Patents

Literature

59results about How to "Limit height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

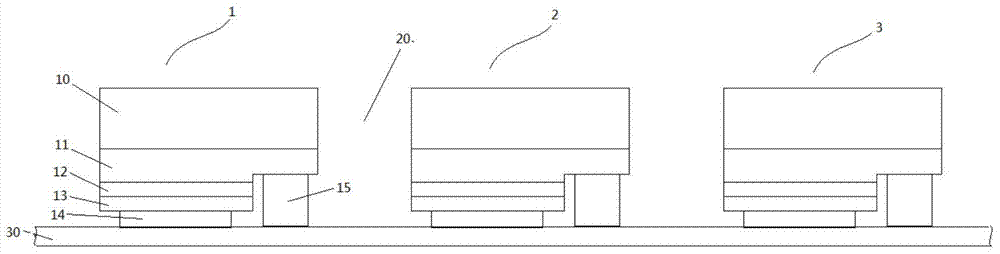

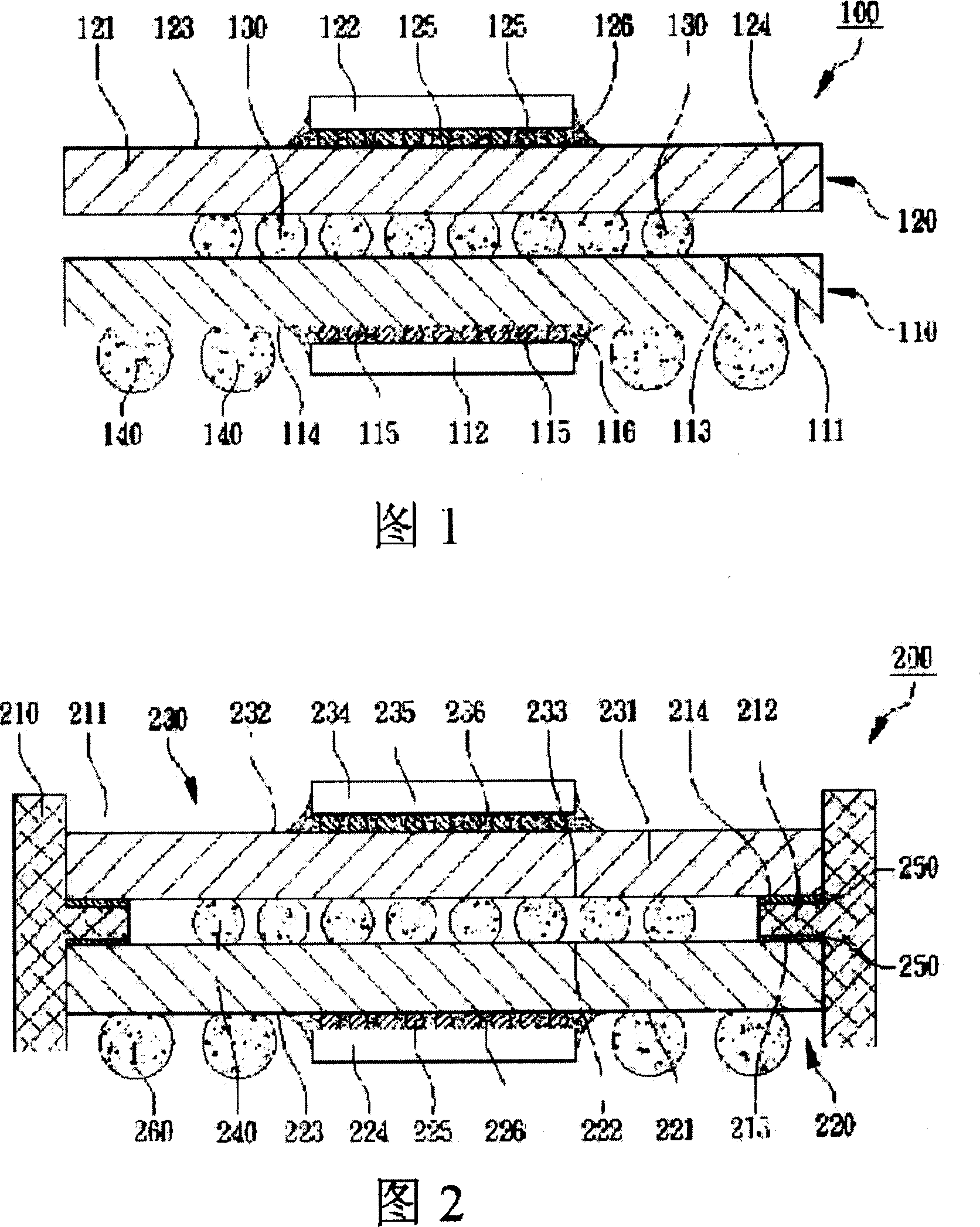

Chip scale packaging method and structure for light-emitting device

ActiveCN104851961ASimplify packaging process stepsReduce system thermal resistanceSolid-state devicesSemiconductor devicesEngineeringElectrical and Electronics engineering

The application discloses a chip scale packaging method for a light-emitting device. The scale packaging method includes steps: at least a flip light-emitting device is arranged on a conversion base film with equal intervals, a main light-outlet surface of the flip light-emitting device is opposite to the conversion base film, dams are formed between the flip light-emitting devices and / or around the flip light-emitting devices on the conversion base film, packaging glue is respectively coated on the flip light-emitting devices and the conversion film, the dams are removed when the packaging glue is cured to be non-liquid, the packaging glue is cut after the packaging glue is completely cured, the conversion base film is removed, and the chip scale packaging structure is obtained after molding. The invention also discloses a chip scale packaging structure for the light-emitting device. According to the chip scale packaging method and the structure for the light-emitting device, packaging process steps of the chip are greatly simplified, a submount of the chip is saved, the cost is lowered, and the work efficiency of users can be more conveniently improved.

Owner:湖南省日晶照明科技有限责任公司

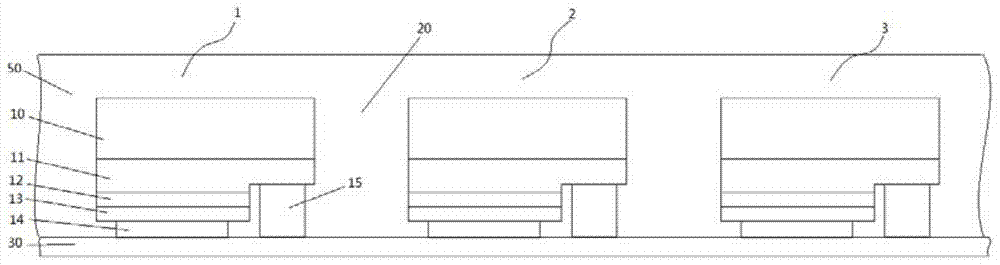

Centrifugal fan impeller

The invention discloses a centrifugal fan impeller, which comprises a front ring and a back ring, wherein a plurality of blades are fixedly arranged between the front ring and the back ring. The centrifugal fan impeller is characterized in that the outlet ends of the blades form a wave-shaped sawtooth type by a plurality of sawteeth. The outlet ends (tail edges) of the blades are provided with structures in the wave-shaped sawtooth type, and the wake vortex shedding positions of the tail edges of the blades are changed, so the distance between the vortex centers is increased, the disturbance of the shedding vortex on the wake flowing is inhabited, and the pneumatic noise caused by the wake vortex and the unsteady pressure fluctuation of the blade surfaces is further reduced. The height and the width of the sawteeth are limited, the noise is further reduced, and the influence of the sawteeth on the pressure and air quantity reduction of a fan can also be reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

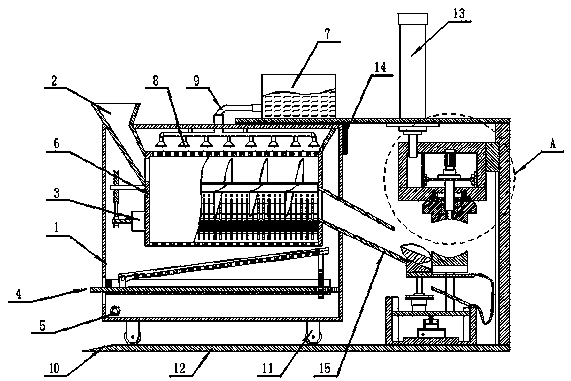

Method for recycling, classifying and utilization of construction solid waste

InactiveCN109403172ASimple componentsImprove processing efficiencySievingRoadwaysSolid waste collectionCrusher

The invention provides a method for recycling, classifying and utilization of construction solid waste. The method includes the following steps that 1, a construction solid waste collection device collects construction solid waste, and then the construction solid waste is classified, screened, recycled and crushed; 2, a metal and non-metal screening device screens metal garbage and non-metal garbage, screening of wood garbage and solid concrete is manually performed, a wood crusher is used for crushing wood garbage to serve as other building auxiliary materials, and the selected solid concreteis then crushed by a crusher to obtain paving subgrade materials; 3, the paving subgrade materials are classified and screened through screening devices used for different sizes of solid concrete, and A-particle-size solid concrete and B-particle-size solid concrete are screened out for standby application; 4, the paving subgrade materials are prepared; 5, paving, repeated compaction and acceptance are performed in sequence. The components of the obtained paving subgrade materials are simple, the construction solid waste is used for recycling, crushing and reuse, the processing efficiency ishigh, the processing cost is low, the comprehensive utilization rate is high and the method is worth popularizing.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

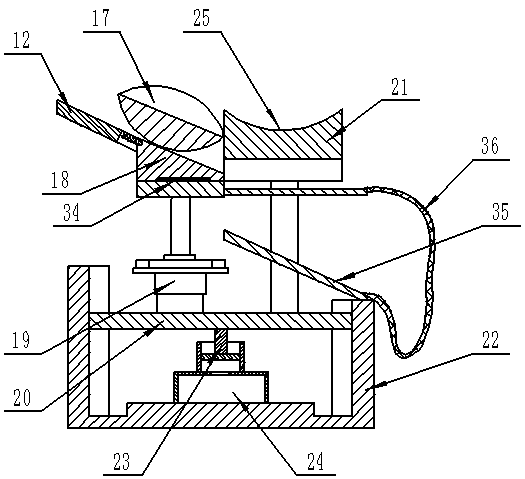

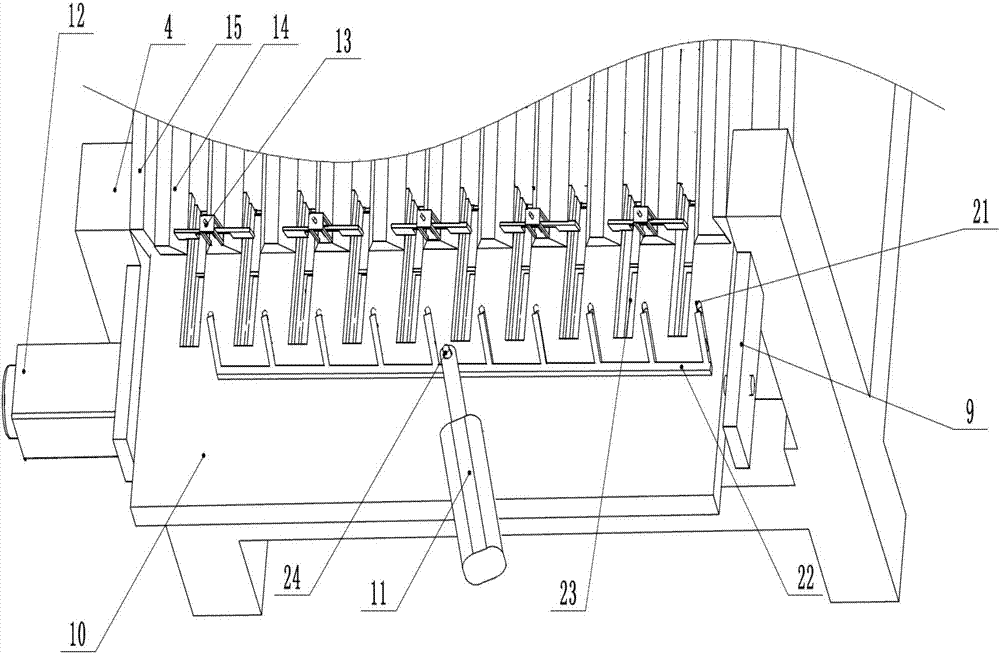

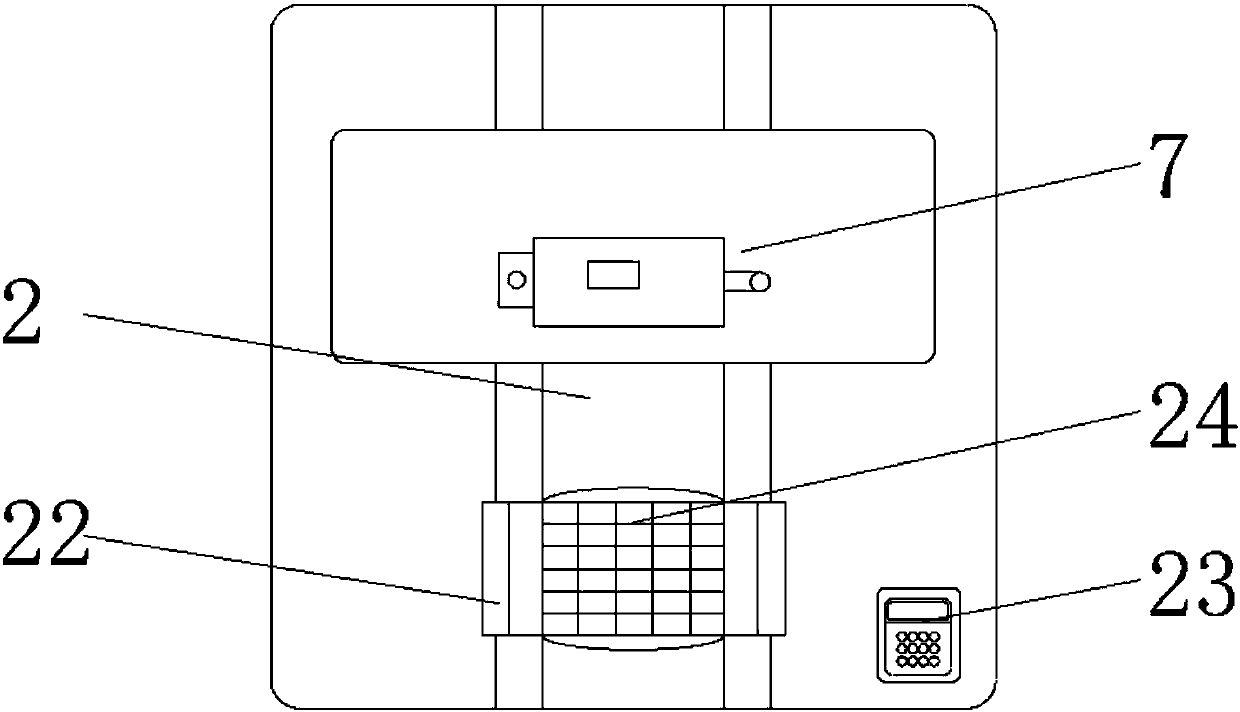

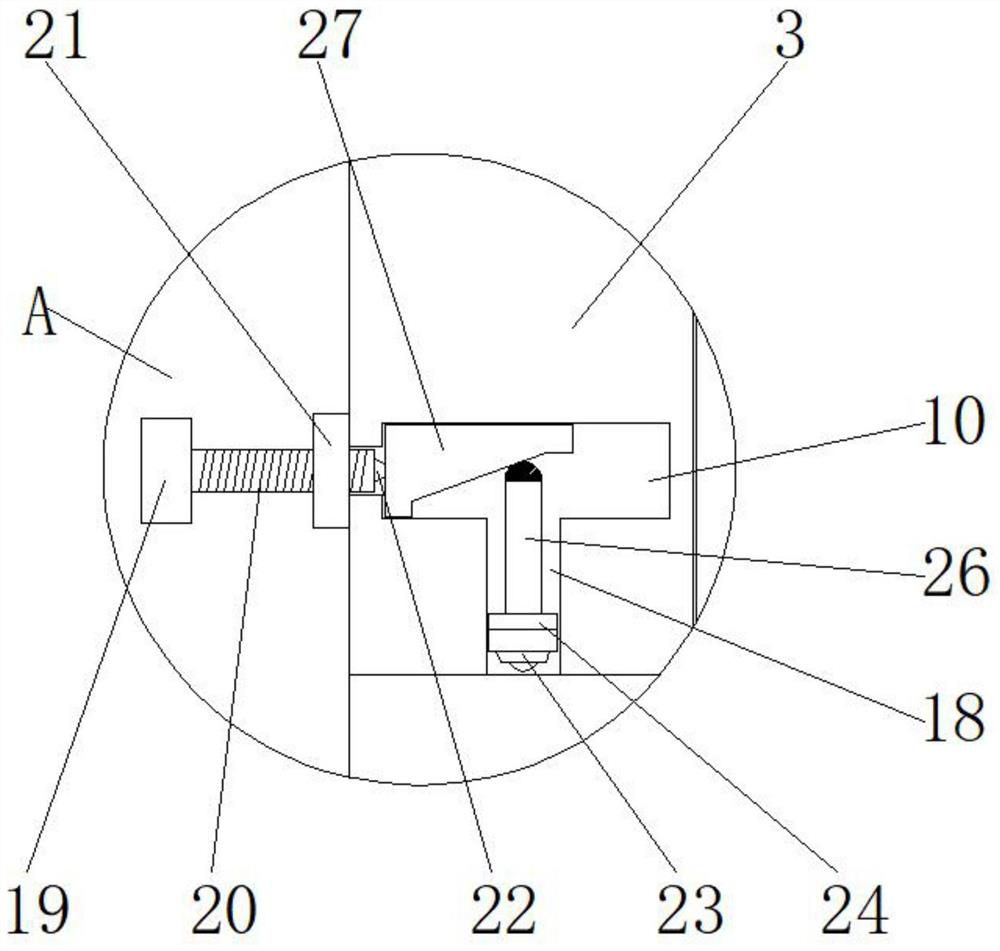

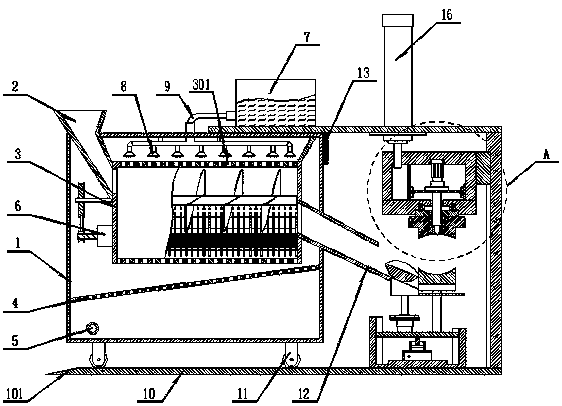

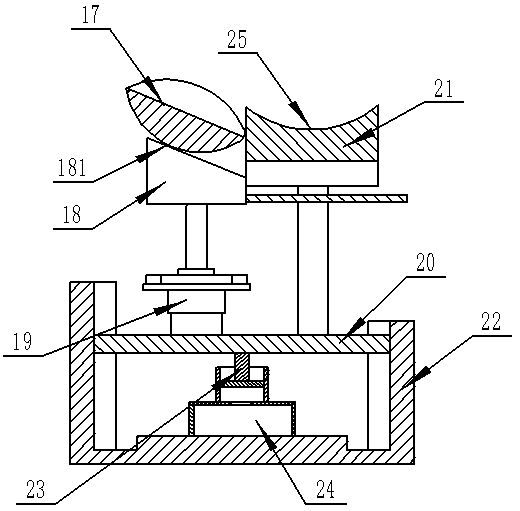

Automatic shell opening device with screening function

InactiveCN108391715AIncrease productionAvoid unclampingClimate change adaptationPisciculture and aquariaFresh water organismButt joint

The invention discloses an automatic shell opening device with a screening function. The device comprises a moving frame and a charging hopper; a cleaning cylinder is arranged in the moving frame, anda spiral propeller and brush rollers are arranged in the cleaning cylinder; a filter assembly is arranged on the moving frame; the cleaning cylinder is in butt joint with a discharging channel, and the discharging channel is hinged to a stop baffle, and a pressure sensor is embedded in a feeding push block; the lower end of the feeding pushing block is connected to a feeding cylinder, and a pressing disc is arranged at the end face, and a guide plate is arranged at the lower end of the pressing disc, and a collecting bag is connected on the guide plate; and an upper pressing disc, a pressingmechanism and a shell-opening assembly are arranged above the upper pressing disc. For the above problems, the invention aims to provide the automatic shell opening device with a screening function, and the device cleans mussel shells before shell opening, realizes full-automatic single-material conveying, carries out shell opening on freshwater mussels by adopting rotary drilling, realizes selection on relatively small freshwater mussels mingled with the mussels, and effectively improves the processing efficiency of the freshwater mussels.

