Method for recycling, classifying and utilization of construction solid waste

A solid waste and treatment method technology, applied in grain treatment, solid separation, construction, etc., can solve problems affecting crushing work, low crushing efficiency, and unsafe operation, and achieve reasonable structural design, high comprehensive utilization rate, and improved The effect of collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

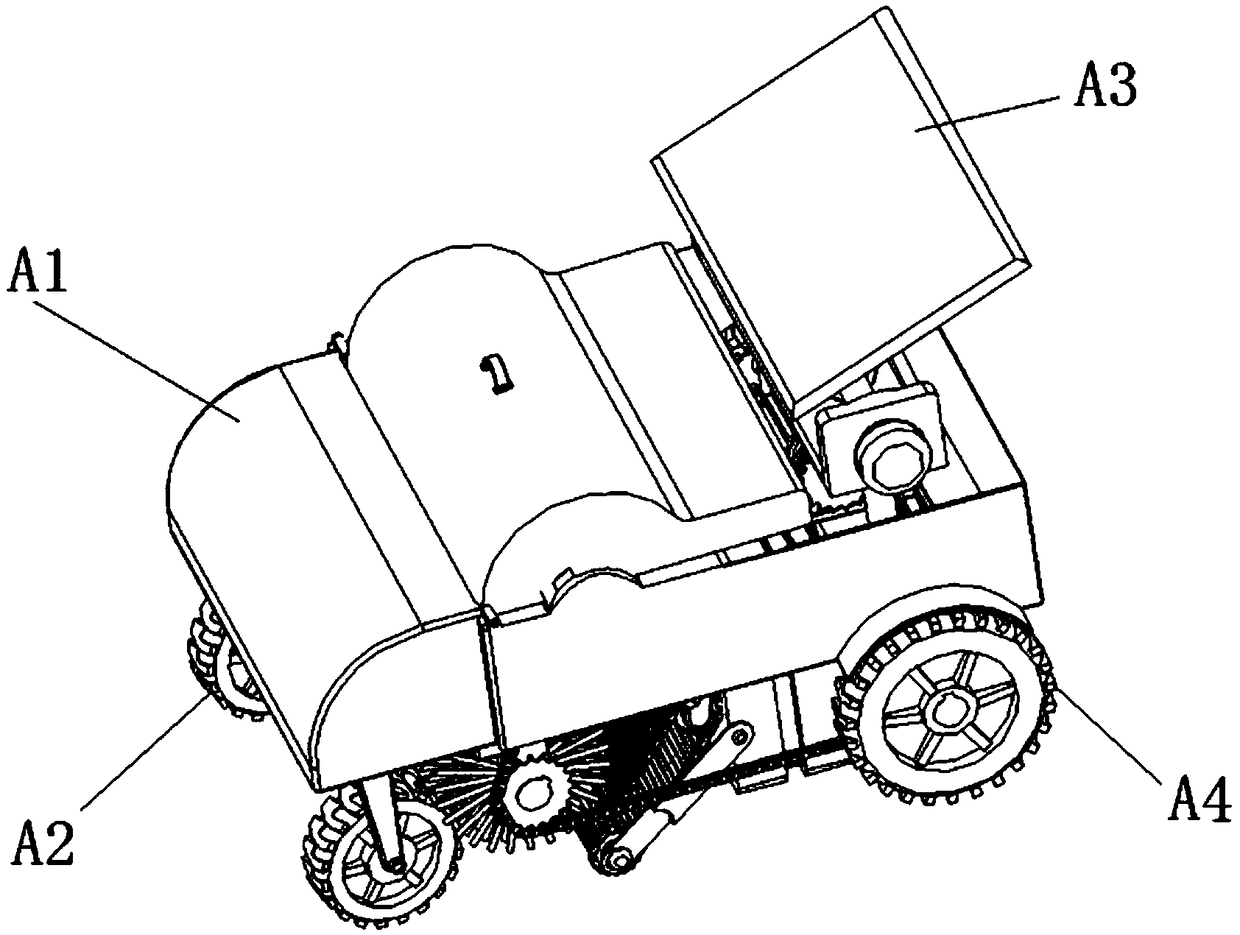

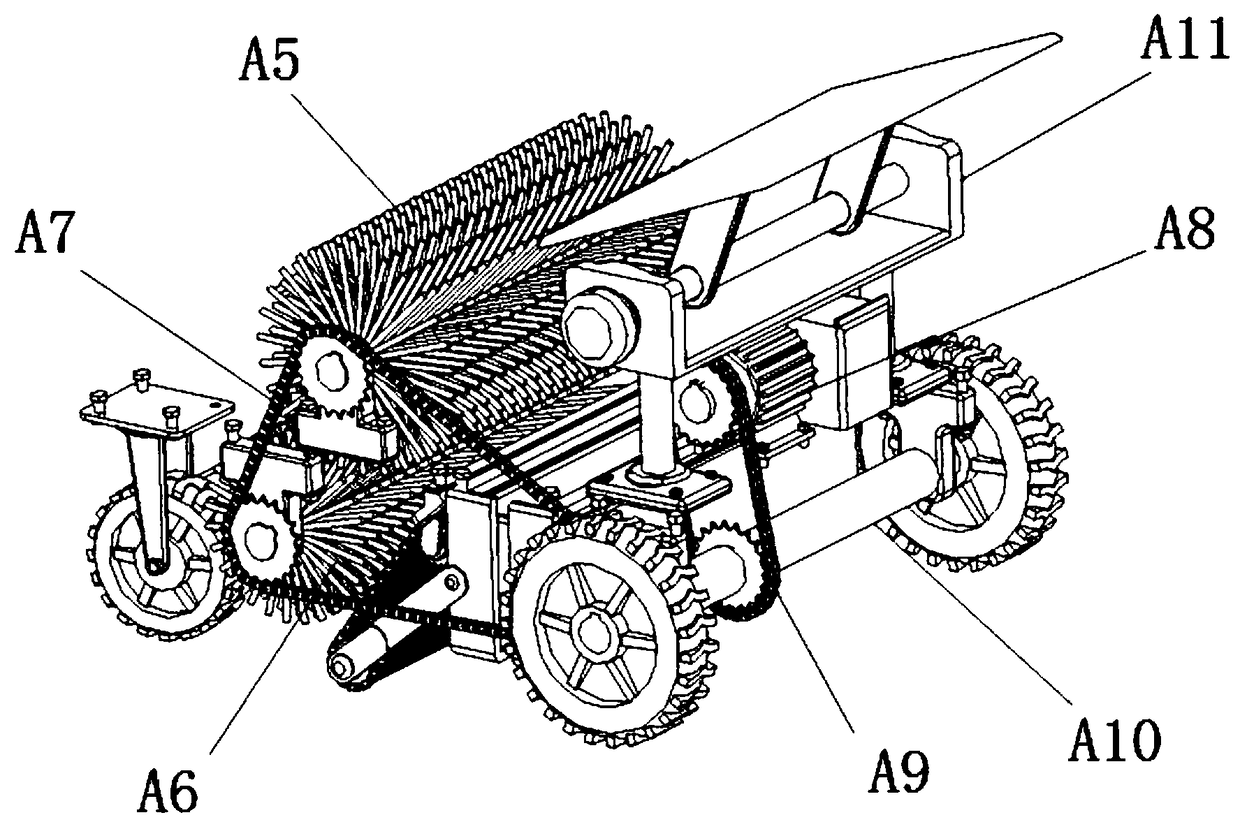

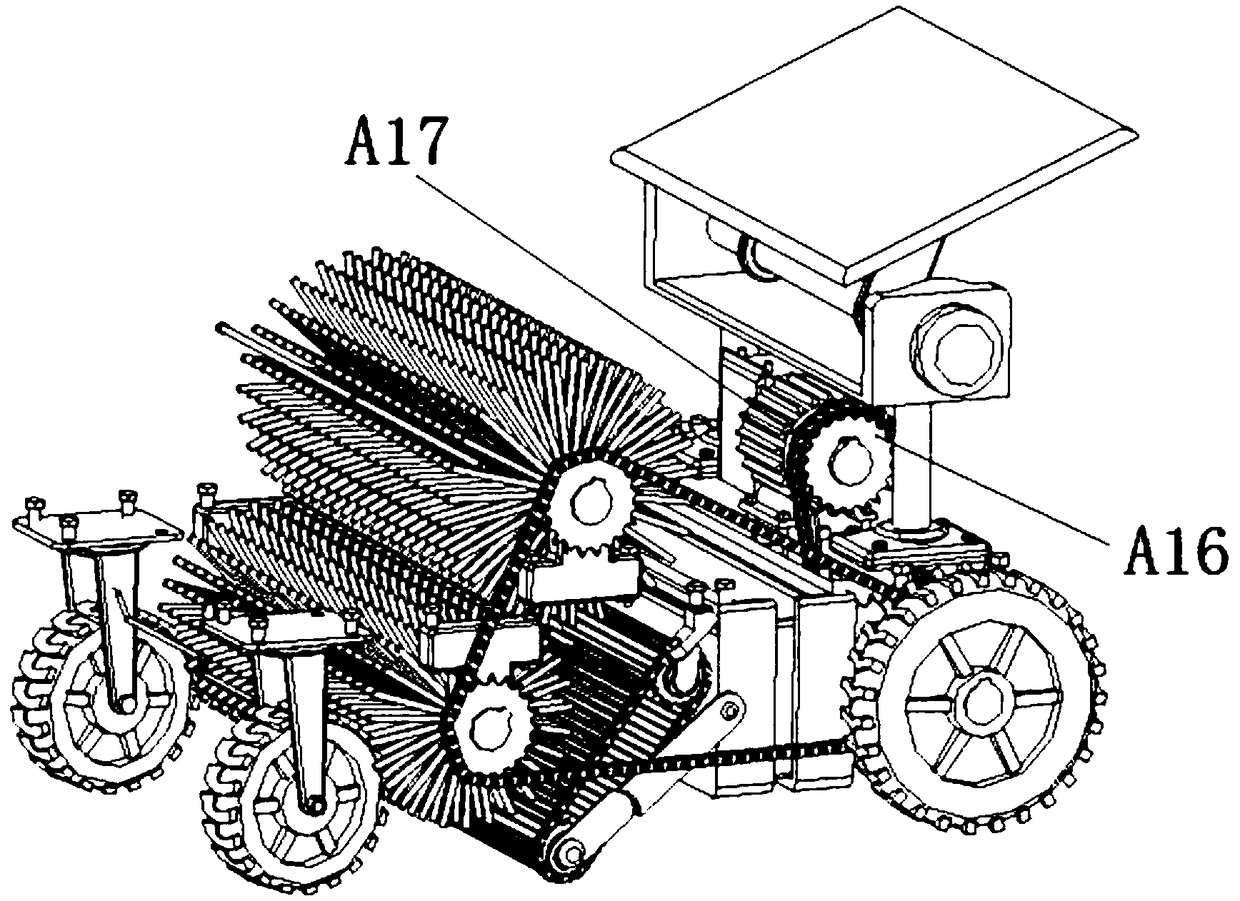

[0058] Embodiment 1: In the garbage collection device A, the frame A11 is used to realize support, the front wheel A2 is provided in front of the frame A11, the rear wheel A4 is provided behind the frame A11, and the front wheel A2 and the rear wheel A4 are all installed on the frame by a wheel bracket On the A11; the setting of the front wheel A2 and the rear wheel A4 facilitates the movement of the car body.

[0059] The rear wheel A4 is connected through the rear wheel axle A10, and the rear wheel synchronous gear A9 is arranged on the rear wheel axle A10; the steering gear A20 for steering is installed on the front side of the