Preposed straw returning machine

A front-mounted, straw technology, applied in the field of machinery, can solve the problems that straw returning machines cannot be processed and affect the use effect, etc., and achieve the effect of high convenience and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

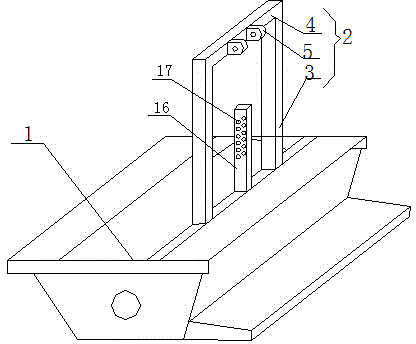

[0015] Such as figure 1 , 2 As shown in .

[0016] Like this, the present invention can be installed in the front of traction device such as tractor, can satisfy some farming requirements.

[0017] Further, the connecting part is that there are two vertical rectangular tubes 3 on the frame, and a beam 4 is arranged above the rectangular tubes, the rectangular tubes and the beams form a frame, and there are also height-adjustable ears on the frame. Sheet 5, hydraulic cylinder 15 is installed below the ear sheet.

[0018] This requires that the front of the traction device has an installation structure that cooperates with the frame body, and cooperates with the installation.

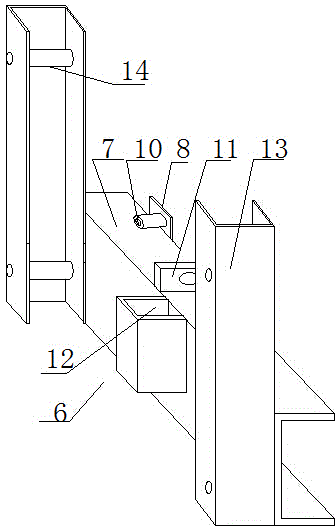

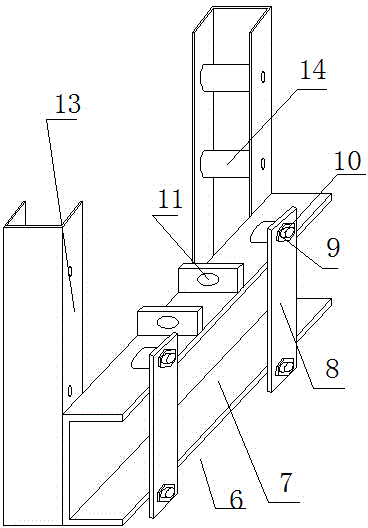

[0019] Further, it also includes a mounting frame 6, and the mounting frame includes a first channel steel 7 with an opening facing rearward and arranged laterally, with first screw holes on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com