Owner:DONGGUAN UNIV OF TECH

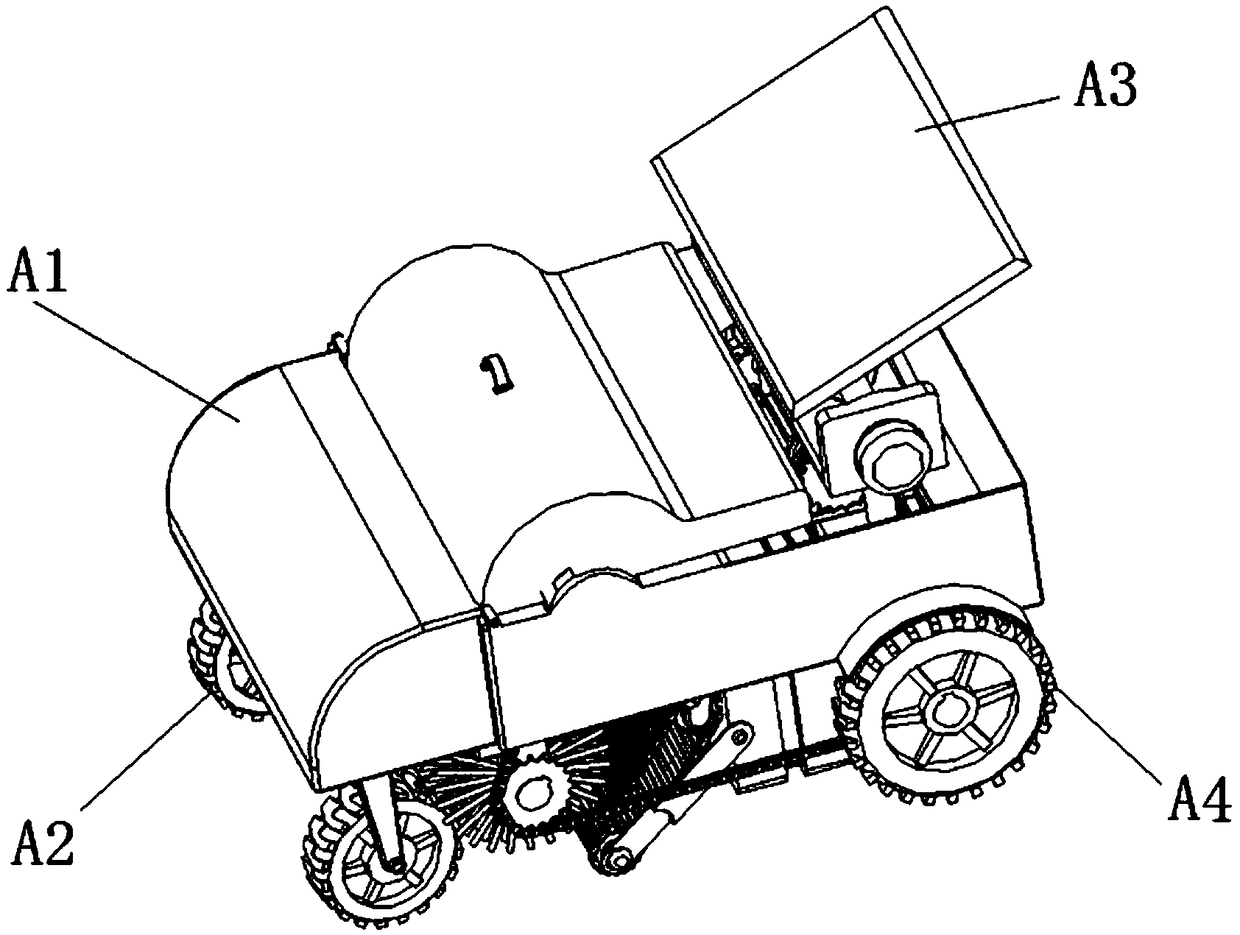

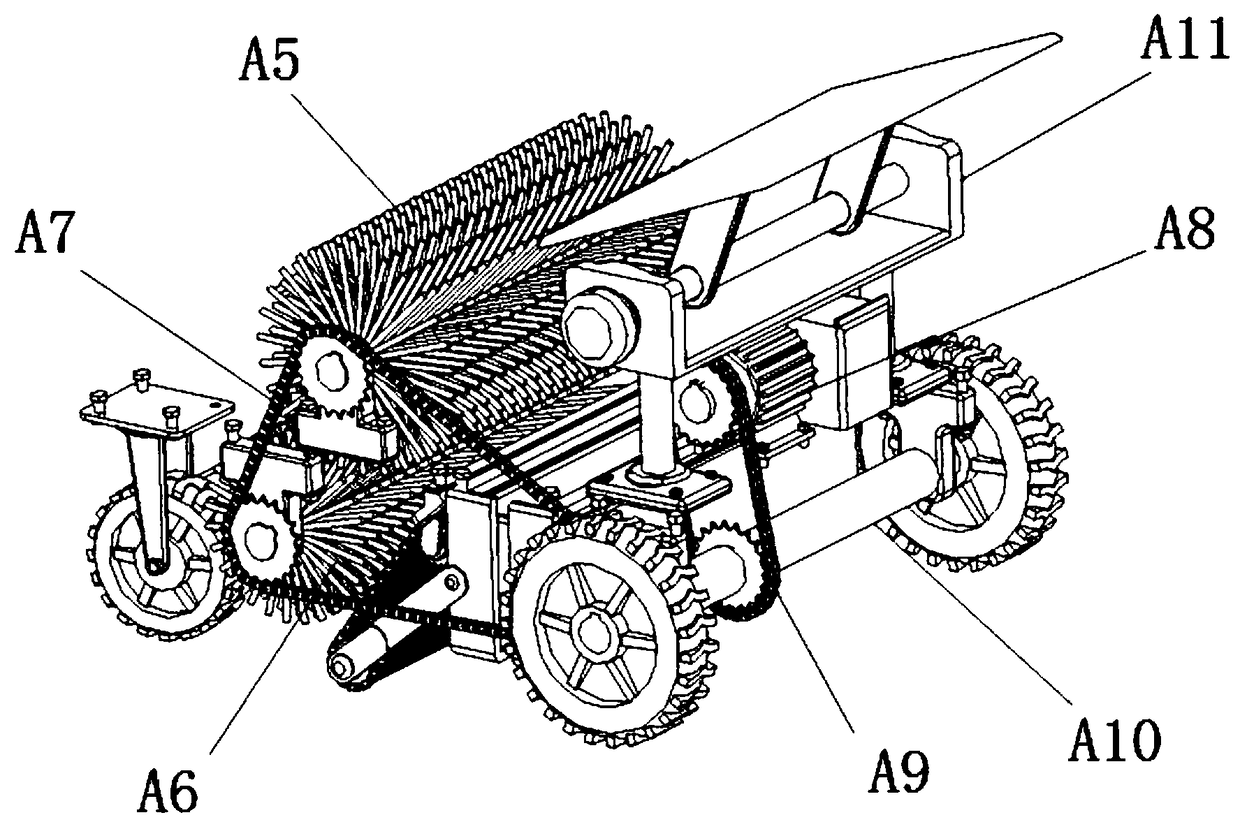

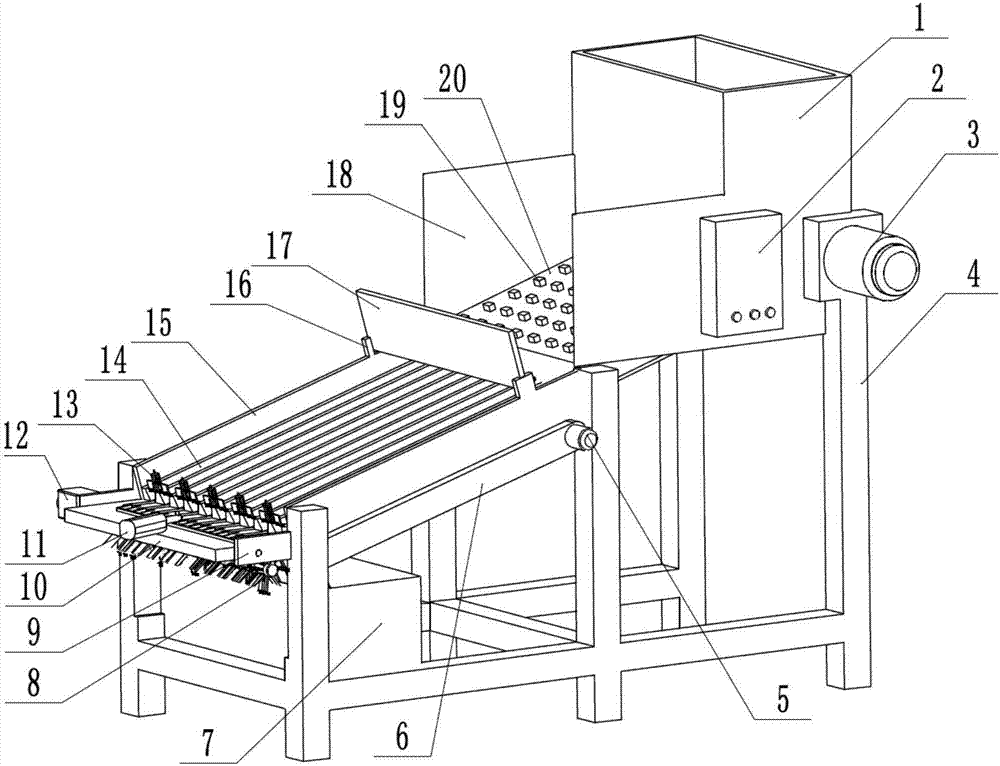

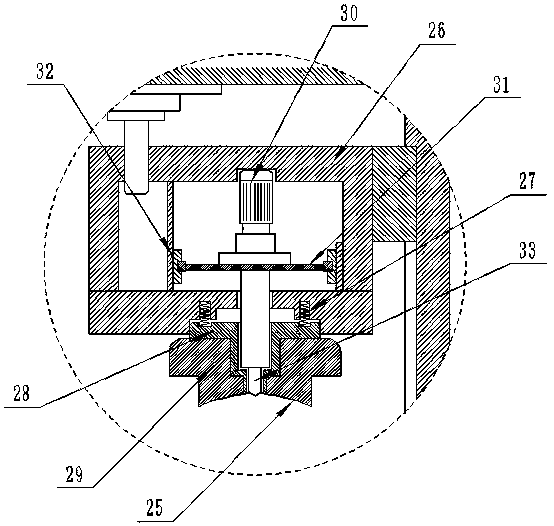

Cone snail tail removing device

The invention provides a cone snail tail removing device and belongs to the field of food machinery. The cone snail tail removing device is composed of a feeding hopper, a controller, a conveying motor, a rack, a sweeping motor, a transmission box, a collection box, sweeping rollers, a lateral base plate, a cutter plate, an air cylinder, a rotary motor, limiting mechanisms, movement guide rods, lateral baffle plates I, height limiting mechanisms, height limiting plates, lateral baffle plates II, lug bosses, a conveyor belt, a sliding column, a push frame, a cutter body, a hinging column, sliding grooves I, groove bodies II, a roller base, sliding grooves III, guide plates, a rotary shaft, roller bases II and bottom frames, wherein the feeding hopper is arranged at the upper end of the rightmost side of the rack; the conveyor belt is arranged at the lower side of the feeding hopper; the lateral baffle plates II are arranged at two sides of the conveyor belt; the lug bosses are distributed on the conveyor belt; the device can be used for efficiently carrying out cone snail tail removing work; reasonable feeding of cone snails is realized through the matching of the conveyor belt and the feeding hopper; the movement guide rods and the sweeping rollers are matched so that posture guide of the cone snails is realized and the height of the cone snails can be effectively limited through the height limiting plates.

Owner:泰安泰山科技有限公司

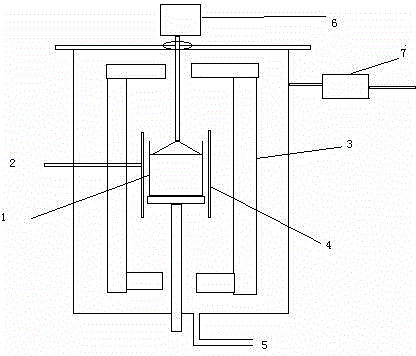

Method for growing large-sized rare-earth-doped barium yttrium fluoride single crystals

InactiveCN104562183ALimit heightImprove integrityPolycrystalline material growthBy pulling from meltRare earthPt element

The invention provides a method for growing large-sized rare-earth-doped barium yttrium fluoride single crystals. The method comprises the following steps: in a heating furnace, putting polycrystals of {xReF3+(1-x)YF3} and BaF2 into a crucible according to a mass ratio, vacuumizing, and introducing argon gas into the heating furnace successively, wherein the mass ratio of {xReF3+(1-x)YF3} to BaF2 is 2 to 1 and x is 0-100%; controlling the heating power by a temperature control instrument to melt the polycrystals, performing heat exchange by flowing of a liquid surface in the crucible and the gas in the furnace to form an axial temperature difference, and forming a radial temperature difference of temperature on a wall of the crucible and temperature in the center of the crucible to cause natural convection of a melt; fixing BaY2F8 seed crystals to a seed crystal rod by a platinum chuck, and lowering the seed crystals to be contacted with the melt for fluoride crystal growth; when fluoride crystals grow to have set sizes, annealing, cooling to the room temperature at a speed of 20 DEG C / hour, adjusting the rotary speed and the heating power, separating the crystals from the melt until the crystal growth is ended, and annealing in the crucible to obtain the large-sized fluoride crystals. The method solves the problems of negative growth factors of difficulty for crystal growth, a large amount of air bubbles in the crystals and the like caused by poor flowability of the fluoride melt.

Owner:SOUTH WEST INST OF TECHN PHYSICS

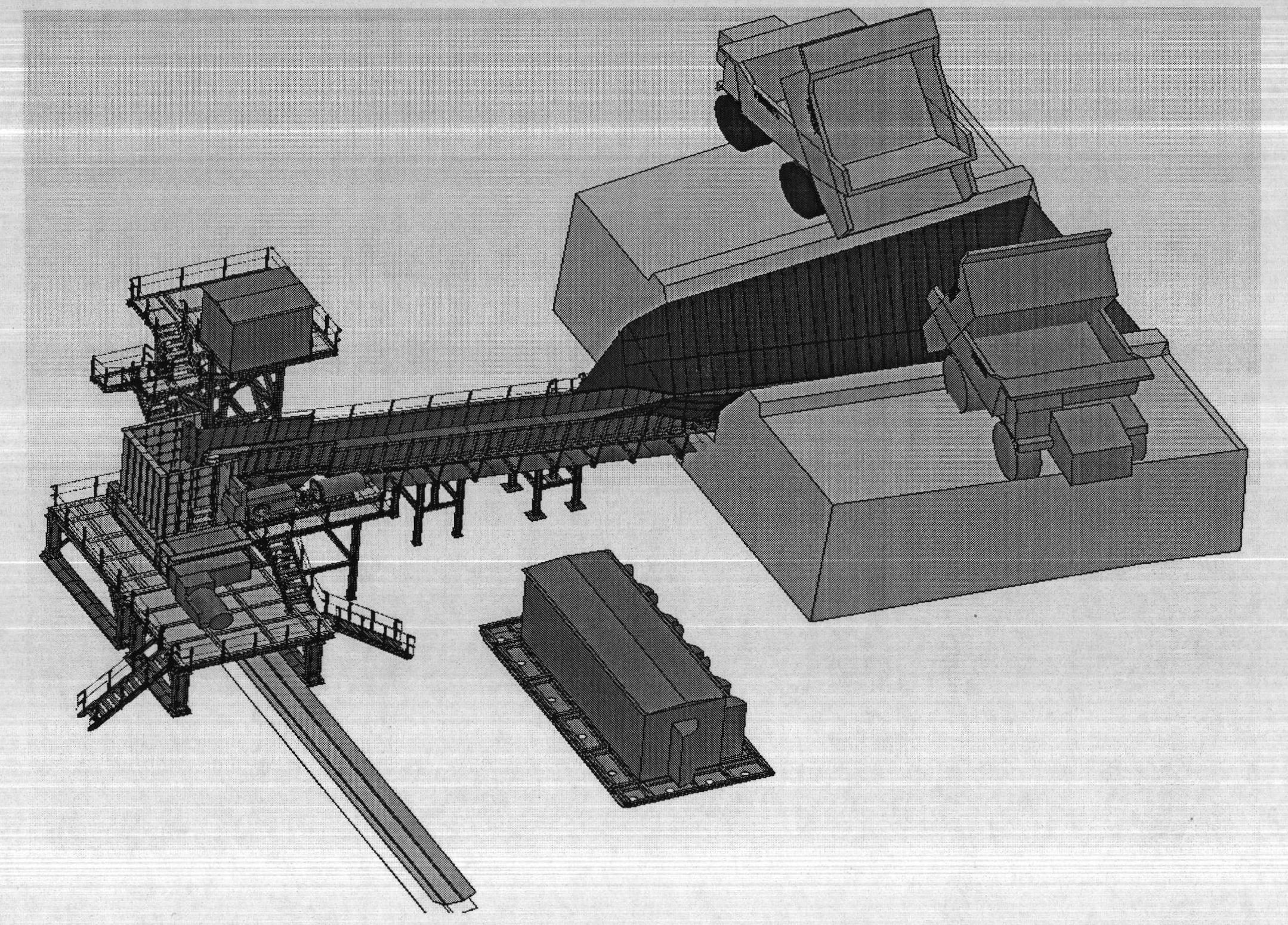

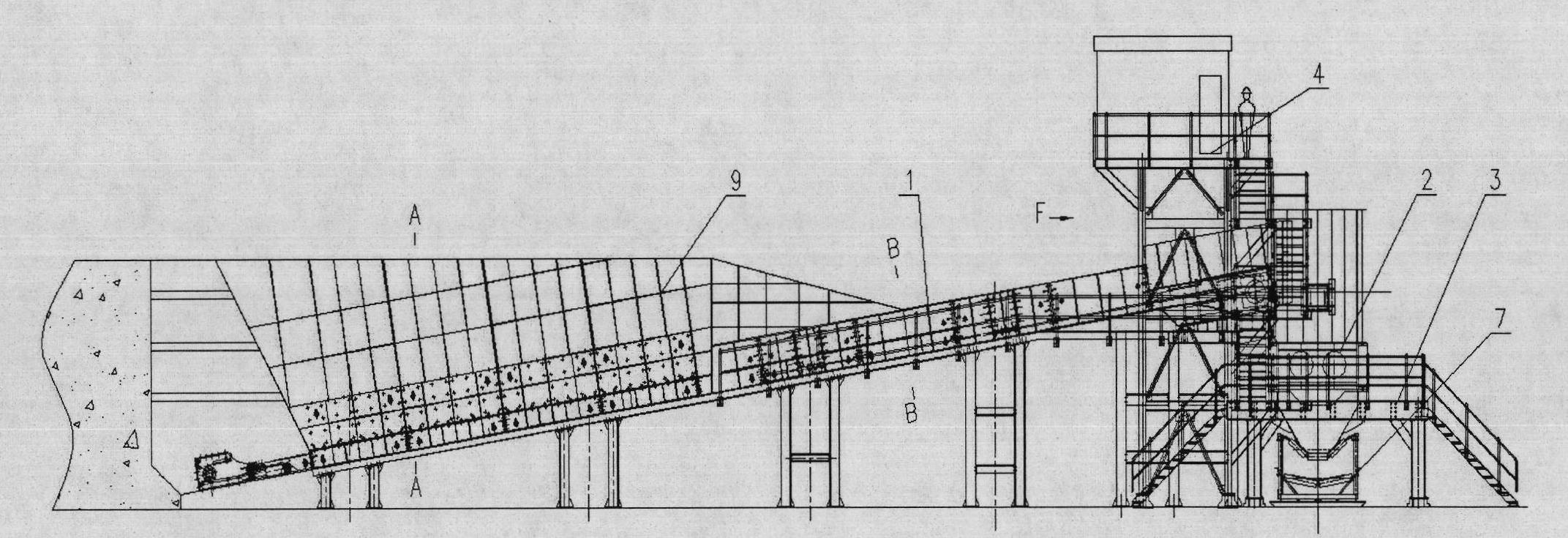

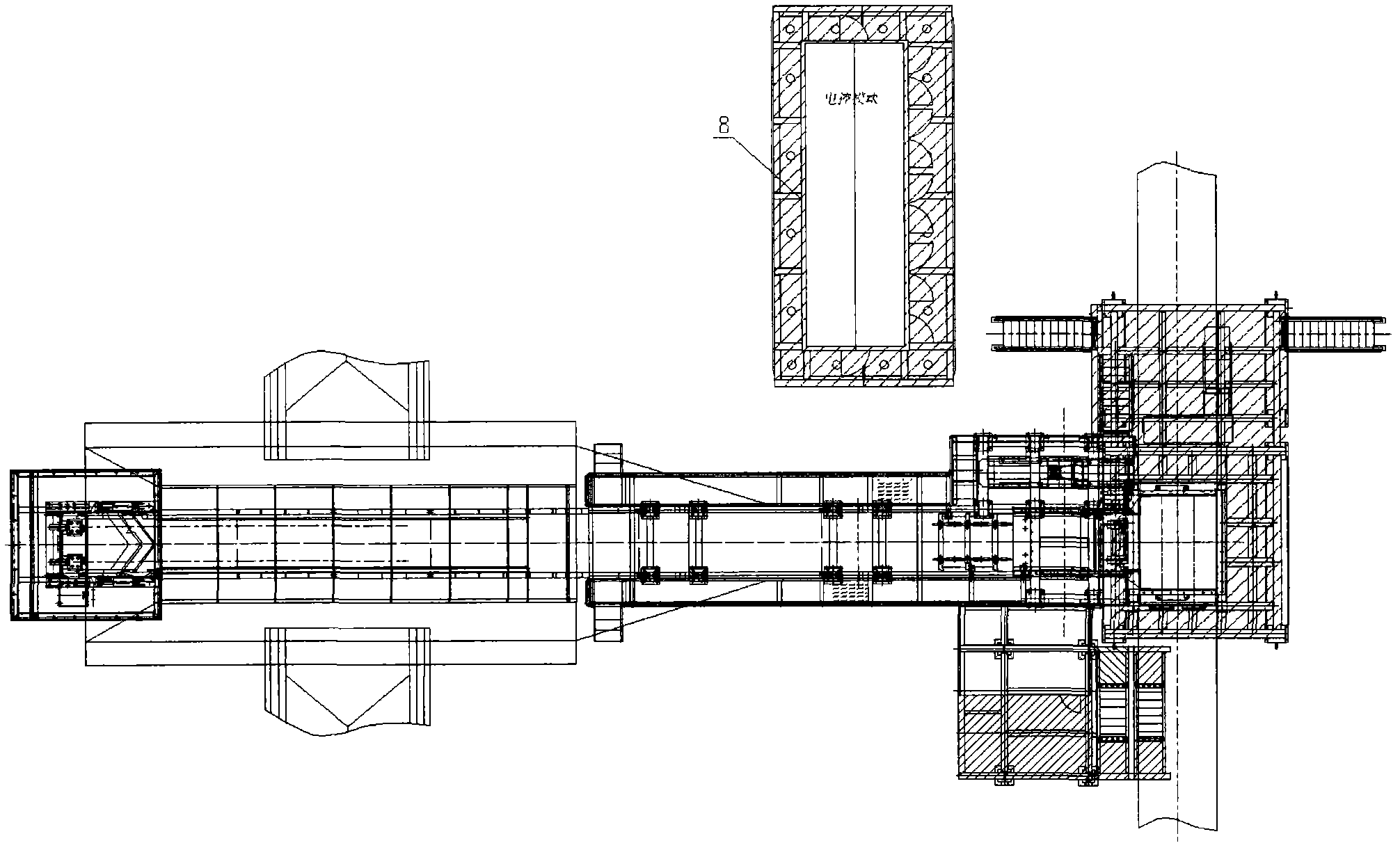

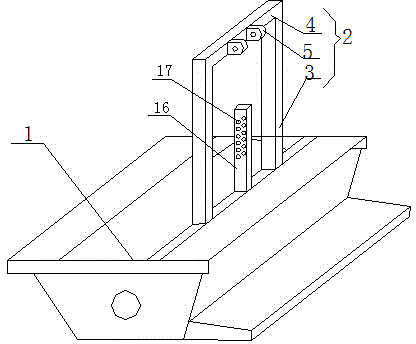

Semi-fixed crushing station

The invention relates to a novel semi-fixed crushing station for raw coal processing in an open pit coal mine, wherein the crushing station mainly consists of a scraper machine, a scraper machine material receiving section coal flow height limiter, a double-tooth-roller crushing machine, a crushing machine support platform, an operation room, a phase change distribution chamber and the like, wherein the scraper machine is in inclined arrangement, the inclined angle is 5 degrees to 11 degrees, the height of a machine head of the scraper machine can be regulated through regulating the length of a hoisting conveying section tank body of the scraper machine or through regulating the inclined angle of the scraper machine, scraper machine material receiving section is provided with a coal flow height limiter, the requirement that the height of the coal layer in the scraper machine is 400 to 700mm is met, the scraper machine adopts the variable-frequency driving, the speed of the scraper machine is regulated according to the height of the coal layer of the scraper machine, all modules are mutually independent, the moving and the installation are convenient, an operation room adopts an independent basis, and the influence on the body and mental health of operators as well as electric control equipment, which is caused by vibration, is reduced. The novel semi-fixed crushing station has the advantages that the starting of the scraper machine is stable, the operation is reliable, the instantaneous overload of the system can be effectively prevented, and the popularization and application values are realized.