frame A11, and the setting of the steering gear A20 is used to realize the steering, and cooperate with the steering gear to steer The head A21 and the steering gear guide rod A22 realize the rotation of the front wheel A2, and then realize the steering of the car body.

[0060] There is a steering gear head A21 under the steering gear A20, and the s...

Embodiment 2

[0068] Embodiment 2: metal and non-metal screening device B, one side of conveying frame B1 is provided with transfer box B17. A number of conveying rollers B2 are arranged on the conveying frame B1, and the two ends of the conveying rollers B2 are connected with the conveying frame B1 through bearings; the conveying motor B4 is fixedly arranged at one end of the conveying frame B1, and the conveying motor B4 is connected to the conveyor through a chain drive assembly. The conveying roller B2 is connected; the conveying roller B2 is provided with a conveying belt B3; one end of the conveying frame B1 is provided with two adjusting plates B5, and the adjusting plate B5 is connected with the conveying frame B1 in a fixed way; the shape of the adjusting plate B5 It is in the shape of a fan, and there is a chute on the adjustment plate B5. The shape of the chute is arc-shaped. Loosen the locking bolt on the side of the height-limiting plate B6, and the angle of the adjustment plate...

Embodiment 3

[0076] Embodiment 3: the broken equipment D of concrete blocks, the frame D1 is a rectangular box-like structure; the front guard D2 is arranged on the upper side of the frame D1, and the front guard D2 is connected with the frame D1 by bolts; the side The guard plate D3 is set inside the frame D1, and the side guard plate D3 is connected to the frame D1 by bolts; the crankshaft D4 is set on the upper side of the frame D1, and the crankshaft D4 is connected to the frame D1 through the bearing seat D5 , the two ends of the crankshaft D4 are respectively provided with a flywheel D6 and a driving wheel D7; the movable jaw D8 is arranged in the middle of the crankshaft D4; the lifting ring D9 is arranged on the upper side of the movable jaw D8, and the lifting ring D9 and the movable jaw D8 are connected by welding; The movable jaw plate D10 is set on the front side of the movable jaw D8, and the movable jaw plate D10 and the movable jaw D8 are fixedly connected by pins; the static...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com