Patents

Literature

37results about How to "Limit width" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

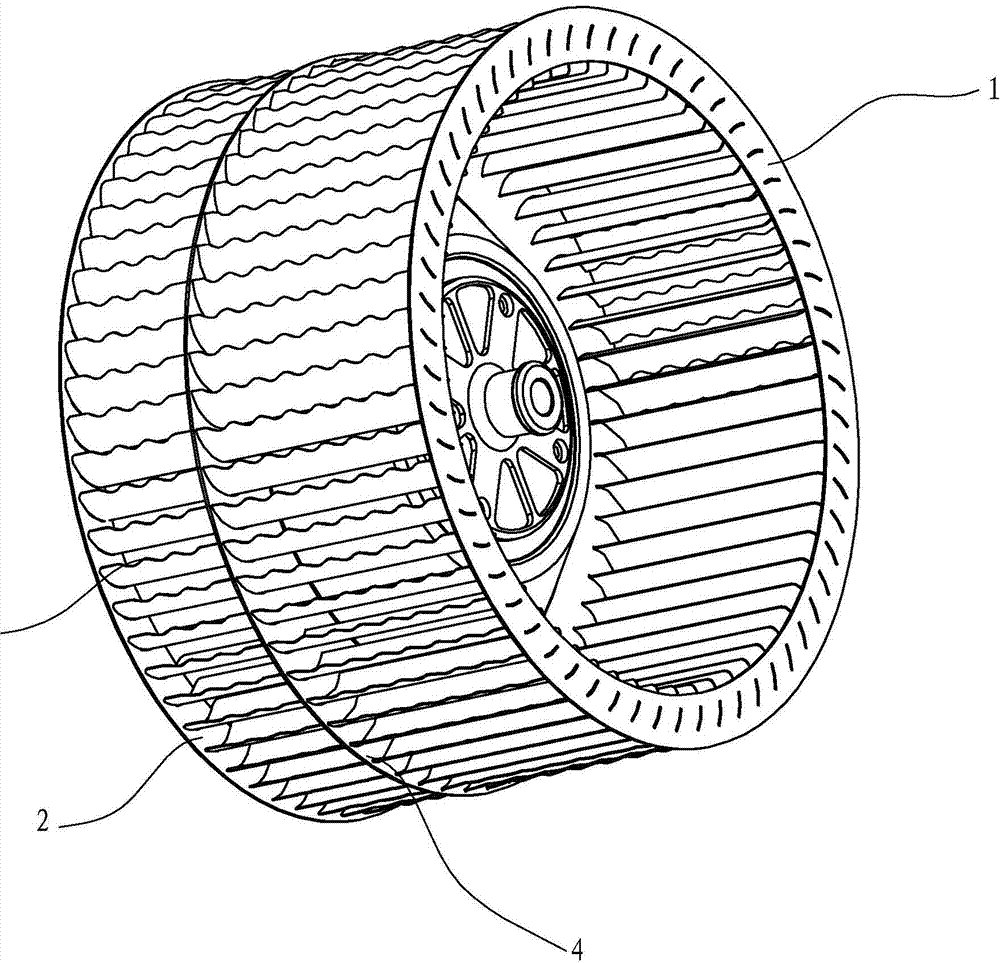

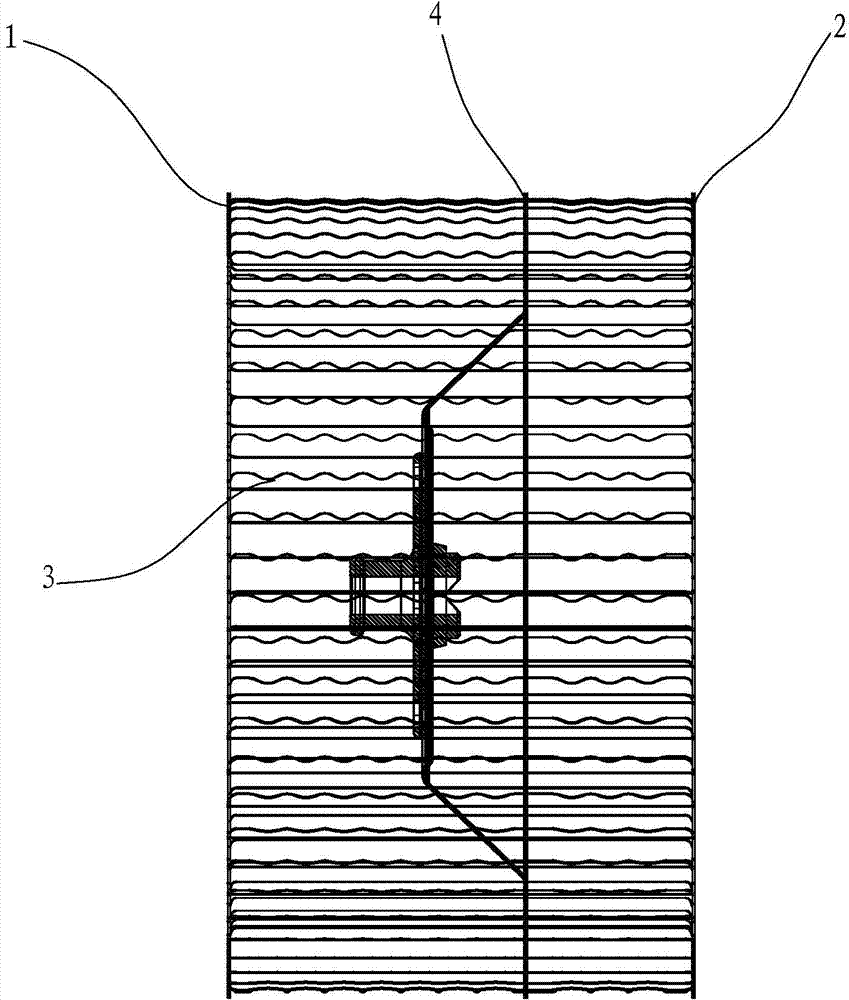

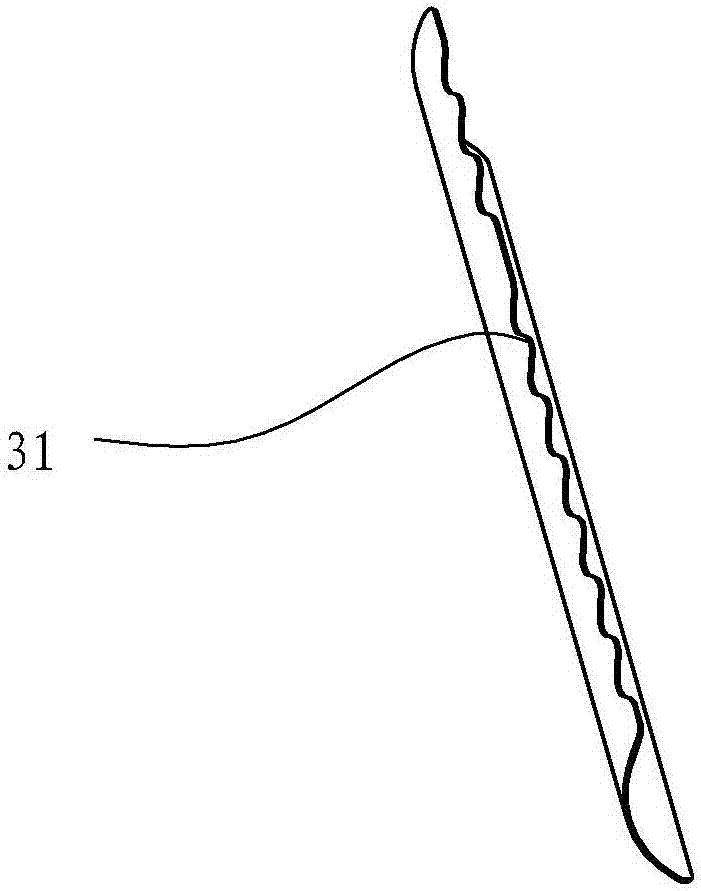

Centrifugal fan impeller

The invention discloses a centrifugal fan impeller, which comprises a front ring and a back ring, wherein a plurality of blades are fixedly arranged between the front ring and the back ring. The centrifugal fan impeller is characterized in that the outlet ends of the blades form a wave-shaped sawtooth type by a plurality of sawteeth. The outlet ends (tail edges) of the blades are provided with structures in the wave-shaped sawtooth type, and the wake vortex shedding positions of the tail edges of the blades are changed, so the distance between the vortex centers is increased, the disturbance of the shedding vortex on the wake flowing is inhabited, and the pneumatic noise caused by the wake vortex and the unsteady pressure fluctuation of the blade surfaces is further reduced. The height and the width of the sawteeth are limited, the noise is further reduced, and the influence of the sawteeth on the pressure and air quantity reduction of a fan can also be reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

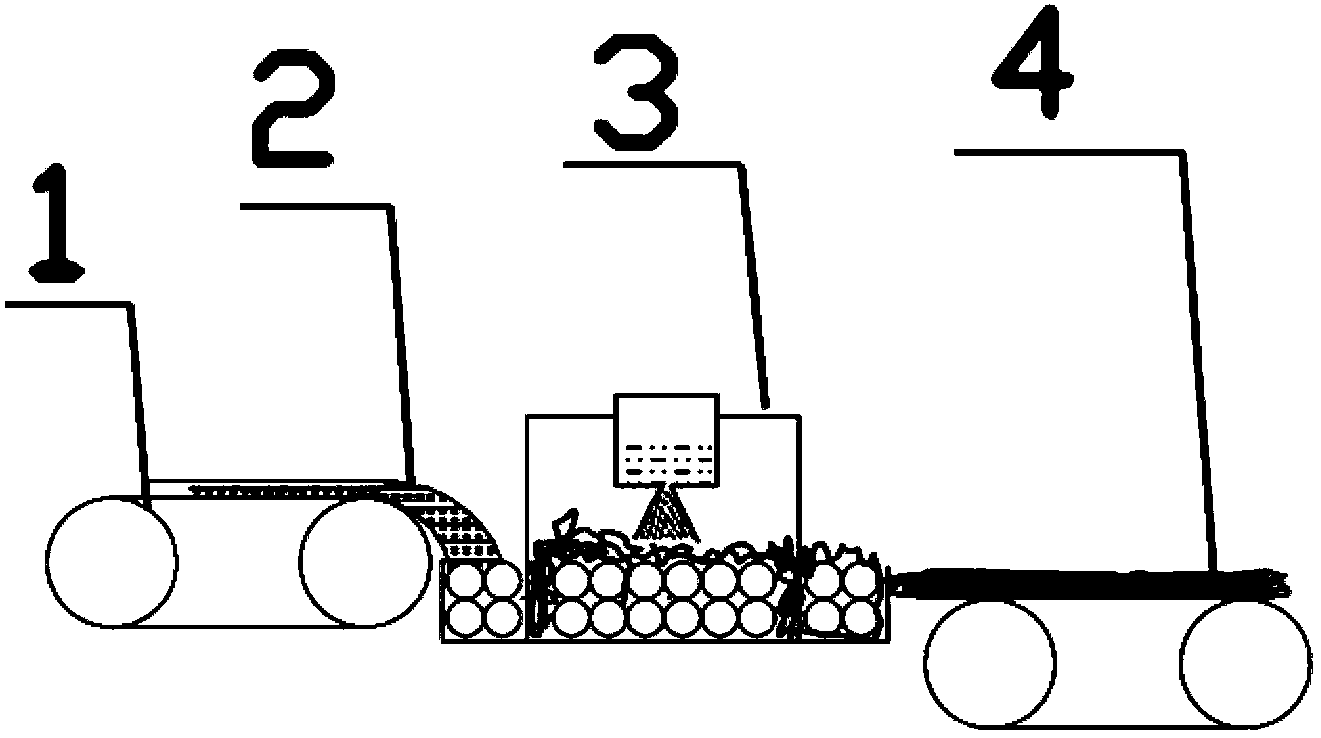

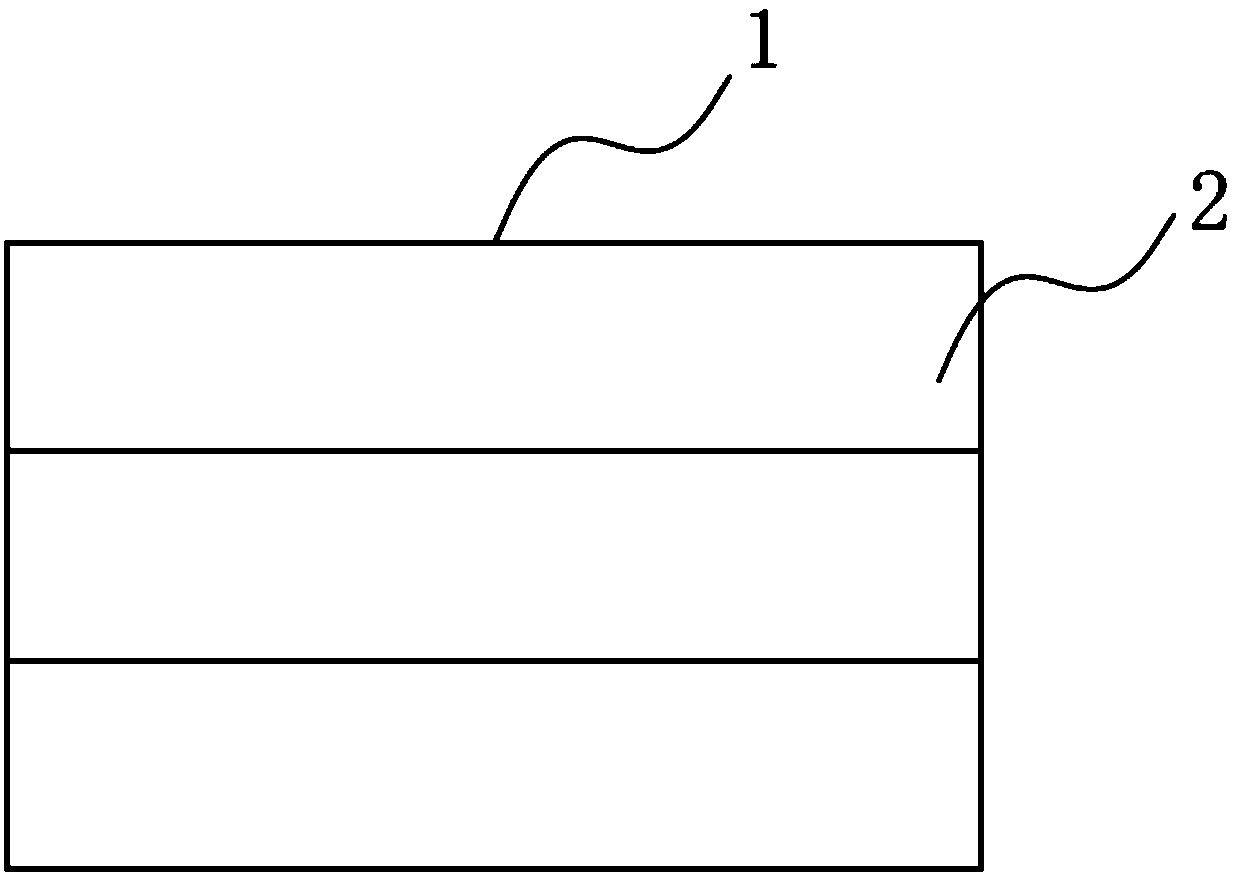

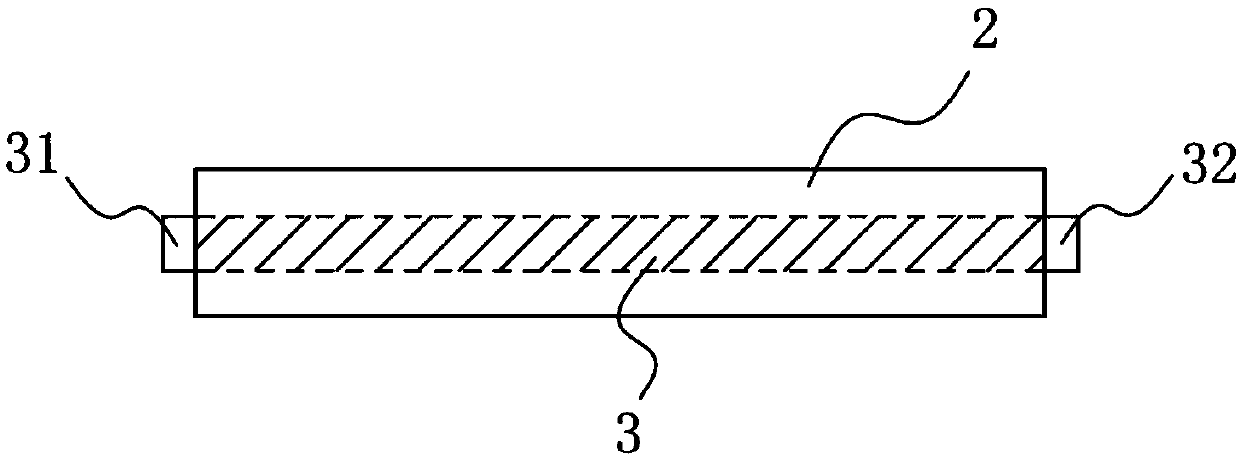

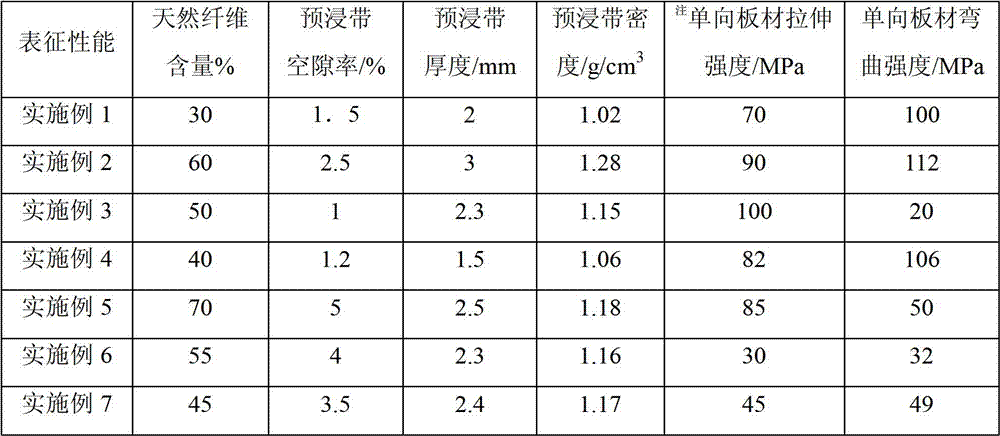

Nature fiber reinforced thermoplastic resin unidirectional prepreg tape and preparation method thereof

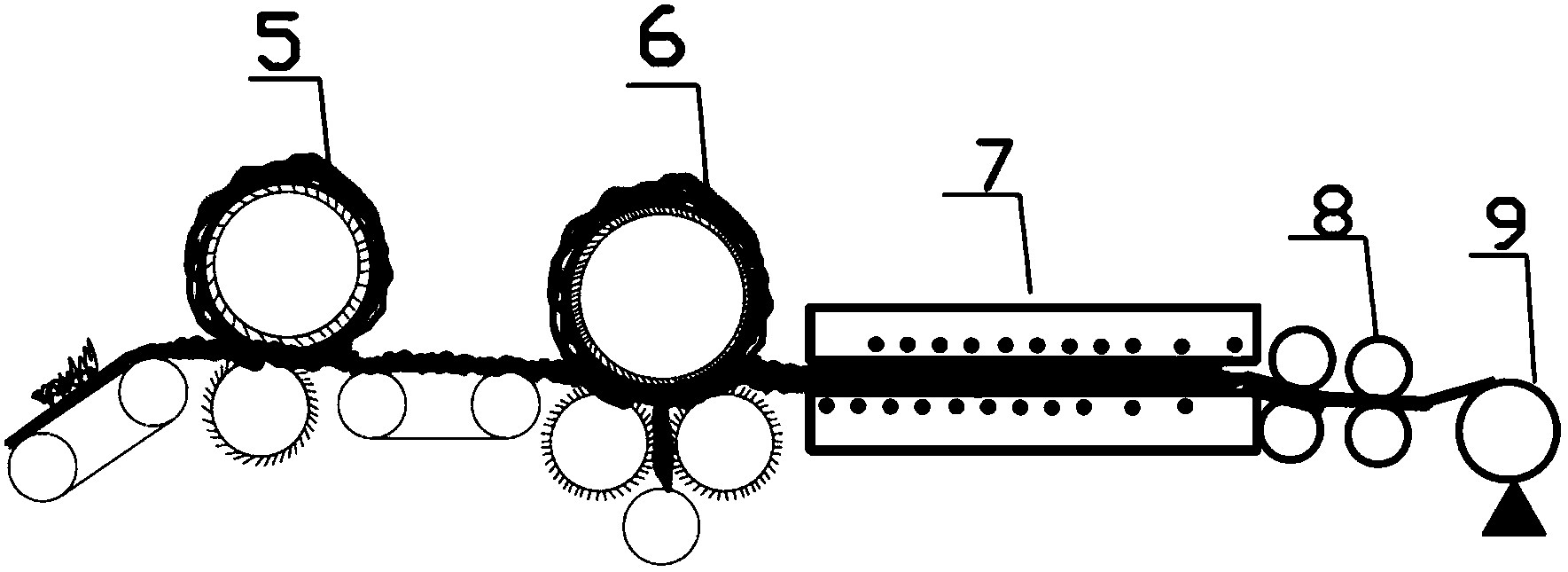

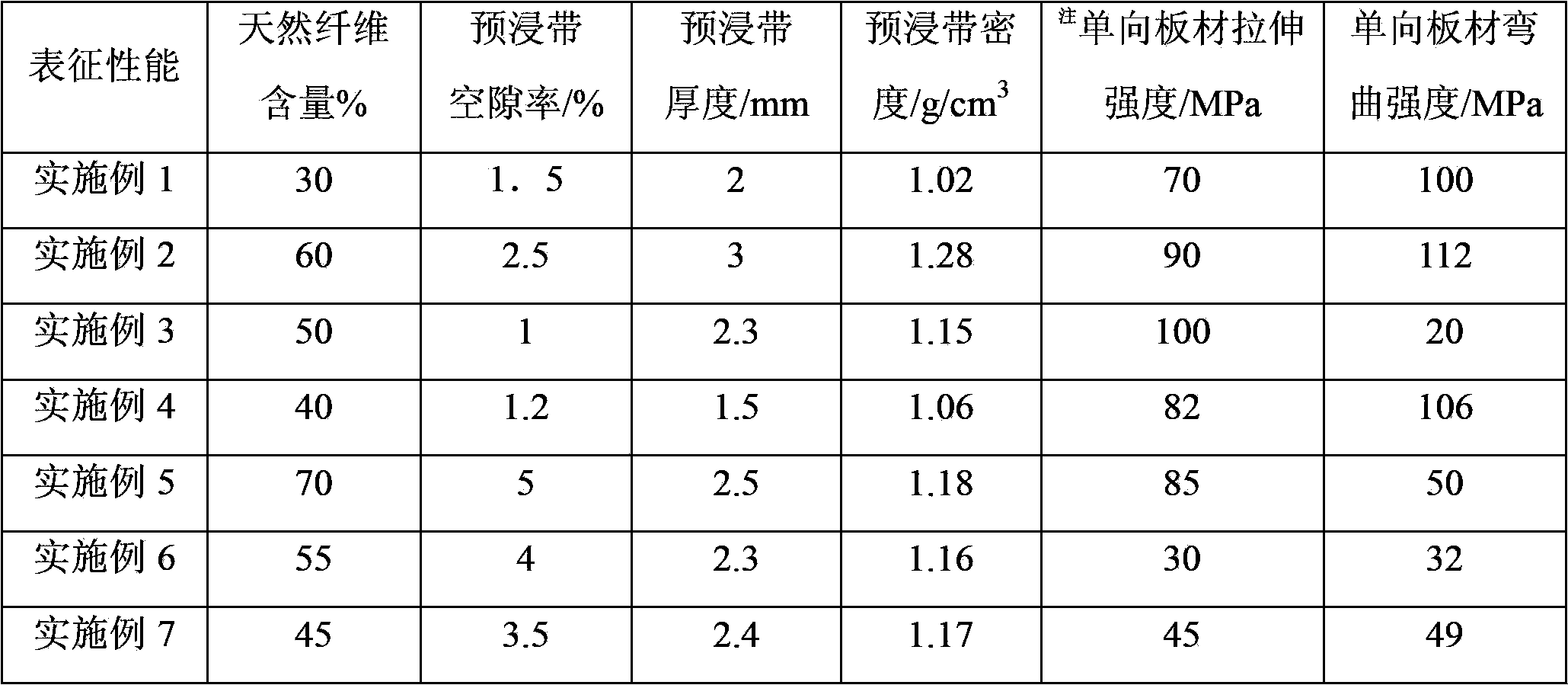

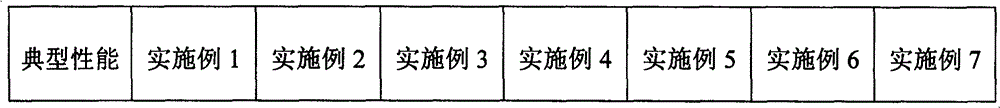

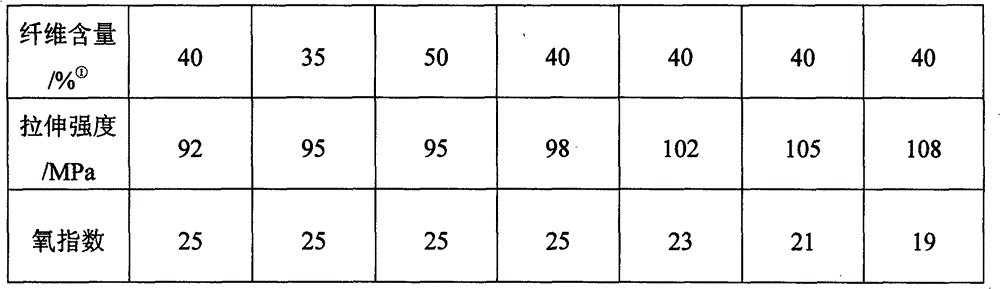

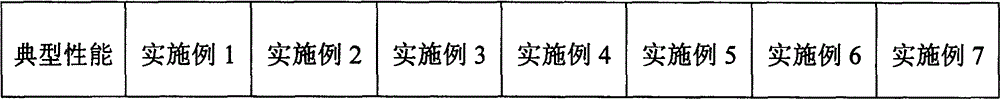

The invention belongs to the field of composite material production and preparation, and relates to a fiber reinforced thermoplastic resin unidirectional prepreg tape and a preparation method thereof. The prepreg tape is prepared from the following components, by weight: 30-70 parts of a thermoplastic resin, 30-70 parts of nature fibers, 0-1 part of a coupling agent, and 0-1 part of an emulsion. Compared with the prepreg tape in the prior art, the prepared nature fiber / thermoplastic resin unidirectional prepreg tape of the present invention has the following advantages and beneficial effects that: mechanical strength is high, the prepreg tape can be stored for a long time, the nature fibers are completely impregnated by the resin and are not exposed to the outside so as to maintain the dry state of the material, particularly the nature fibers, the nature fibers are not easily subjected to mildew deterioration, and the porosity is low so as to ensure performance stability of the product. With the method, the width of the reinforcing material and the nature fibers can be limited so as not to cause nature fiber deviation phenomenon during the subsequent production process.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