Owner:WUHAN DESIGN & RES INST OF CHINA COALTECH & ENG GROUP

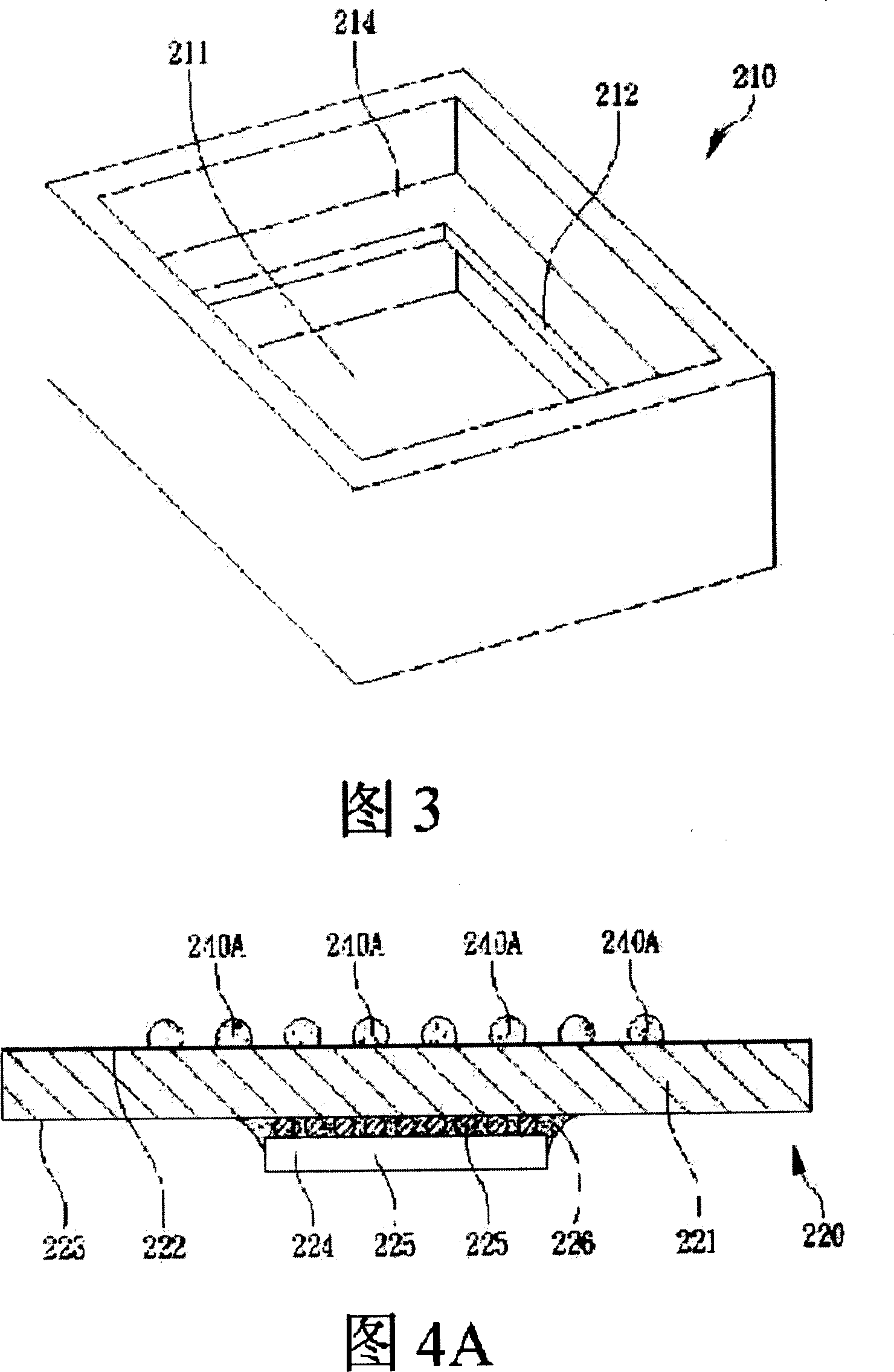

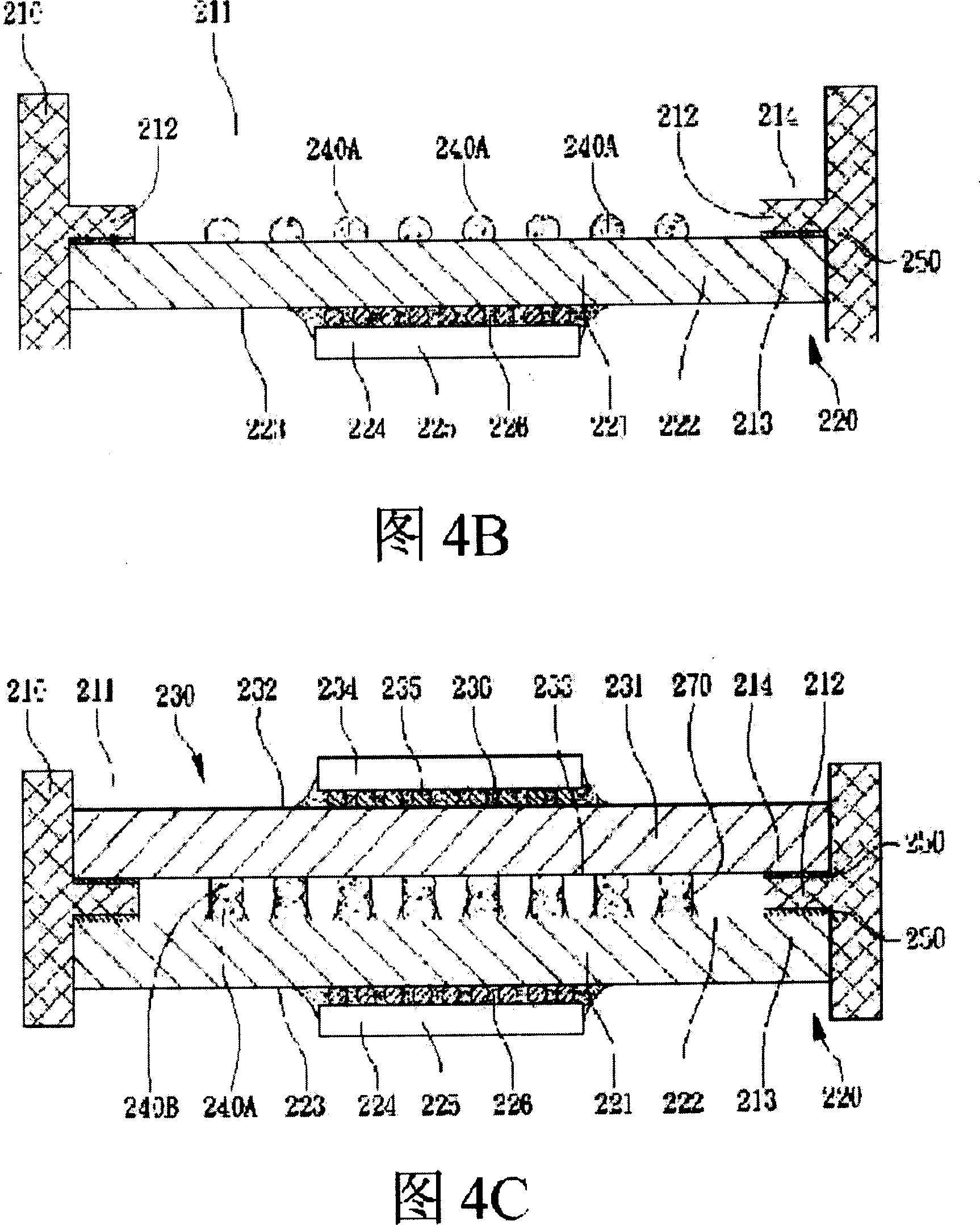

Radiating type stereo package structure and its manufacturing method

ActiveCN101026144AAvoid empty welding or open circuitAvoid warpingSemiconductor/solid-state device detailsSolid-state devicesHeat sinkSolder ball

A heat-radiation solid package structure includes: a heat radiation sheet with an opening, a reinforcement ring set in the opening having a first surface and a second surface, in which, a first base board of a first chip package piece is contained in the opening and set at the first surface of the ring, a second base board of a second package piece is set on the second surface of the ring, and the first base board is connected with the second base board by multiple solder balls, heat generated by the two pieces is radiated by said radiation sheet, and the reinforcement ring can fix the two pieces for preventing that they will generate warp so as to be benefit to the form of solder balls and guarantee electric transmission of the products. This invention also provides a manufacturing method.

Owner:ADVANCED SEMICON ENG INC

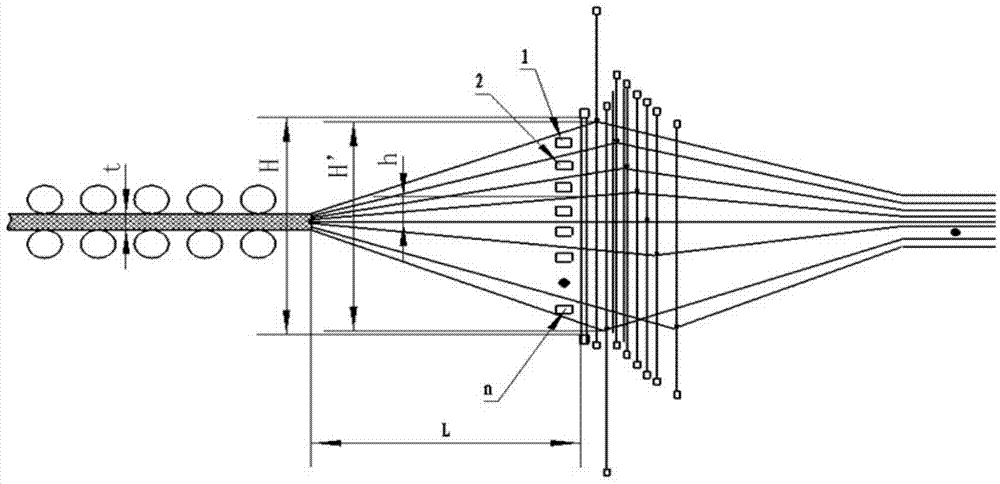

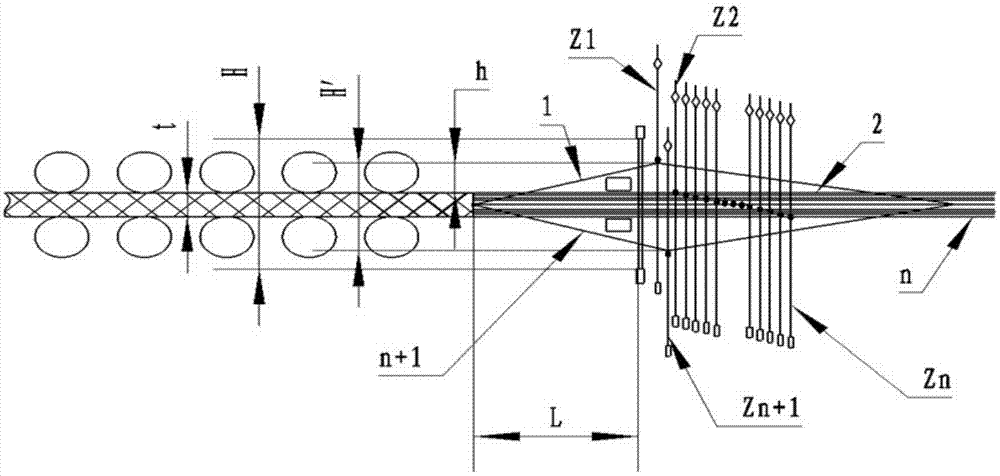

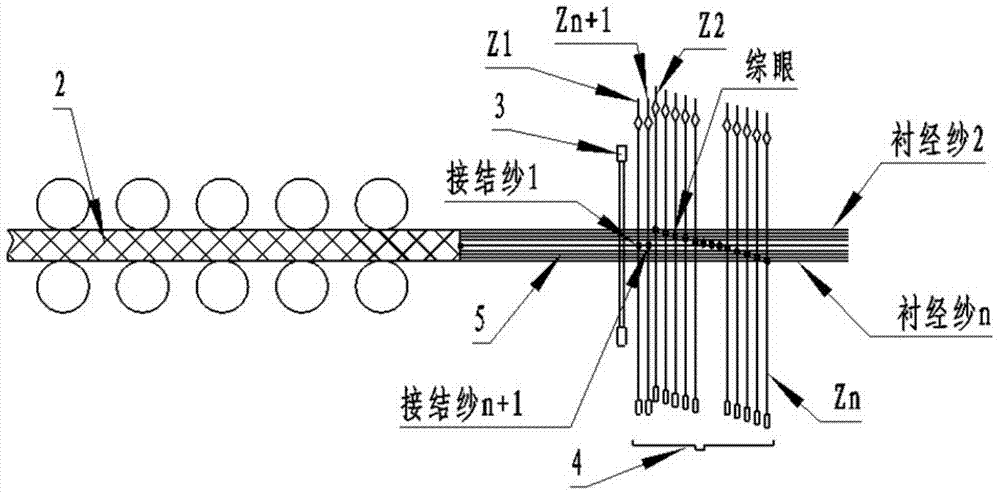

Weaving method of multilayer three-dimensional fabric

The invention provides a weaving method of a multilayer three-dimensional fabric. By opening and guiding wefts layer by layer, the warp drafting manner and opening and weft guiding rules are changed, the problem that the multilayer fabric reed height and the beating up stoke are excessive large is solved, the maximum distance between the top layer of warps and the bottom layer of warps is shortened during opening, strict limits of layers of the fabric are avoided, the layers of the fabric is increased as several times of the original, wear times between warps and harness wires and between warps are reduced, warp breakage rate is decreased, and operating efficiency of a spinner and fabric quality are improved.

Owner:JINGWEI TEXTILE MASCH CO LTD

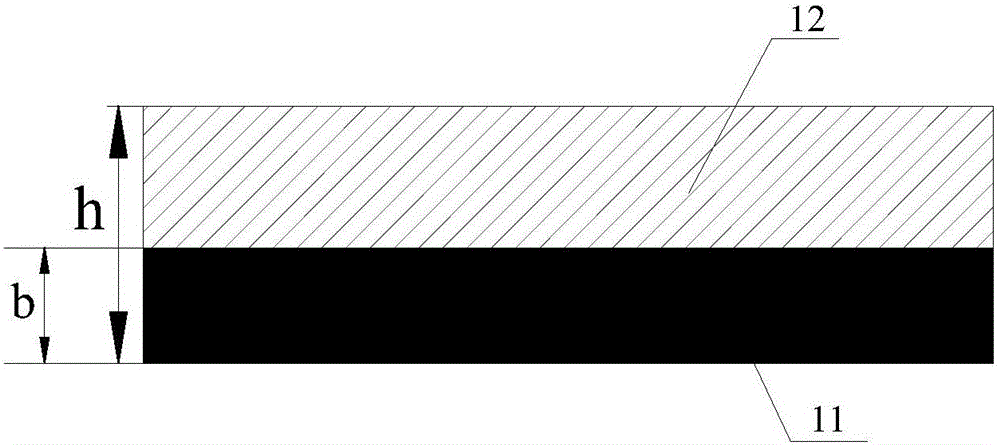

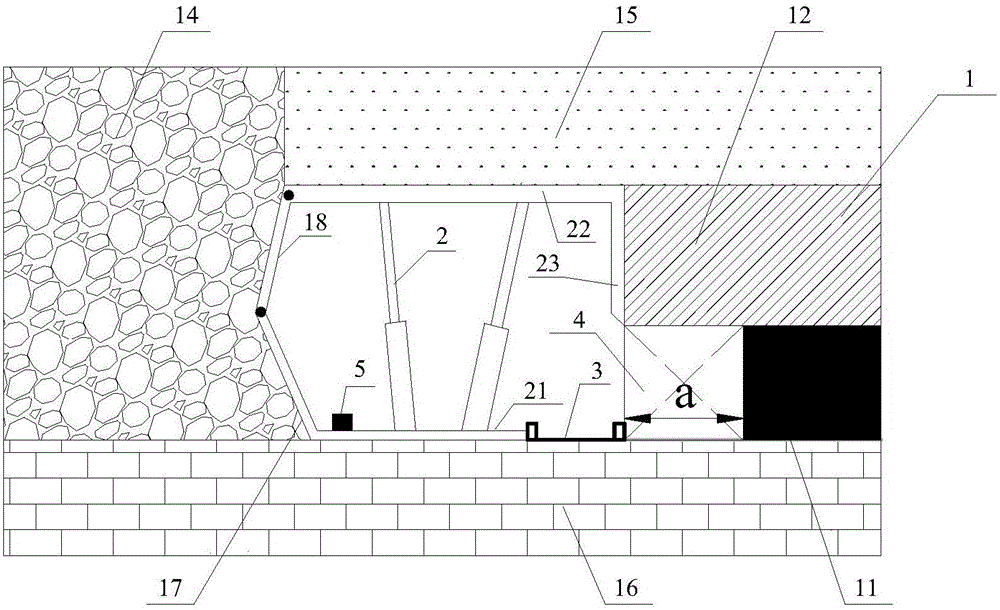

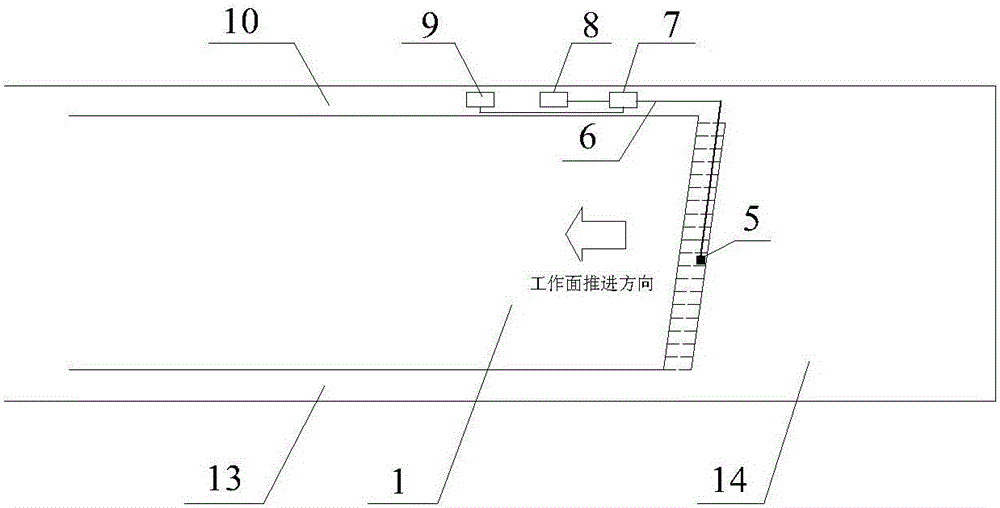

Full-seam extraction method for stoping bottom layering of shallow extremely thick loose coal seam

InactiveCN105927225AReduce coal cutting workloadEasy to operateUnderground miningSurface miningFilling materialsCoal

The invention provides a full-seam extraction method for stoping bottom layering of a shallow extremely thick loose coal seam. The full-seam extraction method comprises the following steps: (a) scientifically dividing an extremely thick loose coal seam; (b) arranging roadways and equipment according to a conventional solid filling mining method so as to form a filling mining system; (c) cutting down the coal seam; (d) filling coal goafs; (e) recycling coal of upper inbreaking coal layers; (f) repeating the steps, and circulating in sequence, thereby completing recycling of the coal seam of a whole section. By adopting the full-seam extraction method for stoping bottom layering of the shallow extremely thick loose coal seam, the coal cutting workload is reduced, limits of conventional filling materials are avoided, the synchronous operation of coal cutting and filling is achieved, and the purposes of sustainable development and green mining in the western areas are achieved; the full-seam extraction method is simple to operate, safe and reliable, high in efficiency, and very high in application and popularization values in ecologically fragile areas in the western China.

