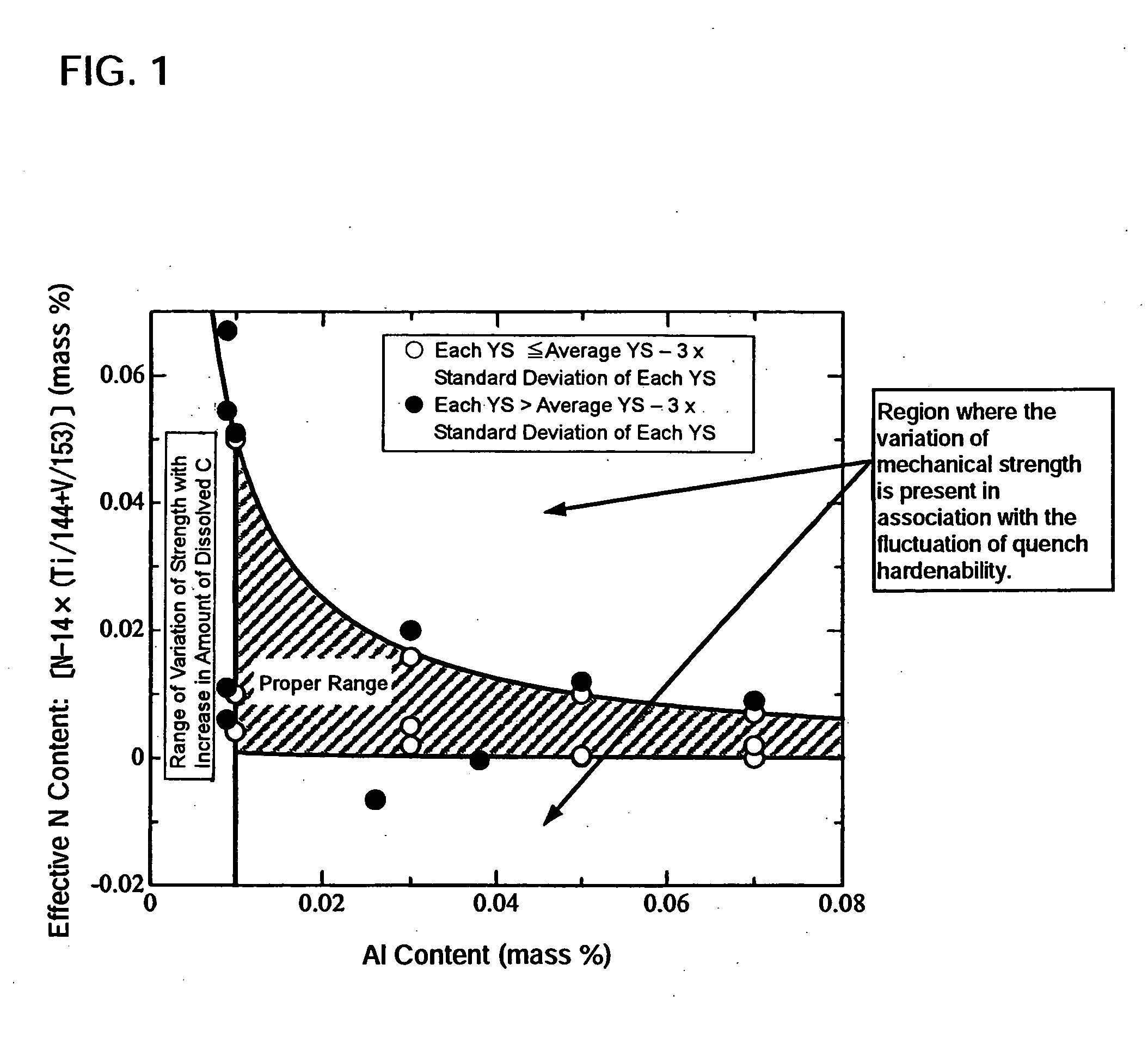

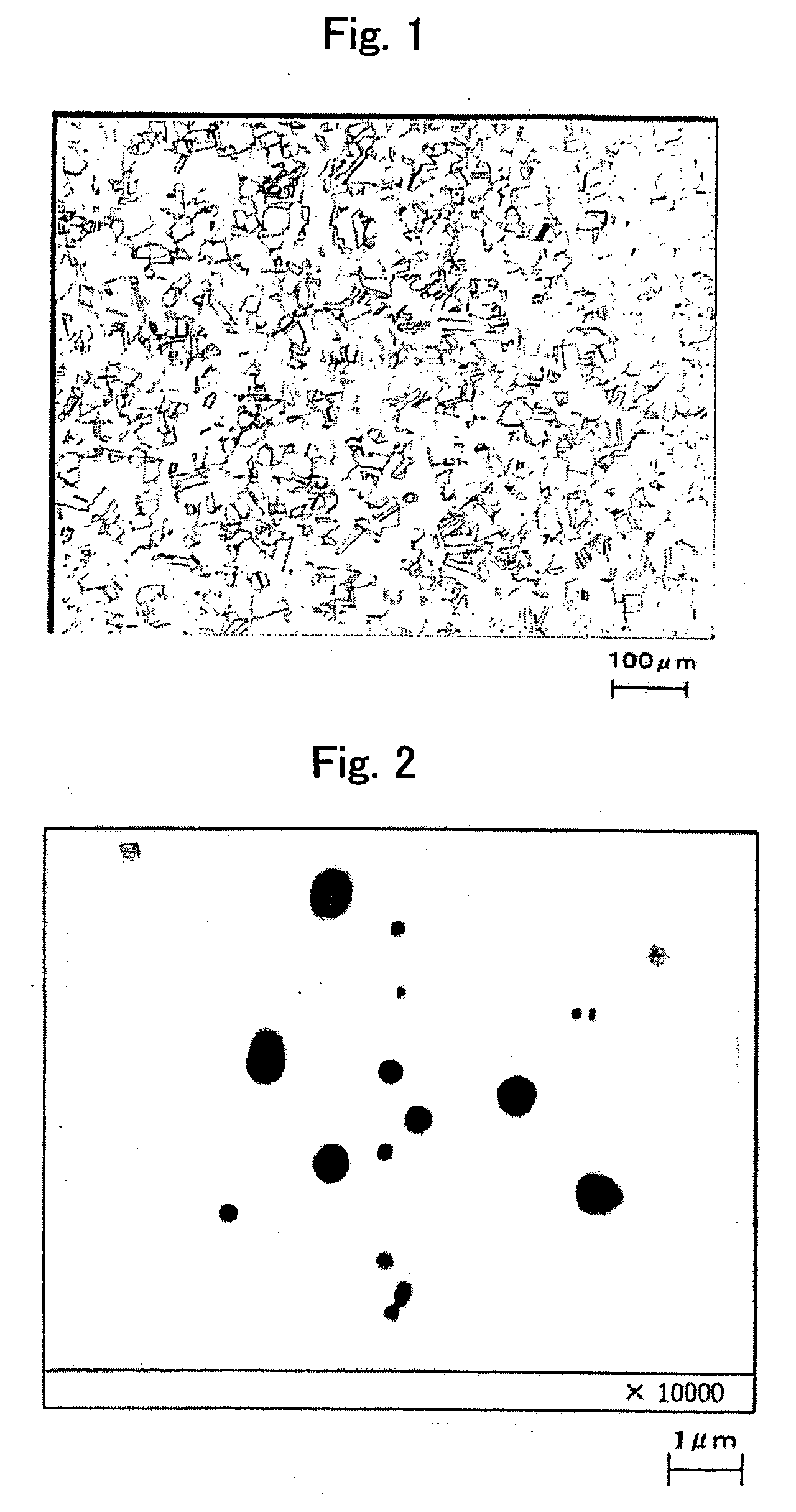

Seamless steel tubes and pipes for use in oil well

InactiveUS20060231168A1Excellent stability in mechanical strengthEffective meanNon-metallic inclusionsStress corrosion cracking

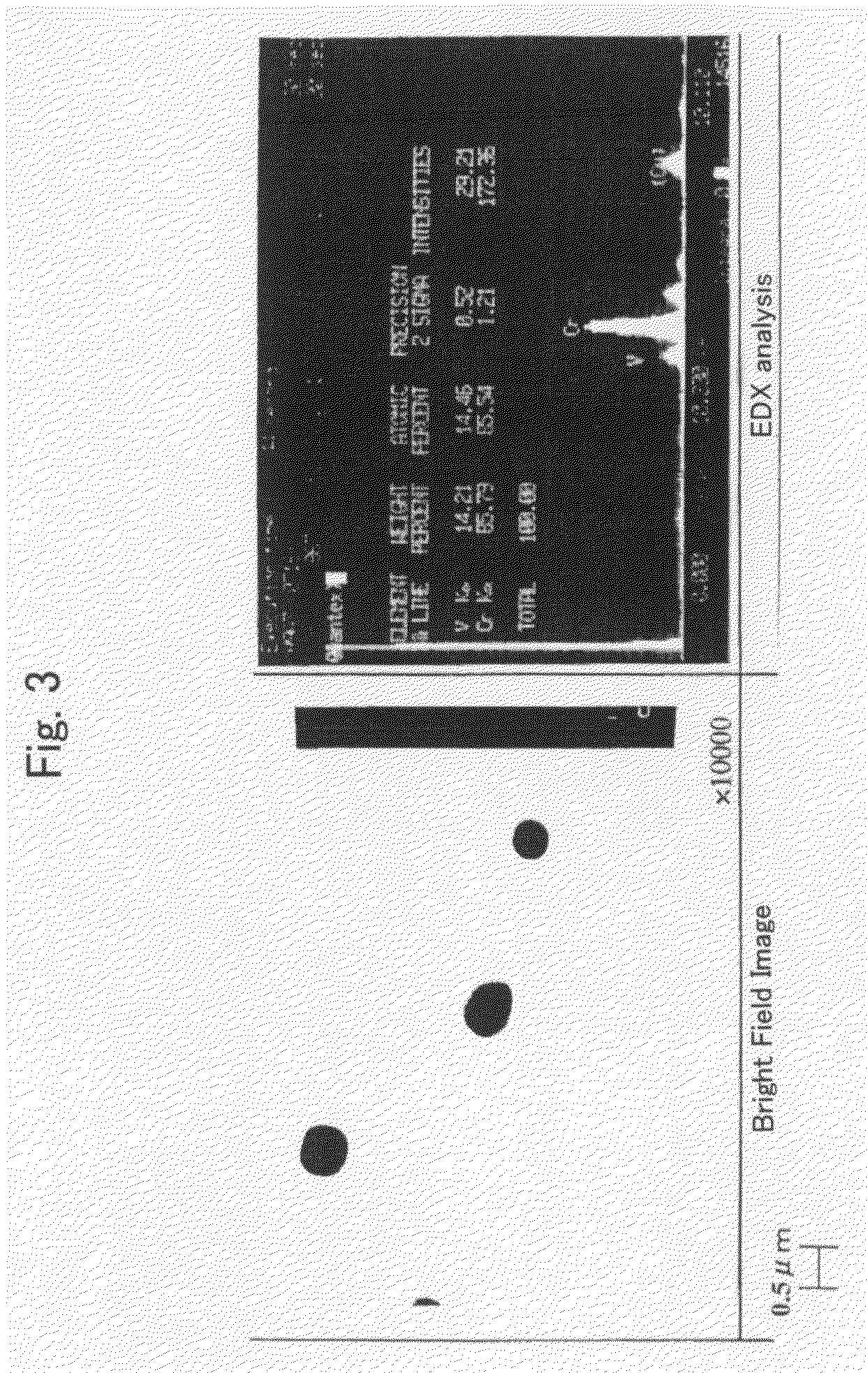

Disclosed are seamless steel tubes for oil well use, comprising C: 0.14-0.35%, Si: 0.05-1.0%, Mn: 0.05-2.0%, Cr: 0.05-1.5%, Mo: 0.05-2.0%, Ti: 0-0.05%, V: 0-0.1%, and Al: not less than 0.010%, wherein the concentration product by Al and N content, corrected by Ti and V, is within the range of 0.00001 to 0.00050, and the residuals are Fe and impurities including P: 0.025% or less, and S: 0.010% or less. Ti, V, Nb, or B is preferably contained to enhance the quench hardenability as well as the resistance to sulfide stress corrosion cracking, and further Ca, Mg and / or REM is preferably contained to improve the shape of non-metallic inclusions, enhancing the resistance to sulfide stress corrosion cracking. Thus, said tubes by the invention can be produced by efficient means realizing energy savings, and widely used as ones having excellent stability in mechanical strength.

Owner:SUMITOMO METAL IND LTD

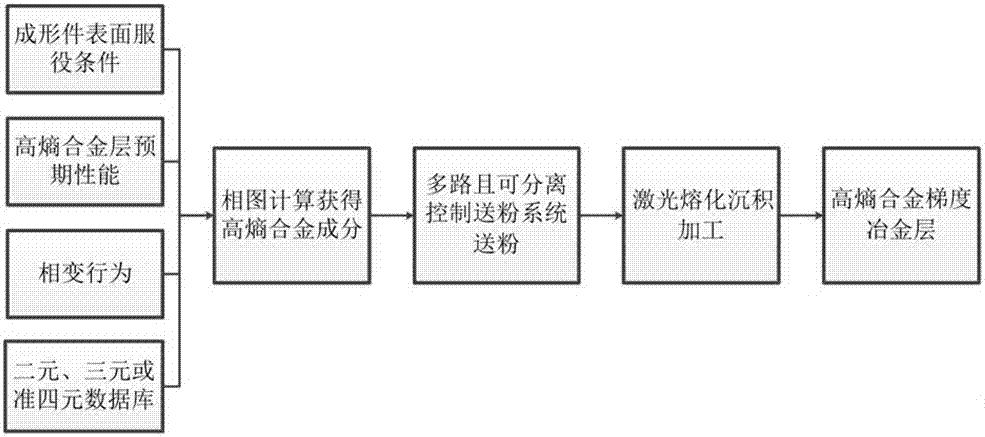

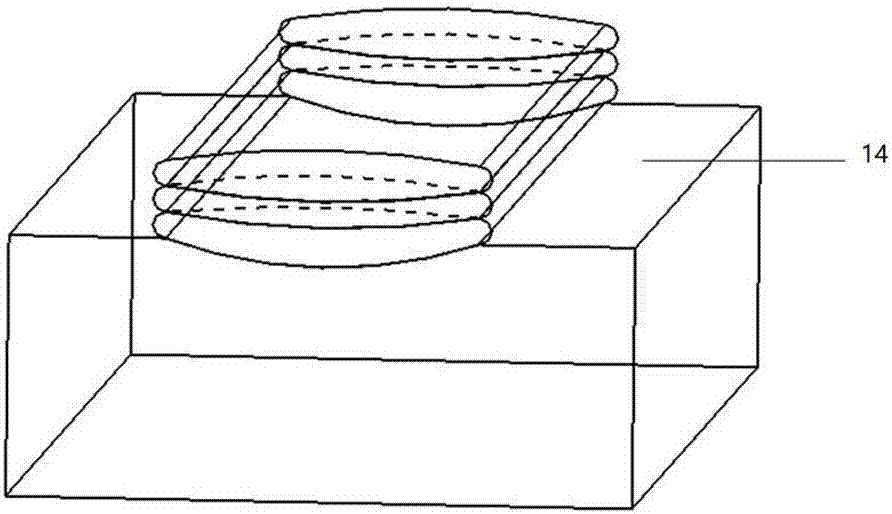

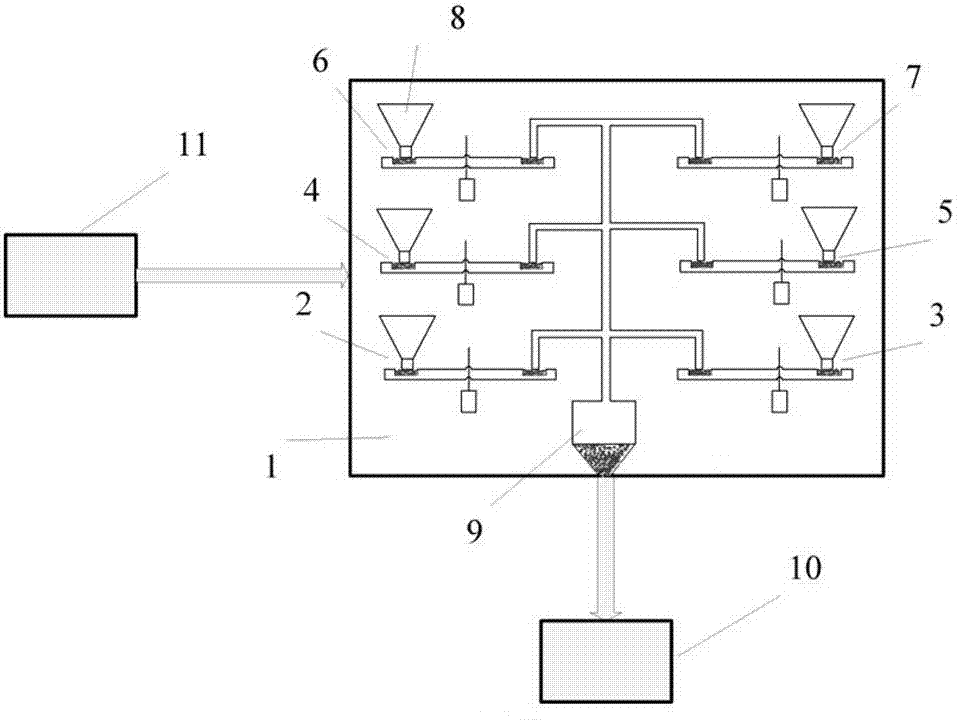

Additive manufacturing method of surface high-entropy alloying gradient metallurgy layer

InactiveCN107971490AReduce distortionImprove work efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyHigh entropy alloysUltimate tensile strength

The invention discloses an additive manufacturing method of a surface high-entropy alloying gradient metallurgy layer, and belongs to the field of surface alloying. The additive manufacturing method comprises the following steps that step one, high-entropy alloying components are obtained through calculation based on a phase diagram; step two, an LMD technological strategy is designed, wherein anLMD technology is designed to carry out laser multilayer melting and sedimentation and increase the content of alloy powder in mixed powder layer by layer from the bottom up, and powder delivering schemes of different gradient coatings are formulated to design a multichannel and separable control powder delivering system; and step three, laser melting and sedimentation machining is carried out, thus the high-entropy alloying gradient metallurgy layer is obtained. The additive manufacturing method achieves the effects that the high-entropy alloying gradient layer excellent in properties is prepared on the surface of a cheap base material, the requirement that the surface properties of a formed part are outstanding is met, the production cost is lowered substantially, the bonding strength between the material surface metallurgy layer and a base is improved, and cracking of the metallurgy layer is inhibited effectively.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