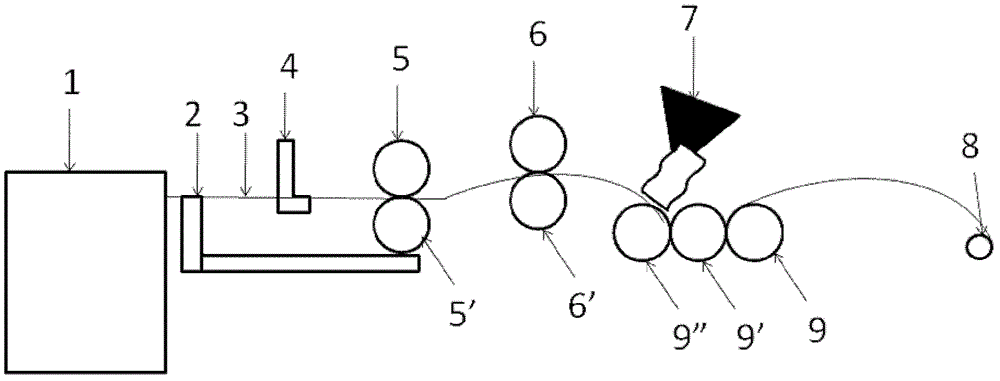

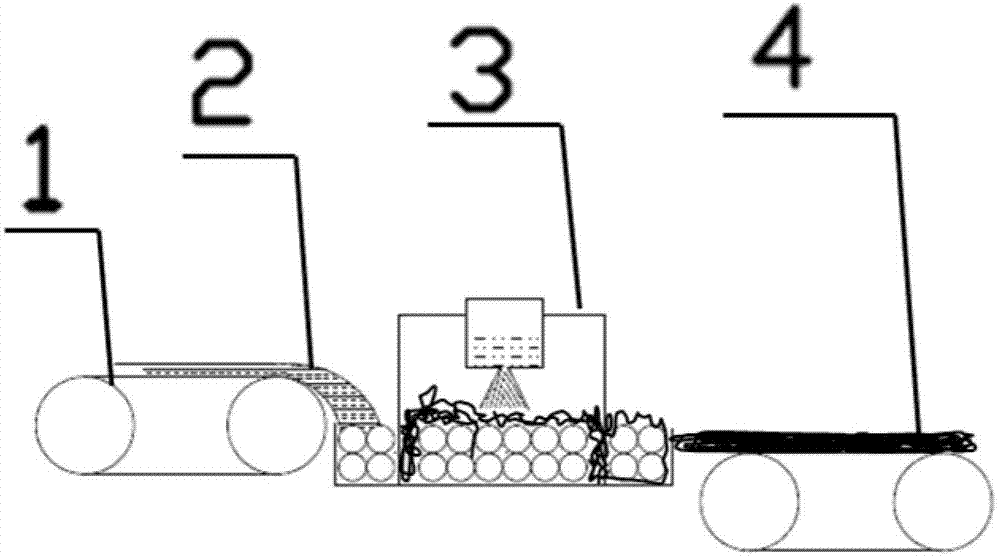

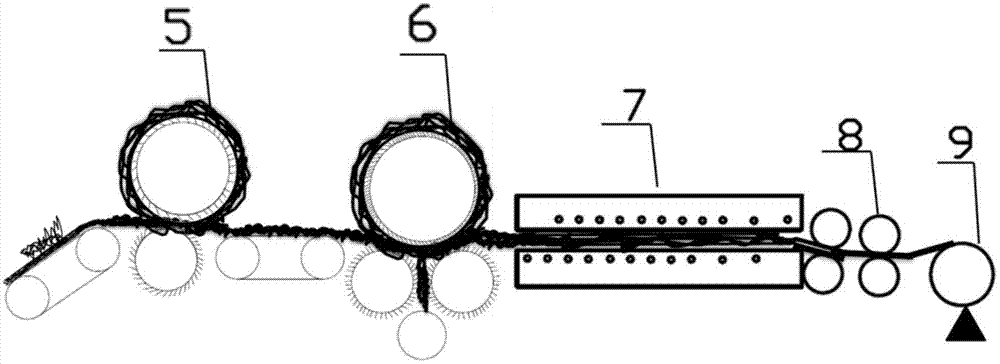

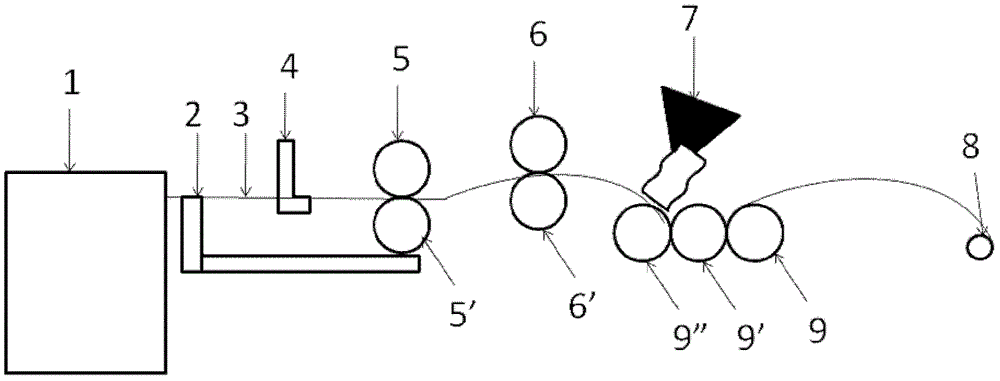

Biodegradable composite prepreg cloth, and preparation method and device for the same

ActiveCN103061162AGood self-extinguishingGenerates less gasPhysical treatmentNatural fiberBiodegradable composites

The invention relates to a biodegradable composite prepreg cloth, and a preparation method and a device for the same. The composite prepreg cloth comprises a modified polylactic acid (PLA) resin accounting for 40-70 wt% of the composite prepreg and natural fiber. The preparation method comprises the following steps: conducting a continuous drying treatment on natural fiber; immersing the fiber with molten modified PLA; coating the modified PLA on the surface of the natural fiber; and rolling, cooling and winding to obtain the prepreg cloth. The device comprises an untwisting machine, an arrangement warping device, a direction control device, a friction roll, a tenslator, a film extruder, a gum dipping cooling device, and a winding device. Compared with the prior art, the invention has the advantages of large fiber draw ratio, obvious PLA enhancement effect, small wear of the extruder screw, simple process, energy saving and environment-friendliness.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

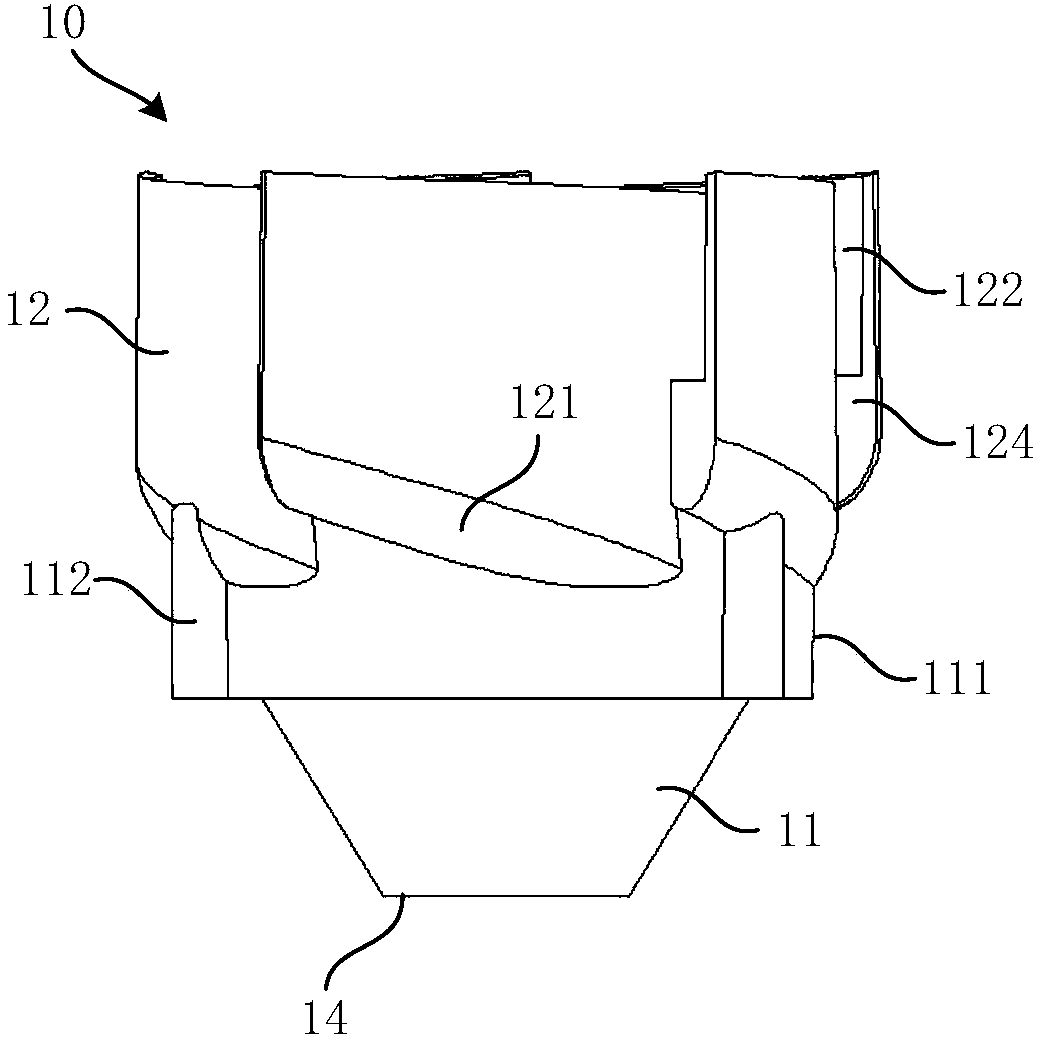

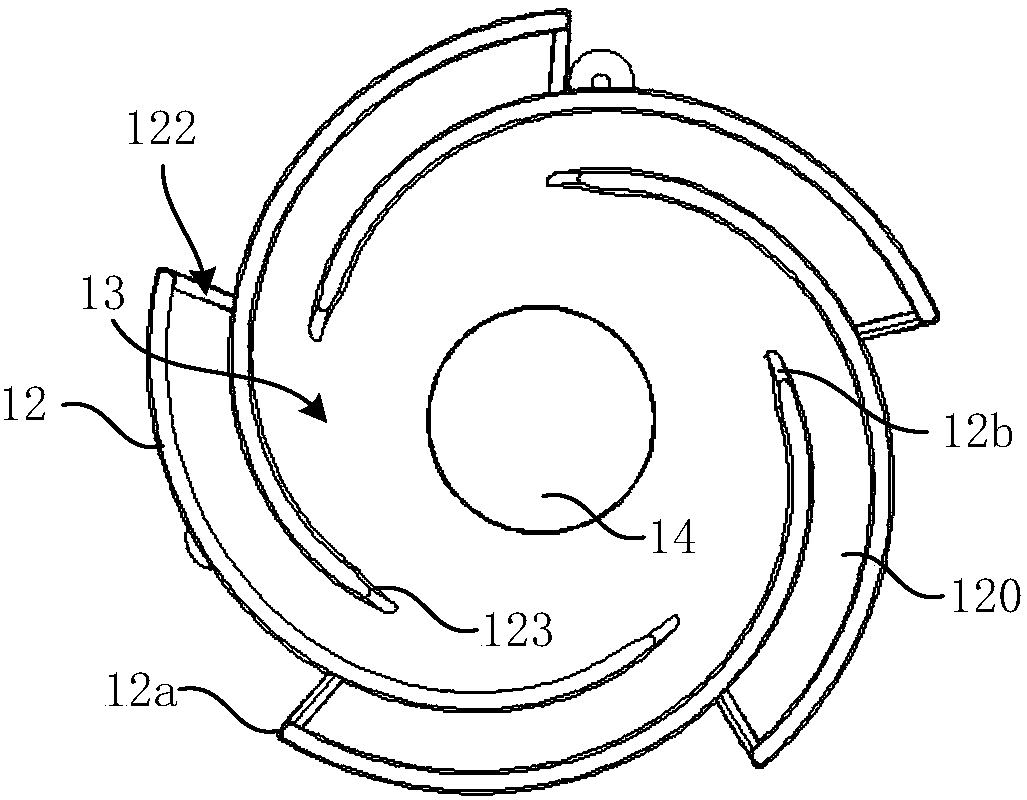

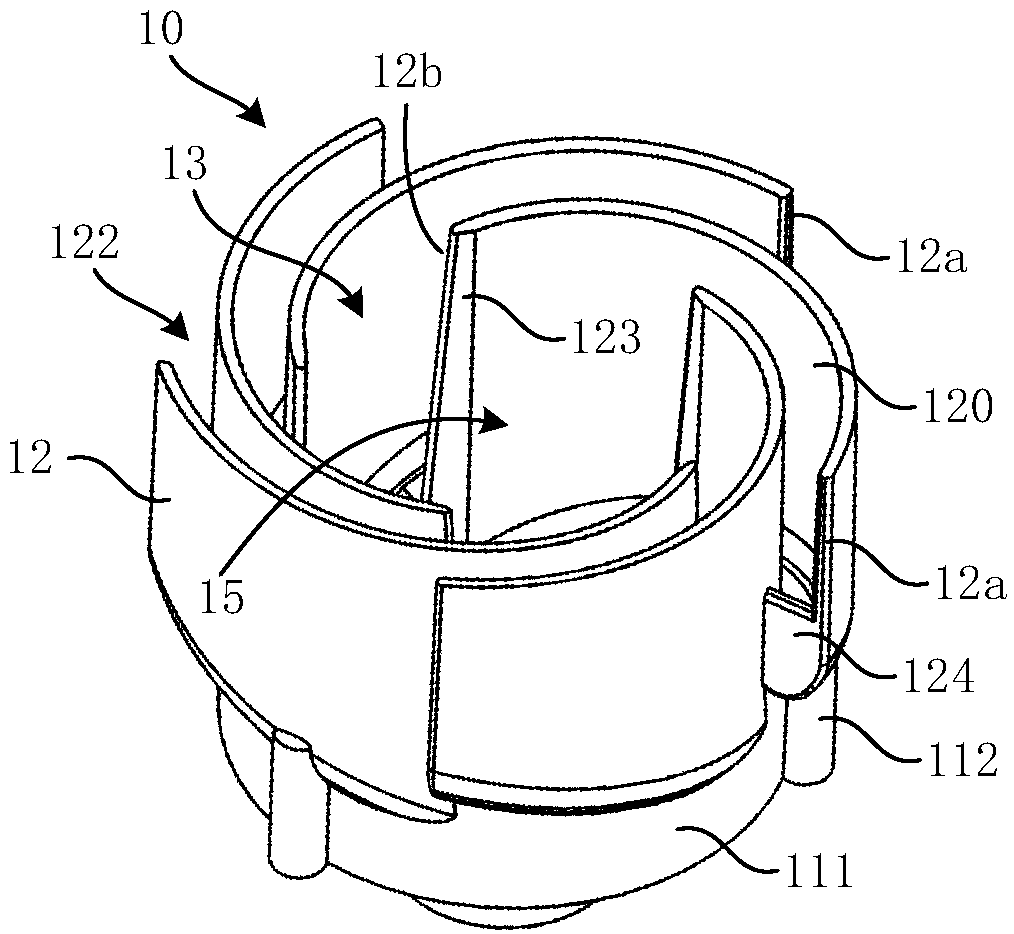

Cyclone separator and filtering assembly

The invention discloses a cyclone separator. The cyclone separator is arranged on a filtering air duct of a vacuum cleaner. The cyclone separator comprises a separation cavity, multiple air guide blades, an air outlet and a dust discharge opening, and the separation cavity is of an inverse conical structure and is longitudinal; the air guide blades are of the same longitudinal arc face structure and uniformly and spirally surround the top of the separation cavity to form multiple air inlet channels, the bottoms of the air guide blades extend inwards to form air duct base plates, each air guideblade is provided with an outer end and an inner end, the outer ends of the air guide blades and the outer walls of adjacent air guide blades form air duct inlets, and the inner ends of the air guideblades and the adjacent air guide blades form air inlets of the separation cavity; the air outlet is formed in the top of the separation cavity; the dust discharge opening is formed in the bottom ofthe separation cavity. The invention further discloses a filtering assembly. By means of the cyclone separator, multiple air inlet channels are formed through the spiral air guide blades, the air guide effect is improved, inlet air is uniform, and thus the separation efficiency is improved.