Owner:ANHUI UNIV OF SCI & TECH

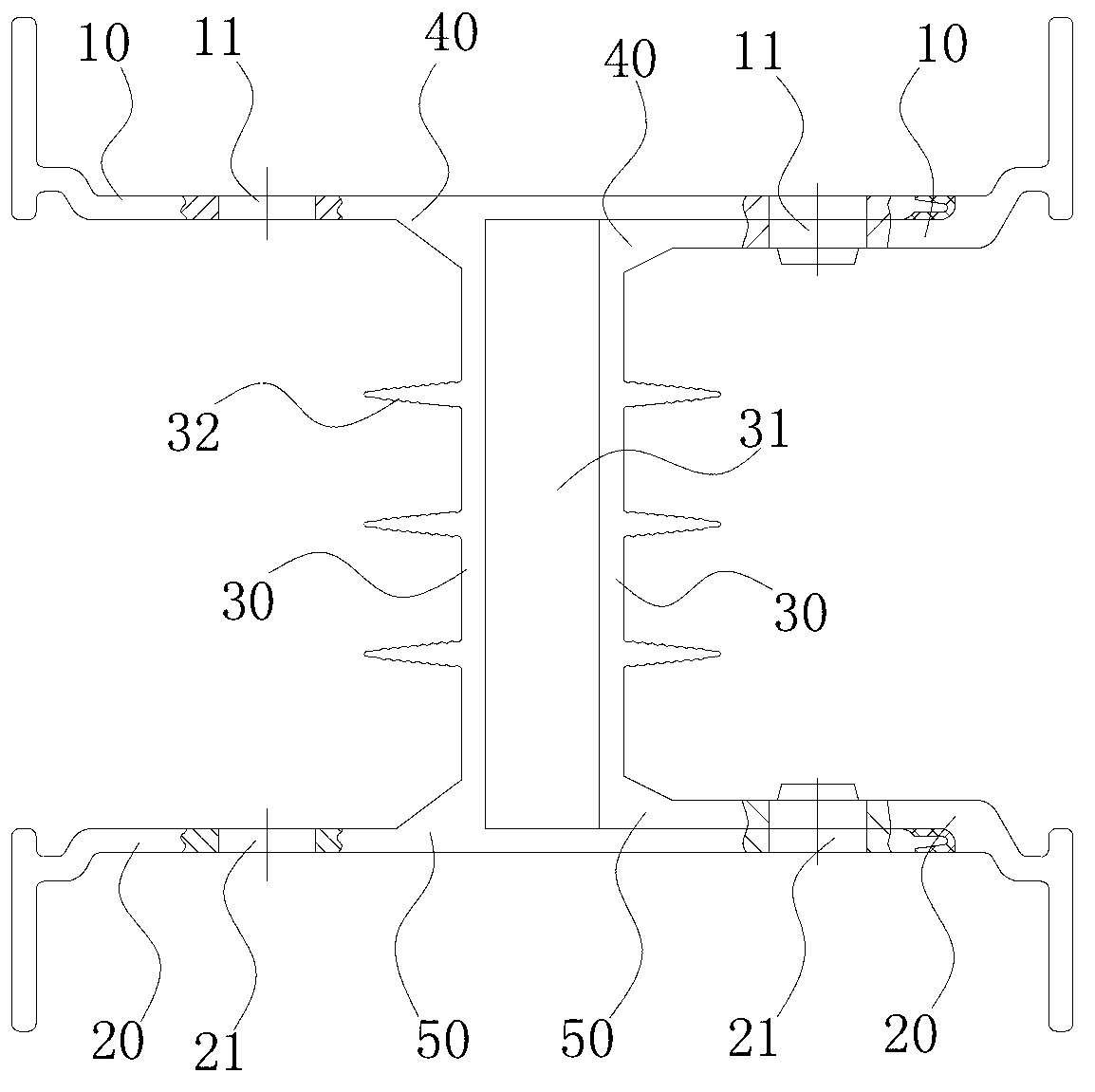

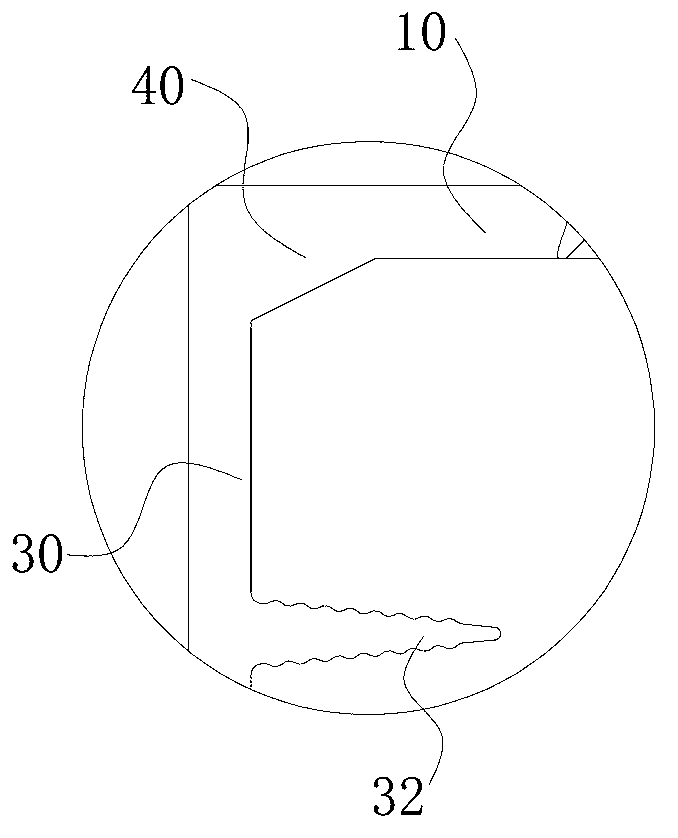

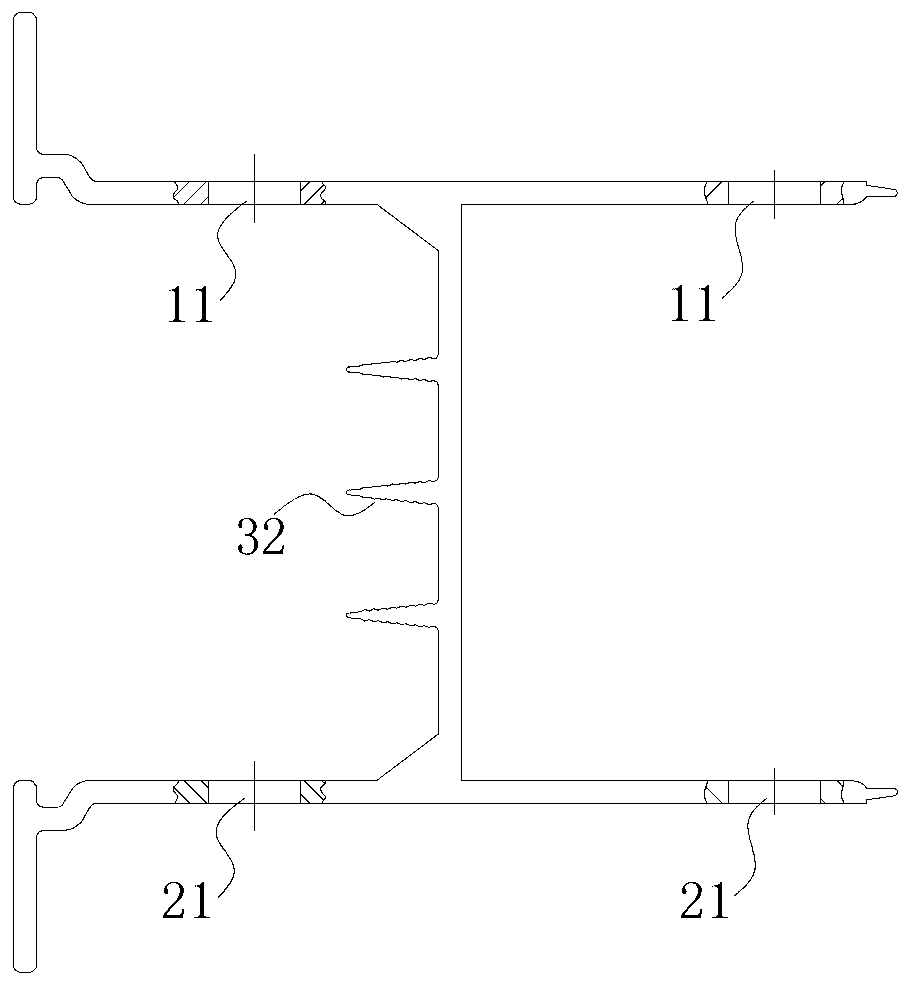

Busway shell

InactiveCN102801125APromote exchangeImprove cooling effectCooling bus-bar installationsPartially enclosed bus-bar installationsEngineeringConvection

The invention discloses a busway shell comprising two upper plates, two lower plates and two side plates, wherein the two side plates are located between the upper plates and the lower plates; a bus laying position is formed between the two side plates; a region formed between each upper plate and each lower plate is a heat radiating region; the two upper plates are provided with upper convection holes; the lower plates are provided with lower convection holes; the upper convection holes are located above the heat radiating regions; and the lower convection holes are located below the heat radiating regions. By using the busway shell, the heat radiating effect of the busway shell can be improved, the reliability of the busway shell can be improved, and the service life of the busway shell can be prolonged.

Owner:广州市半径电力铜材有限公司

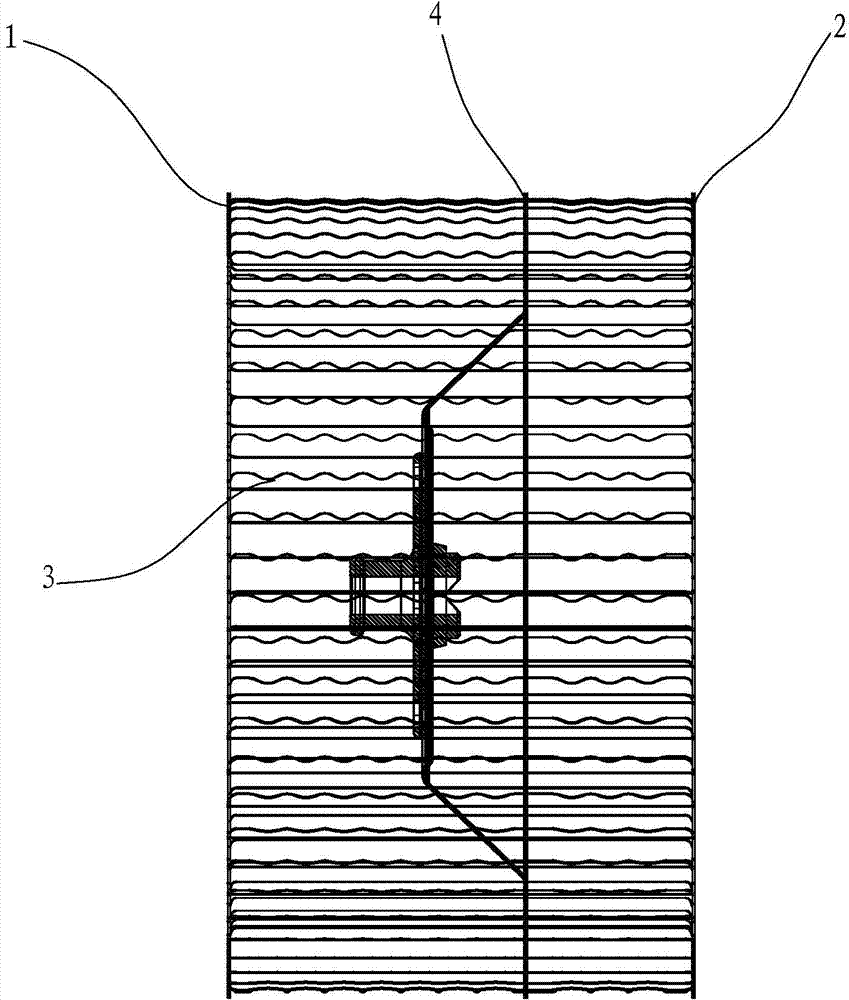

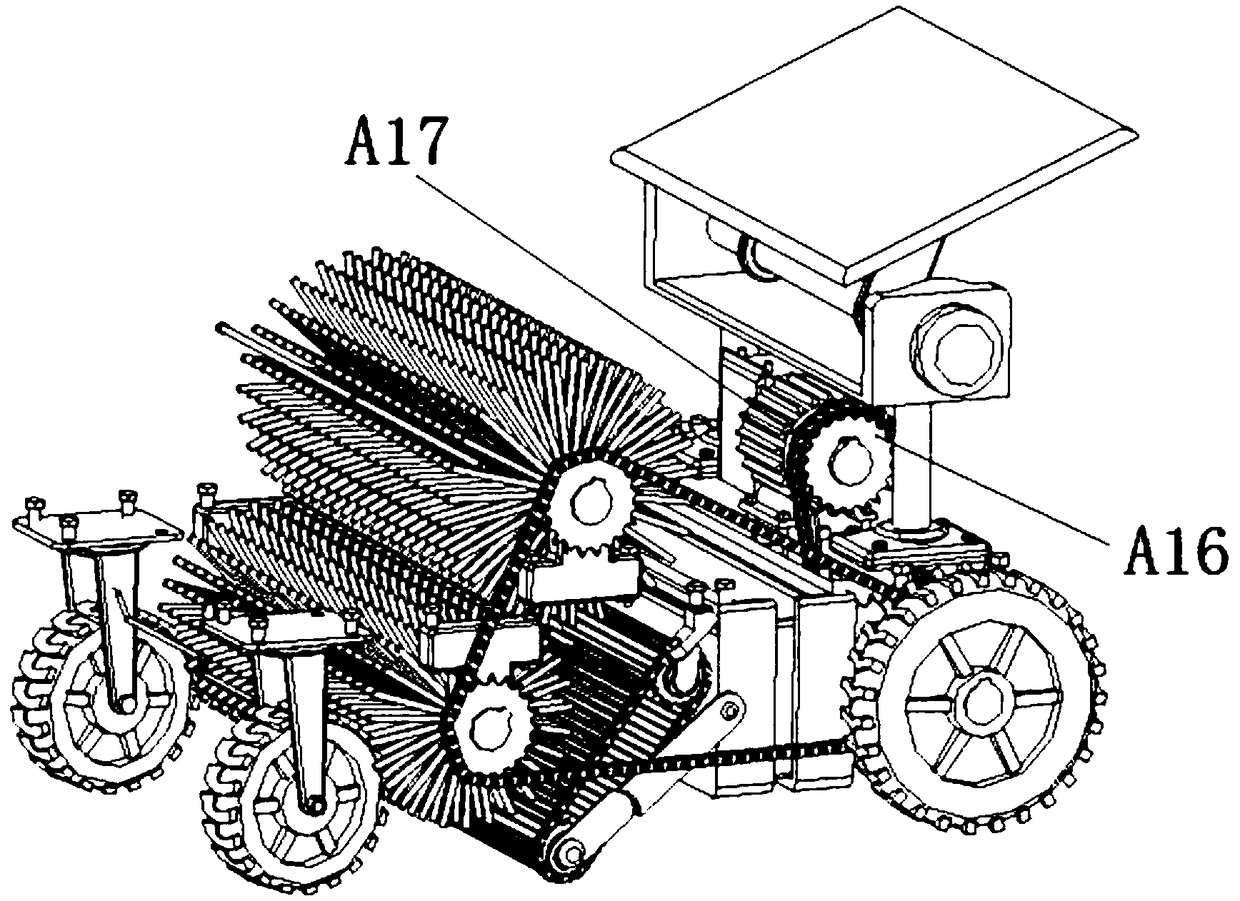

Preposed straw returning machine

ActiveCN104904426AAvoid the disadvantage of poor field return effectLimit heightCrop conditionersMowersHydraulic cylinderPulp and paper industry

The invention relates to the technical field of machinery, and discloses a preposed straw returning machine, which comprises a straw returning machine body, wherein the straw returning machine body comprises a rack; a connecting part is arranged on the rear part of the rack, and comprises two rectangular pipes arranged on the rack; a beam is arranged on the rectangular pipes; the rectangular pipes and the beam form a frame; height regulation lugs are further arranged on the frame; a hydraulic cylinder is arranged below the lugs. The preposed straw returning machine further comprises a mounting frame, wherein the mounting frame comprises a piece of first channel steel which has a backward opening and is transversely arranged; first screw holes are formed in the two sides of the upper and lower parts of the first channel steel; fixed plates are further arranged behind the first channel steel; second screw holes are formed in the two ends of the fixed plates; the first screw holes correspond to the second screw holes, and are connected with the second screw holes through screws; a connecting part of the hydraulic cylinder, the hydraulic cylinder and the like are arranged on the first channel steel. The preposed straw returning machine has the advantages of convenience in use and capability of meeting certain production requirements.

Owner:HENAN KAINONG MACHINERY

Method for cultivating single-cave rice seedlings for mechanical rice transplanting

InactiveCN104255360AImprove the quality ofSeedling leaf density is suitableRice cultivationTransplantingOryza sativa

The invention discloses a method for cultivating single-cave rice seedlings for mechanical rice transplanting. The age of the single-cave rice seedlings is 35-45 days, the leaf age is 4-7 leaves, and the seedling height is not greater than 250mm. The method comprises the following steps: (1) selecting high-quality seeds and preparing cave discs, wherein the mouth of each bowl on the cave discs is 14-18mm in length and 14-18mm in width, the bottom of each bowl is 11-15mm in length and 11-15mm in width, and the depth of each bowl is 22-28mm; (2) filling cultivation soil inside the bowls of the cave discs, wherein the cultivation soil inside each bowl accounts for 2 / 3 of the volume of each bowl; (3) planting seeds in the cave discs, and covering cultivation soil of 3-5mm in thickness into the cave disc bowls subjected to seeding, wherein the number of seeds in each bowl is 1-4; (4) placing the cave discs subjected to seeding on a seedbed, and performing seedling management in a dry nursery seedling management mode. By adopting the method, compact winding of rice seedling root systems is achieved in a single-cave low-density seedling manner, the height of rice seedlings is limited, the requirements of mechanical rice transplanting of bowl-shaped blanket-shaped rice seedlings are met, and the yield increase advantages can be brought into play.

Owner:CROP INST SICHUAN PROVINCE ACAD OF AGRI SCI

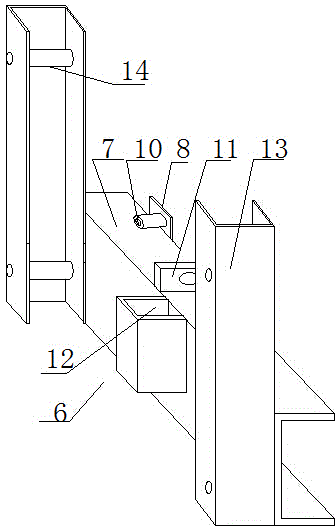

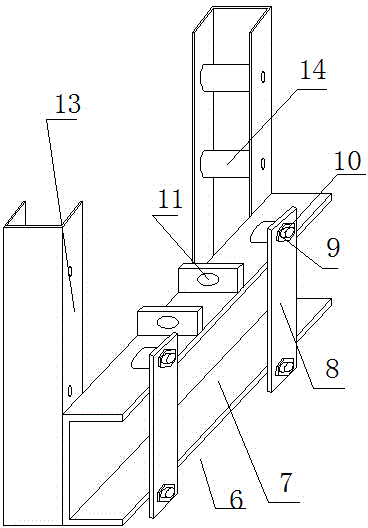

Automatic lighter gas tank feeding device

The invention discloses an automatic lighter gas tank feeding device, which comprises a first spacing sliding chute, a bottom tank and a support plate. The first spacing sliding chute is formed in thetop part of the bottom tank; a movable tray is arranged on a surface of the first spacing sliding chute; a conveyor belt is arranged on the top part of the bottom tank on the inner side of the firstspacing sliding chute; support columns are arranged on the top part of the bottom tank at two sides of the first spacing sliding chute; the support plate is arranged on the top parts of the support columns; an air charging pump is arranged on the top part of the support plate; anti-explosion hose pipes are arranged on the bottom part of the support plate; an installation plate is arranged on the tail ends of the anti-explosion hose pipes; electromagnetic nozzles are arranged on the bottom part of the installation plate; a control electricity box is arranged in the bottom tank; and a servo motor is arranged in the bottom tank on one side of the control electricity box. According to the automatic lighter gas tank feeding device provided by the invention, through arranging a series of structures, multiple lighter gas tanks can be fed simultaneously by the device during a feeding process, so that the production efficiency and the feeding accuracy are improved, and the device is convenientto use.

Owner:涟水新邦电子有限公司

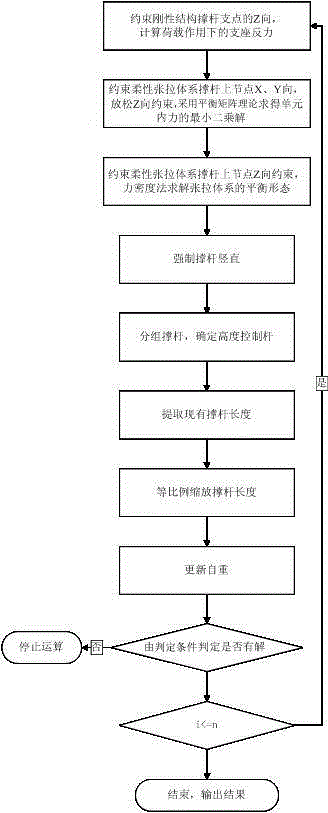

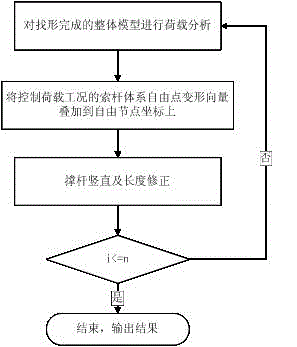

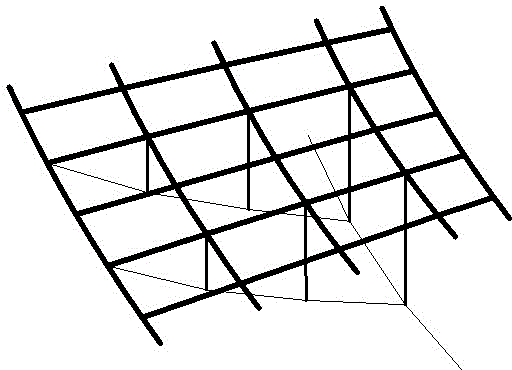

Shape finding method of large-opening cable-supported lattice structure

ActiveCN103953116AFix form-finding resultsReasonable supportBuilding constructionsGymnasiumEngineeringStructure system

The invention discloses a shape finding method of a large-opening cable-supported lattice structure. The shape finding method has the advantages that the reasonable support on an upper rigid system by a lower tensioning cable rod system can be realized, the vertical state of a support rod of the tensioning cable rod system can be maintained, the height of the support rod is limited, the attractive building effect is reached when the stress is reasonable, and the shape finding result of the cable rod system can be further corrected, so the structure system can be suitable for various load work conditions, and the stress is more reasonable.