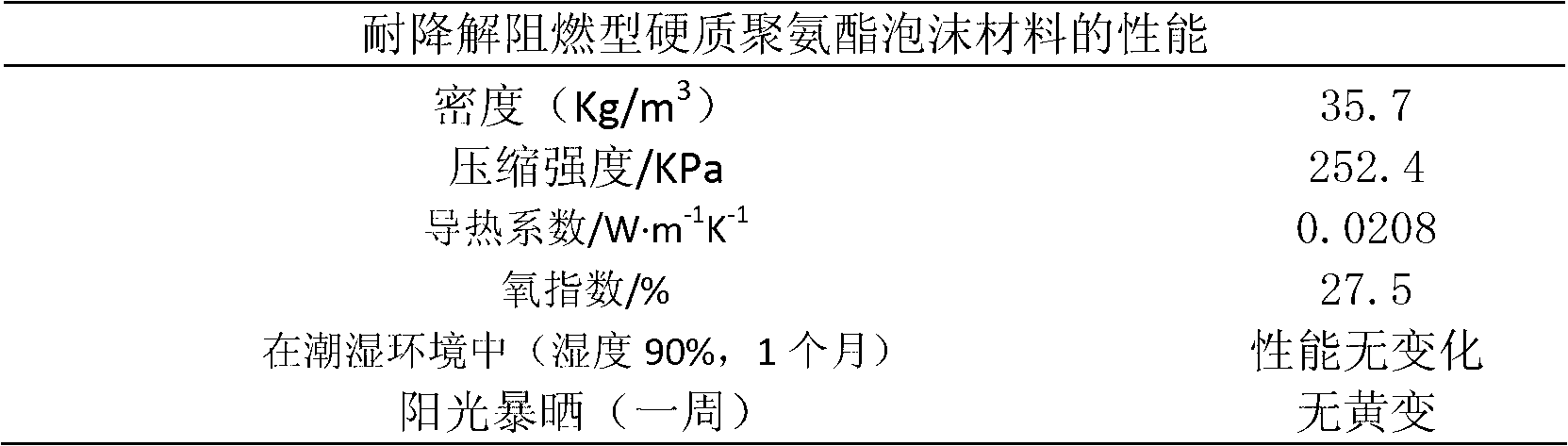

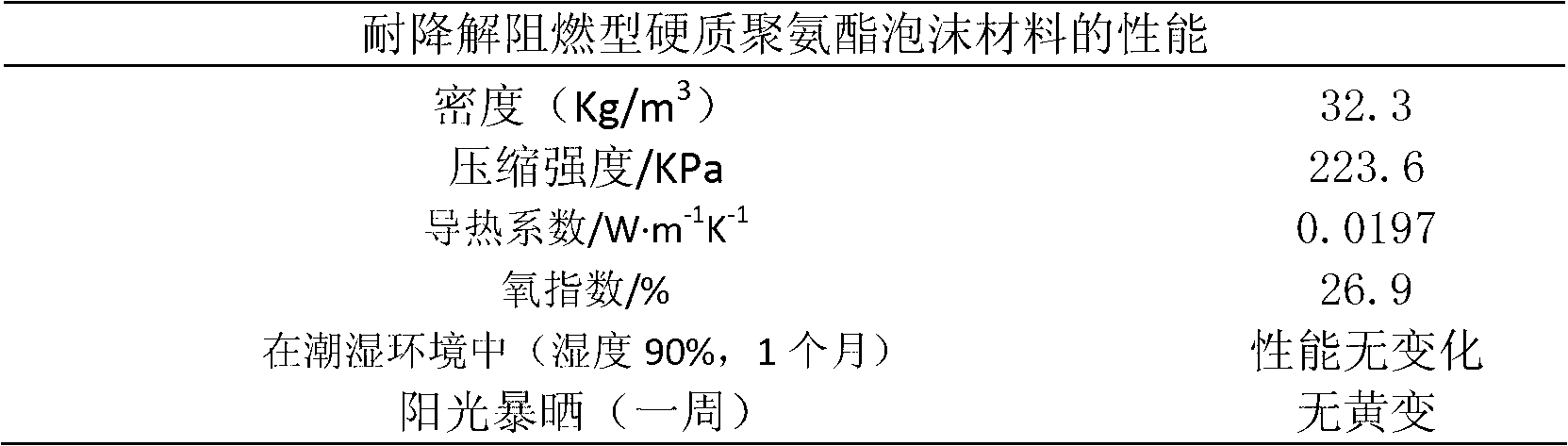

Degradation resistance fire retardation type rigid polyurethane foam material and preparation method thereof

The present invention discloses a degradation resistance fire retardation type rigid polyurethane foam material, which comprises a component A, a component B and a component C, wherein the component A is polyisocyanate with functionality of 2.0-3.5, the component B comprises polyether polyol or polyester polyol, a foaming agent, a cross-linking agent, a chain extender, a foam stabilizer, a catalyst, a composite stabilizer, an additive and the like, and the component C is a composite fire retardation agent. The degradation resistance fire retardation type rigid polyurethane foam material has characteristics of high strength, low combustion value, excellent fire retardation, wear resistance, hydrolysis resistance, corrosion resistance, shock resistance, good size stability, good biodegradability and the like, and can be used in vehicle materials, thermal insulation materials, structural materials, sound insulation materials, building materials, aerospace materials, packaging materials, road repair and the like.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Alloy forged steel and its heat treatment method and use

ActiveCN102953008AGood comprehensive mechanical propertiesImprove hardenability and heat strength propertiesBraking membersAlloy elementCompound (substance)

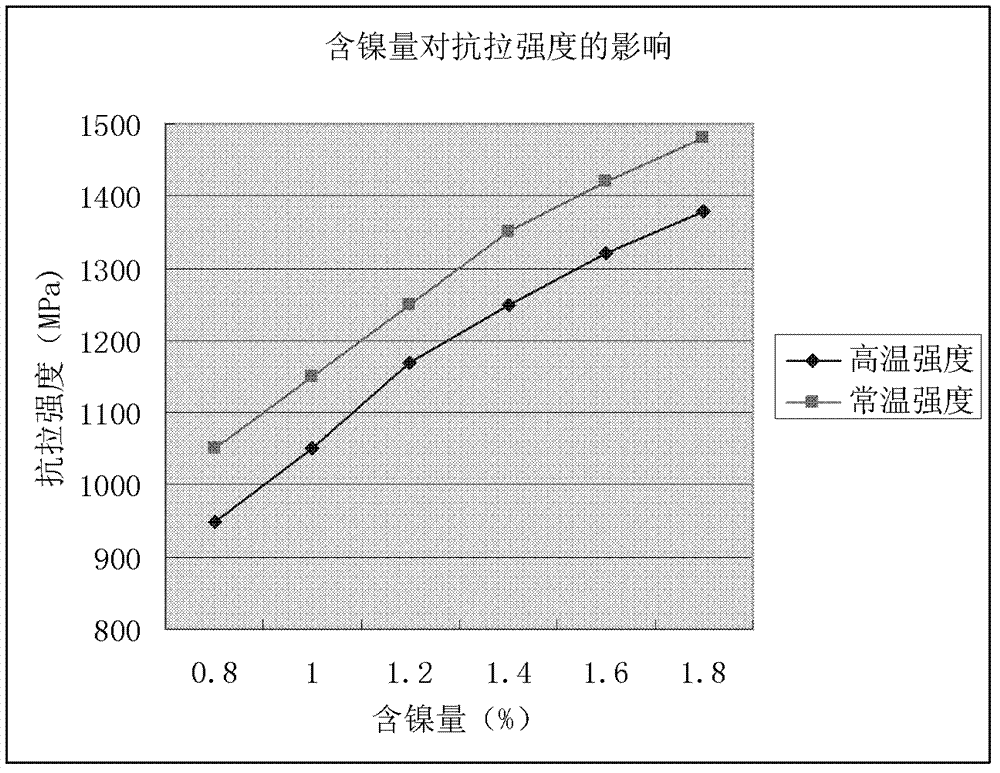

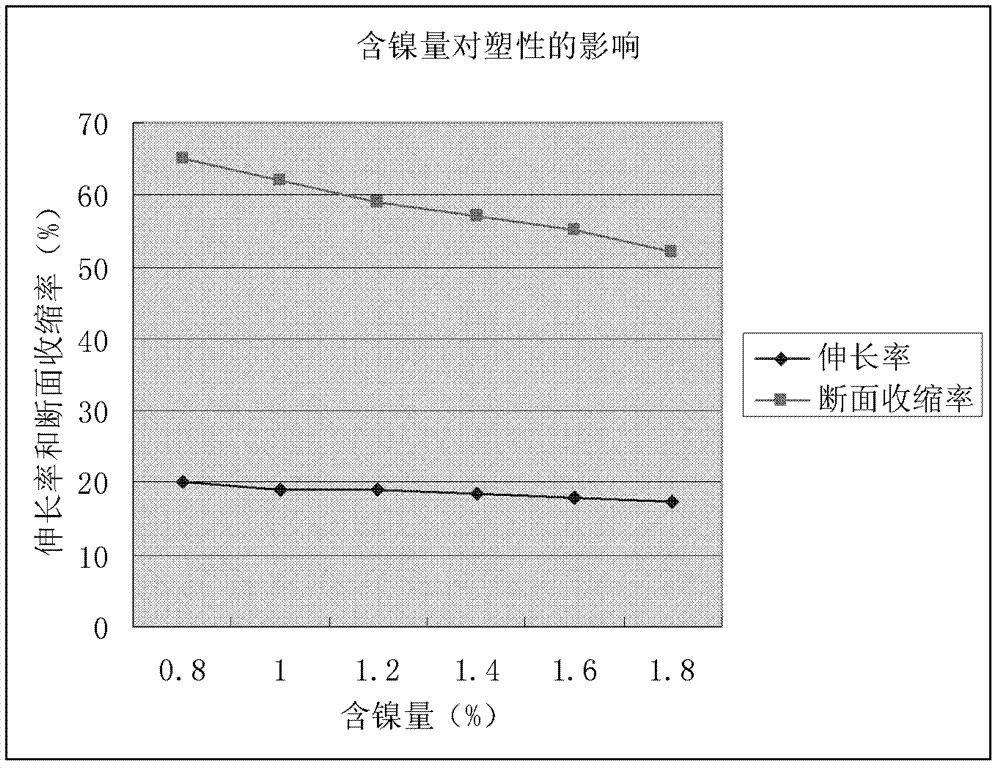

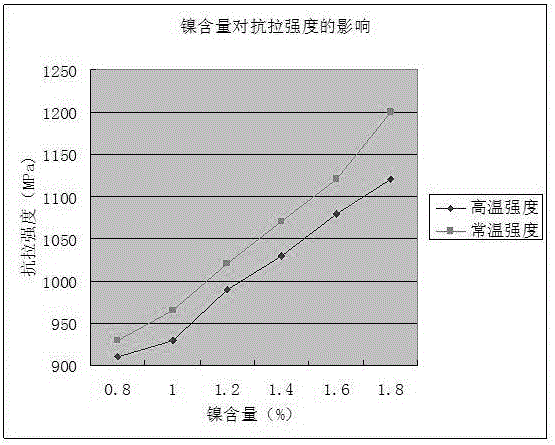

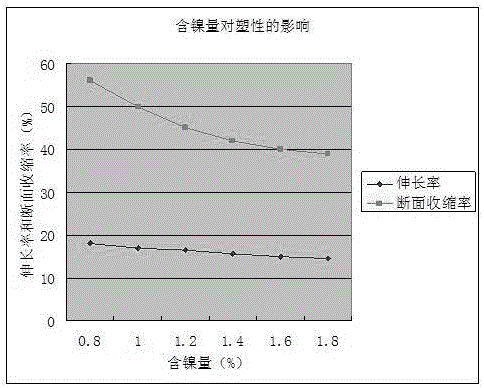

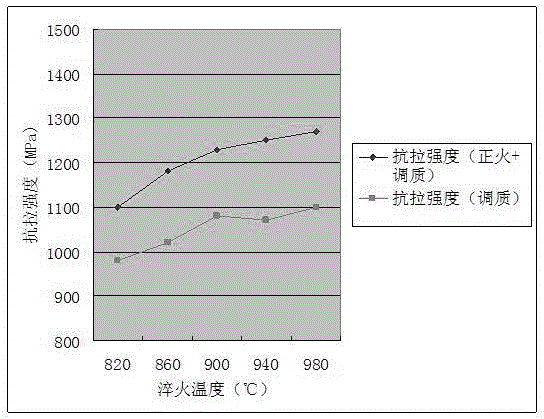

The invention provides an alloy forged steel and its heat treatment method and use. The alloy forged steel comprises: by mass, 0.26 to 0.35% of C, 0.15 to 0.39% of Si, 0.85 to 1.50% of Mn, less than or equal to 0.02% of P, less than or equal to 0.01% of S, 0.80 to 2.00% of Cr, 0.70 to 2.00% of Ni, 0.35 to 1.00% of Mo, and the balance Fe and other elements. Through reasonable proportioning of alloy elements such as Mn, Ni, Cr and Mo, and main chemical components such as C and Si in forged steel materials, through appropriate heat treatment processes, grains are refined; hardenability and heat intensity properties of the alloy forged steel are improved; normal temperature strength and high temperature strength of the alloy forged steel are greatly improved; and excellent comprehensive mechanical properties of the alloy forged steel are obtained.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

Alloy forged steel and production method and application thereof

ActiveCN103352170AImprove the mechanical properties at room temperatureReduce manufacturing costFriction liningSmeltingFerric

The invention relates to alloy forged steel and a production method thereof. The production method comprises the following steps: alloy smelting, wherein the alloy comprises the following components by weight percent: 0.24 percent to 0.31 percent of carbon, 0.20 percent to 0.50 percent of silicon, 0.50 percent to 0.90 percent of manganese, 1.10 percent to 1.50 percent of chromium, 0.50 percent to 0.89 percent of molybdenum, 0.20 percent to 0.40 percent of vanadium, less than or equal to 0.015 percent of phosphorus, less than or equal to 0.012 percent of sulfur, the balance of iron and unavoidable impurities; pouring a steel ingot; diffusion annealing, warming the steel ingot, heat preservation, furnace cooling, and then drawing a charge and wind cooling; forging blank; annealing after forging, warming the blank, heat preservation, furnace cooling, and then drawing a charge and wind cooling; heat treatment, quenching and then tempering. The production method of the alloy forged steel is relatively simple, can produce the alloy forged steel with fine comprehensive mechanical property and higher coefficient of thermal conductivity in the ordinary temperature state and the high temperature state.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Method for recycling, classifying and utilization of construction solid waste

InactiveCN109403172ASimple componentsImprove processing efficiencySievingRoadwaysSolid waste collectionCrusher

The invention provides a method for recycling, classifying and utilization of construction solid waste. The method includes the following steps that 1, a construction solid waste collection device collects construction solid waste, and then the construction solid waste is classified, screened, recycled and crushed; 2, a metal and non-metal screening device screens metal garbage and non-metal garbage, screening of wood garbage and solid concrete is manually performed, a wood crusher is used for crushing wood garbage to serve as other building auxiliary materials, and the selected solid concreteis then crushed by a crusher to obtain paving subgrade materials; 3, the paving subgrade materials are classified and screened through screening devices used for different sizes of solid concrete, and A-particle-size solid concrete and B-particle-size solid concrete are screened out for standby application; 4, the paving subgrade materials are prepared; 5, paving, repeated compaction and acceptance are performed in sequence. The components of the obtained paving subgrade materials are simple, the construction solid waste is used for recycling, crushing and reuse, the processing efficiency ishigh, the processing cost is low, the comprehensive utilization rate is high and the method is worth popularizing.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