Owner:XIAOGOU ELECTRIC INTERNET TECH BEIJING CO LTD

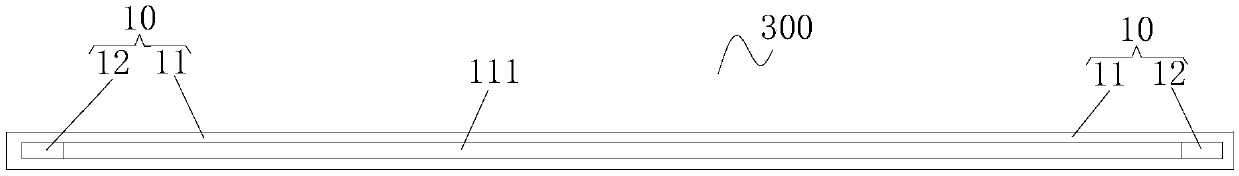

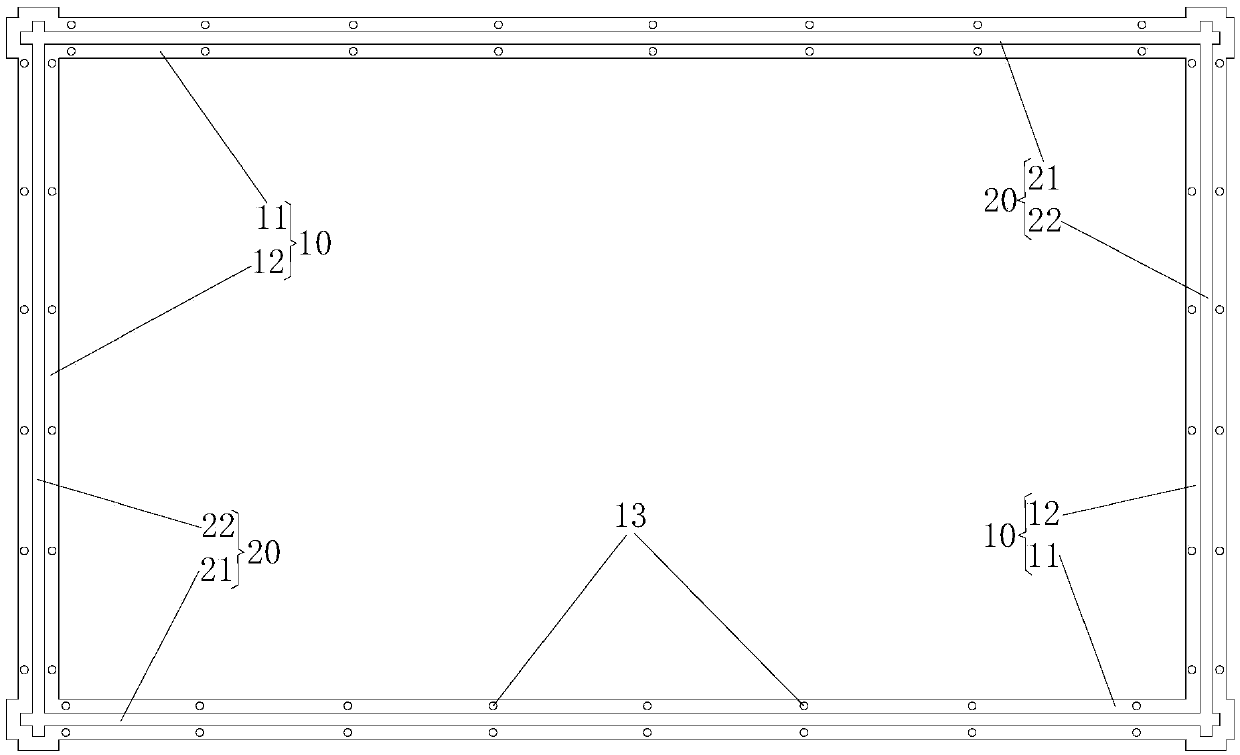

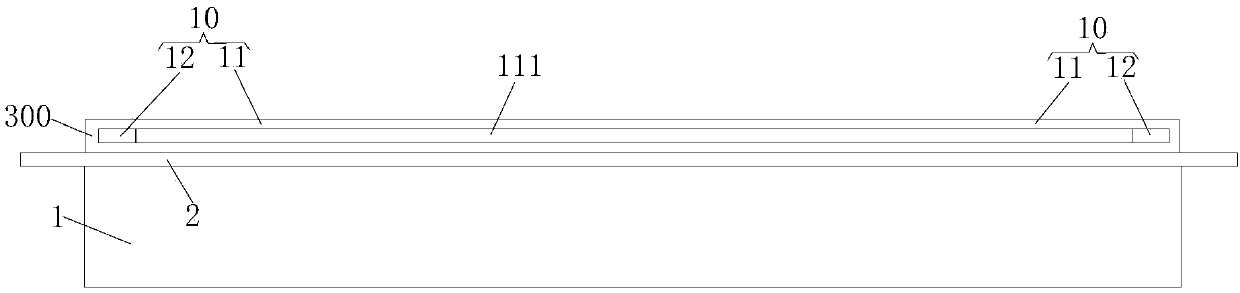

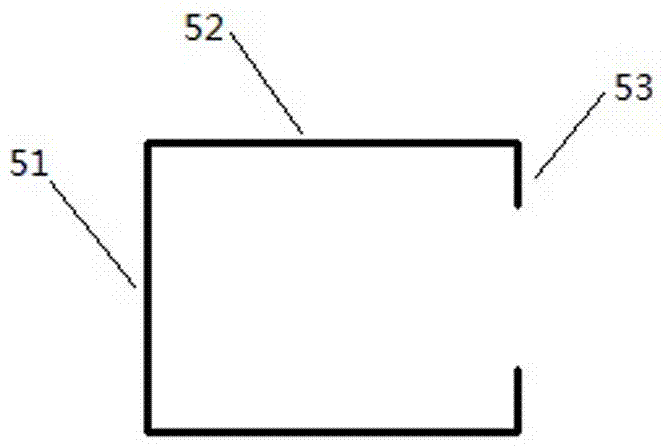

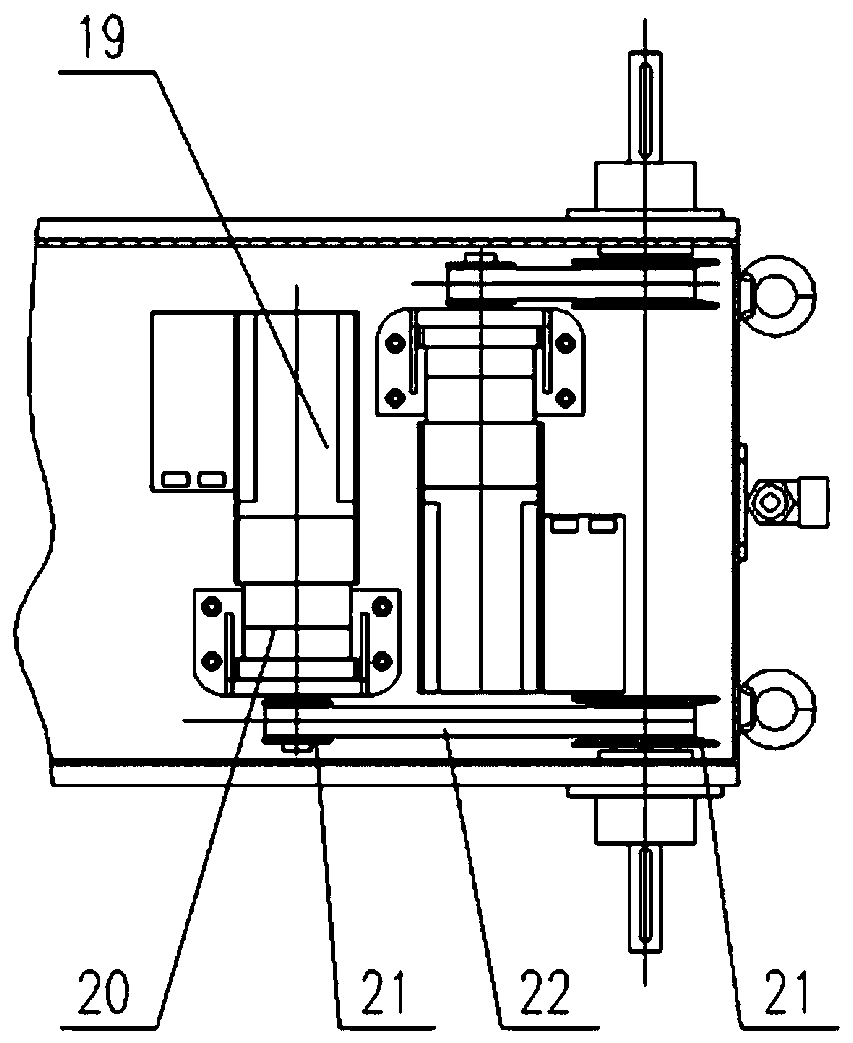

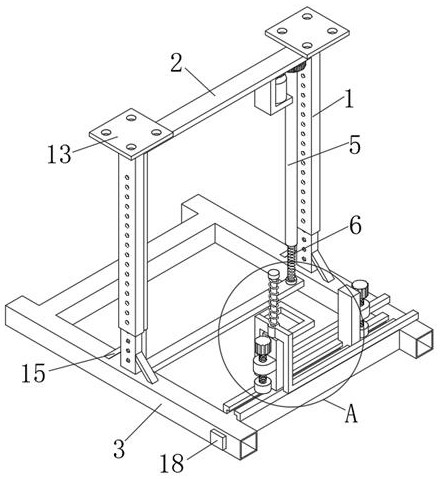

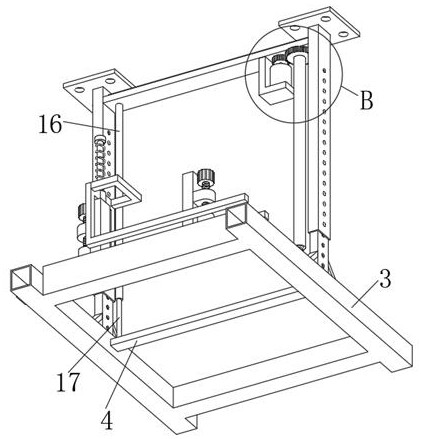

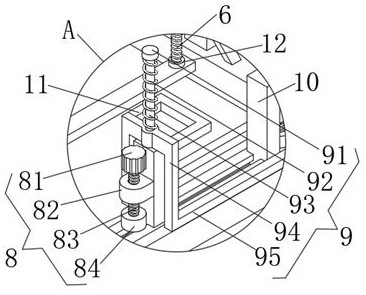

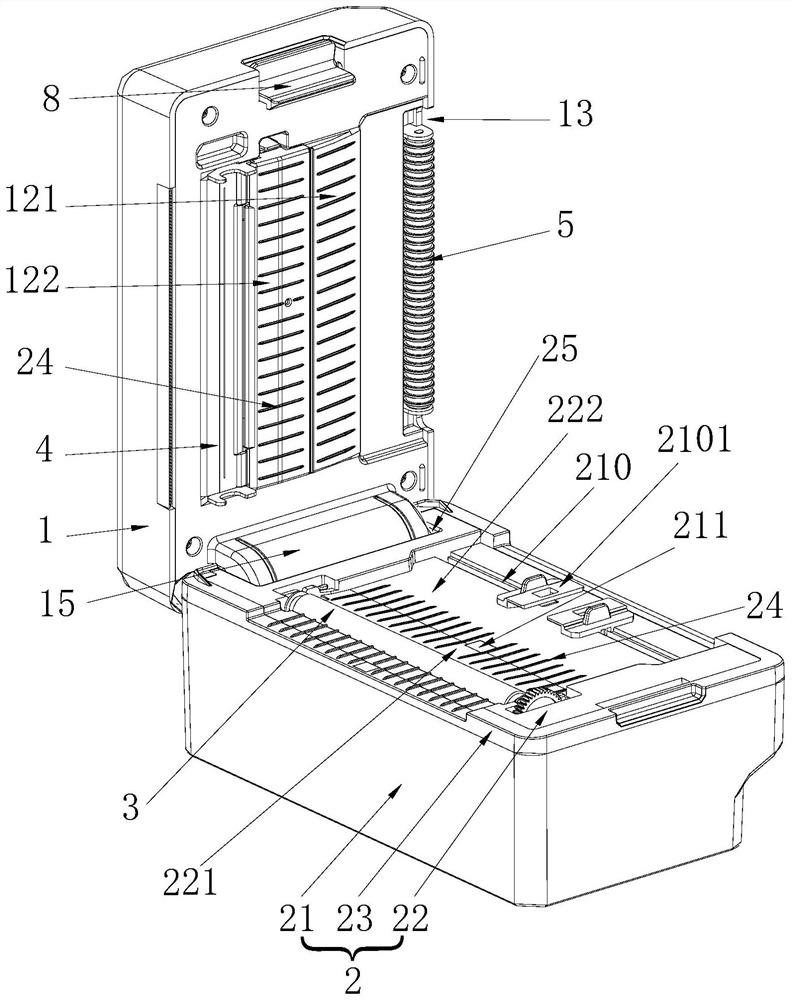

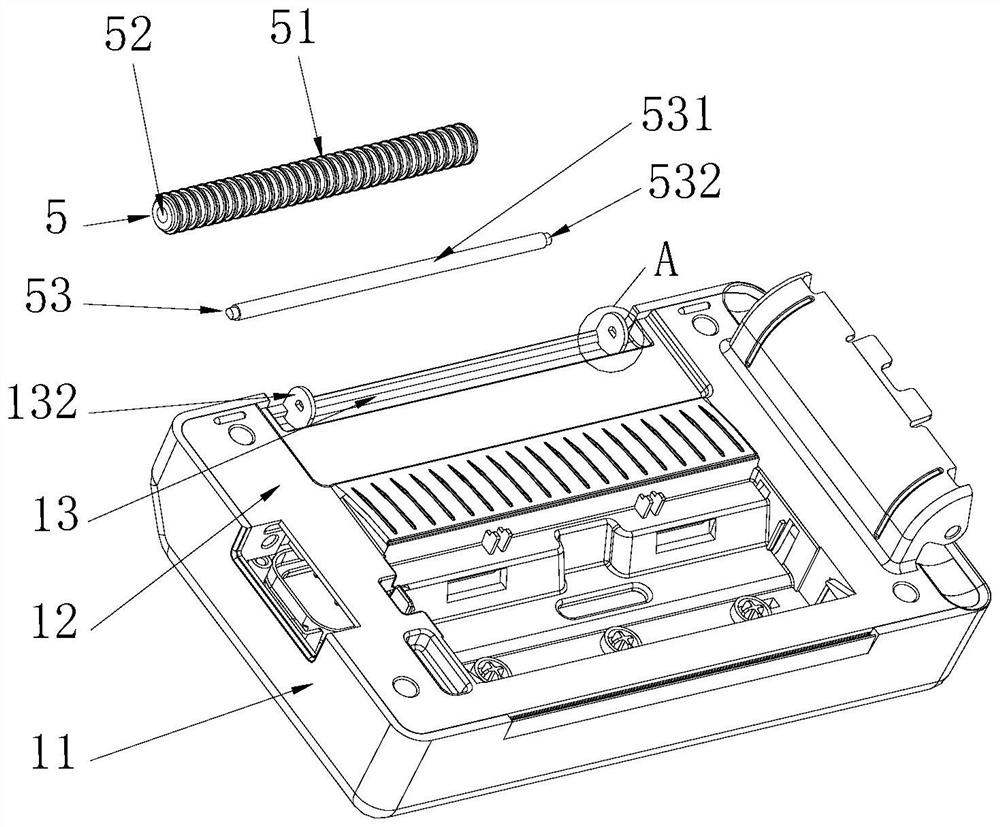

Film pressing fixture and laser film cutting system

ActiveCN107745187AEfficient planning of cutting contoursAvoid loss and wasteLaser beam welding apparatusEngineeringLaser cutting

The invention provides a film pressing fixture and a laser film cutting system. The film pressing fixture comprises a frame body which is installed on a surface of film base material; the frame body is provided with an annular cutting path which is a light transmitting slit opened in the frame body; the light transmitting slit penetrates the frame body in the direction vertical to a plane surrounded by the frame body so that the laser penetrates and the film base material is cut on a display screen. The invention solves the problem that the film base material has a large amount of loss duringthe filming operation of the display screen in the prior art.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Dustproof air outlet device of mobile terminal

PendingCN109600979AGuaranteed circulationAvoid enteringCooling/ventilation/heating modificationsAir convectionEngineering

The invention relates to a dustproof air outlet device of a mobile terminal. The dustproof air outlet device comprises a support frame, a driving mechanism and a plurality of baffle plates, wherein the support frame is arranged at an air discharging hole, a rotation shaft is arranged in the baffle plate, the rotation shaft is used for driving the baffle plate to be opened or closed by rotation, adriving end and a driven protrude out of the baffle plate and are movably arranged on the support frame, and the driving mechanism is connected with the driving end and is used for driving the rotation shaft to rotate by the driving end; when an electric fan runs, the driving mechanism drives the rotation shaft to positively rotate, and the baffle plate is driven to be opened by the rotation shaft; when the electric fan stops running, the driving mechanism drives the rotation shaft to reversely rotate, and the baffle plate is driven to be closed by the rotation shaft; when the electric fan runs, the rotation shaft is driven to positively rotate by the driving mechanism so that the baffle plate is driven to be opened; and when the electric fan stops running, the rotation shaft is driven toreversely rotate by the driving mechanism so that the baffle plate is driven to be closed. By the device, air convection can be ensured, and dust is effectively prevented from entering the mobile terminal.

Owner:NUBIA TECHNOLOGY CO LTD

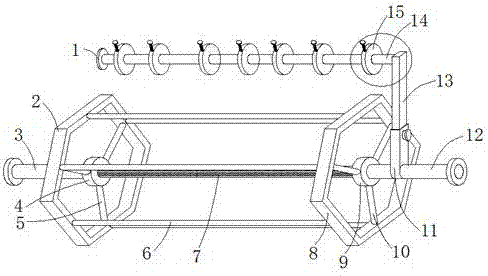

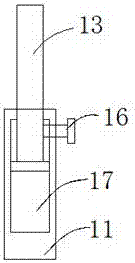

Novel winding roller for textile manufacturing

The invention discloses a novel winding roller for textile manufacturing. The novel winding roller for textile manufacturing comprises a left border frame and a right border frame, the left border frame is connected to a first rotary disc through a first reinforcing rod, and a transmission rod is fixedly connected to the center of the left end face of the first rotary disc; a second rotary disc is connected to the right border frame through a second reinforcing rod, and a connecting rod is fixedly connected between the first rotary disc and the second rotary disc; the winding roller is connected to an edge position between the left boarder frame and the right border frame, a connecting rod is rotatably connected to the center of the right end face of the second rotary disc, and an adjusting sleeve is fixedly connected to the left portion of the connecting rod in the vertical direction; and an adjusting rod is slidably connected with the adjusting sleeve through an adjusting groove in an inserted mode, a limiting rod is horizontally fixed to the side wall of the left side of the top of the adjusting rod, a guide block is slidably connected with the limiting rod in a sleeving mode, and a second set bolt is connected to a cavity of an adapter bore through threads in an inserted mode. The novel winding roller for textile manufacturing not only can wind wires conveniently, but also can limit the width of wire winding, and therefore the wires are not separated as wide as not convenient to gather.

Owner:WUJIANG YISHENG TEXTILE

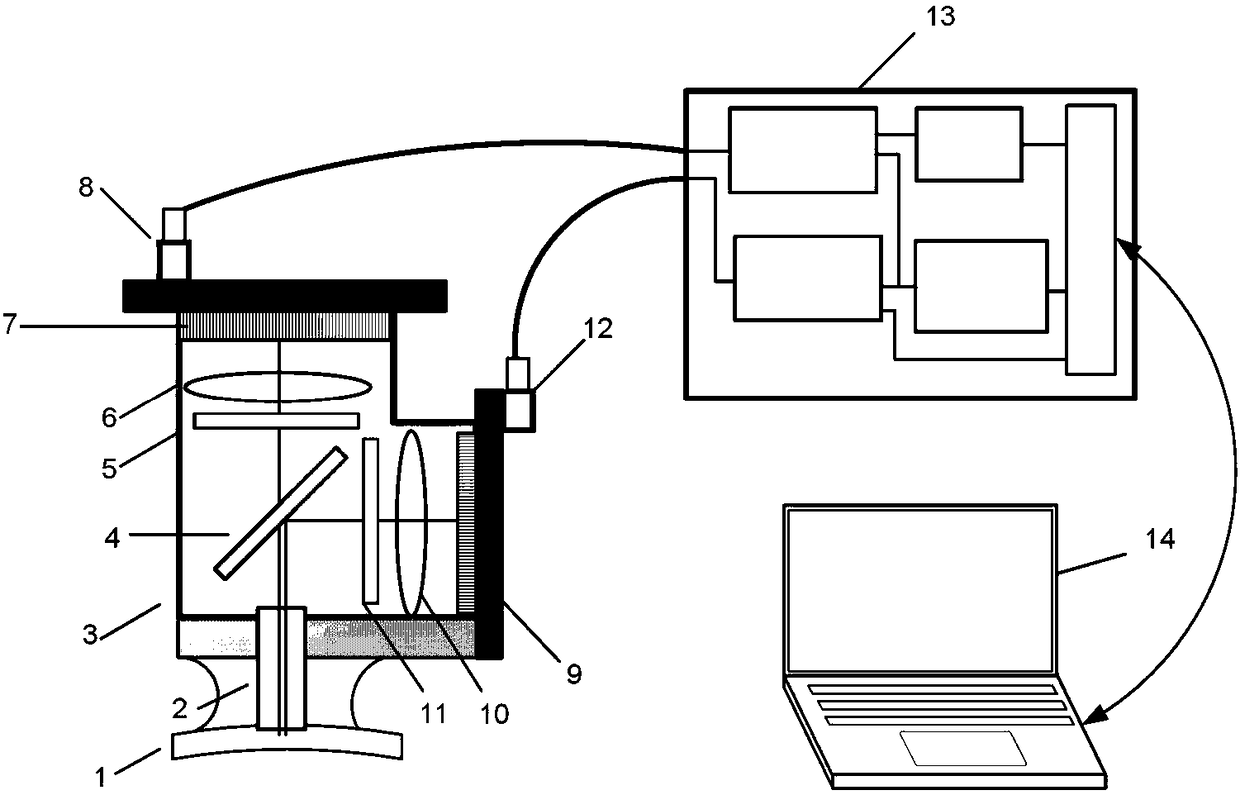

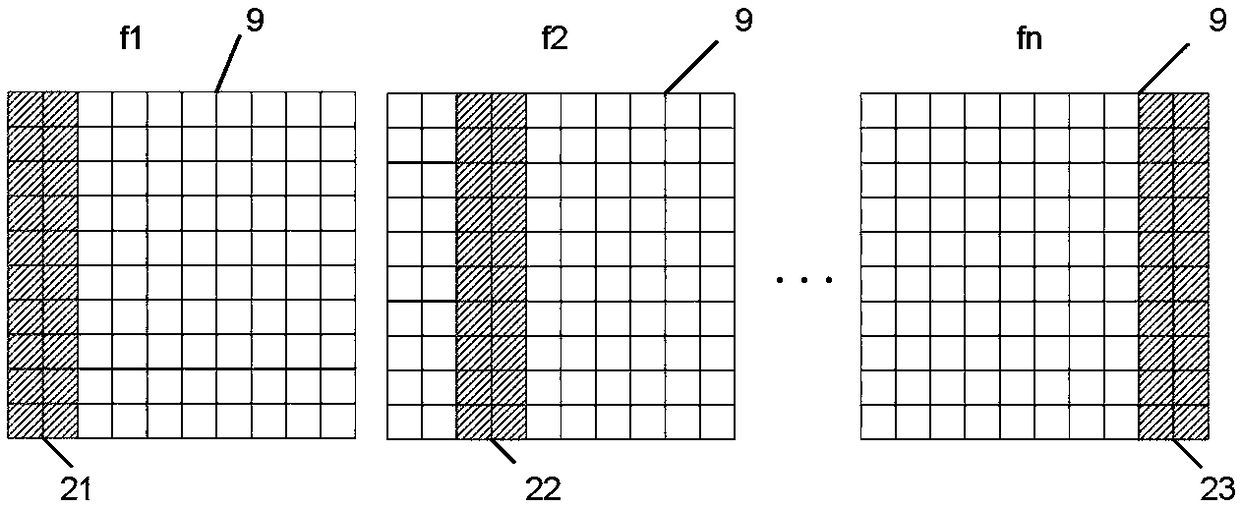

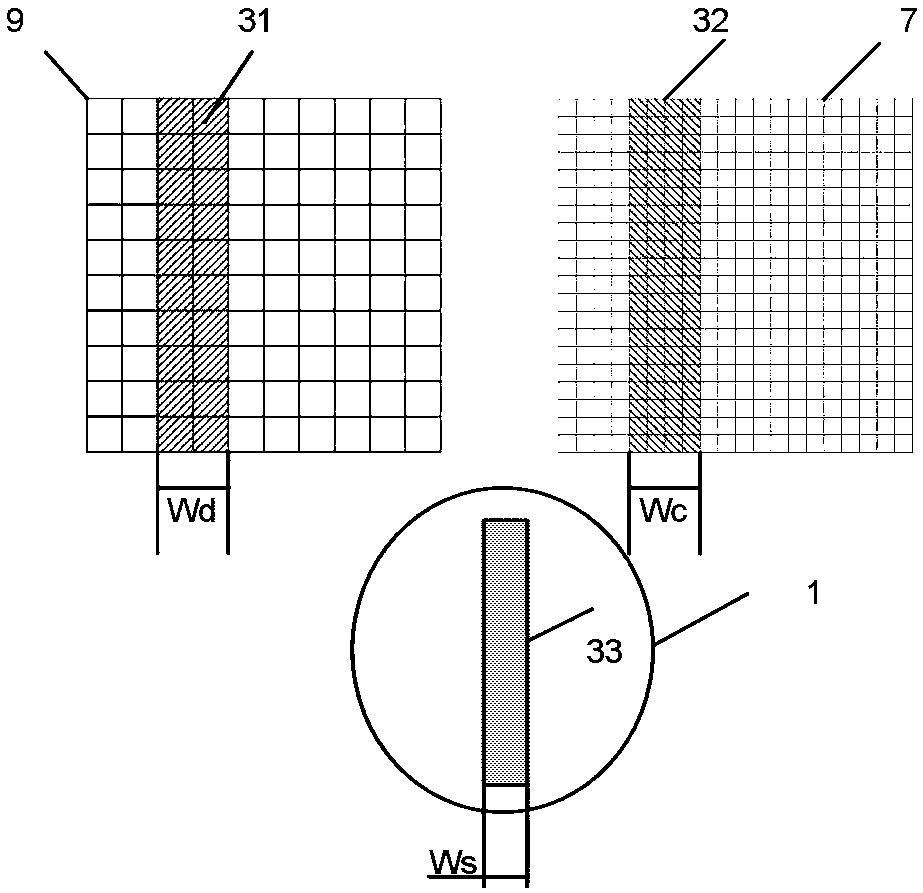

Optical microscopic imaging method and device

ActiveCN108319008AReduce distractionsImprove signal-to-noise ratioMicroscopesPhysicsBiological process

The invention discloses an optical microscopic imaging method and device, and belongs to the field of optical microscopic imaging. The optical microscopic imaging method specifically comprises the steps that a display screen sequentially displays a strip image sequence; sequentially displayed strip images form a moving illumination strip on a sample surface through an objective lens; a sample areailluminated or excited by the moving illumination strip is imaged to a detector through the objective lens; and image sequences obtained by imaging are superimposed to obtain complete image of the sample. The optical microscopic imaging device comprises a small display screen, a lens, a filter, a splitter, an objective lens and a surface array detector. In the imaging process, the width of an illumination area and the width of a detection area are simultaneously limited, the illumination process and the detection process are synchronized, a line scanning and confocal imaging mode is formed, and the restraining ability of small microscope imaging for out-of-focus signals is improved; and the small display screen is utilized, thereby not requiring the application of a mechanical scanning element, being convenient for the miniaturization and integration of a microscope system, and being applicable to performing living body in-situ microscopic imaging on the biological process.

Owner:HUAZHONG UNIV OF SCI & TECH

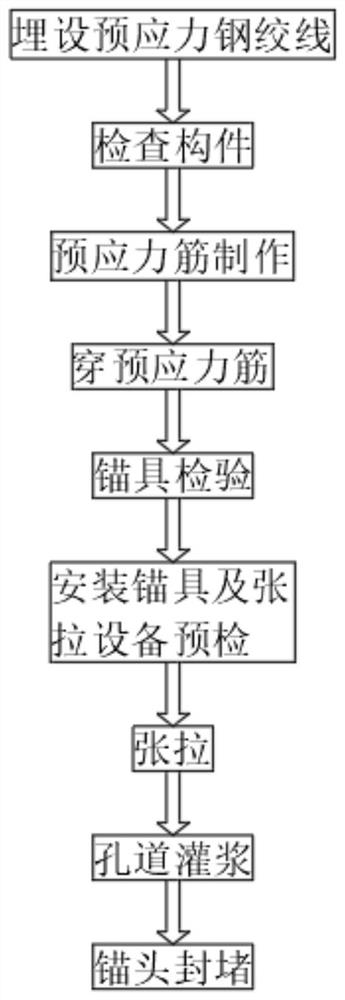

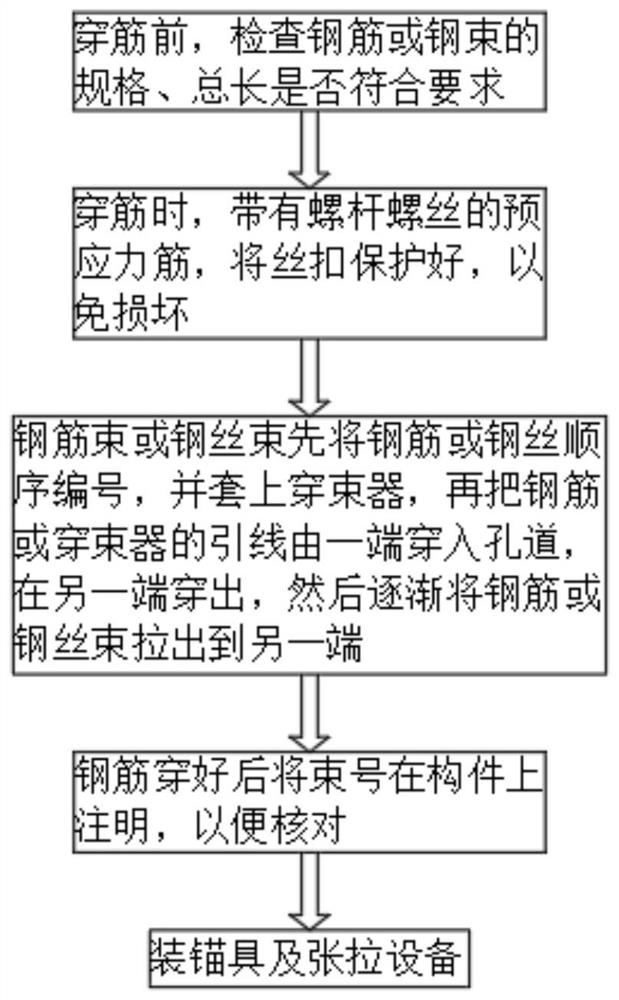

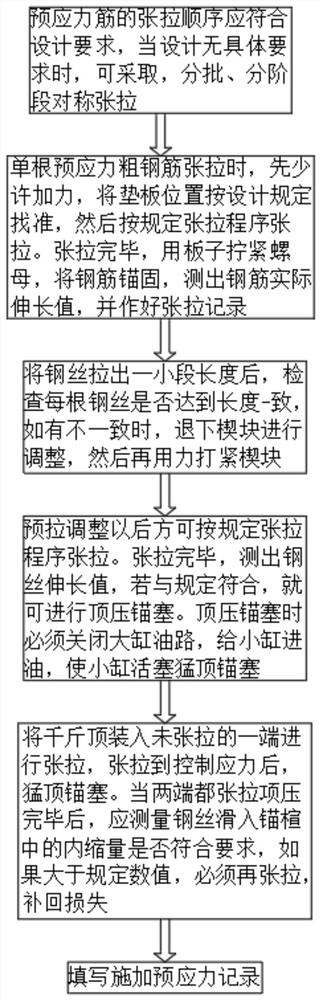

Large-span concrete beam retard-bonded prestressed construction method

The invention discloses a large-span concrete beam retard-bonded prestressed construction method, and relates to the technical field of constructional engineering. The large-span concrete beam retard-bonded prestressed construction method aims to solve the problem that the large-span prestressed construction cost is greatly improved due to the fact that required prestressed tendons are mostly purchased directly during existing large-span prestressed construction. The method comprises the steps of 1, burying prestressed steel strands; 2, checking a component; step 3, manufacturing prestressed tendons; step 4, penetrating prestressed tendons; step 5, inspecting an anchorage device; step 6, installing the anchorage device, and pre-detecting tensioning equipment; step 7, tensioning; step 8, duct grouting; and step 9, plugging an anchor head.