Owner:CHINA SOUTHWEST ARCHITECTURAL DESIGN & RES INST CORP LTD

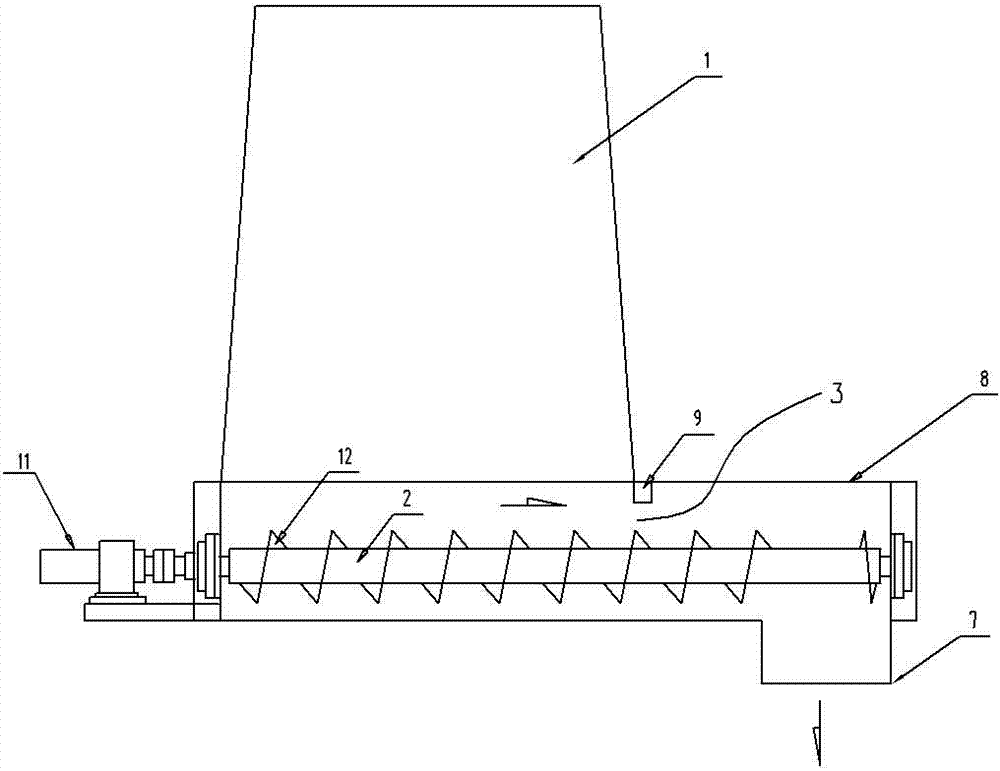

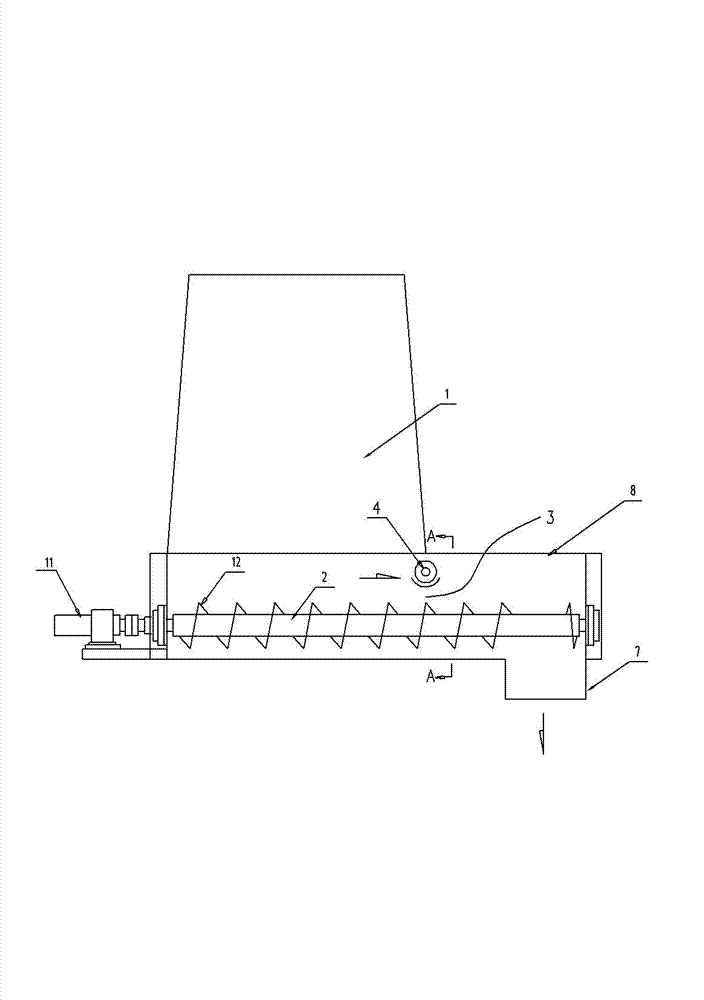

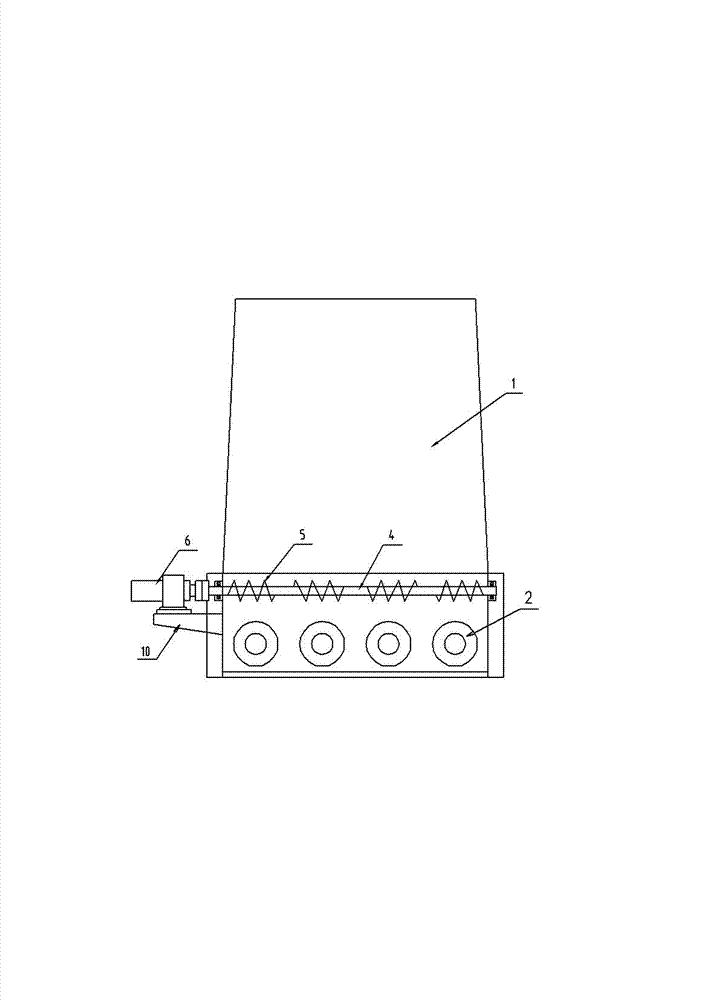

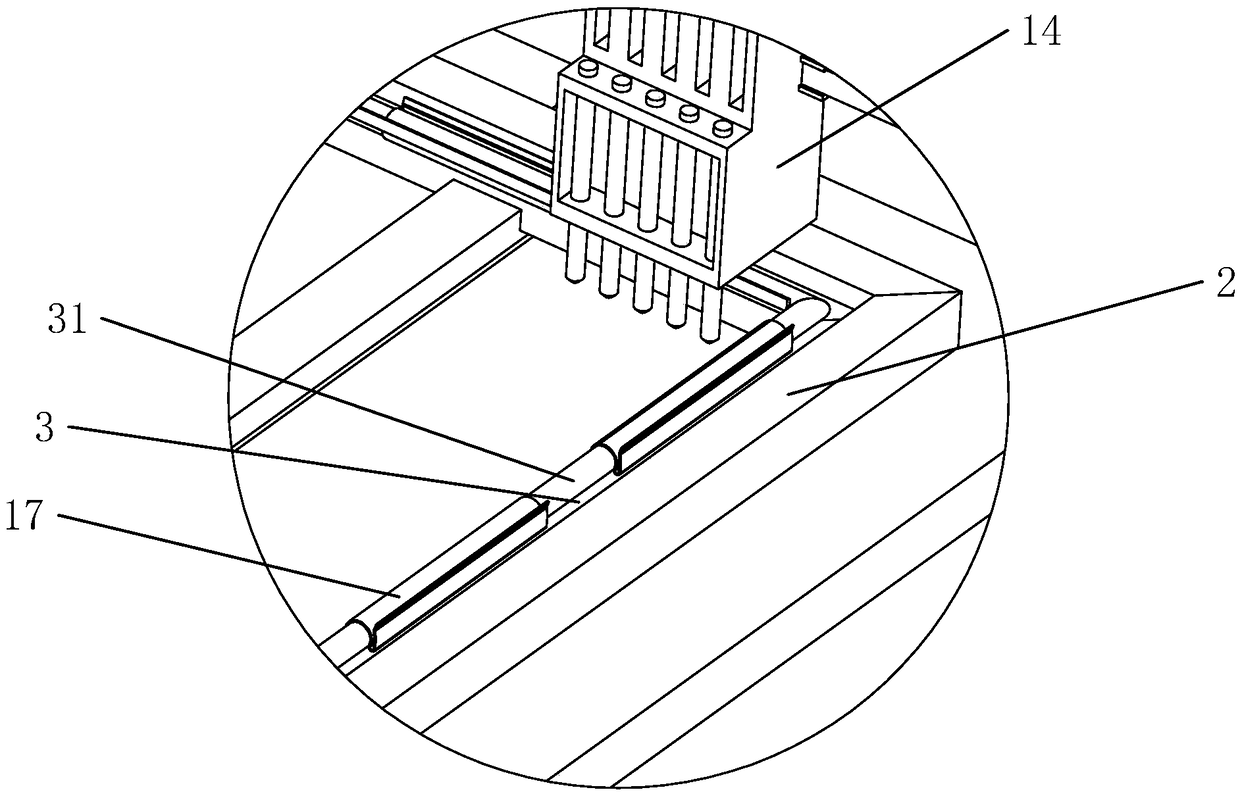

Horizontal anti-blocking conveying structure for raw biomass materials

The invention relates to the field of a raw biomass material conveying device, and in particular relates to a horizontal anti-blocking conveying structure of raw biomass materials, which can effectively maintain the continuous transmission of the raw biomass materials at a bin outlet so as to ensure the normal conveying work of the raw biomass materials in a bin. The horizontal anti-blocking conveying structure of the raw biomass materials comprises the bin, a trough and a horizontal conveying device of the raw biomass materials, wherein a fixed outlet is formed at one end of the bottom of the bin; the trough is located at the bottom of the bin and passes through the fixed outlet; the horizontal conveying device comprises a spiral shaft; the spiral shaft passes through the trough along a transverse direction, and one end part of the spiral shaft is connected with a conveying driving device; and the spiral shaft is provided with a spiral blade. The horizontal anti-blocking conveying structure is characterized in that an anti-blocking device is arranged on the trough, is located at the fixed outlet of the bin and is arranged above the horizontal conveying device.

Owner:WUXI XIDONG ENERGY TECH

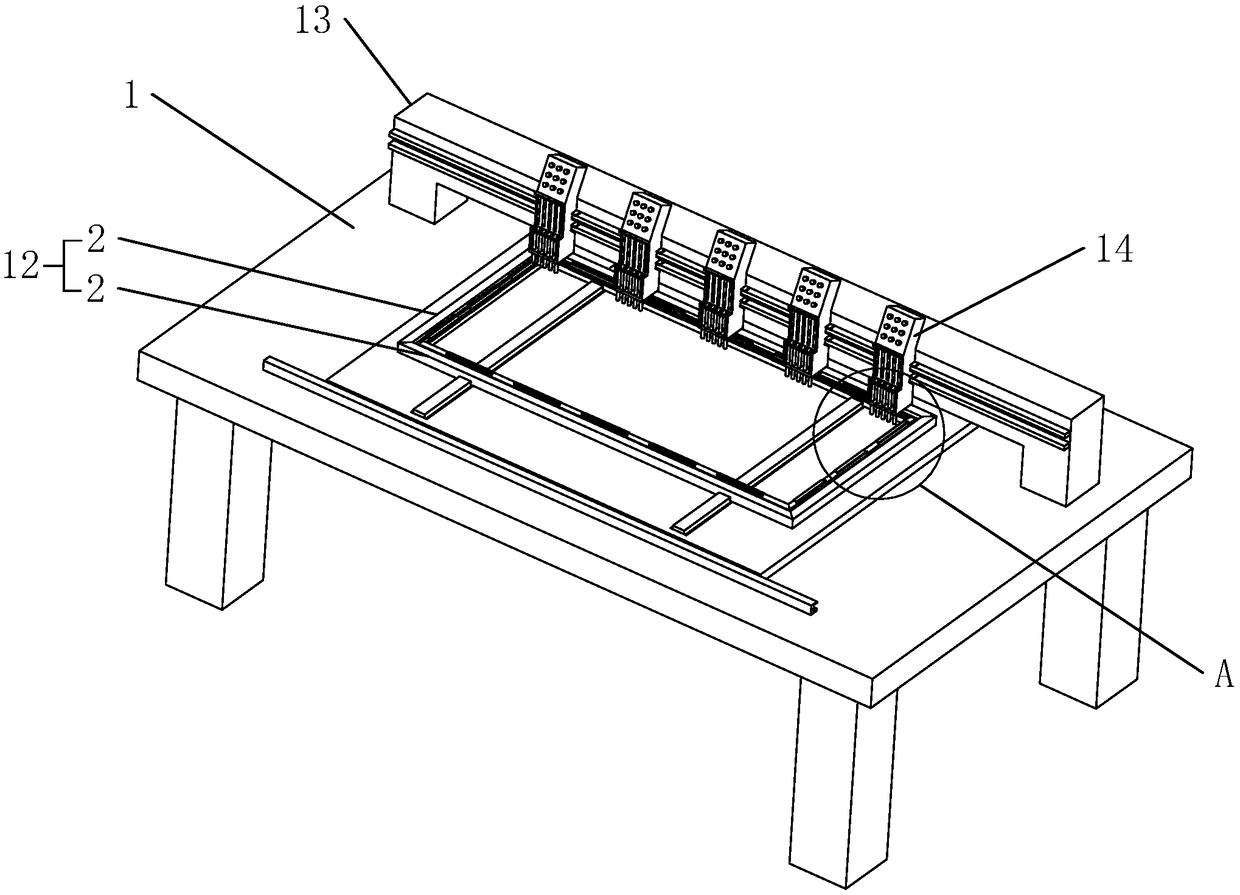

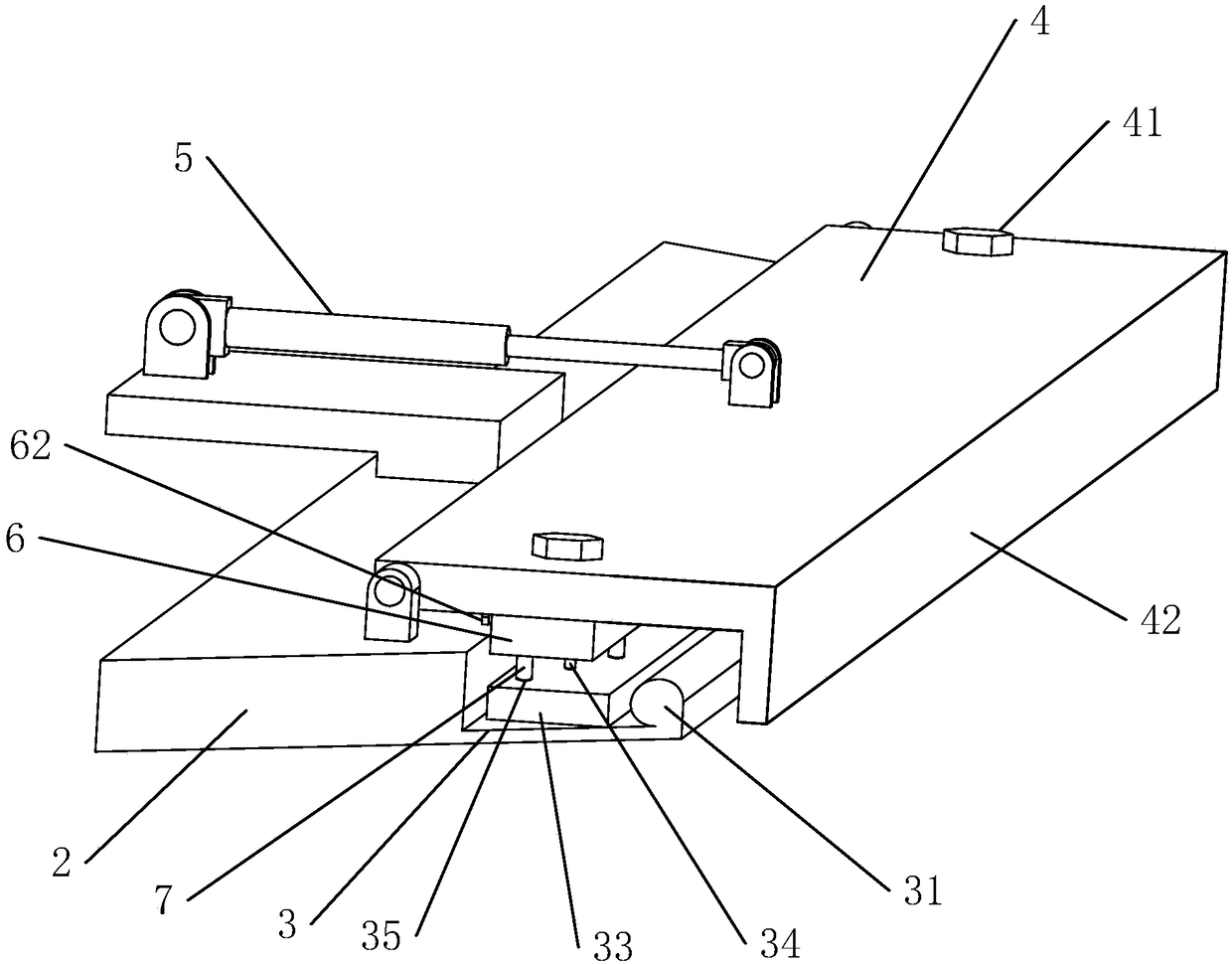

Embroidery machine and embroidery machine cloth fixing device

The invention relates to the technical field of embroidery machines, and discloses an embroidery machine and an embroidery machine cloth fixing device. The embroidery machine cloth fixing device comprises a fixing groove arranged in a fixed frame and extending along the length direction of the fixed frame, a pressing plate arranged on the fixed frame and a driving mechanism for driving the pressing plate to make the pressing plate press the fixed groove. The driving mechanism is used to drive the pressing plate to rotate or move up and down in order to realize the opening and closing of the pressing plate, and the edge of the cloth is pressed between the fixing groove and the pressing plate when the pressing plate is closed, so troubles brought by fixation of the cloth through using a lotof cloth clips by embroidery workers' hands are reduced, and the labor intensity is reduced.

Owner:徐剑清

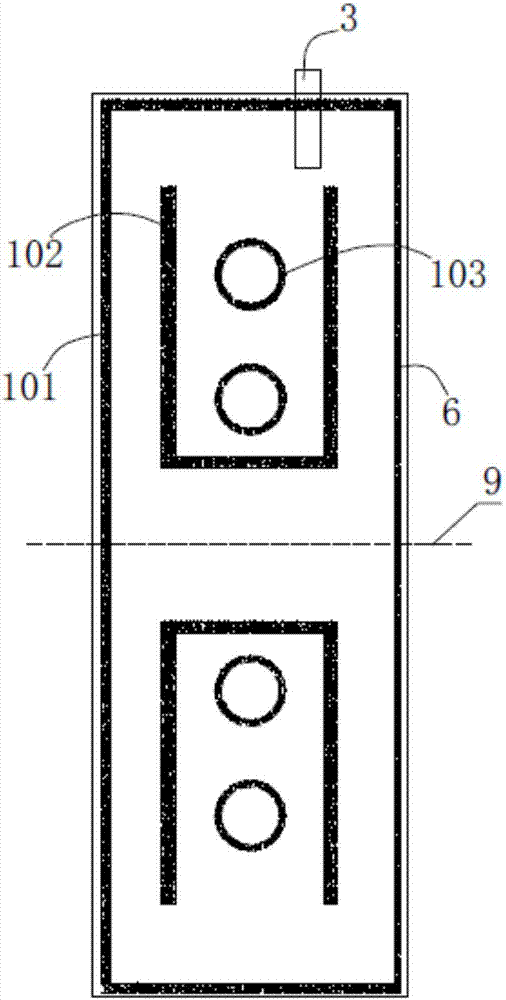

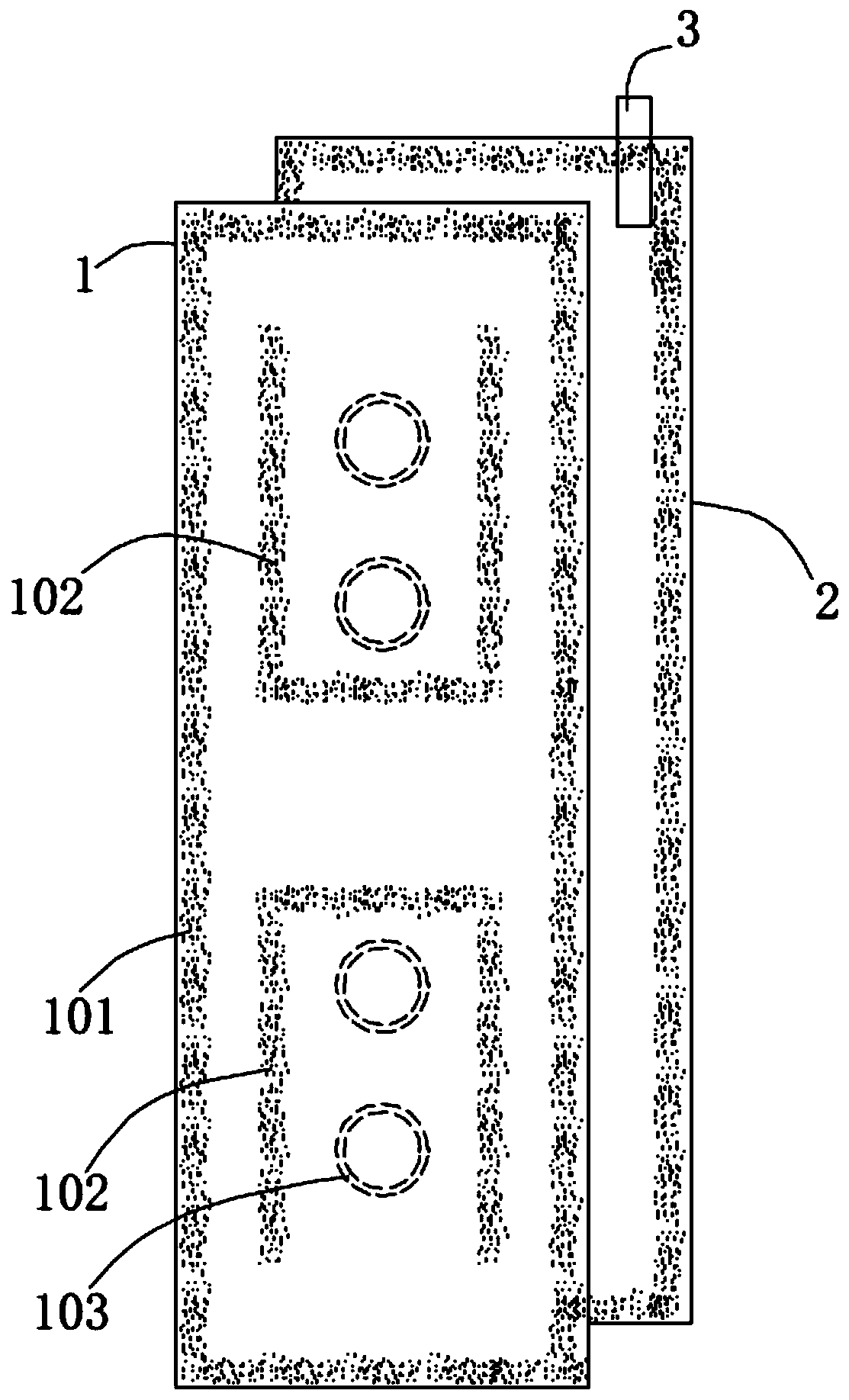

Manufacturing method of hot-melt sealing inflation shakeproof packaging bag and hot-melt sealing inflation shakeproof packaging bag

ActiveCN106986102ALimit heightSo as not to damageContainers to prevent mechanical damageHot meltEngineering

The invention discloses a manufacturing method of a hot-melt sealing inflation shakeproof packaging bag and the hot-melt sealing inflation shakeproof packaging bag. The hot-melt sealing inflation shakeproof packaging bag comprises a first square hot melt film, a second hot melt film identical with the first hot melt film in shape, and a check valve arranged between the first hot melt film and the second hot melt film. By arranging a U-shaped second hot melt zone, a U-shaped air channel forms a U-shaped air column after inflation, on the one hand, through restrict of hot melt connection, the heights of the two sides of the packaging bag are limited to a certain degree, and thus the space is saved; and on the other hand, the U-shaped air column can form an edge protection zone. By arranging a third hot melt zone, through restrict of hot melt connection likewise, the height of the middle of the packaging bag is limited to a certain degree, and thus the space is saved. By forming air holes in the third hot melt zone, the effect that objects do not go bad or cannot be damaged in a certain period can be ensured.

