Turrinella terebra tail removing machine and tail removing method thereof

A conical snail and tailing machine technology, which is applied in the processing of crustaceans, slaughtering, shrimp/lobster processing, etc., can solve the problems of high labor intensity, difficulty in removing tails from conical snails, poor quality of tailing, etc., and achieve fast and easy removal of tails Manual tail removal is difficult, but the tail removal quality is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

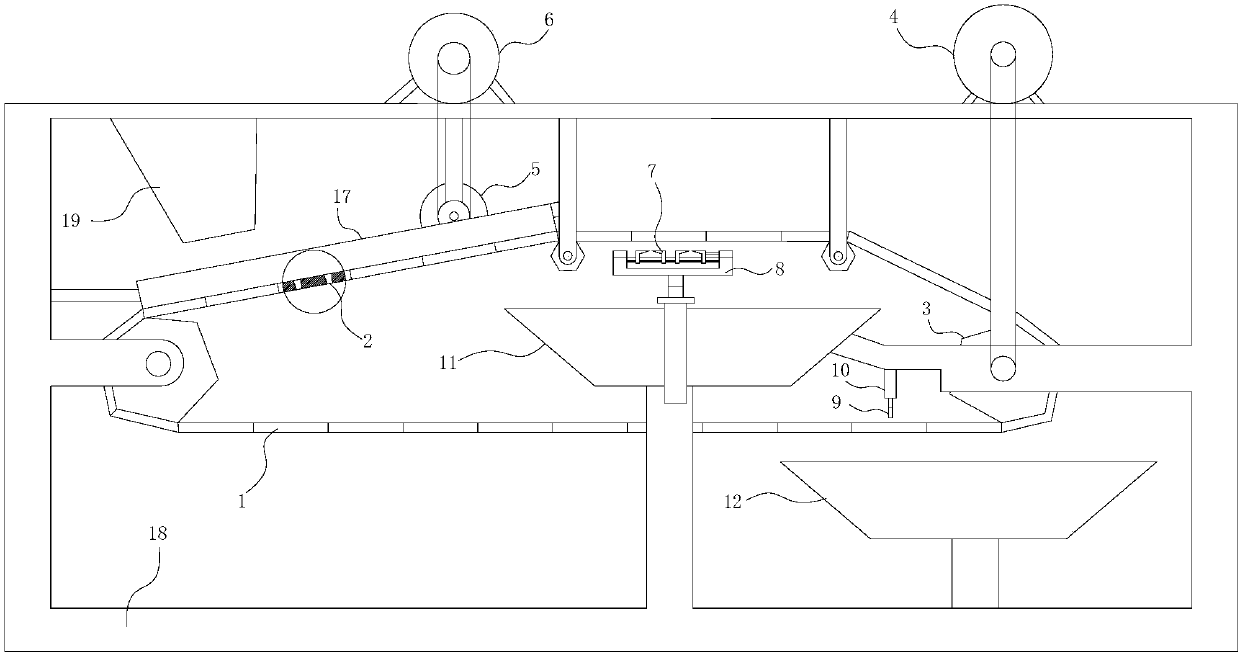

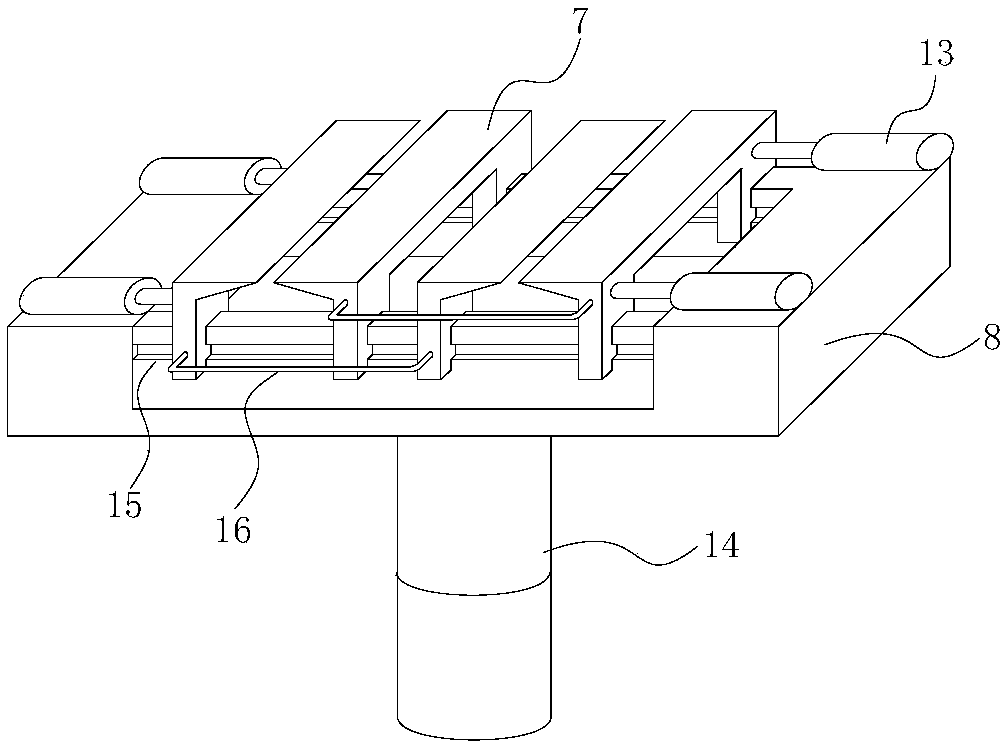

[0030] Please refer to figure 1 Shown, the tapered snail tailing machine of the present invention comprises frame 18, conveying mechanism, sweeping screw mechanism, tailing mechanism, jacking screw mechanism and collection mechanism, and frame 18 is provided with throwing screw port 19, and conveying mechanism, sweeping snail Mechanism, tail removal mechanism, screw jacking mechanism and collection mechanism are installed on the frame 18, and the conveying device transports the cone screw to the screw sweeping mechanism, tail removal mechanism and screw jacking mechanism respectively, and the processed cone screw is stored in the collection mechanism .

[0031] Please refer to figure 1 As shown, the conveying device is provided with a conveyor belt 1, and the thickness of the conveyor belt 1 is 15-25mm. The conveyor belt 1 is connected with a transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com