Owner:ANYI BUILDING GROUP

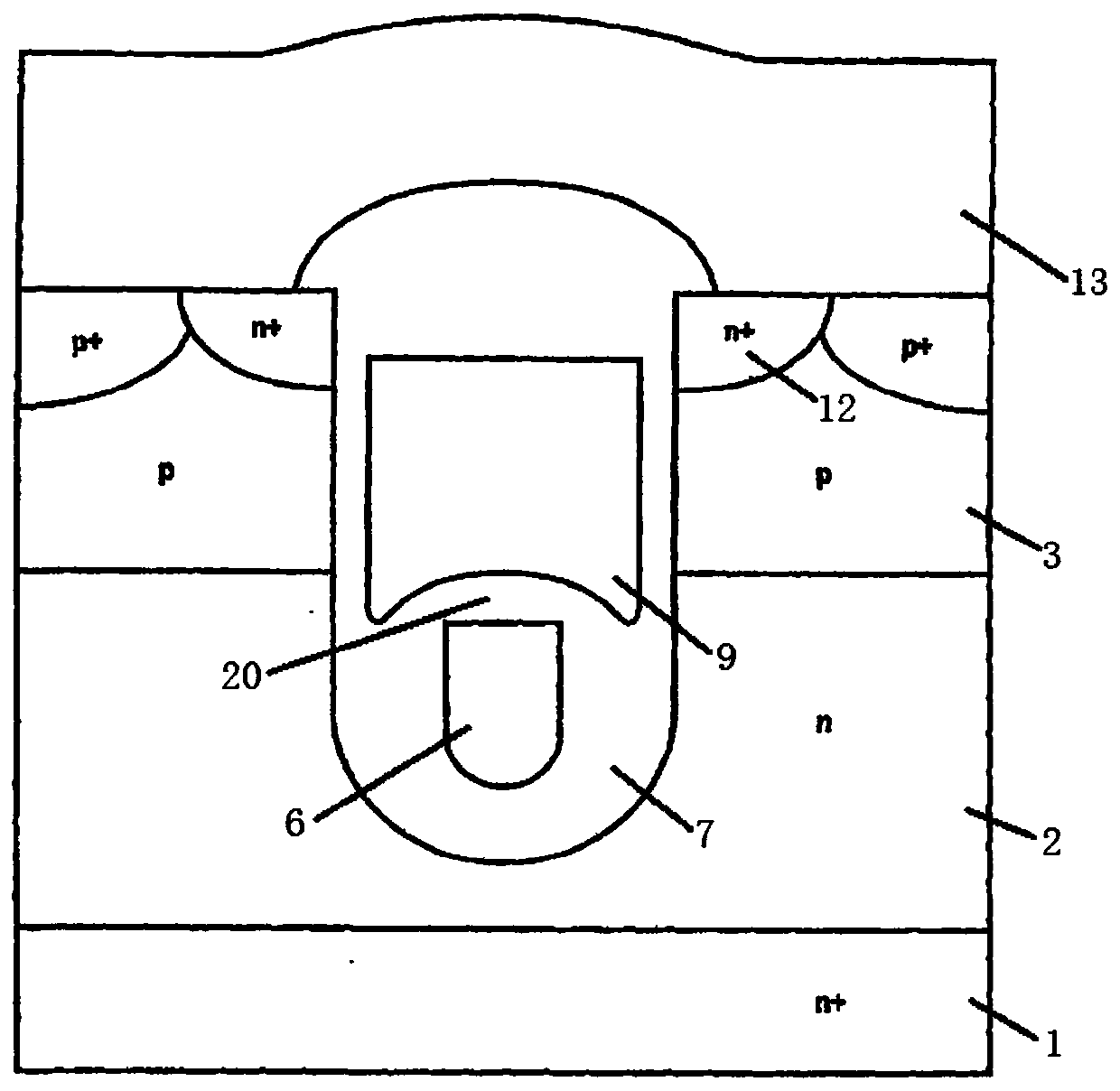

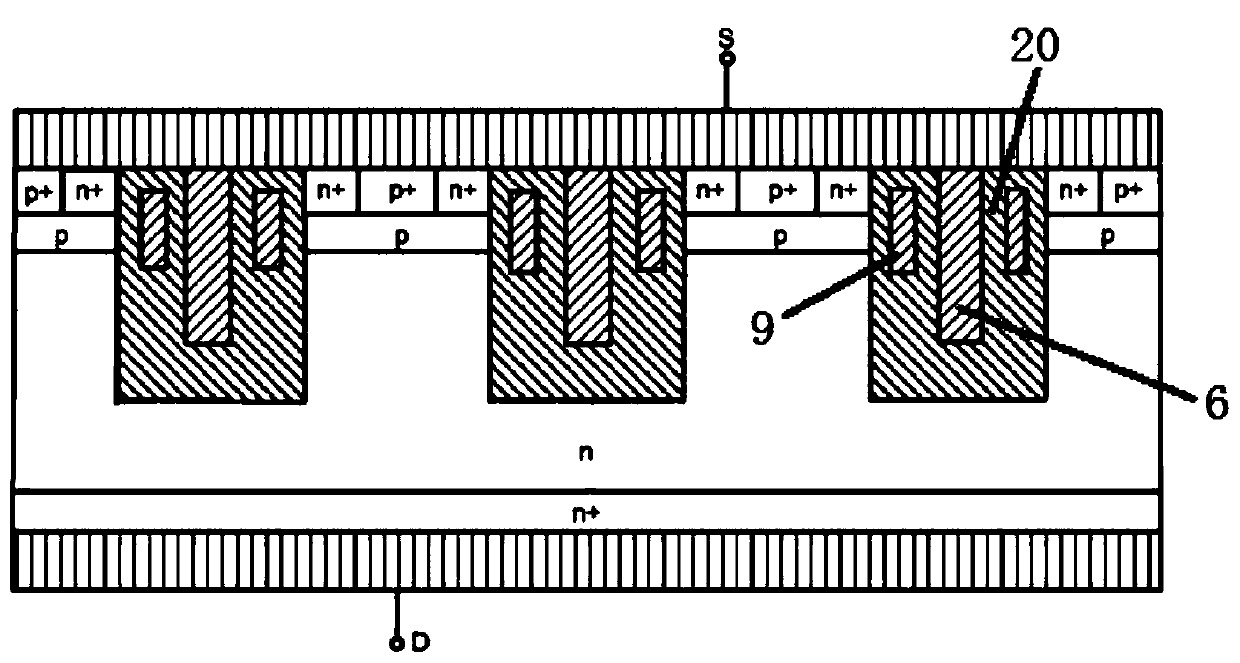

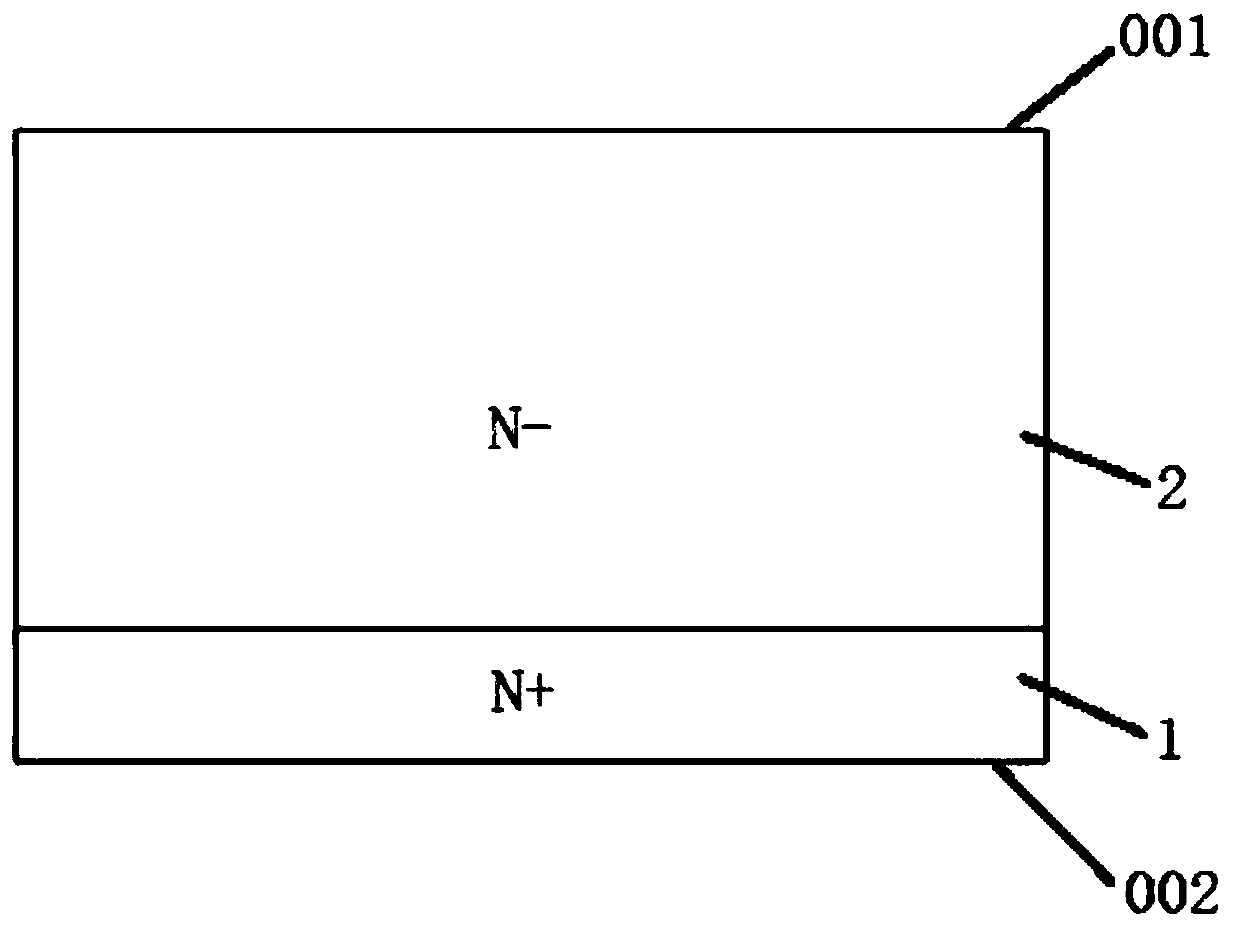

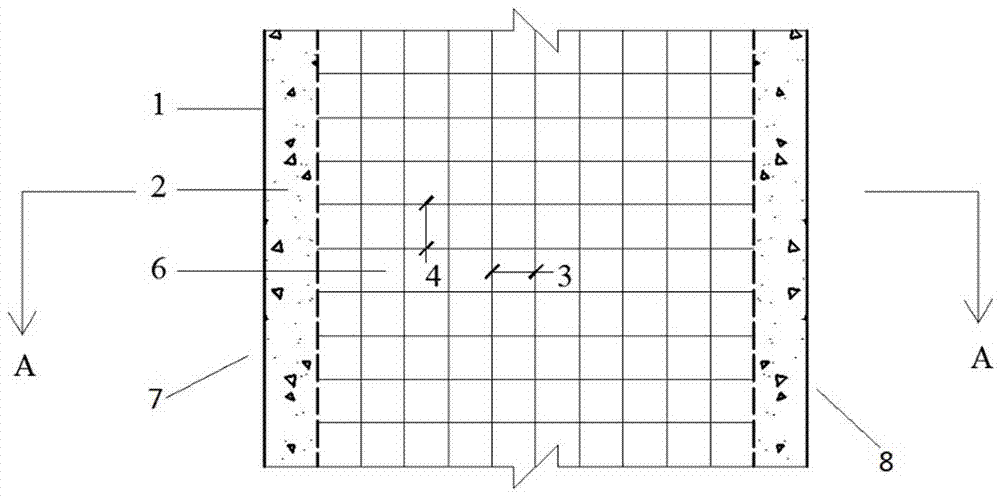

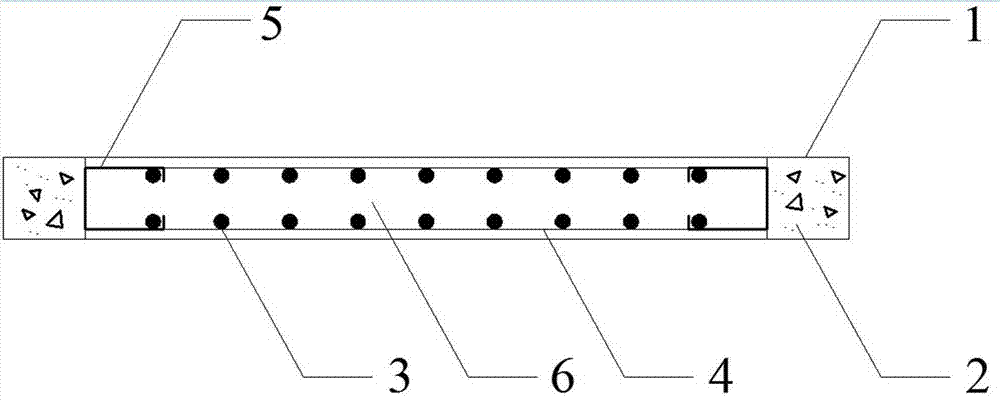

Semiconductor power device structure and manufacturing method thereof

InactiveCN111415867AReduce parasitic capacitanceReduce the risk of leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesParasitic capacitorEngineering

The invention discloses a semiconductor power device structure and a manufacturing method thereof. The structure comprises a substrate of a first conductivity type and an epitaxial layer of the firstconductivity type on the substrate; a well region of a second conductive type is arranged at the upper part of the epitaxial layer; a control gate trench is arranged between the well regions; a separation gate groove is formed in the bottom of the control gate groove; the separation gate trench is filled with separation gate polycrystalline silicon and a separation gate oxide layer wrapping the side surface and the bottom surface of the separation gate polycrystalline silicon; wherein the separation gate polycrystalline silicon is communicated with the control gate trench, gate oxide layers are arranged on the side wall and the bottom wall of the control gate trench, the gate oxide layers cover the tops of the separation gate oxide layers, and gate polycrystalline silicon is arranged on the side wall of the control gate trench formed by the gate oxide layers; and the inner side of the gate polycrystalline silicon is positioned in a region outside the side wall of the separation gate polycrystalline silicon. No overlapping area exists between the grid polysilicon and the separation grid polysilicon, the parasitic capacitance between the source electrode and the grid electrode is very small, and the risk of current leakage between the source electrode and the grid electrode is greatly reduced.

Owner:捷捷微电(上海)科技有限公司

Reinforced concrete shear wall

InactiveCN107060141AAvoid crackingGuaranteed shear performanceWallsProtective buildings/sheltersReinforced concreteMetal framework

The invention relates to a reinforced concrete shear wall, which comprises at least two vertical columns arranged at intervals and a wall body arranged between corresponding two adjacent vertical columns, the vertical columns include metal columns extending in the vertical direction, and the wall body includes wall concrete The layer is fixedly connected to the metal frame between two corresponding adjacent metal columns, and the wall concrete layer is poured into an integral structure with the metal frame and the opposite sides of the corresponding two adjacent metal columns.

Owner:ZHENGZHOU UNIV +1

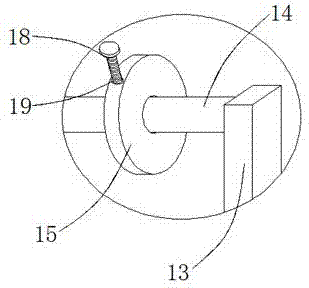

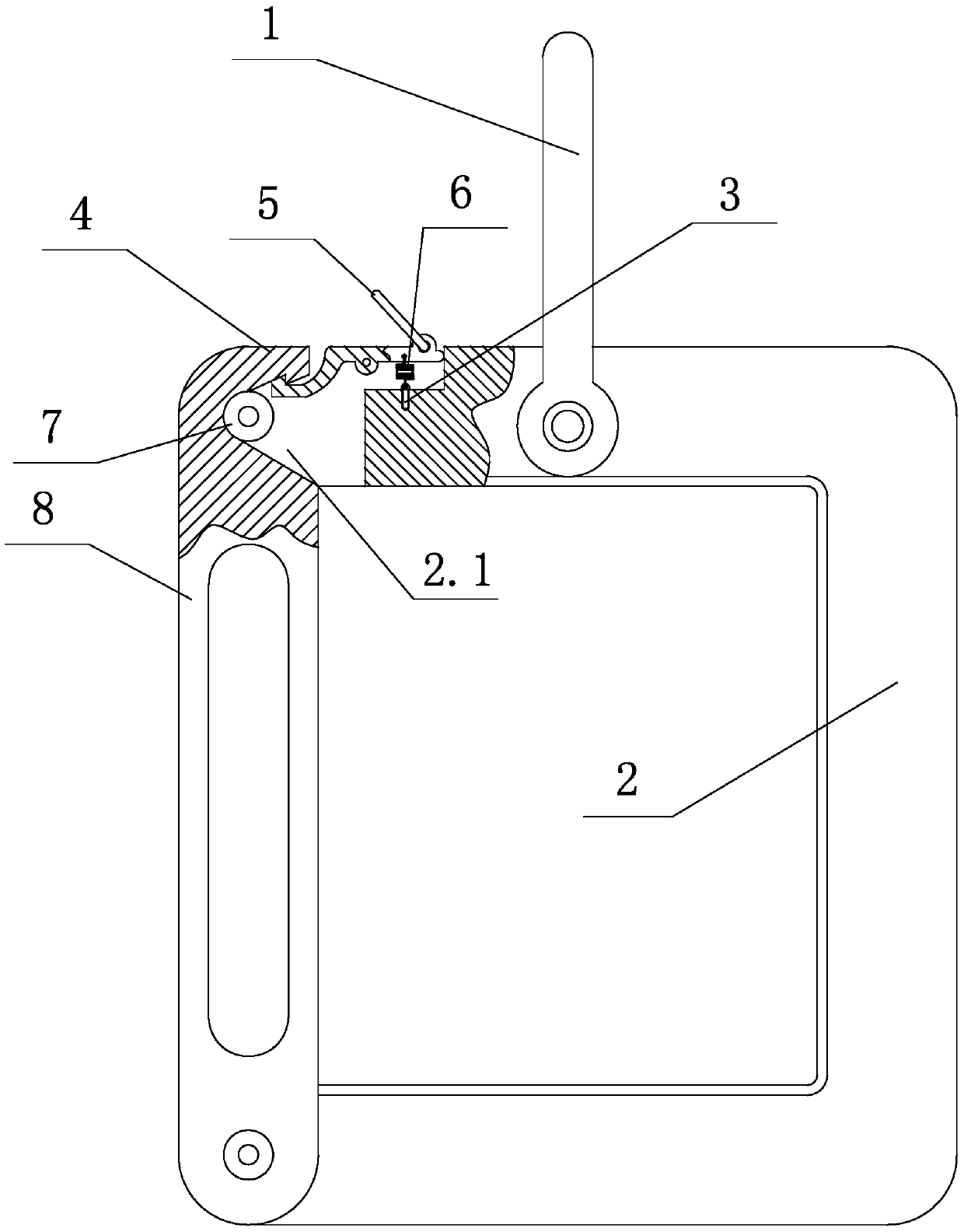

Hook

InactiveCN105502151ALimit widthWon't limit the widthLoad-engaging elementsEngineeringMechanical engineering

Owner:尤桂芬

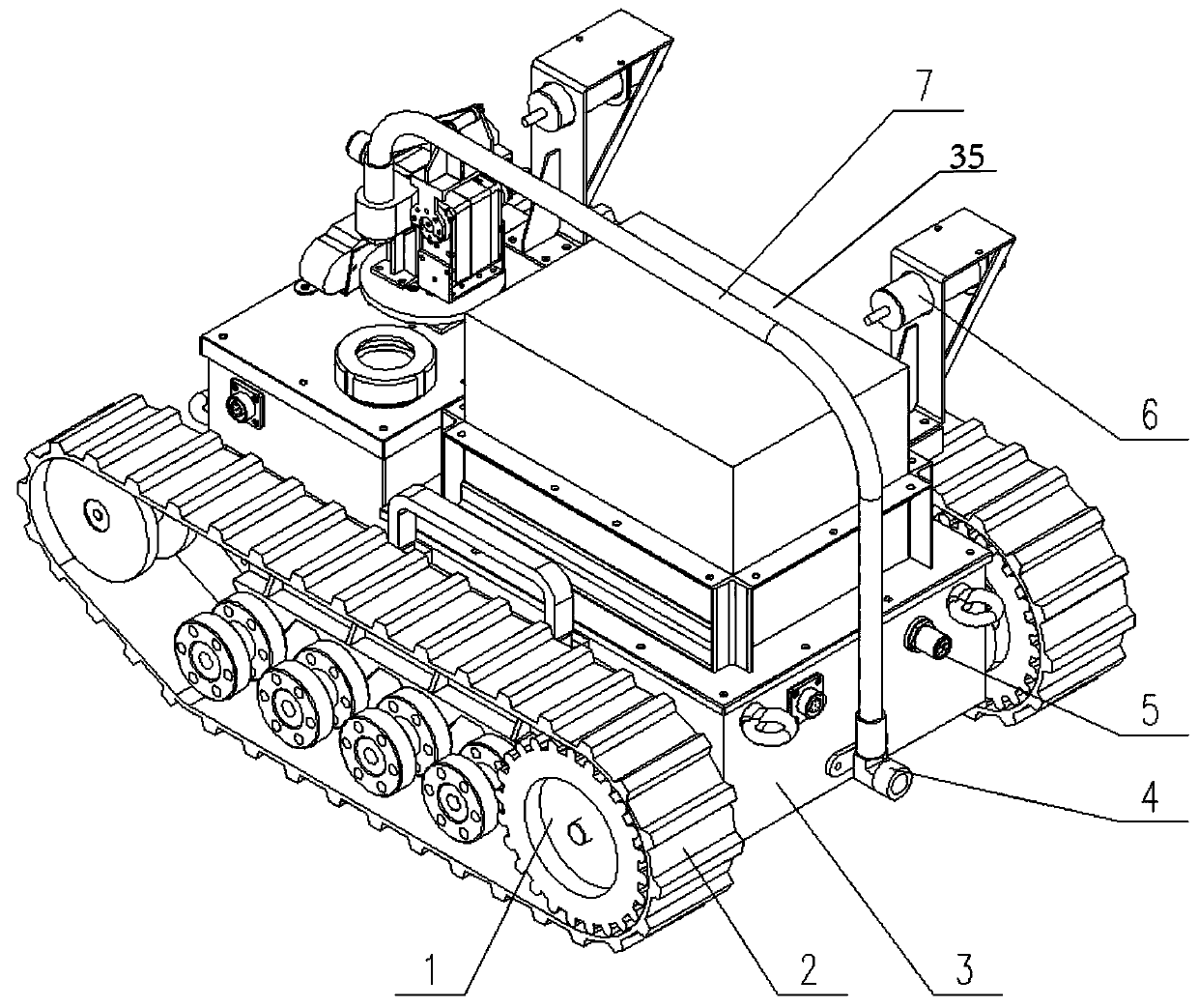

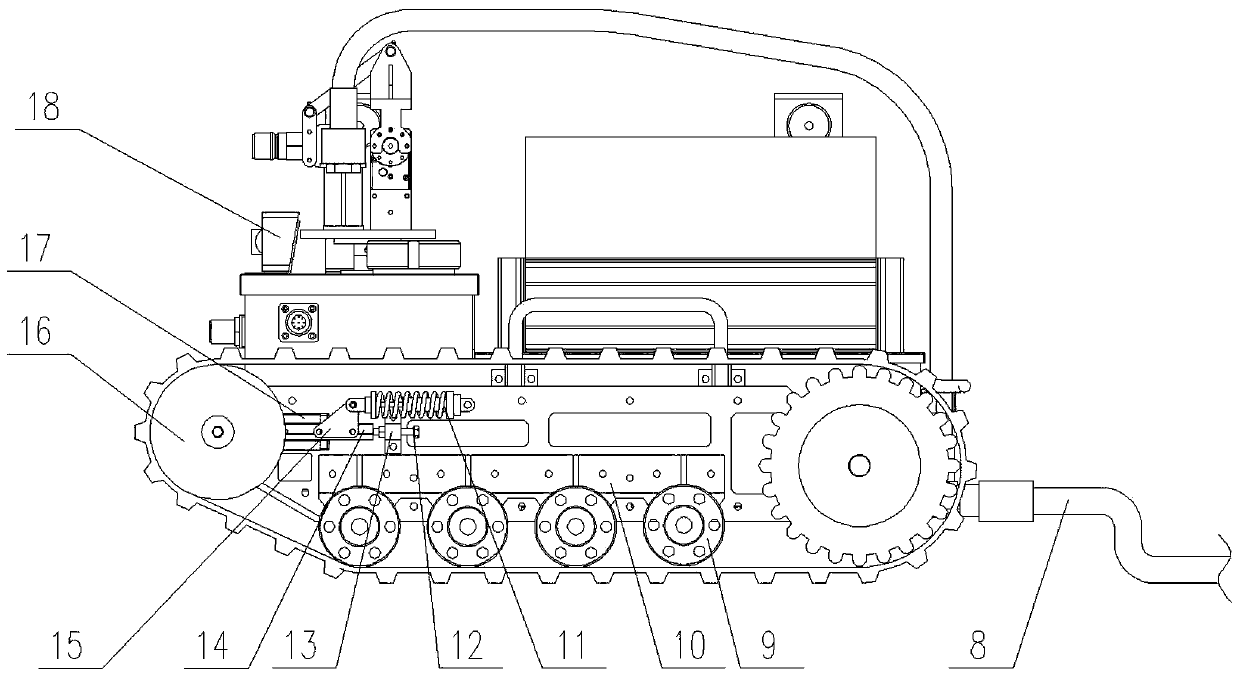

Cleaning robot for dung channel of pig farm

PendingCN111468455ALimit widthGreat driving forceCleaning using liquidsManipulatorPig farmsDrive wheel

The invention relates to a cleaning device for a dung channel of a pig farm, in particular to a cleaning robot for the dung channel of the pig farm. The cleaning robot comprises a vehicle body travelling mechanism and a water spraying mechanism, wherein the vehicle body travelling mechanism is a dual-caterpillar-band type structure, and comprises a vehicle body pedestal, a travelling motor, drivewheels and a caterpillar band, the drive wheels are mounted at the two sides of the vehicle body pedestal, the caterpillar band is mounted on the drive wheels, the travelling motor is connected to thedrive wheels, and drives the drive wheels to rotate, so that the robot is driven to travel; the water spraying mechanism comprises a rotary supporting mechanism, a pitching mechanism and a high-pressure spray head, the rotary supporting mechanism is fixedly arranged on the vehicle body pedestal, the pitching mechanism is fixedly connected on the rotary supporting mechanism, the high-pressure spray head is fixedly connected on the pitching mechanism, the high-pressure spray head is connected to a high-pressure water tube, the rotary supporting mechanism drives the spray head to horizontally rotate, and the pitching mechanism drives the spray head to perform pitching motion, so that all-around movement without a dead angle of the high-pressure spray head is realized. All-around spraying andcleaning of high-pressure water to side walls, ground and a ceiling of the dung channel can be realized while a worker does not need to enter the dung channel.