Owner:SHENZHEN DINGLISHENG TECH

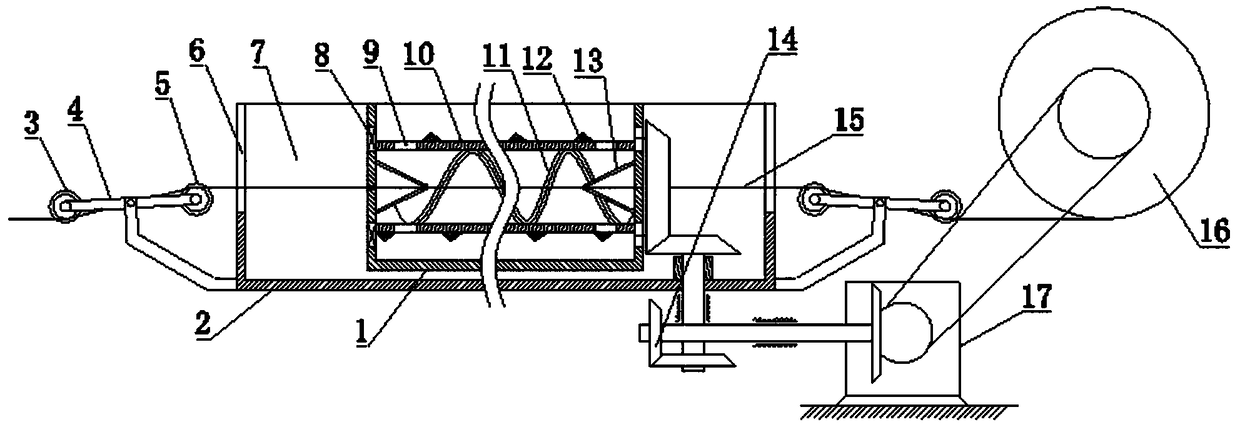

Data wire processing cooling device

ActiveCN109192390AUniform flowGood effect of cooling and stress reliefCable/conductor manufactureThermodynamicsElectric machine

The invention discloses a data wire processing cooling device in the data wire processing field, includes a cooling mechanism and a winding mechanism, A take-up mechanism is connected with a driving motor, the cooling mechanism includes a water tank with an upper end opening, A water tank includes an inlet end and an outlet end, both the inlet and outlet ends of the water tank are provided with sealing plates, the middle part of the seal plate is provided with through holes, A countercurrent pipe is arranged in the water tank, The inner wall of the counter-current pipe is provided with spiralribs facing the inlet end, the outer wall of the counter-current pipe is provided with spiral ribs facing the outlet end, the connecting line of the through holes at the two ends of the water tank islocated on the axis of the counter-current pipe, the two ends of the counter-current pipe are rotatably connected on the sealing plate, the side walls of the two ends of the counter-current pipe are provided with openings, and the counter-current pipe is connected with the driving motor. The invention can solve the problem that the water temperature unevenness after the existing water tank is usedfor a period of time deteriorates the cooling and stress relieving effect of the wire core.

Owner:昆山羿冠电子科技有限公司

Method for making hot-melt sealed inflatable shockproof packaging bag and a hot-melt sealed inflatable shockproof packaging bag

ActiveCN106986102BLimit heightSo as not to damageContainers to prevent mechanical damageEngineeringHot melt

The invention discloses a manufacturing method of a hot-melt sealing inflation shakeproof packaging bag and the hot-melt sealing inflation shakeproof packaging bag. The hot-melt sealing inflation shakeproof packaging bag comprises a first square hot melt film, a second hot melt film identical with the first hot melt film in shape, and a check valve arranged between the first hot melt film and the second hot melt film. By arranging a U-shaped second hot melt zone, a U-shaped air channel forms a U-shaped air column after inflation, on the one hand, through restrict of hot melt connection, the heights of the two sides of the packaging bag are limited to a certain degree, and thus the space is saved; and on the other hand, the U-shaped air column can form an edge protection zone. By arranging a third hot melt zone, through restrict of hot melt connection likewise, the height of the middle of the packaging bag is limited to a certain degree, and thus the space is saved. By forming air holes in the third hot melt zone, the effect that objects do not go bad or cannot be damaged in a certain period can be ensured.

Owner:SHENZHEN DINGLISHENG TECH

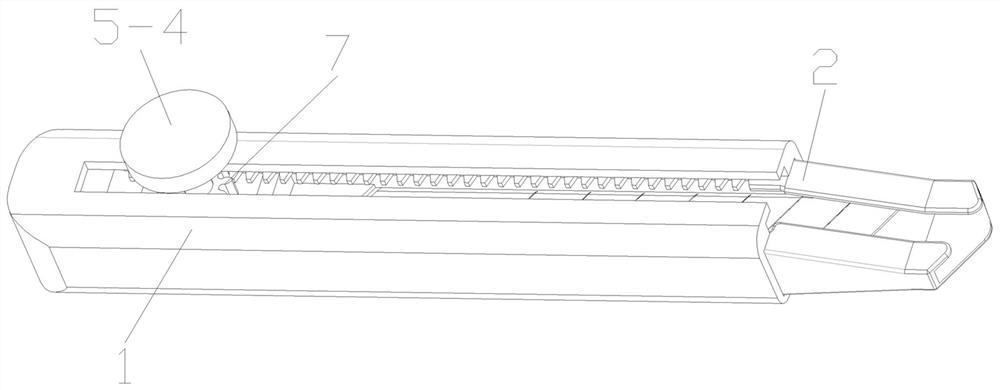

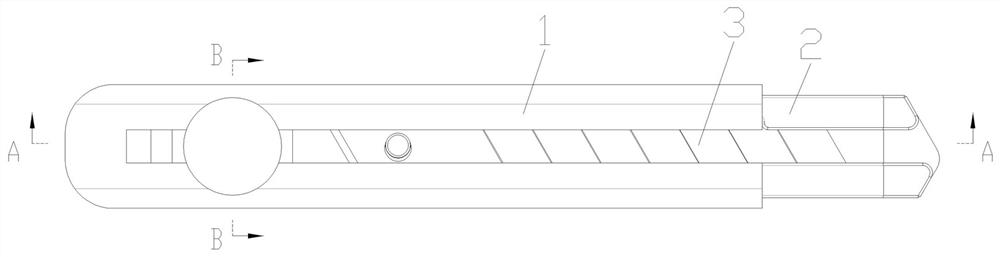

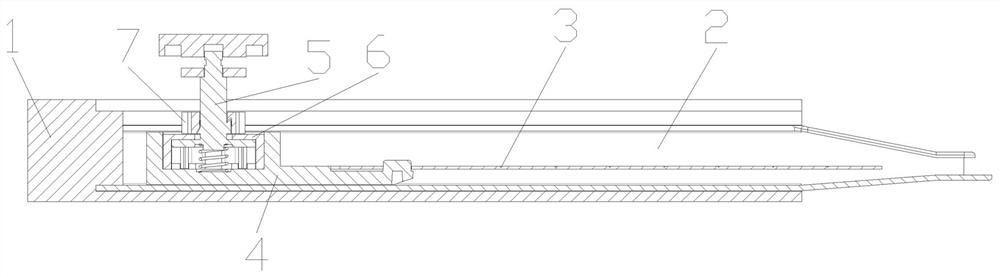

Art knife

Owner:DELI GROUP CO LTD

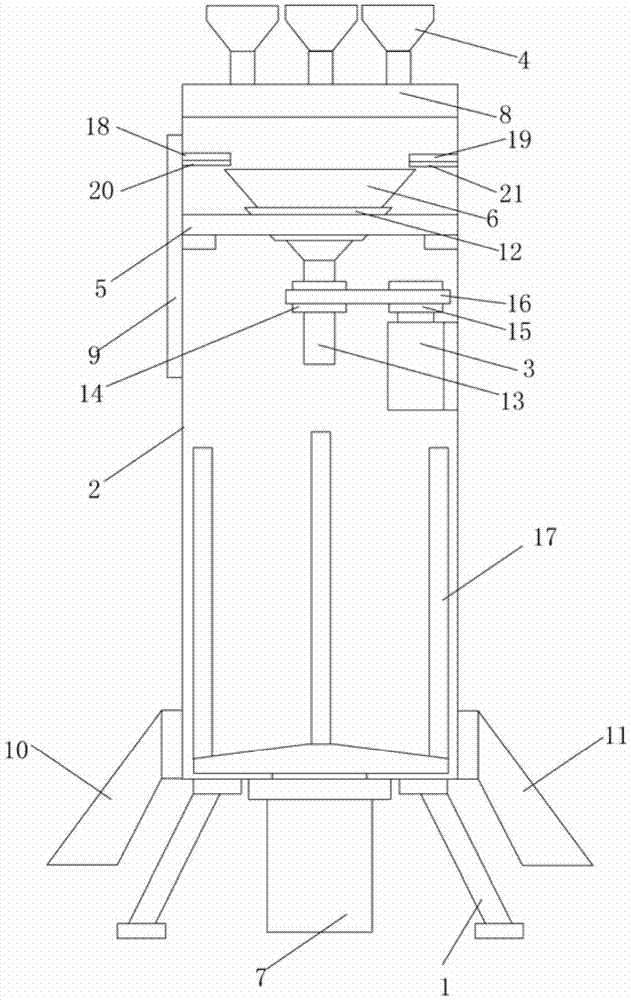

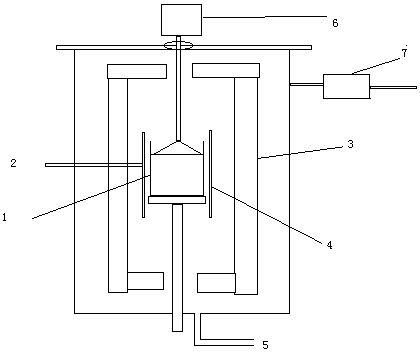

High speed mixer

InactiveCN106938182AWith premix functionIncrease mixing speedTransportation and packagingMixer accessoriesBiochemical engineering

Owner:TIANJIN DEV AREA JINPENG PLASTICS PROFILE MFG CO LTD

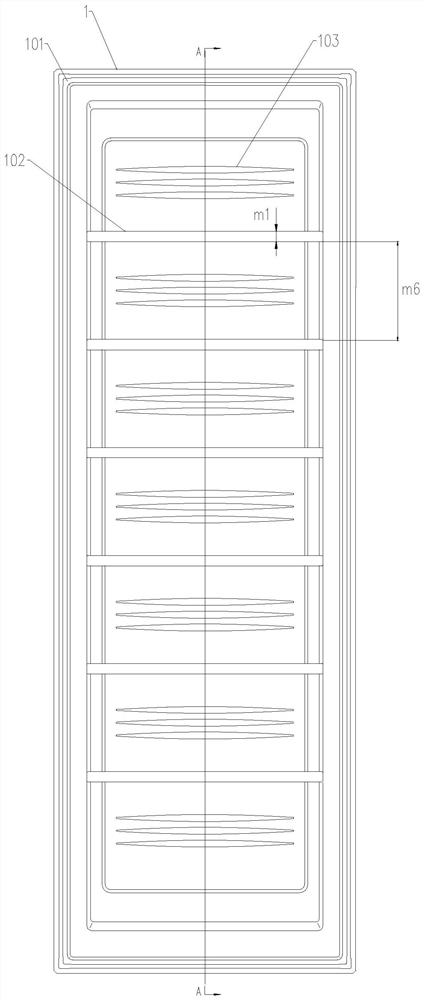

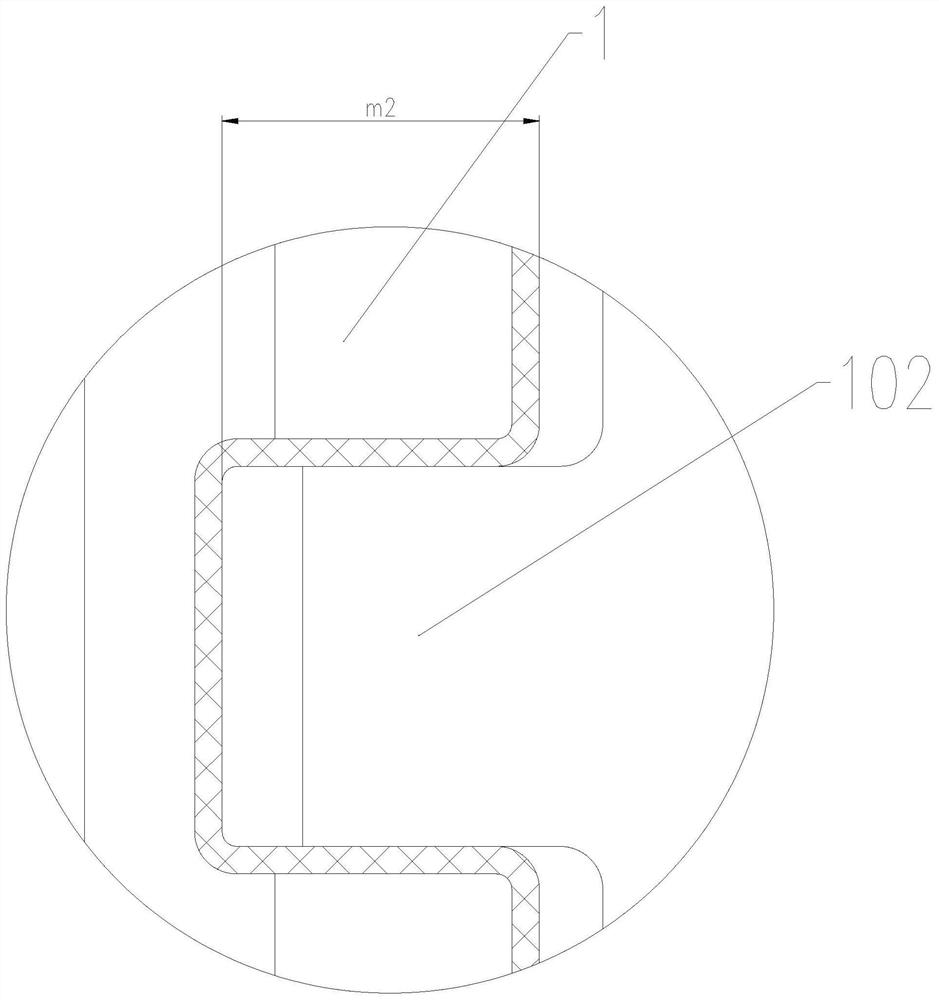

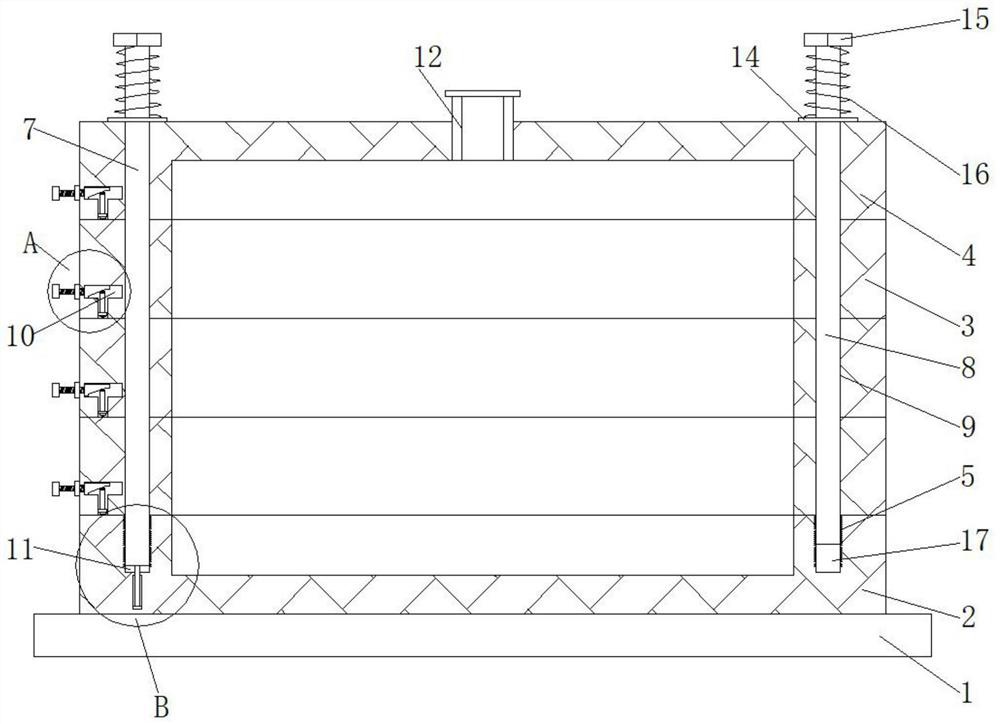

Mechanism for flattening surface of door body during refrigeration of refrigerator

PendingCN111912162ALimit widthLimit outward convexityDomestic cooling apparatusLighting and heating apparatusIceboxEngineering

The invention relates to a mechanism for flattening the surface of a door body during refrigeration of a refrigerator. An upper door strip is arranged at the upper end of a door shell, and a lower door strip is arranged at the lower end of the door shell. An inner container body is clamped in the door shell, and the upper door strip is fixedly connected with the inner container body and the lowerdoor strip is fixedly connected with the inner container body by buckles. The end, far away from the inner container body, of the upper door strip is clamped in the door shell, and the end, far away from the inner container body, of the lower door strip is clamped in the door shell. A plurality of first reinforcing grooves and second reinforcing grooves are formed in one side of the inner container body, and bending parts are arranged on the sides, close to the inner container body, of the two ends of the door shell. As the first reinforcing grooves and the second reinforcing grooves are formed in one side of the inner container body, the phenomena that the width of the door body becomes smaller and the door body protrudes outwards due to a foaming material contracting when cooled can be effectively limited by using the first reinforcing grooves and the second reinforcing grooves. In addition, the bending parts are arranged on the sides, close to the inner container body, of the two ends of the door shell, so that the door body can have sufficient strength to limit the phenomena that the height of the door body becomes smaller and the door body protrudes outwards due to the foamingmaterial contacting when cooled.

