Embroidery machine and embroidery machine cloth fixing device

A fixing device and technology for embroidery machines, applied in the field of embroidery machines, can solve the problems of long consumption time and painful palms, and achieve the effects of speeding up production efficiency, reducing labor intensity, and facilitating material loading and placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

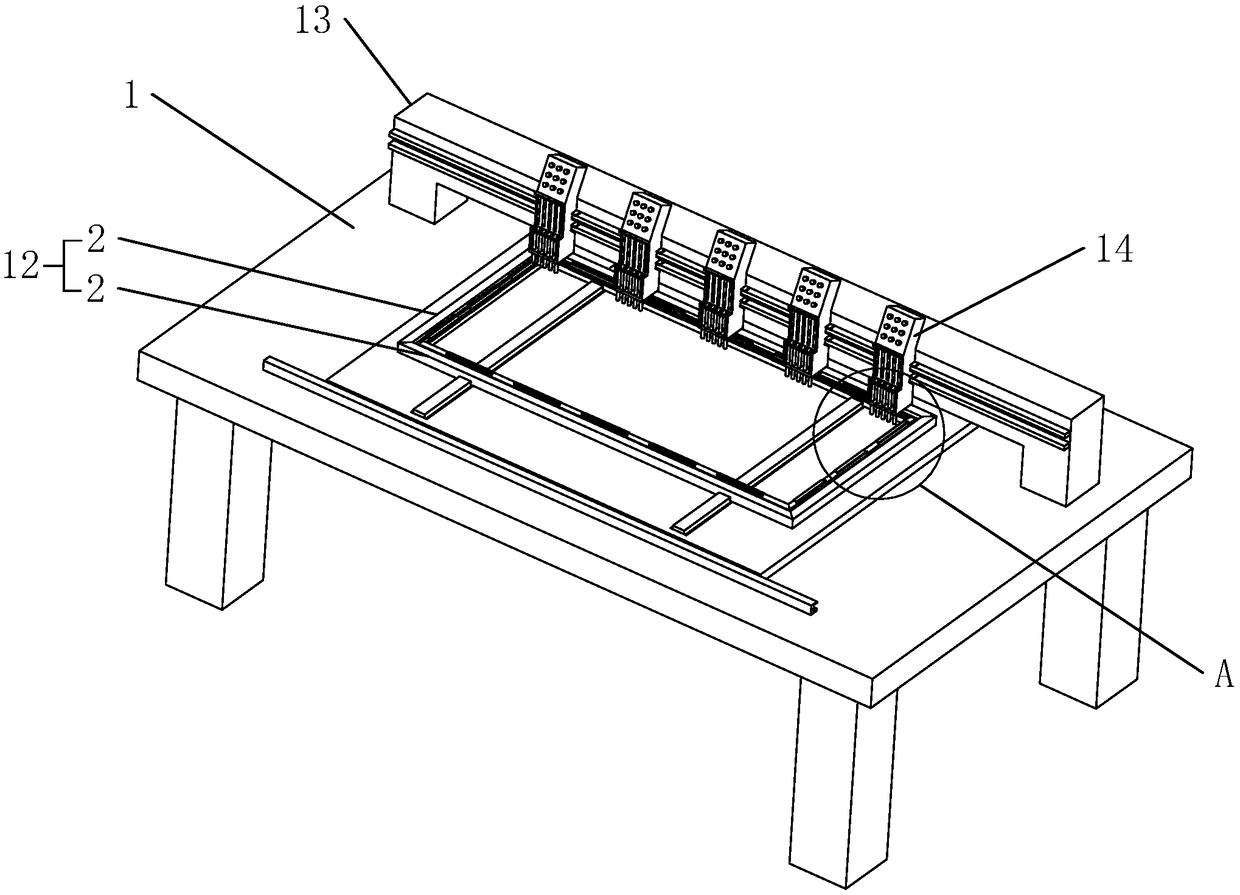

[0039]Embodiment 1: An embroidery machine, including an embroidery machine cloth fixing device.

