Busway shell

A technology of bus duct and housing, applied in the field of bus duct housing, can solve the problems such as the heat dissipation structure does not play a role in heat dissipation, the heat dissipation effect of the bus duct housing is reduced, and the reliability of the product is reduced, so as to improve the heat dissipation effect and the heat dissipation effect. Good, improve the effect of strength and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

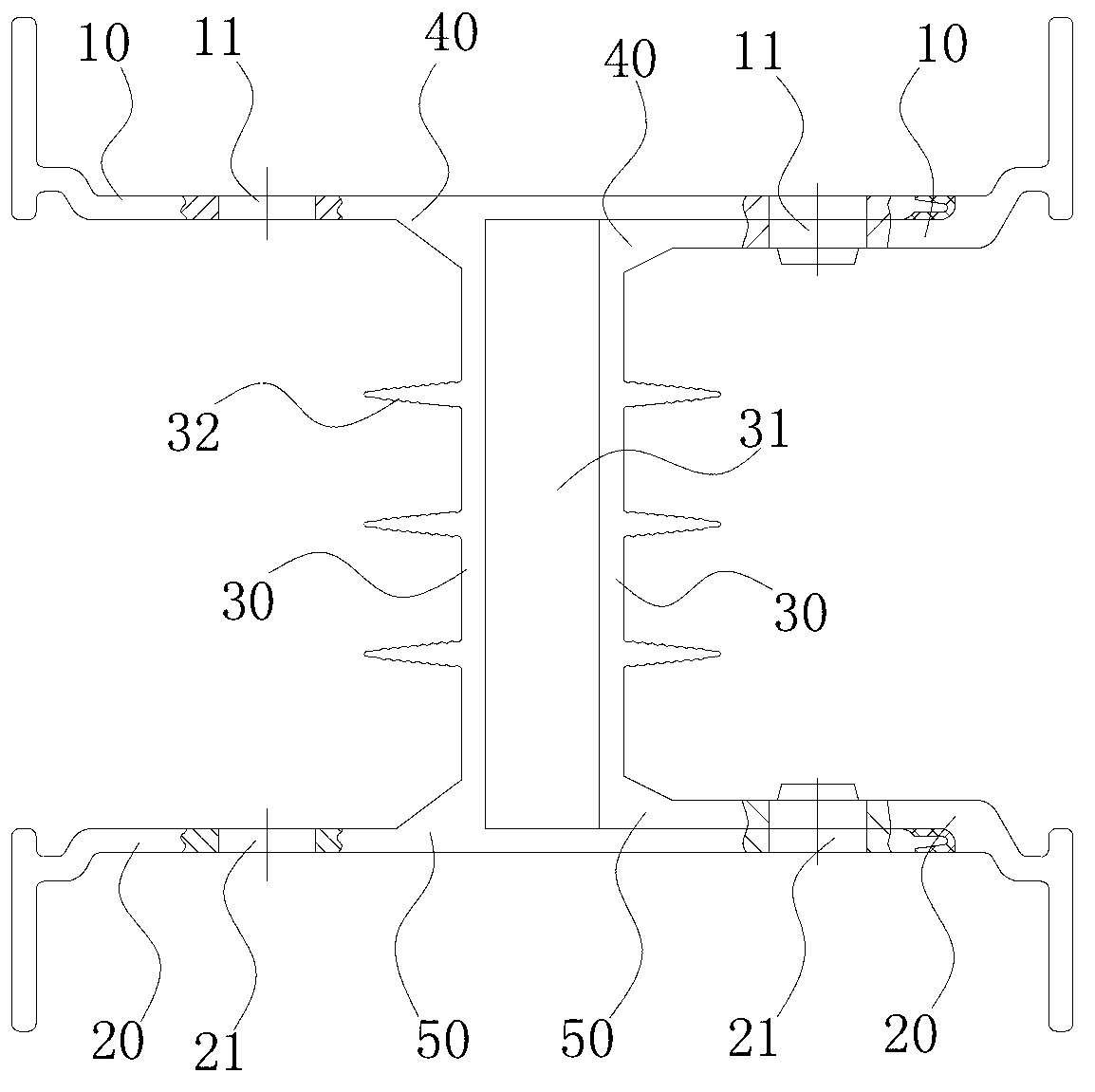

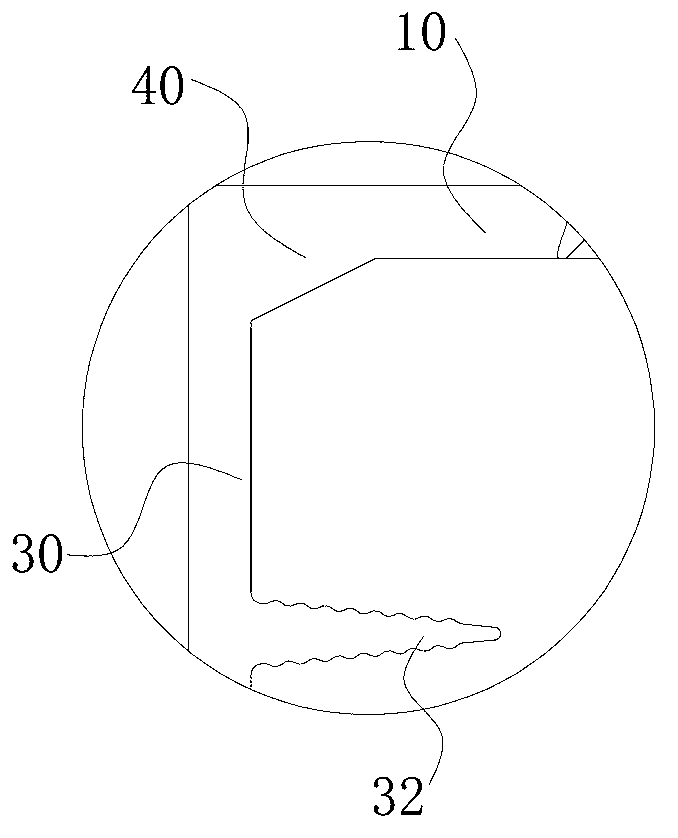

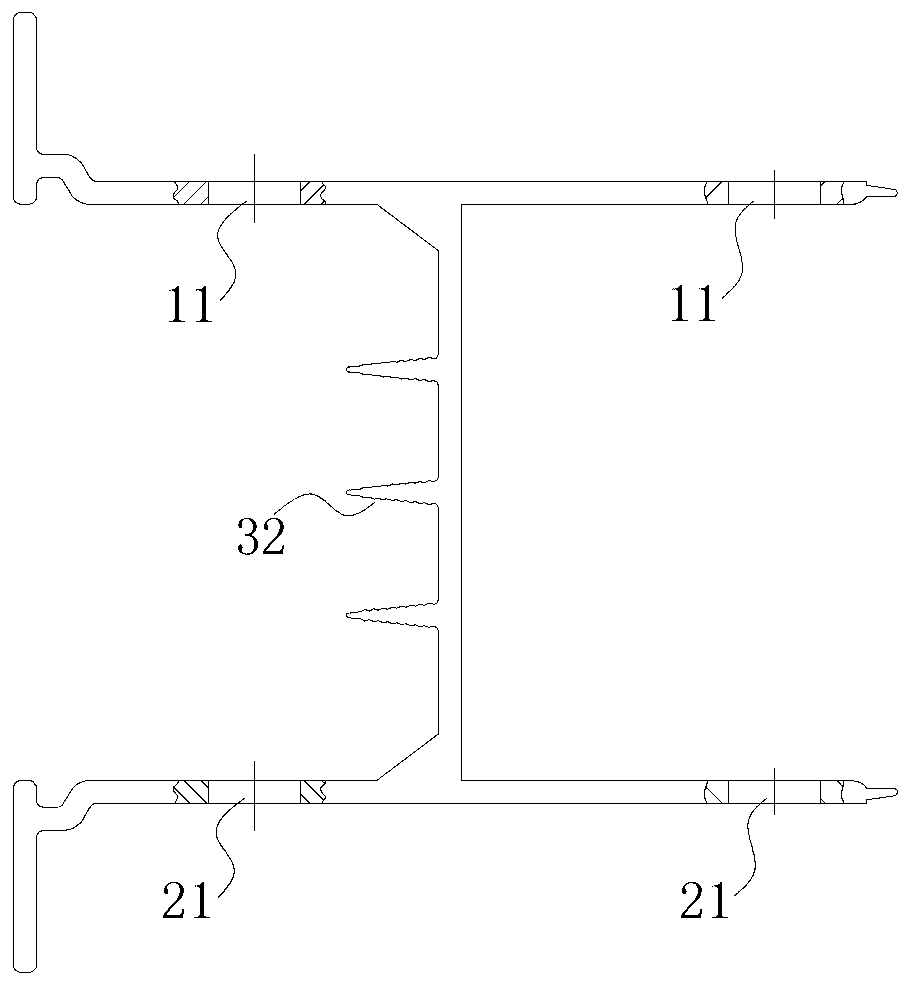

[0037] Such as Figure 1 to Figure 5 As shown, a busway housing includes two upper plates 10, two lower plates 20 and two side plates 30, the two side plates 30 are located between the upper plate 10 and the lower plate 20, and the two side plates 30 forms a bus bar placement position 31, the area between the upper plate 10 and the lower plate 20 is a heat dissipation area, the upper convection holes 11 are provided on the two upper plates 10, and the lower convection holes 21 are provided on the lower plates 20, The upper convection hole 11 is located above the heat dissipation area, and the lower convection hole 21 is located below the heat dissipation area.

[0038] Among them, the bus duct housing includes an "I" shape and a "C" shape. The cross section of the "I" shape is "I" shape, and the cross section of the "C" shape is "C" shape; the "C" shape is snapped into the In the "worker" shape, a pair of upper plates 10 and lower plates 20 are respectively located at the upp...

Embodiment 2

[0047] Such as Image 6 , Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that, in order to avoid the appearance of "quilt effect", the method adopted in this embodiment is: the height of the heat dissipation protrusion 32 is 3 mm to 5 mm (preferably 4 mm), and the distance between two adjacent heat dissipation protrusions 32 is 4 mm to 8 mm (preferably 6 mm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com