Owner:ZHEJIANG XINGXING REFRIGERATION CO LTD

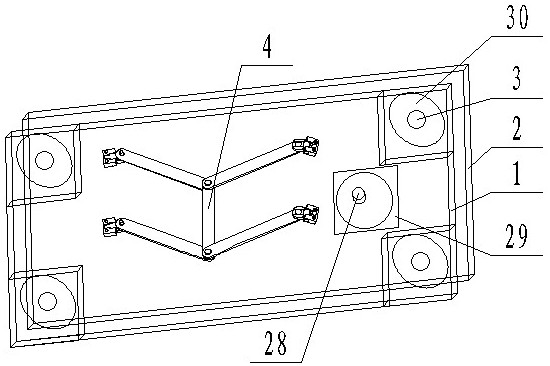

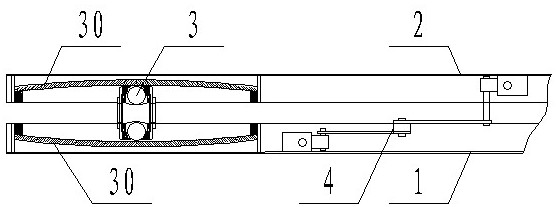

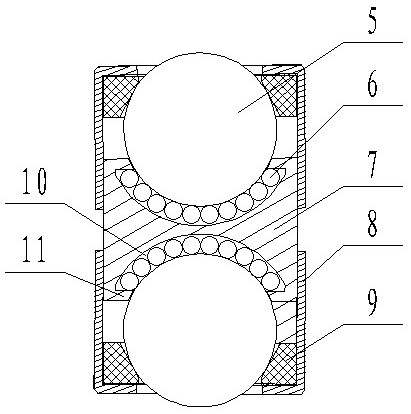

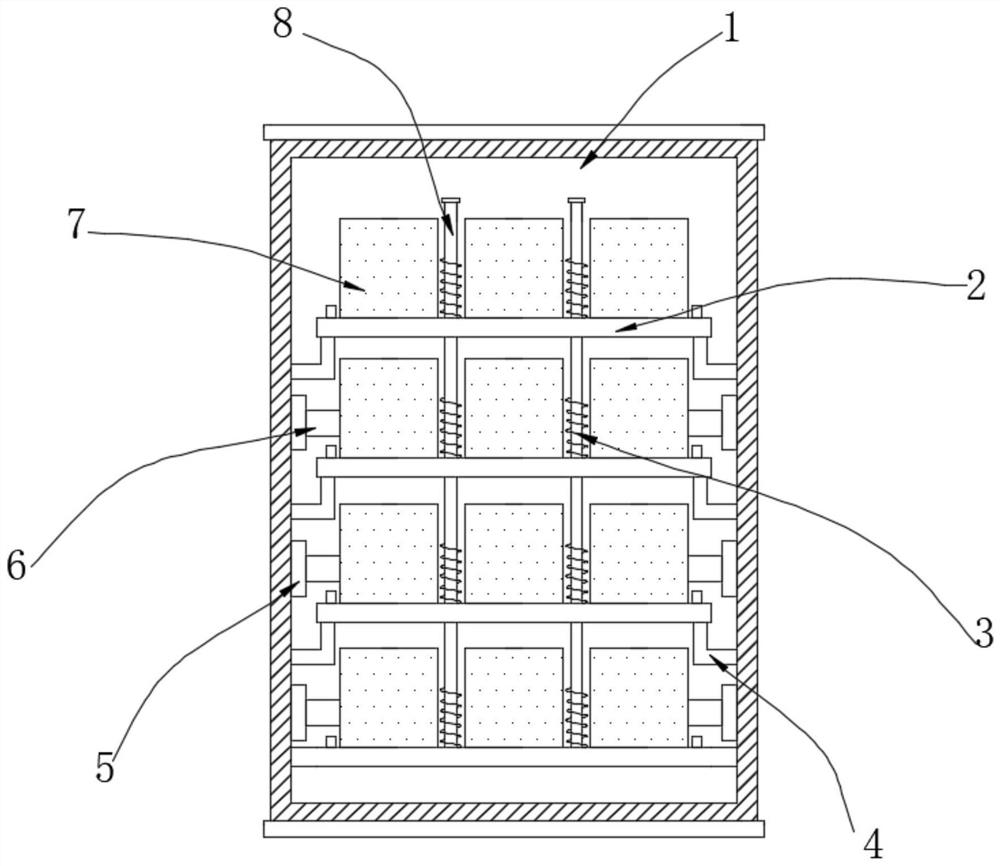

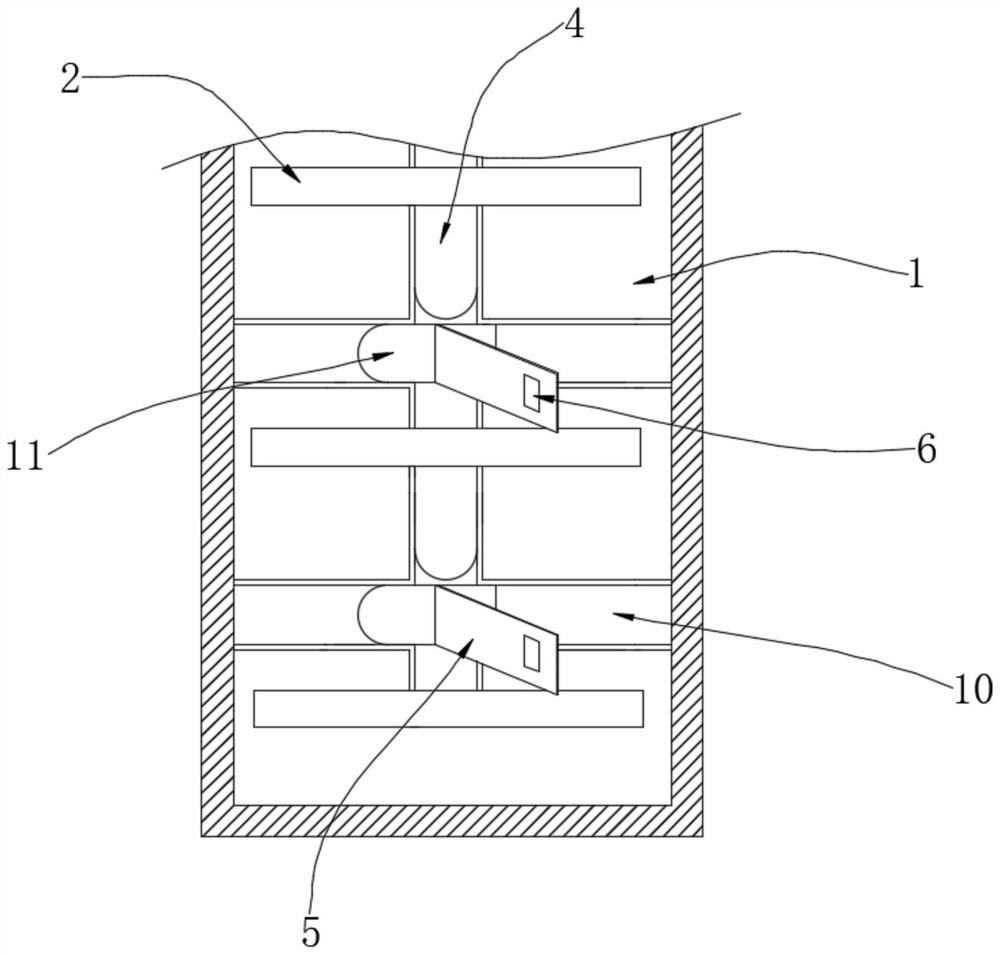

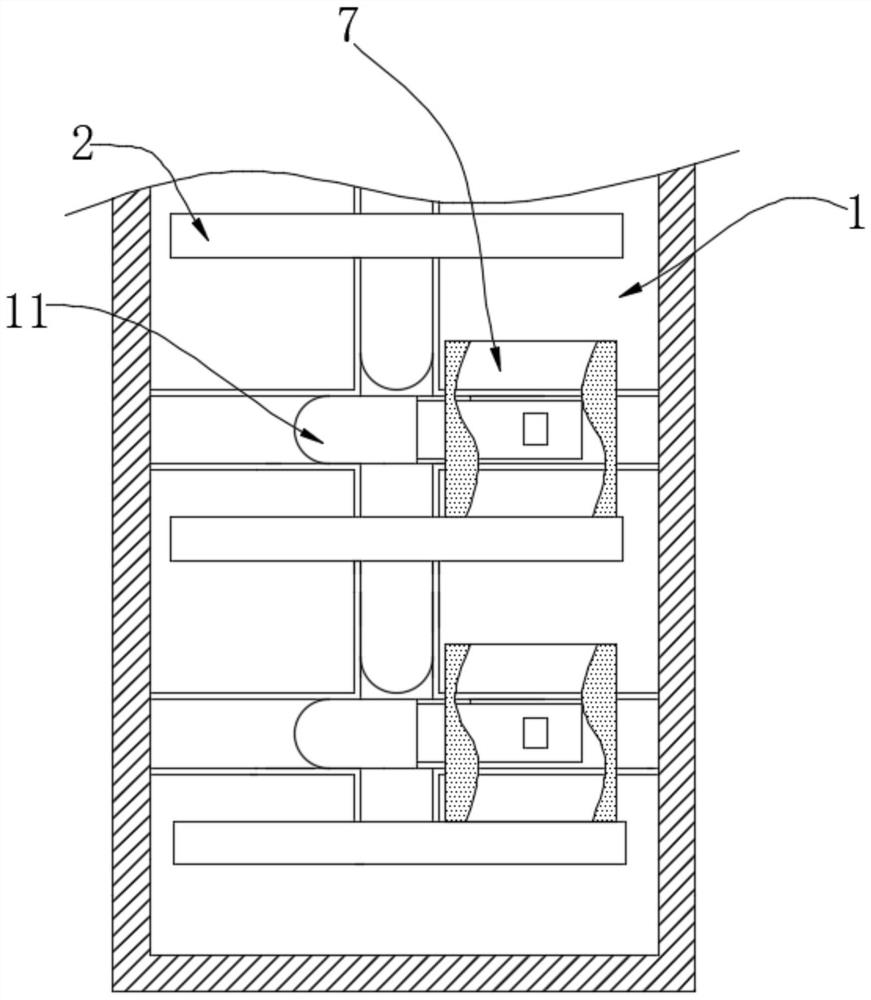

Damping ball type anti-torsion seismic isolation table

PendingCN111664213AReduce scrolling speedReduce displacementSpringsNon-rotating vibration suppressionClassical mechanicsEngineering

The invention discloses a damping ball type anti-torsion seismic insulation table. The damping ball type anti-torsion seismic insulation table comprises a base, an upper panel, damping adjusting universal ball devices and a connecting rod mechanism, wherein the damping adjusting universal ball devices are arranged on the base and used for supporting the upper panel; the damping adjusting universalball devices are arranged between the base and the upper panel, and the base and the upper panel are connected through the connecting rod mechanism; a connecting rod device of the connecting rod mechanism does plane translational motion, and the connecting rod device does not rotate; and the damping adjusting universal ball devices are connected through connecting devices I, so that the relativepositions of the damping adjusting universal ball devices are not changed. According to the damping ball type anti-torsion seismic insulation table, the structure is reasonable, using is convenient, and object displacement can be effectively avoided under the action of seismic waves.

Owner:张玉峰

Rotary opening type precision die structure capable of achieving fixed-point disassembly and maintenance

Owner:上海虹译电子科技股份有限公司

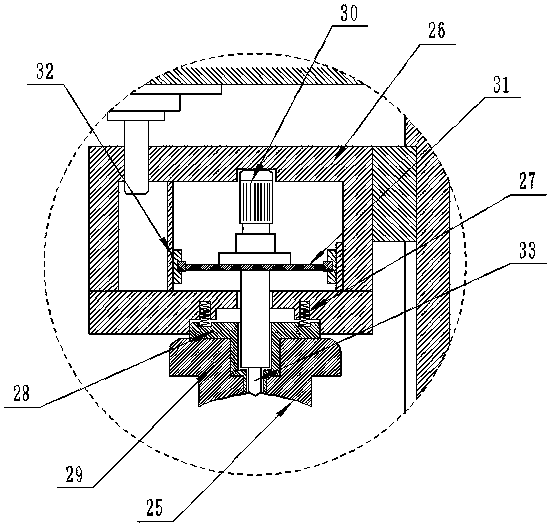

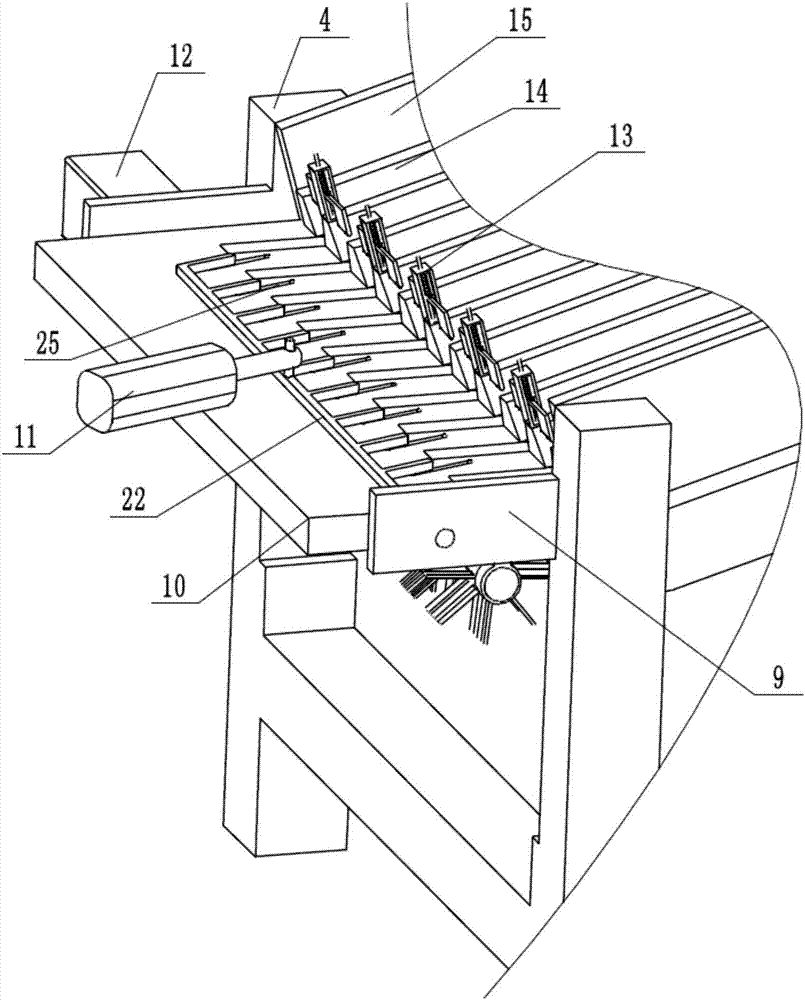

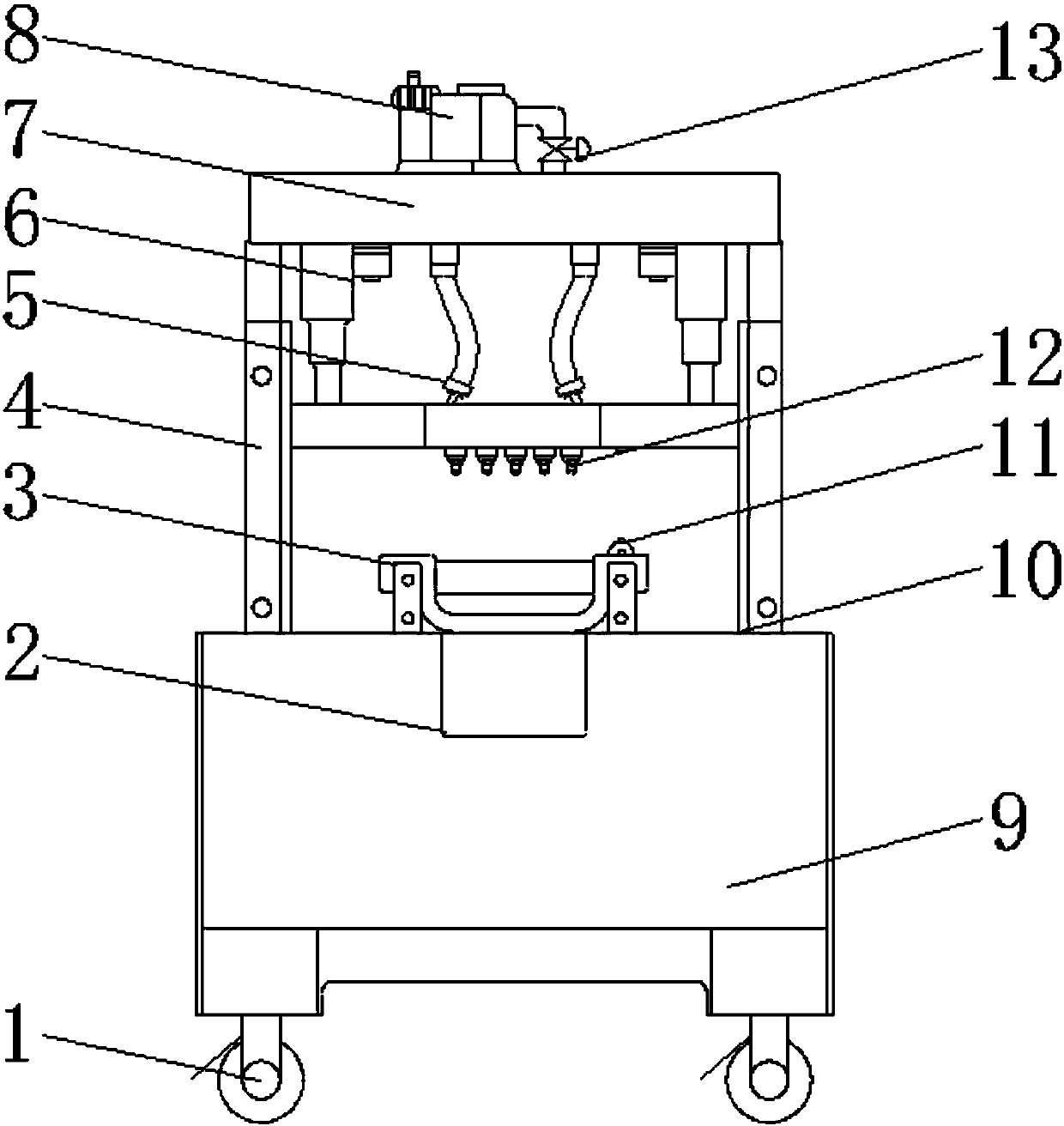

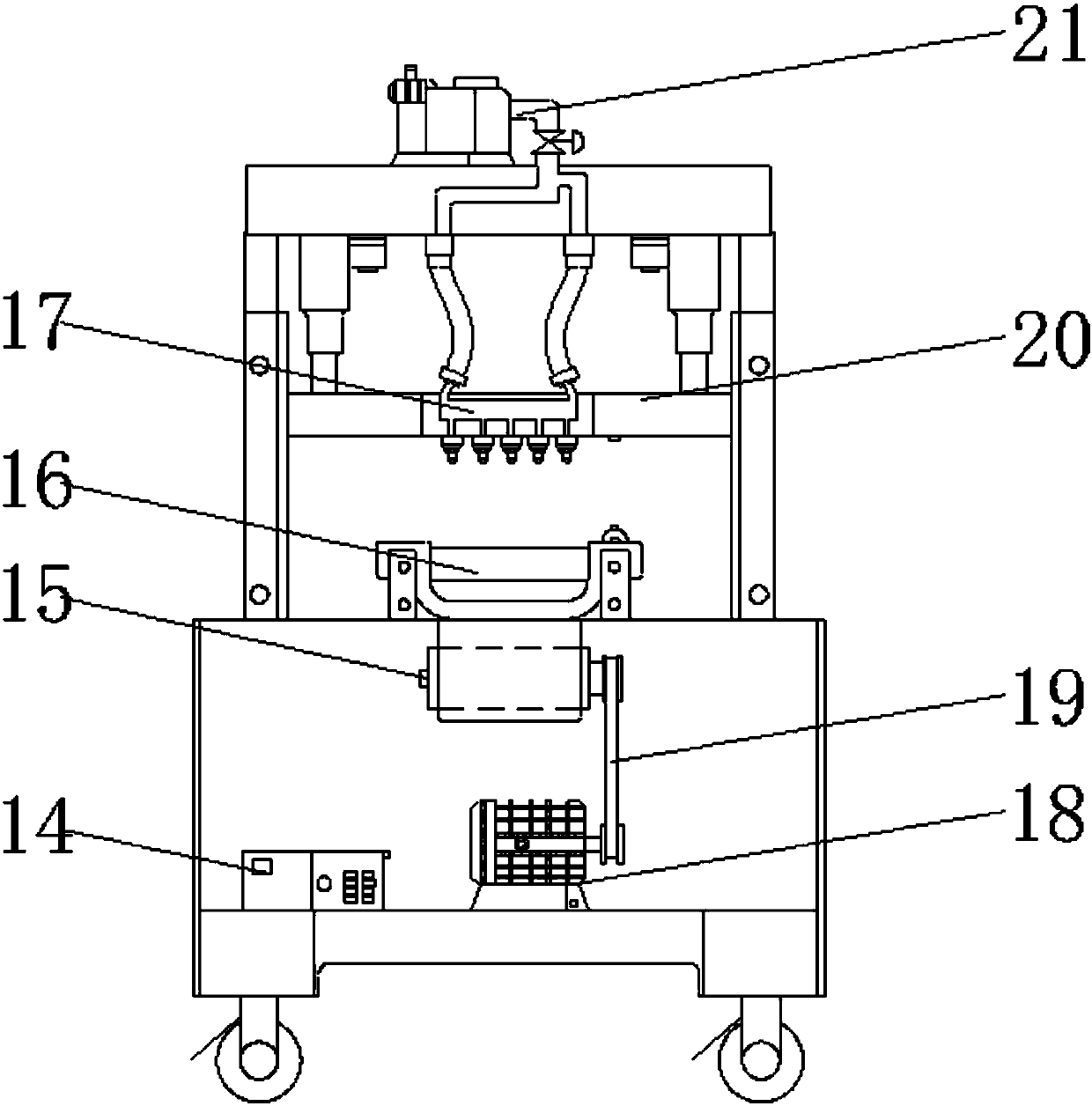

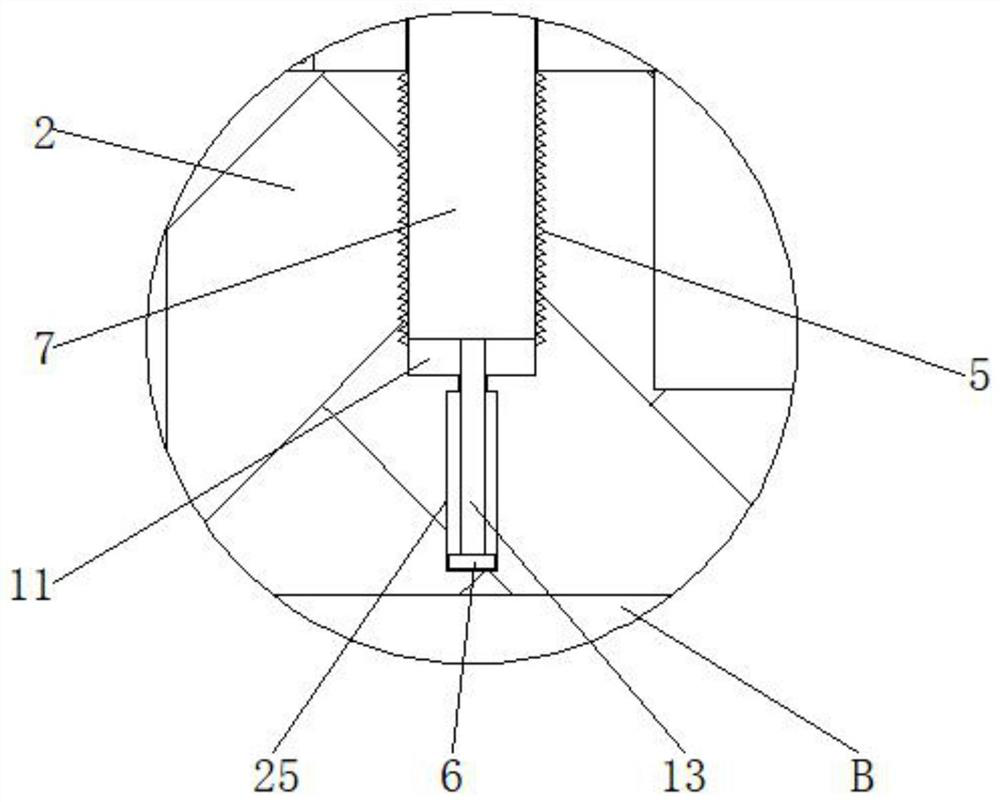

Continuous automatic shelling device

InactiveCN108477287AImprove processing efficiencyRealize fully automatic single material conveyingBivalves processingFresh water organismButt joint

The invention discloses a continuous automatic shelling device. The device comprises a moving frame and a feeding hopper; a cleaning cylinder is arranged in the moving frame, the feeding hopper communicates with the cleaning cylinder, a screw propeller and washing brushing rollers are arranged in the cleaning cylinder, and cleaning brushes are arranged on the washing brushing rollers; liquid discharging holes are arranged on the rotating drum of the cleaning cylinder; the discharging end of the cleaning cylinder is in butt joint with a discharging channel, the discharging channel is connectedto a loading push block, the lower end of the loading push block is connected to a loading cylinder, and the end surface along the inclined direction is provided with a lower pressing plate; and an upper pressing plate, a lower pressing mechanism and a shelling assembly are arranged above the lower pressing plate, and concave recesses are formed on the upper pressure plate and the lower pressing plate. The invention aims to provide the continuous automatic shelling device against the above problems, and the device cleans freshwater mussel shells before the shelling, realizes full-automatic single-mussel conveying, carries out shelling on freshwater mussels by adopting a rotary drilling mode, and effectively avoids the problem that the mussels cannot be clamped due to different size specifications and easy slipping.