Owner:鞍山极致创新科技有限公司

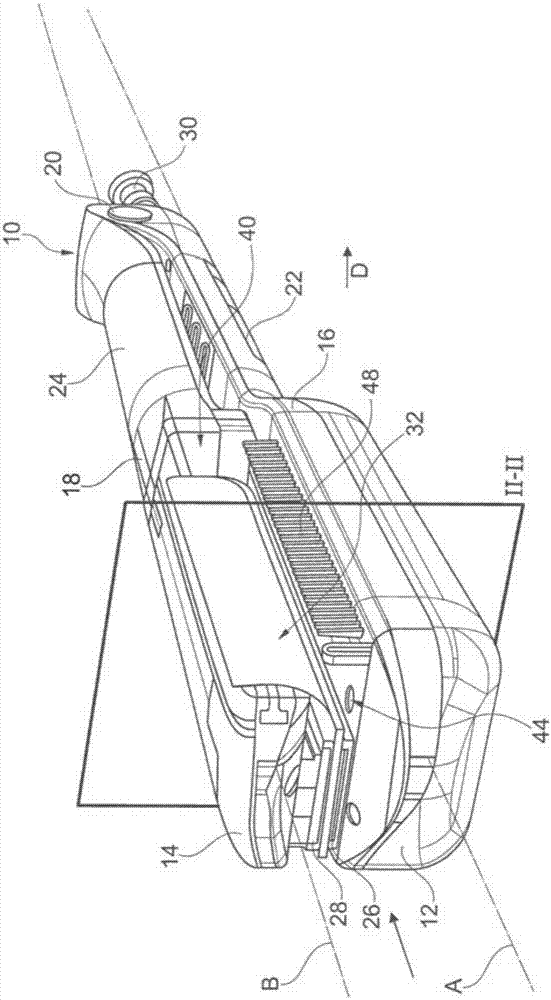

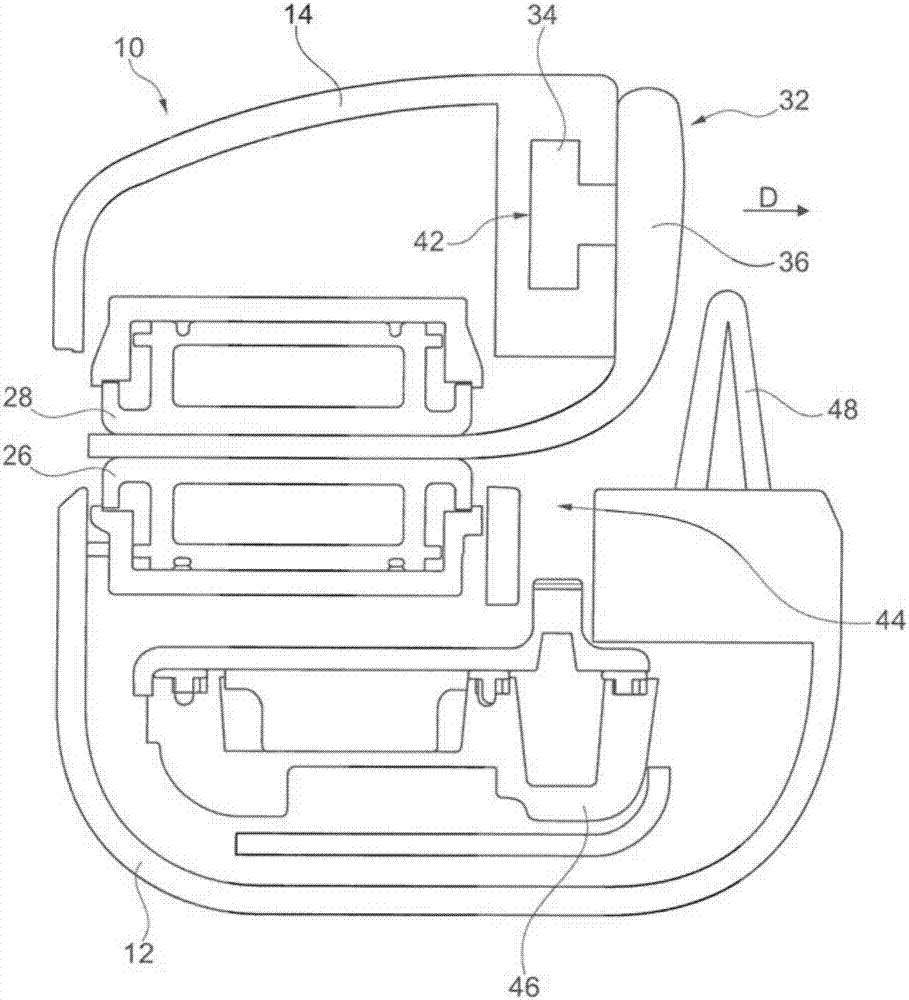

Cosmetic product refill for a device for treating the hair having a heating element, and device for treating the hair including such a refill

ActiveCN106974412ALimited volumeLimit widthCurling-ironsCurling-tongsBiomedical engineeringHeating element

The invention relates to a cosmetic product refill (32) for a device for treating the hair that comprises at least one heating element (26; 28), the cosmetic product refill (32) comprising a means for fastening the refill (32) to the device and a cosmetic product applicator element in the form of a sheet, such that the means for fastening the refill is designed to fasten the cosmetic product refill (32) to the device for treating the hair in such a way that a part of the cosmetic product refill (32) is offset laterally with respect to the heating element(s) (26; 28), and such that at least one portion of the applicator element is designed to extend next to the heating element(s) (26; 28). The invention also relates to a device for treating the hair (10) including such a refill.

Owner:SEB SA

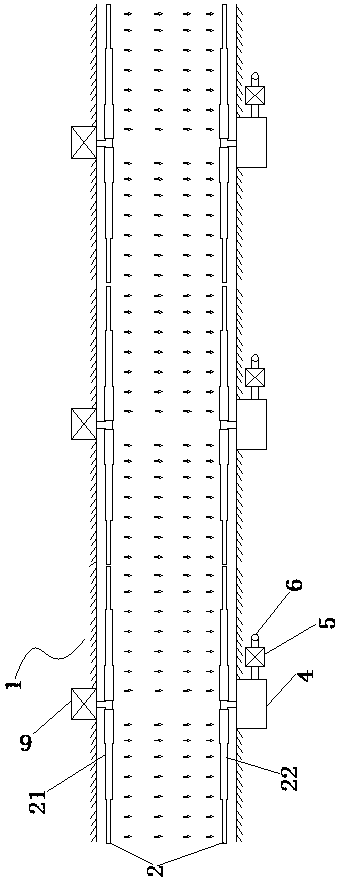

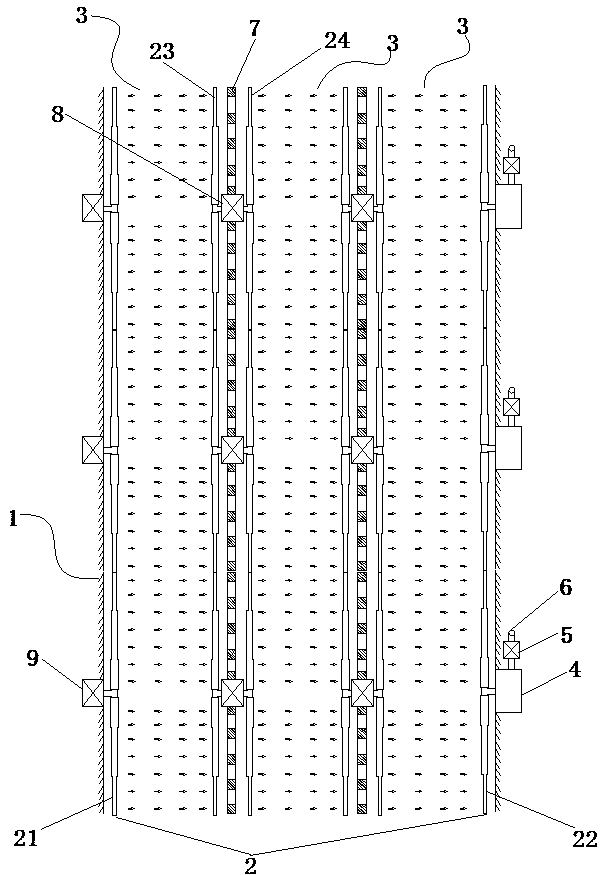

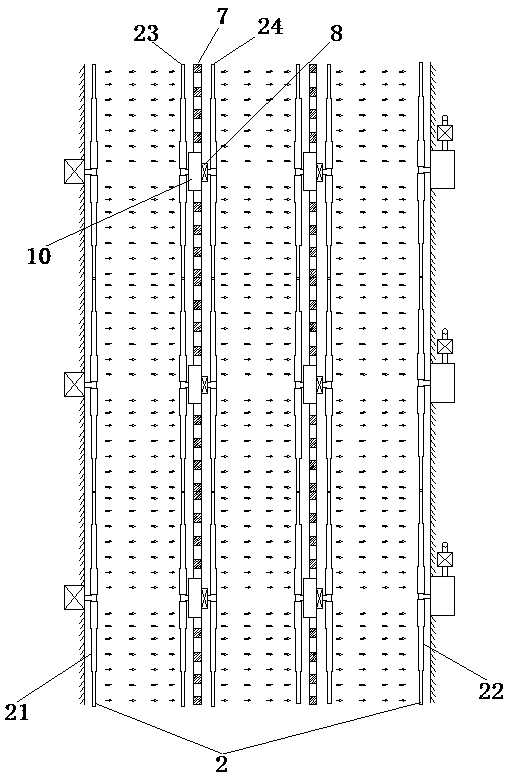

Forward flow type smoke purification system and purification flow field thereof

PendingCN109745788ARealize air deliveryAvoid turbulenceDispersed particle filtrationAir cycleThree-dimensional space

The invention discloses a forward flow type smoke purification system. The forward flow type smoke purification system comprises an air blower and n groups of pipelines which are arranged on two sidesof the inside of a plant, n is greater than or equal to 1, each group of pipelines comprise an air supply pipeline and an air suction pipeline which are oppositely arranged on two sides of the plant,an air inlet of the air blower is arranged outside the plant, each air supply pipeline communicates with an air outlet of the air blower, each air suction pipeline communicates with a suction fan, and a dust remover is further arranged between each air suction pipeline and the suction fan in a communicating manner; m rows of vertical columns can be arranged in the plant, m is greater than or equal to 1, workshop units are formed on the left side and the right side of each row of vertical columns, and an air suction pipeline a and an air supply pipeline a are respectively fixed on the two sides of each vertical column. According to the purification flow field of the forward flow type smoke purification system, purification treatment is realized through the forward air flow in a two-dimensional plane space or a three-dimensional space. According to the invention, indoor and outdoor air circulation is realized, air flow delivery of a plurality of unit workshops is realized through the forward air flow, the purification effect is improved, the energy consumption is reduced, and finally, purified gas can be discharged at high altitude in an organized manner.

Owner:河南中创科源环保科技有限公司

Cabling rack for communication engineering

PendingCN113629624AFixed fastImprove efficiencyMechanical energy handlingThreaded pipeTelecommunications engineering

The invention discloses a cabling rack for a communication engineering. The cabling rack comprises telescopic pipes, a threaded pipe control unit, clamping rod fixing units and a wire pressing unit, the number of the telescopic pipes is two, a mounting frame is fixedly connected to the upper portions of the inner sides of the two telescopic pipes, and a threaded pipe is rotatably connected to the rear side of the lower surface of the mounting frame; a frame is fixedly connected to the lower ends of the telescopic pipes, a supporting rod is fixedly connected to the middle of the frame, and a threaded shaft is fixedly connected to the rear side of the upper surface of the supporting rod; the threaded shaft is in threaded connection with the threaded pipe, a rail is arranged at the right side of the frame, and two clamping rods are slidably connected into the rail. The threaded pipe control unit is mounted at the rear side of the mounting frame, and the clamping rod fixing units are mounted on the clamping rods. When the cabling rack for communication engineering is used, the height can be adjusted up and down as required, and when a cable is fixed, the speed is high, the efficiency is high, and the cabling rack is very convenient.

Owner:吴建国

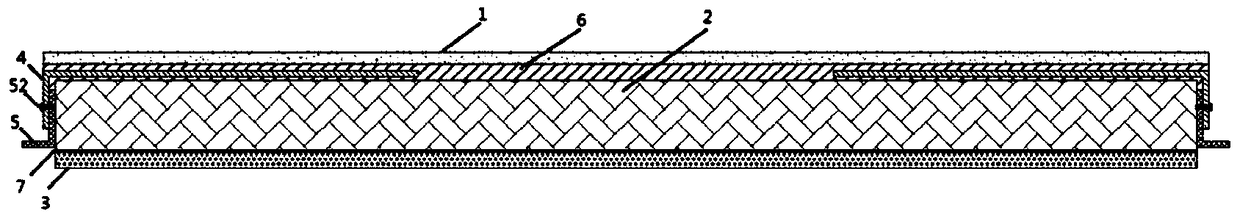

Soft rock or soft porcelain heat preservation integrated board

The invention discloses a soft rock or soft porcelain heat preservation integrated board. The board comprises a soft rock or soft porcelain layer, a heat preservation material layer, a fiber board layer and an L-shaped supporting plate; the soft rock or soft porcelain layer, the heat preservation material layer and the fiber board layer are sequentially stuck together through adhesives from top tobottom in sequence, a transverse plate of the L-shaped supporting plate is clamped between the soft rock or soft porcelain layer and the heat preservation material layer and adhesively fixed throughan adhesive; a fixing piece is arranged on a vertical plate of the L-shaped supporting plate, and the soft rock or soft porcelain layer is a surface decorative layer. The soft rock or soft porcelain is adopted as the panel, the requirement of the market for stone or porcelain decorative surface heat preservation decorative boards is met, the technical problem that traditional hard stone is likelyto be broken is solved, the fixing piece is more reasonably designed, the structure is stable, installation is convenient, and the quality and practicability of the heat preservation board are greatlyimproved.

Owner:安徽泰升节能科技有限公司

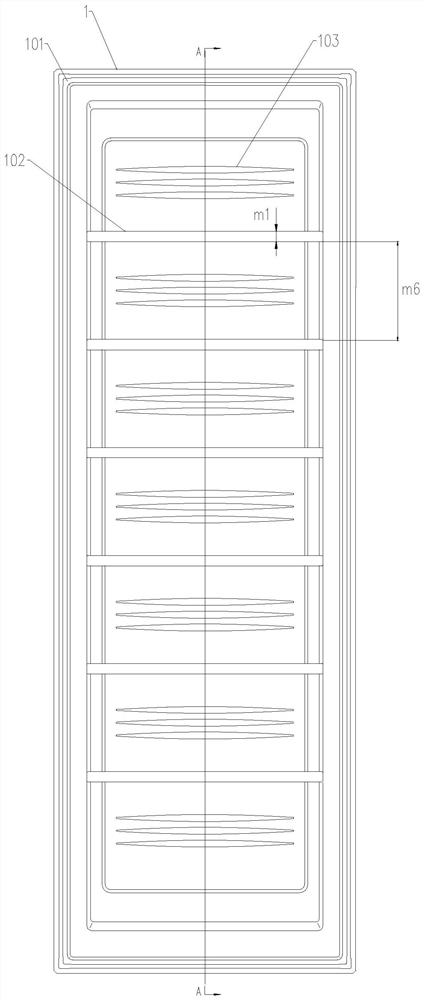

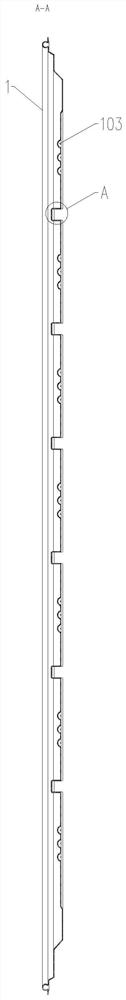

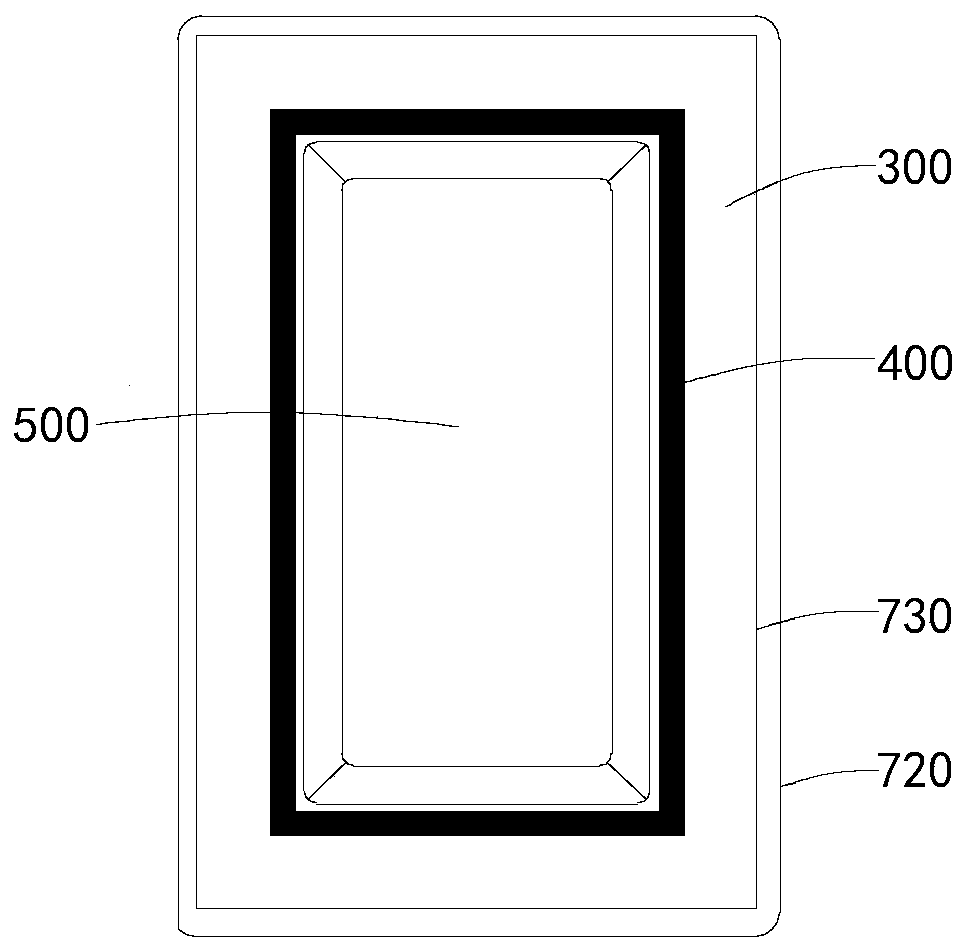

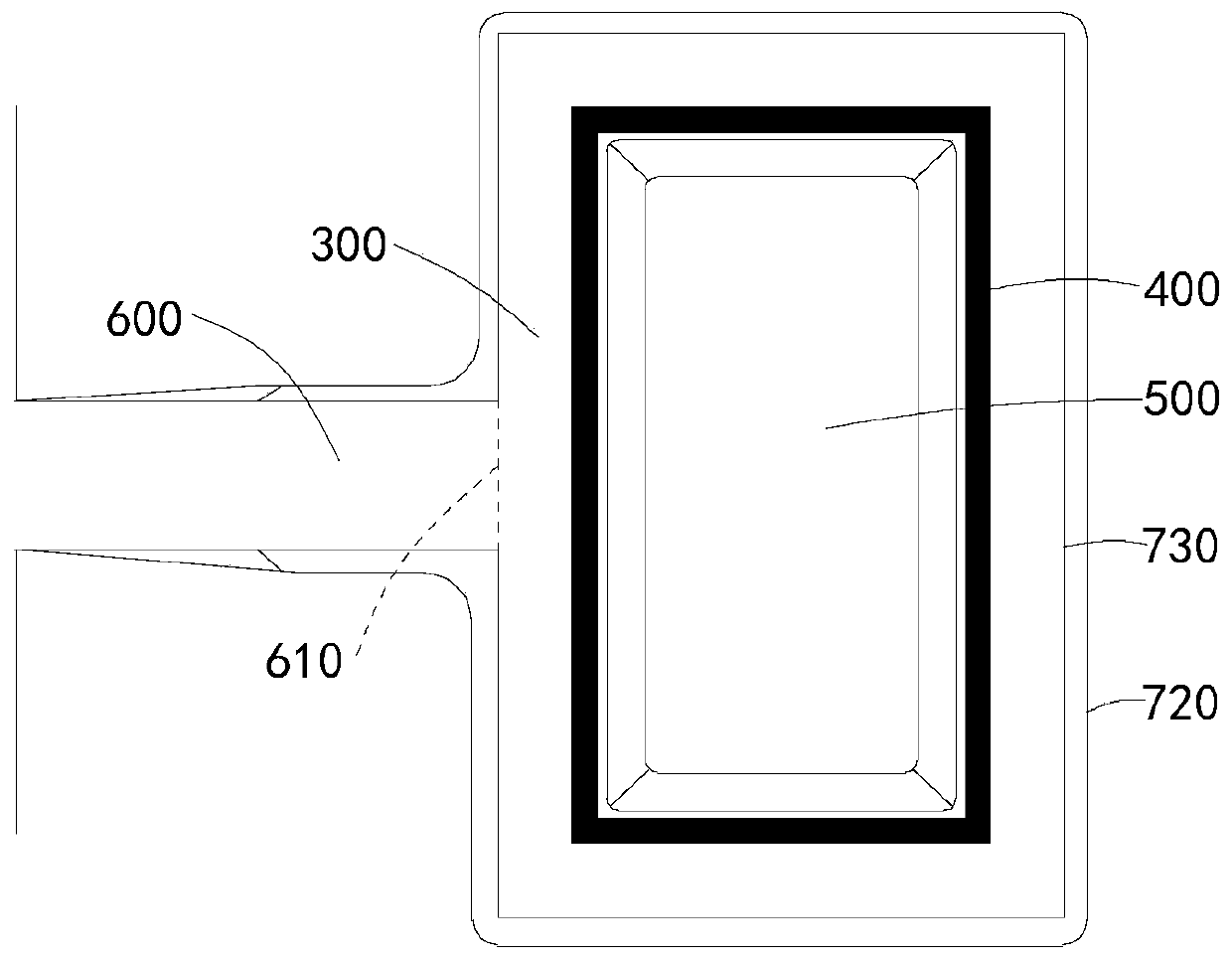

Mechanism for flattening surface of door body during refrigeration of refrigerator

PendingCN111912162ALimit widthLimit outward convexityDomestic cooling apparatusLighting and heating apparatusIceboxEngineering

The invention relates to a mechanism for flattening the surface of a door body during refrigeration of a refrigerator. An upper door strip is arranged at the upper end of a door shell, and a lower door strip is arranged at the lower end of the door shell. An inner container body is clamped in the door shell, and the upper door strip is fixedly connected with the inner container body and the lowerdoor strip is fixedly connected with the inner container body by buckles. The end, far away from the inner container body, of the upper door strip is clamped in the door shell, and the end, far away from the inner container body, of the lower door strip is clamped in the door shell. A plurality of first reinforcing grooves and second reinforcing grooves are formed in one side of the inner container body, and bending parts are arranged on the sides, close to the inner container body, of the two ends of the door shell. As the first reinforcing grooves and the second reinforcing grooves are formed in one side of the inner container body, the phenomena that the width of the door body becomes smaller and the door body protrudes outwards due to a foaming material contracting when cooled can be effectively limited by using the first reinforcing grooves and the second reinforcing grooves. In addition, the bending parts are arranged on the sides, close to the inner container body, of the two ends of the door shell, so that the door body can have sufficient strength to limit the phenomena that the height of the door body becomes smaller and the door body protrudes outwards due to the foamingmaterial contacting when cooled.

