Full-seam extraction method for stoping bottom layering of shallow extremely thick loose coal seam

A coal mining method and coal seam technology, which is applied in special mining, ground mining, mining equipment, etc., can solve problems such as coal wall prone to flakes, loose coal seam poor stability, difficulties, etc., to reduce the workload of coal cutting, high application The effect of promotion value and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

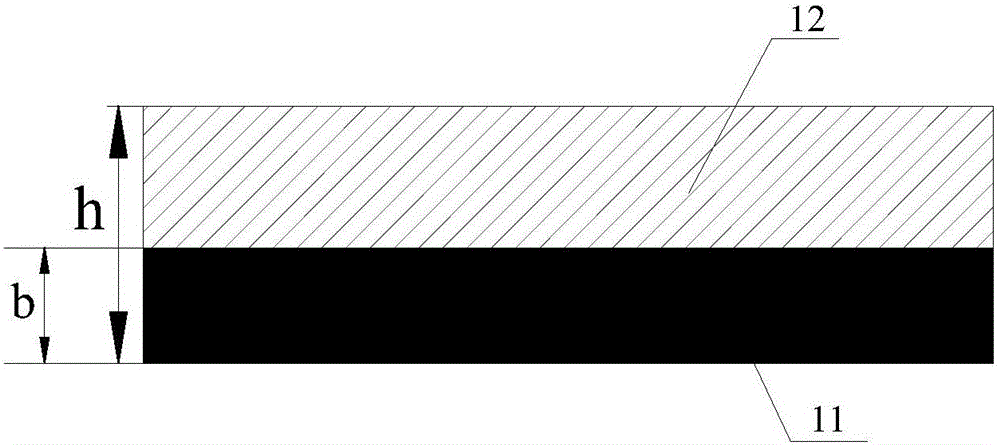

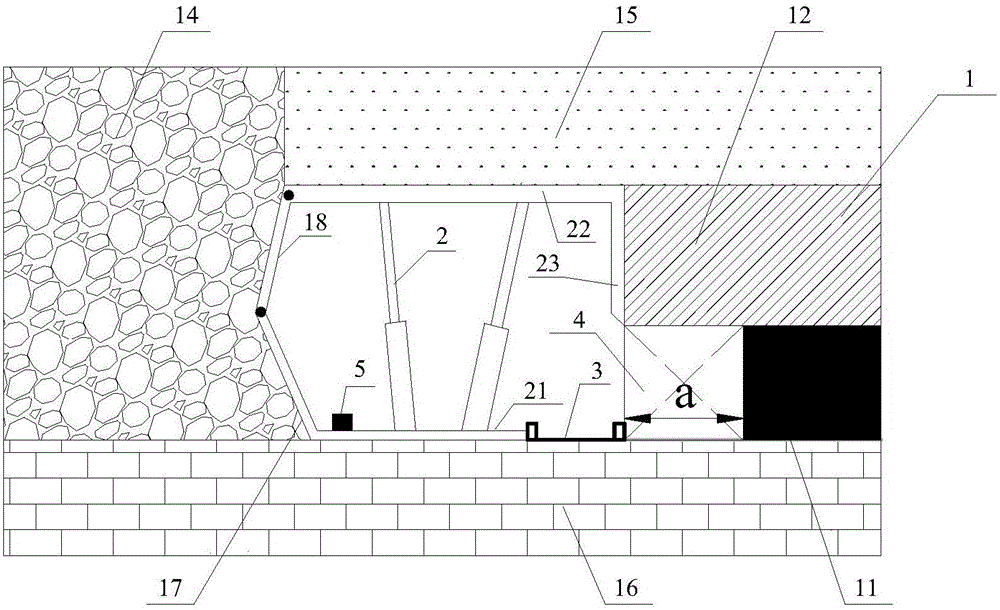

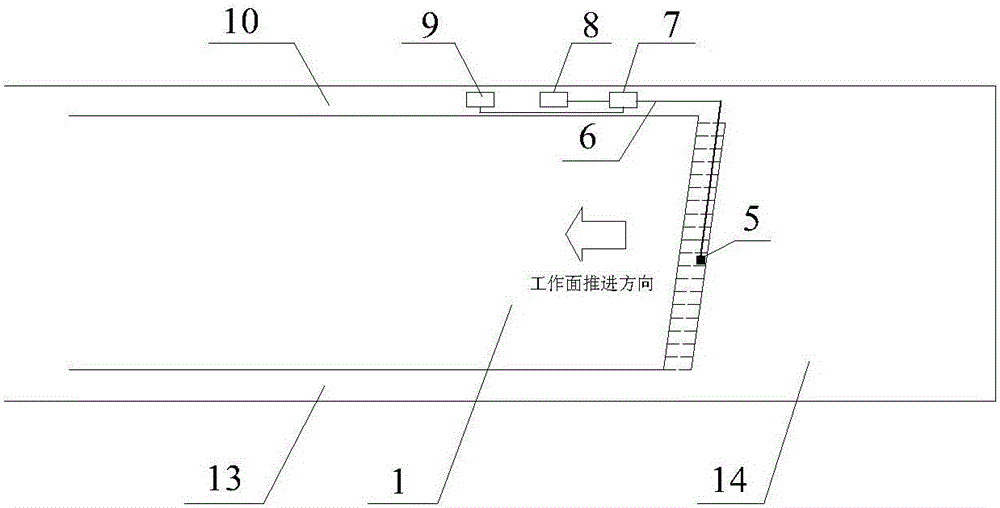

[0034] The present invention first scientifically divides the shallow buried deep extra-thick loose coal seam, and divides the extra-thick coal seam into upper and lower parts. The empty area is filled and compacted, and then the front drum of the shearer cuts the coal that has not fallen from the upper coal seam under the action of high mine pressure, and the rear drum of the shearer cuts the coal that has fallen from the upper coal seam and the coal that has been cut by the front drum All the coal is pushed into the scraper conveyor, and finally all the coal is transported out of the stope through the transfer conveyor at the end of the coal mining face.

[0035] Such as figure 1 , figure 2 with image 3 As shown, the whole layer coal mining method of a kind of shallow burial extra-thick loose coal seam back mining bottom stratification in the present embodiment, taking a certain extra-thick loose coal seam as an example, comprises the following steps:

[0036] (a) Scien...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com