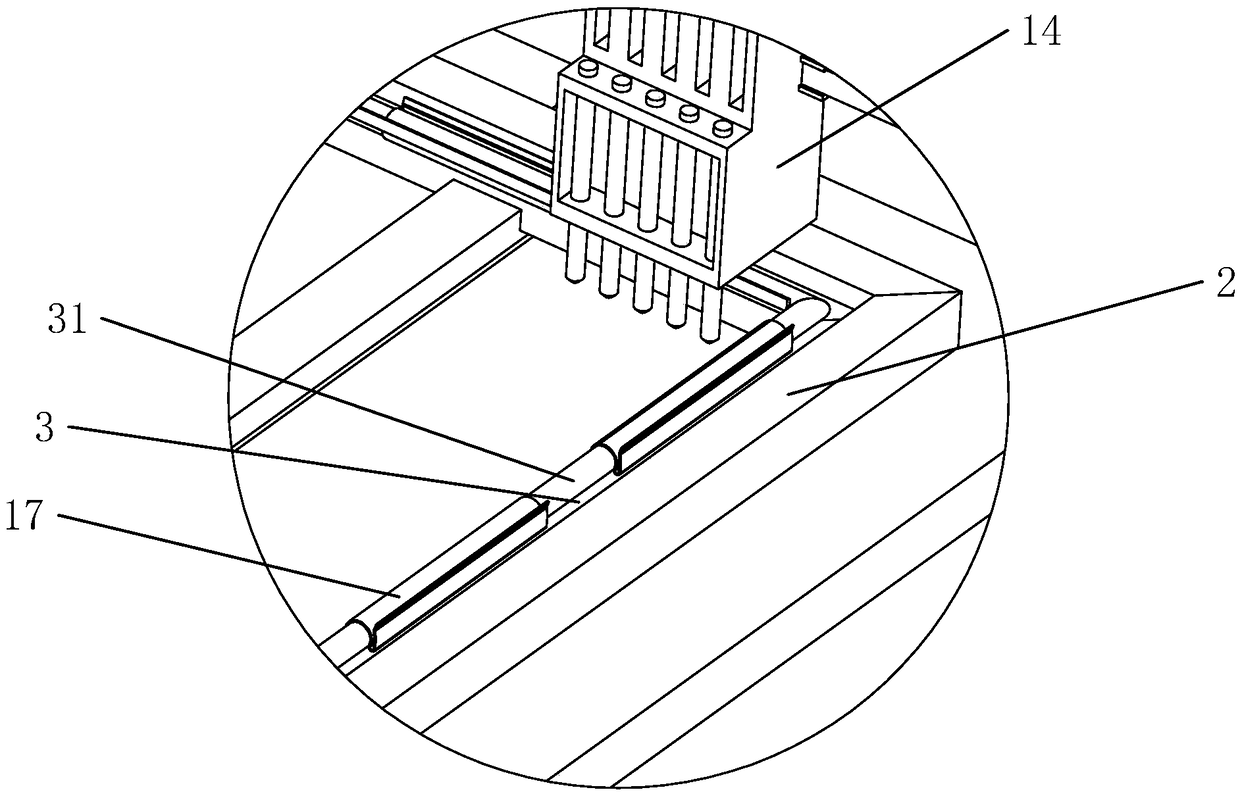

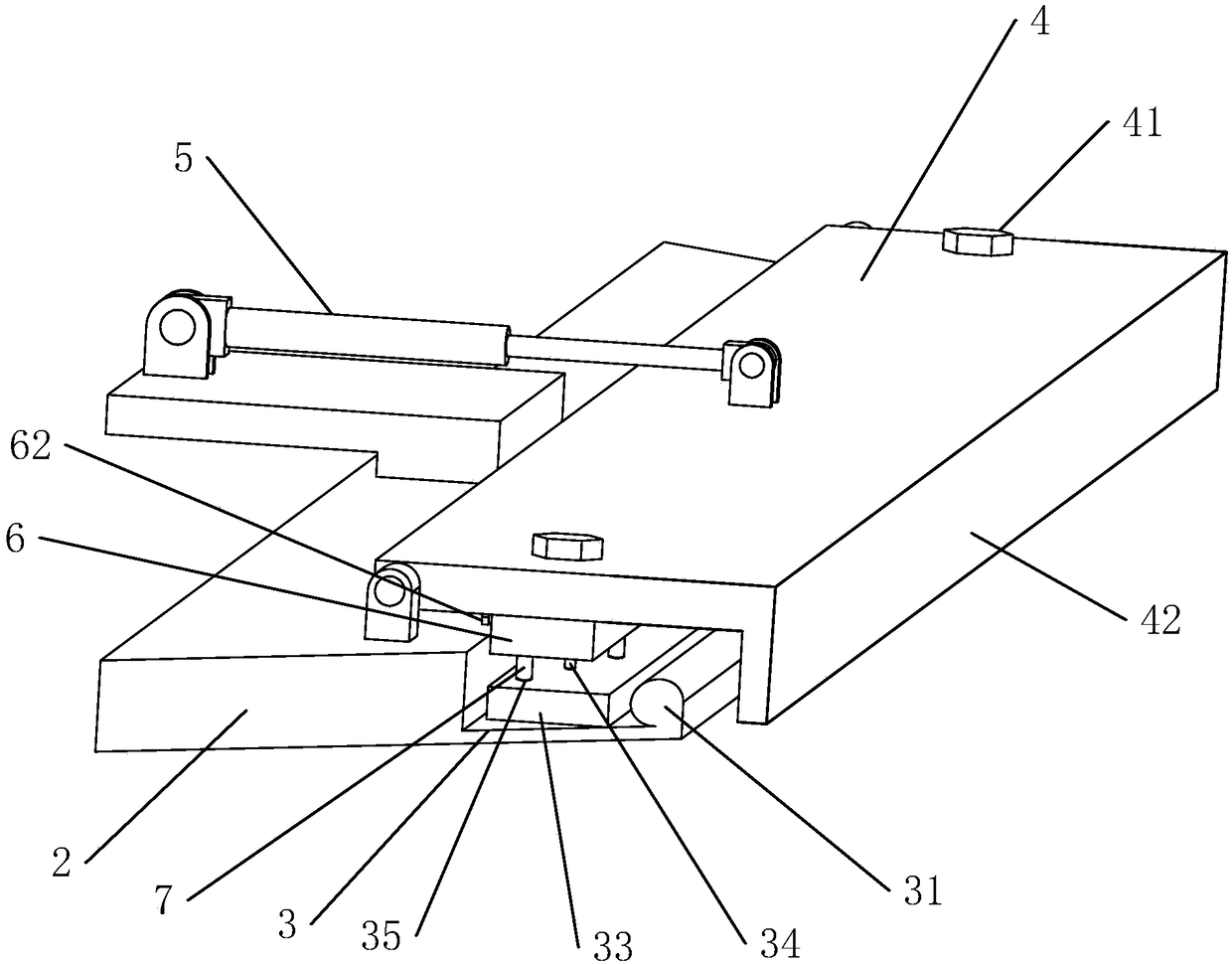

[0040] An embroidery machine cloth fixing device, such as image 3 and Figure 4 As shown, it includes a fixing groove 3, a pressing plate 4 and a driving mechanism 5. The fixing groove 3 is opened on the fixing frame 2 of the embroidery machine, and is located at the edges of the four fixing frames 2 close to the center of the fabric. The fixing groove 3 is along the edge of the fixing frame 2. The length direction extends, and the adjacent fixing grooves 3 are vertical in pairs and communicate with each other.

[0041] Such as image 3 and Figure 4 As shown, the pressing plate 4 is hinged on the fixing frame 2 and can rotate around the hinge so as to realize two states of opening and pressing the fixing groove 3 .

[0042] Such as image 3 and Figure 4 As shown, the edge of the fixing groove 3 close to the center of the cloth is integrally provided with a convex strip 31...

Embodiment 2

[0052] Embodiment 2: The difference between embodiment 2 and embodiment 1 is that the connection mode between the pressing pin 7 and the pressing bar 6 is different, such as Figure 7 As shown, in the embodiment 2, the pressing pin 7 and the pressing bar 6 are integrally formed, which can save a lot of manufacturing cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com