Owner:ZHEJIANG XINGXING REFRIGERATION CO LTD

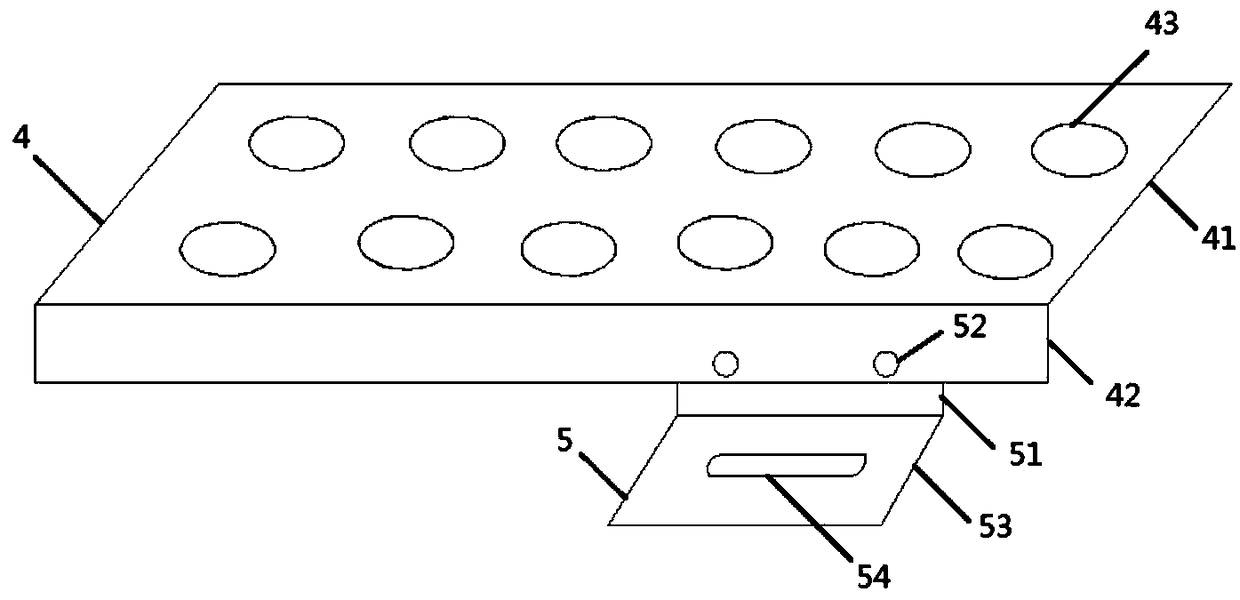

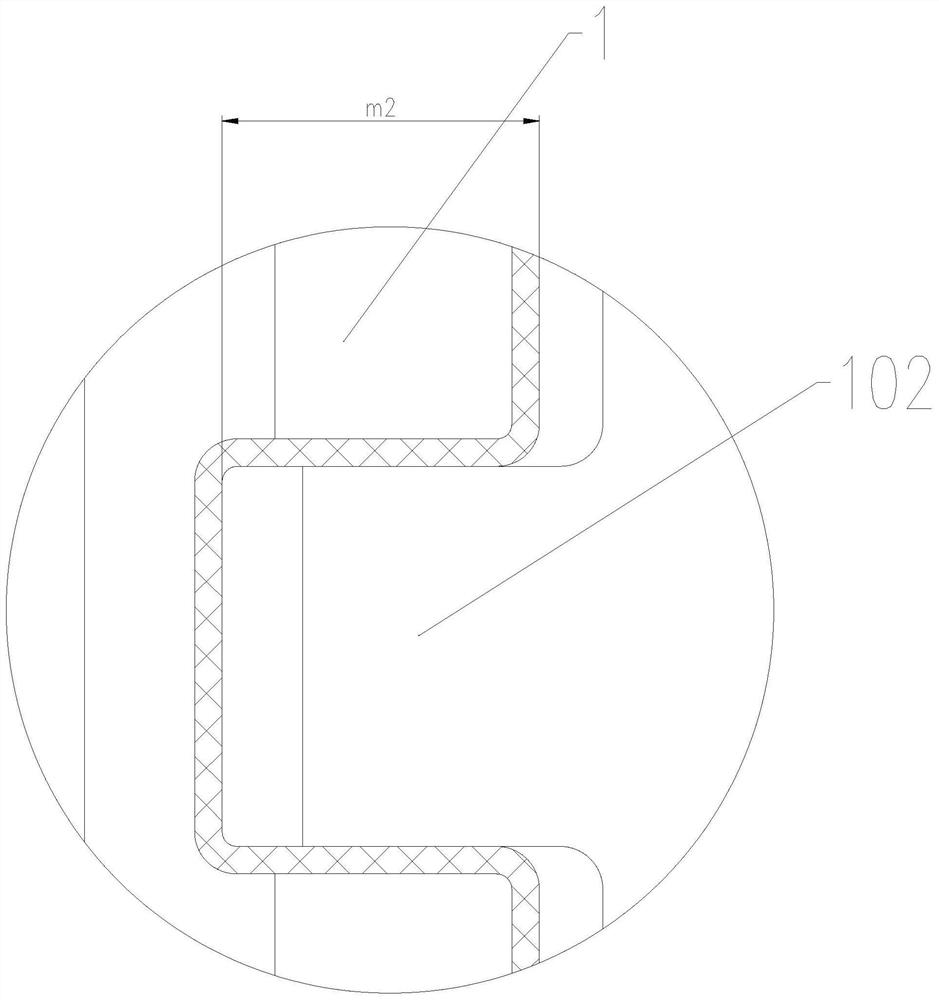

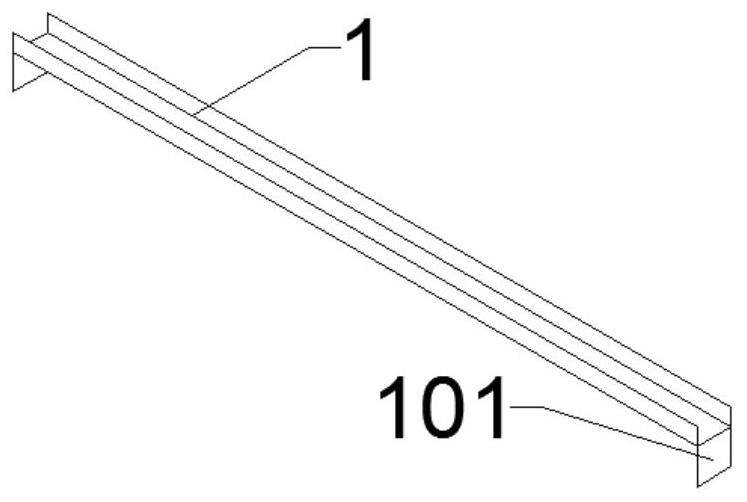

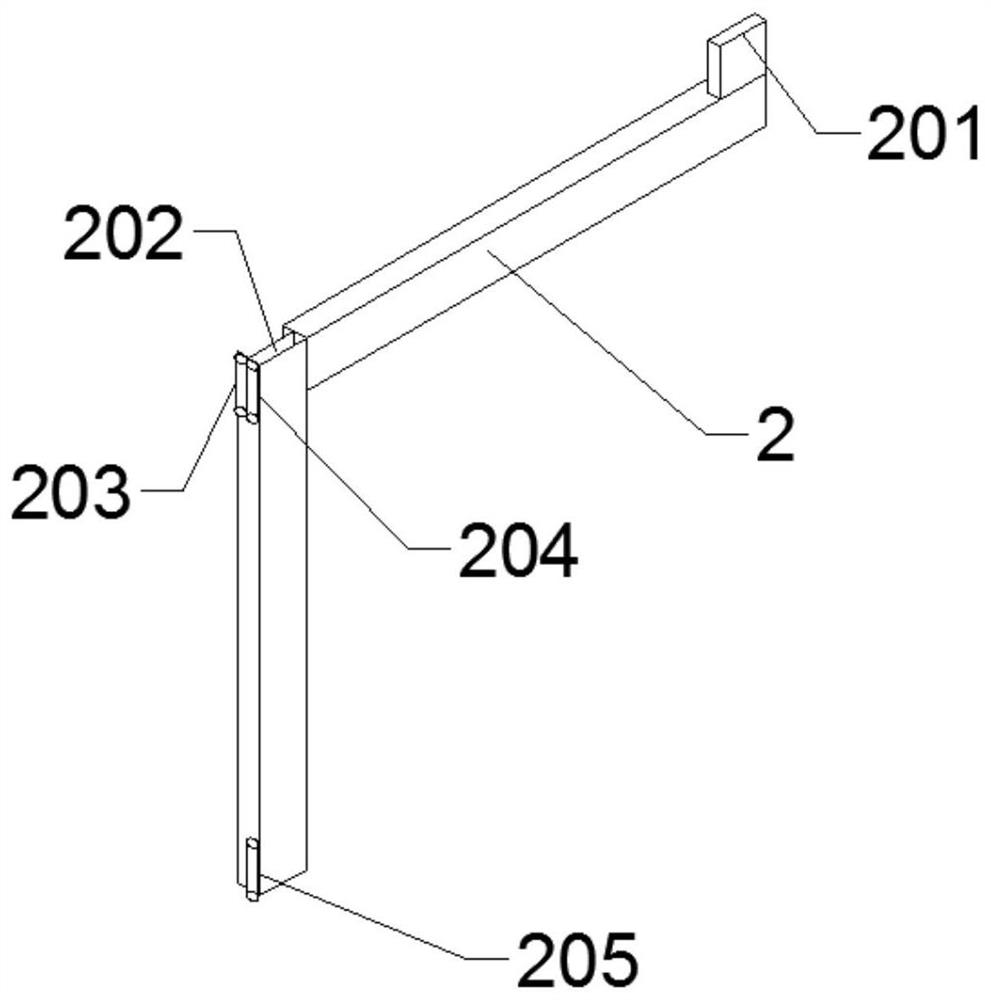

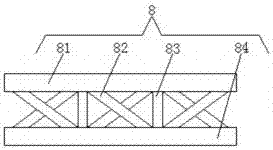

Rack for binding prefabricated box girder top plate reinforcement cage

PendingCN114054647AOperational securitySpacing limitWire networkBridge erection/assemblyClassical mechanicsEngineering

The invention relates to a rack for binding a prefabricated box girder top plate reinforcement cage; the rack comprises at least two support units, two parallel reinforcement limiting components, at least two parallel first reinforcement supporting components and at least one second reinforcement supporting component. Each support unit is of a T-shaped structure, all the support units are arranged side by side, the projections of the support units coincide, and the two reinforcement limiting components are connected to the two transverse ends of each support unit respectively, so that an elongated T-shaped structure is formed. Each first reinforcement supporting component is located between the two reinforcement limiting components and is parallel to the reinforcement limiting components, each first reinforcement supporting component is connected to the support unit, each first reinforcement supporting component is provided with a plurality of steel bar positioning grooves distributed according to preset intervals, and all the steel bar positioning grooves are aligned in the transverse direction and the longitudinal direction; the groove bottom of each steel bar positioning groove, the bottom face of the reinforcement limiting component and the second reinforcement supporting component are located on the same horizontal plane.

Owner:HEBEI CONSTR GRP CO LTD

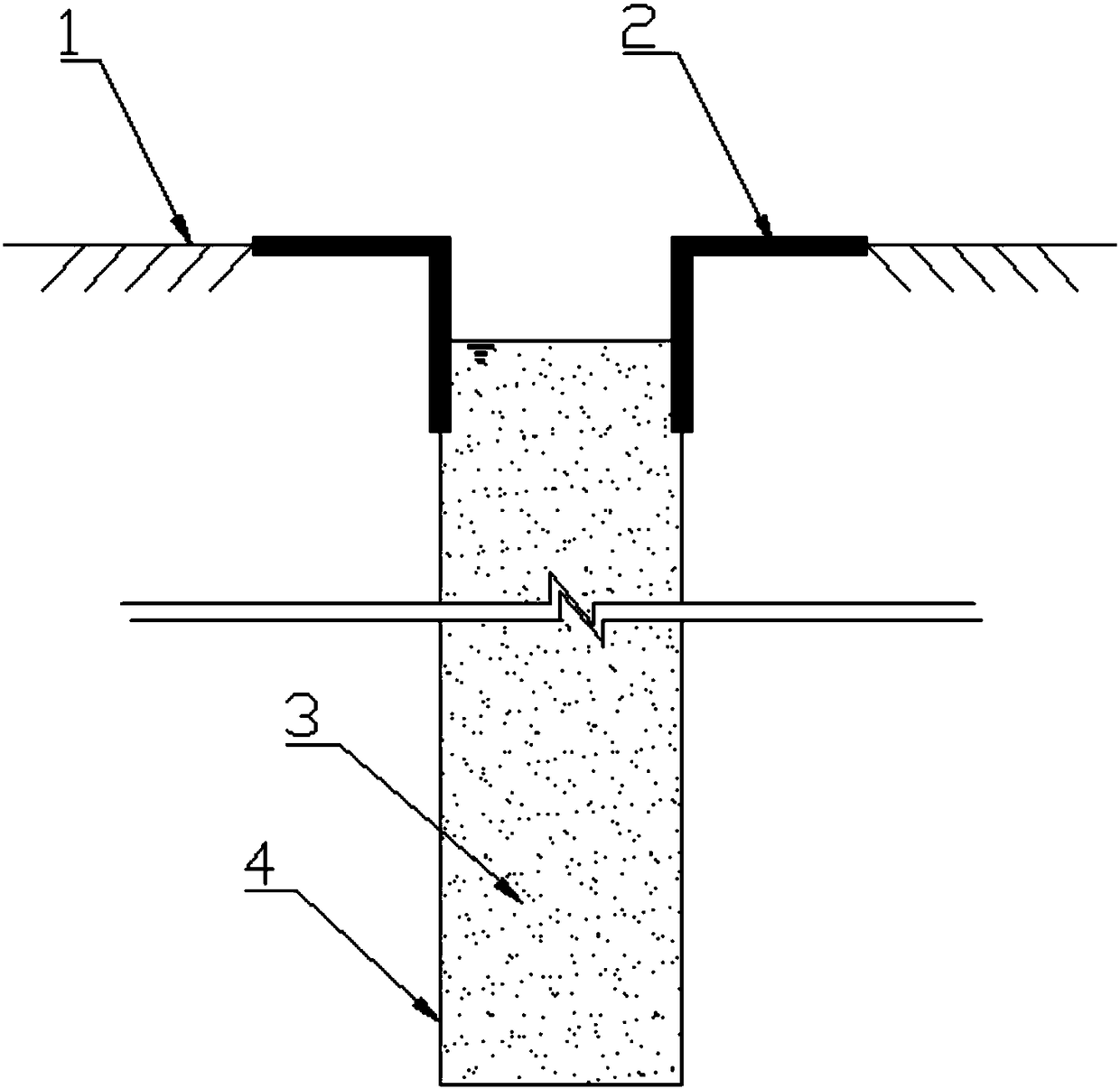

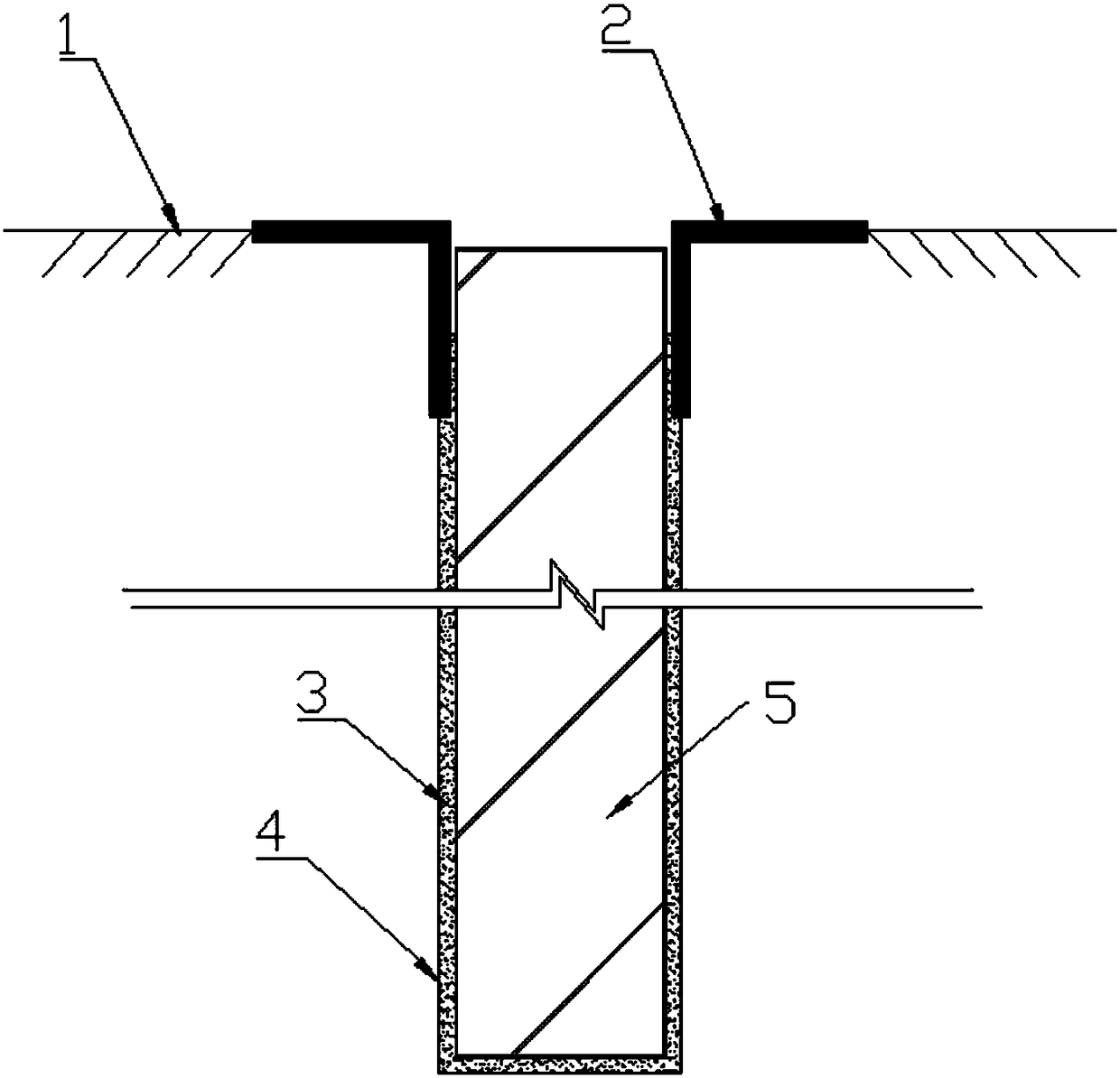

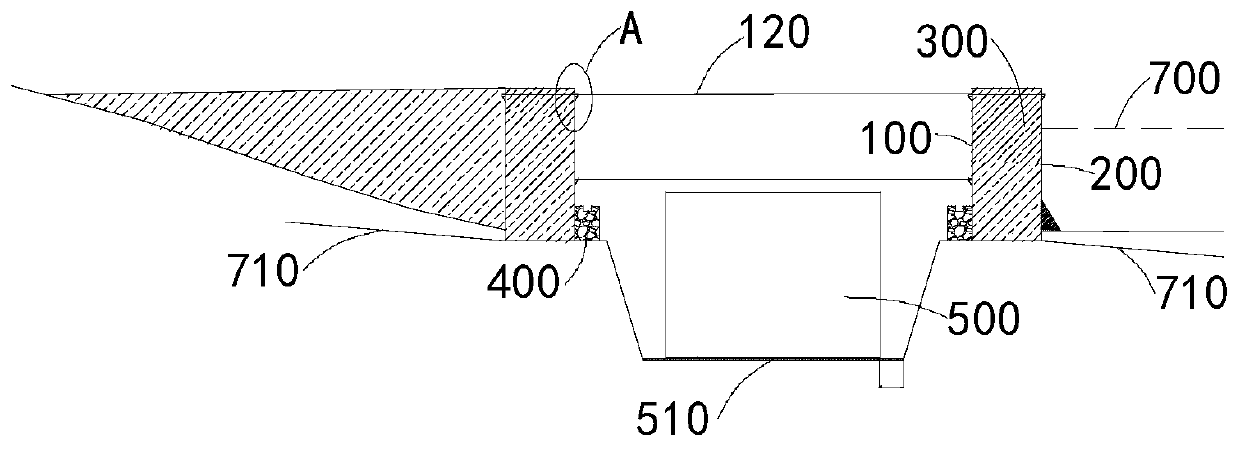

Sheet pile sinking method and pile foundation trench

InactiveCN108487230AHigh top heightImproving the efficiency of pile sinking constructionBulkheads/pilesEngineeringHydraulic engineering

The invention discloses a sheet pile sinking method and a pile foundation trench and relates to the field of water conservancy projects. The construction method comprises the steps of (1) surveying and setting-out; (2) guide wall construction; (3) earth excavation and trench forming; (4) sheet pile driving; (5) sheet pile deviation rectifying; and (6) sheet pile sinking. The sheet pile sinking method has the advantages that operation is easy, the construction efficiency is high, the quality of sheet piles can be protected, and the construction difficulty is reduced.