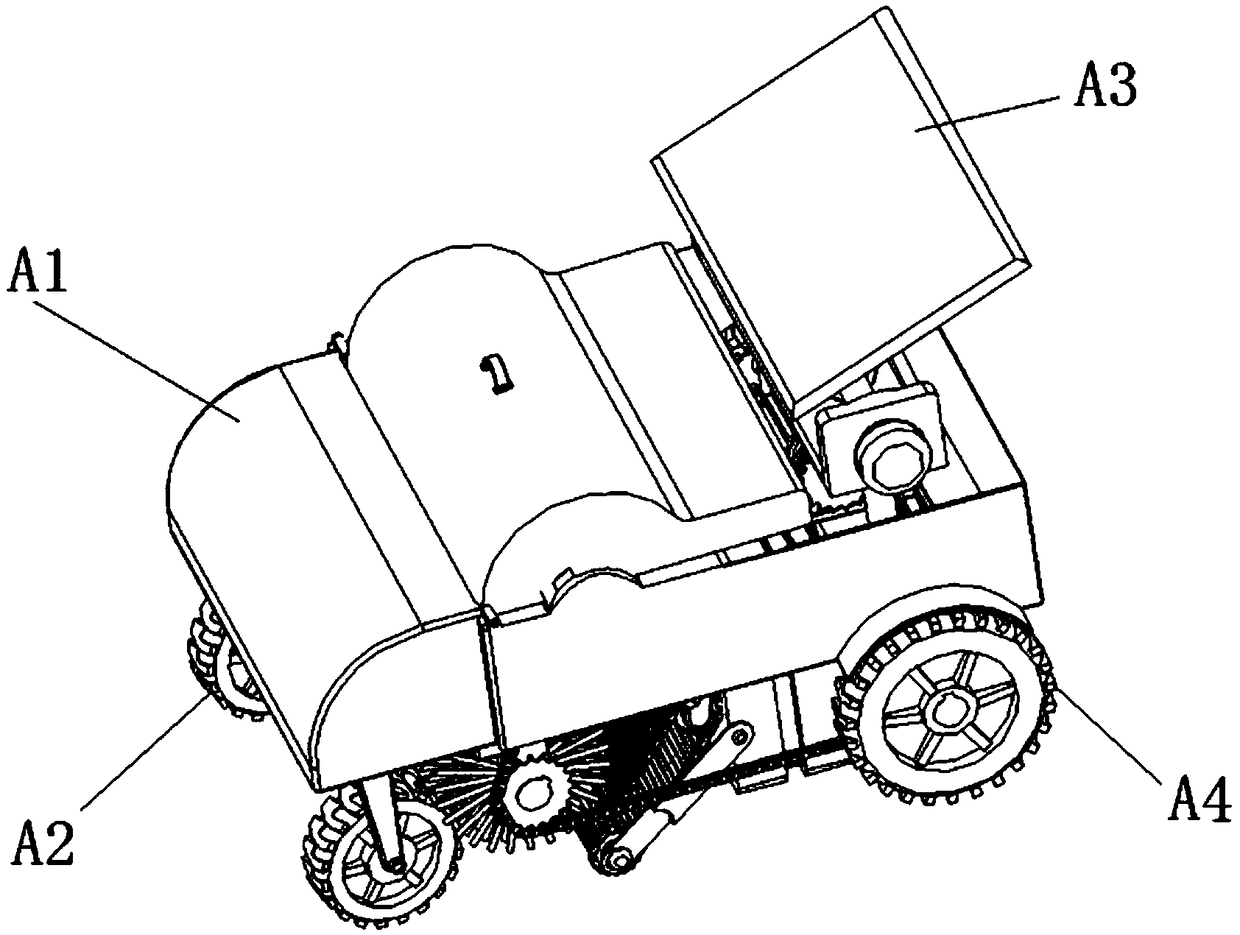

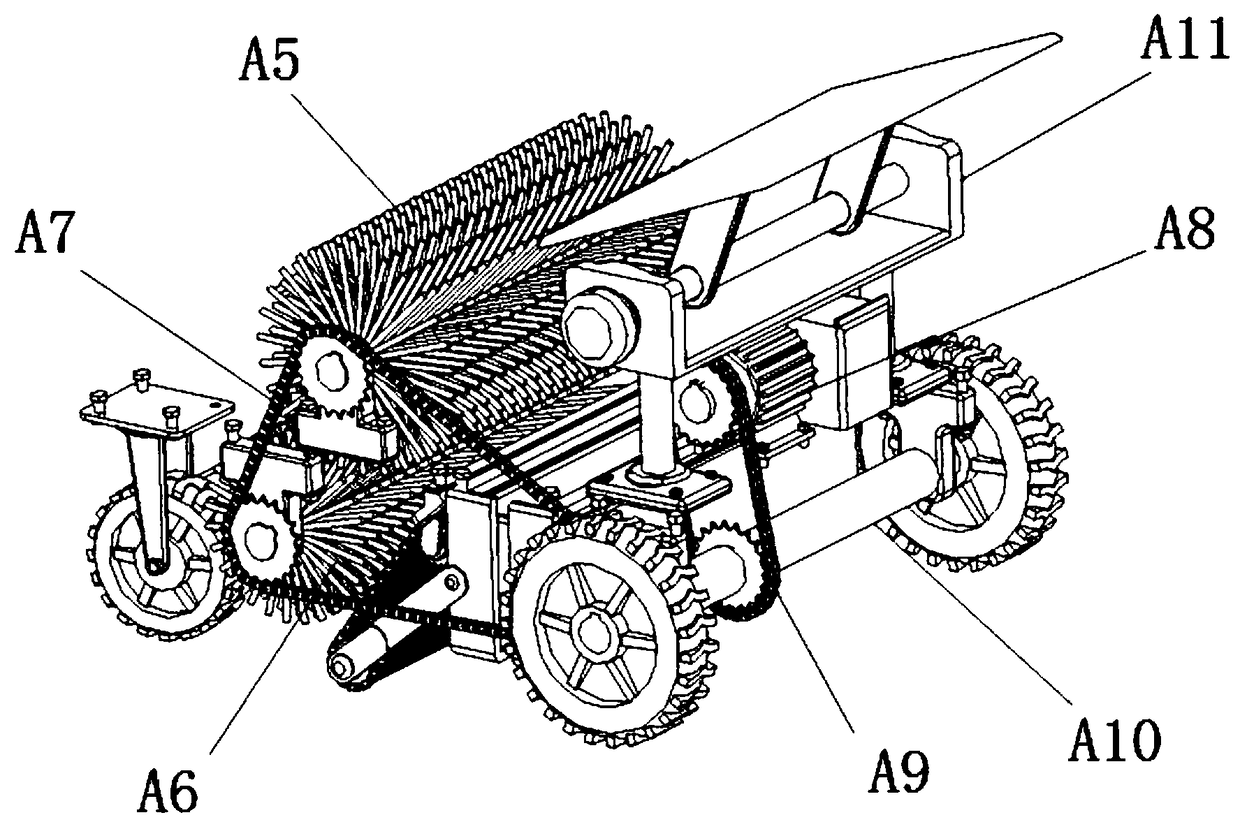

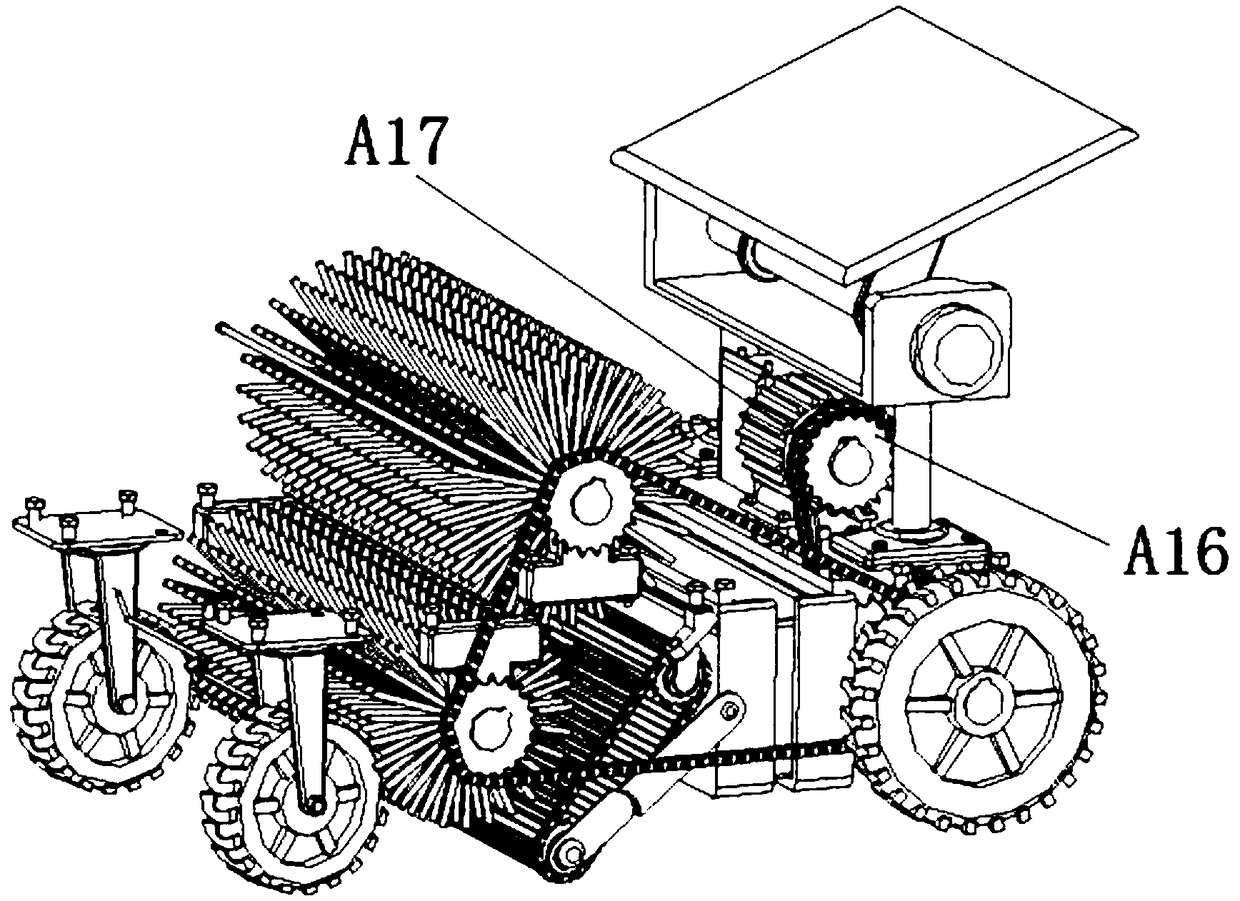

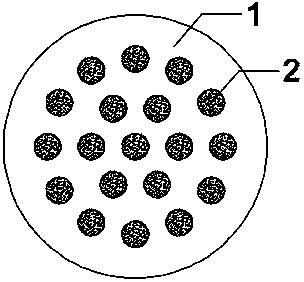

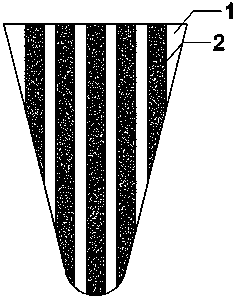

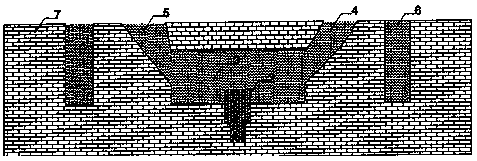

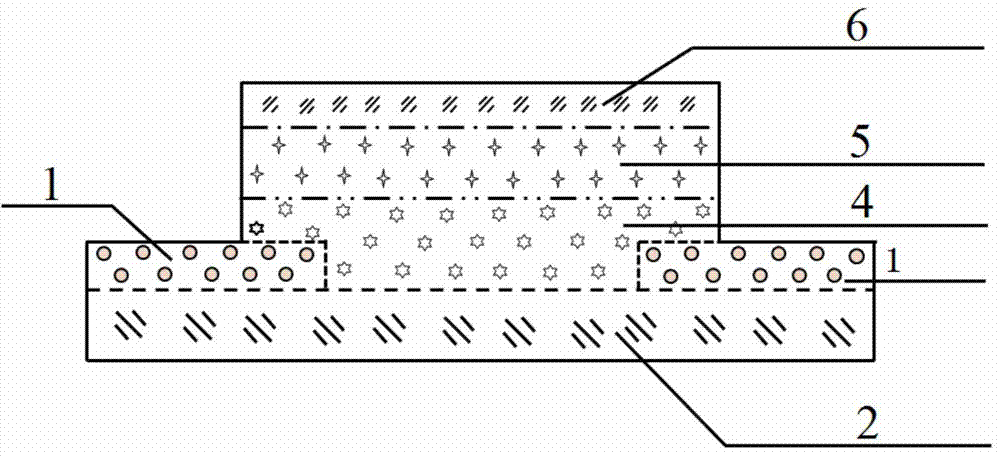

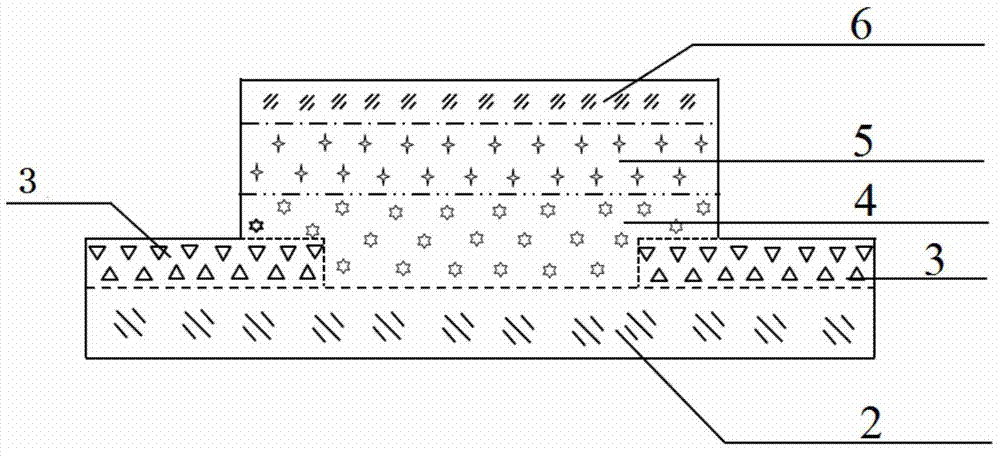

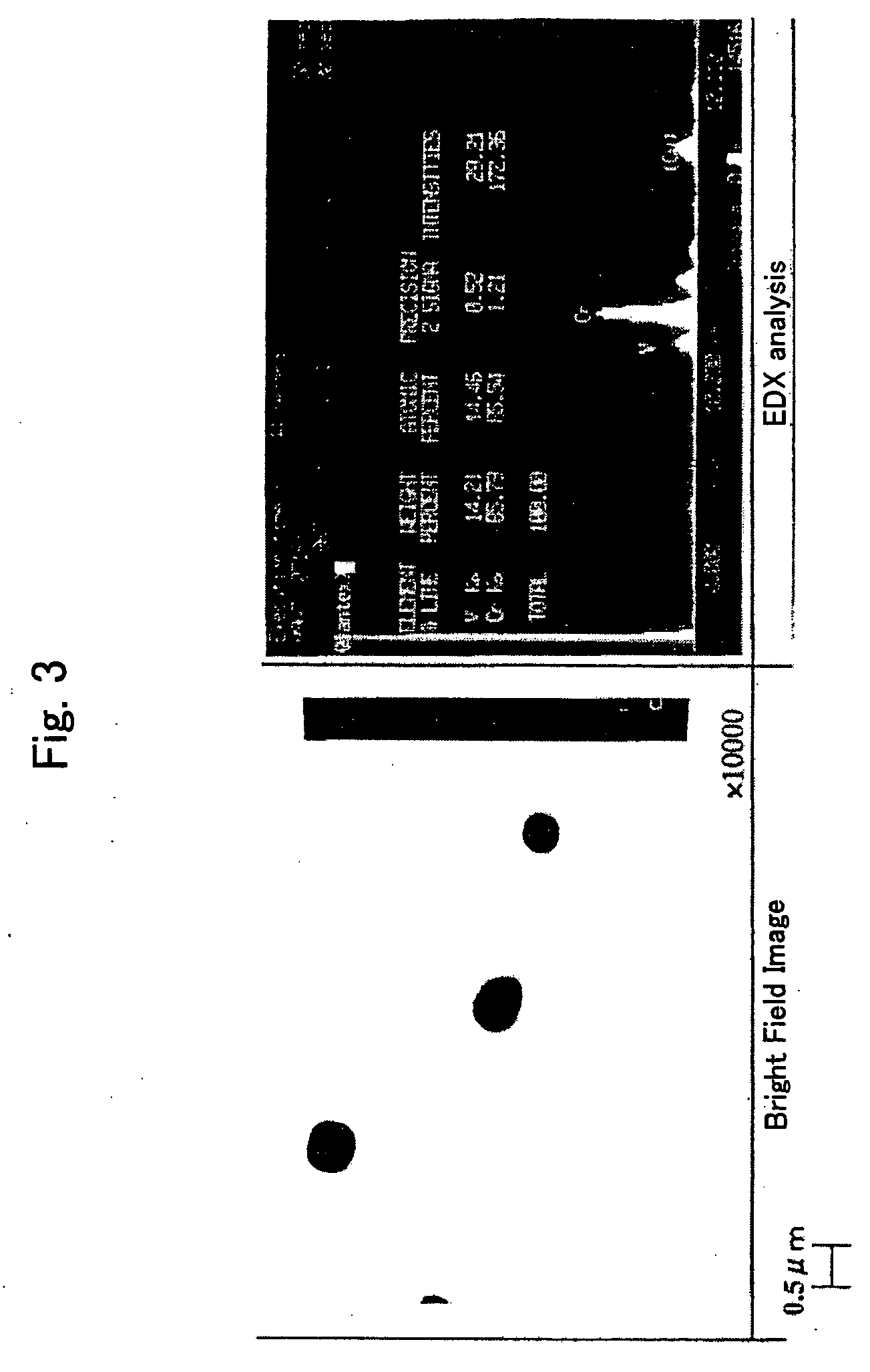

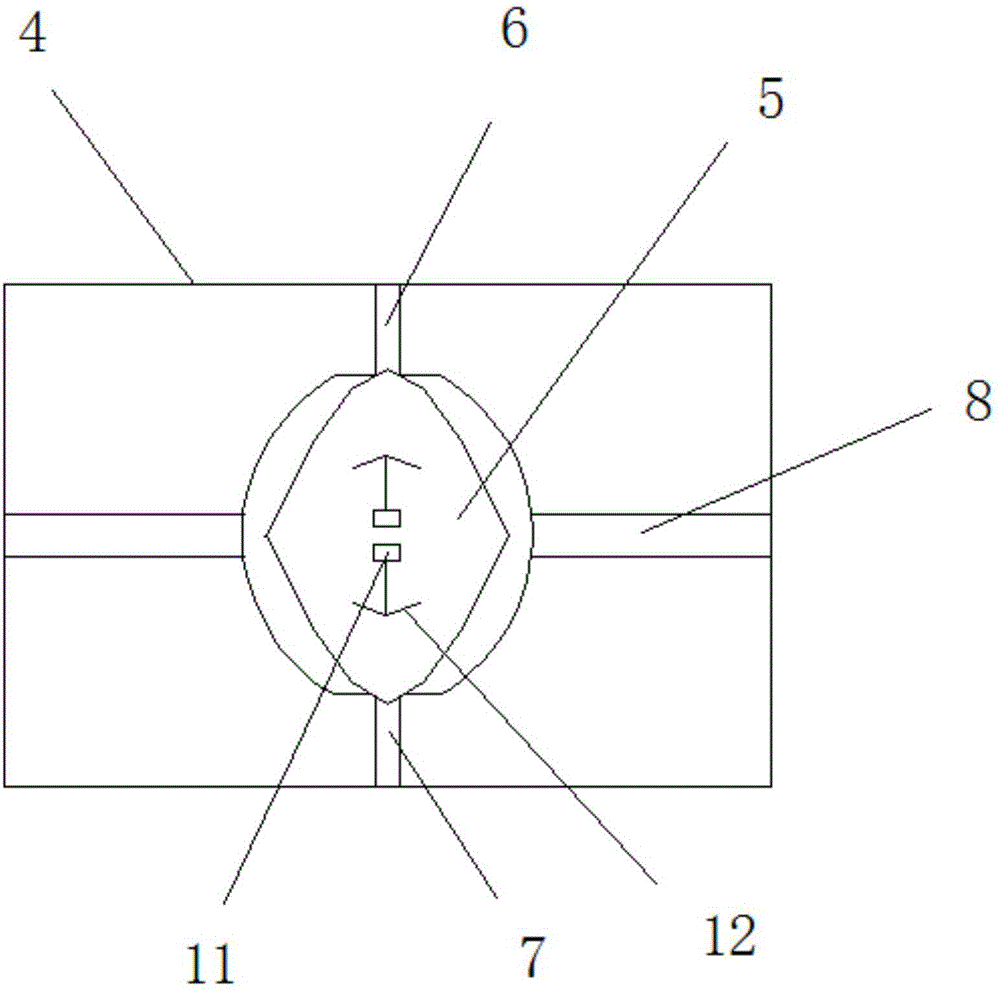

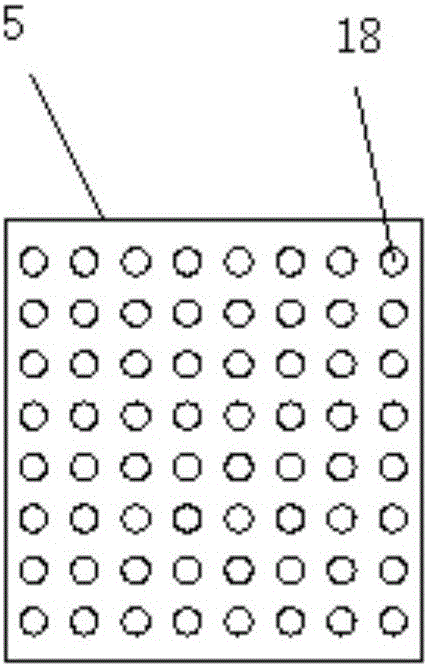

Ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head and manufacturing method thereof

ActiveCN108380850AFacilitate compounding processEfficient feedingBallastwayTransportation and packagingManufacturing technologyWear resistant

The invention discloses a ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head and a manufacturing method of the ceramic particle multi-scale reinforced metalbase composite wear-resistant raking tooth head, and belongs to the field of part manufacturing. According to the manufacturing method, ceramic particles and alloy powder are compacted and sintered tomanufacture rod-shaped composite materials, the rod-shaped composite materials are embedded into a metal base through the combination of the powder metallurgy technology and the embedment casting technology, and the purpose that the metal base covers the uniformly-distributed rod-shaped composite materials is achieved. The ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head solves the problems that an ordinary raking tooth is prone to being worn, and a homogeneous composite wear-resistant part is poor in toughness, brittle and low in impact resistance. Compared with overall metallurgical sintering, the manufacturing method has the advantages that by means of the technology of combination of powder metallurgy and embedment casting, the dimensionalaccuracy of parts is guaranteed, the requirements of specific parts for using performance are met, the assembling working procedure is omitted, the manufacturing technology is simplified to a certainextent, the part manufacturing cost is greatly reduced, the organization is compact, the metallurgical bonding is good, and the ceramic particle multi-scale reinforced metal base composite wear-resistant raking tooth head can be applied to cleaning and screening vehicles for railway maintenance and parts of raking teeth of scraper loaders.

