Cone snail tail removing device

A technology of conical screw and electric motor, which is applied in the processing of crustaceans, slaughtering, food science, etc., and can solve the problems of incomplete tail removal, physical fatigue, and easy accidental injury to the operator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

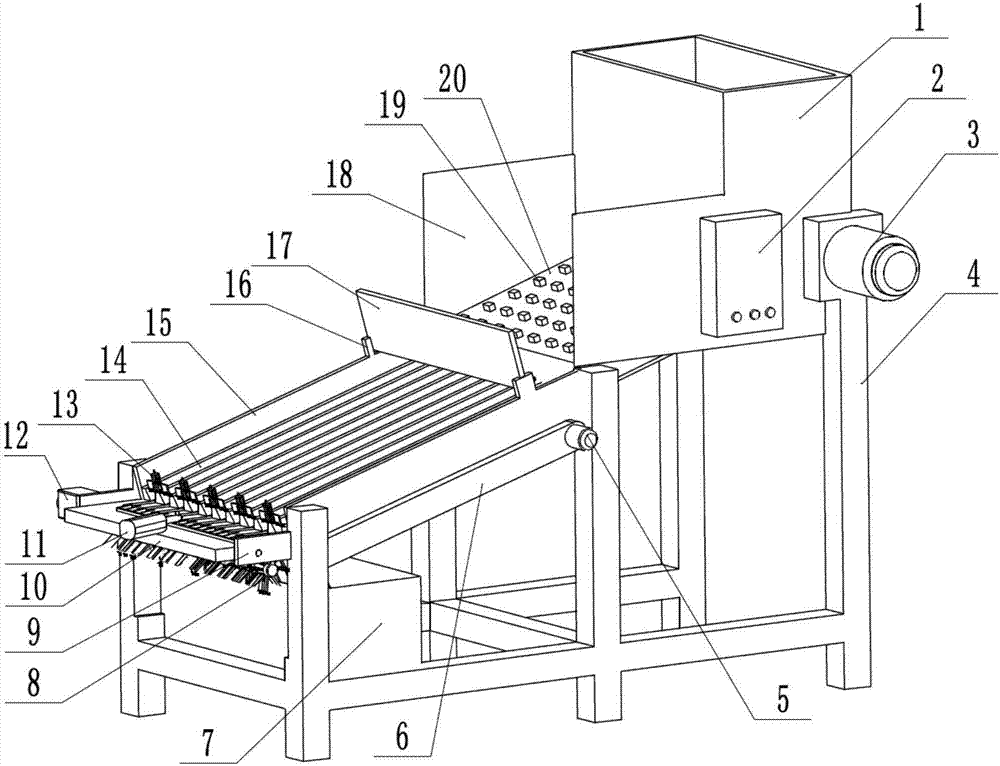

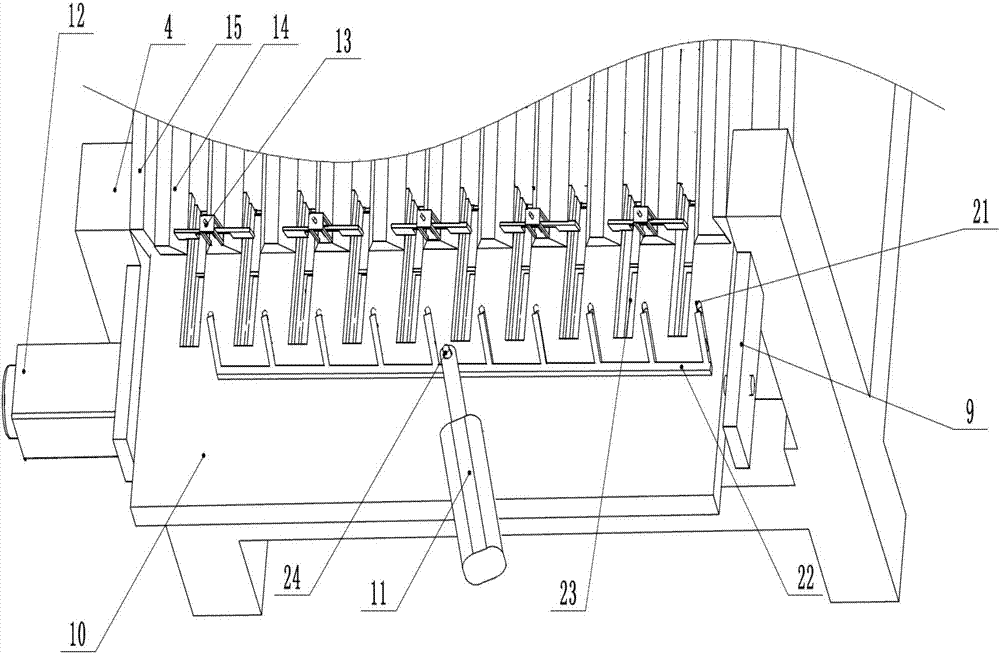

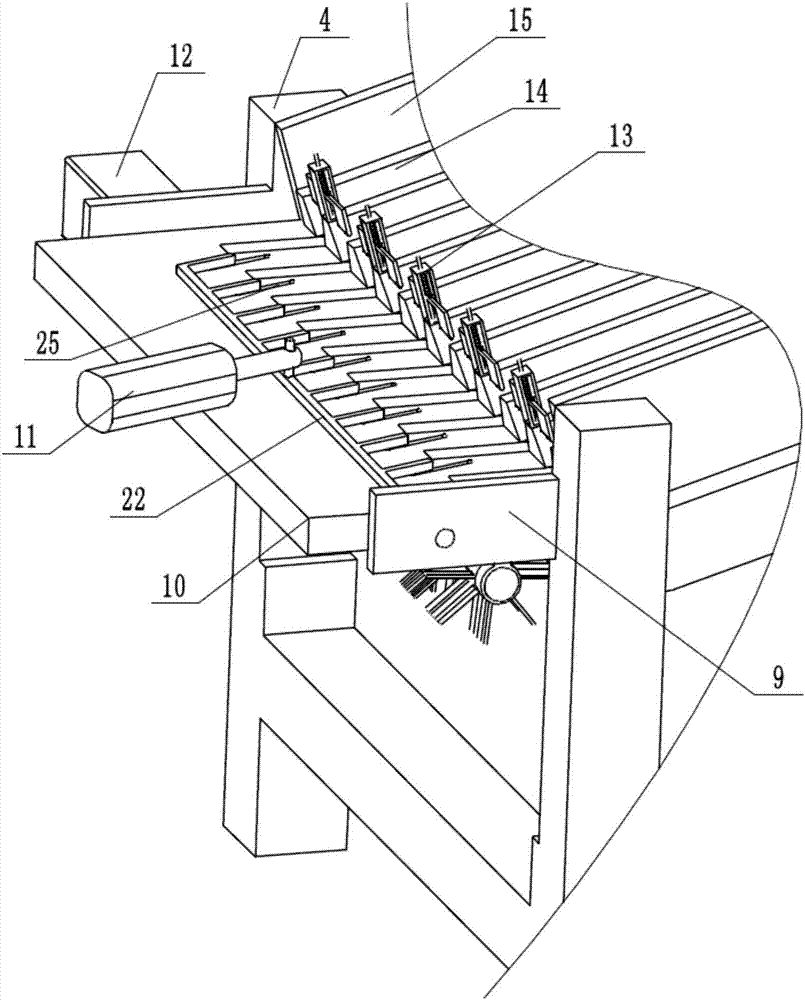

[0021] A cone screw tail removal device is composed of a feed hopper 1, a controller 2, a transmission motor 3, a frame 4, a sweeping motor 5, a transmission box 6, a collection box 7, a sweeping roller 8, a side base plate 9, a knife Plate 10, cylinder 11, rotating motor 12, limit mechanism 13, guide rod 14, side baffle 1 15, height limiting mechanism 16, height limiting plate 17, side baffle 2 18, bump 19, conveyor belt 20, slide Column 21, push frame 22, cutter body 23, hinged column 24, chute 1 25, chute body 2 26, roller base 27, chute 3 28, guide plate 29, rotating shaft 30, roller base 2 31 and chassis 32, the feed hopper 1 is arranged at the upper end of the rightmost side of the frame 4, a conveyor belt 20 is arranged below the feed hopper 1, and side baffles 2 18 are arranged on both sides of the conveyor belt 20, so There are bumps 19 distributed on the conveyor belt 20, a controller 2 is arranged on one side of the feed hopper 1, and a conveying motor 3 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com