Pile stabilizing platform mounting process

An installation process and platform technology, applied in sheet pile walls, infrastructure engineering, construction and other directions, can solve the problems of low sensitivity, inconvenient platform hoisting, inconvenient adjustment, etc., to improve vertical accuracy, improve hoisting efficiency, and improve construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

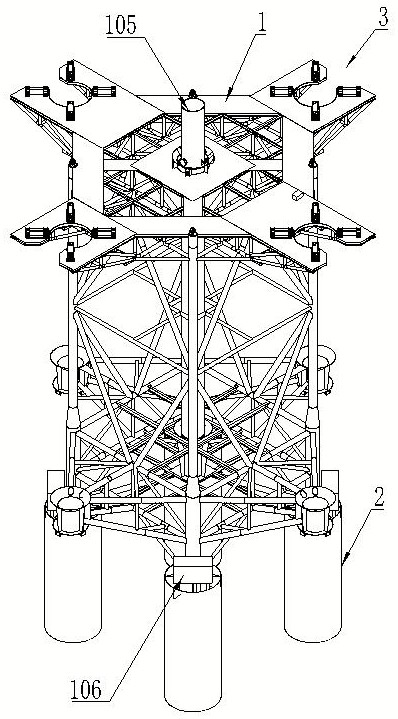

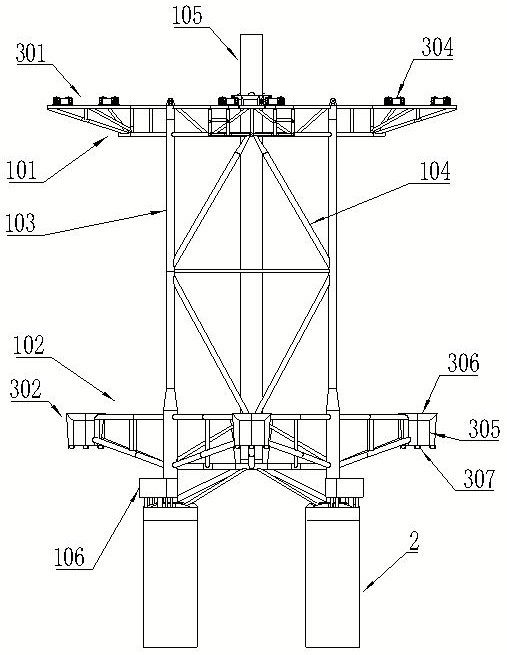

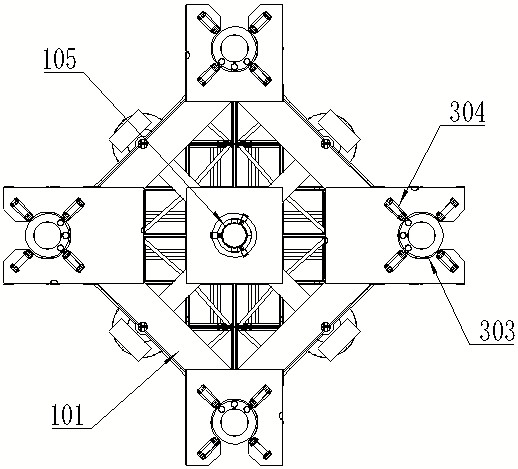

[0030] see Figure 1~3 , a kind of pile stabilizing platform installation process that the present invention relates to, and described pile stabilizing platform installation process is realized based on a kind of negative pressure barrel stabilizing platform, and described negative pressure barrel stabilizing platform comprises platform body 1 and is arranged on platform body 1 bottom negative pressure cylinder 2, the platform body 1 includes a top platform 101 and a bottom platform 102, which are connected by a vertical steel pipe 103 between the top platform 101 and the bottom platform 102; the negative pressure cylinder pile stabilization platform also includes Positioning guiding device 3, described positioning guiding device 3 comprises the centralizer 301 that is arranged on the top surface of top platform 101 and the guide bushing 302 that is arranged on the side of bottom platform 102, the position of centering device 301 and guide bushing 302 Corresponding up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com