Owner:KUNMING UNIV OF SCI & TECH

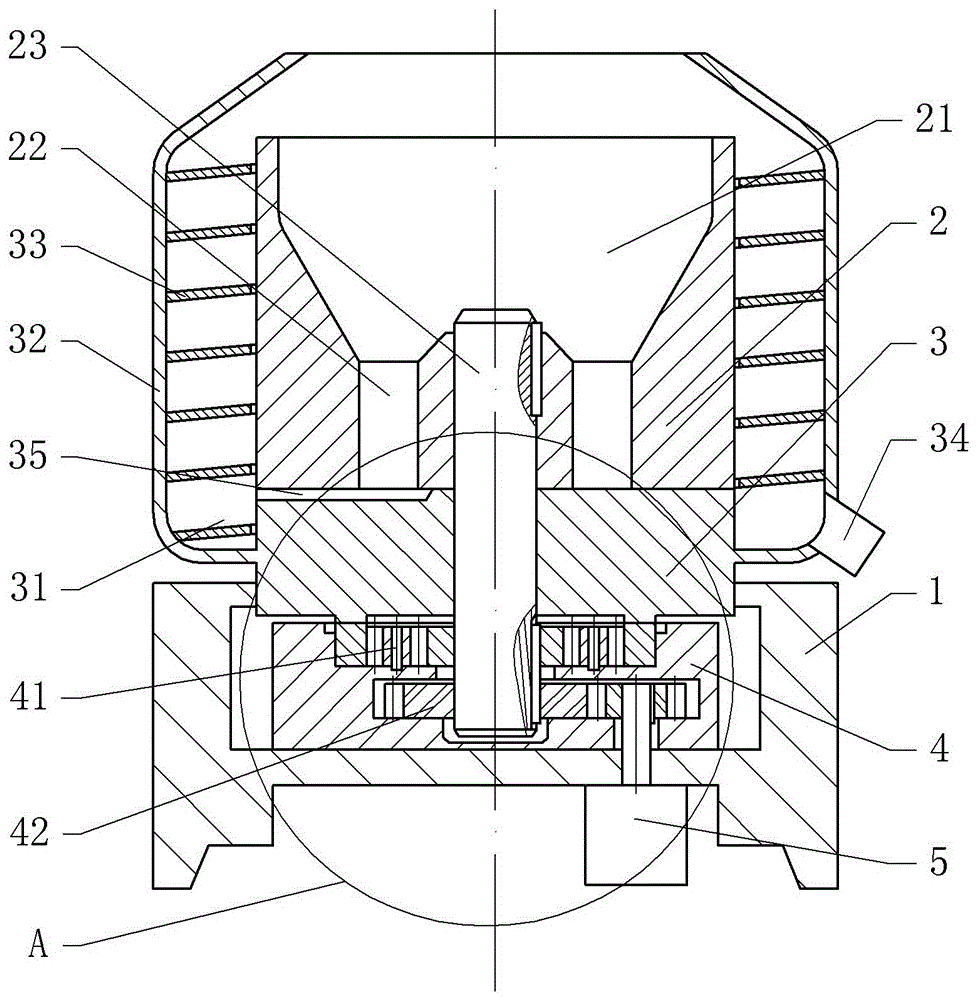

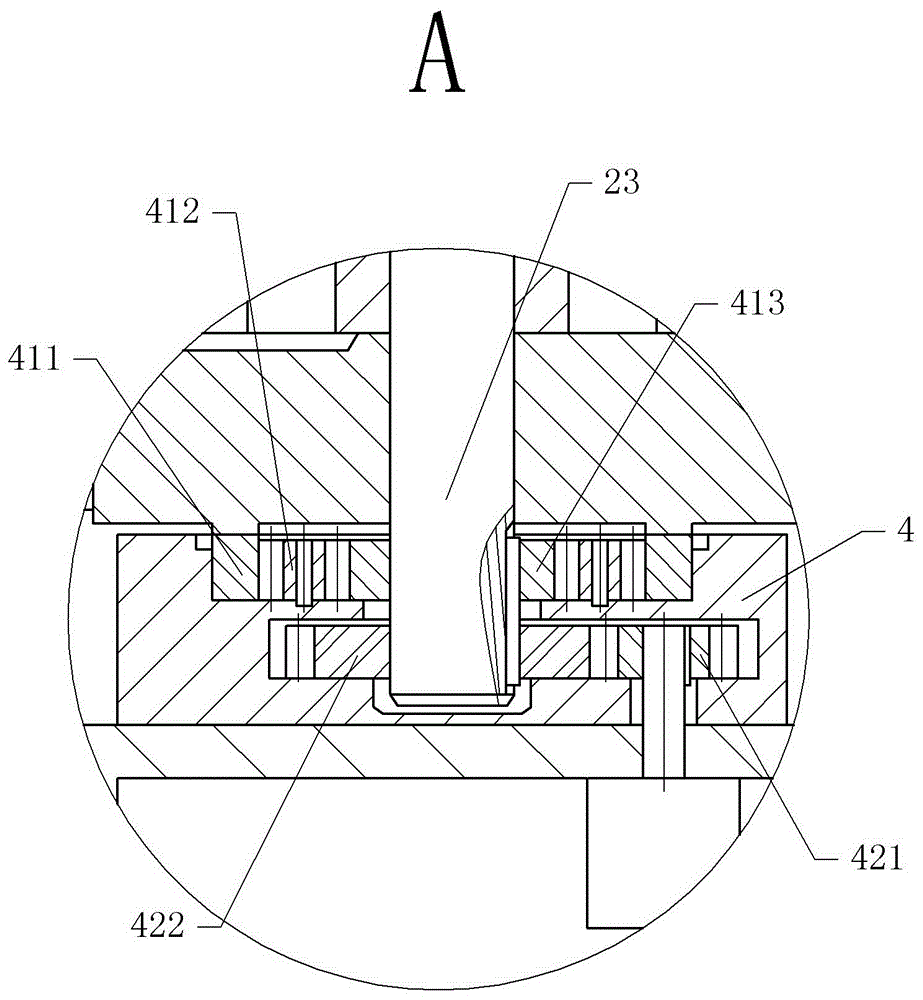

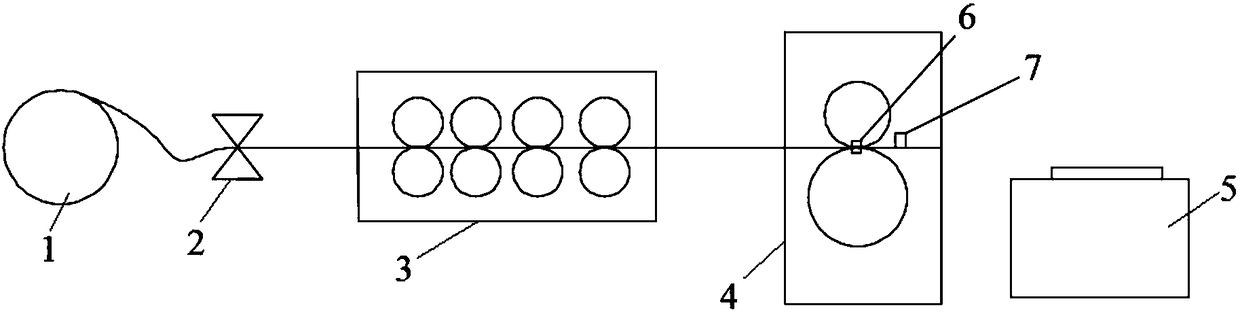

Plastic recycling crusher

InactiveCN105965727AAchieve the opposite effectSimple structurePlastic recyclingCocoaDrive motorEngineering

The invention discloses a plastic recycling crusher, and relates to the technical field of plastic machines. The plastic recycling crusher comprises a rack, a feeding hopper arranged at the upper portion of the rack, a lower crushing wheel arranged on the rack, and an upper crushing wheel arranged above the lower crushing wheel. The center of the upper crushing wheel is fixedly connected with a rotating shaft, and the rotating shaft is rotationally connected with the lower crushing wheel and the rack. The lower crushing wheel is fixedly or rotationally connected with the rack. The lower surface of the upper crushing wheel and the upper surface of the lower crushing wheel are grinding faces matched with each other. The feeding hopper is located above the upper crushing wheel. The upper crushing wheel is internally further provided with a plurality of feeding ports communicating with the feeding hopper and the grinding faces. Material collecting grooves are formed in the periphery of the lower crushing wheel. The rack is further provided with a drive motor and a gear case. The drive motor is connected with the rotating shaft through the gear case. According to the plastic recycling crusher, the characteristic of tenacity of plastic particles is avoided, the plastic particles are crushed through friction force, and the crushing effect and efficiency are improved.

Owner:重庆敏驰塑胶有限公司

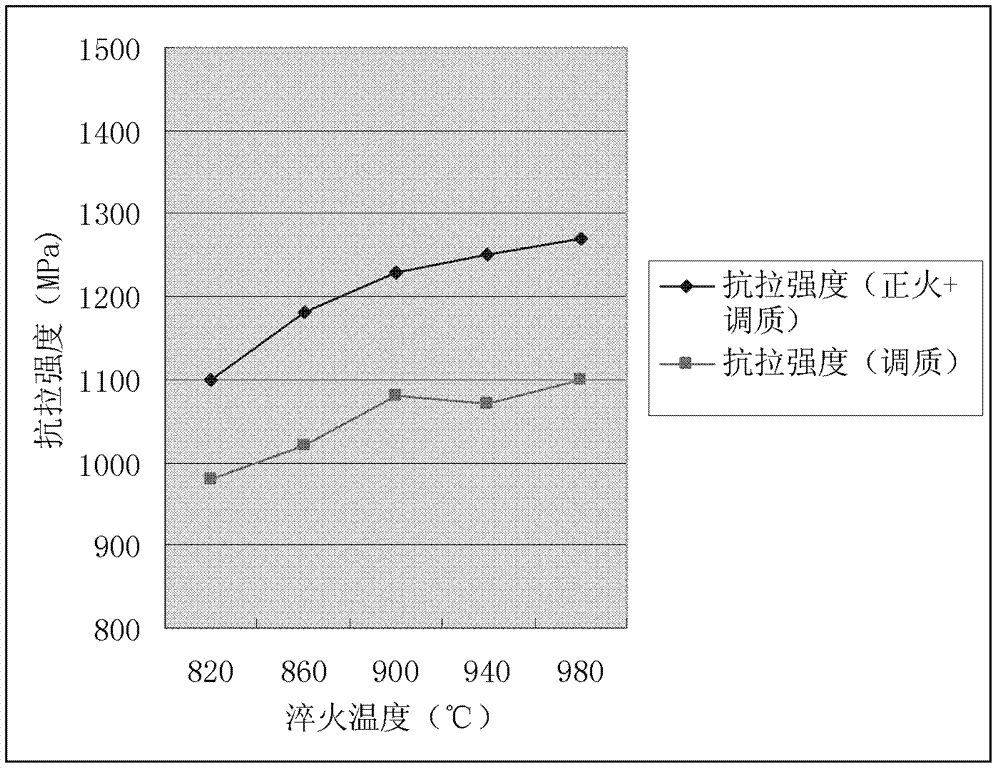

Alloy cast steel used for high-speed train brake disc and high-speed train brake disc manufactured through alloy cast steel

The invention discloses alloy cast steel used for a high-speed train brake disc and the high-speed train brake disc manufactured through the alloy cast steel. The alloy cast steel in the claim 1 comprises, by weight percent, 0.18%-0.26% of carbon, 0.30%-0.50% of silicon, 0.68%-1.40% of manganese, smaller than or equal to 0.025% of phosphorus, smaller than or equal to 0.013% of sulfur, 1.10%-1.82% of chromium, 0.90%-1.50% of nickel, 0.65%-1.02% of molybdenum, 0.22%-0.34% of vanadium, smaller than or equal to 0.30% of the sum of the content of other components and the balance iron, wherein tungsten is smaller than 0.1%. The alloy cast steel has the main beneficial effects that grains are refined through reasonable matching and heat treatment of alloy elements such as manganese, nickel, chromium, molybdenum and vanadium and main components such as carbon and silicon in a cast steel material, hardenability and the thermal strength performance of the alloy cast steel material are improved, the constant-temperature strength and the high-temperature strength are greatly improved, and the good comprehensive mechanical property is achieved. The brake disc manufactured through the alloy cast steel can completely meet the technical requirement for use of high-speed trains under the working condition.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

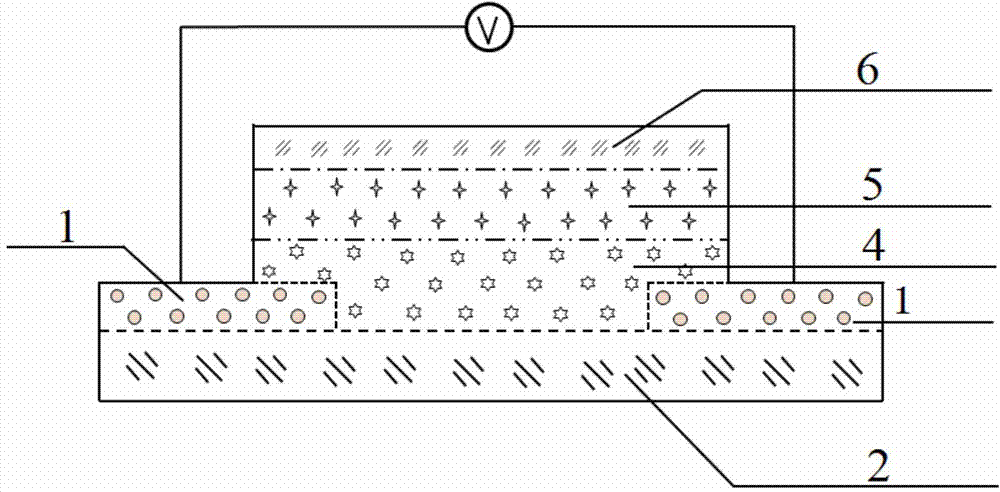

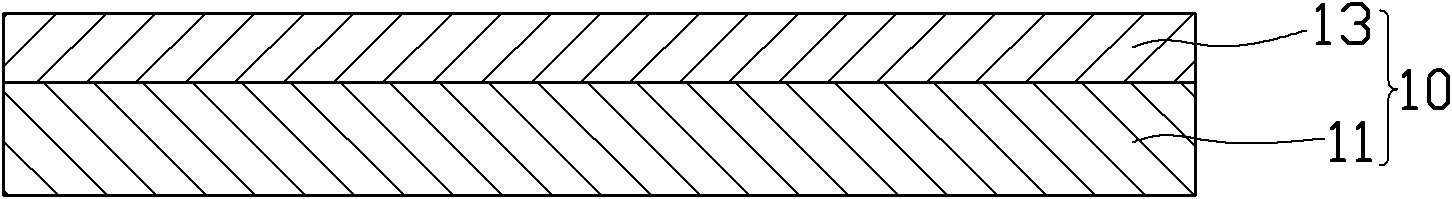

High-temperature nano-electrothermal film of double-film structure and preparation method thereof

InactiveCN103796346AImprove effective utilizationIncrease contact areaLayered productsVacuum evaporation coatingComposite filmSurface oxidation

A high-temperature nano-electrothermal film of a double-film structure is composed of a quartz substrate, an alloy film electrode and a silicon carbide and molybdenum disilicide composite film layer. By means of a method of magnetron sputtering, first the alloy film electrode is arranged on the quartz substrate in a mask sputtering mode, then a silicon carbide film layer and a molybdenum disilicide film layer sequentially deposit; finally, high temperature annealing is conducted, and the surface of the molybdenum disilicide film layer is oxidized into a thin silicon dioxide protective layer. The alloy film electrode is a platinum alloy film electrode or a cobalt-base alloy film electrode. Two types of high temperature nanometer materials including silicon carbide and molybdenum disilicide with the purity of 99.950% are adopted in the electrothermal film, the surface of the film layer is oxidized to a silicon dioxide polycrystalline structure, oxygen is isolated, the service life of the electrothermal film is effectively prolonged, and the safety factor is effectively improved. The advantages of the two materials are utilized by the high-temperature nano-electrothermal film, work temperature is as high as 1000 DEG C, meanwhile heat efficiency is 98% or so, and the high-temperature nano-electrothermal film can be widely applied to the technical field of high temperature heating and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

High-chromium wear-resistant steel ball and preparation method thereof

InactiveCN106191703AIncrease temperatureToughness to avoidFurnace typesHeat treatment furnacesWear resistantSteel ball

The invention discloses a high-chromium wear-resistant steel ball. The high-chromium wear-resistant steel ball comprises, by weight percentage, 1-1.5% of C, 0.5-0.7% of Si, 1.2-1.4% of Mn, 12-14% of Cr, 0.03-0.05% of Ni, 0.1-0.12% of Mo, 0.1-0.3% of W, 0.08-0.1% of Al, 0.1-0.2% of Cu, 0.003-0.004% of B, 0.02-0.03% of Ti, 0.2-0.3% of Nb, 0.15-0.2% of V, not larger than 0.2% of P, not larger than 0.01% of S and the balance Fe, wherein the expression of Nb+10.3(C / Cr)<1.55% is met. The invention further discloses a preparation method of the high-chromium wear-resistant steel ball. The high-chromium wear-resistant steel ball and the preparation method have the beneficial effects that wear resistance is good and toughness is high.

