Sheet pile sinking method and pile foundation trench

A technology of sinking piles and sheet piles, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc. It can solve the problems of difficulty in meeting the accuracy requirements of large-volume sheet piles, sheet piles are damaged and inclined, and piles are difficult to unload, etc., to achieve construction Quality is easy to control, improve efficiency, and ensure the effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

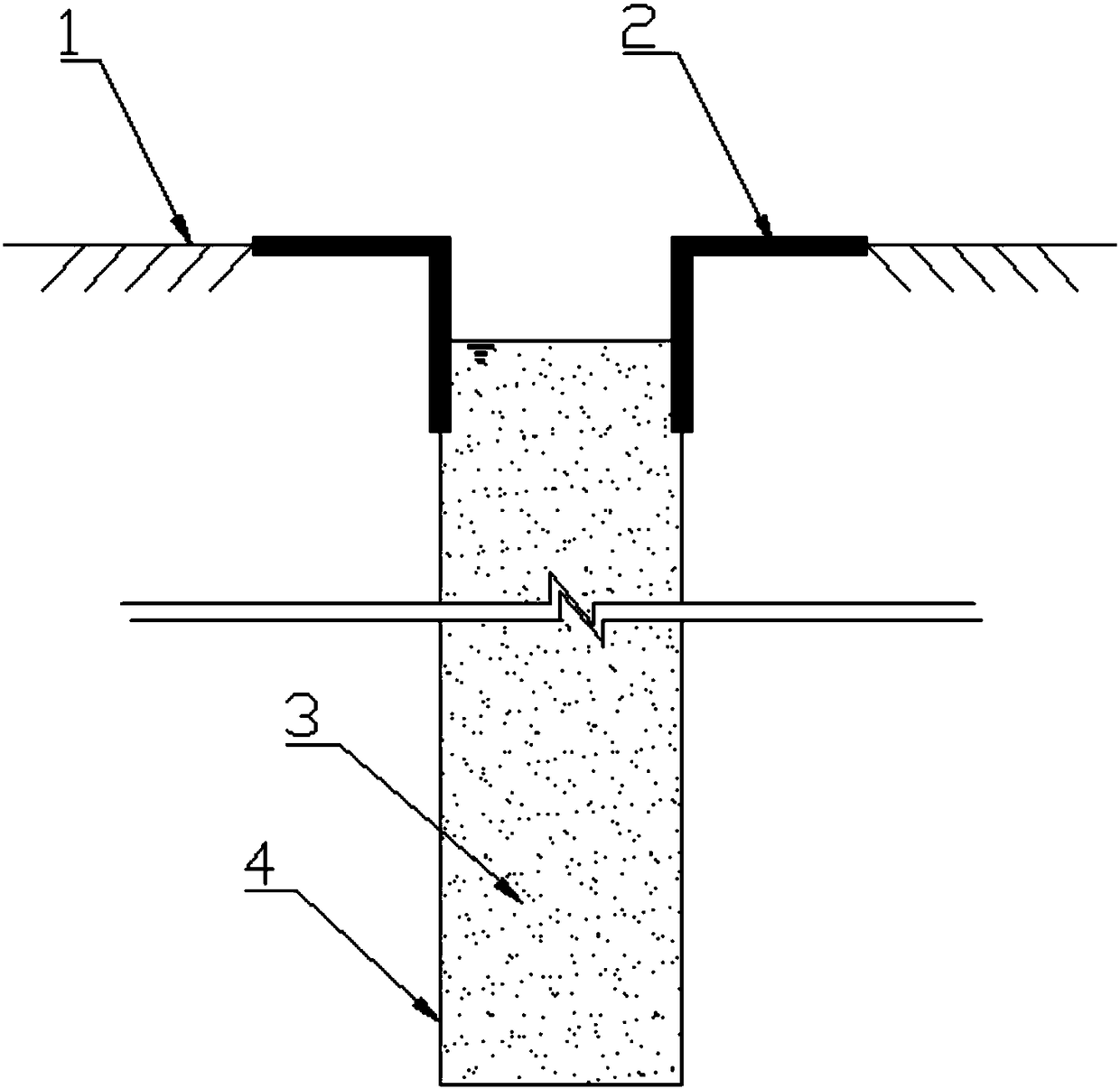

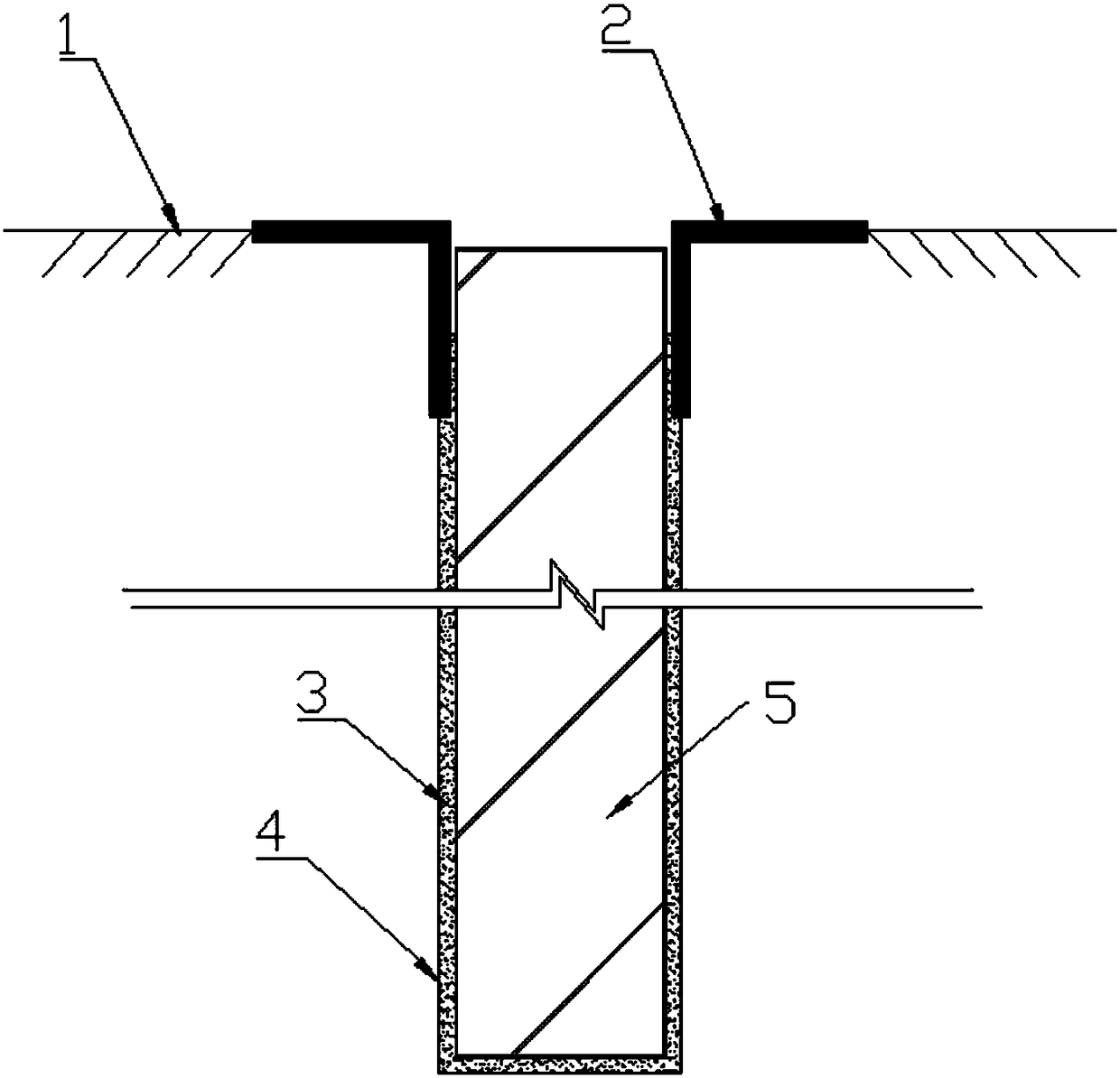

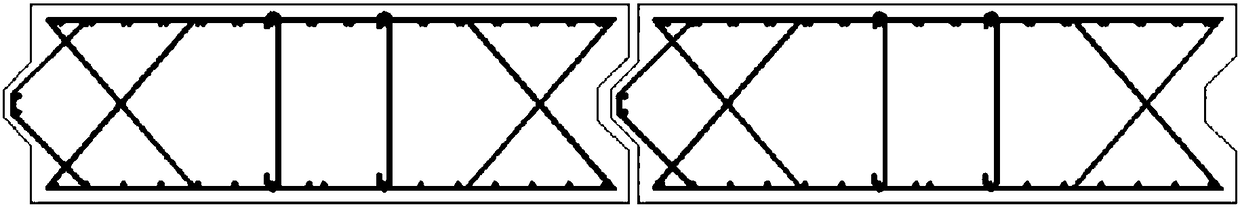

[0033] A kind of sheet pile 5 pile sinking methods, such as Figure 1-4 As shown, the construction steps include:

[0034] ①Measuring and setting out: measure the position of the foundation 11, and determine the construction axis of the guide wall 2;

[0035] ②Construction of guide wall 2: according to the construction axis, guide wall 2 formworks on both sides are set up, concrete is poured and maintained;

[0036] ③ Excavation and trenching: use ground-to-wall trenching machine to excavate earthwork along the direction of guide wall 2, and use mud pump to pour wall protection slurry 3 into preformed trench 4 at the same time during the excavation process to form preformed trench 4 and form preformed trench 4. Check the position accuracy of the pre-groove 4 after the groove 4 is formed.

[0037] ④ Pile sinking of sheet pile 5: Lift the sheet pile 5 with a lifting device, align it with the construction axis and vertically put it into the preformed groove 4, and sink the pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com