Art knife

A utility knife and blade technology, which is applied in the field of utility knives, can solve the problems of inability to achieve infinite adjustment, troublesome, and unaffected by users.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

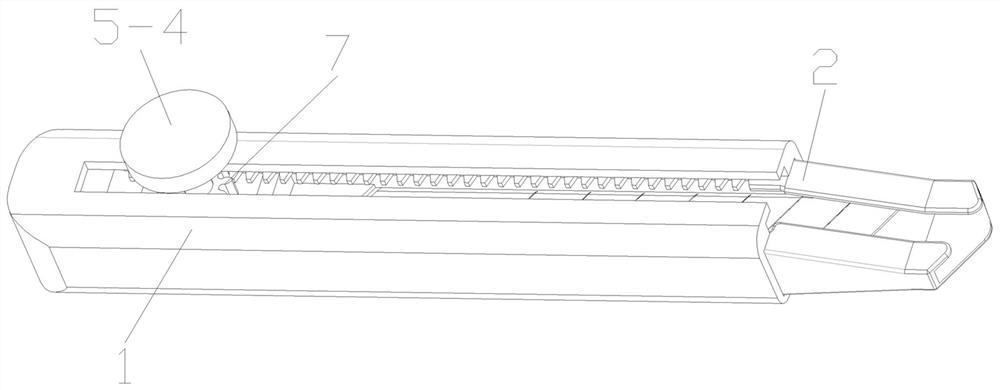

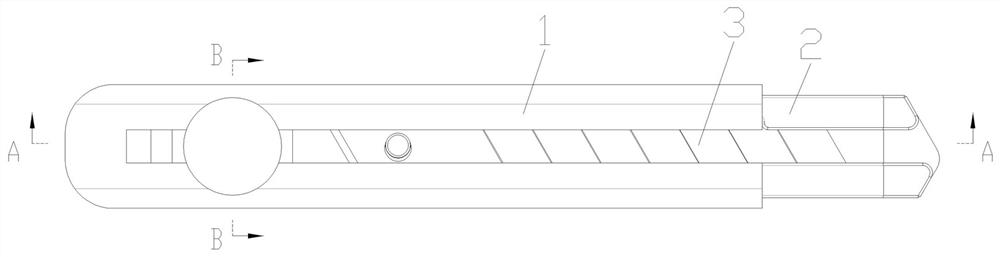

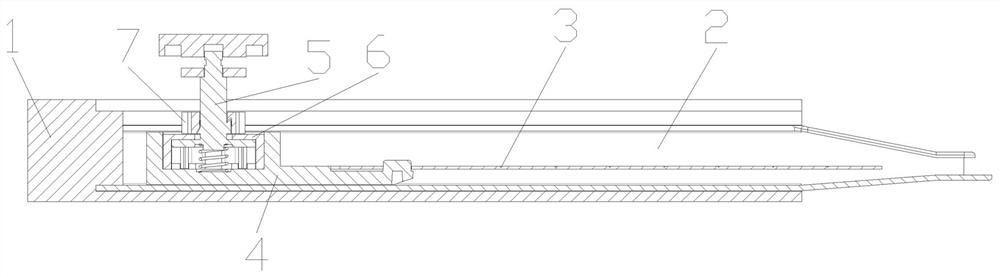

[0027] Such as Figure 1 to Figure 6 As shown in , the utility knife of the present invention includes a protective case 1, a bushing 2, a slider 4, a blade 3, a gear mounting part 5, a limit block 6 and a gear 7, the bushing 2 is arranged in the protective case 1, and the bushing 2 is provided with a chute 2-1, a side of the chute 2-1 along the length direction is provided with a rack 2-2, the slider 4 is slidably arranged in the chute 2-1, and the blade 3 is arranged on the On the slider 4, the bushing 2 is provided with a blocking portion 2-3 and a knife edge 2-4 at one end of the chute 2-1, the slider 4 drives the blade 3 to slide so that the blade 3 protrudes out of the knife edge 2-4, When the slider 4 moves to contact with the blocking portion 2-3, the blocking portion 2-3 limits the slider 4, and at this time the length of the blade 3 protruding out of the knife edge 2-4 is the largest.

[0028] The gear mounting part 5 is integrally formed with a gear shaft 5-3 and f...

Embodiment 2

[0033] The difference between the utility knife of this embodiment and Embodiment 1 is that the second limit structure of the slider 4 to the circumferential limit of the gear mounting part 5 is different. In this embodiment, the gear mounting part 5 is provided with a bayonet, and the sliding The block 4 is provided with a detachable buckle head that cooperates with the buckle, and the shaft cap 5-4 is pulled upward to make the gear mounting part 5 rise, so that the bayonet and the buckle head are buckled and connected, and the slider 4 is connected to the gear. The mounting part 5 is limited in the circumferential direction, and the gear mounting part 5 is lowered by pressing the shaft cap 5-4, so that the bayonet can be disengaged from the buckle, and the slide block 4 cannot limit the gear mounting part 5 in the circumferential direction.

[0034] Since the gear mounting part 5 and the gear shaft 5-3 are integrally formed, it can be understood that the lifting of the gear m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com