Owner:DONGGUAN UNIV OF TECH

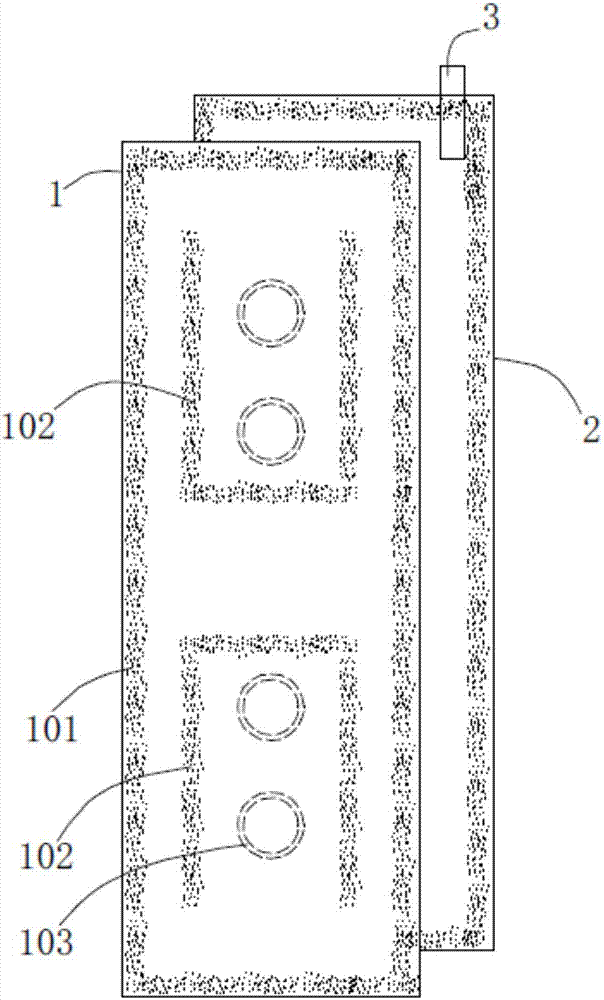

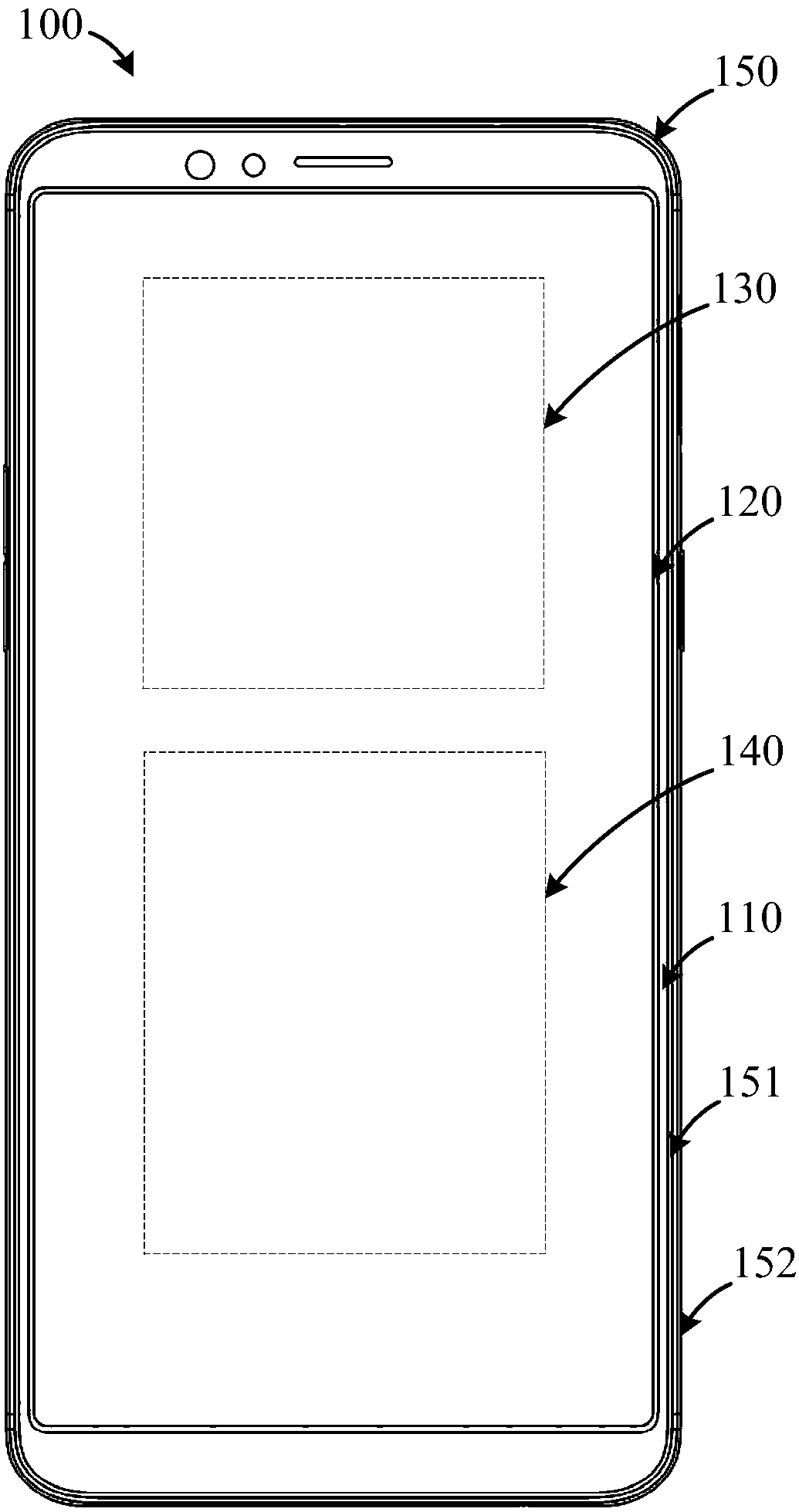

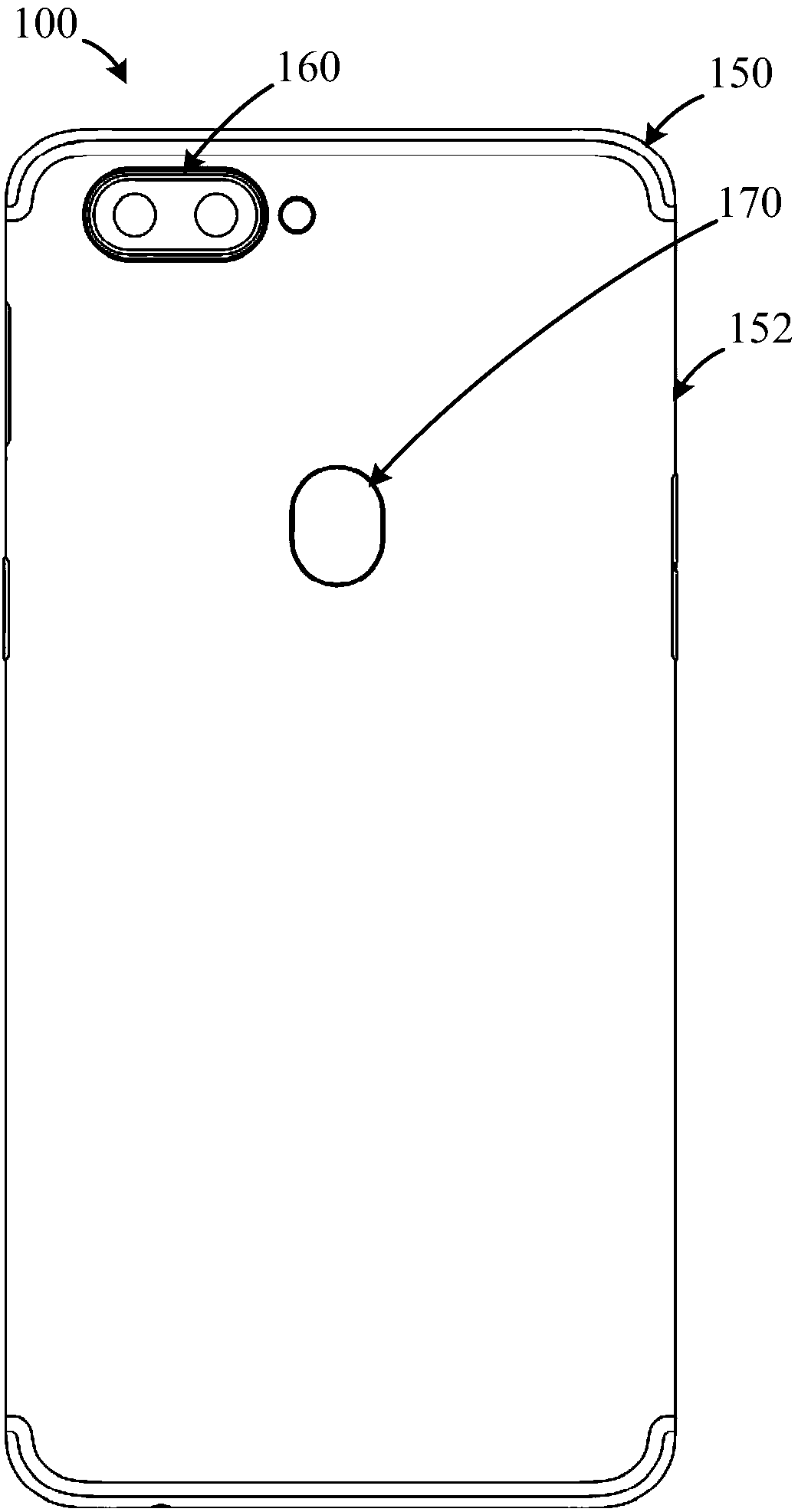

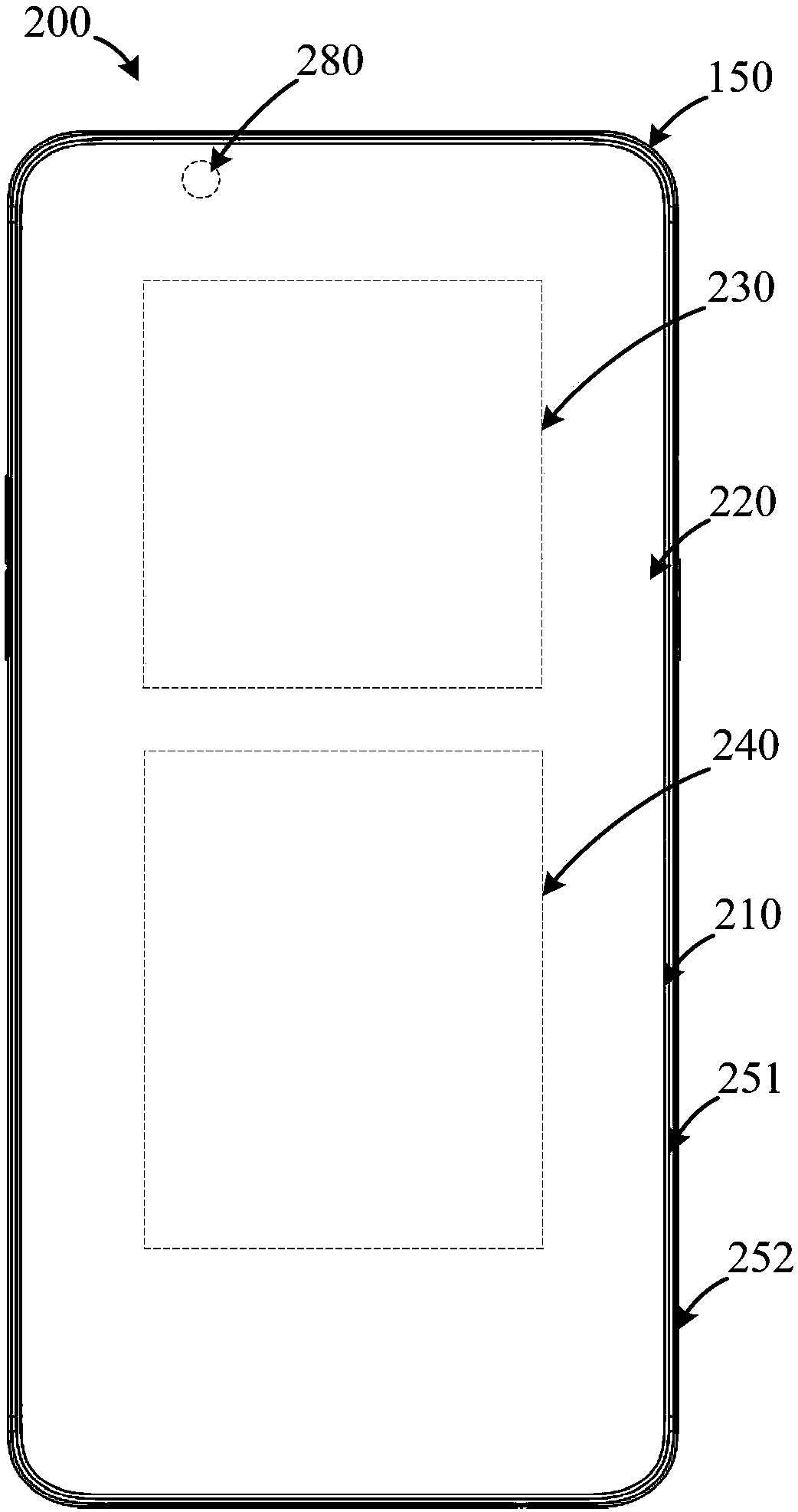

Display screen control circuit board component, display screen component and electronic equipment

ActiveCN108170216AGuaranteed waterproof performanceNot easy to affect thin and light requirementsDigital data processing detailsControl circuitLightness

The invention discloses a display screen control circuit board component, a display screen component and electronic equipment. The display screen control circuit board component comprises a substrate;waterproof foam and a plurality of elements are arranged on the substrate; the plurality of elements form an element setting area on the substrate; the waterproof foam is arranged to surround the periphery of the element setting area so as to surround the plurality of elements; a waterproof plate is arranged on the waterproof foam; a sealed space is formed by the waterproof plate, the waterprooffoam and the substrate; and the plurality of elements are arranged in the sealed space. Through forming the sealed space by the waterproof foam, the waterproof plate and the substrate, the whole waterproof effect can be ensured, the whole height can be well limited, and the requirements for lightness and thinness of the electronic equipment are not easy to be influenced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

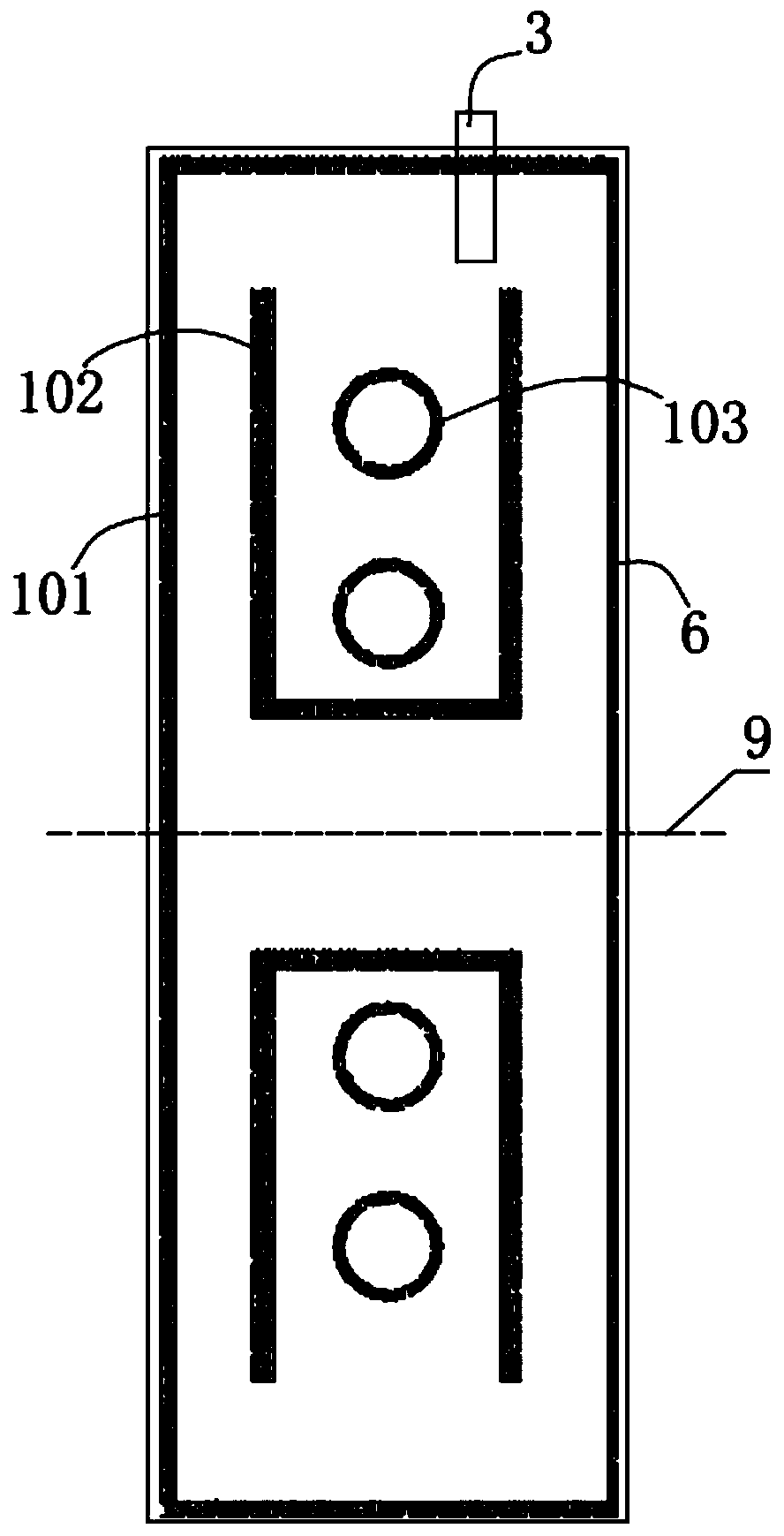

Battery cabinet for base station

InactiveCN114069076AEasy to carryAvoid damageBatteries circuit arrangementsSecondary cells charging/dischargingStructural engineeringMechanical engineering

The invention relates to the technical field of battery cabinets, and discloses a battery cabinet for a base station. The battery cabinet comprises a cabinet body and batteries, a plurality of support plates are sequentially mounted in the cabinet body from top to bottom at intervals, the batteries are placed on the support plates, support legs are fixedly connected to two sides of the bottom of each support plate, and cross-shaped sliding grooves are formed in two sides of the inner wall of the cabinet body. A sliding block capable of sliding is arranged in the transverse sliding groove, a pressing plate is hinged to the outer surface of the sliding groove, and a connecting rod is fixedly connected to the surface of one side of the pressing plate. By arranging damping springs, the bottoms of the supporting plates make contact with the bottoms of the damping springs during descending, height descending is stopped, buffering protection can be conducted on the batteries which are not completely unloaded on the surfaces of the supporting plates, and the situation that the batteries are damaged due to too large vibration force during descending is avoided; the batteries can be separated, while the heat dissipation effect is improved, the left-right overturning of the batteries can be limited when the cabinet body is carried, so the situation that strong short-circuit current is generated after the exposed batteries collide with poles is avoided.

Owner:董武昌

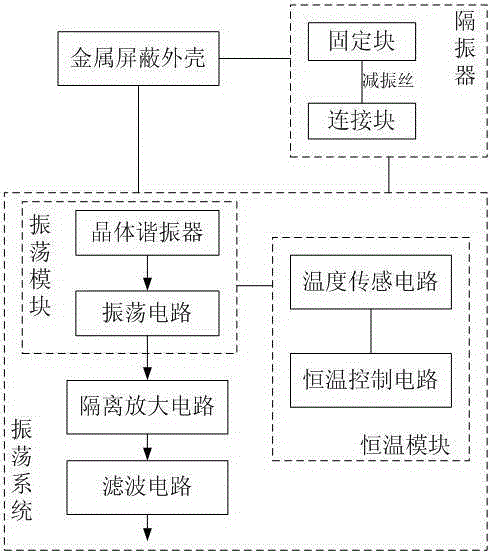

High vibration-resistant crystal oscillator based on constant temperature control

ActiveCN103346750BSimple structureLow costImpedence networksGenerator stabilizationTemperature controlParticle physics

Owner:CHENGDUSCEON ELECTRONICS

Large-scale rare earth doped yttrium barium fluoride single crystal growth method

InactiveCN104562183BLimit heightImprove integrityPolycrystalline material growthBy pulling from meltRare earthSingle crystal

Owner:SOUTH WEST INST OF TECHN PHYSICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com