Centrifugal fan impeller

A centrifugal fan and impeller technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of jet-wake at the outlet of the impeller, increased noise, etc., to reduce aerodynamic noise, increase distance, and suppress disturbances Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

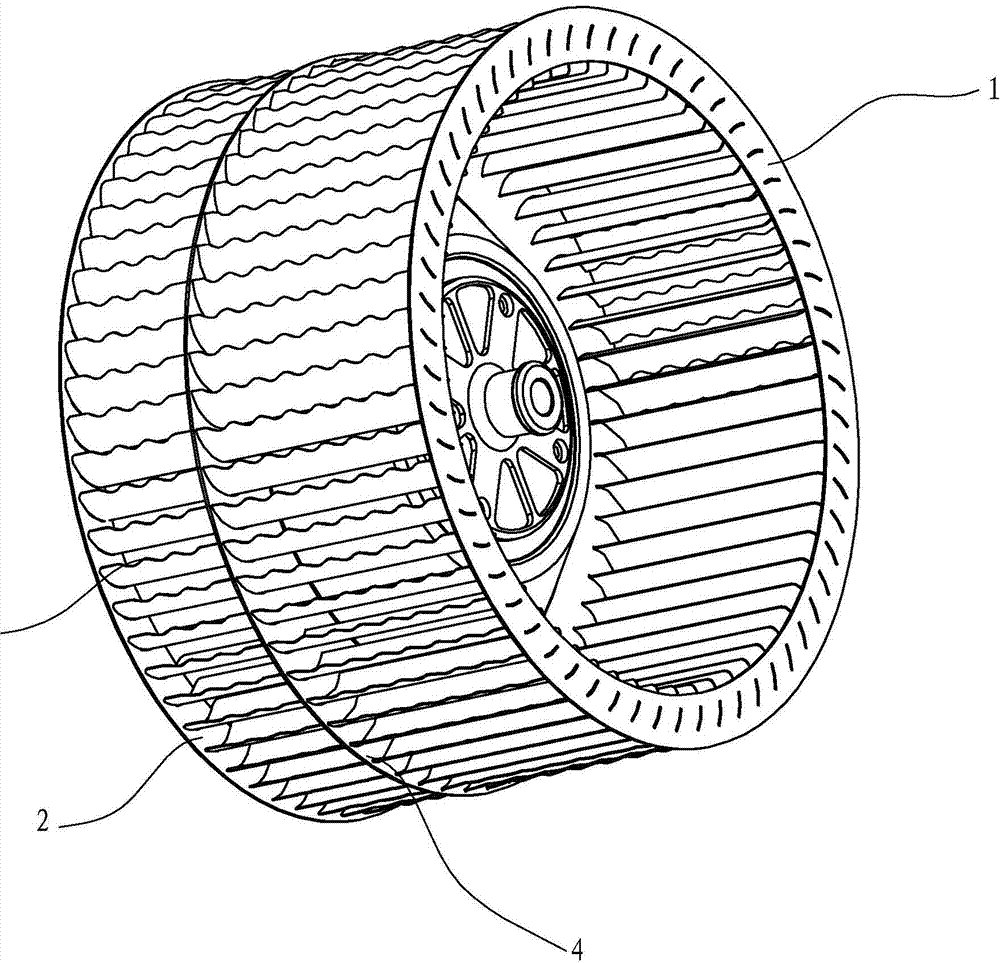

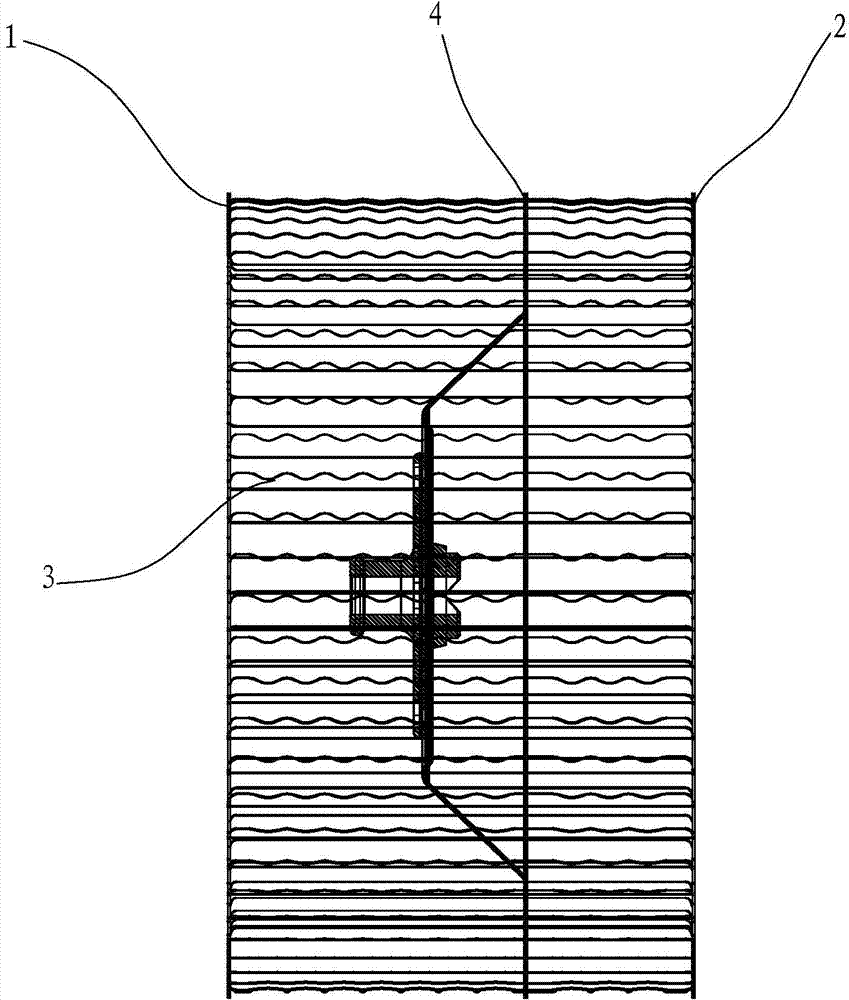

[0019] see figure 1 with figure 2 , an impeller of a centrifugal fan, including a front ring 1 and a rear ring 2, a plurality of blades 3 are fixed between the front ring 1 and the rear ring 2, and the blades 3 are riveted with the front ring 1 and the rear ring 2 in an existing conventional way fixed together. A middle plate 4 is also provided between the front ring 1 and the rear ring 2, thereby forming a two-way air intake structure.

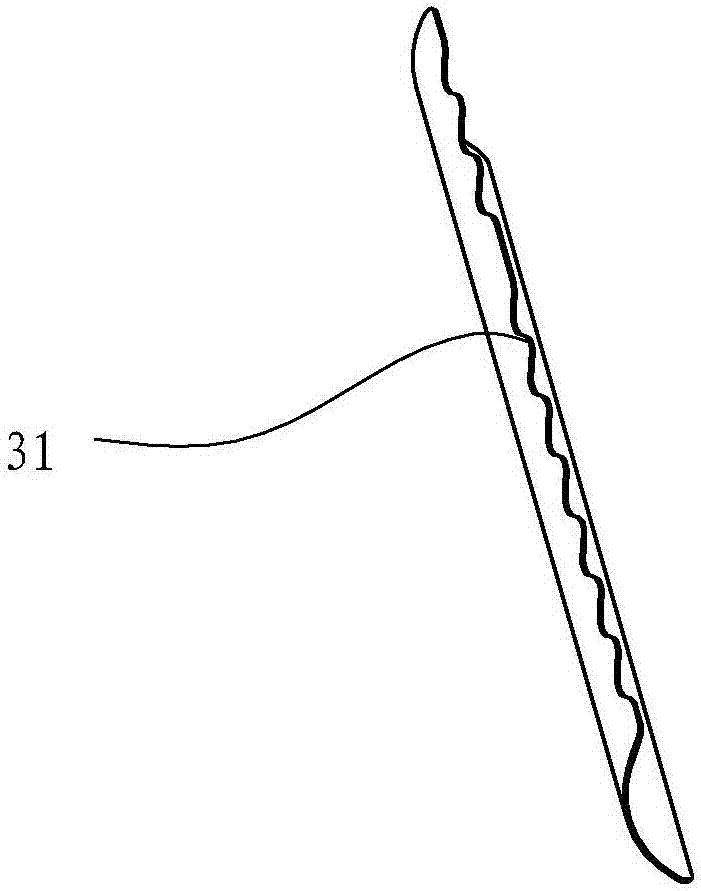

[0020] see image 3 , the outlet end 31 of the blade 3 (the trailing edge towards the outside of the impeller) is wavy and serrated; see Figure 4 , the outlet end 31 of the blade 3 includes a plurality of sawtooth 311, the sawtooth 311 is arranged along the length extension direction of the blade 3, the height of each sawtooth 311 is h, and the width is t, preferably, 0.5mm<h<3mm, 0.1< h / t<0.6, more preferably h / t=0.25.

[0021] The blade 3 is divided into front and rear two sections at the middle plate 4, the distance from the startin...

Embodiment 2

[0023] see Figure 5 , the difference between this embodiment and Embodiment 1 is that the centrifugal fan is a single-inlet type, and no middle disk is provided. The distance of 1 is a, and the distance between the end of the last sawtooth 311 (the sawtooth near the back circle 2) and the back circle 2 is b, preferably, 0<

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com