Owner:CHINA STATE CONSTR PORT ENG GRP

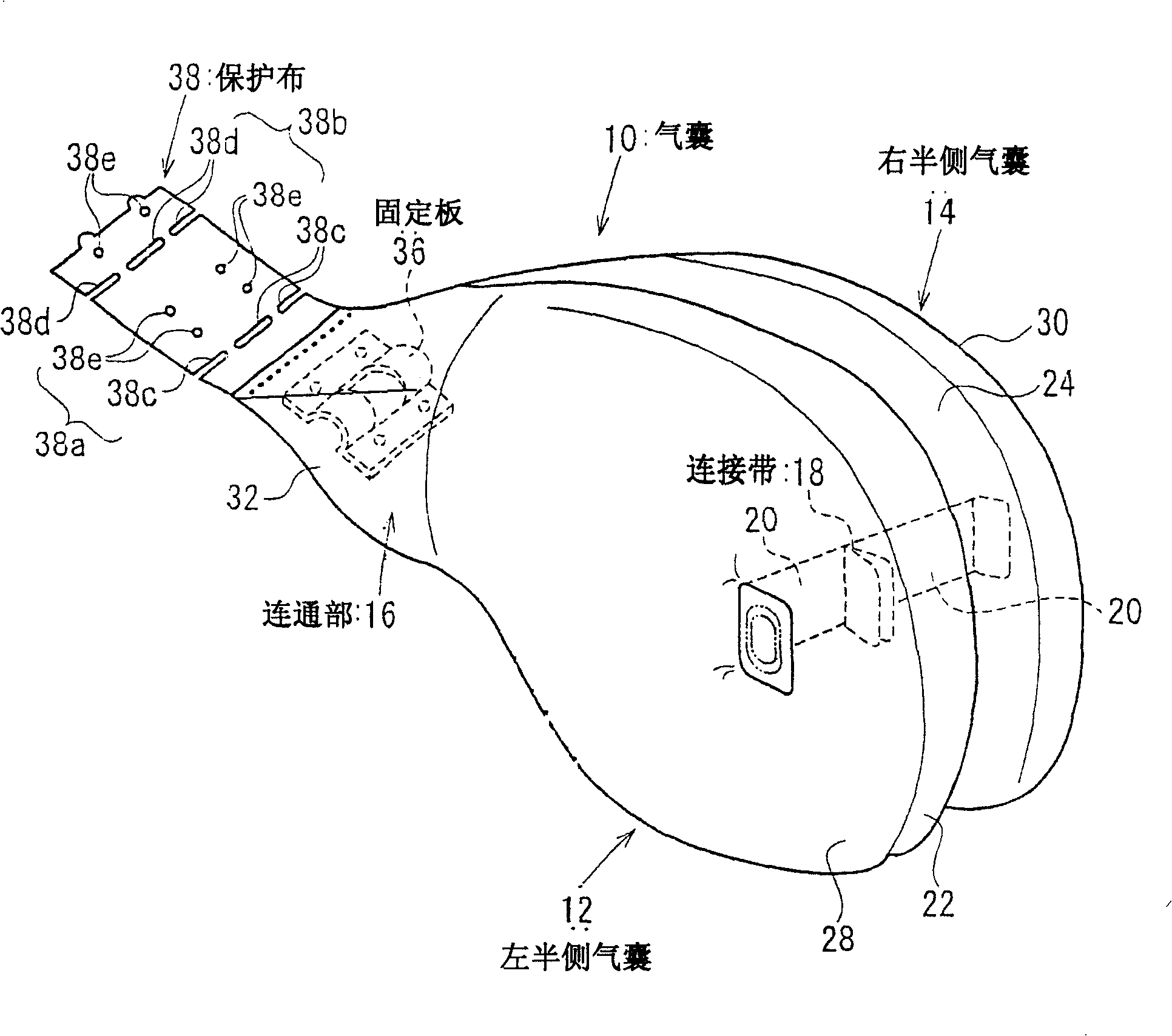

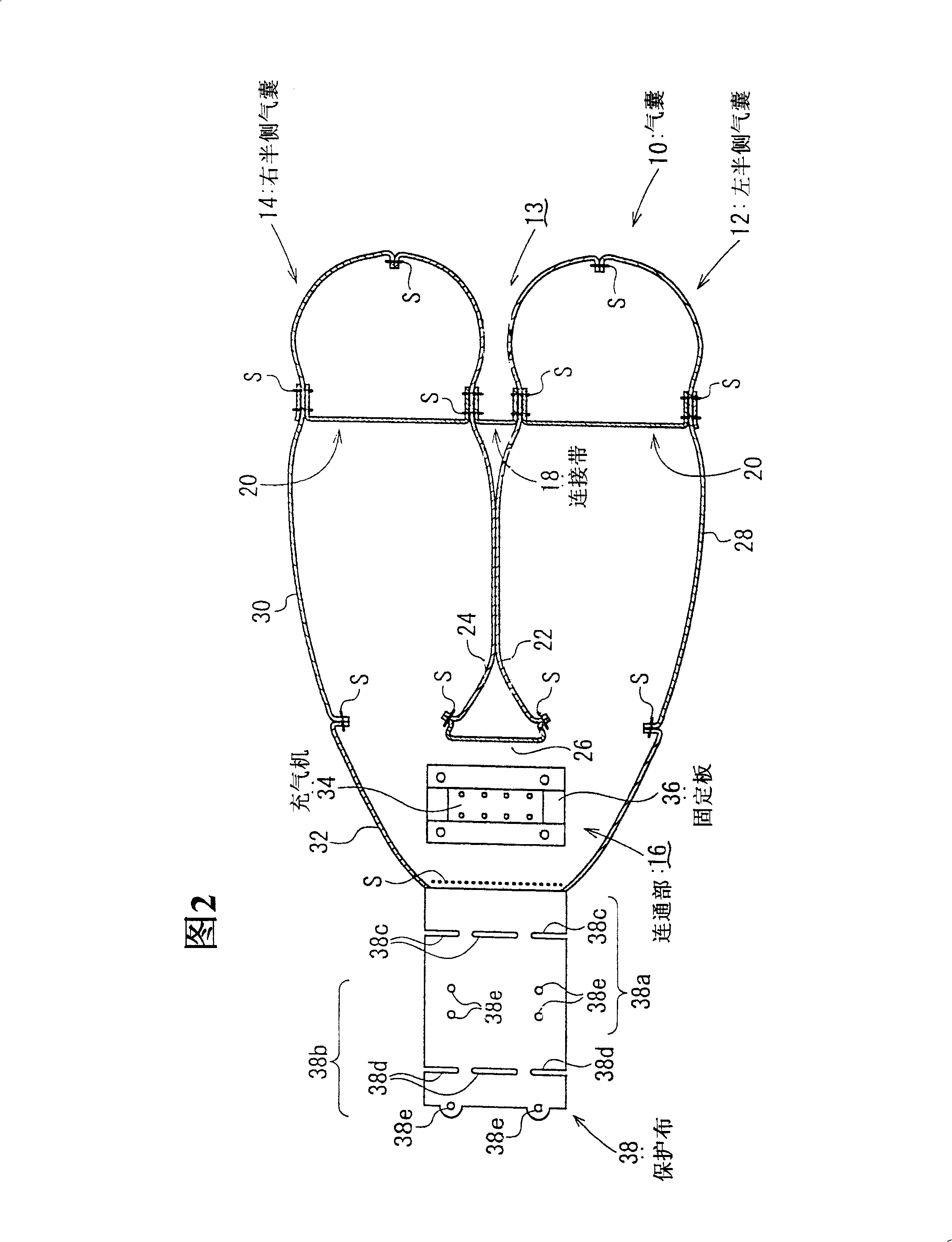

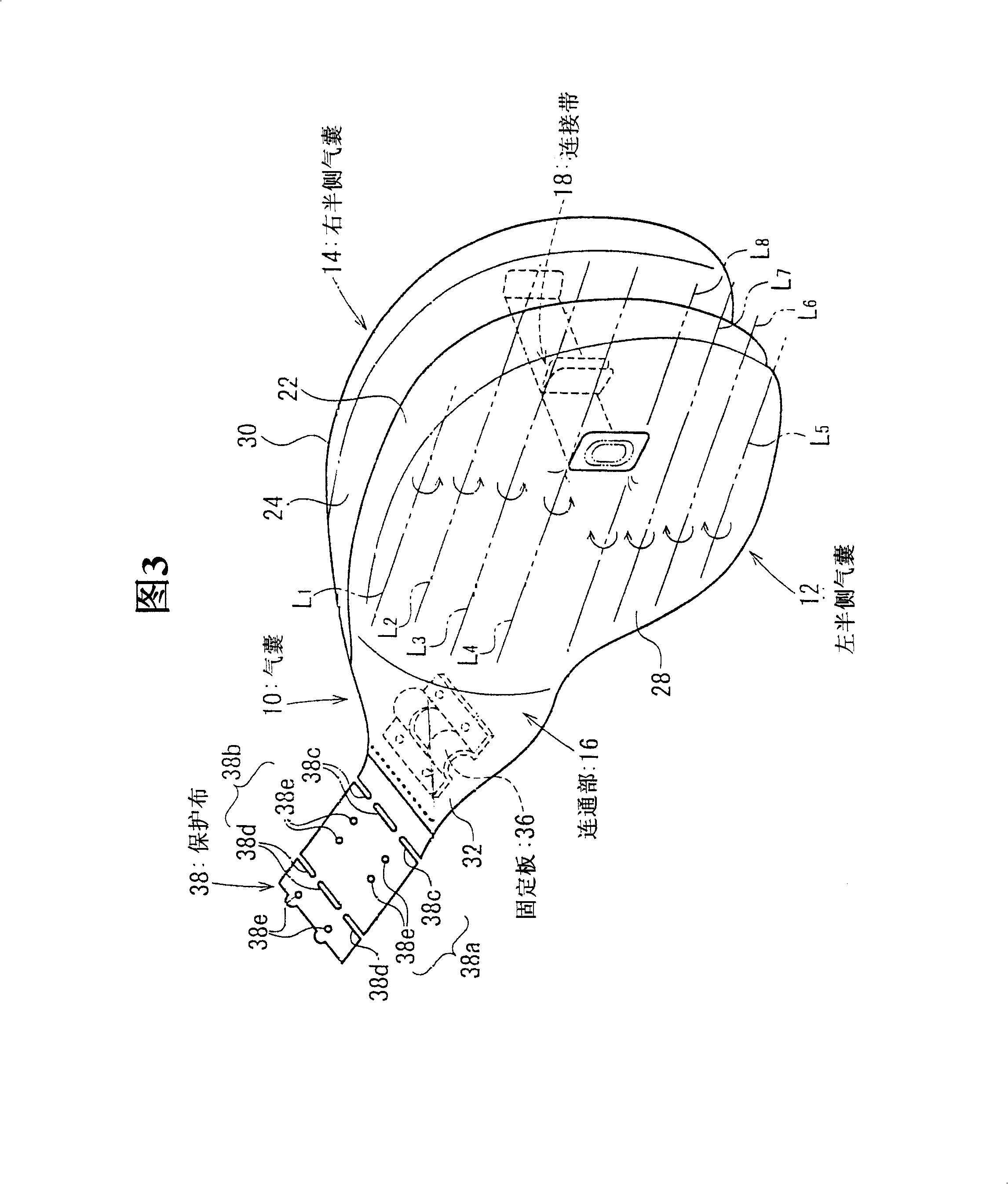

Airbag apparatus and method of folding an airbag

InactiveCN100417551CReduce the burden onReduce widthPedestrian/occupant safety arrangementLeft breastRight breast

Owner:TAKATA CORPORATION

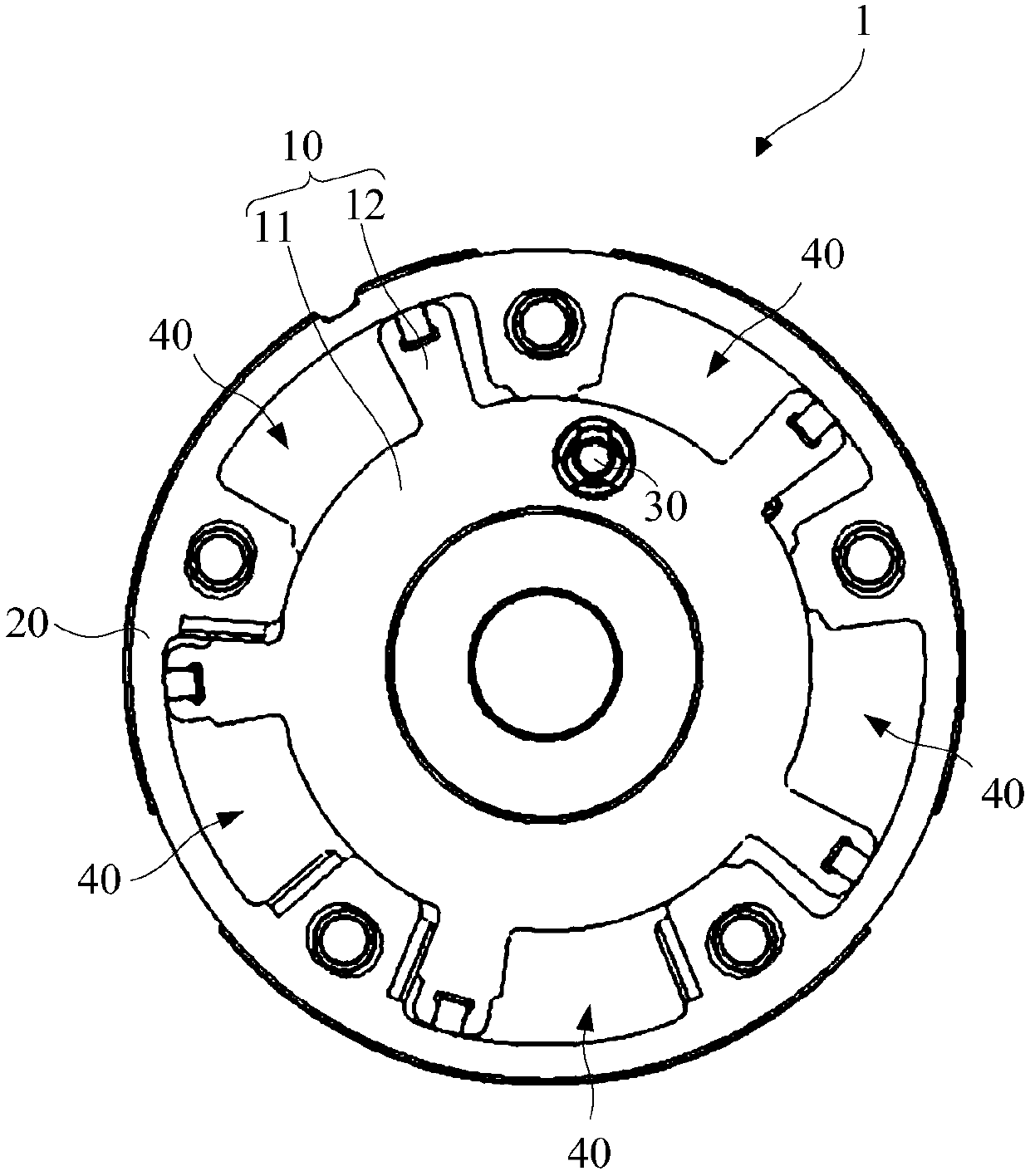

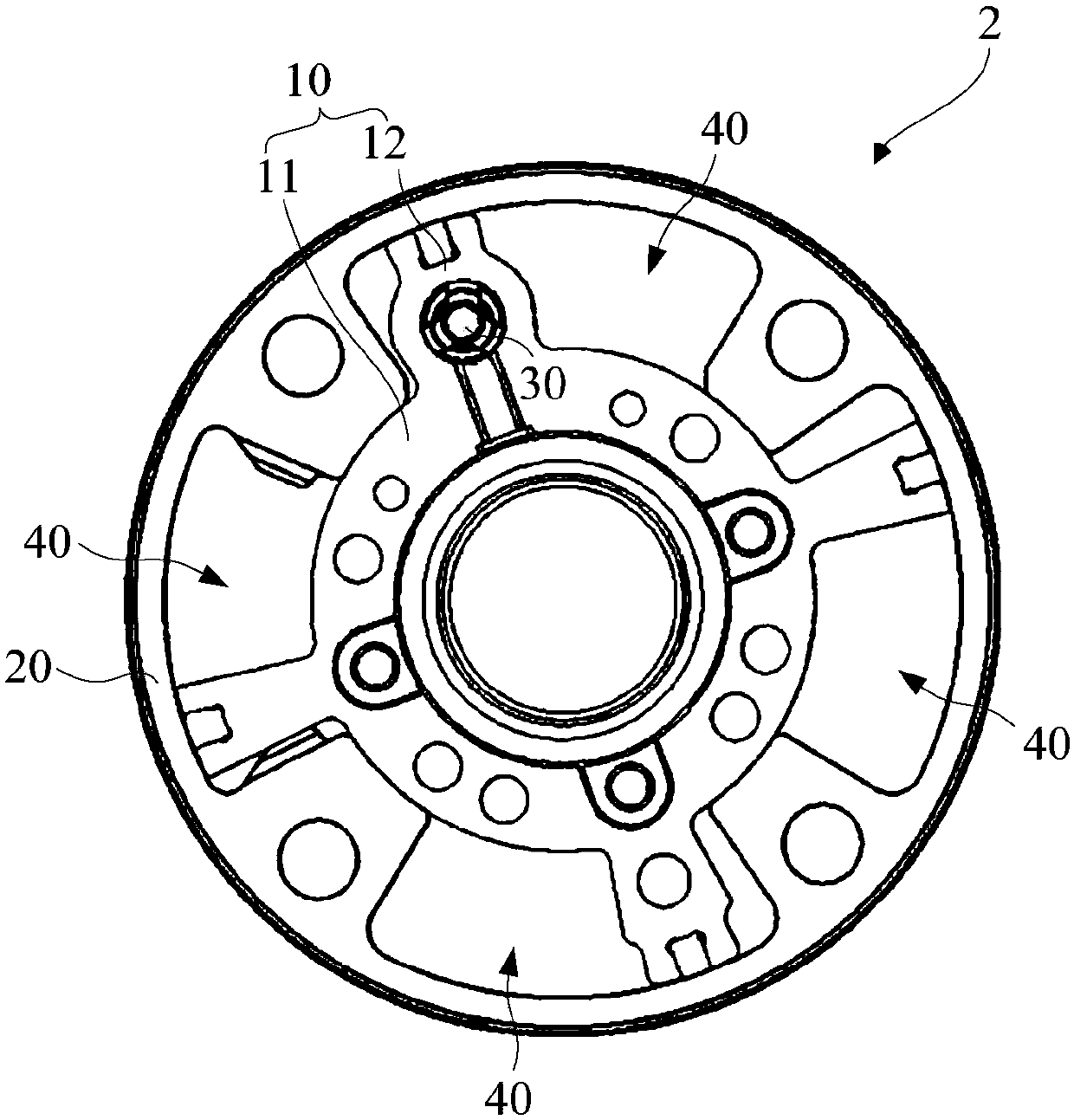

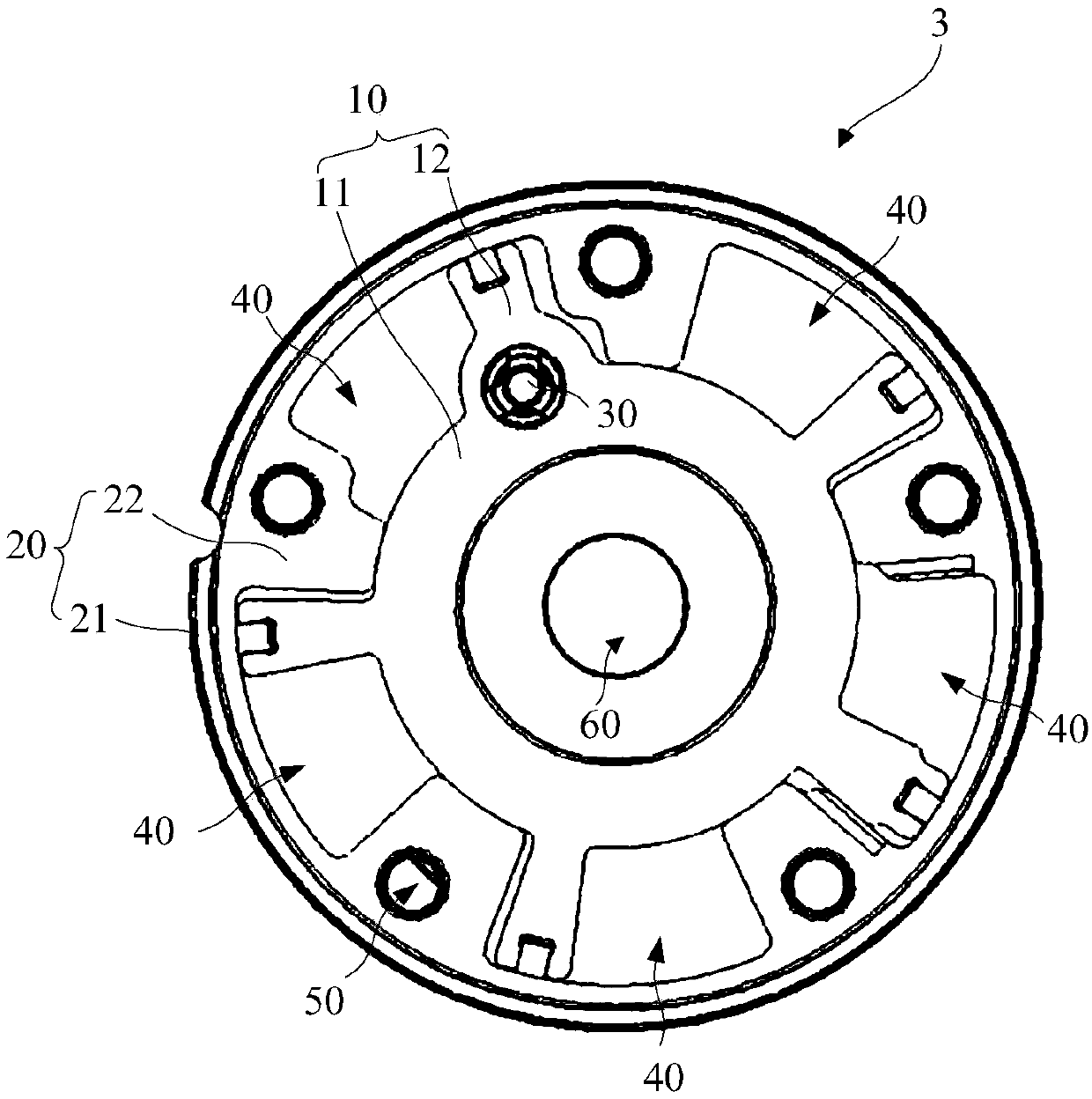

Vane type cam phaser

The invention discloses a vane type cam phaser. The vane type cam phaser comprises a rotor, a stator and a locking unit. The rotor comprises a rotor base and a plurality of vanes, and the vanes are distributed in the circumferential direction of the rotor base. The rotor is mounted in the stator and the rotor and the stator are coaxial. The locking unit is disposed at the joint of the rotor base and the vanes for locking the rotation of the rotor relative to the stator. By arranging the locking unit at the joint of the rotor base and the vanes, the miniaturization of the vane type cam phaser is realized while meeting the high twist-compression ratio requirement.

Owner:SCHAEFFLER TECH AG & CO KG

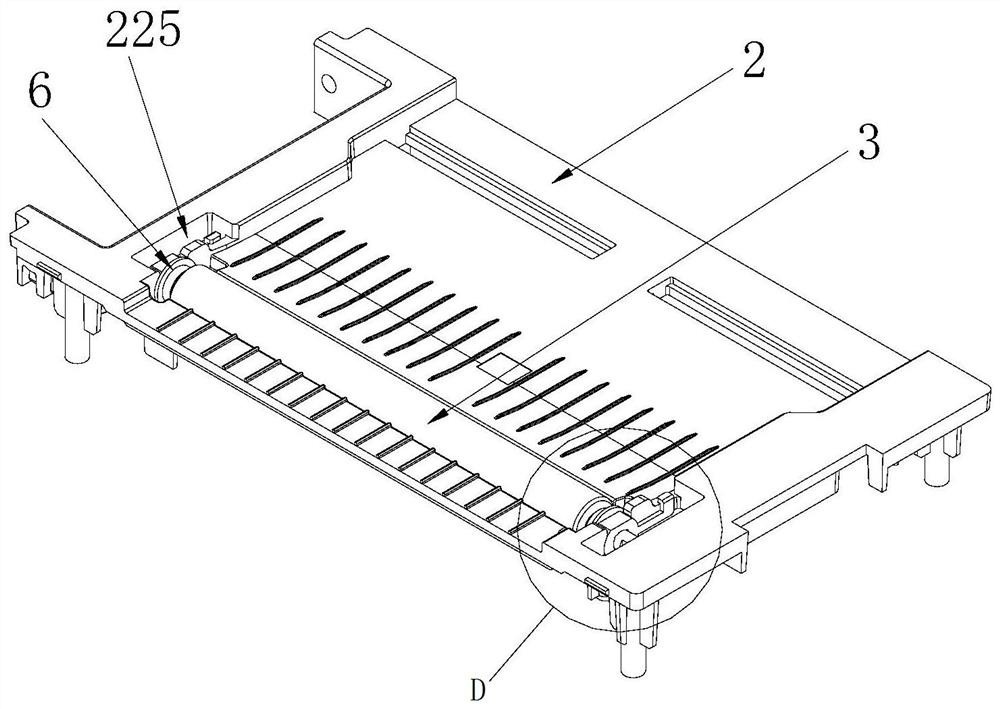

Thermal printer

ActiveCN112339445AEasy to adjust the positionLimit widthOther printing apparatusComputer printingEngineering

Owner:珠海恒盛条码设备有限公司 +1

A kind of natural fiber reinforced thermoplastic resin unidirectional prepreg tape and its preparation method