Owner:ANHUI RUITAI NEW MATERIALS TECH

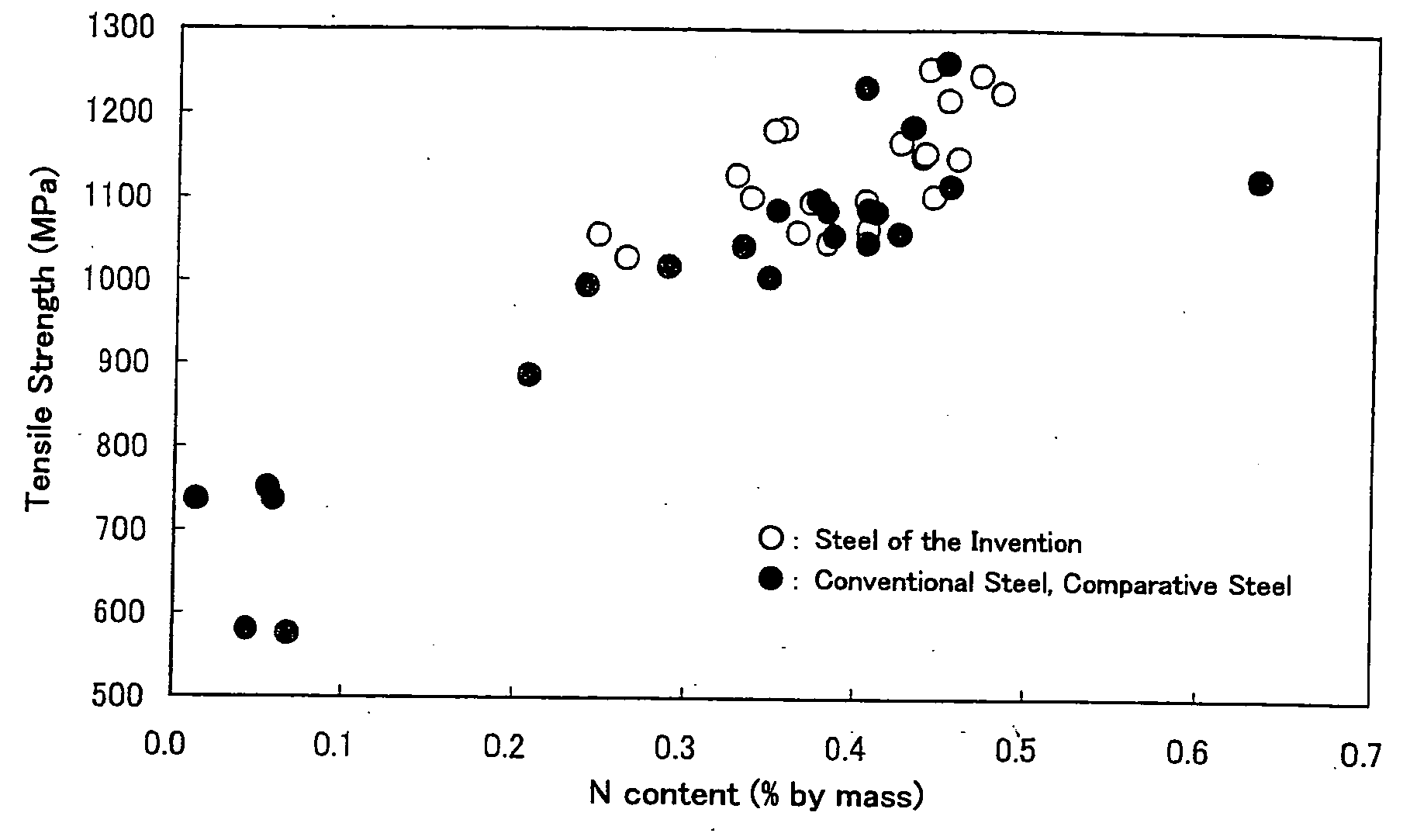

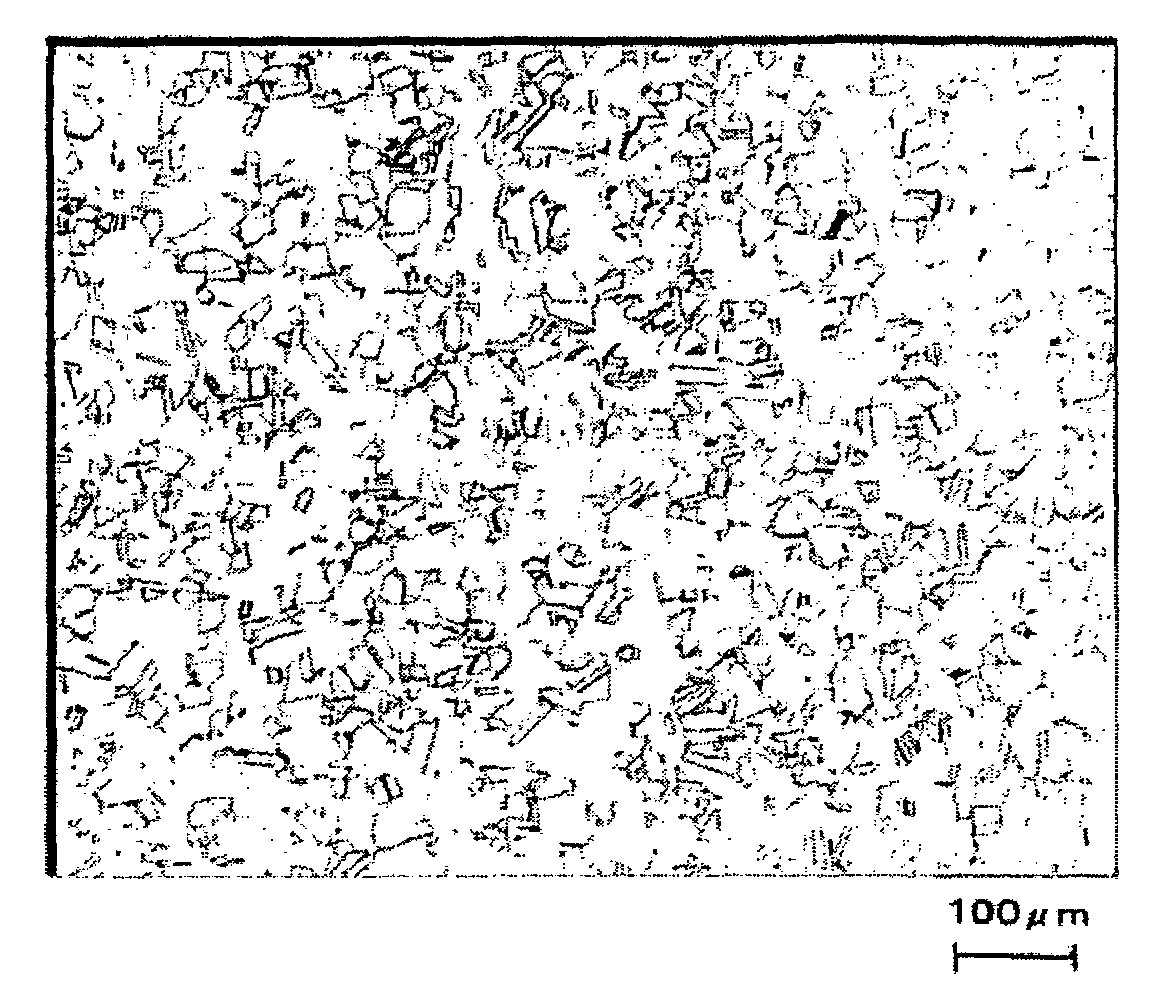

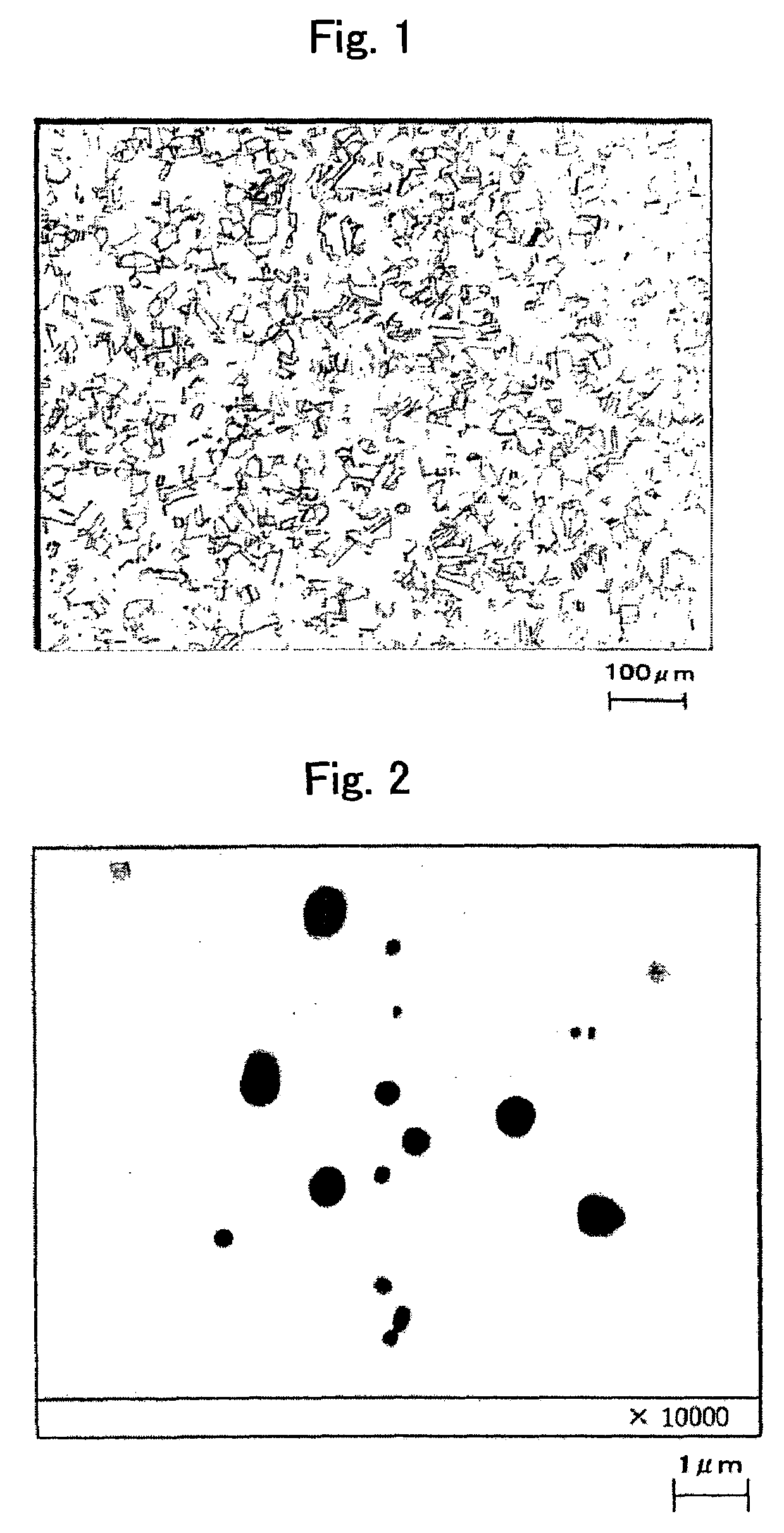

Stainless steel for high-pressure hydrogen gas, and container and device made of same

InactiveUS20050178478A1Superior mechanical property and corrosion resistanceImproves stress corrosion crackingWelding/cutting media/materialsRigid pipesHigh pressure hydrogenHigh intensity

A high-strength stainless steel, having good mechanical properties and corrosion resistance in a high-pressure hydrogen gas environment, and excellent in stress corrosion cracking resistance, and a container or other device for high-pressure hydrogen gas, which is made of the said stainless steel, are provided. The stainless steel is characterized in that it consists of, by mass %, C: not more than 0.02%, Si: not more than 1.0%, Mn: 3 to 30%, Cr: more than 22% but not more than 30%, Ni: 17 to 30%, V: 0.001 to 1.0%, N: 0.10 to 0.50% and Al: not more than 0.10%, and the balance Fe and impurities. Among the impurities, P is not more than 0.030%, S is not more than 0.005%, and Ti, Zr and Hf are not more than 0.01% respectively, and the contents of Cr, Mn and N satisfy the following relationship [1]: 5Cr+3.4Mn≦500N [1]

Owner:NIPPON STEEL CORP

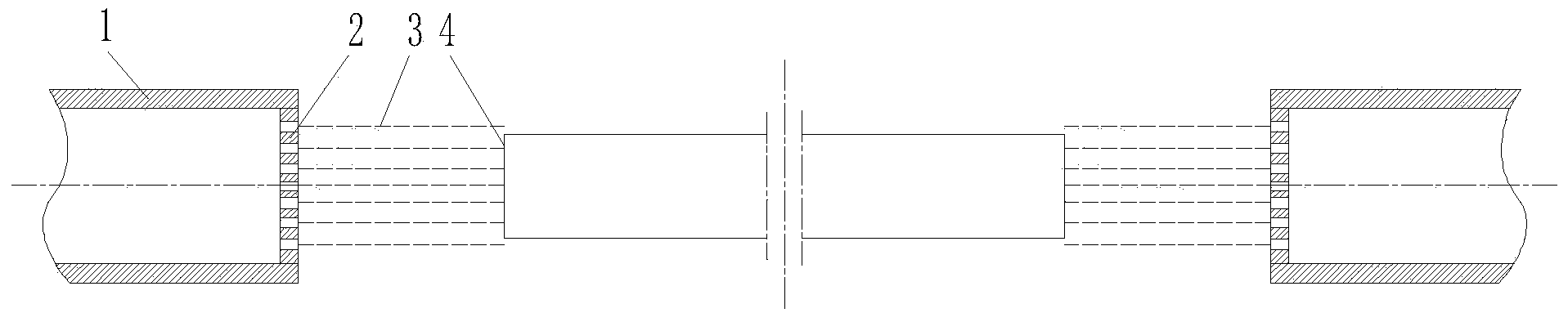

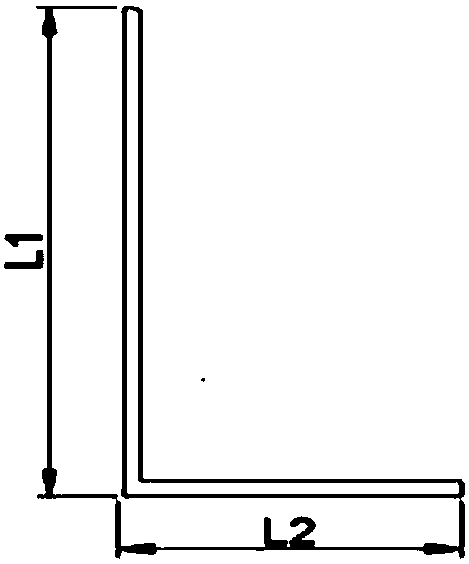

Method for preventing cracking of water quenching end faces of shaft alloy steel parts

ActiveCN103484605AAvoid crackingAchieve strengthFurnace typesHeat treatment process controlQuenchingSupersaturation

The invention provides a method for preventing cracking of water quenching end faces of shaft alloy steel parts. The method comprises the following steps: (1) increasing the cooling speed of an end face except the excircle region of the end face, decreasing the temperature difference between the surface beyond the excircle region of the end face and the excircle region of the end face, and reducing the tensile stress at the junction between surface beyond the excircle region of the end face and the excircle region of the end face; (2) decreasing the cooling speed at the excircle region of the end face, decreasing the temperature difference between the excircle region of the end face and the surface beyond the excircle region of the end face, and reducing the tensile stress at the junction between the excircle region of the end face and the surface beyond the excircle region of the end face; and (3) in a water-air alternative quenching cooling process, prolonging the air cooling time of several times of primary water quenching procedures to increase the self-tempering degree of the excircle region of the end face, reduce the degree of supersaturation of carbon in martensite in the excircle region of the end face already occurring martensitic transformation and improve the anti-cracking ability of the junction between the excircle region of the end face and the surface beyond the excircle region of the end face.

Owner:SHANGHAI JIAO TONG UNIV

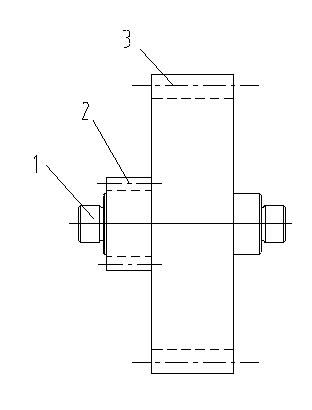

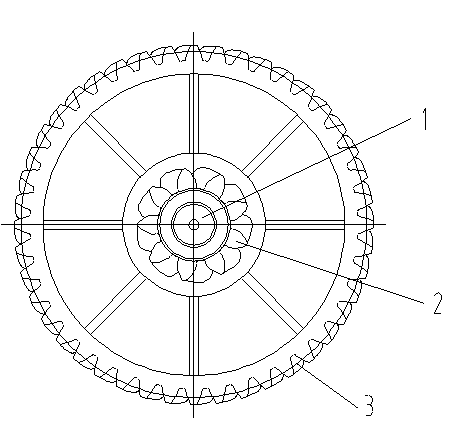

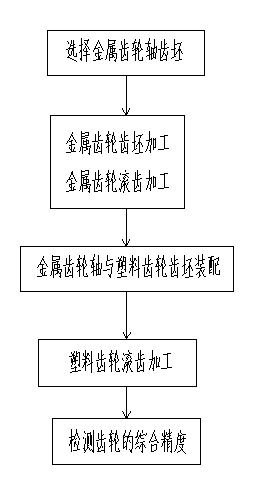

Dual gear and machining process for same

InactiveCN102705476AImprove the lubrication effectImprove wear resistancePortable liftingGear teethGlass fiberLow noise

The invention discloses a dual gear and a machining process for the same. The dual gear comprises a metal gear which is integrally formed on a metal gear shaft. A plastic gear and the metal gear are coaxially assembled on the metal gear shaft. The plastic gear comprises polyamide 66 and 33 percent fiberglass. The machining process comprises the following steps of: machining a metal gear shaft blank, and machining the metal gear on the gear forming section of the metal gear shaft by using a generating method; coaxially assembling a plastic gear blank on the metal gear shaft by using an injection molding process; and machining the plastic gear on the plastic gear blank by using the generating method. In such a way, the 33 percent fiberglass is added into the conventional plastic gear, so that the performance of the plastic gear is greatly improved; and the machining process is optimized, and the gears are machined by the generating method, so that the gear has a high lubricating property, high abrasion resistance, low noise and higher tooth profile, tooth alignment and radial run-out accuracy.

Owner:常州奥立思特电子有限公司

Stainless steel for high-pressure hydrogen gas

InactiveUS7531129B2Superior mechanical property and corrosion resistanceImproves stress corrosion crackingWelding/cutting media/materialsRigid pipesHigh pressure hydrogenHigh intensity

A high-strength stainless steel, having good mechanical properties and corrosion resistance in a high-pressure hydrogen gas environment, and excellent in stress corrosion cracking resistance, and a container or other device for high-pressure hydrogen gas, which is made of the said stainless steel, are provided. The stainless steel is characterized in that it consists of, by mass %, C: not more than 0.02%, Si: not more than 1.0%, Mn: 3 to 30%, Cr: more than 22% but not more than 30%, Ni: 17 to 30%, V: 0.001 to 1.0%, N: 0.10 to 0.50% and Al: not more than 0.10%, and the balance Fe and impurities. Among the impurities, P is not more than 0.030%, S is not more than 0.005%, and Ti, Zr and Hf are not more than 0.01% respectively, and the contents of Cr, Mn and N satisfy the following relationship [1]:5Cr+3.4 Mn≦500 N [1].

Owner:NIPPON STEEL CORP

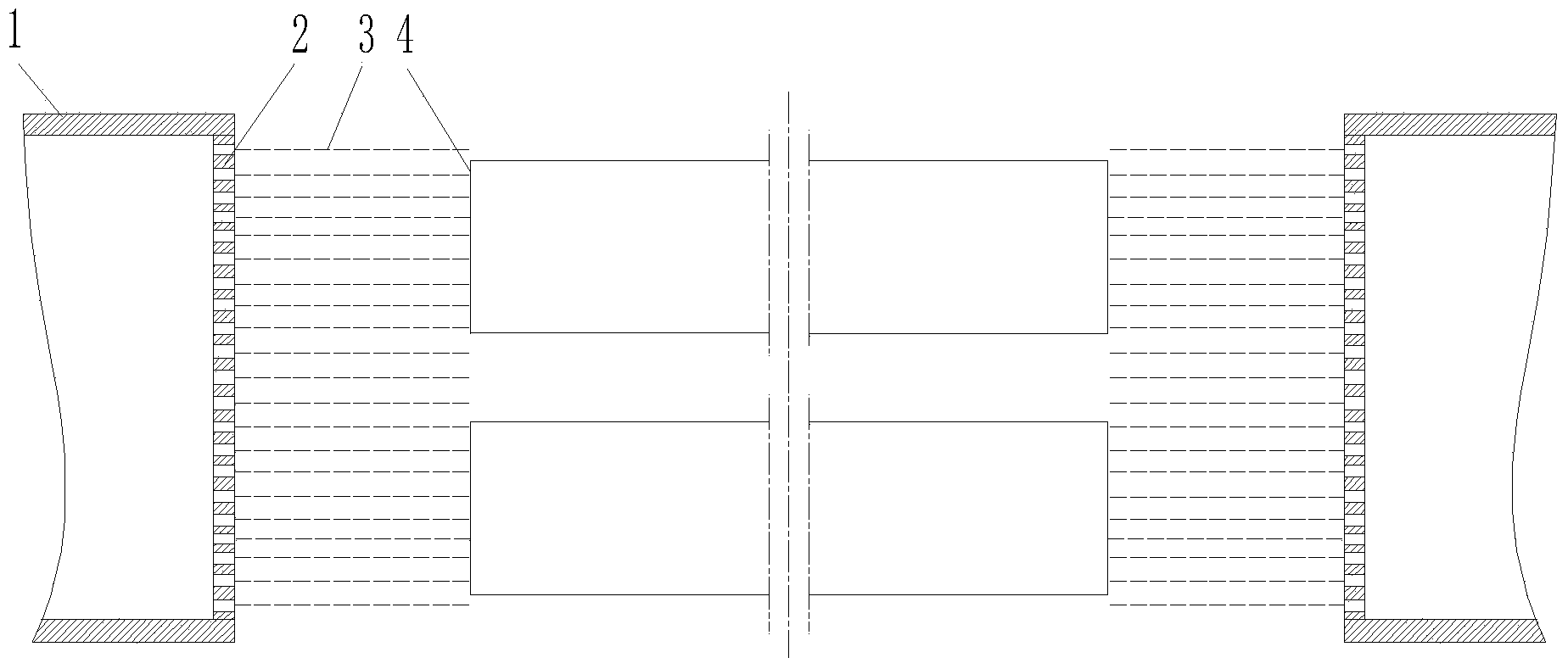

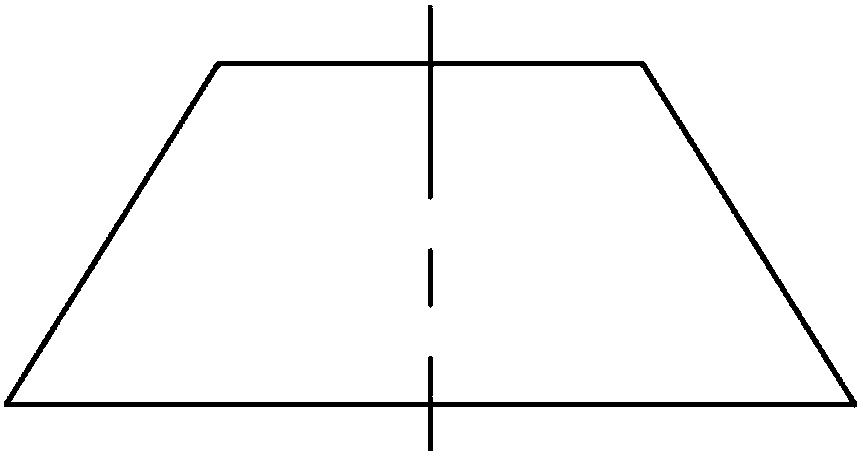

Method for preventing cracking of water-quenched edges and angles of rectangular alloy steel member

ActiveCN103498023AAvoid intensityToughness to avoidFurnace typesHeat treatment process controlMartensite transformationSupersaturation

The invention provides a method for preventing cracking of water-quenched edges and angles of a rectangular alloy steel member. The method comprises the following approaches: (1) increasing the cooling rate of surface areas not including edges and angles, decreasing difference between the temperature of the surface areas without the edges and angles and the temperature of the edges and angles and reducing pulling stress at the junctions of the surface areas and the edges and angles; (2) decreasing the cooling rate of the edges and angles, reducing difference between the temperature of the edges and angles and the temperature of the surface areas without the edges and angles and reducing pulling stress at the junctions of the edges and angles and the surface areas; and (3) in a water-air alternative quenching process, prolonging air cooling time in first few times of water quenching to increase the self tempering degree of the edges and angles, reduce the supersaturation degree of carbon in martensite in edge and angle areas having undergone martensite transformation and improve anti-cracking capability of the junctions of the edges and angles and the surface areas. With the method provided by the invention, the rectangular alloy steel member has desired strength and toughness on the premise that cracking of the rectangular alloy steel member in the processes of water quenching and water-air alternative quenching is avoided.

