Welding method for P355NH and 18MnD5 dissimilar steel

A welding method and dissimilar steel technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as brittle fracture and welding cracks, and achieve the effects of reducing crack tendency, slowing down tissue stress, and accurate temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

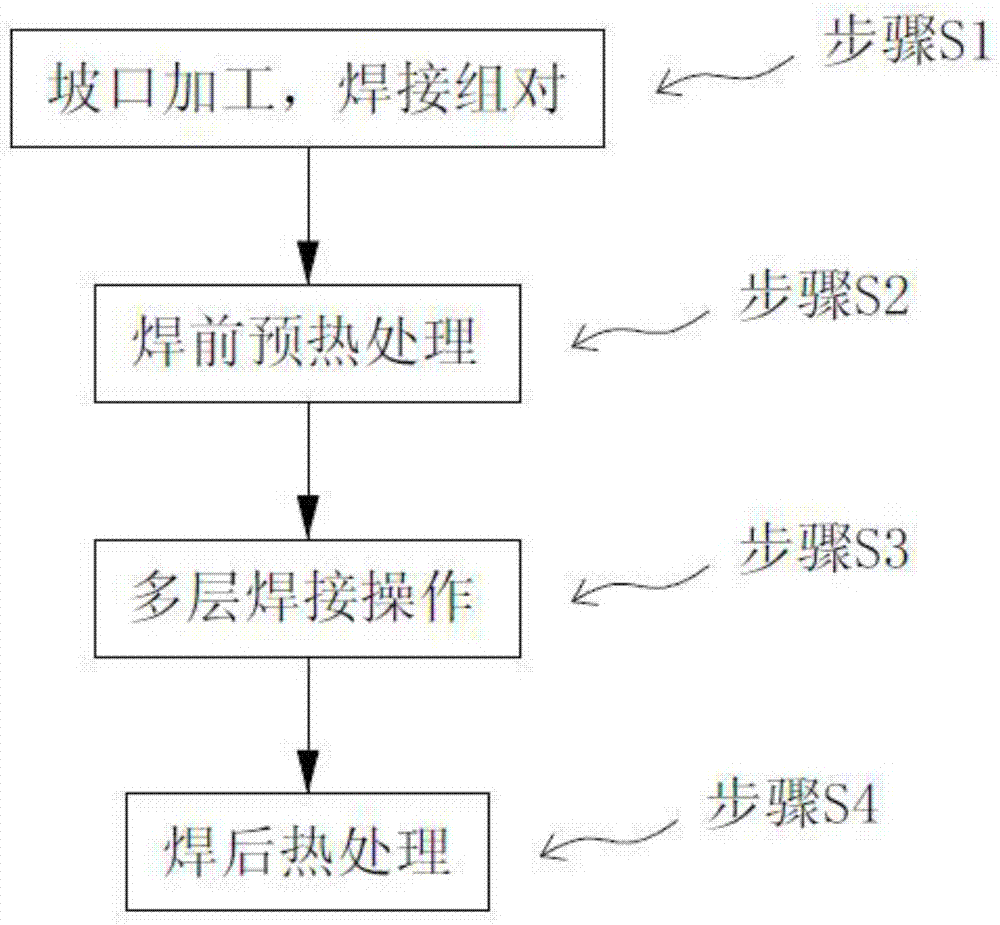

Method used

Image

Examples

Embodiment 1

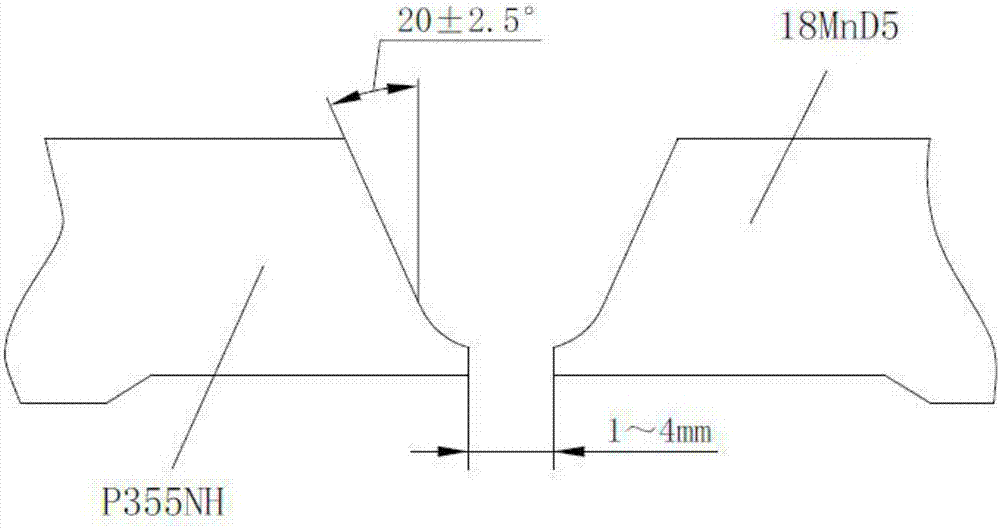

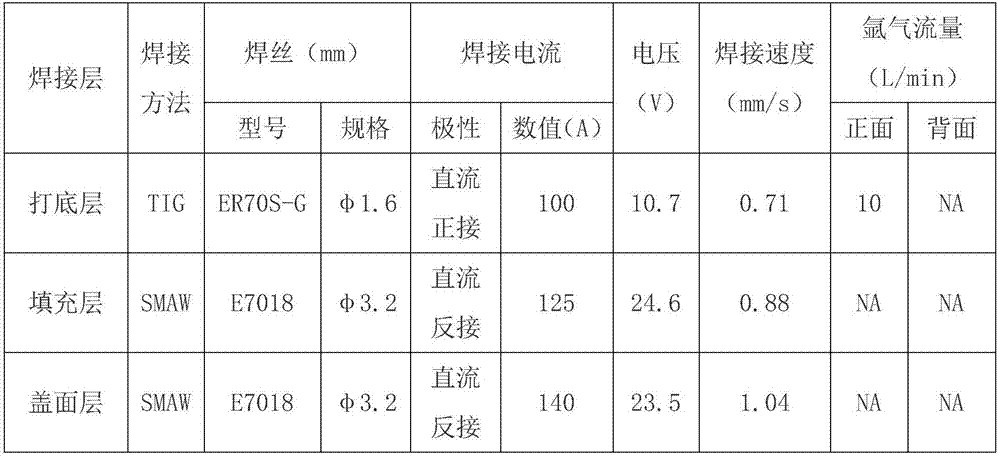

[0037] Example 1, a section of P355NH steel and a section of 18MnD5 steel base material are taken. First, the welding parts of the two sections of P355NH and 18MnD5 dissimilar steel base materials to be welded are processed into a 20° U-shaped groove, and the surface of the groove and its surrounding area are cleaned to avoid the existence of impurities and pollutants. The P355NH and 18MnD5 dissimilar steel base materials that have completed the groove processing are combined, and the gap between the groups is controlled between 1 and 4mm. Then, the P355NH and 18MnD5 dissimilar steel base materials that have completed the groove processing were preheated before welding by means of electric heating, and the preheating temperature was controlled at 140 ° C by means of a far-infrared thermometer. Then, according to the welding parameters in Table 1, the base metals of P355NH and 18MnD5 dissimilar steels were welded in sequence for the base layer, the filler layer, and the cover l...

Embodiment 2

[0040] Embodiment 2, adopt the welding method identical with embodiment 1 to carry out welding operation to P355NH and 18MnD5 dissimilar steel base material, its difference is: embodiment 2 adopts the welding parameter in table 2 to carry out welding operation to P355NH and 18MnD5 dissimilar steel base material At the same time, in the post-weld heat treatment, in the first stage, the temperature of the welded joint is freely raised to 350°C; in the second stage, the welded joint is heated to 620°C at a heating rate of 200°C / h, and kept at 620°C for 2 hours ; In the third stage, the welded joint was cooled to 350°C at a cooling rate of 200°C / h; in the fourth stage, the welded joint was freely cooled to room temperature to obtain the welded product X2.

[0041] Table 2

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com