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

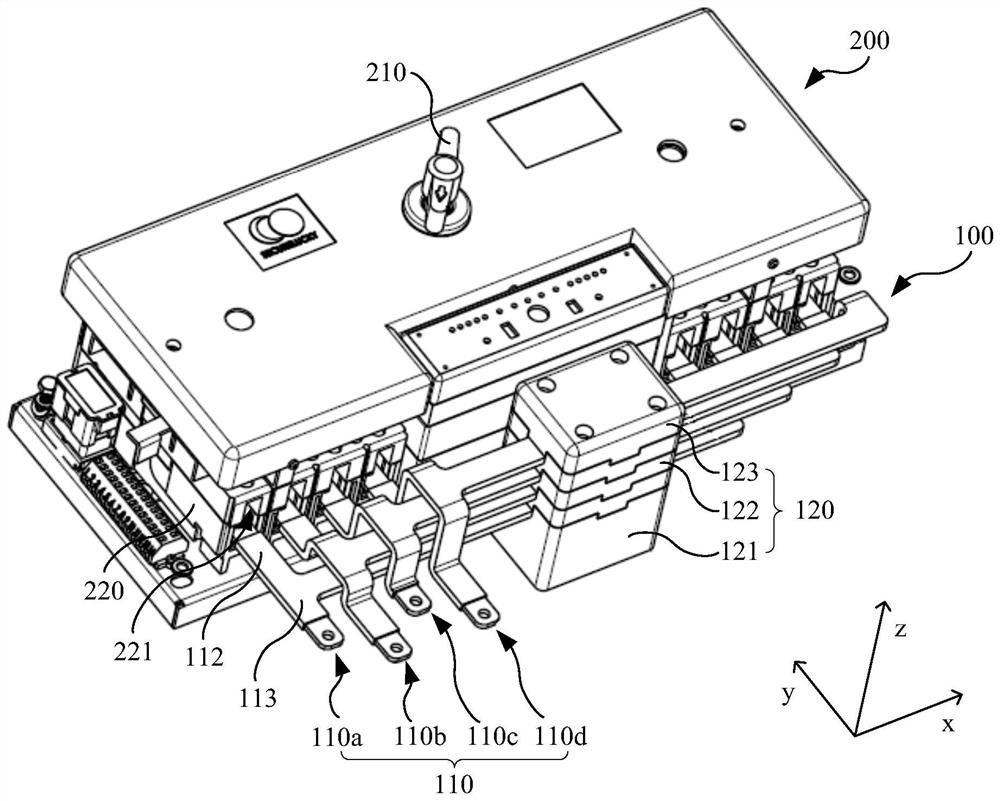

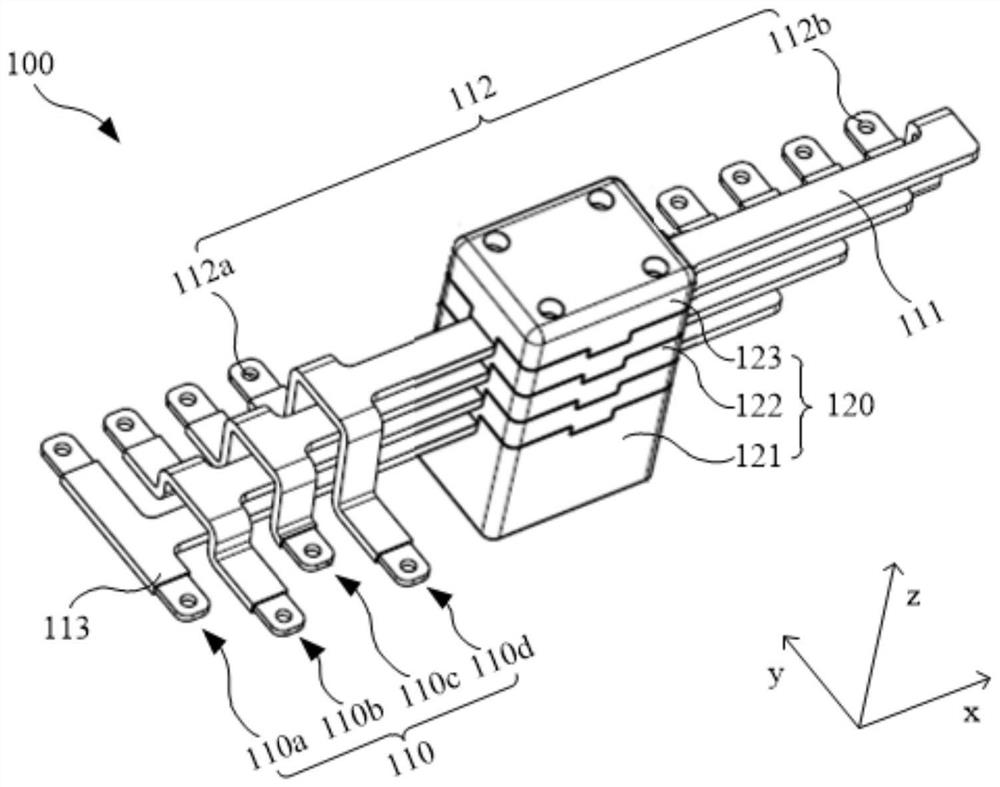

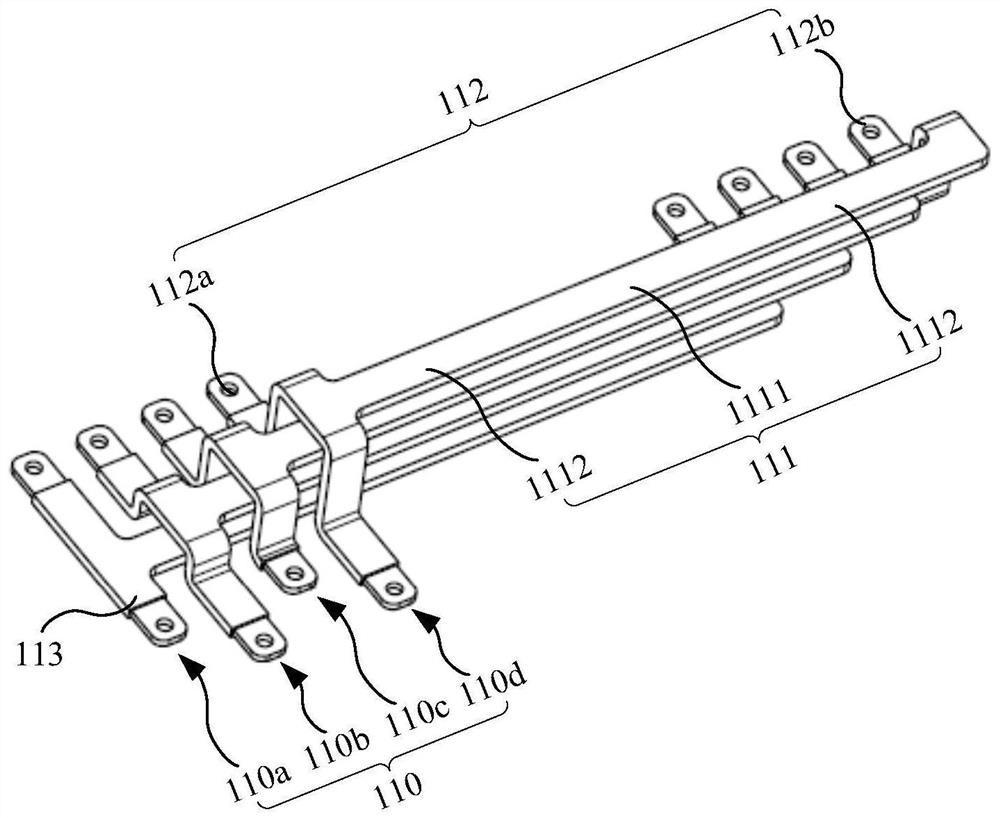

Copper bar assembly and power supply change-over switch

PendingCN114743811APrevent breakdownReduce floor areaContact electric connectionInformation technology support systemElectrical connectionStructural engineering

The invention provides a copper bar assembly and a power change-over switch, and the copper bar assembly comprises an insulating seat and a plurality of copper bars, each copper bar is connected to the insulating seat, and the copper bars are arranged at intervals in the height direction of the insulating seat; the copper bar comprises a main body part, an output part and at least two input parts; the main body part comprises a middle section and suspended sections located on the two sides of the middle section, the middle section is connected to the insulating base, the suspended sections on the two sides are suspended on the two sides of the insulating base, the input parts extend out of the sides, facing the switch main body, of the suspended sections, and the input parts are used for being connected with corresponding power connection ports in all sets of power connection potentials of the switch main body respectively; and the output part extends out of one side, deviating from the switch main body, of the suspended section and is used for being electrically connected with an electric appliance. According to the copper bar assembly and the power supply change-over switch provided by the invention, parallel connection among a plurality of power supplies can be realized by using the copper bars, so that the number of cables connected with the power supply change-over switch is reduced, the occupied space of the cables is reduced, and layout is facilitated.

Owner:BEIJING HYPERSTRONG TECH

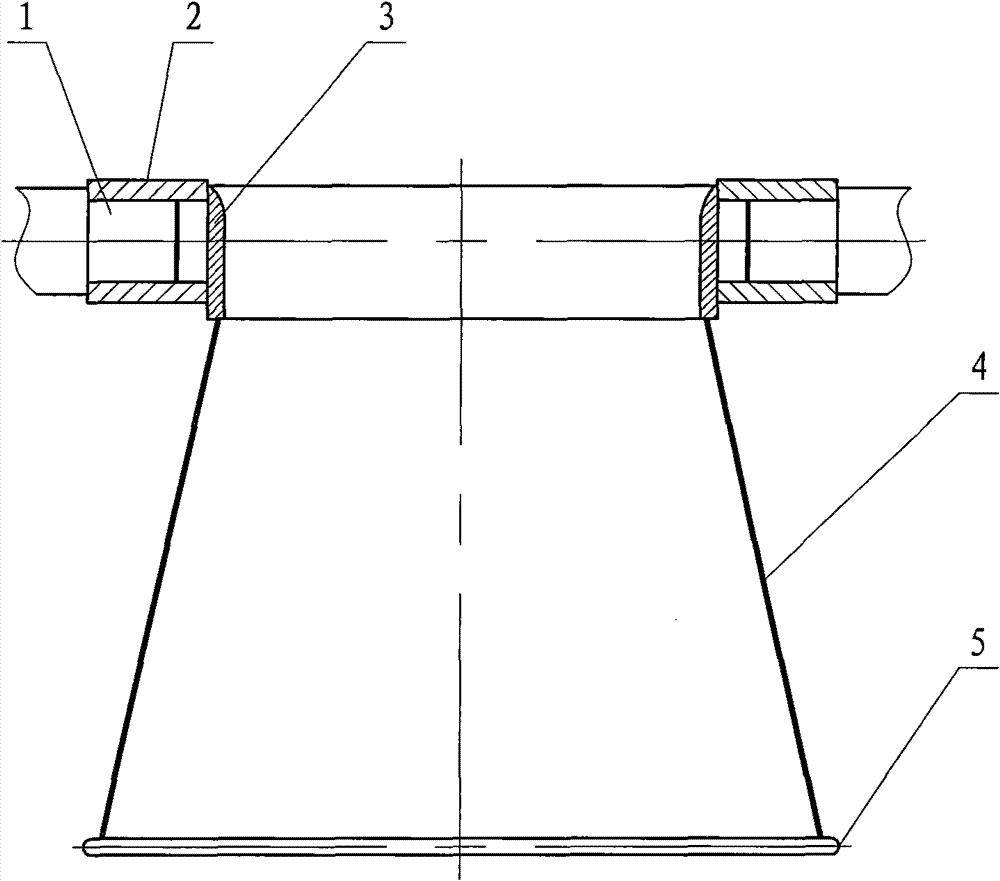

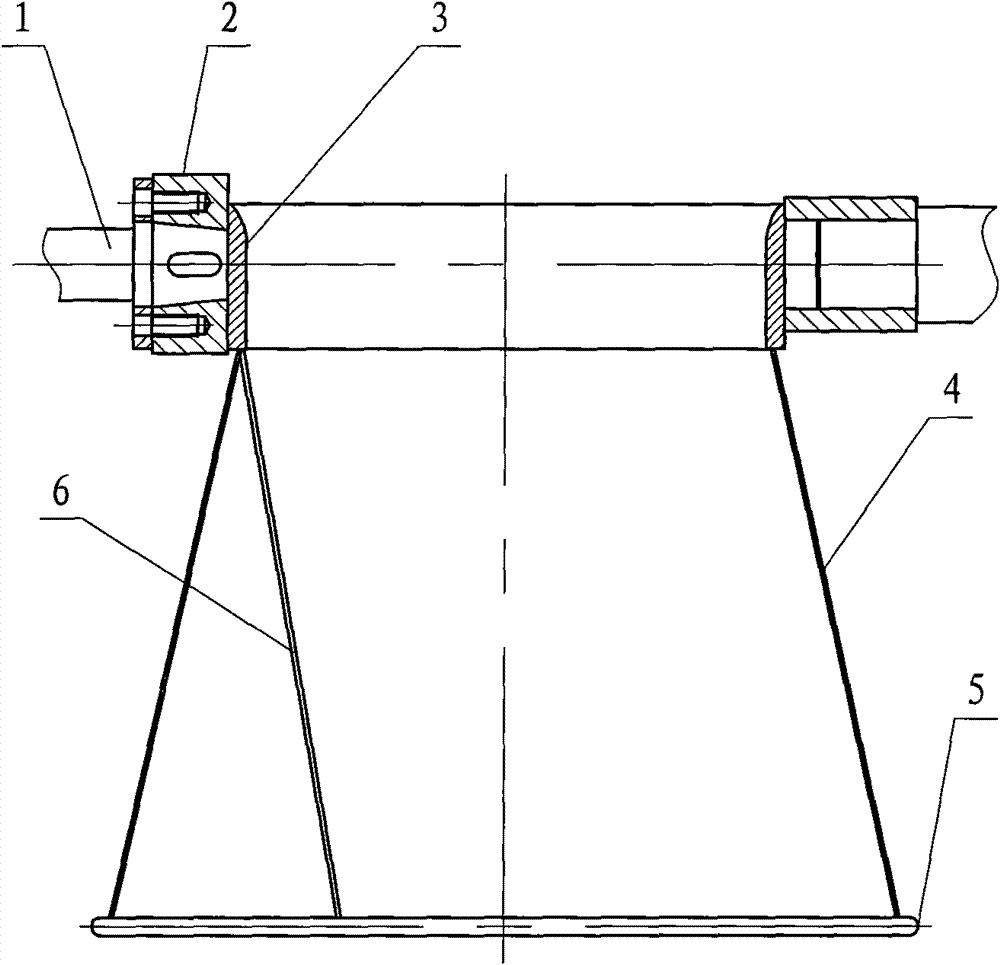

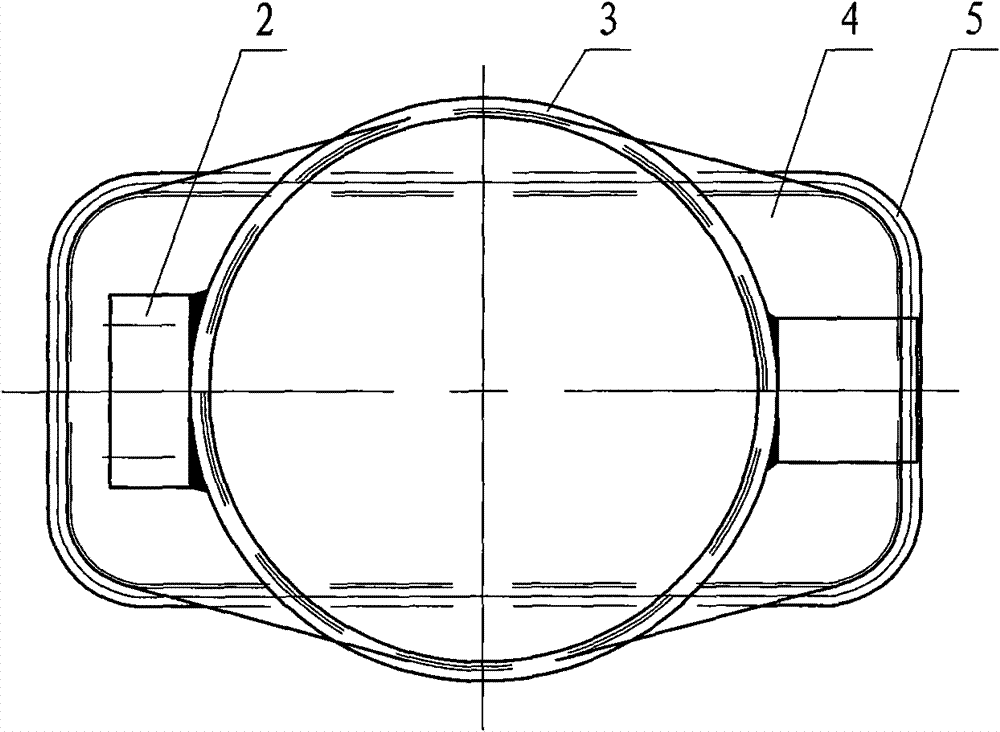

Swing cloth hopper device of airflow dyeing machine

ActiveCN101613920BWill not affect circulationLimit widthTextile storage in superimposed formLiquid/gas/vapor treatment of propelled fabricsEngineeringAirflow

Owner:WUXI DONGBAO MACHINERY MFG

A kind of degradable composite material prepreg and its preparation method and device

ActiveCN103061162BImprove interfacial adhesionGood self-extinguishingPhysical treatmentNatural fiberBiodegradable composites

The invention relates to a biodegradable composite prepreg cloth, and a preparation method and a device for the same. The composite prepreg cloth comprises a modified polylactic acid (PLA) resin accounting for 40-70 wt% of the composite prepreg and natural fiber. The preparation method comprises the following steps: conducting a continuous drying treatment on natural fiber; immersing the fiber with molten modified PLA; coating the modified PLA on the surface of the natural fiber; and rolling, cooling and winding to obtain the prepreg cloth. The device comprises an untwisting machine, an arrangement warping device, a direction control device, a friction roll, a tenslator, a film extruder, a gum dipping cooling device, and a winding device. Compared with the prior art, the invention has the advantages of large fiber draw ratio, obvious PLA enhancement effect, small wear of the extruder screw, simple process, energy saving and environment-friendliness.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

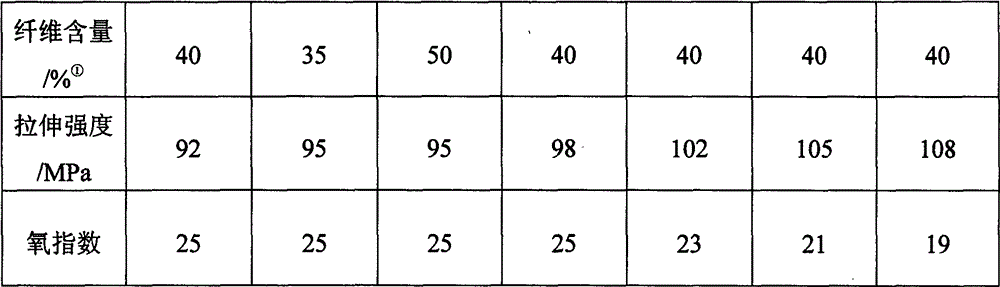

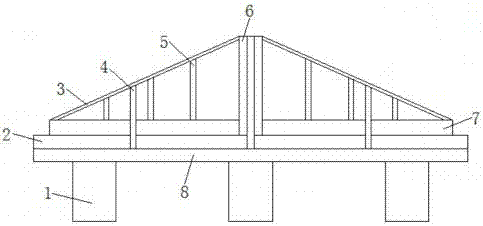

Bridge with good pressure distributing effect

InactiveCN107022946ADoes not affect drivingEasy accessClosed circuit television systemsBridge structural detailsEngineeringSupport plane

The invention discloses a bridge with good pressure distributing effect. The bridge comprises a main bridge, wherein piers which are distributed at equal distance are fixedly mounted on the lower surface of the main bridge; buffering areas are connected to tow ends of the main bridge; a supporting frame of which the top part is connected with a connecting rope is fixedly mounted in the middle part of the upper surface of the main bridge; one end, far away from the supporting frame, of the connecting rope, outwards extend to one end of the main bridge and is fixedly connected with the main bridge; supporting rods which are distributed at equal distance are arranged at two sides of the supporting frame; the height of the supporting rods gradually decreases from the supporting frame to two sides, and each supporting rod is fixedly connected with the connecting rope; the supporting rods are arranged into two parallel ranks. According to the bridge with the good pressure distributing effect, secondary bridges are arranged at two sides of the main bridge, so that people can walk conveniently without influencing vehicle running, and as a result, the normal traffic can be ensured, and moreover, the traffic pressure can be relieved; the design is reasonable; the weight of the bridge can be reduced; the secondary bridges can be conveniently mounted; and moreover, the cost can be decreased.

Owner:郑华

Steel plate pile and earth dam combined cofferdam and cofferdam construction method

PendingCN111535346ASmall water blocking areaImprove impermeabilityBulkheads/pilesSteel platesBridge engineering

The invention relates to the technical field of bridge engineering construction and provides a steel plate pile and earth dam combined cofferdam which comprises an inner-layer steel plate pile, an outer-layer steel plate pile, and an earth dam filling area defined by the inner-layer steel plate pile and the outer-layer steel plate pile. According to the steel plate pile and earth dam combined cofferdam, the step-slope and the occupied river channel width of the earth dam cofferdam can be limited, the cofferdam construction operating range can be controlled, the water blocking area of the cofferdam is reduced, the impervious capacity is improved, and the overall stability of the cofferdam is high.

Owner:中铁二局第二工程有限公司

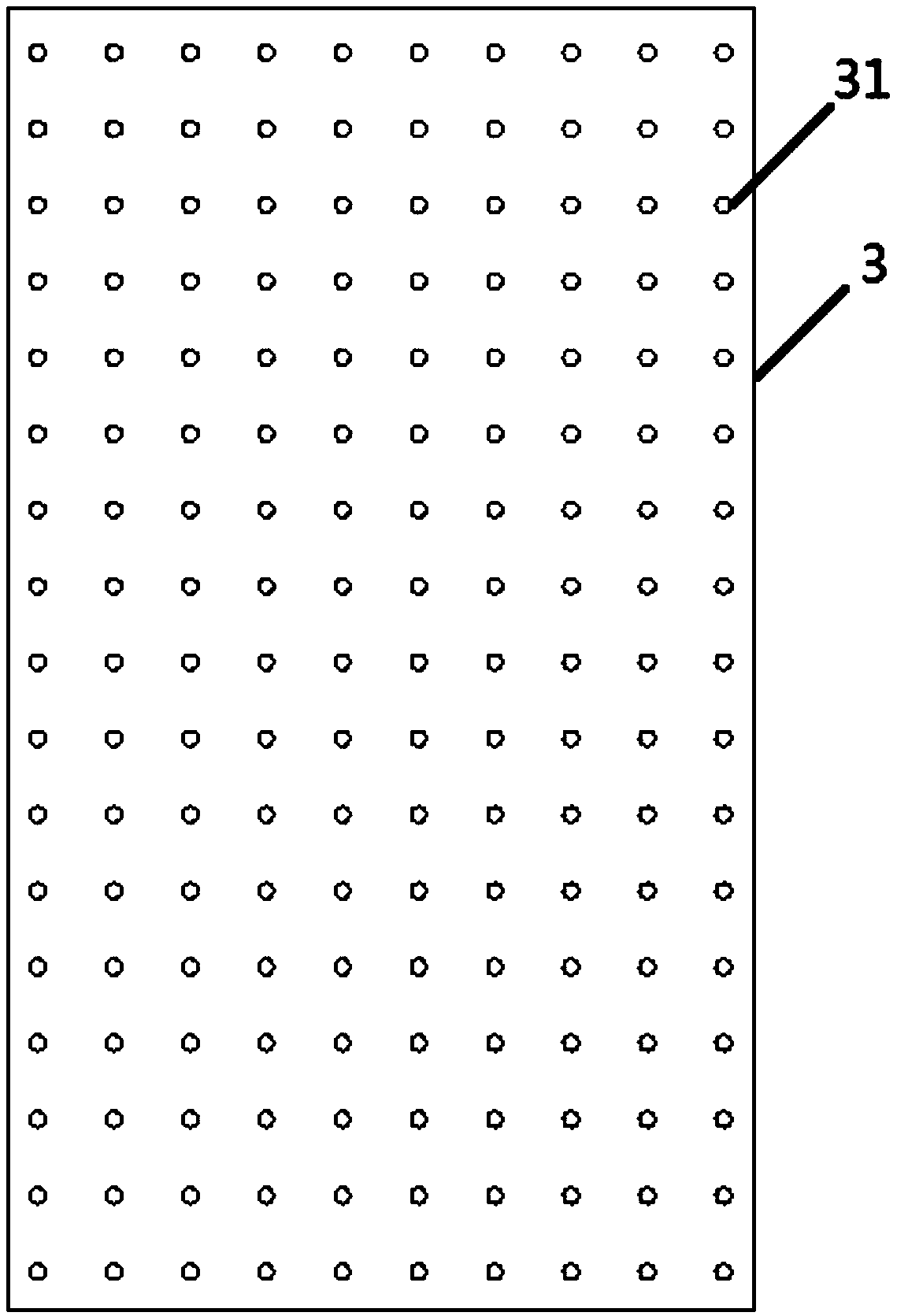

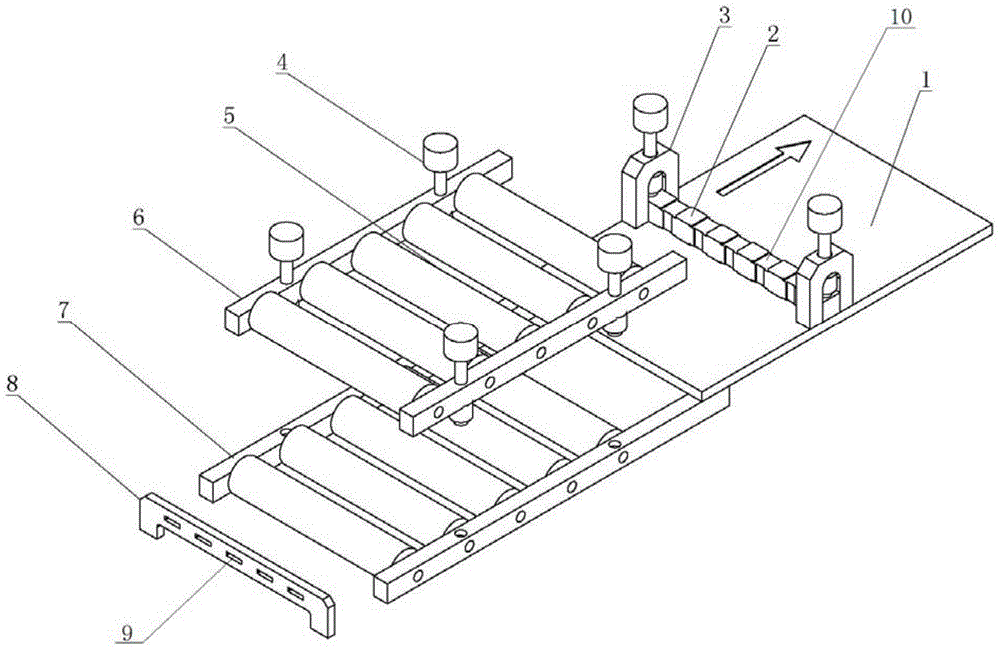

Interconnect strip cutting and conveying device for crystalline silicon solar cell modules

InactiveCN104518049BNo limit widthLimit widthFinal product manufactureSemiconductor/solid-state device manufacturingInterconnectorEngineering

The invention relates to a crystalline silica solar cell assembly interconnector cutting transmission device comprising a work table, a straightener assembly and a positioning guide assembly fixed on the work table; the straightener assembly is connected with the work table; the interconnector penetrates the straightener assembly, and is positioned by the positioning guide assembly and placed on the work table, so the work table can dragged by outer force so as to convey the interconnector. Compared with the prior art, the crystalline silica solar cell assembly interconnector cutting transmission device is simple in operation, high in operation precision, and high in section bar compatibility.

Owner:CEEG SHANGHAI SOLAR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com