Owner:SHANGHAI JIAO TONG UNIV

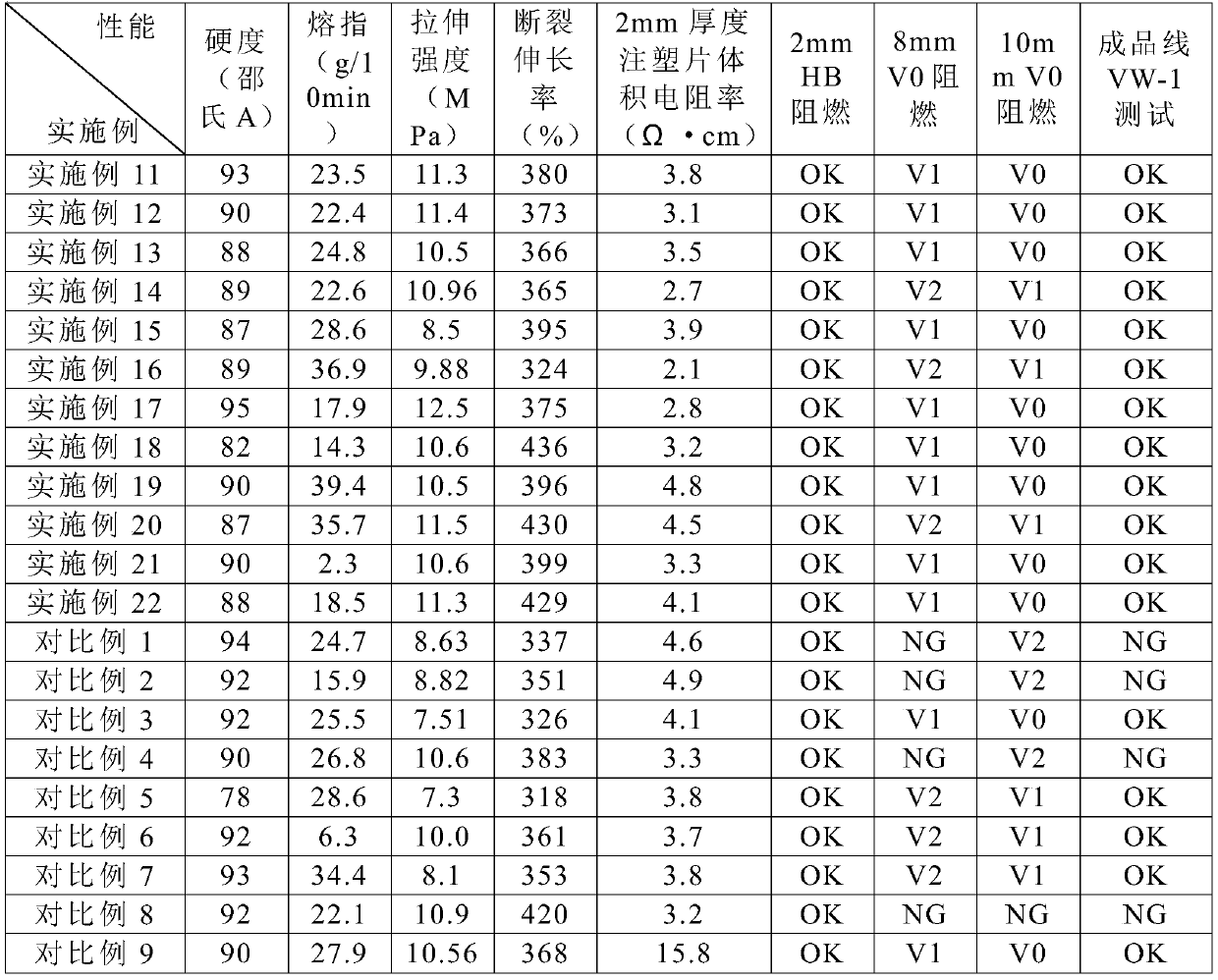

Halogen-free flame retardant conductive elastomer used for electromagnetic shielding of data cable and preparation method of halogen-free flame retardant conductive elastomer

The invention relates to a halogen-free flame retardant conductive elastomer used for electromagnetic shielding of a data cable and a preparation method of the halogen-free flame retardant conductiveelastomer, and belongs to the technical field of high polymer materials. The halogen-free flame retardant conductive elastomer comprises the following ingredients by weight percentage: 5%-20% of ethylene acrylate copolymers, 5%-30% of polyethylene, 10%-40% of SEBS (styrene-hydrogenated butadiene-styrene copolymers), 5%-20% of a melt viscosity regulator, 8%-20% of a halogen-free flame retardant, 10%-40% of a conductive additive and 0.1%-5% of a processing agent, wherein the sum of the weight percentages of the ingredients is 100%. The halogen-free flame retardant conductive elastomer is used for electromagnetic shielding of the data cable and has good conductivity, flame retardant property and mechanical property.

Owner:NINGBO QINGHU ELASTOMER SCI & TECH

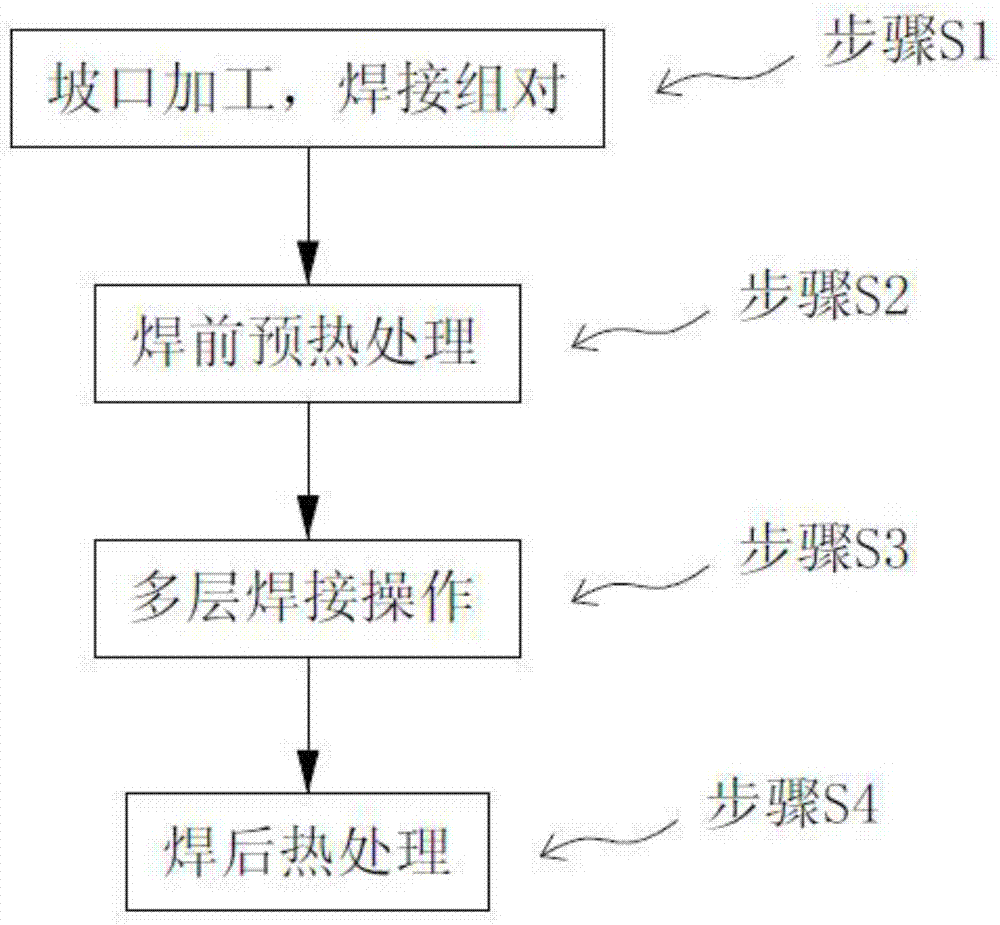

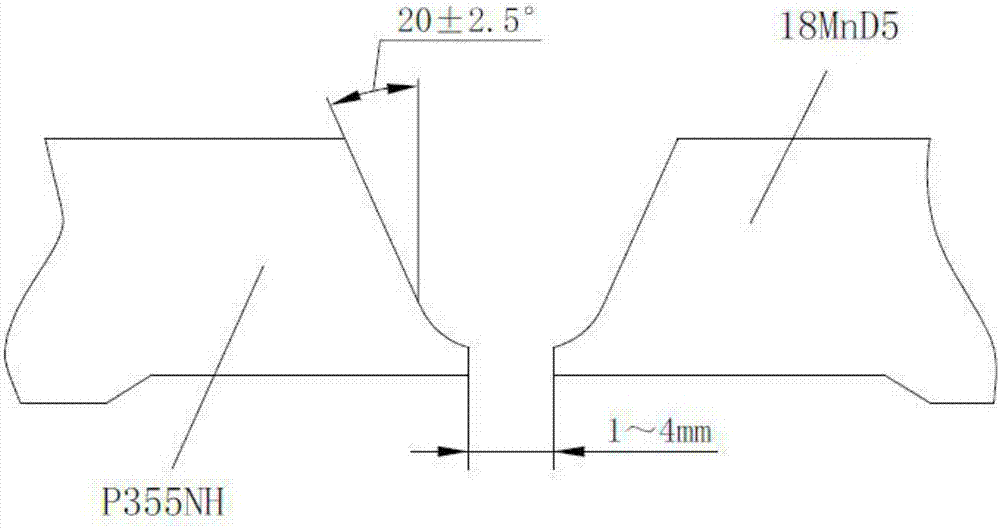

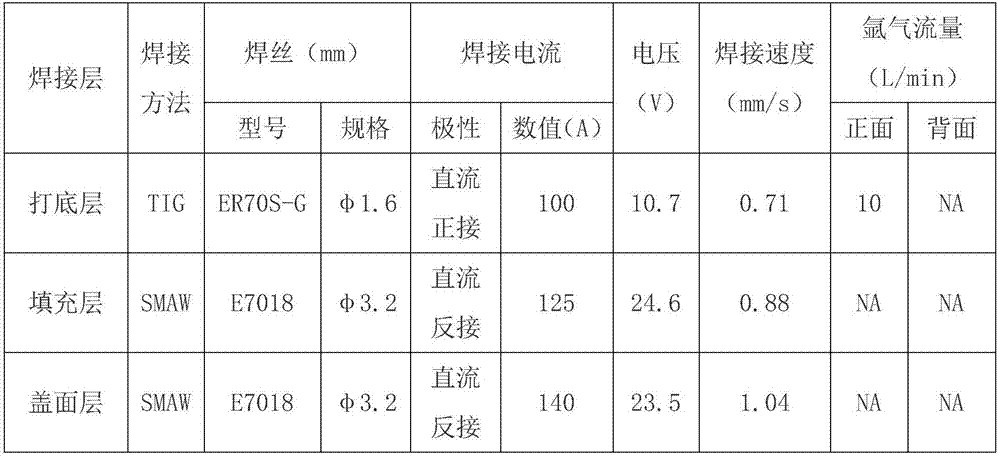

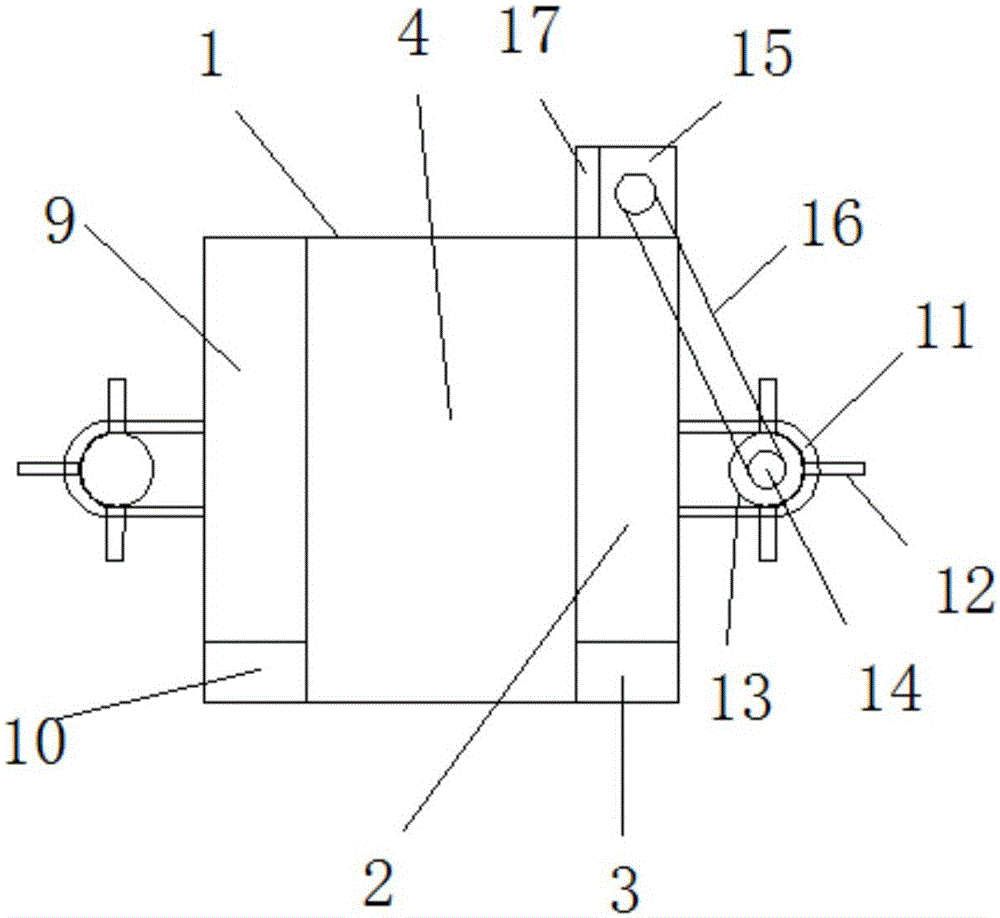

Welding method for P355NH and 18MnD5 dissimilar steel

InactiveCN107498143AControl cooling rateReduced tendency to crackArc welding apparatusBrittle fractureHeat treated

The invention belongs to the technical field of welding of dissimilar steel, particularly relates to a welding method for P355NH and 18MnD5 dissimilar steel, and discloses a welding method for P355NH and 18MnD5 dissimilar steel in order to solve the problem that welding cracks and brittle fracture are likely to be produced in a welding joint area of P355NH and 18MnD5 when the P355NH and the 18MnD5 are welded. The method comprises the steps that 1, edge preparation and welding assembling are carried out on P355NH and 18MnD5 dissimilar steel base metal to be welded; 2, preweld preheat treatment is carried out on the P355NH and 18MnD5 dissimilar steel base metal to be welded; 3, multi-layer welding operation is carried out on the P355NH and 18MnD5 dissimilar steel base metal, wherein the multi-layer welding operation sequentially comprises base coat welding, filling layer welding and cover face layer welding; and 4, a P355NH and 18MnD5 dissimilar steel welding joint obtained after welding is subjected to postweld heat treatment. In the welding method, the parameters in the welding operation process are selected and controlled, so that welding for P355NH and 18MnD5 dissimilar steel is completed, and the welding joint with the excellent welding performance is obtained.

Owner:CHINA NUCLEAR IND 23 CONSTR

Steam setter for shoemaking

The invention discloses a steam setter for shoemaking. A preheating bin is arranged on the right side of an inner cavity of a case. The left side of the preheating bin is connected with a steam setting bin. A channel is arranged in the steam setting bin. The top of the channel is connected with an air outlet pipe. The other end of the air outlet pipe is connected with the upper wall of the steam setting bin. The bottom of the channel is connected with a water outlet pipe. The other end of the water outlet pipe is connected with the lower wall of the steam setting bin. The left sidewall and the right sidewall of the channel are each connected with a steam pipeline which is externally connected with a steam device. Air outlets are reserved in the left sidewall and the right sidewall of the channel respectively. The left side of the steam setting bin is connected with a precooling bin. A conveying belt is arranged in the case. The conveying belt passes through the preheating bin, the channel and the precooling bin in sequence. Hooks are evenly mounted on the conveying belt. Fixed shafts are mounted at the two ends of the conveying belt respectively. One end of the fixed shaft at the right end of the conveying belt is connected with a belt pulley. A motor is mounted on the top of the case and connected with the belt pulley through a belt. The left side of the motor is connected with a controller.

Owner:江苏华驰机械有限公司

Silicon-manganese-iron alloy

The invention discloses a silicon-manganese-iron alloy. The silicon-manganese-iron alloy comprises the following components in percentages by weight: 22-35% of silicon, 18-65% of manganese, less than or equal to 2% of carbon, less than or equal to 0.6% of unavoidable impurities and the balance of iron. The silicon-manganese-iron alloy disclosed by the invention is lower in silicon content and higher in manganese content, so as to increase manganese content in molten steel during low-carbon steel smelting process to effectively reduce oxygen content in steel. The silicon-manganese-iron alloy is good in deoxidization effect and is capable of avoiding problems of reduced plasticity and ductility of steel caused by excessive silicon content.

Owner:铜陵百荣木业有限公司

Composite insulation board

InactiveCN105130276AIncrease fire and flame retardant propertiesToughness to avoidPolyesterThermal insulation

The invention discloses a composite insulation board. The composite insulation board comprises the following components: limestone, phenolic resin, polyester amine, nano zinc oxide, an organic material water repellent, a plaster foaming agent, aluminum sulfate, an aqueous solution, petroleum sulfur aluminum and a curing agent. The raw materials comprise the following components in parts by weight: 30-80 parts of limestone, 40-60 parts of phenolic resin, 10-15 parts of polyurethane, 3-6 parts of nano zinc oxide, 0.8-1.6 parts of organic material water repellent, 5-10 parts of plaster foaming agent, 12-15 parts of aluminum sulfate, 30-40 parts of aqueous solution, 7-15 parts of petroleum sulfur aluminum and 16-35 parts of curing agent. The composite insulation board disclosed by the invention has the characteristics of light weight, high hardness and durability, and has high thermal insulation performance of organic materials; and the composite insulation board is easy to install, and has the advantages of both organic and inorganic materials, so that functional advantages of the composite insulation board can be improved.

