High-temperature nano-electrothermal film of double-film structure and preparation method thereof

A nano-electric heating film and double-layer film technology is applied in the field of semiconductor heating and infrared radiation, which can solve the problems of high power and low thermal efficiency, and achieve the effect of high safety factor, high thermal efficiency and shortening heating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

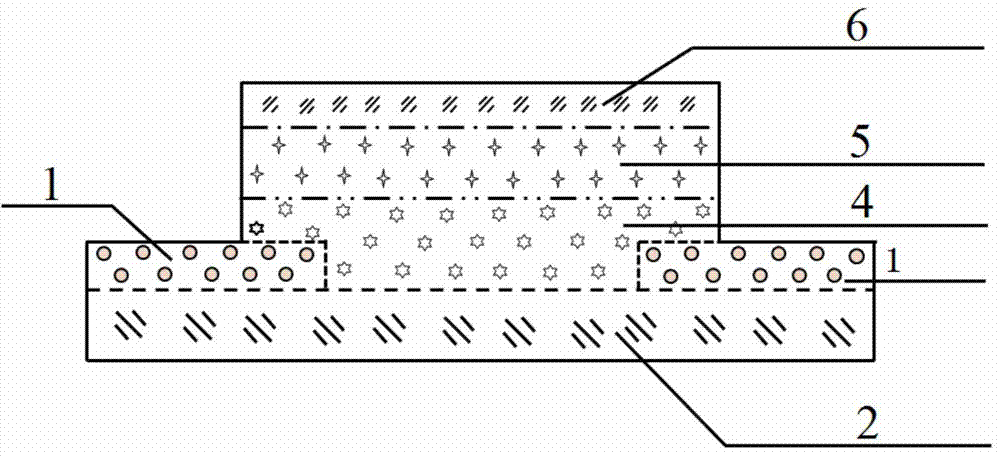

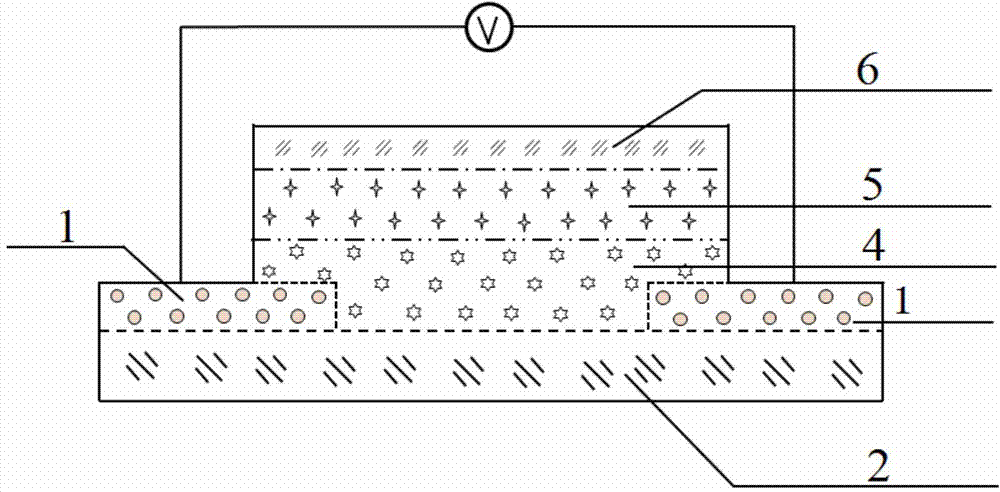

[0024] A high-temperature nanometer electric heating film with a double-layer film structure, such as figure 1 As shown, it consists of a platinum alloy thin film electrode 1, a quartz substrate 2, a silicon carbide film layer 4, and a molybdenum disilicide film layer 5. The quartz substrate is a high temperature resistant quartz plate or quartz tube, or is shaped as a curved high temperature resistant quartz substrate.

[0025] The preparation method of the high-temperature nanometer electrothermal film of double-layer film structure, its steps are as follows:

[0026] Substrate cleaning: The quartz substrate is cleaned with an ultrasonic cleaner with an ultrasonic frequency of 20-50KHz. It is first cleaned in deionized water, and then cleaned in the order of acetone, absolute ethanol, and deionized water. Each cleaning time is 10-50KHz. 15 minutes; then take out the quartz substrate, blow off the water droplets on the surface with an ear washing ball, put it into an electri...

Embodiment 2

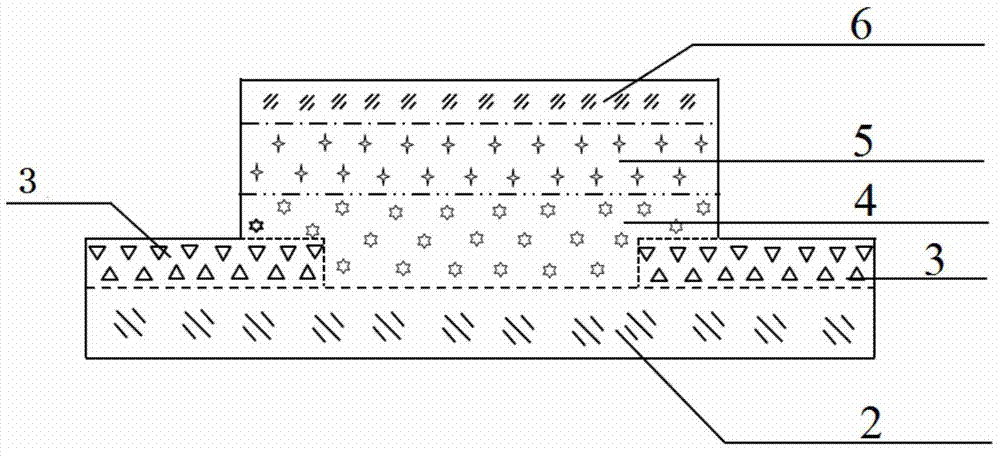

[0032] A high-temperature nanometer electric heating film with a double-layer film structure, such as figure 2 As shown, it consists of a cobalt-based alloy thin-film electrode 3 , a quartz substrate 2 , a silicon carbide film layer 4 , and a molybdenum disilicide film layer 5 . The quartz substrate is a high temperature resistant quartz plate or quartz tube, or is shaped as a curved high temperature resistant quartz substrate.

[0033] The preparation method of the high-temperature nanometer electrothermal film of double-layer film structure, its steps are as follows:

[0034] Substrate cleaning: The quartz substrate is cleaned with an ultrasonic cleaner with an ultrasonic frequency of 20-50KHz. It is first cleaned in deionized water, and then cleaned in the order of acetone, absolute ethanol, and deionized water. Each cleaning time is 10-50KHz. 15min. Then take out the substrate, blow off the water droplets on the surface with an ear washing ball, put it into an electric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com