Owner:滁州市瑞景园林股份有限公司

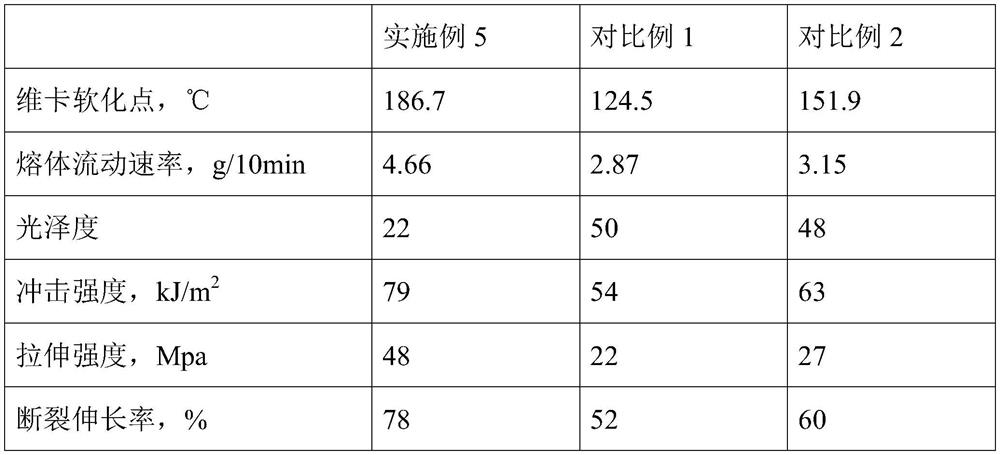

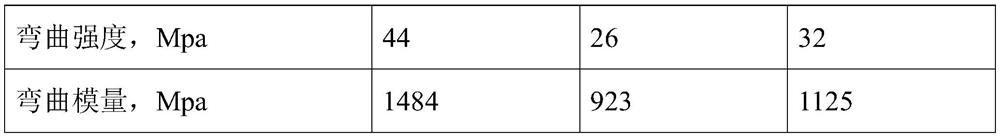

Composite plastic for power supply bracket and preparation method of composite plastic

The invention discloses a preparation method of composite plastic for a power supply bracket, which comprises the following steps: mixing expanded graphite and an ethanol water solution, carrying out35-45kHz ultrasonic dispersion for 20-30 minutes, conducting stirring at 80-90 DEG C under a reflux state for 1-2 hours, and conducting cooling to 40-50 DEG C to obtain pretreated expanded graphite; stirring the pretreated expanded graphite, slowly dropwise adding tetraethoxysilane in a stirring state, continuously conducting stirring after the tetraethoxysilane is completely dropwise added, conducting cooling to room temperature, performing suction filtration, conducting washing to be neutral, conducting dispersing in an ethanol aqueous solution, and performing spray drying to obtain a silicon dioxide-expanded graphite compound; and uniformly mixing polypropylene, a styrene thermoplastic elastomer, the silicon dioxide-expanded graphite compound, fumed silica, wollastonite powder, ceramicfibers, talcum powder, maleic anhydride grafted polypropylene, far infrared ceramic powder, lignocellulose, a coupling agent, a flexibilizer, a lubricant and an antioxidant, carrying out melt extrusion, cooling, and granulating with a granulator, and conducting drying to obtain the composite plastic for the power supply bracket.

Owner:安徽越洋达新能源科技有限公司

Manufacturing method for steel coil packaging protection corners

The invention discloses a manufacturing method for steel coil packaging protection corners. The manufacturing method comprises the steps that S1, sample preparation is carried out, wherein a coiled material is divided, and narrow steel belt coils are formed; S2, uncoiling is carried out, wherein the divided narrow steel belt coils are put on an uncoiling machine to be uncoiled, and steel belt strips are formed; S3, shearing is carried out, wherein the steel belt strips are sheared, blanks are formed, and the blanks are precoated steel plates; S4, bending is carried out, wherein the blanks arebent; and S5, rolling forming is carried out, wherein the bent blanks are subjected to rolling forming, and the protection corners are formed. According to the manufacturing method for the steel coilpackaging protection corners, the precoated steel plates are adopted to be manufactured into the protection corners, a spraying process in the later period in the cold-rolled sheet production processis avoided, the machining of the steel coil packaging protection corners is facilitated, pollution is reduced, the cost is saved, the physical and psychological health of workers is protected, the defects that the strength is not enough and the tenacity is not good when plastic is used for preparing the steel coil packaging protection corners are avoided, and the manufactured steel coil packagingprotection corners are high in strength and anti-rust capacity and good in attractiveness.

Owner:MAANSHAN IRON & STEEL CO LTD

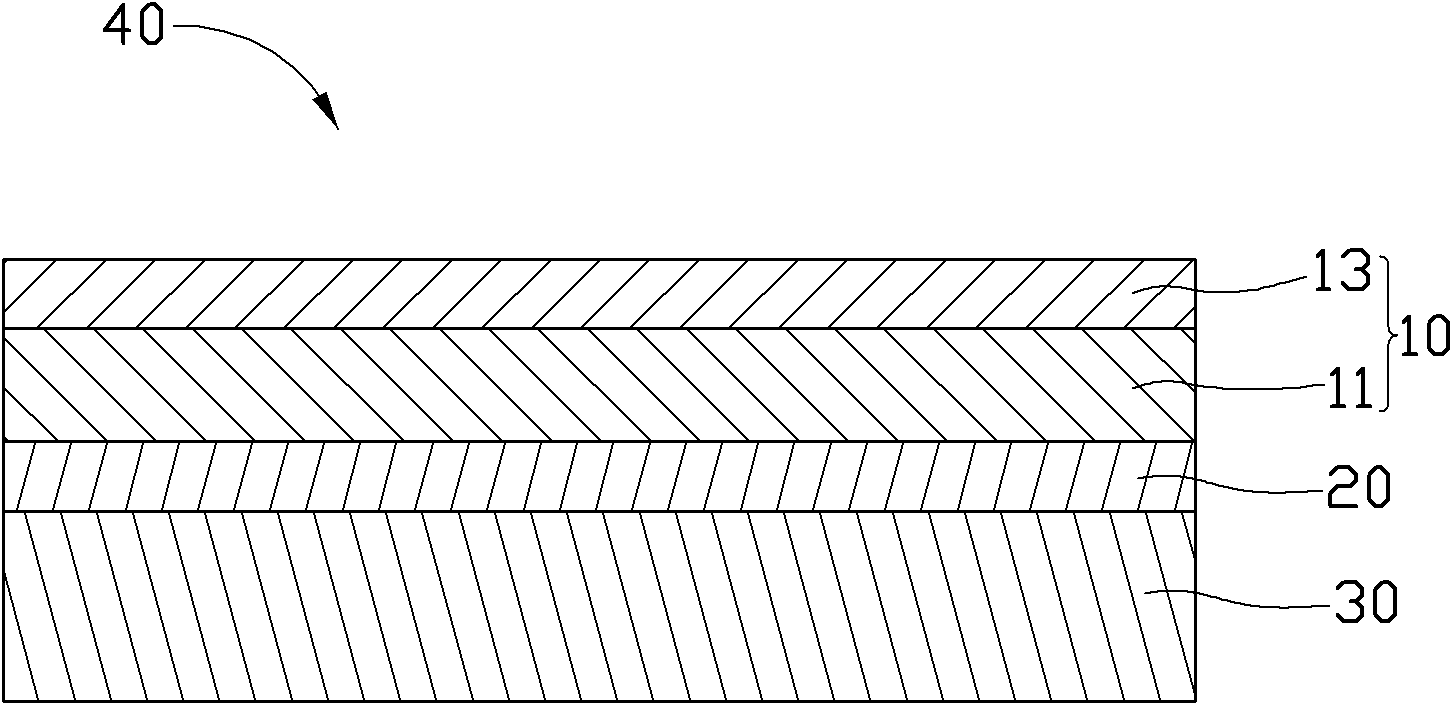

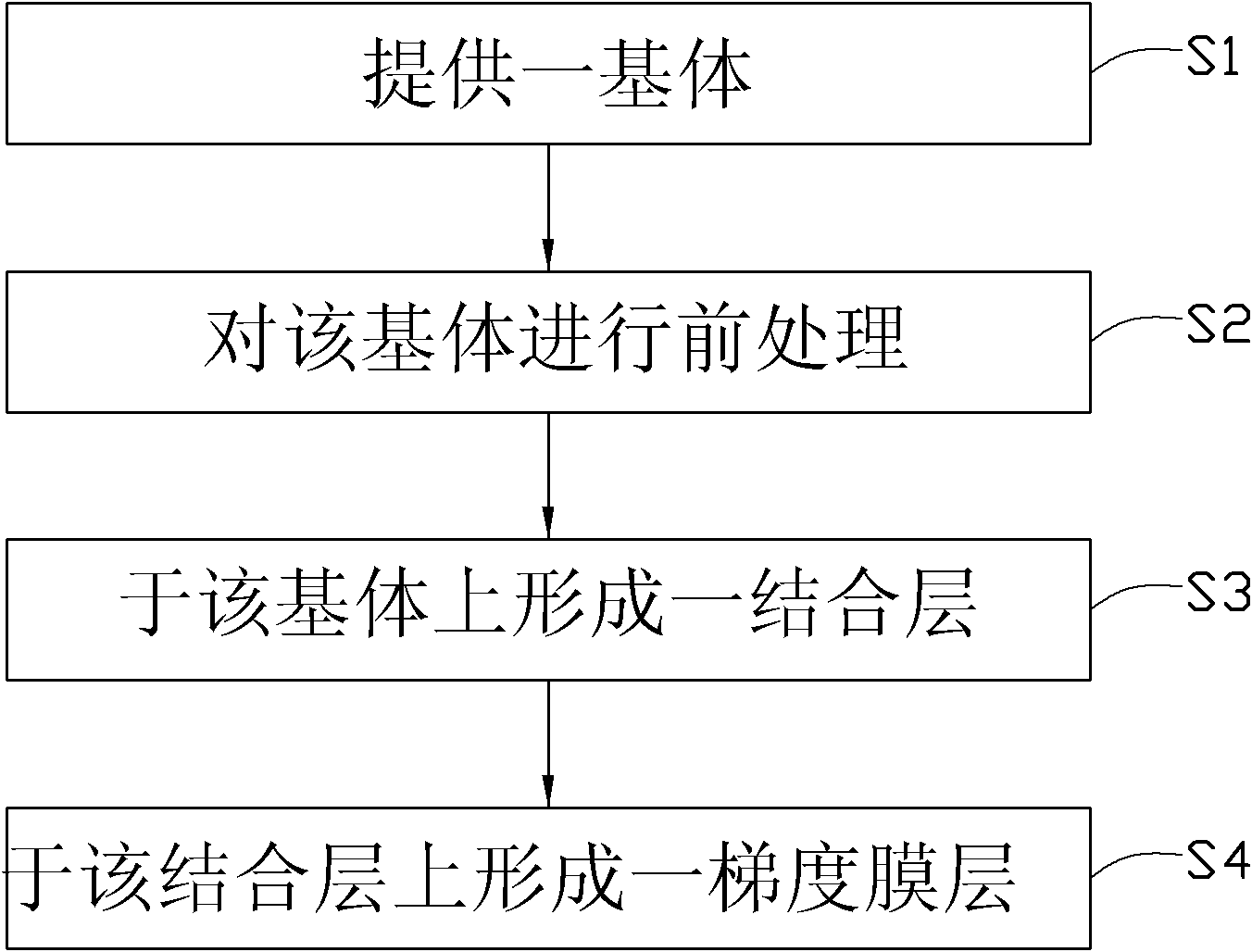

Coating, covered part with the coating and preparation method of covered part

InactiveCN102373426AImprove bindingImprove toughnessLayered productsVacuum evaporation coatingHardnessWear resistance

The invention provides a coating which comprises a ZrBN gradient coating and has high hardness, good corrosion resistance and wear resistance. The invention also provides a covered part with the above coating. The covered part comprises a hard matrix and a coating formed on the hard matrix. The coating contains the ZrBN gradient coating formed on the hard matrix. In addition, the invention also provides a preparation method of the above covered part.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

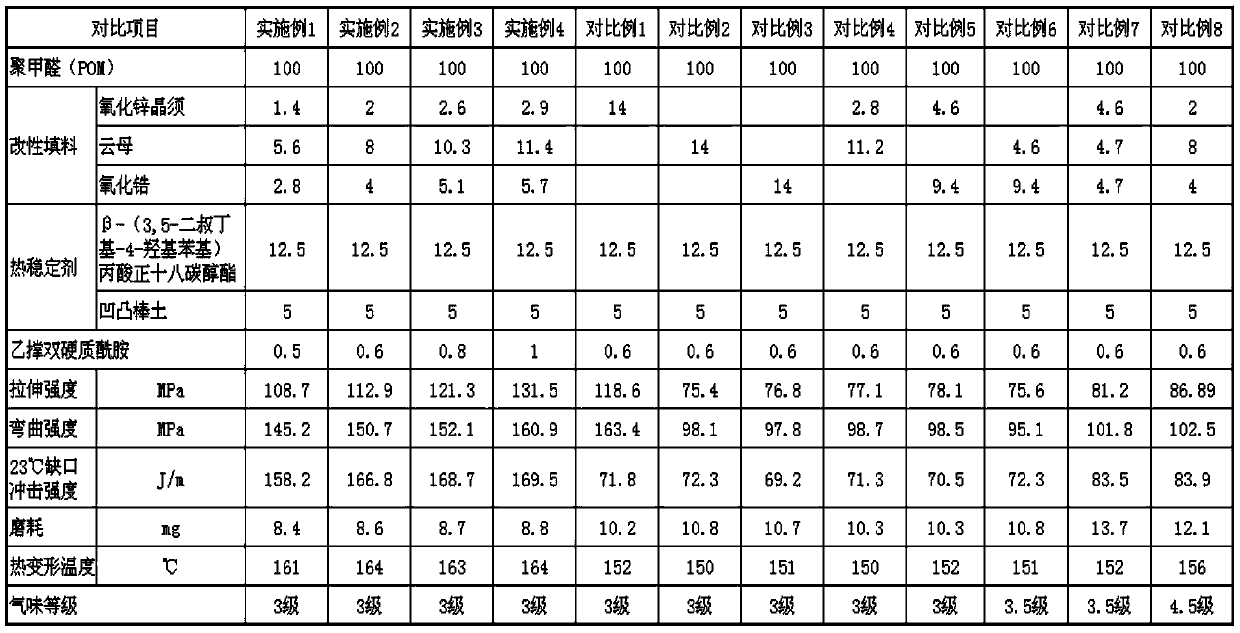

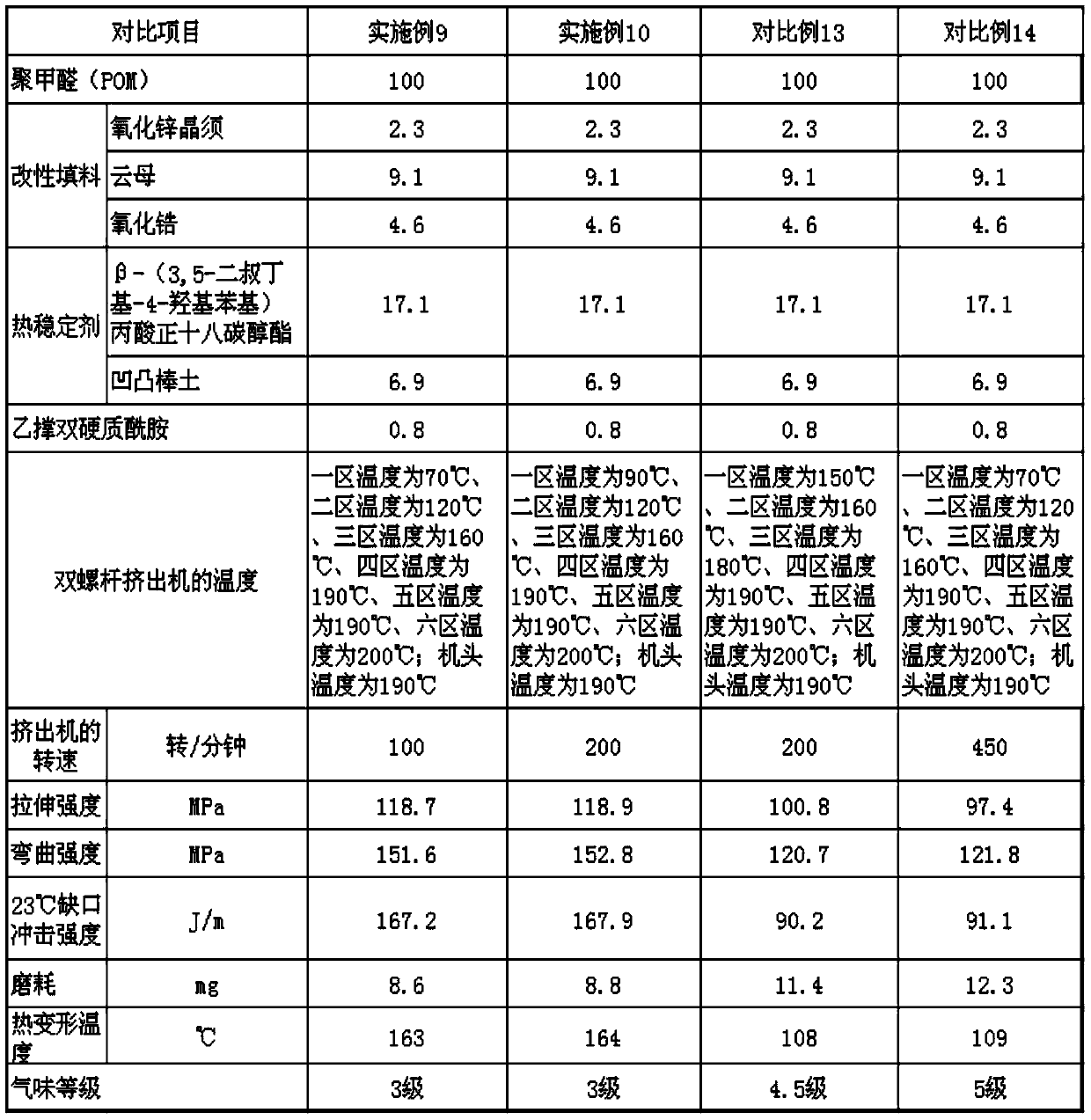

Novel polyformaldehyde composite material and preparation method thereof

InactiveCN109749349AImprove mechanical propertiesImprove wear resistanceMixed materialsTwin screw extruder

The invention discloses a novel polyformaldehyde composite material. The novel polyformaldehyde composite material is prepared through the following steps of (1) weighing out and feeding, by weight part, 100 parts of POM (polyoxymethylene), 10-20 parts of modified filler, 10-26 parts of heat stabilizer and 0.1-1 part of lubricant into a high-speed mixer for mixing at normal temperature for 5-10 min to obtain a mixed material; (2) feeding the mixed material into a double-screw extruder for melting, extrusion and pelletizing. The modified filler is prepared by compounding zinc oxide whisker, mica and zirconium oxide at a weight ratio of 1:4:2; the heat stabilizer is prepared by compounding beta-(3, 5-di-tert-butyl-4-hydroxybenzyl) n-octadecanol propionate and attapulgite. The prepared novelpolyformaldehyde composite material is excellent in mechanical performance, wear resistance and heat resistance.

Owner:安徽华米生物科技有限公司

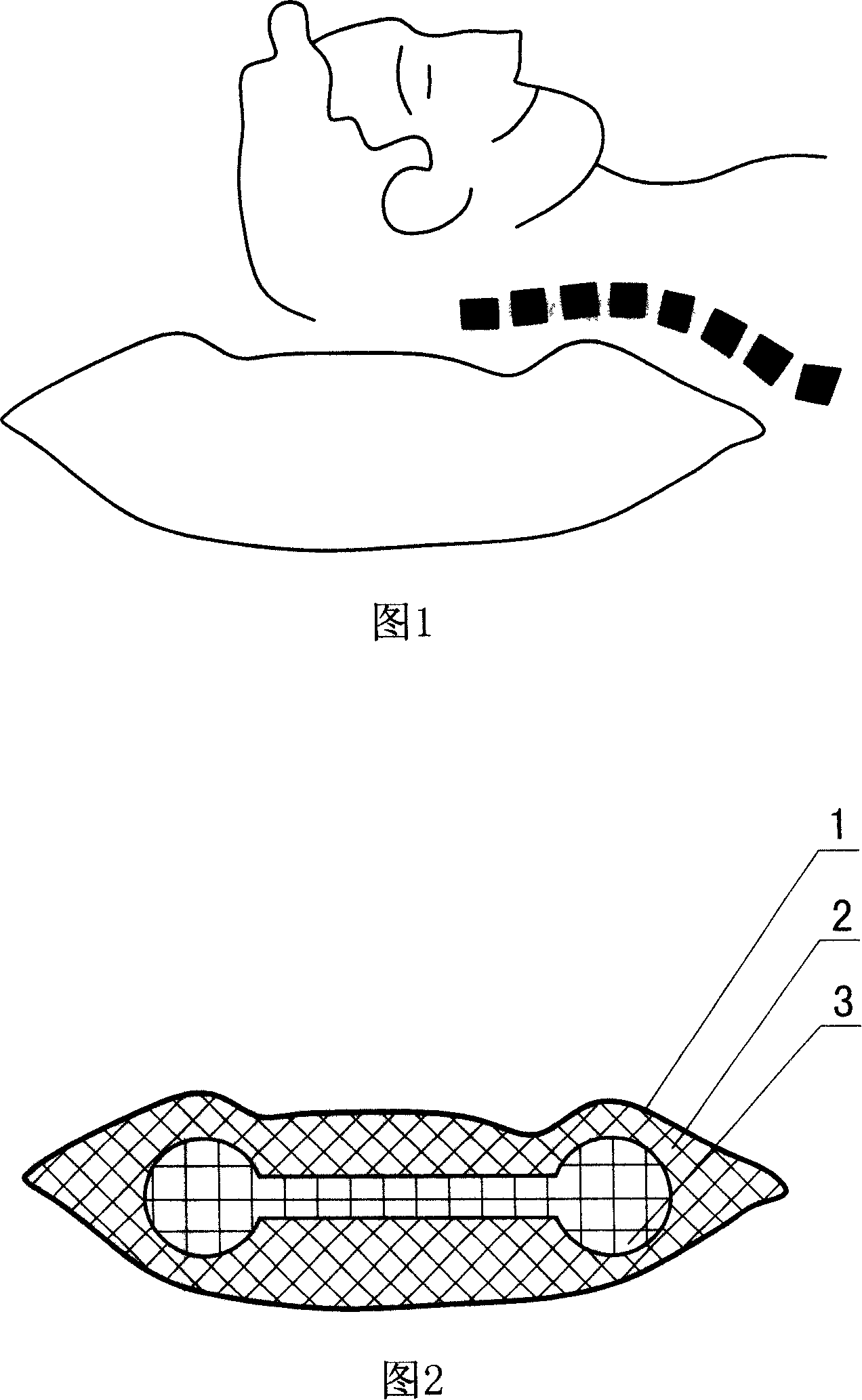

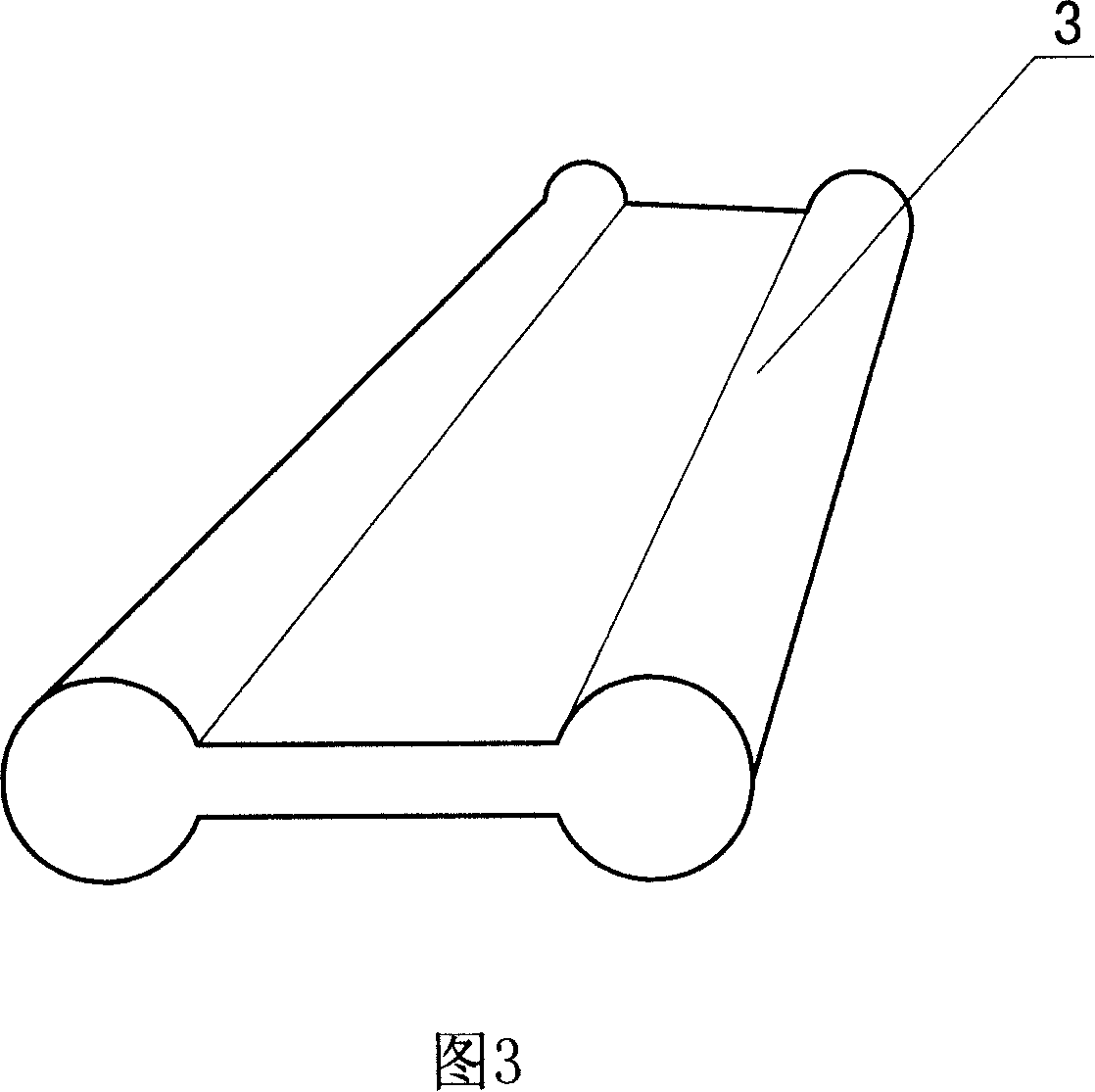

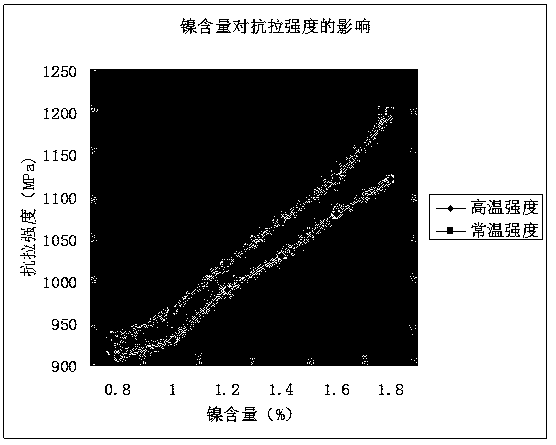

Pillow

InactiveCN101015411AToughness to avoidAvoid excessive muscle tensionPillowsUpholstery fillingMedicineCervical spine

The invention discloses a pillow, which consists of pillow sleeve (1) and pillow core (3), wherein the pillow core is assembled in the sleeve, whose intersection displays dumb-bell shape made of flexible material (2); the pillow core maintains normally physiological radian to contain skull in the relaxing condition.

Owner:黄寿良

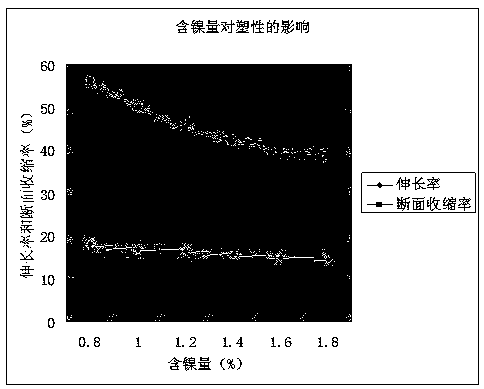

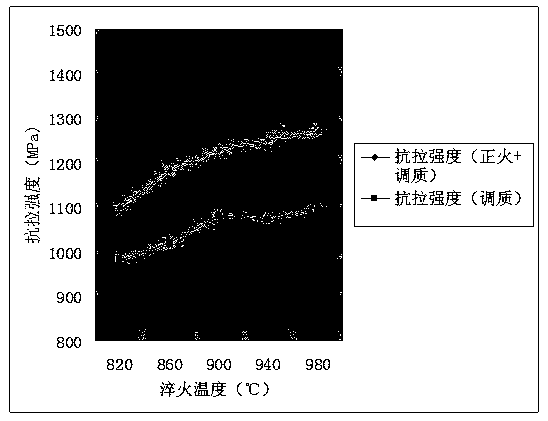

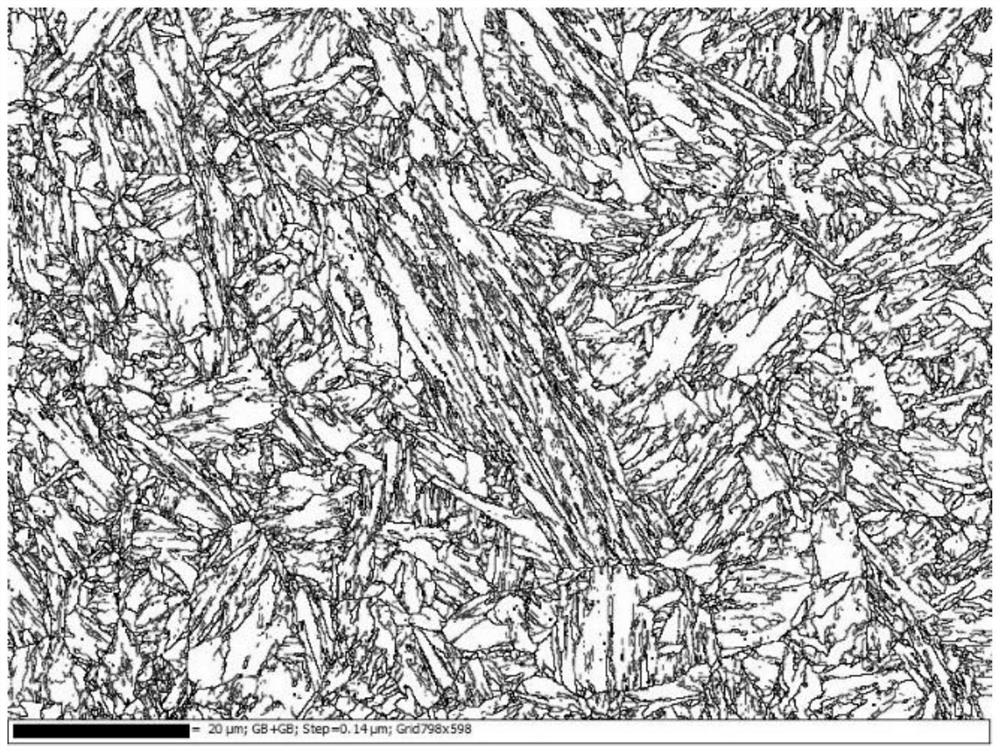

Alloy cast steel for high-speed train brake discs and high-speed train brake discs made of the alloy cast steel

The invention discloses an alloy cast steel used for a high-speed train brake disc and a high-speed train brake disc made of the alloy cast steel, its components and the weight percentage of each component are: according to claim 1 The alloy cast steel is characterized in that its components and the weight percentage of each component are: carbon 0.18-0.26%; silicon 0.30-0.50%; manganese 0.68-1.40%; phosphorus ≤ 0.025%; sulfur ≤0.013%; chromium 1.10~1.82%; nickel 0.90~1.50%; molybdenum 0.65~1.02%; The beneficial effects of the present invention are mainly reflected in: through the reasonable proportioning and heat treatment of alloying elements such as manganese, nickel, chromium, molybdenum, vanadium and the main components such as carbon and silicon in the cast steel material, the crystal grains are refined and the alloy casting is improved. The hardenability and thermal strength of the steel material, and the normal temperature strength and high temperature strength have been greatly improved, and it has excellent comprehensive mechanical properties. The brake disc manufactured by it can fully meet the technical requirements for the use of high-speed trains under working conditions.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

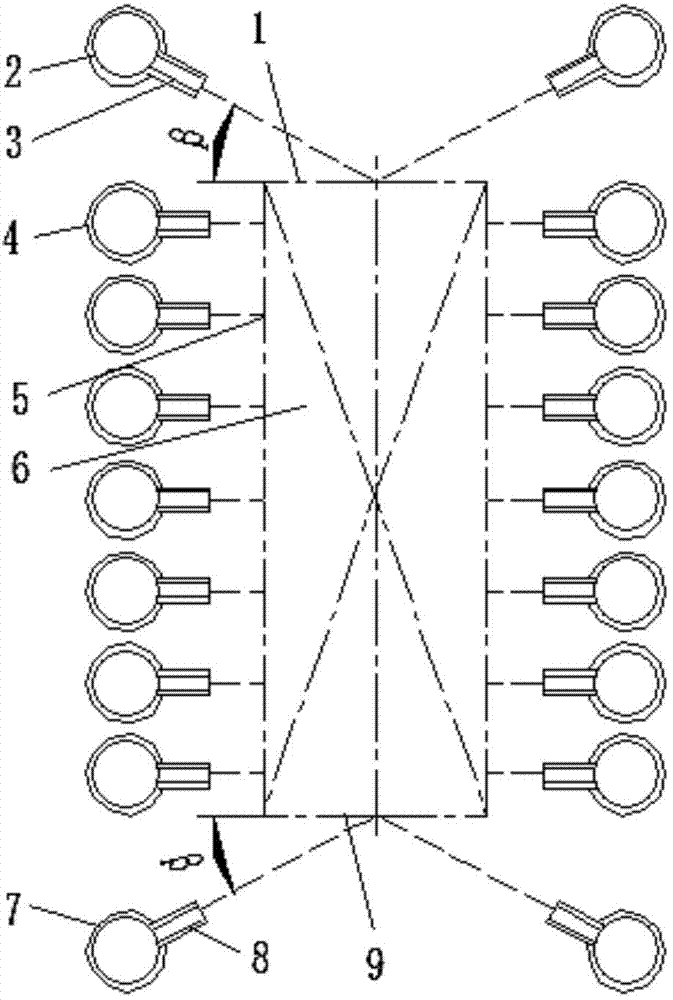

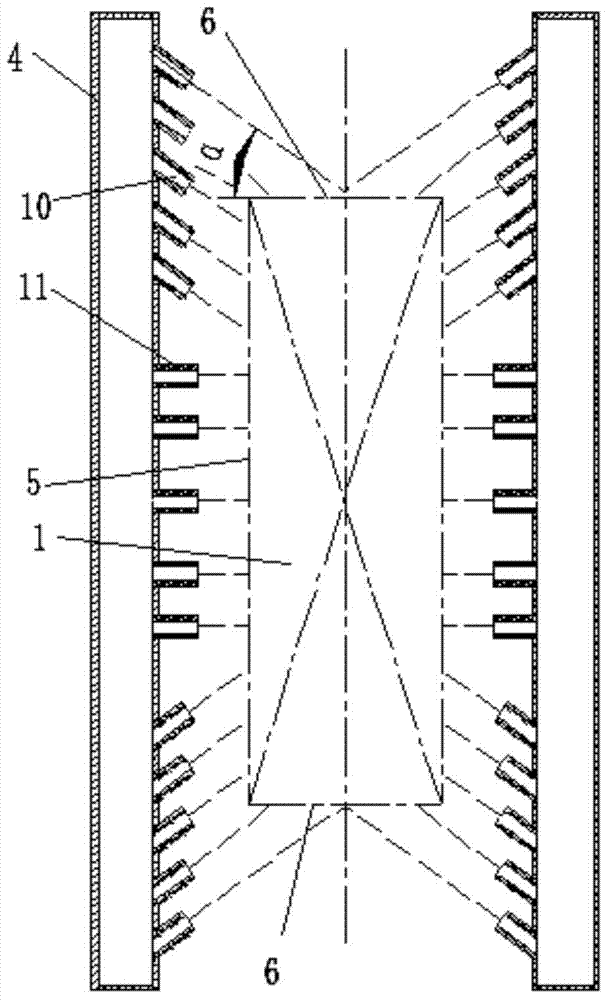

Production process for producing differentiated polyester staple fibers by using PET plastic bottle sheets

ActiveCN104846448AExtended service lifeAvoid pollutionArtificial filament heat treatmentMelt spinning methodsPolyesterEngineering

The invention relates to a production process for producing differentiated polyester staple fibers by using PET plastic sheets. The production process includes the steps of bottle sheet pre-treatment, bottle sheet spinning and winding, drafting, tension heat setting, curling, relaxation heat setting, cutting and packaging, and inspection and warehouse entering. In the tension heat setting, heating rollers which are distributed in two layers in a staggered manner, wherein the upper layer includes nine heating rollers, and the lower layer includes eight heating rollers. The bottle sheet preprocessing step further comprises a color proportioning process of the bottle sheets. According to the color proportioning process of the bottle sheets, when staple fibers for clothes and home textiles are produced, blue and white net bottle sheets are adopted, while staple fibers for the fillers of toys are produced, net bottle sheets in other colors are adopted. The staple fibers produced by adopting the production process are soft and have high resilience. When contacting products made of the staple fibers, people can feel comfortable. The products made through adopting the production process have a bright market prospect.

Owner:河北金怡化纤有限公司

High-strength and high-toughness steel as well as preparation method and application thereof

The invention provides high-strength and high-toughness steel as well as a preparation method and application thereof, and belongs to the technical field of engineering machinery and protective steel. The high-strength and high-toughness steel provided by the invention comprises the following components in percentage by mass: 0.12-0.28% of C; 0.50% to 2.00% of Mn; si < = 0.40%; 0.50% to 2.00% of Cr; 0.50% to 3.00% of Ni; 0.10% to 0.85% of Mo; 0.01% to 0.35% of V or Nb; ti: 0.01 to 0.30%; b: 0.0010% to 0.0035% of the total weight of the raw 0.01 to 0.045 percent of Al; less than or equal to 0.025% of P; less than or equal to 0.015% of S and the balance of iron. The result of the embodiment shows that the yield strength of the high-strength and high-toughness steel is larger than or equal to 1100 MPa; the tensile strength is greater than or equal to 1250MPa; the elongation after fracture is greater than or equal to 10%, and the Charpy impact energy of a V-shaped notch at-40 DEG C is greater than or equal to 55J.

Owner:SHANGHAI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com